Page 1

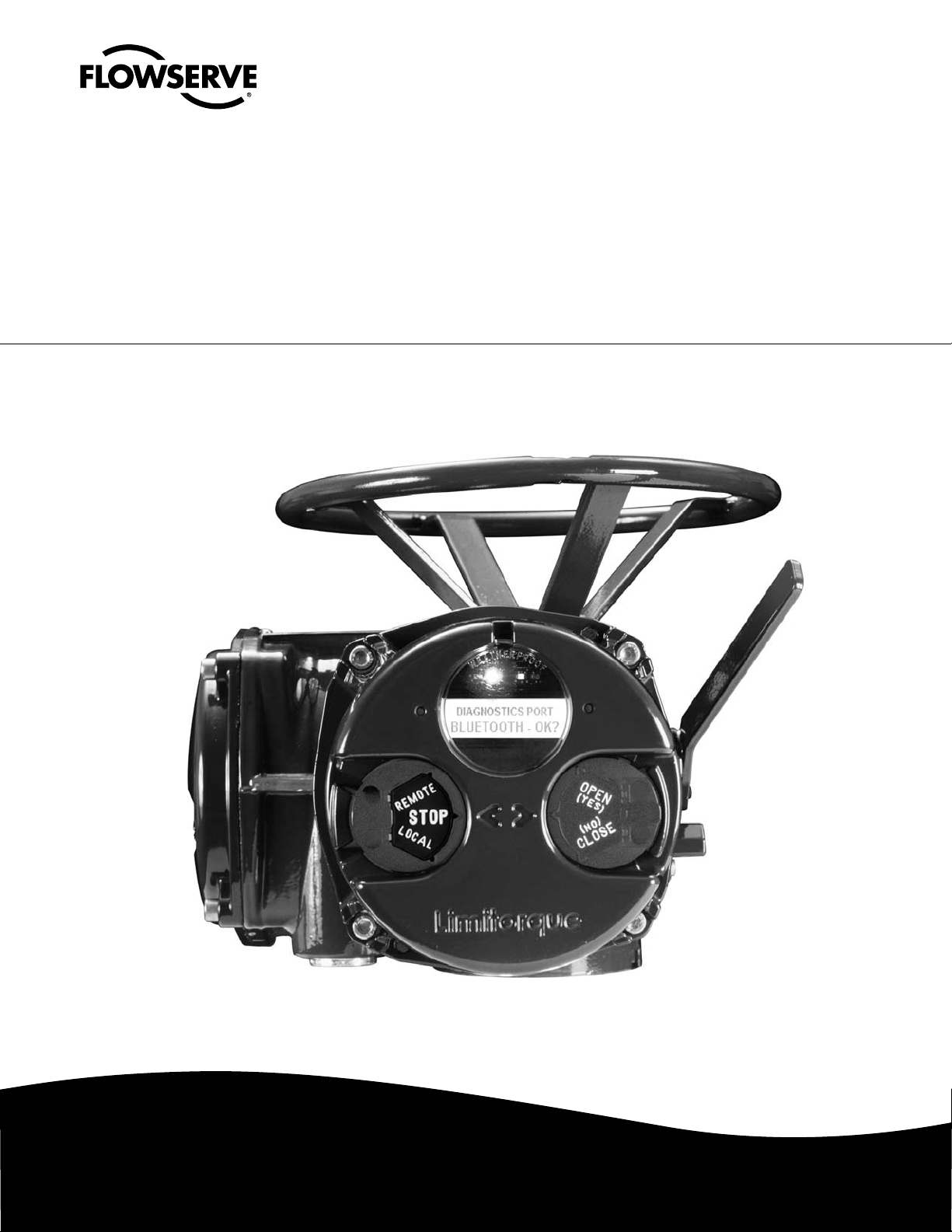

USER INSTRUCTIONS

MX/DDC-100 Field Unit

FCD LMENIM2329-01 – 03/11

Installation

Operation

Maintenance

Experience In Motion

Page 2

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

MX/DDC-100 Field Unit Installation and Operation Manual

©2011 Copyright Limitorque. All rights reserved. Printed in the United States of America.

Disclaimer

This document is meant for use with MX Installation and Operation Manual for MX-05 through MX-40. Information

in this document is also applicable to MX-85 through MX-150. No part of this book shall be reproduced, stored in a

retrieval system, or transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise without

the written permission of Limitorque. While every precaution has been taken in the preparation of this book, the

publisher assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained herein.

This document is the proprietary information of Limitorque, furnished for customer use ONLY. No other uses are

authorized without written permission from Limitorque.

Limitorque reserves the right to make changes, without notice, to this document and the product it describes.

Limitorque shall not be liable for technical or editorial errors or omissions made herein; nor for incidental and

consequential damages resulting from the furnishing, performance or use of this document.

The choice of system components is the responsibility of the buyer, and how they are used cannot be the liability of

Limitorque. However, Limitorque’s sales team and application engineers are always available to assist you in making

your decision.

This manual contains information that is correct to the best of Limitorque’s knowledge. It is intended to be a guide

and should not be considered as a sole source of technical instruction, replacing good technical judgment, since all

possible situations cannot be anticipated. If there is any doubt as to exact installation, configuration, and/or use, call

Limitorque at (434) 528-4400. The latest revisions to this document are available at www.flowserve.com.

2

Page 3

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Contents

1 Introduction 5

1.1 Purpose 5

1.2 How to Use this Manual 5

1.3 User Safety 5

1.4 User Knowledge 6

1.5 DDC-100 System Capabilities and Features 6

1.6 General Specifications 7

2 System Components 8

2.1 Introduction 8

2.2 Hardware 8

2.2.1 MX Actuator 9

2.2.2 DDC–100 Field Unit 9

2.2.3 Host Controller 10

2.2.4 Master Station II 11

2.2.5 Network Cable 12

2.3 Software 13

2.3.1 Modbus Protocol 13

2.3.2 Modbus Function Codes 14

2.3.3 Modbus Function Code 01 (Read Coil Status) 14

2.3.4 Modbus Function Code 02 (Read Input Status) 15

2.3.5 Modbus Function Code 03 (Read Holding Register) 17

2.3.6 Modbus Function Code 04 (Read Input Register) 21

2.3.8 Modbus Function Code 06 (Preset Single Register) 23

2.3.9 Modbus Function Code 08 (Diagnostics) 26

2.3.10 Modbus Function Code 15 (Force Multiple Coils) 27

2.3.11 Modbus Function Code 16 (Preset Multiple Registers) 28

3 Installation and Configuration 30

3.1 Site and Network Cable Preparation 30

3.1.1 Site Preparation 30

3.1.2 Network Cable Preparation 30

3.2 Installation Verification 38

3.2.1 Network Cabling Installation Verification 38

3.2.2 Field Unit Installation Verification 38

3.3 Field Unit Configuration 39

3.3.1 Configuring Field Unit Parameters 39

3.4 Configuration Confirmation 44

3.4.1 Checking Connections 44

3.4.2 View Settings 44

3.4.3 Checking the Normal Display 44

4 Associated Documents 46

5 Troubleshooting 48

6 How to Order Parts 50

Appendix – Wiring Diagram 52

Appendix – MX/DDC Register Definitions 56

Appendix – Typical DDC-100 Network Installation Assignments 62

3

flowserve.com

Page 4

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

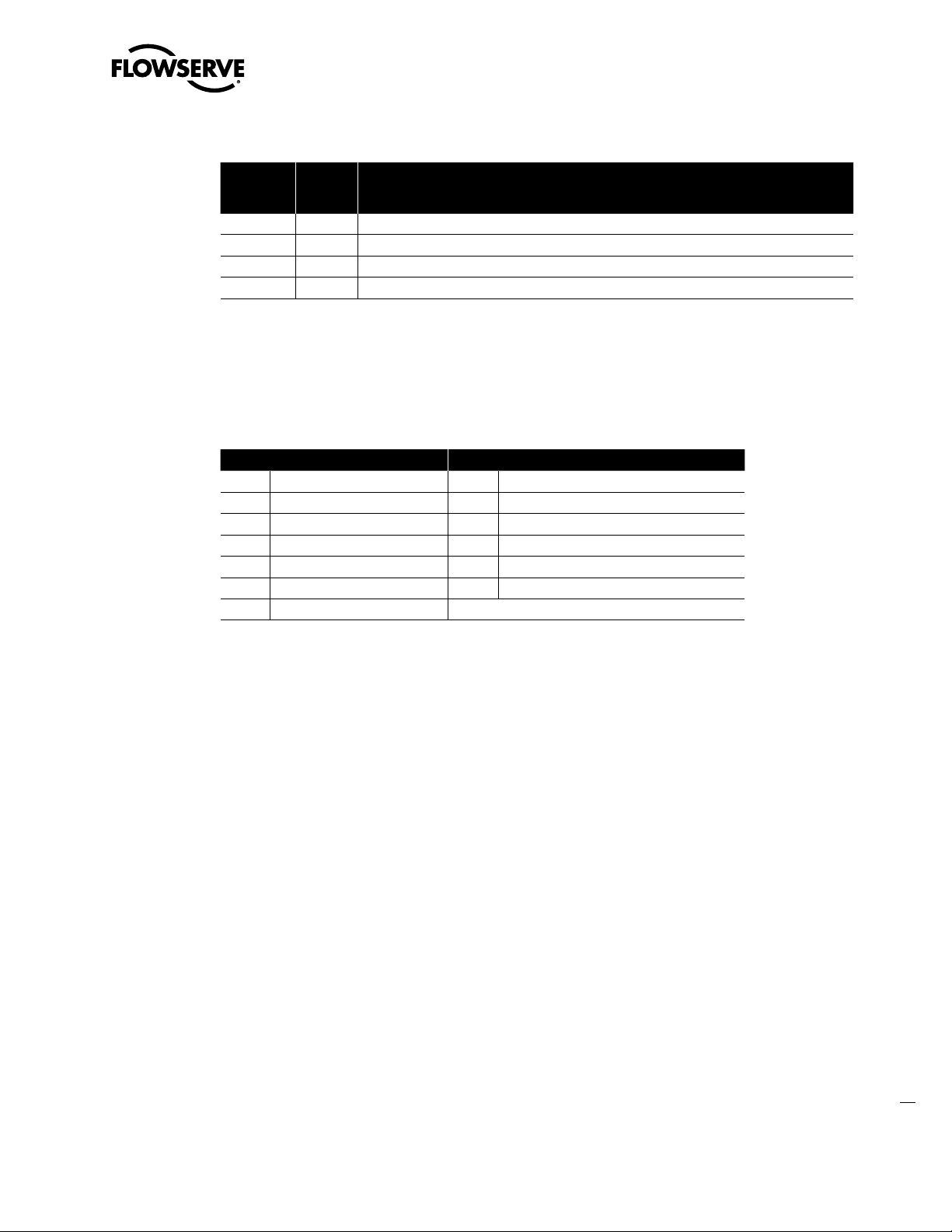

Figures

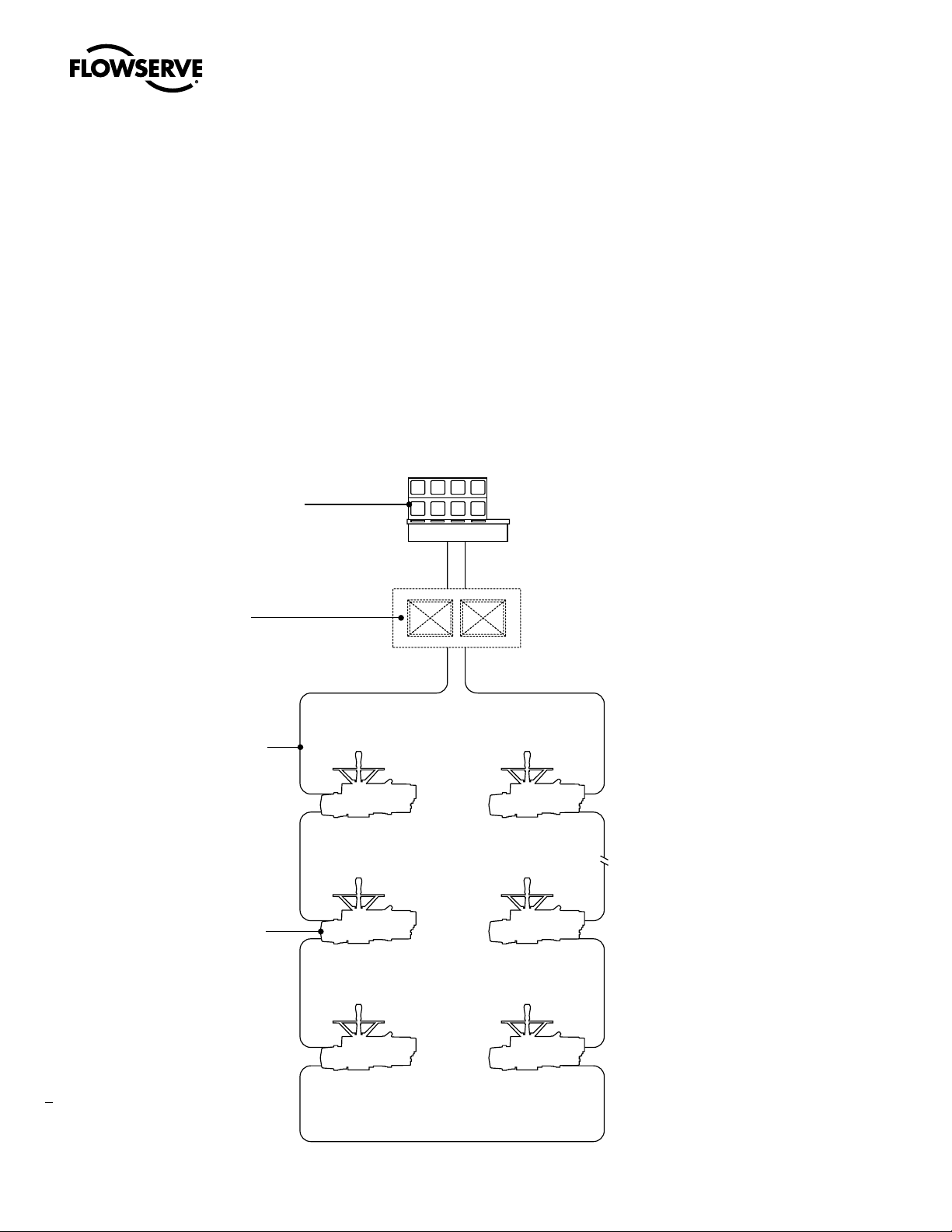

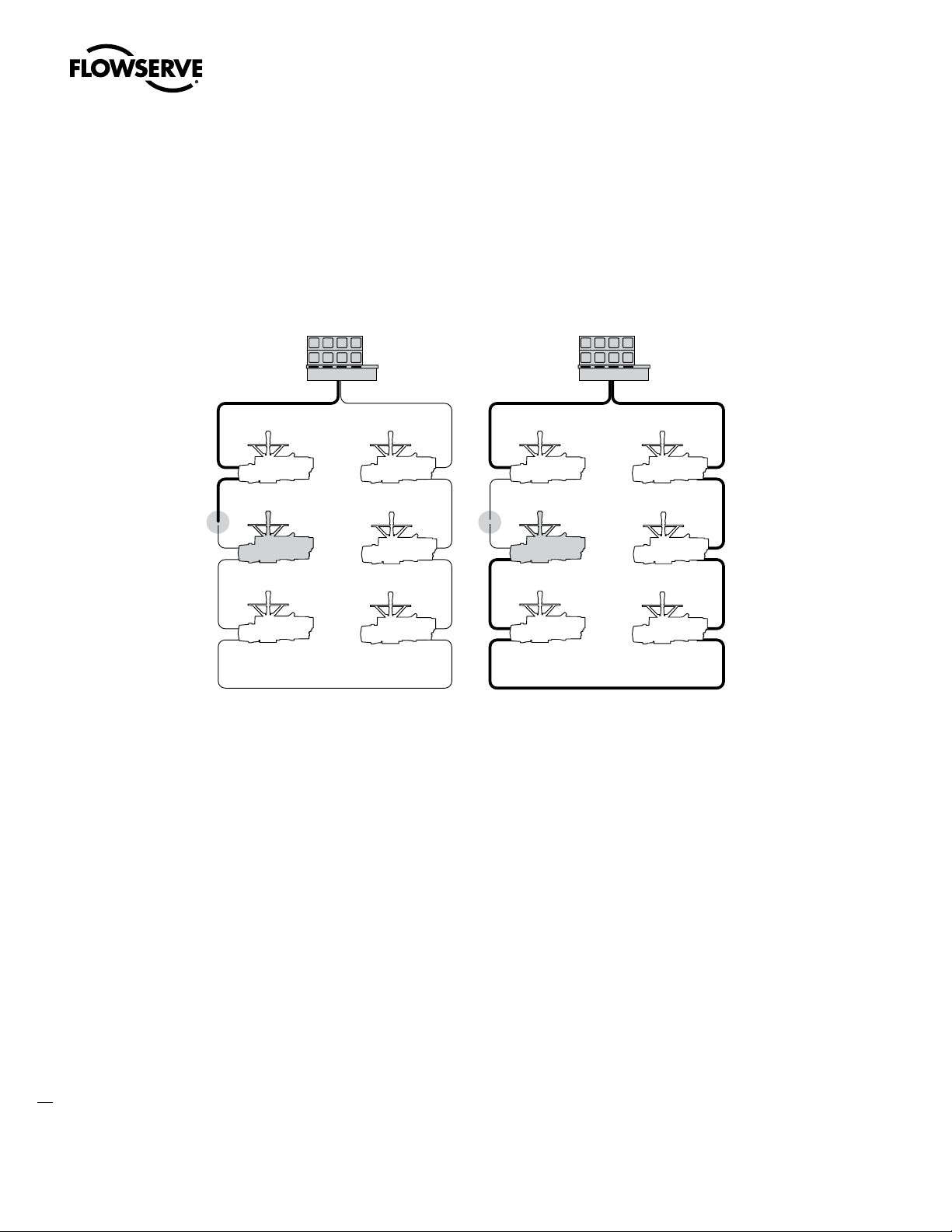

Figure 1.1 – Typical DDC-100 system with or without a Master Station II 6

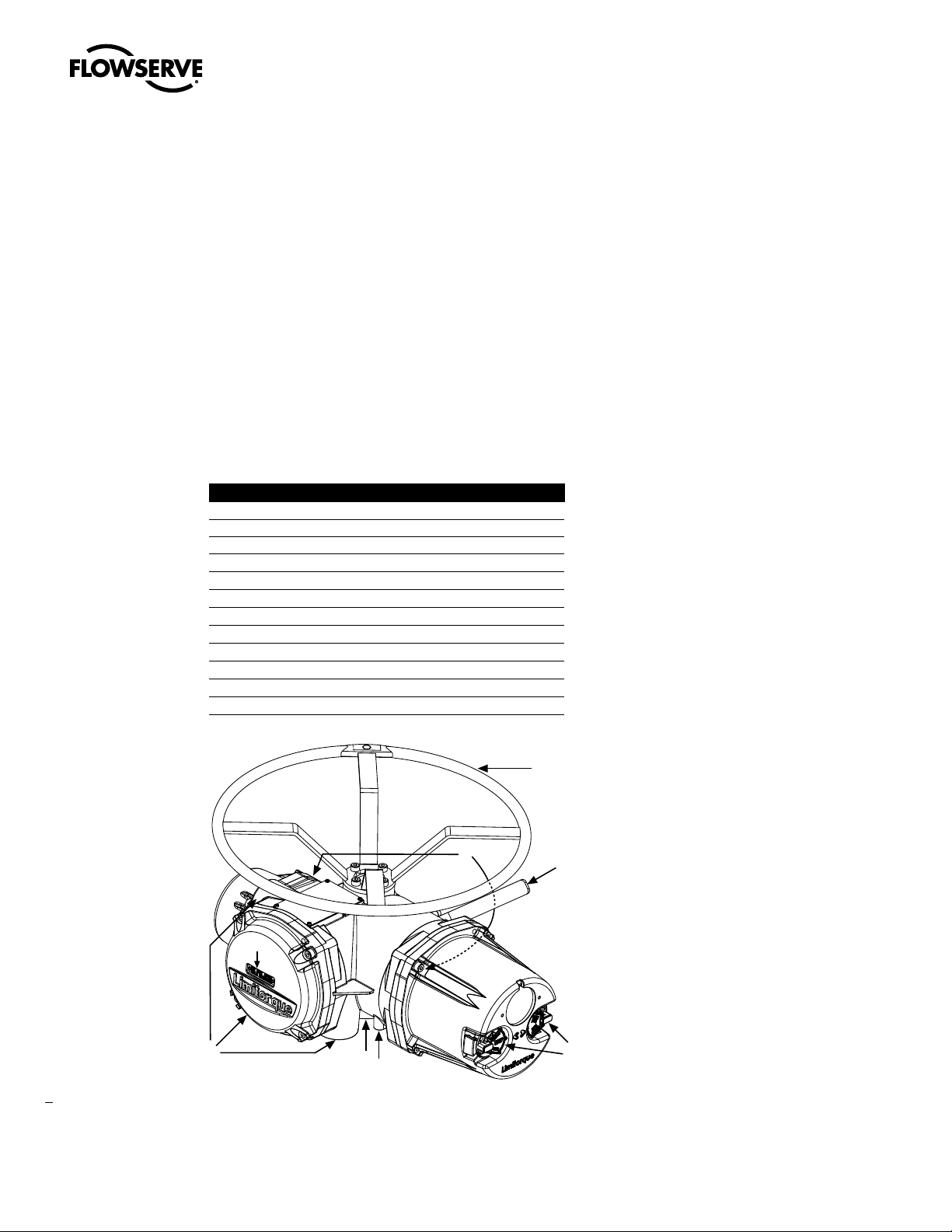

Figure 2.1 – MX-05 actuator 8

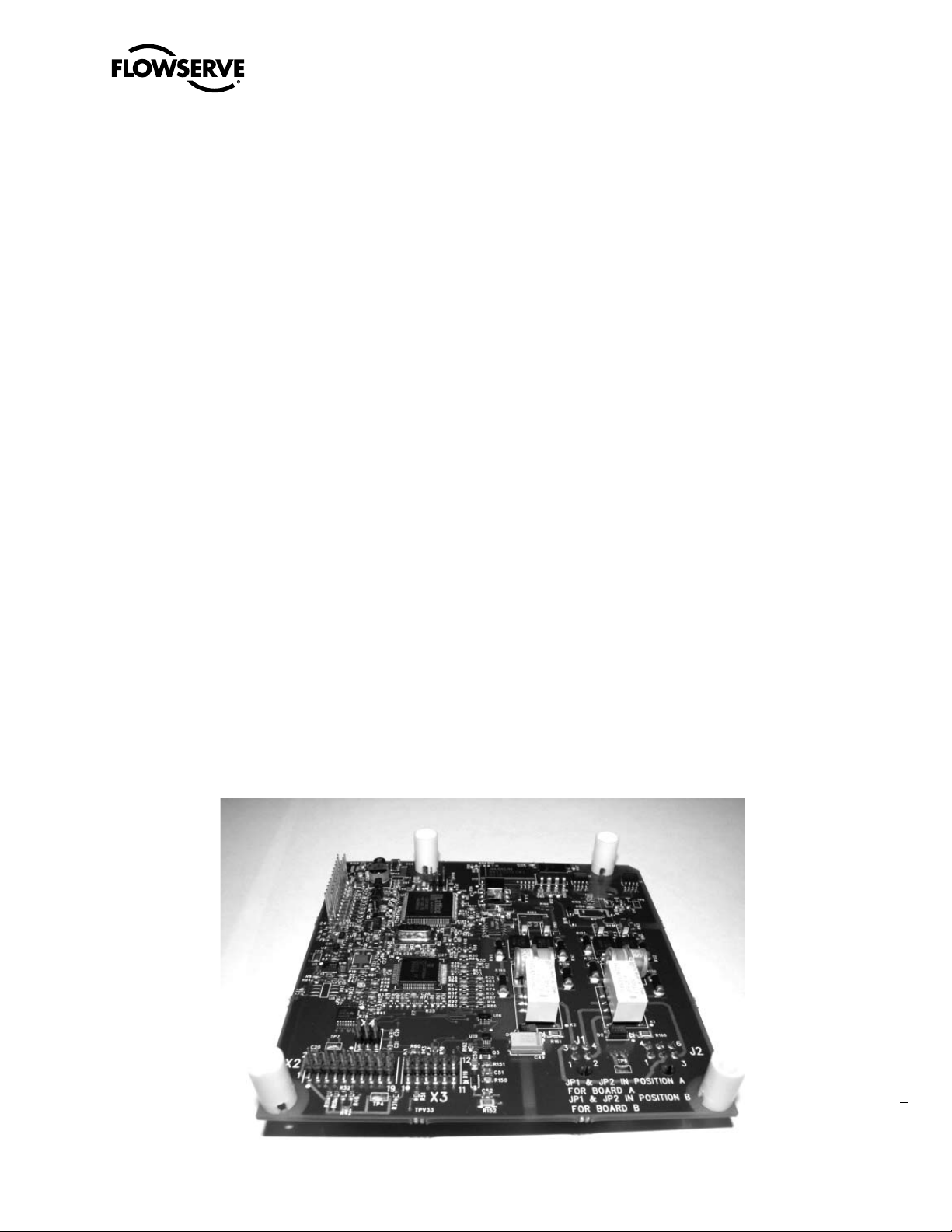

Figure 2.2 – DDC-100 field unit 9

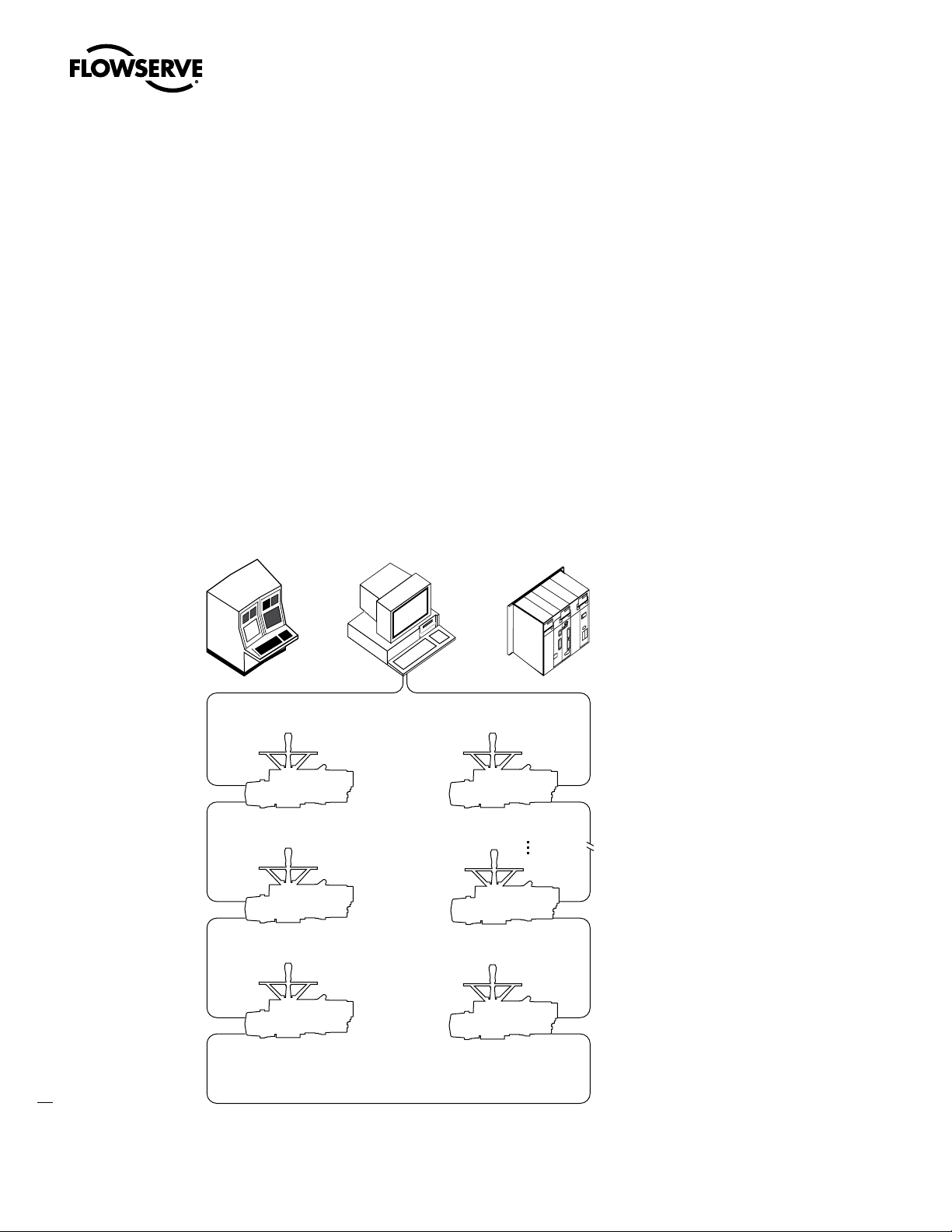

Figure 2.3 – Typical direct-to-host arrangement 10

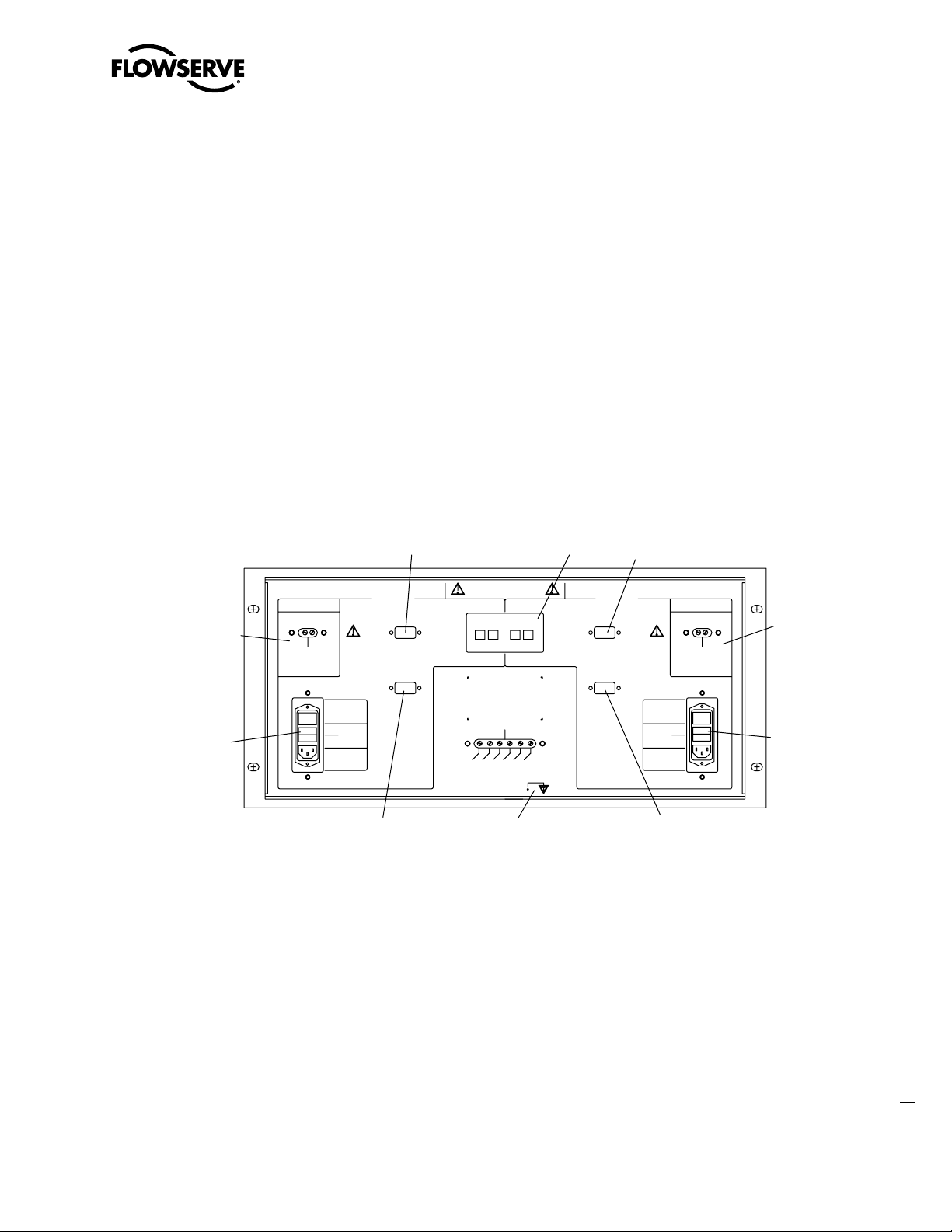

Figure 2.4 – Typical Master Station II (rear view) 11

Figure 2.5 – Redundant connection operation in redundant host loop topology 12

Figure 3.1 – Network connections 30

Figure 3.2 – Removing outer plastic jacket 31

Figure 3.3 – Separating cable parts 32

Figure 3.4 – Stripping conductors 32

Figure 3.5 – Applying heat shrink tubing 33

Figure 3.6 – Ring tongue connectors 33

Figure 3.7 – Connecting network cable to MX terminal block 34

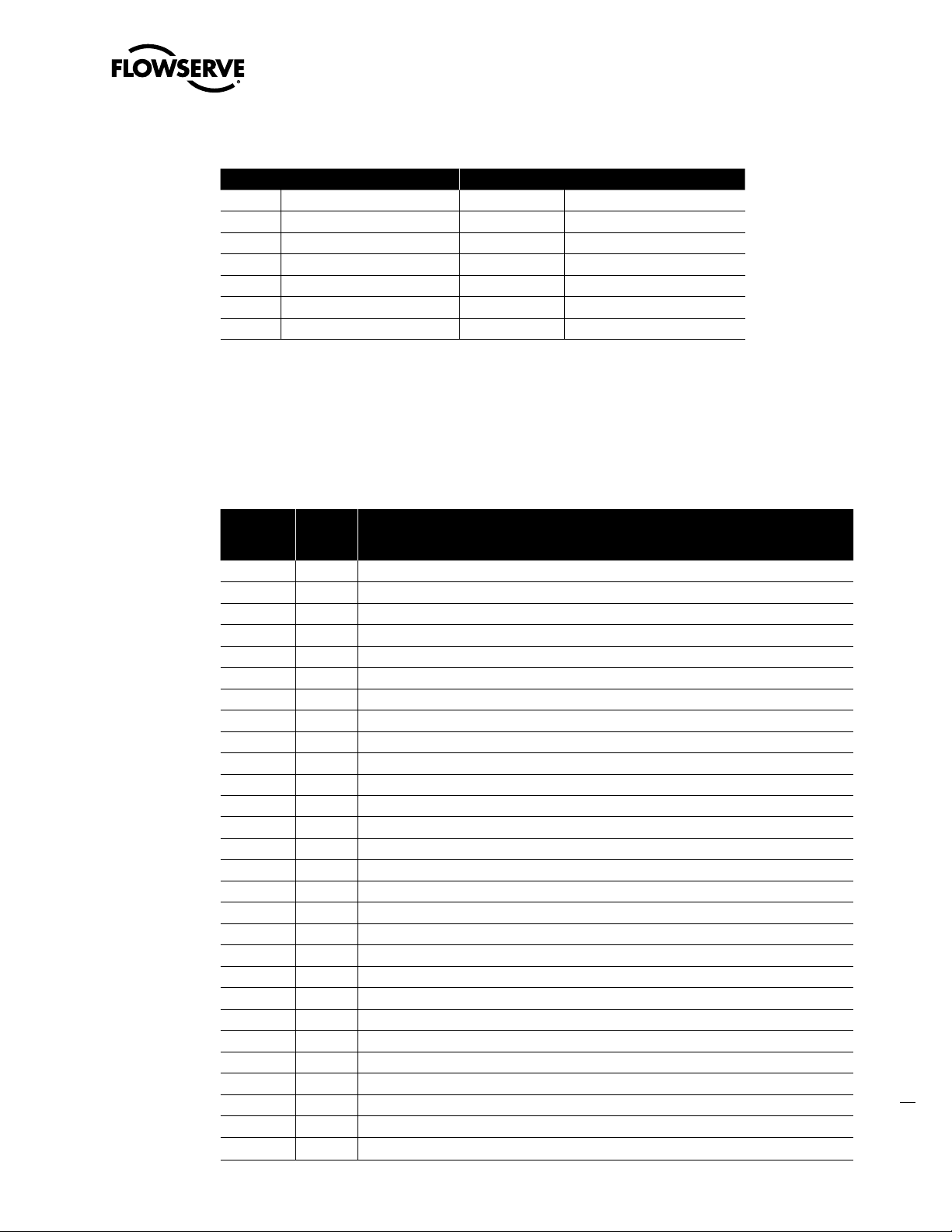

Figure 3.8 – Redundant bi-directional loop topology 36

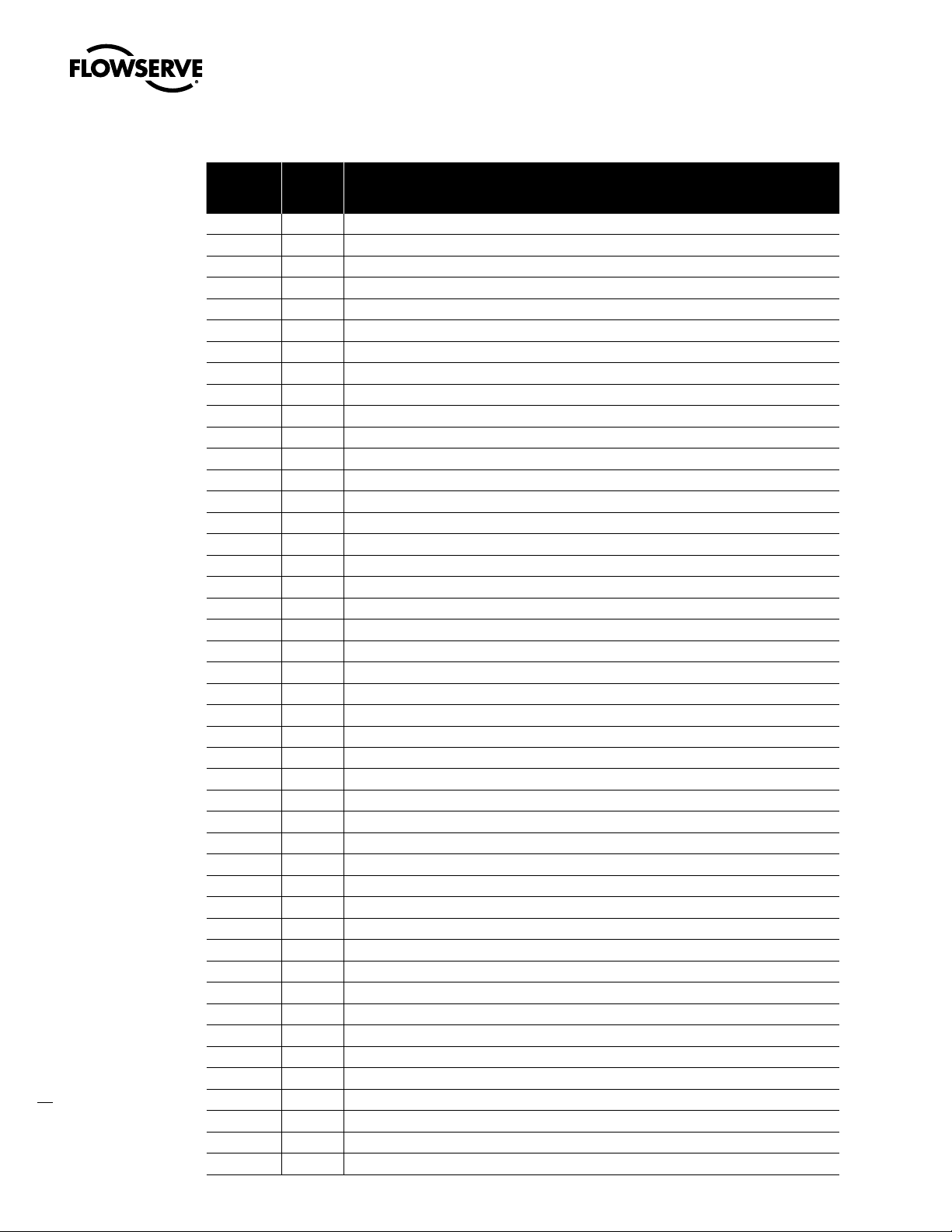

Figure 3.9 – Daisy chain topology 37

Figure 3.10 – Error Messages 44

Figure A.1 (1 of 2) – Typical MX/DDC-100 wiring diagram 52

Figure A.1 (2 of 2) – Typical MX/DDC-100 wiring diagram 53

Figure A.2 - MX Terminal block 54

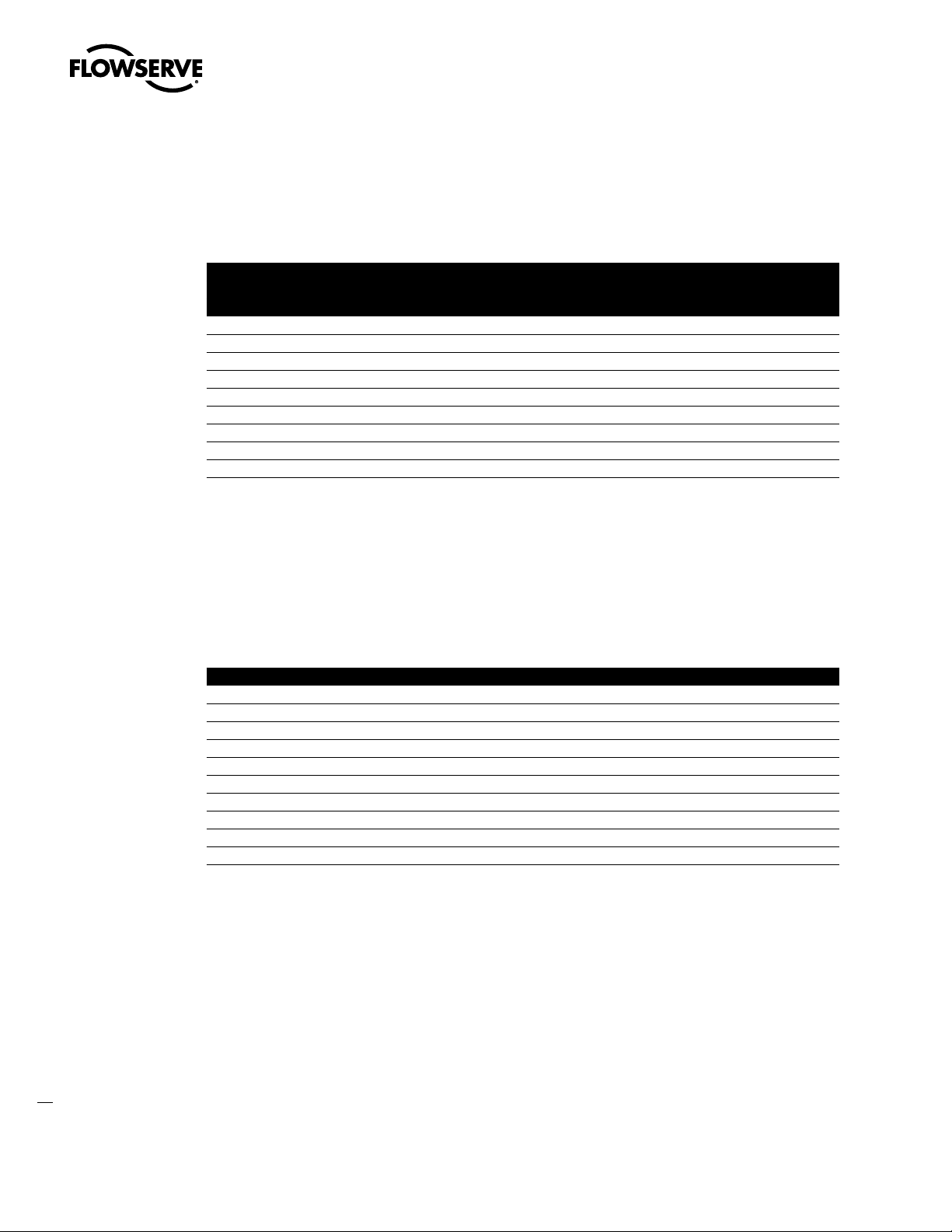

Tables

Table 2.1 – Modbus function codes supported 14

Table 2.2 – DDC-100 coil assignments, Modbus 05 command usage for digital outputs 14

Table 2.3 – Status Bit Definitions 15

Table 2.3 – Status Bit Definitions (continued) 16

Table 2.4 – Register definitions 18

Table 2.4 – Register definitions (continued) 19

Table 2.4 – Register definitions (continued) 20

Table 2.5 – DDC-100 coil assignments, Modbus 05 command usage for digital outputs 22

Table 2.6 – Modbus 06 command and field unit holding register 40001 24

Table 2.7 – Diagnostic Codes Supported by the DDC-100 Field Unit 27

Table 3.3 – Network cable terminations 34

Table 3.4 – MX/DDC digital input configurations (only one selection per row is permitted) 42

Table 3.5 – MX/DDC digital inputs (cross-reference of various inputs) 42

Table 3.6 – Digital input voltages 43

Table 3.7 – MX/DDC digital outputs S1-2 and R1-8 43

4

Page 5

1

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Introduction

1.1 Purpose

This manual explains how to install and operate the Flowserve Limitorque MX™/DDC-100 field unit and is to be used

as an addendum to Bulletin FCD LMENIM2306, MX Electronic Actuator Installation and Operation Manual. Up to 250

actuators, each containing a DDC-100 field unit, may be connected by a single twisted-pair cable to form a DDC-100

network. This network permits the actuators to be operated by various control room devices such as a distributed

control system (DCS), a programmable logic controller (PLC), or a personal computer (PC). The DDC-100 system

communicates status and alarm data from each MX and valve.

1.2 How to Use this Manual

Each section provides the MX user with information on installing and operating the MX field unit.

Section 1 - Introduction

Details user safety and knowledge requirements, system capabilities, and features.

Section 2 - System Components

Focuses on the description of the DDC-100 system hardware and software components.

Section 3 - Installation and Configuration

Provides details for installing and configuring a field unit.

Section 4 - Associated Documents

Provides a list of documents on related subjects for additional MX and DDC-100 system information.

Section 5 - Troubleshooting

Section 6 - How to Order Parts

Appendix A - Wiring Diagram

Details wiring connections.

Appendix B - MX/DDC Register Definitions

Appendix C - Typicl DDC-100 Network Installation Assignments

1.3 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage

to the equipment. The user must read and be familiar with these instructions before attempting installation, operation,

or maintenance. Failure to observe these precautions could result in serious bodily injury, damage to the equipment,

warranty void, or operational difficulty. User must follow local and state safety regulations.

Safety notices are presented in this manual in three forms:

WARNING: c Refers to personal safety. Alerts the user to potential danger. Failure to follow warning notices could

result in personal injury or death.

CAUTION: a Directs the user’s attention to general precautions that, if not followed, could result in personal injury

and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and operation.

flowserve.com

5

Page 6

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

1

2

34

5

250

.

.

.

Host controller

Optional

Master

Station

Network

RS-485

MX field

units

(up to 250)

1.4 User Knowledge

It is recommended that the user read this manual in its entirety before the DDC-100 equipped actuator is installed and

operated.

The user needs to have a fundamental knowledge of electronics and microprocessor concepts. An understanding of

valve actuators and digital control systems is beneficial to the field unit user.

1.5 DDC-100 System Capabilities and Features

Limitorque’s distributed digital control (DDC) valve control network supports up to 250 actuators over a single

twisted-pair cable using Modbus™ protocol. MX actuators and other devices can be accessed from a control room

for integration with a plant asset management (PAM) system, distributed control system (DCS), programmable

logic controller (PLC), or personal computer (PC) based network. The DDC-100 system consists of a host system,

controller, network, and field units. A typical DDC-100 system is shown in Figure 1.1.

Figure 1.1 – Typical DDC-100 system with or without a Master Station II

6

Page 7

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

1.6 General Specifications

Direct-to-Host Specifications:

Direct connection to host controller•

Communicates using the Modbus protocol and the RS-485 electrical standards•

Configurable bitmap•

High-level surge protection on network•

Network Specifications:

Redundant bi-directional loop or daisy chain topology•

Modbus protocol and the RS-485 electrical standards•

High speed—up to 19.2 kbaud communications•

MX Field Unit Specifications:

“• OPEN,” “STOP,” and “CLOSE” commands

“• ESD” and “MOVE–TO” position commands

Actuator status and alarm messages•

Six digital inputs and two analog inputs for user (see • Table 2.2, Register Definitions)

Two surge-protected and mutually isolated communication channels•

MX local control panel configuration•

Torque output (for reference only) and position feedback•

User’s analog input feedback•

Nine digital outputs maximum (three standard/six optional)•

Master Station II (Optional) Specifications:

Supports all Limitorque DDC-100 field units: MX, L120, LY•

Controls up to 250 MOVs•

User-friendly touch panel operator interface:•

Permits configuration and control of DDC-100 network•

Configures communication to host or DCS (Distribution Control System)•

Password protected•

Optional Hot Standby Configuration: Automatically assumes control on Primary Master Failure or on command •

from the DCS or touch panel

Provides realtime status of field units through continuous cyclical polling•

Modbus RTU and TCP/IP:•

Addressable•

RS-232/485/422•

10/100 baseT•

Built-in Web server for ease of actuator and network diagnostics•

7

flowserve.com

Page 8

Piece Description

1 Handwheel

2 Declutch Lever

3 Oil Fills (dotted arrow depicts fill on declutch side)

4 Controls Compartment (field unit location)

5 LCD Display

6 Control Knobs

7 Ground Lug

8 Thrust/Torque Base

9 Conduit Entries

10 Terminal Compartment

11 Motor

12 Nameplate

1

2

3

7

8

4

5

11

12

10

6

9

2

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

System Components

2.1 Introduction

This section gives an overview of the components used in the DDC-100 system. The field unit is installed in each MX

actuator. The network cable connects the field unit to the network via the actuator terminal block. The network cable is

connected to a host controller or Master Station II.

2.2 Hardware

NOTE: Recommended storage procedures are detailed in Bulletin FCD LMENIM2314, MX Maintenance and Spare

Parts Manual. Failure to comply with recommended procedures will void the warranty. For longer-term storage,

contact Flowserve for procedures and recommendations.

Figure 2.1 – MX-05 actuator

8

Page 9

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

2.2.1 MX Actuator

The MX is a multi-turn valve actuator designed for operation of ON-OFF and modulating valve applications. This

actuator controls the opening and closing of valves. See Figure 2.1.

Features of the MX include:

Non-intrusive setup•

Separately sealed terminal chamber•

Absolute encoder for valve position sensing (no battery required) •

32-character graphical LCD display with 180° rotation •

Sophisticated electronic control, monitoring, and diagnostic capabilities with LimiGard™ technology •

2.2.2 DDC–100 Field Unit

The DDC-100 field unit is installed in the MX controls compartment. This unit permits the actuator to be controlled by

a host controller or Master Station II via the DDC-100 network. The field unit includes two high-level, surge-protected,

and isolated network communication channels, configurable digital I/O, and configuration via LCD screen. The

following commands and information may be transmitted over the DDC-100 network:

“• OPEN,” “STOP,” and “CLOSE” commands

“• ESD” and “MOVE–TO” position commands

Actuator status and alarm messages•

Six digital inputs and two analog inputs for user (see • Table 2.2, Register Definitions)

Two surge-protected and mutually isolated communication channels•

MX local control panel configuration•

Torque output (for reference only) and position feedback•

User’s analog input feedback•

Nine digital outputs maximum (three standard/six optional)•

Figure 2.2 – DDC-100 field unit

flowserve.com

9

Page 10

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

DCS PC/PAM PLC

1 250

52

3 4

RS-485

2.2.3 Host Controller

In the DDC-100 system, the network can be connected directly to a host controller without an interposing Master

Station II.

In this configuration, the host sends commands and messages to, and gathers responses from, the field units. The

commands and messages are sent via RS-485 data signals. The gathered responses are stored in a data table in the

host and are periodically updated by sequential polling of the field units. The host controls up to 250 field units. See

Section 3.1.2.3, Network Cable Connection to Host System or Master Station II.

When a host controller is used to directly communicate with the field units, i.e., direct-to-host communications, it

communicates using the Modbus protocol and the RS-485 electrical standard. This host controller can be one of the

following:

Distributed control system (DCS)•

Programmable logic controller (PLC) •

Personal computer (PC)•

Plant Asset Management (PAM) system•

Figure 2.3 – Typical direct-to-host arrangement

10

Page 11

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-00 – 2/08

o

l

FUSES

FUSES

l

o

ETHERNET

DO NOT USE

SINGLE

--

+

24VDC

PROPER OPERATION

INSIDE OF UNIT FOR

INPUT ONLY

EXTERNAL 24VDC

MOVE JUMPERS ON

250 V

INPUT

POWER

~1.5A

100-240VAC

ON

OFF

FUSES

2 AMP

DCS

DATA *

GND

CHANNEL B

PRINTER / DEBUG

WITH 110-240VAC

OPTIONAL

DO NOT USE

HOT STANDBY

GND

DATA *

DATA

DCS

PRINTER / DEBUG

ON

OFF

~1.5A

INPUT

100-240VAC

250 V

POWER

2 AMP

FUSES

--

+

24VDC

PROPER OPERATION

INSIDE OF UNIT FOR

INPUT ONLY

EXTERNAL 24VDC

MOVE JUMPERS ON

WITH 110-240VAC

CHANNEL A

DATA

NO SERVICEABLE PARTS INSIDE

1

2

3

5

4

6

9

7

8

10

2.2.4 Master Station II

A Master Station II may be used in the DDC-100 system. Master Station II’s are normally located in the control room,

and serve as the interface between the field units and the host controller. The following functions are provided:

Continuous polling of actuator network•

Message routing to/from field units •

Data concentration •

Data logging •

In this configuration, the Master Station II receives commands from a host controller. The Master Station II communicates with the host controller using the Modbus Protocol and the RS-232 or RS-485 electrical standard. See Bulletin

FCD LMENIM5001, DDC-100 Master Station II Installation and Operation Manual for details.

The Master Station II sends commands and messages to, and gathers responses from, the field units. The

commands and messages are sent via RS-485 data signals. The gathered responses are stored in a poll table in the

Master Station II and are periodically updated by sequential polling of the field units. The Master Station II controls up

to 250 field units. See Section 3.1.2.3, Network Cable Connection to Host System or Master Station II.

Figure 2.4 – Typical Master Station II (rear view)

1. Ethernet ports

2. Printer/Debug port

3. DCS port

4. Auxiliary 24 VDC power connection

5. Main power switch and connector for 120-240 VAC

6. Electrostatic ground

7. Hot Standby unit main power switch and connector for 120-240 VAC

8. Hot Standby auxiliary 24 VDC power connection

9. Hot Standby DCS Port

10. Hot Standby Printer/Debug Port

11

flowserve.com

Page 12

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Signal initiated from host fails to reach

field unit which is located after fault...

Instead, signal routes to field unit using

other side of the loop cable and

completes connection.

2.2.5 Network Cable

The network consists of a shielded, twisted-pair cable that connects all field units and the host/Master Station II. The

cable is normally connected in a loop fashion so that any single break or short will not disable communication.

Figure 2.5 – Redundant connection operation in redundant host loop topology

12

The network cable connects the field units to the host controller or Master Station II. Belden 3074F, 3105A, or 9841

shielded, twisted-pair cable should be used. The use of other cables may result in a reduction of internodal distances

or increased error rate, and is the user’s responsibility.

Belden 3074F Specifications

Key Specifications

Total cable length between repeaters or nodes with repeaters, up to 19.2 kbps: 5000 ft (1.52 km) For loop •

mode, this is the total length between operating field units. If a field unit loses power, then the relays internal

to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of the cable

(assuming a single field unit fails). To ensure operation within specifications in the event of power failure to

field units, this consideration must be added. Example: To ensure operation within specification when any two

consecutive field units lose power, the maximum length of cable, up to 19.2 kbps, should not exceed 5000 ft

(1.52 km) per every four field units. See Section 3.1.2.3, Network Cable Connection to Host Controller or

Master Station II.

Resistance/1000 ft = 18 AWG (7 x 26) 6.92 ohms each conductor (13.84 ohms for the pair)•

Capacitance/ft = 14 pF (conductor-to-conductor)•

Capacitance/ft = 14 pF (conductor-to-shield)•

Page 13

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Belden 3105A Specifications

Total cable length between repeaters or nodes with repeaters, up to 19.2 kbps: 4500 ft (1.37 km) For loop •

mode, this is the total length between operating field units. If a field unit loses power, then the relays internal

to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of the cable

(assuming a single field unit fails). To ensure operation within specifications in the event of power failure to

field units, this consideration must be added. Example: To ensure operation within specification when any two

consecutive field units lose power, the maximum length of cable, up to 19.2 kbps, should not exceed 4500 ft

(1.37 km) per every four field units. See Section 3.1.2.3, Network Cable Connection to Host Controller or

Master Station II.

Key Specifications

Resistance/1000 ft = 22 AWG (7 x 30) 14.7 ohms each conductor (29.4 ohms for the pair)•

Capacitance/ft = 11.0 pF (conductor-to-conductor)•

Capacitance/ft = 20.0 pF (conductor-to-shield)•

Belden 9841 Specifications

Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 3500 ft (1 km) For loop mode, •

this is the total length between operating field units. If a field unit loses power, then the relays internal to the

field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of the cable (assuming

a single field unit fails). To ensure operation within specifications in the event of power failure to field units, this

consideration must be added. Example: To ensure operation within specification when any two consecutive

field units lose power, the maximum length of cable, up to 19.2 kbps, should not exceed 3500 ft (1 km) per

every four field units. See Section 3.1.2.3, Network Cable Connection to Host Controller or Master Station II.

Key Specifications

Resistance/1000 ft = 24 AWG (7 x 32) 24 ohms each conductor (48 ohms for the pair)•

Capacitance/ft = 12.8 pF (conductor-to-conductor)•

Capacitance/ft = 23 pF (conductor-to-shield)•

2.3 Software

2.3.1 Modbus Protocol

The Modbus protocol was developed by AEG Modicon® for communicating to various networked devices. The

relationship between these devices and a central controller is called a master-slave relationship in which the master

(host device) initiates all communication. The slave devices (DDC-100 field units in the actuators) respond to the

queries from the master.

Modbus only permits one device to communicate at any given time (simultaneous communication is prohibited) to

ensure process control integrity.

flowserve.com

13

Page 14

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

2.3.2 Modbus Function Codes

The controlling device (master) must conform to the Modbus protocol as defined in the Modbus-IDA Modbus

Application Protocol Specification V1.1a (http://www.Modbus-IDA.org) and support Modbus function codes 01

through 06, 08, 15, and 16. These function codes are a subset of the complete protocol and are defined in Table 2.1.

Table 2.1 – Modbus function codes supported

Extended

Function Bit/Register Addressing

Code Name Addressing Range

01 Read Coil Status Bit 0,000 - 9,999

02 Read Discrete Inputs Bit 10.000 - 19,999

03 Read Holding Register Register 40,000 - 49,999

04 Read Input Register Register 30,000 - 39,999

05 Force Single Coil Bit 0,000 - 9,999

06 Preset Single Register Register 40,000 - 49,999

08 Diagnostics N/A N/A

15 Force Multiple Coils Bit 0,000 - 9,999

16 Preset Multiple Registers Register 40,000 - 49,999

See Table 2.2 for a complete listing of MX/DDC holding registers.

2.3.3 Modbus Function Code 01 (Read Coil Status)

This function code is used to read the coil status in the DDC-100 Field Unit. There are nine coils available to be read

on DDC-100 Field Units as shown in Table 2.2. For the MX/DDC, Coil 1 indicates CLOSE contactor and is interlocked

with Coil 2, Coil 2 indicates OPEN contactor and is interlocked with Coil 1. When the I/O Module is used in non-MOV

(motor-operated valve) mode, relays 1 through 6 or coils 3 through 8 are available for user configuration.

Table 2.2 – DDC-100 coil assignments, Modbus 05 command usage for digital outputs

Coil Number Bit Number Function

1 00 Close/Stop

2 01 Open/Stop

3 02 S1 or R1 (Opt) Latched

4 03 S2 or R2 (Opt) Latched

5 04 R3 (Opt) Latched

6 05 R4 (Opt) Latched

7 06 R5 (Opt) Latched

8 07 R6 (Opt) Latched

9 08 R7 (Opt) Latched

10 09 R8 (Opt) Latched

The normal response to the (05) command is an echo of the command.

Example

Poll field unit number 3 for 8 coils starting at coil 1.

Query: 0301000000083C2E

14

Response: 03010118503A

Page 15

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Message Breakdown

Query Response

03 Slave (Field Unit) Address 03 Slave (Field Unit) Address

01 Function 01 Function

00 Starting Address Hi 01 Byte Count

00 Starting Address Lo 18

00 No. of Points Hi 503A Error Check (CRC)

08 No. of Points Lo

3C2E Error Check (CRC)

Note 1: 18h equals 00011000 or coils 4 and 5 are ON.

1

Data (Coils 8 - 1)

2.3.4 Modbus Function Code 02 (Read Input Status)

This function code is used to read the discrete input status bits in the DDC-100 Field Unit. The use of this function

code will provide the user with the input status bits that are used to develop holding registers 9 through 13. The

status bit inputs are contained in locations 10129-10208 for each DDC-100 Field Unit and are defined in Table 2.3.

Table 2.3 – Status Bit Definitions

Bit Number

129 128 Opened

130 129 Closed

131 130 Stopped in mid-travel

132 131 Opening

133 132 Closing

134 133 Valve jammed

135 134 Not in remote

136 135 Combined fault

137 136 Over-temperature fault

138 137 Actuator failing to de-energize

139 138 Channel A fault

140 139 Channel B fault

141 140 Open torque switch fault

142 141 Close torque switch fault

143 142 Valve operated manually fault

144 143 Phase error

145 144 Open inhibit active

146 145 Close inhibit active

147 146 Not used

148 147 Not used

149 148 One or more phases is missing

150 149 Reverse phase sequence is occurring

151 150 ESD conflict

152 151 Inhibit conflict

153 152 Use in local/stop (input must be set for CSE and enabled)

154 153 Not used

155 154 Network emergency shutdown (ESD) is active

156 155 Local emergency shutdown is active

Modbus

Bit

Address

MX/DDC

15

flowserve.com

Page 16

16

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.3 – Status Bit Definitions (continued)

Bit Number

157 156 Field unit microprocessor has reset since the last poll

158 157 MX in stop move

159 158 Opening in local mode

160 159 Closing in local mode

161 160 Close contactor (interlocked)

162 161 Open contactor (interlocked)

163 162 S1 or R1 (opt)

164 163 S2 or R2 (opt)

165 164 R3 (opt)

166 165 R4 (opt)

167 166 R5 (opt)

168 167 R6 (opt)

169 168 R7 (opt)

170 169 Network relay

171 170 R8 (opt)

172 171 Not used

173-176 172-175 Mov series (0=1, A=9)

177 176 Remote switch

178 177 Thermal overload

179 178 Open torque switch

180 179 Open limit switch

181 180 Close torque switch

182 181 Close limit switch

183 182 Not used

184 183 Not used

185 184 User Input 0

186 185 User Input 1

187 186 User Input 2

188 187 Remote stop input

189 188 Remote open input

190 189 Remote close input

191 190 Not used

192 191 Not used

193 192 Analog board 1 present

194 193 Analog board 2 present

195 194 Analog Input #1 lost

196 195 Analog Input #2 lost

197 196 Network Channels A/B timed out

198 197 Relay board R5-R8 present

199 198 DDC board present

200 199 Relay board R1-R4 and RM present

201 200 FF board present

202 201 PB PA board present

203 202 CLE assigned for input 2

204 203 DNET board present

Modbus

Bit

Address

MX/DDC

Page 17

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.3 – Status Bit Definitions (continued)

Bit Number

205 204 Lost Phase Input

206 205 Phase Reverse Input

207 206 Not used

208 207 PB DP board present

Example

Poll field unit number 22 for 16 inputs starting at input 129 with the actuator opening.

Query: 1602008000107B09

Response: 1602020108CDED

Message Breakdown

Query Response

16 Slave (Field Unit) Address 16 Slave (Field Unit) Address

02 Function 02 Function

00 Starting Address Hi 02 Byte Count

80 Starting Address Lo 01

00 No. of Points Hi 08

10 No. of Points Lo CDED Error Check (CRC)

7B09 Error Check (CRC)

Note 1: 01h equals 0000 0001 (actuator open input bit is ON).

Modbus

Bit

Address

MX/DDC

1

Data (Inputs 10136 - 10129)

2

Data (Inputs 10144 - 10137)

Note 2: 08h equals 0000 1000 (actuator Channel B Fail bit is ON).

2.3.5 Modbus Function Code 03 (Read Holding Register)

This function code is used to read the binary contents of holding registers in the DDC-100 Field Unit. This function

code is typically used during the network polling cycle. A network poll should consist of field unit registers 9 (Status)

and 10 (Fault) as a minimum. Holding register 8 should also be polled when the actuator is configured for the analog

feedback option or position control. See Table 2.4 for a complete listing of the holding registers.

17

flowserve.com

Page 18

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.4 – Register definitions

Register # Description Meaning

1 Command Registers 1 and 2 are write-only registers used for Modbus

Function Code 06

2 Argument Registers 1 and 2 are write-only registers used for Modbus

Function Code 06

3 Analog Output 1 Analog Output 1 Value (Default 0-100)

4 Analog Output 2 Analog Output 2 Value (Default 0-100)

5 Analog Input Main Power (Volts)

6 Analog Input Analog Input 1 (Default 0-100)

7 Analog Input Analog Input 2 (Default 0-100)

8 Position Valve Position, Scaled Value (Default 0-100)

9 Status Register 16 Bits of field unit status:

Bit 0 Opened

Bit 1 Closed

Bit 2 Stopped in Mid-Travel

Bit 3 Opening

Bit 4 Closing

Bit 5 Valve jammed

Bit 6 Not in Remote

Bit 7 Combined fault

2

3

Bit 8 Over temperature fault

Bit 9 Future Implementation

Bit 10 Network Channel A fault

Bit 11 Network Channel B fault

Bit 12 Open torque switch fault

Bit 13 Close torque switch fault

Bit 14 Valve-operated manually fault

Bit 15 Phase error

NOTE 1: Default value is scaled 0-100 of span. Changes made to “Analog Scale” affect analog registers (3, 4, 6, 7, 8)

and “move-to” commands. (0-100, 0-255, 0-4095)

1

1

1

User 4-20 mA / 0-20 mA Input

1

User 4-20 mA / 0-20 mA Input

4

(Terminals 5 and 4)

4

(Terminals 13 and 14)

1

18

NOTE 2: MX/DDC actuators shipped after 2nd QTR, 1999, have the following definition of Register 9 Bit 6. When this

bit has a value of 1 or true, the actuator is in LOCAL or STOP (unavailable for network control). The actuator

selector switch in REMOTE (available for network control) is indicated by Register 12 Bit 0 having a value of 1

or true.

IMPORTANT: Verify host program when installing an MX/DDC actuator shipped after 2nd QTR, 1999, on a network

commissioned before 2nd QTR, 1999, for proper indication of selector switch values. Failure to verify proper selector

switch indication at the host may cause unsafe conditions at the facility.

MX/DDC actuators shipped prior to 2nd QTR, 1999, have the following definition for Register 9 Bit 6. When this bit has

a value of 1 or true, the actuator selector switch is in LOCAL mode. This bit does not indicate STOP or REMOTE. The

actuator selector switch in REMOTE (available for network control) is indicated by Register 12 Bit 0 having a value of 1

or true. Register 9 Bit 6 value 0 (zero) or false AND Register 12 Bit 0 value 0 (zero) or false indicates selector switch is

in the STOP position.

NOTE 3: Combined Fault bit is high when Bit 5 or 8 or 9 or 15 or (Bits 10 and 11) is high.

NOTE 4: Channel A is physical connection A1. Channel B is physical connection A2. (See Appendix A.)

Page 19

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.4 – Register definitions (continued)

Register # Description Meaning

10 Fault Register 16 Bits of field status

Bit 0 Open inhibit active

Bit 1 Close inhibit active

Bit 2 Not Used

Bit 3 Not Used

Bit 4 One or more phases are missing

Bit 5 Reverse phase sequence is occurring

Bit 6 ESD conflict

Bit 7 Inhibit conflict

Bit 8 CSE in local/stop (input must be set for CSE and enabled)

Bit 9 Not Used

Bit 10 Network emergency shutdown is active

Bit 11 Local PB emergency shutdown is active

Bit 12 Field unit microprocessor has reset since the last poll

Bit 13 MX in stop mode

Bit 14 Opening in local mode

Bit 15 Closing in local mode

11 Digital Outputs Value of 16 Digital Outputs

Bit 0 Close contactor (Interlocked)

Bit 1 Open contactor (Interlocked)

Bit 2 S1 or R1 (Opt)

Bit 3 S2 or R2 (Opt)

Bit 4 R3 (Opt)

Bit 5 R4 (Opt)

Bit 6 R5 (Opt)

Bit 7 R6 (Opt)

Bit 8 R7 (Opt)

Bit 9 Network Relay

Bit 10 R8 (Opt)

Bit 11 Not Used

BIT 12-15 MOV Series (0 = 1, A = 9)

12 Digital Inputs 1 Value of 16 Digital Inputs

Bit 0 Remote Switch

Bit 1 Thermal Overload

Bit 2 Open Torque Switch

Bit 3 Open Limit Switch

Bit 4 Close Torque Switch

Bit 5 Close Limit Switch

Bit 6 Not Used

Bit 7 Not Used

Bit 8 User Input 0 (Default=ESD), Terminal 30

Bit 9 User Input 1 (Default=Open Inhibit), Terminal 34

Bit 10 User Input 2 (Default=Close Inhibit), Terminal 35

Bit 11 Remote Stop Input, Terminal 26

Bit 12 Remote Open Input, Terminal 25

Bit 13 Remote Close Input, Terminal 27

Bits 14-15 Not Used

flowserve.com

19

Page 20

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.4 – Register definitions (continued)

Register # Description Meaning

13 Digital Inputs 2 Value of 16 Digital Inputs

Bit 0 Analog board 1 present

Bit 1 Analog board 2 present

Bit 2 Analog Input 1 lost

Bit 3 Analog Input 2 lost

Bit 4 Network Channels A/B timed out

Bit 5 Relay board R5-R8 present

Bit 6 DDC board present

Bit 7 Relay board R1-R4 and RM present

Bit 8 Foundation Fieldbus board present

Bit 9 Profibus PA board present

Bit 10 CSE chosen for input 2

Bit 11 DeviceNet board present

Bit 12 Phase lost

Bit 13 Phase reverse

Bit 14 Not Used

Bit 15 Profibus DP board present

14 Timers and Analog Channels Internal compartment temperature

15 User Faults Bits 0-15 Not Used

16 Current State Bits 0-15 Not Used

17 Field Unit Holding Register Special Applications Only

18 Field Unit Holding Register Special Applications Only

19 Field Unit Holding Register Special Applications Only

20 Field Unit Holding Register Special Applications Only

21 Field Unit Holding Register Special Applications Only

22 Field Unit Holding Register Special Applications Only

23 Field Unit Holding Register Special Applications Only

24-44 Reserved Special Applications Only

45-47 Not Named Special Applications Only

48 TP_START_POSITION Special Applications Only

49 TP_STOP_POSITION Special Applications Only

50 TP_SAMPLE Special Applications Only

51 TP_MID_T_HIGH Special Torque Applications Only

52 TP_MID_T_POS Special Applications Only

53 TP_MID_T_AV_VAL Special Torque Applications Only

54 TP_STOP_VAL Special Applications Only

55 TP_BEFORE_ MID_T_HIGH Special Torque Applications Only

56 TP_AFTER_ MID_T_HIGH Special Torque Applications Only

Note 1: Range is +90°C to -55°C. High byte 00 indicates positive (+) and 01 indicates negative (-). Low byte indicates temperature

value.

Example: 0x0019 = +25°C

0x011E = -30°C

1

20

Example

Poll field unit number 125 for 3 registers starting at register 8 with the actuator stopped between the limits and in

local mode.

Query: 7D0300070003BFF6

Response: 7D0306003D084400003E07

Page 21

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Message Breakdown

Query Response

7D Slave (Field Unit) Address 7D Slave (Field Unit) Address

03 Function 03 Function

00 Starting Address Hi 06 Byte Count

07 Starting Address Lo 00 Data Hi (Register 40008)

00 No. of Points Hi 3D

03 No. of Points Lo 08 Data Hi (Register 40009)

BFF6 Error Check (CRC) 44

Note 1: 003Dh equals 61 Decimal (actuator Analog Input 1 in percent format).

Note 2: 0844h equals 2116 Decimal or 0000 1000 0100 0100 Binary (actuator stopped between limits,

local mode, and Channel B Fail bit is ON).

1

2

00 Data Hi (Register 40010)

00 Data Lo (Register 40010)

3E07 Error Check (CRC)

Data Lo (Register 40008)

Data Lo (Register 40009)

2.3.6 Modbus Function Code 04 (Read Input Register)

This function code is used to read the binary contents of input registers in the DDC-100 Field Unit. The typical use

of this function code is to read the analog input registers. If the field unit is configured for scaled analog data, the

register information will be returned as a percent from 0 to 100 (see NOTE below). The first analog input register

(Analog 4) will start at register 30005 through (Analog 1) Input Register 30008.

This function code may also be used to read the information available in registers 9 through 16.

NOTE: Limitorque field units can be configured to report analog data in several formats. See the appropriate field unit

manual for details.

Example

Poll field unit number 70 for 4 registers starting at register 5 (Analog Input Registers 1-4).

(This example assumes that the field unit is configured for scaled analog data.)

Query: 460400040004BF7F

Response: 460408FFFFFFFF002B001EDBA8

flowserve.com

21

Page 22

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Message Breakdown

Query Response

46 Slave (Field Unit) Address 46 Slave (Field Unit) Address

04 Function 04 Function

00 Starting Address Hi 08 Byte Count

04 Starting Address Lo FF Data Hi (Register 40005)

00 No. of Points Hi FF

04 No. of Points Lo FF Data Hi (Register 40006)

BF7F Error Check (CRC) FF

Note 1: FFFFh equals 65535 Decimal (actuator Analog Input 4 value).

Note 2: FFFFh equals 65535 Decimal (actuator Analog Input 3 value).

Note 3: 002Bh equals 43 Decimal (actuator Analog Input 2 value).

Note 4: 001Eh equals 30 Decimal (actuator Analog Input 1 in percent format).

1

Data Lo (Register 40005)

2

Data Lo (Register 40006)

00 Data Hi (Register 40007)

3

2B

00 Data Hi (Register 40008)

1E

DBA8 Error Check (CRC)

Data Lo (Register 40007)

4

Data Lo (Register 40008)

2.3.7 Modbus Function Code 05 (Force Single Coil)

This function code is used to force a single coil in the DDC-100 Field Unit. Forcing the individual coil either ON (1) or

OFF (0) will energize or de-energize a coil (digital output) in the field unit. Coil 1 in the field unit closes the actuator

and Coil 2 opens the actuator. If the actuator is opening or closing, changing the status of coil 1 or 2 from a value of

1 to 0 will stop the actuator (the coil will automatically be set to zero when the actuator reaches the full open or full

close position).

Available digital outputs for DDC-100 Field Units are listed in Table 2.5. Force-coil commands should be issued

only once for the desired field unit control. Repeated issuance of an acknowledged command will degrade network

performance.

NOTE: See Bulletin LMAIM1329, Accutronix Installation and Operation for MX-DDC Field Unit to configure AS and

AR Relays for DDC control.

Table 2.5 – DDC-100 coil assignments, Modbus 05 command usage for digital outputs

Coil Number Bit Number Function

1 00 Close/Stop

2 01 Open/Stop

3 02 S1 or R1 (Opt) Latched

4 03 S2 or R2 (Opt) Latched

5 04 R3 (Opt) Latched

6 05 R4 (Opt) Latched

7 06 R5 (Opt) Latched

8 07 R6 (Opt) Latched

9 08 R7 (Opt) Latched

10 09 R8 (Opt) Latched

The normal response to the (05) command is an echo of the command.

22

Page 23

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Example of force coil command

Force coil 1 of field unit 49 ON. This will CLOSE the valve controlled by field unit 49.

Query: 31050000FF0089CA

Response: 31050000FF0089CA

Message Breakdown

Query Response

31 Slave (Field Unit) Address 31 Slave (Field Unit) Address

05 Function 05 Function

00 Coil Address Hi 00 Coil Address Hi

1

00

FF Force Data Hi FF Force Data Hi

2

00

89CA Error Check (CRC) 89CA Error Check (CRC)

Note 1: 0000h equals Coil Address 00000001 (field unit coil 1).

0001h equals Coil Address 00000010 (field unit coil 2).

Note 2: FF00h requests the coil to be ON. (0000h requests the coil to be OFF)

Coil Address Lo 00 Coil Address Lo

Force Data Lo 00 Force Data Lo

2.3.8 Modbus Function Code 06 (Preset Single Register)

This function code is used to preset a single register in the field unit. The function code is typically used to command

the DDC-100 Field Unit by writing values to the 40001 and 40002 registers. A predetermined value may be used to

open/stop/close the actuator, move the actuator to a preset position, activate/deactivate network ESD, reset the field

unit, etc.

The Modbus function code 06 is also used to command a throttling actuator to “move-to” a position of 0-100% of

open. The field unit will compare the new position value with the current position and open or close the valve to meet

the new position requirement. This is a two-step command: the first step is to write the desired position value to the

field unit register 40002, then write the value of 6656 to field unit register 40001. This sequence of commands loads

the desired position, then instructs the field unit to execute the command.

For field units containing Modbus Firmware 2.00 or greater and MX-DDC field units containing Firmware 02/01.00 or

greater, the “move-to” command may be executed with a one-step command.

Modbus function code 06 command values for controlling the DDC-100 Field Unit are given in Table 2.6. Each

command should be issued only one time for the desired field unit control. Repeated issuance of an acknowledged

command will degrade network performance.

The normal response to the (06) command is an echo of the command.

NOTE:

1) Only use values listed in Table 2.6 For field unit register 40001.

2) Field Unit Register 40002 should only be used for “move-to” position input.

3) The Host MUST issue “move-to” commands in the proper sequence. Failure to issue this two-step command

in the correct sequence will result in the field unit waiting for the proper command sequence execution before

performing the “move-to” function.

4) The “move-to” command should only be used with field units that include the position control option.

5) Do not write to Field Unit Registers 5-16.

flowserve.com

23

Page 24

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Table 2.6 – Modbus 06 command and field unit holding register 40001

Host Commands to Field Unit Register 1 Value (Decimal) Function

Null Command 0 No action

Open 256 Open actuator

Stop 512 Stop actuator

Close 768 Close actuator

Reset Field Unit 1024 Reset processor

Start Network ESD 1280 ESD initiate

Stop Network ESD 1536 ESD terminate

Engage Relay #1 2304 S1 or R1 (opt)

Engage Relay #2 2560 S2 or R2 (opt)

Engage Relay #3 2816 R3 (opt)

Engage Relay #4 3072 R4 (opt)

Engage Relay #5 3328 R5 (opt)

Engage Relay #6 3584 R6 (opt)

Engage Relay #7 3840 R7 (opt)

Disengage Relay #1 4352 S1 or R1 (opt)

Disengage Relay #2 4608 S2 or R2 (opt)

Disengage Relay #3 4864 R3 (opt)

Disengage Relay #4 5120 R4 (opt)

Disengage Relay #5 5376 R5 (opt)

Disengage Relay #6 5632 R6 (opt)

Disengage Relay #7 5888 R7 (opt)

Move-To (Enable)

Engage Relay #8 6912 R8 (opt)

Disengage Relay #8 7168 R8 (opt)

Note 1: This is a two-step command. A valid value must be written to Register 2 before issuing this command.

(See Note 1 of Table 2.2.)

Other registers may also be preset to control or change other functions but care must always be taken to properly

change these values. An improper value written to a register can cause undesirable actions from the DDC-100 Field

Unit.

1

6656 Initiates “move-to”

24

NOTE: Null Command–The field unit takes no action when this command is received. This command is typically used

by a Host to reset the Host output register when required.

Example of Field Unit Command

Write the command to open an actuator (actuator open) to field unit number 179. This corresponds to writing the

value 256 into field unit register 40001.

Query: B306000001009388

Response: B306000001009388

Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

1

00

01 Force Data Hi 01 Preset Data Hi

2

00

9388 Error Check (CRC) 9388 Error Check (CRC)

Note 1: 0000h equals Register Address 40001 (field unit register 1, command register).

Note 2: 0100h requests the register to be preset with 256 Decimal (engage open contactor).

Register Address Lo 00 Register Address Lo

Force Data Lo 00 Preset Data Lo

Slave (Field Unit)

Address

Page 25

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Example of “Move-To” Command

Move an actuator at address 179 to 42% of open by first writing the value of 42 to the field unit 40002 register. After

receiving a response from the field unit, write the value of 6656 to the field unit 40001 register. The actuator will then

move to a position of 42% of open.

First Command

Query: B3060001002A4207

Response: B3060001002A4207

First Command Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

1

01

00 Force Data Hi 00 Preset Data Hi

2

2A

4207 Error Check (CRC) 4207 Error Check (CRC)

Note 1: 001h equals Register Address 40002 (field unit register 2, argument register).

Register Address Lo 01 Register Address Lo

Force Data Lo 2A Preset Data Lo

Slave (Field Unit)

Address

Note 2: 002Ah equals 42.

Second Command

Query: B30600001A009978

Response: B30600001A009978

Second Command Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

1

00

1A Force Data Hi 1A Preset Data Hi

2

00

9978 Error Check (CRC) 9978 Error Check (CRC)

Note 1: 0000h equals Register Address 40001 (field unit register 1, command register).

Note 2: 1A00h equals 6656.

Register Address Lo 00 Register Address Lo

Force Data Lo 00 Preset Data Lo

Slave (Field Unit)

Address

Example of single register write “move-to” command

This command allows a Host to issue the “move-to” command with a single write utilizing the Modbus function code

06. Register 1 will be used to complete this command.

Rules for utilizing this command:

Field unit scaling must be configured for 0-100.•

To use the hexadecimal method of determining a single write “move-to” command, 0x4B is always placed into the •

Hi Byte of Register 1. The desired position value is always placed into the Lo Byte of Register 1.

25

flowserve.com

Page 26

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

To move the actuator to a position of 50%, place the value 0x4B in the high byte and the value of 0x32 (50 decimal) •

into the low byte.

Example:

Hex format: 0x4B32

To use the decimal method of determining a single write “move-to” command, add the desired position value to

19200.

Example:

Desired position: 50%

19200 + 50 = 19250

Example of single write “move-to” command

Move an actuator at address 1 to 50% of open by writing the value of 19250 (0x4B32) to the field unit 40001 register.

The actuator will then move to a position of 50% open.

Example

Query: 010600004B323EEF

Response: 010600004B323EEF

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

06 Function 06 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

4B Preset Data Hi 4B Preset Data Hi

32 Preset Data Lo 32 Preset Data Lo

3EEF Error Check (LRC or CRC) 3EEF Error Check (LRC or CRC)

2.3.9 Modbus Function Code 08 (Diagnostics)

This function code provides a series of tests for checking the communication system between the Host and field units

(slaves), or for checking various error conditions within the field unit. This function code uses a two-byte subfunction

code field in the query to define the type of test to be performed. The field unit echoes both the function code and

subfunction code in a normal response. It does not affect the field unit in any way. If this exchange is successful, then

the communication is successful.

A listing of the supported diagnostic two-byte subfunction codes is given in Table 2.7.

Example

Request a loopback (return query data) from the field unit at network address 3.

26

Query: 030800000000E1E9

Response: 030800000000E1E9

Page 27

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Message Breakdown

Query Response

03 Slave (Field Unit) Address 03 Slave (Field Unit) Address

08 Function 08 Function

00 Subfunction Hi 00 Subfunction Hi

00 Subfunction Lo 00 Subfunction Lo

00 Data Hi 00 Data Hi

00 Data Lo 00 Data Lo

E1E9 Error Check (CRC) E1E9 Error Check (CRC)

Table 2.7 – Diagnostic Codes Supported by the DDC-100 Field Unit

Code Name

00 Return Query Data

01 Restart Communication Option

02 Return Diagnostic Register

03 Change ASCII Input Delimiter

04 Force Listen-Only Mode

10 (0A Hex) Clear Counters and Diagnostics Register

11 (0B Hex) Return Bus Message Count

12 (0C Hex) Return Bus Communication Error Count

13 (0D Hex) Return Bus Exception Error Count

14 (0E Hex) Return Slave Message Count

Note 1: Contains DDC-100 Field Unit diagnostic information. For engineering use only.

1

2.3.10 Modbus Function Code 15 (Force Multiple Coils)

This function code allows the user to force multiple coils with a single command and uses the same coil assignments

as the function code 05.

It should be noted that the coils are operated from the lowest coil number to the highest. Forcing coil 1 or 2 OFF (0) is

considered a stop command, sending a 15 command to force two coils starting with coil 1, with coil 1 ON and coil 2

OFF, would result in the unit stopping, since coil 2 is forced OFF after coil 1 is forced ON.

To prevent inadvertent Stop commands from being issued, it is recommended to force one coil at a time.

Available digital outputs for DDC-100 Field Units are listed in Table 2.5. Force multiple coil commands should be

issued only once for the desired field unit control. Repeated issuance of an acknowledged command will degrade

network performance.

NOTE: This function code is implemented in UEC-3-DDC Modbus Firmware 2.00 and greater and MX-DDC Firmware

02/01.00 and greater

Example of force coil command

Force coil 1 of field unit 1 ON. This will CLOSE the valve controlled by field unit 1.

Query: 010F000000010101EF57

Response: 010F00000001940B

27

flowserve.com

Page 28

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

0F Function 0F Function

00 Coil Address Hi 00 Coil Address Hi

00 Coil Address Lo 00 Coil Address Lo

00 Quantity of Coils Hi 00 Quantity of Coils Hi

01 Quantity of Coils Lo 01 Quantity of Coils Lo

01 Byte Count 940B Error Check (LRC or CRC)

01 Force Data Lo

EF57 Error Check (LRC or CRC)

Note: 000000010101h equals Coil Address 00000001 (field unit coil 1)

000100010101h equals Coil Address 00000010 (field unit coil 2)

2.3.11 Modbus Function Code 16 (Preset Multiple Registers)

This function code is used to preset single or multiple registers in the field unit and uses the same predetermined

register values as the function code 06. This function code is typically used to command the DDC-100 Field Unit by

writing values to the 40001 and/or 40002 registers.

28

Modbus function code 16 command values for controlling the DDC-100 Field Unit are given in Table 2.6. Each

command should be issued only one time for the desired field unit control. Repeated issuance of an acknowledged

command will degrade network performance.

The normal response returns the slave address, function code, starting address, and quantity of registers preset.

NOTE: This function code is implemented in DDC Modbus Firmware 2.00 and greater and MX-DDC Firmware

02/01.00 and greater.

Example of Field Unit Command

Write the command to open an actuator (actuator open) to field unit number 1. This corresponds to writing the value

256 into field unit register 40001.

Query: 011000000001020100A7C0

Response: 01100000000101C9

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

10 Function 10 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

00 Number of Registers Hi 00 Number of Registers Hi

01 Number of Registers Lo 01 Number of Registers Lo

02 Byte Count 01C9 Error Check (LRC or CRC)

01 Preset Data Hi

00 Preset Data Lo

A7C0 Error Check (LRC or CRC)

Page 29

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Example of “Move-To” Command

Move an actuator at address 1 to 50% of open by presetting registers 40001 with the value 6656, and register 40002

with the value 50 in a single write command. The actuator will receive this message and move to a position of 50%

open.

Query: 011000000002041A0000327562

Response: 01100000000241C8

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

10 Function 10 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

00 No. of Registers Hi 00 No. of Registers Hi

02 No. of Registers Lo 02 No. of Registers Lo

04 Byte Count 41C8 Error Check (LRC or CRC)

1A Preset Data Hi

00 Preset Data Lo

00 Preset Data Hi

32 Preset Data Lo

7562 Error Check (LRC or CRC)

Note: The single register write “Move-to” command may also be used with the function code 16.

This function code may also utilize the Single Register write “move-to” command.

29

flowserve.com

Page 30

3

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Installation and Configuration

3.1 Site and Network Cable Preparation

3.1.1 Site Preparation

Prepare the site and associated equipment for operation of the DDC-100 controlled MX actuators as follows:

1. Prepare a detailed site plan consisting of the following:

Actuator locations, tag numbers, DDC addresses•

Junction boxes, terminal strip locations, and tag numbers •

2. Provide free access to the MX control panel and terminal block for setup, configuration, and troubleshooting.

3. Prepare cable and label all wires. See Section 3.1.2, Network Cable Preparation.

4. nstall power and control wires in separate conduits. Shielding is not sufficient to prevent induction of stray

voltages onto signal leads from the power lines.

5. Install and verify earth grounds.

NOTE: Limitorque defines an effective local earth ground as a low impedance (less than 5 ohms) path to:

A ground electrode placed in close vicinity of the actuator that is free of ground loop currents. • OR

A safety ground that is free of ground loop currents running from the actuator back to the system ground elec-•

trode. If the signal wiring is run on aerial cable where it may be exposed to high-energy electrostatic discharge

(such as lightning), a low impedance path to ground that is capable of high current must be provided a short

distance from the actuator as described above. OR

A power distribution grid identifying the impact of power isolation to a particular actuator or group of actuators •

should be provided.

3.1.2 Network Cable Preparation

3.1.2.1 Network Cable Connection to the Field Unit

The DDC-100 field unit is connected to the network via the MX terminal block. The network cable is connected to the

terminal block as shown in Figure 3.1.

Figure 3.1 – Network connections

30

NOTE:

1. Shielded, twisted-pair cables should be used.

2. Shields are connected to earth ground at one end only to avoid ground loops.

Page 31

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

3. Clean earth-ground connection (less than 5 ohms) enhances noise rejection and provides a clear/safe path for

surge currents.

Prepare the network cable for connection to the MX terminal block as follows.

CAUTION: a Strip stranded conductors carefully; do not damage the strands. This will weaken the conductor. Do

not nick conductors or conductor insulation when stripping away the insulation. Nicking stresses the conductor

and can cause the conductor to break. This type of damage may not be apparent and failure can occur later

without warning.

NOTE: Multi-pair cables should provide shielding for each conductor pair.

NOTE: Excess cable should be cut, not coiled or looped, to prevent noise induction into the network and to reduce

signal loss through unnecessarily long cable runs.

Cable Preparation

1. Remove two to three inches (5 to 8 cm) of the outer plastic jacket as shown in Figure 3.2.

Figure 3.2 – Removing outer plastic jacket

flowserve.com

31

Page 32

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

2. Separate the cable parts. Unbraid the shield and peel back the foil shield to the same point where the outer jacket

was removed as shown in Figure 3.3.

Figure 3.3 – Separating cable parts

3. Cut away the braided shield and the foil shield. Strip the insulation from the conductors approximately 0.4 inch (1

cm) as shown in Figure 3.4.

Figure 3.4 – Stripping conductors

32

Page 33

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

4. Apply heat shrink tubing to insulate the drain wire and to provide stress relief to the cable as shown in

Figure 3.5.

Figure 3.5 – Applying heat shrink tubing

CAUTION: a Do not melt the insulation.

NOTE: Ungrounded drain wires should be cut even with the cable sheath. The brand foil and drain wire should have

heat shrink tubing applied.

5. Install ring tongue connectors as shown in Figure 3.6.

Flowserve recommends the use of Thomas & Betts #RZ22-6 for optimum results.

Figure 3.6 – Ring tongue connectors

flowserve.com

33

Page 34

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

6. Connect the network cables to the MX terminal block as shown in Figure 3.6. Table 3.3 defines each network cable

termination. Refer to Figure 3.8 and 3.9 for topology-specific wiring connections.

Table 3.3 – Network cable terminations

Terminal Block Number Function

4 NETWORK

5 NETWORK

14 NETWORK

13 NETWORK

3 NETWORK SURGE (EGND)

NOTE: Ground each segment of the cabling at only one point to prevent ground loops, which can affect system

performance. Verify the actuator is properly grounded.

7. Install jumper cable from terminal block pin 3 to earth ground or ground lug.

Figure 3.7 – Connecting network cable to MX terminal block

34

Page 35

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

3.1.2.2 Network Cable Connection to Host Controller or Master Station II

Two network topologies are commonly used and supported for the MX:

Redundant bi-directional loop (recommended)•

Daisy chain•

Redundant Bi-Directional Loop

The redundant bi-directional loop topology requires two serial communication ports on the host device.

Each field unit can be accessed by two host/master ports.•

The connections from the serial ports to the field units and connections between field units are made with •

shielded, twisted-pair cable in a loop configuration.

A single line break or short can occur while maintaining communication to all field units. • Figure 3.8 shows the

redundant bi-directional loop network topology for a direct-to-host connection.

The redundant bi-directional loop topology is wired as follows: see Figure 3.8.

1. Connect the host device port 1, through an RS-232 to RS-485 converter if required, to the first field unit port

A1 at MX terminal block numbers 4 and 5.

2. Connect the port A2 at MX terminal block numbers 14 and 13 to the next field unit’s port A1.

3. Each subsequent field unit is connected in the same manner – receiving data through its port A1, then passing

the data out through its port A2 to the next field unit.

4. The last field unit’s port A2 is connected to the host device’s port 2. The host device should be configured to

ignore messages that it sends out when it returns to its other port.

The direction of data flow can be reversed because of the bi-directional capability of the serial ports.

a. Communications can be initiated by connecting host port 2 to first field unit port A2.

b. Port A1 of the first field unit is then connected to port A2 of the next field unit.

c. Port A1 of the last field unit is then connected to host port 1.

In either direction, the signal is regenerated in each field unit to permit long-distance communication with reduced

noise sensitivity and improved reliability.

flowserve.com

35

Page 36

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

N/C

Notes:

1. Belden 3074F, 3105A, or 9841 shielded cable is recommended.

2. Correct polarity for field unit and network controller connection is

necessary for proper operation.

3. Connections shown are typical. The number of MOVs shown may not

indicate true system size.

4. Earth ground: ground rod

5. Earth ground: ground rod or lug in actuator if actuator is grounded.

Diagnostic note:

Polarity and level of the network’s data connection can be checked by

measuring voltage between data and data* terminals. This voltage should

be greater than +200 mV DC with network controller (host) network ports

disconnected. Data terminal is positive with respect to data* terminal.

Earth ground note:

If low impedance earth ground is not available at each actuator, contact

engineering for alternative earth ground surge protection strategies.

Legend

MOV

N/C

Data terminal is positive with respect to data* terminal

Data 1

Earth ground

(See Note 4)

Host

RS-485

PORT

1

Network port A

RS-485

PORT

2

Network port B

A1*

MOV-1

See Note 5

N/C

A2*

N/C

MOV-249

See Note 5

N/C

MOV-3

See Note 5

N/C

5

4

13

14

14

13

Ground 3

Data* 2

Data 1

Data* 2

4

33

33

3

3

5A2A1

A1*

A2*

14

13

4

5A2A1

A1*

A2*

14

13

4

5A2A1

- Motor-operated valve

- Data A1

- Data A1*

- Data A2

- Data A2*

- Shield

- No connection

N/C

Earth ground

(See Note 4)

Ground 3

N/C

MOV-2

See Note 5

A1*

A2*

14

13

4

5A2A1

MOV-248

See Note 5

A1*

A2*

14

13

4

5A2A1

MOV-250

See Note 5

A1*

A2*

14

13

4

5A2A1

(Network

controller)

Figure 3.8 – Redundant bi-directional loop topology

Daisy Chain

The daisy chain topology is identical to the redundant loop topology with the following exception: only one end of the

network is connected to the host device.

The daisy chain topology is wired as follows:

1. Connect the host port 1 to the first field unit port A1 at MX terminal block numbers 4 and 5.

2. Connect port A2 of this field unit at MX terminal block numbers 14 and 13 to port A1 of the next field unit.

3. Continue steps 1 and 2 until the last field unit is connected.

NOTE: If a stub cable is run from port A2 of the last field unit (MX terminal block numbers 14 and 13) to a planned

field unit location, or the last field unit is disconnected, the open end of the cable must be terminated with a 120 ohm

resistor to prevent unacceptable signal reflections. Termination impedance is supplied when the actuator field unit is

36

the last unit.

The daisy chain topology utilizes the field unit repeater circuitry, and therefore supports the same number of field

units and distances as the redundant bi-directional loop topology. However, the daisy chain topology is less reliable

than the redundant bi-directional loop topology because the host can only reach the field units from one direction. If a

data cable break occurs, communication will be lost to all nodes on the far side of the break.

Page 37

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

Figure 3.9 – Daisy chain topology

Legend

MOV

- Motor-operated valve

5

- Data A1

- Data A1*

4

- Data A2

13

14

- Data A2*

- Shield

N/C

- No connection

Data terminal is positive with respect to data* terminal

Host

(Network controller)

RS-485

PORT 1

Network port A

Data 1

Data* 2

Ground 3

N/C

Earth ground

(See Note 4)

MOV-1

See Note 5

3

A1*

4

A1

5

14

A2*

A2

13

MOV-2

See Note 5

3

A1*

4

A1

5

14

N/C

A2*

A2

13

N/C

MOV-3

See Note 5

3

A1*

4

5A2A1

14

A2*

13

N/C

MOV-250

See Note 5

3

4

A1*

5A2A1

14

A2*

13

Notes:

1. Belden 3074F, 3105A, or 9841 shielded cable is recommended.

2. Correct polarity for field unit and network controller connection is

necessary for proper operation.

3. Connections shown are typical. The number of MOVs shown may not

indicate true system size.

4. Earth ground: ground rod

5. Earth ground: ground rod or lug in actuator if actuator is grounded.

MOV-249

See Note 5

3

4

A1*

5A2A1

14

N/C

A2*

13

N/C

MOV-248

See Note 5

3

4

A1*

5A2A1

14

A2*

13

Diagnostic note:

Polarity and level of the network’s data connection can be checked by

measuring voltage between data and data* terminals. This voltage should

be greater than +200 mV DC with network controller (host) network ports

disconnected. Data terminal is positive with respect to data* terminal.

Earth ground note:

If low impedance earth ground is not available at each actuator, contact

engineering for alternative earth ground surge protection strategies.

flowserve.com

37

Page 38

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

3.2 Installation Verification

3.2.1 Network Cabling Installation Verification

After installation is complete and prior to operation, inspect the network cable and its connection to each field unit for

the following:

NOTE: Units should be disconnected from power. Network should be disconnected from host.

1. There should be:

No nicks in the insulation—this can cause a short between conductors or to the grounded shield.•

No cut strands in a stranded conductor—this can cause a poor connection and eventually an open circuit.•

2. Verify that there is data wiring on each actuator per wiring diagram.

3. Cable armor should not be shorted to the cable shield/drain wire. Cable armor may not be at ground potential and

could be subject to lightning surges.

4. The shield/drain wire should only be grounded at one end of each cable segment (the section between adjacent

actuators or between the host system/Master Station II and an actuator) to avoid ground loop problems.

5. The ground/earth connection should be at true ground potential and effective at all times. See No. 5 in Section

3.1.1, Site Preparation.

For the redundant bi-directional loop, use a voltmeter in the control room. Determine the following by measuring

resistance of individual wires in the network cables:

NOTE: Power must be OFF on all field devices, and A1/A2 cables must be disconnected from the network host.

1. Data wire A1 to data wire A2 should be equal to the resistance value of network cable length/cable resistance per

1000 ft.

2. Data* wire A1 to data* wire A2 should be equal to the resistance value of network cable length/cable resistance per

1000 ft.

3. Confirm open circuit between data and data* cables.

4. Confirm open circuit between data, data*, and shield.

5. Confirm open circuit between shield and shield.

3.2.2 Field Unit Installation Verification

NOTE: Connect to either 24 VDC power or mains and activate power.

Verify the field unit is installed as follows:

1. Enter the “SETUP” mode as detailed in Bulletin LMENIM2306, MX Installation and Operation Manual.

38

2. In the “SETUP” mode, use the black control knob to select “YES” to the main menu selection “VIEW

DIAGNOSTICS?”

3. Select “YES” to the display “VIEW HARDWARE STATUS?”

4. Select “YES” to scroll through the menu selections. The LCD will read “DDC (OK) – NEXT?” if installed.

NOTE: If the “DDC (OK) – NEXT?” does not appear, contact Flowserve for assistance.

5. To return to the normal display, use the red knob to select either “LOCAL” or “REMOTE.”

Page 39

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

3.3 Field Unit Configuration

The actuator has been configured with all customer-specified parameters and no further calibration should be

necessary. Only the address needs to be configured. If full valve data was not provided when ordering, or if changes

are needed for parameters other than the DDC option, refer to Bulletin LMENIM2306, MX Installation and Operation

Manual. If any changes to the DDC configuration are required, see Section 3.3.1, Configuring Field Unit Parameters.

3.3.1 Configuring Field Unit Parameters

The following instructions assume that all MX and DDC parameters are set, except the address.

1. Enter the “SETUP” mode as detailed in Bulletin LMENIM2306, MX Installation and Operation Manual.

2. When LCD reads “CHANGE SETTINGS?”, use the black knob to select “YES.”

3. Enter password. (100=Default)

4. The LCD will display the “CHANGE SETTINGS” mode menu items. Select “NO” until screen displays “CHANGE

DDC?” Select “YES.” LCD will display DDC menu items.

5. Select “YES” to each menu item until “DDC ADDRESS OK?” appears. Select “NO” if address displayed is not

correct.

6. Enter an address from 1 to 250 by toggling “NO” until the correct address is displayed.

7. Return red selector switch to “REMOTE” or “LOCAL” to save address.

CAUTION: a The network address must be entered in accordance with the user address assignment sheet.

This assignment sheet should correspond to the contract specifications. The same address must not be used

anywhere else in the same network.

All DDC parameters have been factory-set in accordance with customer specifications or defaults. These parameters

may be viewed or changed as described in Bulletin LMENIM2306, MX Installation and Operation Manual.

3.3.1.1 Viewing DDC Parameters

Enter the “VIEW SETTINGS” mode and “VIEW DDC?” as detailed in Bulletin LMENIM2306, MX Installation and

Operation Manual. The display will show the state or value of the following menu items:

Status (ON or OFF)•

DDC Address•

Protocol (Baud Rate)•

Analog Scale•

ESD Action•

Proportional Band•

Deadband•

Offset•

Move To•

Comm Loss Delay•

Comm Loss Action•

NOTE: “VIEW DDC?” will not appear if the DDC-100 Network Board is not installed. If the “VIEW DDC?” does not

appear, contact Limitorque.

39

flowserve.com

Page 40

MX/DDC-100 Field Unit Installation and Maintenance FCD LMENIM2329-01 – 03/11

3.3.1.2 Changing DDC Parameters

Enter the “CHANGE SETTINGS” mode and “CHANGE DDC?” as detailed in Bulletin LMENIM2306, MX Installation

and Operation Manual. The following parameters may be changed:

Status (ON or OFF)•

Protocol (Baud Rate)•

DDC Address •

Analog Scale •

ESD Action•

Proportional Band•

Deadband•

Offset•

Move To•

Comm Loss Delay•

Comm Loss Action•

Each parameter is discussed below:

40

Status (ON or OFF)

This parameter activates or deactivates the field unit.

NOTE: When the field unit is installed at the factory, the default status is ON. If DDC status is OFF, the LCD screen will

display “XXX% OPEN, DDC OFF.”