Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 16 i / 160 i–LA

Parameter Manual

GFZ-63200EN/02 July 2000

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B–63200EN/02

PREFACE

PREFACE

Applicable Models

Related Manuals

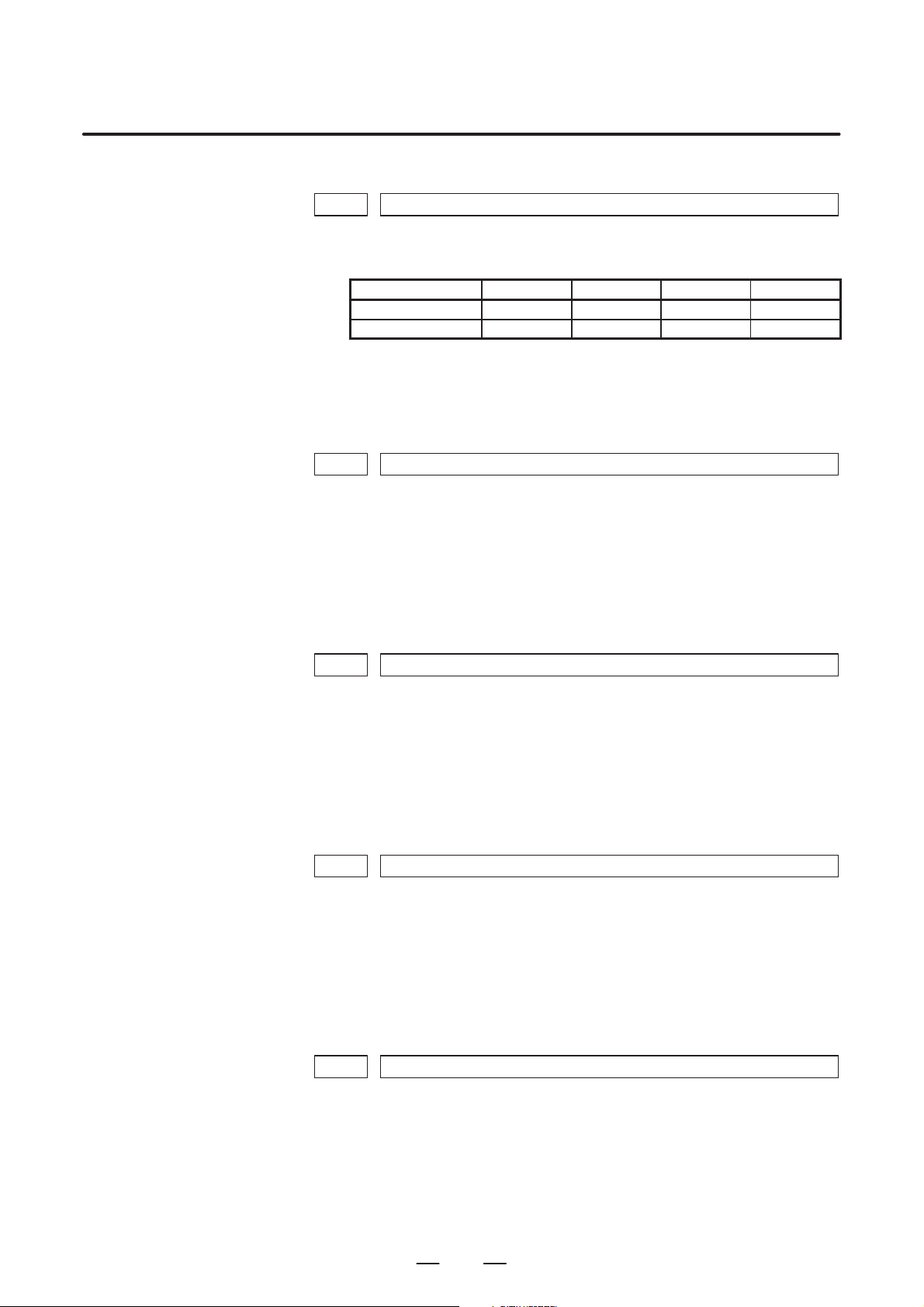

The mode covered by this manual, and their abbreviations are :

Product Name Abbreviations

FANUC Series 16i–LA 16i–LA

FANUC Series 160i–LA 160i–LA

The table below lists manuals related to Series 16i–LA and 160i–LA. In

the table, this manual is marked with an asterisk (*).

Table 1 List of related manuals for Series 16i/160i–LA

Manual name

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL A

DESCRIPTIONS

FANUC Series 16i/18i/21i/20i/160i/180i/210i–MODEL A

CONNECTION MANUAL (HARDWARE)

FANUC Series 16i/18i/21i/20i/160i/180i/210i–MODEL A

CONNECTION MANUAL (FUNCTION)

FANUC Series 16i/18i/160i/180i–MODEL A

P ARAMETER MANUAL

FANUC Series 16i/160i–LA DESCRIPTIONS B–63192EN

FANUC Series 16i/160i–LA CONNECTION MANUAL B–63193EN

FANUC Series 16i/160i–LA OPERATOR’S MANUAL B–63194EN

FANUC Series 16i/160i–LA MAINTENANCE MANUAL B–63195EN

FANUC Series 16i/160i–LA PARAMETER MANUAL B–63200EN

FANUC Series 16/18/20/21 PROGRAMMING MANUAL

(Macro Compiler/Macro Executer)

FAPT MACRO COMPILER PROGRAMMING MANUAL B–66102E

Specification

Number

B–63002EN

B–63003EN

B–63003EN–1

B–63010EN

B–61803E–1

p–1

Page 4

B–63200EN/02

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAYING PARAMETERS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SETTING PARAMETERS FROM MDI 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERF ACE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE 5. . . . . . . .

3.2 INPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE 6. . . . . . . . . .

4. DESCRIPTION OF PARAMETERS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 SETTINGS FOR ENABLING/DISABLING FUNCTIONS 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 DISCHARGE TUBE SELECTION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CONTOURING CONDITIONS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 EDGE MACHINING CONDITIONS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 PIERCING CONDITIONS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 POWER CONTROL 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 SETTINGS RELATED TO ASSIST GAS PRESSURE AND TIME 22. . . . . . . . . . . . . . . . . . . . . . . .

4.8 LASER MAINTENANCE/INSPECTION TIME DISPLAY FUNCTION 25. . . . . . . . . . . . . . . . . . . .

4.9 PARAMETERS RELATED TO OSCILLATOR CONTROL 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 PARAMETERS RELATED TO DISCHARGE 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 PARAMETERS RELATED TO GAS PRESSURE CONTROL (1) 32. . . . . . . . . . . . . . . . . . . . . . . . .

4.12 HIGHLY REFLECTIVE MATERIAL ALARMS 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 LASER POWER/VOLTAGE DECREASE 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 POWER TABLE SETTINGS 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 AUTOMATIC AGING FUNCTION 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 PARAMETERS RELATED TO THE PMC–WINDOW 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 POWER CONTROL (2) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18 SETTINGS RELATED TO TRACING (DETECTION) 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 SETTING RELATED TO TRACING (DISPLAY) 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.20 SETTINGS RELATED TO TRACING (INTEGRATION) 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 SETTINGS RELATED TO TRACING (PHASE COMPENSATION) 47. . . . . . . . . . . . . . . . . . . . . . .

4.22 SETTINGS RELATED TO TRACING (DISPLACEMENT) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 SETTINGS RELATED TO TRACING (VELOCITY COMMAND) 50. . . . . . . . . . . . . . . . . . . . . . . .

4.24 SETTINGS RELATED TO TRACING (APPROACH) 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.25 SETTINGS RELATED TO THREE–DIMENSIONAL AXIAL MOVEMENT

(ANGULAR AXIS) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.26 PROGRAM RESUMPTION/NEIGHBORING POINT SEARCH 59. . . . . . . . . . . . . . . . . . . . . . . . . .

4.27 TEACHING BOX 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 SETTINGS RELATED TO MACHINING RESUMPTION 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.29 CONSTANT OPTICAL PATH CONTROL 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30 LASER GAS MIXTURE FUNCTION 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.31 THE STEP CONTROL FUNCTION 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 5

Table of Contents

B–63200EN/02

4.32 STEP FEED FUNCTION AND RETURN FUNCTION 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.33 PARAMETERS RELATED TO GAS PRESSURE CONTROL (2) 74. . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 6

B–63200EN/02

1

1. DISPLAYING PARAMETERS

DISPLAYING PARAMETERS

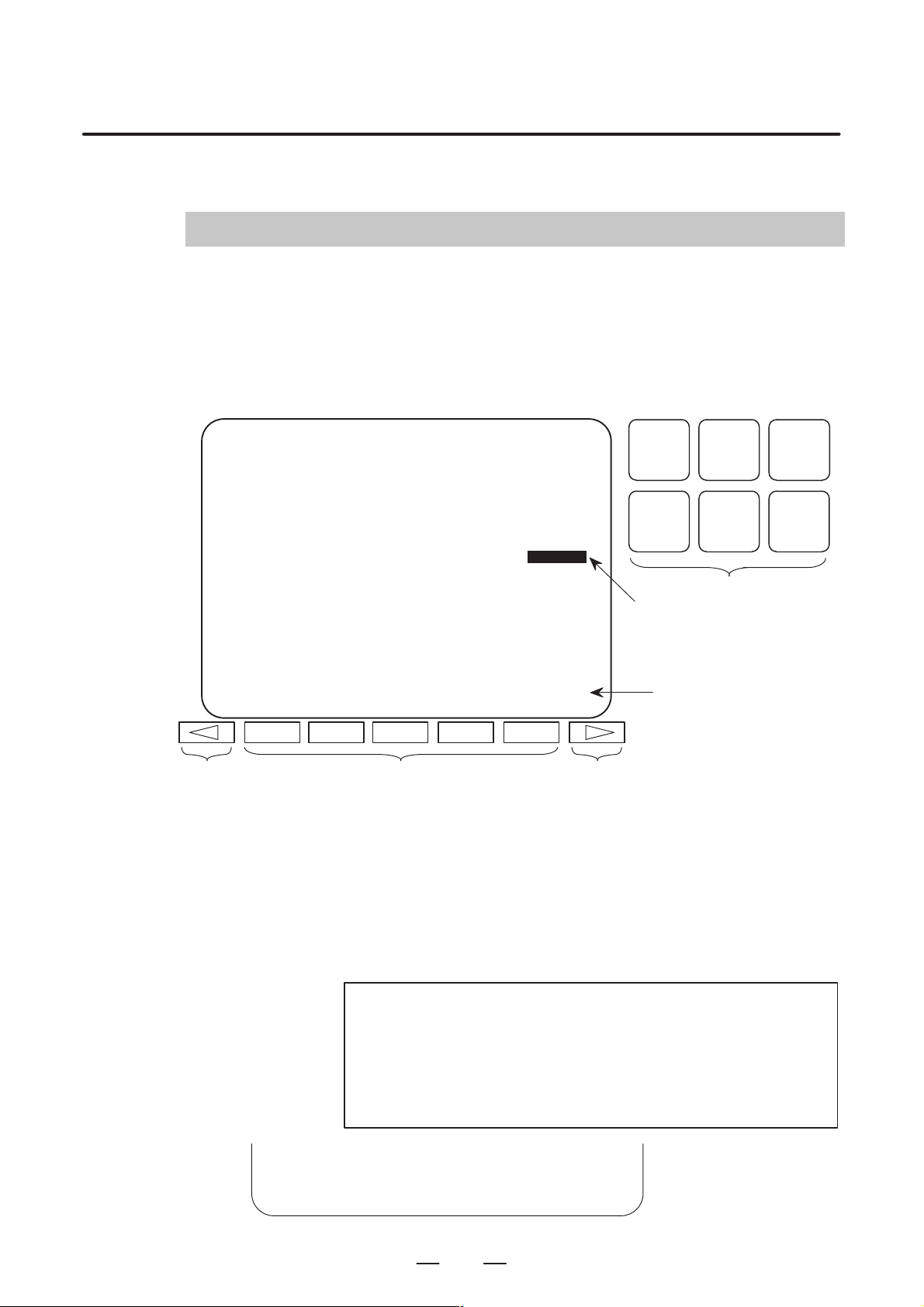

Follow the procedure below to display parameters.

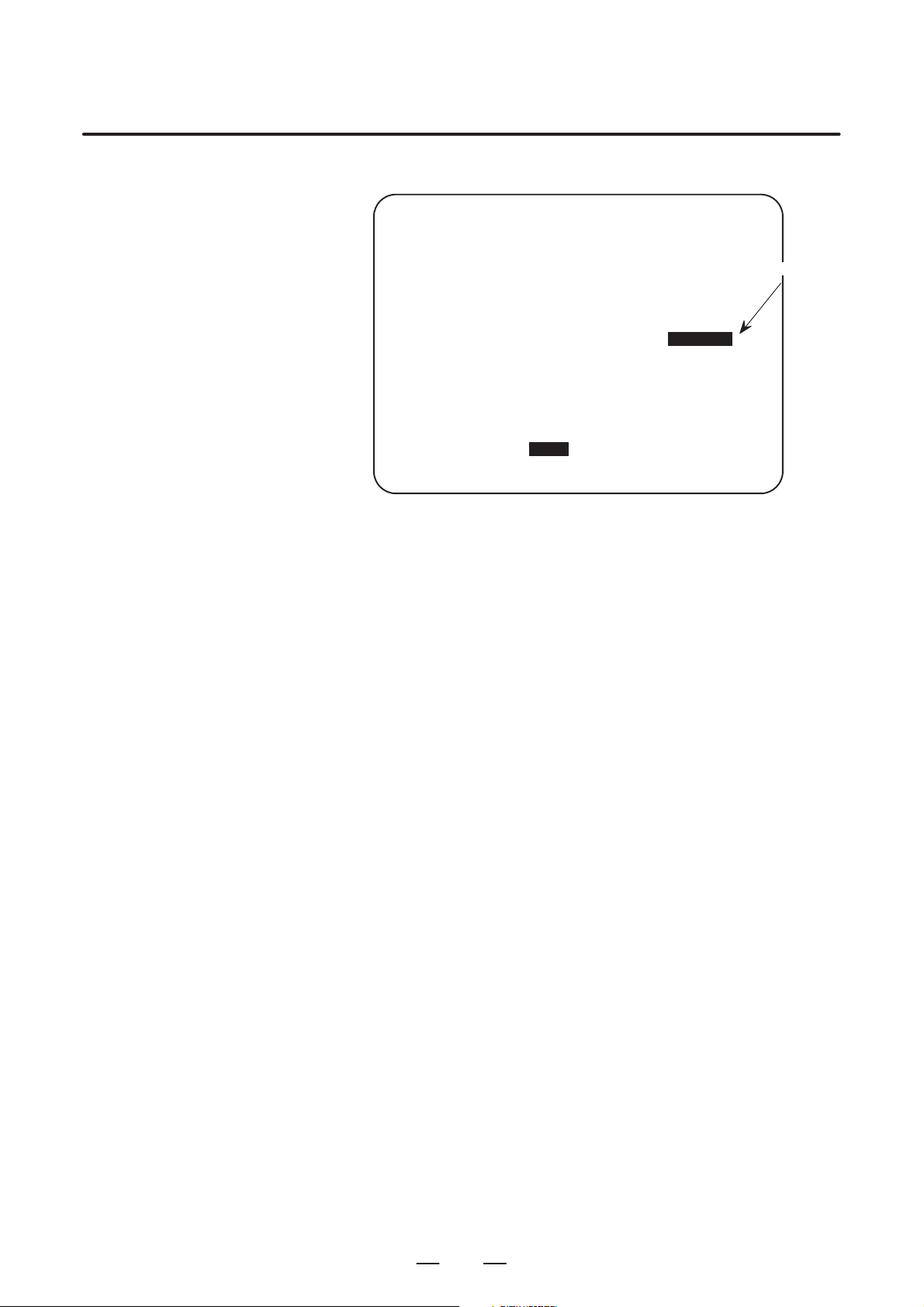

(1) Press the <SYSTEM> function key on the MDI as many times as

required, or alternatively, press the <SYSTEM> function key once,

then the [P ARAM] section display soft key. The parameter screen is

then selected.

PARAMETER (FEEDRATE) O0001 N12345

1401 RDR JZR RF0 LRP RPD

0 0 0 0 0 0 0 0

1402 DLF HFC

0 0 0 0 0 0 0 0

1410 DRY RUN FEEDRATE 10000

1411 INIT.CUTTING F 0

1420 RAPID FEEDRATE X 15000

Y 15000

Z 15000

>

MEM STRT MTN FIN *** 10:02:35

[PARAM] [DGNOS] [ PMC ] [SYSTEM] [(OPRT)]

Return menu key Soft key Continuous menu key

POS PROG

SYSTEM MESSAGE

Cursor

(2) The parameter screen consists of multiple pages. Use step (a) or (b)

to display the page that contains the parameter you want to display.

(a) Use the page select key or the cursor move keys to display the de-

sired page.

(b) Enter the data number of the parameter you want to display from

the keyboard, then press the [NO.SRH] soft key. The parameter

page containing the specified data number appears with the cursor positioned at the data number. (The data is displayed in reverse video.)

OFFSET

SETTING

CUSTOM

GRAPH

Function key

Soft key display

(section select)

NOTE

If key entry is started with the section select soft keys

displayed, they are replaced automatically by operation

select soft keys including [NO.SRH]. Pressing the [(OPRT)]

soft key can also cause the operation select keys to be

displayed.

>1410

MEM STRT MTN FIN *** 10:02:34

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT ]

1

Data entered from

←

the keyboard

Soft key display

←

(section select)

Page 7

2. SETTING PARAMETERS FROM MDI

SETTING P ARAMETERS FROM MDI

2

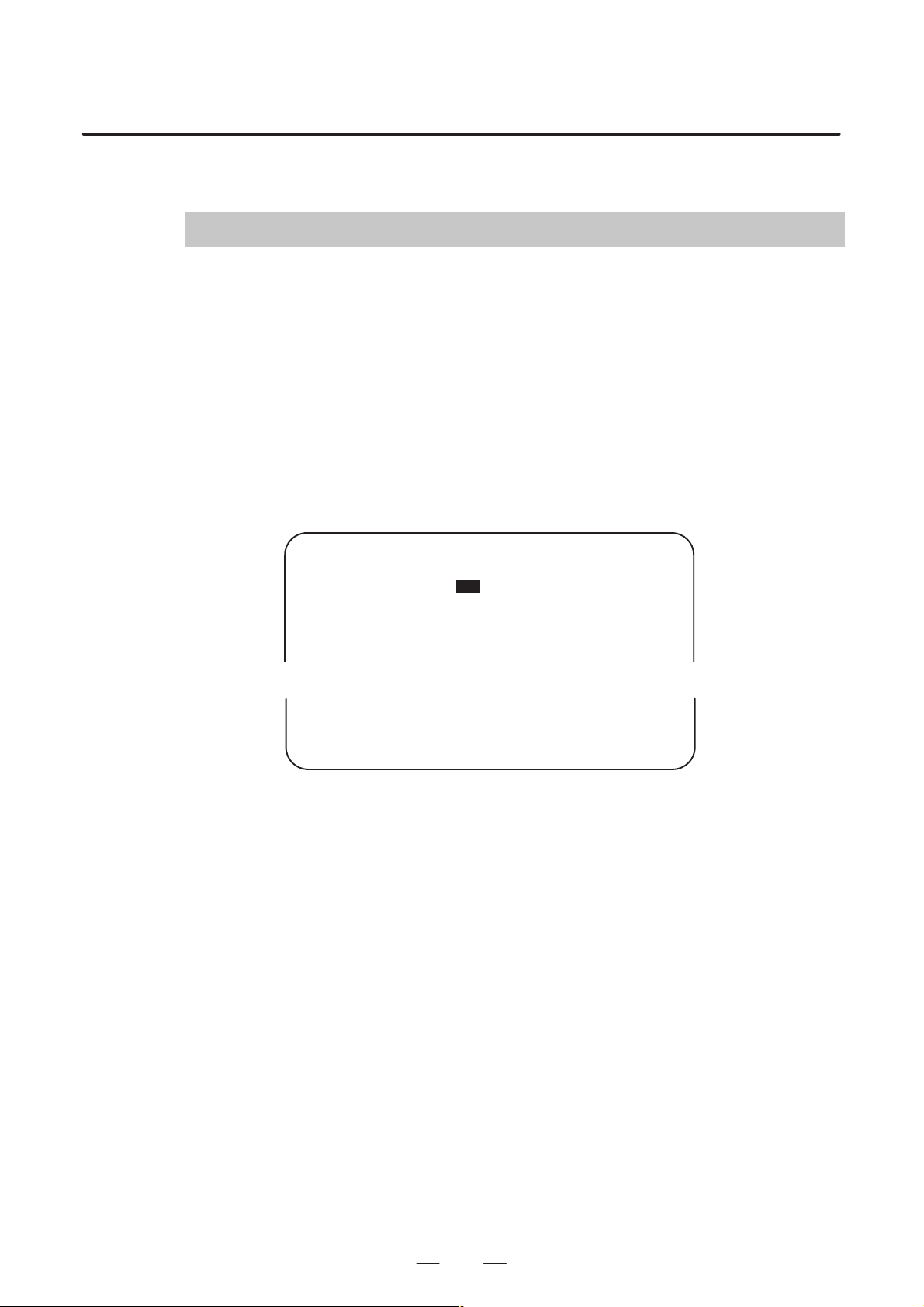

Follow the procedure below to set parameters.

(1) Place the CNC in the MDI mode or the emergency stop state.

(2) Follow the substeps below to enable writing of parameters.

SETTING (HANDY) O0001 N00010

B–63200EN/02

1. To display the setting screen, press the <OFFSET/SETTING>

function key as many times as required, or alternatively press the

<OFFSET/SETTING> function key once, then the <OFFSET/

SETTING> section select soft key. The first page of the setting

screen appears.

2. Position the cursor on “P ARAMETER WRITE” using the cursor

move keys.

PARAMETER WRITE = (0:DISABLE 1:ENABLE)

TV CHECK = 0 (0:OFF 1:ON)

PUNCH CODE = 0 (0:EIA 1:ISO)

INPUT UNIT = 0 (0:MM 1:INCH)

I/O CHANNEL = 0 (0–3:CHANNEL NO.)

3. Press the [(OPRT)] soft key to display operation select soft keys.

>

MDI STOP *** *** *** 10:03:02

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

4. To set “PARAMETER WRITE=” to 1, press the ON:1 soft key,

or alternatively enter 1 and press the [INPUT] soft key . From now

on, the parameters can be set. At the same time an alarm condition (P/S100 PARAMETER WRITE ENABLE) occurs in the

CNC.

(3) T o display the parameter screen, press the <SYSTEM> function key

as many times as required, or alternatively press the <SYSTEM>

function key once, then the [PARAM] section select soft key.

(See “1. Displaying Parameters.”)

(4) Display the page containing the parameter you want to set, and

position the cursor on the parameter. (See “1. Displaying

Parameters.”)

0

← Soft key display

(section select)

(5) Enter data, then press the [INPUT] soft key. The parameter indicated

by the cursor is set to the entered data.

2

Page 8

B–63200EN/02

2. SETTING PARAMETERS FROM MDI

[Example] 12000 [INPUT]

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

00000000

1402 JRV

00000000

1410 DRY RUN FEEDRATE

1412 0

1420 RAPID FEEDRATEX 15000

Y 15000

Z 15000

>

MDI STOP *** *** ALM 10:03:10

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

12000

Cursor

Data can be entered continuously for parameters, starting at the selected

parameter, by separating each data item with a semicolon (;).

[Example] Entering 10;20;30;40 and pressing the [INPUT] key assigns values 10,

20, 30, and 40 to parameters in order starting at the parameter indicatedby

the cursor.

(6) Repeat steps (4) and (5) as required.

(7) If parameter setting is complete, set “PARAMETER WRITE=” to 0

on the setting screen to disable further parameter setting.

(8) Reset the NC to release the alarm condition (P/S100).

If an alarm condition (P/S000 PLEASE TURN OFF POWER) occurs

in the NC, turn it off before continuing operation.

3

Page 9

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERF ACE

3

This section explains the parameter input/output procedures for

input/output devices connected to the reader/puncher interface.

The following description assumes the input/output devices are ready for

input/output. It also assumes parameters peculiar to the input/output

devices, such as the baud rate and the number of stop bits, have been set

in advance.

B–63200EN/02

4

Page 10

B–63200EN/02

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

3.1

OUTPUTTING

PARAMETERS

THROUGH THE

READER/PUNCHER

INTERFACE

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

1402 JRV

1410 DRY RUN FEEDRATE

1412 0

1420 RAPID FEEDRATEX 15000

>

MDI STOP *** *** ALM 10:03:10

[NO.SRH] [ON:1] [OFF:0] [+INPUT] [INPUT]

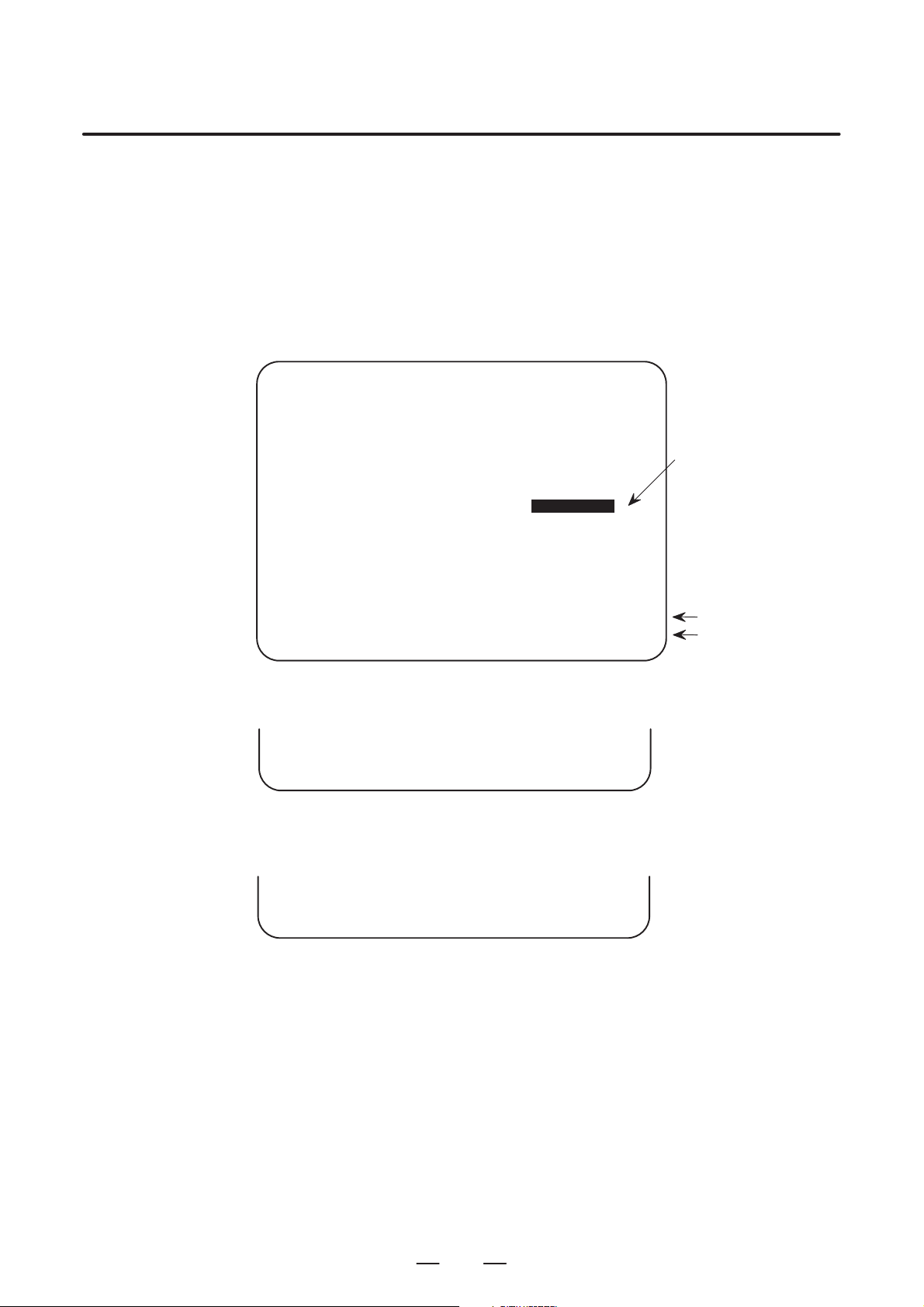

(1) Select the EDIT mode or set to Emergency stop.

(2) T o select the parameter screen, press the <SYSTEM> function key as

many times as required, or alternatively press the <SYSTEM>

function key once, then the [PARAM] section select soft key.

(3) Press the [(OPRT)] soft key to display operation select soft keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select keys including

[PUNCH].

00000000

00000000

12000

Y 15000

Z 15000

Cursor

State display

Soft key display

(operation select)

(4) Pressing the [PUNCH] soft key changes the soft key display as shown

below:

>

EDIT STOP *** *** *** 10:35:03

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(5) Press the [EXEC] soft key to start parameter output. When

parameters are being output, “OUTPUT” blinks in the state display

field on the lower part of the screen.

>

EDIT STOP *** *** *** 10:35:04 OUTPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(6) When parameter output terminates, “OUTPUT” stops blinking. Press

the <RESET> key to interrupt parameter output.

← OUTPUT blinking

5

Page 11

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

B–63200EN/02

3.2

INPUTTING

PARAMETERS

THROUGH THE

READER/PUNCHER

INTERFACE

(1) Place the CNC in the emergency stop state.

(2) Enable parameter writing.

1. To display the setting screen, press the <OFFSET/SETTING>

function key as many times as required, or alternatively press the

<OFFSET/SETTING> function key once, then the [SETTING]

section select soft key. The first page of the setting screen appears.

2. Position the cursor on “P ARAMETER WRITE” using the cursor

move keys.

3. Press the [(OPRT)] soft key to display operation select soft keys.

4. To set “PARAMETER WRITE=” to 1, press the ON:1 soft key ,

or alternatively enter 1, then press the [INPUT] soft key. From

now on, parameters can be set. At the same time an alarm condition (P/S100 PARAMETER WRITE ENABLE) occurs in the

CNC.

(3) T o select the parameter screen, press the <SYSTEM> function key as

many times as required, or alternatively press the <SYSTEM> key

once, then [PARAM] soft key.

(4) Press the [(OPRT)] soft key to display operation select keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select soft keys including

[READ].

>

EDIT STOP ALM 10:37:30

[ ] [ READ ] [PUNCH] [ ] [ ]

–EMS– ALM

(5) Pressing the [READ] soft key changes the soft key display as shown

below:

>

EDIT STOP ALM 10:37:30

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMS– ALM

(6) Press the [EXEC] soft key to start inputting parameters from the

input/output device. When parameters are being input, “INPUT”

blinks in the state display field on the lower part of the screen.

>

EDIT STOP ALM 10:37:30 INPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMS– ALM

(7) When parameter input terminates, “INPUT” stops blinking. Press the

<RESET> key to interrupt parameter input.

(8) When parameter read terminates, “INPUT” stops blinking, and an

alarm condition (P/S000) occurs in the NC. Turn it off before

continuing operation.

← State display

← Soft key display

← INPUT blinking

6

Page 12

B–63200EN/02

4

DESCRIPTION OF P ARAMETERS

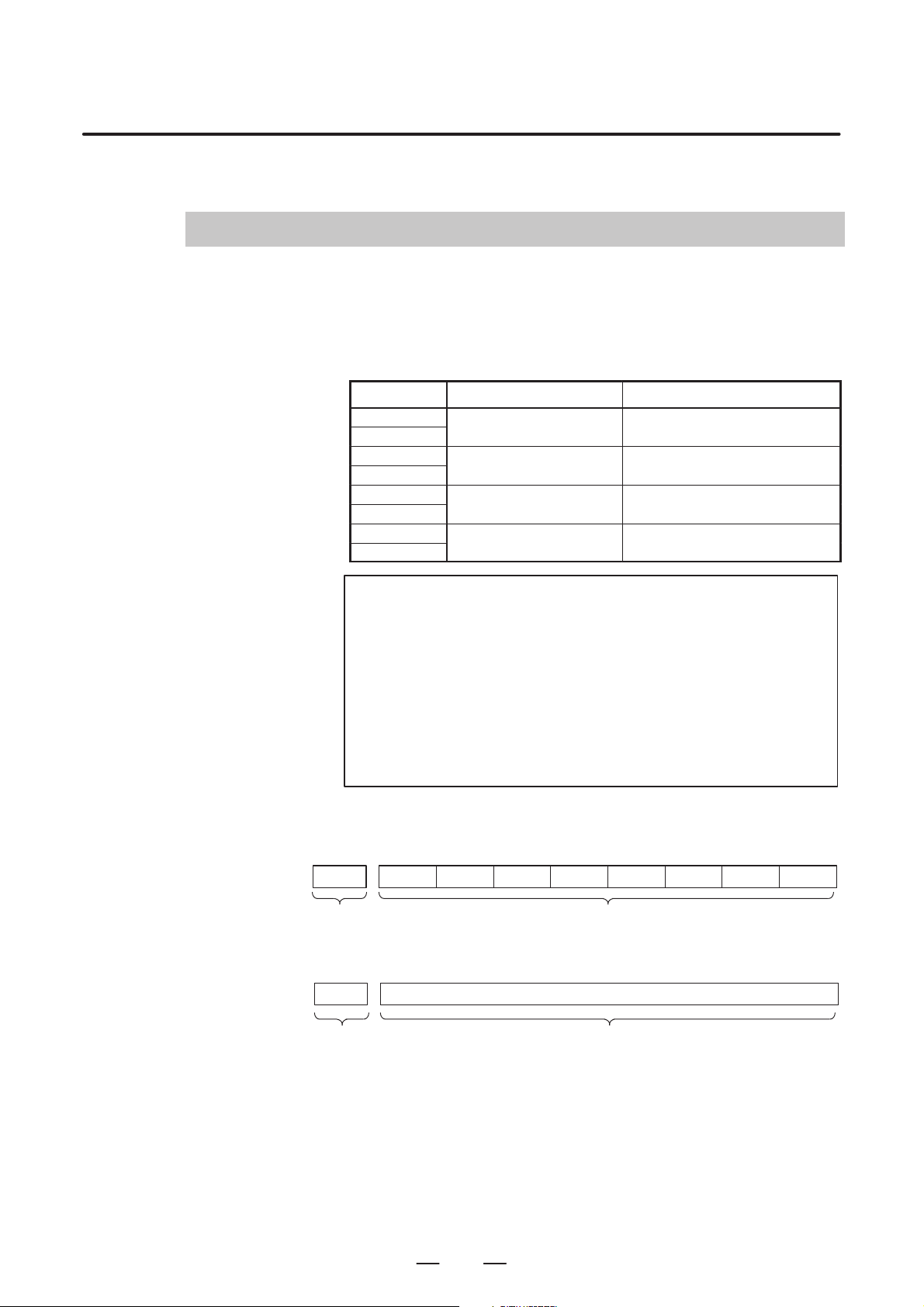

Parameters are classified by data type as follows:

Table 4 Data T ypes and Valid Data Ranges of Parameters

Data type Valid data range Remarks

Bit

Bit axis

Byte

Byte axis

Word

Word axis

2–word

2–word axis

0 or 1

0 to 255 In some parameters, signs are

0 to 255

–128 to 127

0 to 65535 In some parameters, signs are

0 to 65535

–32768 to 32767

–99999999 to 99999999

4. DESCRIPTION OF PARAMETERS

In some parameters, signs are

ignored.

In some parameters, signs are

ignored.

[Example]

0000

Data No.

1023 Servo axis number of a specific axis

Data No.

NOTE

1 For the bit type and bit axis type parameters, a single data

number is assigned to 8 bits. Each bit has a different

meaning.

2 The axis type allows data to be set separately for each

control axis.

3 The valid data range for each data type indicates a general

range. The range varies according to the parameters. For

the valid data range of a specific parameter, see the

explanation of the parameter.

(1) Notation of bit type and bit axis type parameters

#7

#6 #5

SEQ

#4 #3 #2

Data #0 to #7 are bit positions.

INI

#1

ISO

(2) Notation of parameters other than bit type and bit axis type

Data.

#0

TVC

7

Page 13

4. DESCRIPTION OF PARAMETERS

4.1

SETTINGS FOR ENABLING/DISABLIN G FUNCTIONS

[Data type] Bit

15000

LPC Power control is:

LGC The in–tube pressure control gain selection of two types is:

AGA The assist gas is:

BMO When the shutter is closed, the function to turn the beam on is:

#7

#6 #5

FLT

#4

CLB#3BMO#2AGA

0 : Disabled. (Normal operation)

1 : Enabled.

0 : Disabled.

1 : Enabled. (Normal operation)

(When this bit is set to 1, parameter No. 15245 is enabled.)

0 : Enabled. (Normal operation)

1 : Disabled. (Maintenance)

0 : Disabled. (Normal operation)

1 : Enabled. (Manual operation only, maintenance)

B–63200EN/02

#1

LGC

LPC

#0

CLB Power calibration is:

0 : Disabled.

1 : Enabled. (Normal operation)

FLT During power control, the filter is:

0 : Disabled.

1 : Enabled. (Normal operation)

#7

15001

#6

LHC

#5 #4

PC8#3NGC

[Data type] Bit

EXA An assist gas can be selected from:

0 : Three types. (Normal operation)

1 : Seven types.

G0B Beam output by G00 is

0 : Disabled. (Normal operation)

1 : Enabled.

PES In the machine lock or dry run state, the piercing time is:

0 : Executed. (Normal operation)

1 : Not executed.

NGC The integral for gas pressure control is:

0 : Not preset.

1 : Preset.

#2

PES

#1

G0B

#0

EXA

PC8 The power calibration function of:

0 : Correction by constant power.

1 : Power is raised to eight steps.

LHC The oscillator is:

0 : Not controlled by an external signal. (Normal operation)

1 : Controlled by an external signal.

8

Page 14

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

#7

15002

#6

PSH

#5 #4 #3 #2 #1

[Data type] Bit

BMA When the shutter is closed in automatic operation, beam output is:

0 : Disabled. (Normal operation)

1 : Enabled. (Maintenance)

ADC AD conversion–2 data is judged with:

0 : The select signal.

1 : The DI signal. (Normal operation)

PSH Of the discharge tubes,

0 : All are used.

1 : Half are used.

#7

15003

#6 #5 #4 #3 #2

GVW#1HPT

[Data type] Bit

TIV The sign (+/–) of the tracing displacement amount is:

0 : Not inverted.

1 : Inverted.

HPT When piercing is lengthened or reduced, a parameter setting is:

0 : Rewritten.

1 : Not rewritten.

GVW RUN–OFF evacuation is:

0 : Disabled. (Maintenance)

1 : Enabled. (Normal operation)

ADC

#0

BMA

#0

TIV

#7

CWY15004

#6

ECH

#5 #4

EDG

#3 #2

SPB

[Data type] Bit

AGC The ”G32 P_;” command (with Q, T, and R not specified) is used as:

0 : A flow pattern command.

1 : A direct gas pressure control command.

STC The shutter is controlled by:

0 : A G code.

1 : An external signal.

SPB During a skip, beam output is:

0 : Performed.

1 : Not performed.

EDG When the assist gas is switched in edge machining, the beam is:

0 : Turned off.

1 : Not turned off.

ECH Upon reset, the active E number is:

0 : Not cleared.

1 : Cleared.

CWY The oscillator of the:

0 : CO2 laser is used.

1 : CW–YAG laser is used.

#1

STC

#0

AGC

9

Page 15

4. DESCRIPTION OF PARAMETERS

B–63200EN/02

#7

DLY15005

#6

ITR

#5 #4

GNS

[Data type] Bit

INB Beam output is stopped:

0 : Upon the completion of distribution.

1 : After an in–position check.

TTD A single laser power supply unit drives:

0 : A single discharge tube.

1 : Two discharge tubes.

BPV The bypass valve:

0 : Is opened while correcting power.

1 : Is not opened while correcting power.

GNS At the time of assist gas switching, the beam is:

0 : Stopped. (Normal operation)

1 : Not stopped.

ITR Tracing control interlock signal *TRIL (G227, #6) is:

0 : Disabled.

1 : Enabled.

DLY The beam output condition delay function is:

0 : Disabled.

1 : Enabled.

#3

BPV

#2

TTD

#1 #0

INB

#7

15006

#6 #5

PCN

#4

PCL

#3 #2

PIN

#1

TRM#0NCC

[Data type] Bit

NCC The cutting condition setting screen is:

0 : Displayed.

1 : Not displayed.

TRM On the trace setting screen, the zero–point, start–point, and end–point soft

keys are:

0 : Enabled.

1 : Disabled.

PIN The address–P value of G13 is specified using:

0 : Metric input.

1 : Inch input.

PCL The assist gas pressure is displayed on the screen in units of:

2

0 : kg/cm

.

1 : MPa.

PCN When power correction is not executed, the power correction coefficient is:

0 : Rewritten with 1024.

1 : Not rewritten, but remains unchanged from the previous value.

10

Page 16

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

#7

15007

#6 #5

STO

#4

XSC

#3

ECK

#2

ESE

#1 #0

ESE If piercing is to be executed in edge machining, it is:

0 : Executed upon the completion of distribution.

1 : Executed after a smoothing error check is performed upon the

completion of distribution.

ECK In edge machining, the angle is judged with:

0 : The actual machining path.

1 : The path in the machining program.

XSC In exact stop mode, the edge machining function is:

0 : Not executed.

1 : Executed.

STO If an assist gas is specified with the same type and the same flow pattern:

0 : Neither the after flow nor pre flow is executed.

1 : Both the after flow and pre flow are executed.

#7

RMP15008

#6

EGE

#5 #4 #3

SOC

#2

TAL

#1

GPC#0MST

[Data type] Bit

MST The signs (+ and –) of the reference displacement amount indicate the

following directions of tracing:

0 : + indicates approach towards the workpiece, while – indicates

withdrawal from the workpiece.

1 : + indicates withdrawal from the workpiece, while – indicates

approach towards the workpiece.

GPC Tracing control is performed according to:

0 : The reference displacement.

1 : The gap (distance from the nozzle to the workpiece).

TAL If the trace check mode signal (G225#2, TRCKM) is set to 1:

0 : The tracing range over alarm is disabled.

1 : The tracing range over alarm and tracing displacement large alarm are

disabled.

SOC When the machining condition setting function is used, the reference

displacement amount of tracing control is used as the reference

displacement amount of piercing:

0 : Except during machining.

1 : Only during piercing.

EGE The automatic aging function is:

0 : Disabled.

1 : Enabled.

RMP Step control:

0 : Only the up/down step distance.

1 : Both the up/down step distance and specified feedrate.

11

Page 17

4. DESCRIPTION OF PARAMETERS

B–63200EN/02

#7

TEM15009

#6

BCG#5BEM

#4

AFZ

#3

BS2

[Data type] Bit

These parameters are related to the laser gas mixture function, which store

and monitor the operating states of the mixer. The parameters are

automatically set and need not be set manually.

AS2, AS1 Indicate the state of tank A.

AS2 AS1

0 0 : Tank A is being supplied with gases.

0 1 : Tank A is mixing the gases.

1 0 : Tank A is supplying the mixed gas.

1 1 : Tank A is being prepared for gas supply.

BS2, BS1 Indicate the state of tank B.

BS2 BS1

0 0 : Tank B is being supplied with gases.

0 1 : Tank B is mixing the gases.

1 0 : Tank B is supplying the mixed gas.

1 1 : Tank B is being prepared for gas supply.

AFZ In calculation for actual cutting feedrate display, the Z–axis is:

0 : Included.

1 : Not included.

BEM The supply pressure of the gas cylinder:

0 : Has fallen.

1 : Is normal.

BCG The gas cylinder:

0 : Has been replaced.

1 : Has not yet been replaced.

TEM The supply pressure of the tank:

0 : Has fallen.

1 : Is normal.

#2

BS1

#1

AS2

#0

AS1

#7

OVE15010

#6 #5

TRG

#4 #3 #2 #1 #0

[Data type] Bit

TRG The trigger pulse command control function is:

0 : Disabled.

1 : Enabled.

OVE Edge machining and feedrate clamp by arc radius:

0 : Cannot be used at the same time.

1 : Can be used at the same time.

12

Page 18

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

#7

OPV15011

#6 #5

CSC

#4 #3

LVE

#2 #1 #0

[Data type] Bit

EDS The cutting conditions to be assumed during the execution for the return

distance in edge machining and start–up machining are:

0 : The same as usual.

1 : Not the same as usual. For the laser power, assist gas type, and assist

gas pressure, the piercing operation conditions for edge machining are

used.

LVE The assist gas switching to be performed at the start of edge machining

and at the start of the subsequent return distance cutting is:

0 : Of the conventional type.

1 : Not of the conventional type. If the gas type and gas pressure do not

change, the stabilization time is ignored.

CSC If, in start–up machining mode, the four items S, P , Q, and F are specified

at the same time in the first G01, G02, or G03 block after G24:

0 : Start–up machining is executed as usual, regardless of the

specification of S, P, Q, and F.

1 : The start–up machining operation is canceled, and cutting is

performed with the specified S, P, Q, F values.

OPV The external piping exhaust valve:

0 : Is operated only once after the power is turned on. (Same as usual)

1 : Is always operated at RUN–ON time.

EDS

13

Page 19

4. DESCRIPTION OF PARAMETERS

4.2

B–63200EN/02

DISCHARGE TUBE SELECTION

[Data type] Bit

PS1 to PS16 Discharge tube selection when half of the discharge tubes are used

[Data type] Bit

PS1 to PS16 Discharge tube selection when all of the discharge tubes are used

#7

PS815025

PS1615026 PS15 PS14 PS13 PS12 PS11 PS10 PS9

#6

PS7

#5

PS6

#4

PS5

#3

PS4

#2

PS3

#1

PS2

#0

PS1

Four of eight discharge tubes can be selected. Set the bit corresponding to

the discharge tube to be used to 1. Set the other bits to 0.

NOTE

Parameter No.15026 is provided for extension of the

discharge tubes. This parameter is not used at present. Set

all bits to 0.

#7

PS815027

PS1615028 PS15 PS14 PS13 PS12 PS11 PS10 PS9

#6

PS7

#5

PS6

#4

PS5

#3

PS4

#2

PS3

#1

PS2

#0

PS1

All of the eight discharge tubes can be selected. Set the bit corresponding

to the discharge tube to be used to 1. Set the other bits to 0.

NOTE

Parameter No.15028 is provided for extension of the

discharge tubes. This parameter is not used at present. Set

all bits to 0.

14

Page 20

B–63200EN/02

4.3

CONTOURING CONDITIONS

[Valid data range] 0 to 7000

[Valid data range] 5 to 2000

4. DESCRIPTION OF PARAMETERS

15040 Output power

[Data type] Word

[Unit of data] W

15041 Pulse frequency

[Data type] Word

[Unit of data] Hz

15042 Pulse duty ratio

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

15

Page 21

4. DESCRIPTION OF PARAMETERS

4.4

B–63200EN/02

EDGE MACHINING CONDITIONS

[Data type] Word

[Unit of data] Degree

[Valid data range] 0 to 180

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

15050 Edge detection angle

When an angle formed by two blocks is smaller than this setting, the

portion is assumed to be a corner.

15051 Piercing peak power

Specify the peak power of piercing at the vertex of a corner.

15052 Piercing pulse frequency

Specify the pulse frequency of piercing at the vertex of a corner.

15053 Piercing pulse duty ratio

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

Specify the pulse duty ratio of piercing at the vertex of a corner.

15054 Piercing time

[Data type] Two–word

[Unit of data] Millisecond

[Valid data range] 0 to 99999999

Specify a piercing time at the vertex of a corner.

15055 Piercing assist gas pressure

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

Specify a piercing assist gas pressure at the vertex of a corner.

15056 Piercing assist gas type

2

[Data type] Word

[Unit of data]

[Valid data range] 0 to 7

Select the gas type for piercing at the vertex of a corner.

16

Page 22

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15057 Return distance

[Data type] Two–word

[Unit of data]

Increment system Unit IS–A IS–B IS–C

Metric input mm 0.01 0.001 0.0001

Inch input inch 0.001 0.0001 0.00001

[Valid data range] 0 to 65000

Specify the return distance of movement from the vertex of a corner to the

next block.

15058 Return speed

[Data type] Word

[Unit of data] mm/min

[Valid data range] 0 to 9999

Specify the return speed of movement from the vertex of a corner to the

next block.

15059 Return peak power

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

Specify the return peak power of movement from the vertex of a corner to

the next block.

15060 Return frequency

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

Specify the return frequency of movement from the vertex of a corner to

the next block.

15061 Return duty ratio

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

Specify the return duty ratio of movement from the vertex of a corner to

the next block.

17

Page 23

4. DESCRIPTION OF PARAMETERS

4.5

PIERCING CONDITIONS

15080 Piercing power

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

15081 Initial frequency of piercing

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

B–63200EN/02

Specify a piercing power.

Specify the initial frequency of piercing.

15082 Incremental value of piercing frequency

[Data type] Word

[Unit of data] Hz

[Valid data range] 0 to 2000

Specify a value by which the piercing frequency is incremented.

15083 Initial duty ratio of piercing

[Data type] Byte

[Unit of data] %

[Valid data range] 0 to 100

Specify the initial duty ratio of piercing.

15084 Incremental value of piercing duty ratio

[Data type] Byte

[Unit of data] %

[Valid data range] 0 to 100

Specify a value by which the piercing duty ratio is incremented.

15085 Piercing step time

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

Specify a piercing step time.

18

Page 24

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15086 Piercing step count

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

Specify the number of piercing steps.

15087 Piercing end time

[Data type] Two–word

[Unit of data] Millisecond

[Valid data range] 0 to 99999999

Specify a piercing end time.

19

Page 25

4. DESCRIPTION OF PARAMETERS

4.6

B–63200EN/02

POWER CONTROL

[Data type] Bit

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

#7

LP815089

#6

LP7

#5

LP6

#4

LP5

#3

LP4

#2

LPZ

LP* The speed calculation of the power control function:

0 : Does not use the * axis.

1 : Uses the * axis.

When nothing is specified, the system assumes that the first axis (LPX)

and second axis (LPY) are specified.

In general, specify an axis used for interpolation. Do not specify other

axes such as the synchronization axis used for simple synchronization

control or the PMC axis.

15090 Minimum output power

15091 Minimum pulse frequency

#1

LPY

#0

LPX

15092 Minimum pulse duty ratio

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

Specify the minimum pulse duty ratio.

15094 Power control filter time constant

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

Specify the time constant of the power control filter.

15095 Allowable variation in power control speed

[Data type] Byte

[Unit of data] mm/min (in B8F1–08 or earlier, specified unit)

[Valid data range] 0 to 255

Specify the allowable variation in power control speed. This parameter is

effective only when parameter No. 15450 is 0. To set a value equal to

greater than 156, use parameter No. 15450.

20

Page 26

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

#7

EGM15096

#6 #5 #4 #3 #2

[Data type] Bit

PCP During power control, the output is:

0 : Not controlled according to the feedrate.

1 : Controlled according to the feedrate.

PCF During power control, the frequency is:

0 : Not controlled according to the feedrate.

1 : Controlled according to the feedrate.

PCD During power control, the duty ratio is:

0 : Not controlled according to the feedrate.

1 : Controlled according to the feedrate.

EGM In edge machining mode and start–up machining mode:

0 : Power control mode is canceled.

1 : Power control is stopped only during the return distance movement in

edge machining and start–up machining.

Edge machining mode and start–up machining mode refer to the states in

which E numbers specifying the respective cutting conditions for edge

machining and start–up machining have been selected.

PCD

#1

PCF

#0

PCP

15097 Reference value for calculating the output inclination (output when feedrate F is 0)

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

15098 Reference value for calculating the frequency inclination (frequency when feedrate F is 0)

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

15099 Reference value for calculating the inclination of the duty ratio (duty ratio when feedrate F is 0)

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

21

Page 27

4. DESCRIPTION OF PARAMETERS

4.7

SETTINGS RELATED TO ASSIST GAS PRESSURE AND TIME

15100 Assist gas selection

[Data type] Word

[Unit of data]

[Valid data range] 0 to 7 (when bit 0 of parameter No. 15001 is set to 1)

15101 Flow pattern selection

[Data type] Word

B–63200EN/02

0 to 3 (when bit 0 of parameter No. 15001 is set to 0)

Specify an assist gas type.

[Unit of data]

[Valid data range] 1 to 3

Specify an assist gas flow pattern.

15102 Pre–flow time 1

15103 Pre–flow time 2

15104 Pre–flow time 3

[Data type] Word

[Unit of data] 10 milliseconds

[Valid data range] 0 to 32767

Specify the pre–flow time of the assist gas.

15108 After–flow time 1

15109 After–flow time 2

15110 After–flow time 3

[Data type] Word

[Unit of data] 10 milliseconds

[Valid data range] 0 to 32767

Specify the after–flow time of the assist gas.

22

Page 28

B–63200EN/02

15114 Pre–flow pressure 1

15115 Pre–flow pressure 2

15116 Pre–flow pressure 3

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

Specify the pre–flow pressure of the assist gas.

15120 Machining flow pressure 1

15121 Machining flow pressure 2

15122 Machining flow pressure 3

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

4. DESCRIPTION OF PARAMETERS

2

2

[Valid data range] 0 to 255

Specify the machining flow pressure of the assist gas.

15126 After–flow pressure 1

15127 After–flow pressure 2

15128 After–flow pressure 3

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

Specify the after–flow pressure of the assist gas.

15132 Maximum assist gas pressure

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

Specify a gas pressure with which an analog output of 10V is obtained.

2

2

15135 Assist gas pressure stabilization time

[Data type] Word

[Unit of data] 10 milliseconds

[Valid data range] 0 to 32767

Specify an assist gas pressure stabilization time.

23

Page 29

4. DESCRIPTION OF PARAMETERS

15136 Assist gas pressure

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

15137 Stabilization time of the assist gas pressure for piercing

[Data type] Word

[Unit of data] 10 milliseconds

[Valid data range] 0 to 32767

15138 Assist gas pressure for piercing

B–63200EN/02

2

Specify an assist gas pressure.

Specify the stabilization time of the assist gas pressure for piercing.

[Data type] Word

[Unit of data] 0.01 MPa or 0.1 kg/cm

[Valid data range] 0 to 255

Specify an assist gas pressure for piercing.

15139 Assist gas stop time

[Data type] Word

[Unit of data] 10 msec

[Valid data range] 0 to 32767

Specify the wait time in which the assist gas is stopped.

2

24

Page 30

B–63200EN/02

4.8

LASER MAINTENANCE/ INSPECTION TIME DISPLAY FUNCTION

[Data type] Two–word

[Unit of data] 0.1 hour

[Valid data range] 0 to 99999999

[Data type] Two–word

[Unit of data] 0.1 hour

4. DESCRIPTION OF PARAMETERS

15150 Laser RUN–ON period

The total RUN–ON time is automatically specified.

15151 Vacuum pump operation period

[Valid data range] 0 to 99999999

The total operation period of the vacuum pump is automatically specified.

15152 Shutter alarm mask time

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

Specify a time from when the shutter operation is specified until the alarm

monitor starts.

#7

15153

[Data type] Bit

LCK The leak check function is:

0 : Disabled.

1 : Enabled.

15154 Leak judgment time

#6 #5 #4 #3 #2 #1 #0

LCK

[Data type] Word

[Unit of data] sec

[Valid data range] 3 to 65535

Specify the time in which the valve is to be closed and the in–discharge–

tube pressure is to be maintained for a leak check.

In the specified time, the in–discharge–tube pressure is measured a total of

four times. If 0 to 2 is specified, the leak check function is not executed.

25

Page 31

4. DESCRIPTION OF PARAMETERS

B–63200EN/02

#7

15160

#6 #5 #4 #3 #2 #1

[Data type] Bit

MNT The laser maintenance screen is:

0 : Not displayed.

1 : Displayed.

Even if the screen is not displayed, the storage of compensation

coefficients and the totaling of operation time are performed, so that the

screen can be displayed for confirmation when needed.

MDS On the laser maintenance screen, data entry is:

0 : Disabled.

1 : Enabled.

On the laser maintenance screen, data entry is disabled to prevent end

users from entering operation time and other data items accidentally.

(Data can only be viewed.) Setting this bit enables data entry.

MDS#0MNT

26

Page 32

B–63200EN/02

4.9

PARAMETERS RELATED TO OSCILLATOR CONTROL

[Valid data range] 0 to 32767

4. DESCRIPTION OF PARAMETERS

15200 Power specified for power calibration when half of the discharge tubes are used

[Data type] Word

[Unit of data] W

Specify the power to be specified to obtain a power calibration coefficient

when half of the discharge tubes are used.

15201 Power specified for power calibration when all the discharge tubes are used

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

Specify the power to be specified to obtain a power calibration coefficient

when all the discharge tubes are used.

15203 Power calibration limit

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

When the power calibration coefficient exceeds this setting, the output

drop alarm signal (F220#6 MWRN) is output to indicate that the mirror

should be cleaned or replaced.

15204 Power calibration coefficient

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

The coefficient is used to calibrate the specified power according to the

actual power. This parameter is automatically specified during power

calibration after the oscillator start signal (G222#6, RUN) is turned on.

15205 Power calibration time

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

Specify a power calibration time.

27

Page 33

4. DESCRIPTION OF PARAMETERS

15206 Time constant of power sensor input filter

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 8 to 32767

15207 Upper limit on power

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

B–63200EN/02

The time constant is used when the primary delay filter is applied to the

laser power monitor value input from the power sensor.

When the specified power value exceeds this setting after power

calibration and power feedback addition, the actual power is clamped to

this setting.

15208 Laser power feedback gain

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

Specify a laser power feedback gain.

15209 Power feedback amount clamp

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

The power specification is clamped to this setting in power feedback.

15210 Maximum output power

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

When an output power higher than this setting is specified, the actual

power is clamped to this setting.

15211 Minimum output power

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

When an output power lower than this setting is specified, the actual

power is clamped to this setting.

28

Page 34

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15212 Upper limit on power when the duty ratio is not clamped

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

When the duty ratio is not clamped to 50% according to parameter No.

15213 and when the specified power exceeds this setting after power

calibration and power feedback addition, the actual power is clamped to

this setting. When 0 is specified, the value of parameter No. 15207 is

assumed.

15213 Criterion for clamping the duty ratio

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

When the product of the specified power and override exceeds this setting,

the duty ratio is always limited to 50%, and the peak value is clamped to

the value specified in parameter No. 15210. When 0 is specified, the value

of parameter No. 15210 is assumed.

15214 Maximum CW–Y AG laser frequency

[Data type] Word

[Unit of data] Hz

[Valid data range] 0 to 32767

The frequency of the CW–YAG laser oscillator is clamped to this setting.

15215 Power input calibration coefficient

[Data type] Word

[Unit of data] W

[Valid data range] 102 (0.1 2

is assumed.)

Specify a power input calibration coefficient.

10

) to 10240 (10 210) (When 0 is specified, 1024 (1 210)

15216 Time constant of power display filter

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

Specify a time constant for the filter that suppresses flickering of the

power display.

29

Page 35

4. DESCRIPTION OF PARAMETERS

15217 Beam stop delay time

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

15218 Power for clamping the duty ratio of the CW–Y AG laser

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

B–63200EN/02

Specify the period from when an in–position check is completed until the

beam stops.

When laser power Pc, specified for the CW–YAG laser, exceeds this setting,

the upper limit of the duty ratio is clamped to:

No.15218

Pc

100(%) When

0 is specified, 500 W is assumed.

15219 Beam output condition delay time

[Data type] Byte

[Unit of data] 8 milliseconds

[Valid data range] 0 to 8

Specify the delay time from the point the CNC specifies beam output

conditions until the output conditions for the beam to be output from the

oscillator are actually changed.

30

Page 36

B–63200EN/02

4.10

PARAMETERS RELATED TO DISCHARGE

[Valid data range] 0 to 32767

[Valid data range] 0 to 32767

4. DESCRIPTION OF PARAMETERS

15220 Maximum specifiable bias value at the start of discharge

[Data type] Word

[Unit of data] mV

Specify the maximum bias value that can be specified at the start of

discharge.

15221 Discharge start voltage

[Data type] Word

[Unit of data] V

Specify a discharge start voltage.

15222 Discharge start wait time

[Data type] Word

[Unit of data] 10 milliseconds

[Valid data range] 0 to 32767

Specify a wait time from when the bias value is maximized at the start of

discharge until actual discharge is confirmed.

15223 Bias value

[Data type] Word

[Unit of data] mV

[Valid data range] 0 to 32767

Specify a bias value.

15224 Modulation voltage

[Data type] Word

[Unit of data] mV

[Valid data range] 0 to 3000

V alue by which the normal bias value is to be reduced during modulation.

15225 Modulation time

[Data type] Word

[Unit of data] 10 msec

[Valid data range] 0 to 32767

Time in which the bias value is to be reduced.

31

Page 37

4. DESCRIPTION OF PARAMETERS

4.11

PARAMETERS RELATED TO GAS PRESSURE CONTROL (1)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

[Data type] Word

[Unit of data] (1=13 Pa)

15240 Negative pressure for completing evacuation

15241 In–tube pressure at the start of discharge

B–63200EN/02

The negative pressure is applied to evacuate the discharge tube during the

laser startup sequence.

[Valid data range] 0 to 32767

The discharge tube has the gas pressure at the start of discharge.

15242 In–tube pressure during oscillation (50 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

The discharge tube has the gas pressure during laser oscillation (50 Hz).

15243 In–tube pressure during oscillation (60 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

The discharge tube has the gas pressure during laser oscillation (60 Hz).

15244 Gas pressure control gain

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

The feedback gain is used to maintain a constant gas pressure in the

discharge tube.

32

Page 38

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15245 In–tube pressure control gain 2

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

Specify a gas pressure control gain for reference discharge. This setting is

valid when bit 1 (LGC) of parameter No. 15000 is set to 1.

15246 Pressure control integral gain

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

The setting is the feedback gain of an integral element for gas pressure

control.

15247 Pressure control integral element preset value

[Data type] Word

[Unit of data]

[Valid data range] –32768 to 32767

The setting is the preset value of an integral element for gas pressure

control.

15248 Lowest permissible gas pressure

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

When the gas pressure is low but reaches this setting, no alarm is raised.

15249 Gas pressure rise time

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

Specify a gas pressure rise time in sequence 27.

15255 Evacuation time at RUN start

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

Specify an evacuation time at RUN start.

33

Page 39

4. DESCRIPTION OF PARAMETERS

15256 RUN–OFF evacuation time

[Data type] Word

[Unit of data] Second

[Valid data range] 600 to 32767

15257 Abnormal vibration detection count

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

B–63200EN/02

When bit 2 (GVW) of parameter No. 15003 is set to 1 and when the

oscillator start signal (bit 6 (RUN) of G222) goes to 0, evacuation of the

specified time is executed.

When the abnormal vibration count, detected over ten minutes, is not

smaller than this setting, an alarm is raised.

15258 T ime constant of filter for reducing the laser gas pressure variation

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 17 to 32767 (When the setting is 16 or lower, the filter is disabled.)

15259 RUN–ON evacuation time

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

Specify a RUN–ON evacuation time.

15260 Discharge valve open time for external piping

[Data type] Byte

[Unit of data] Second

[Valid data range] 0 to 60

Specify the operation time of the external piping discharge valve.

34

Page 40

B–63200EN/02

4.12

HIGHLY REFLECTIVE MA TERIAL ALARMS

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

4. DESCRIPTION OF PARAMETERS

15265 Maximum permissible output increase

When the difference between the specified power and actual power

exceeds this value, an alarm 4068 (beam reflection error) is raised.

15266 Output limit

When the actual power exceeds this value, an alarm 4068 (beam reflection

error) is raised.

35

Page 41

4. DESCRIPTION OF PARAMETERS

4.13

LASER POWER/VOLTAGE DECREASE

15270 Normal discharge tube voltage

[Data type] Word

[Unit of data] V

[Valid data range] 0 to 32767

15271 Permissible power decrease

[Data type] Word

[Unit of data] W

B–63200EN/02

Specify a discharge tube voltage in normal reference discharge. This

parameter is automatically rewritten after the discharge start signal

(G222#7 HVON) turned “ON”.

[Valid data range] 0 to 32767

When the difference between the specified power and actual power is not

smaller than this value, an output decrease alarm is raised.

15272 Permissible decrease in discharge tube voltage

[Data type] Word

[Unit of data] V

[Valid data range] 0 to 32767

When the difference in the discharge tube voltage between the laser being

used and at laser activation is not smaller than this value, an alarm 4088

(voltage decrease) is raised.

15276 Laser gas replacement time

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

Time after which new gas is to be injected to the internal piping system.

36

Page 42

B–63200EN/02

4.14

POWER TABLE SETTINGS

[Valid data range] 0 to 32767

[Standard setting] Refer to the appended parameter sheet.

4. DESCRIPTION OF PARAMETERS

15280 Power table interval when half of the discharge tubes are used

15281 Power table interval when all of the discharge tubes are used

[Data type] Word

[Unit of data]

Specify a power setting interval, in Watts.

15290 Value 0 when half of the discharge tubes are used

15291 Value 1 when half of the discharge tubes are used

15292 Value 2 when half of the discharge tubes are used

15293 Value 3 when half of the discharge tubes are used

15294 Value 4 when half of the discharge tubes are used

15295 Value 5 when half of the discharge tubes are used

15296 Value 6 when half of the discharge tubes are used

15297 Value 7 when half of the discharge tubes are used

15298 Value 8 when half of the discharge tubes are used

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

[Standard setting] Refer to the appended parameter sheet.

Specify power settings 0 to 8 at the table intervals, in the indicated order,

when half of the discharge tubes are used.

37

Page 43

4. DESCRIPTION OF PARAMETERS

15300 Value 0 when all of the discharge tubes are used

15301 Value 1 when all of the discharge tubes are used

15302 Value 2 when all of the discharge tubes are used

15303 Value 3 when all of the discharge tubes are used

15304 Value 4 when all of the discharge tubes are used

15305 Value 5 when all of the discharge tubes are used

15306 Value 6 when all of the discharge tubes are used

15307 Value 7 when all of the discharge tubes are used

15308 Value 8 when all of the discharge tubes are used

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 32767

B–63200EN/02

[Standard setting] Refer to the appended parameter sheet.

Specify power settings 0 to 8 at the table intervals, in the indicated order,

when all of the discharge tubes are used.

38

Page 44

B–63200EN/02

4.15

AUTOMATIC AGING FUNCTION

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

4. DESCRIPTION OF PARAMETERS

15320 Laser power in normal calibration

15321 Oscillation frequency in normal calibration

15322 Pulse duty ratio in normal calibration

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

15323 Calibration time of normal calibration

[Data type] Word

[Unit of data] Second

[Valid data range] 0 to 32767

15324 Gas pressure in normal calibration (50 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

15325 Gas pressure in normal calibration (60 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

15326 Laser power in aging

[Data type] Word

[Unit of data] W

[Valid data range] 0 to 7000

39

Page 45

4. DESCRIPTION OF PARAMETERS

15327 Oscillation frequency in aging

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

15328 Pulse duty ratio in aging

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

15329 Calibration time in aging

[Data type] Word

B–63200EN/02

[Unit of data] Second

[Valid data range] 0 to 32767

15330 Gas pressure in aging (50 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

15331 Gas pressure in aging (60 Hz)

[Data type] Word

[Unit of data] (1=13 Pa)

[Valid data range] 0 to 32767

15332 Pulse frequency in normal calibration

[Data type] Word

[Unit of data] Hz

[Valid data range] 5 to 2000

15333 Pulse duty ratio in normal calibration

[Data type] Word

[Unit of data] %

[Valid data range] 0 to 100

40

Page 46

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15334 Aging count

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767 (automatically specified by the CNC)

15335 Time data 1 at HVOFF after LSTR

[Data type] Double word

[Unit of data]

[Valid data range] 0 to 99999999 (automatically specified by the CNC)

15336 Time data 2 at HVOFF after LSTR

[Data type] Double word

[Unit of data]

[Valid data range] 0 to 99999999 (automatically specified by the CNC)

15337 Time data 3 at HVOFF after LSTR

[Data type] Double word

[Unit of data]

[Valid data range] 0 to 99999999 (automatically specified by the CNC)

15338 Time data 4 at HVOFF after LSTR

[Data type] Double word

[Unit of data]

[Valid data range] 0 to 99999999 (automatically specified by the CNC)

15339 Stop time of the oscillator that requires an aging operation

[Data type] Word

[Unit of data] Hour

[Valid data range] 0 to 32767 (valid range: 30 to 120)

If the setting is less than 30, internal processing assumes it to be 60.

The parameters related to automatic aging (Nos. 15320 to 15338) must

not, as a rule, be changed from their preset values or those automatically

set by the CNC.

41

Page 47

4. DESCRIPTION OF PARAMETERS

4.16

PARAMETERS RELATED TO THE PMC–WINDOW

15350 M code for reading a comment

[Data type] Word

[Unit of data]

[Valid data range] 0 to 999

15360 Start address of the R area of the PMC

[Data type] Word

[Unit of data]

[Valid data range] 1 to 997

B–63200EN/02

Specify an M code for reading the comment of function code 140.

Specify the start address of the R area of the PMC.

42

Page 48

B–63200EN/02

4.17

POWER CONTROL (2)

[Data type] Word

[Unit of data] mm/min

[Valid data range] 0 to 32767

[Standard setting] 4

4. DESCRIPTION OF PARAMETERS

15450 Allowable variation in power control speed

Specify the allowable variation in power control speed. If this parameter

is 0, parameter No. 15095 is effective. Parameter No. 15095 and this

parameter have different valid data ranges.

43

Page 49

4. DESCRIPTION OF PARAMETERS

4.18

SETTINGS RELATED TO TRACING (DETECTION)

[Data type] Word

[Unit of data]

[Valid data range] 0 to 65536

[Data type] Word

[Unit of data]

[Valid data range] –32768 to 32767

15500 Detection gain coef ficient

15502 Detection zero point

B–63200EN/02

Specify the gain coefficient of the displacement detector in Z–axis tracing

control.

NOTE

This parameter can be set on the trace setting screen.

The zero point calibration value is used to calibrate the zero point of the

displacement detector in Z–axis tracing control.

NOTE

This parameter can be set on the trace setting screen.

15503 Filter time constant

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767 (Must not set to 1)

[Standard setting] 0

The setting is the time constant of a filter for eliminating the disturbance

component from the displacement in Z–axis tracing control.

15504 Displacement multiplier

[Data type] Word

[Unit of data]

[Valid data range] 1 to 5

[Standard setting] 1

Specify a multiply ratio for supporting a large detection amount in Z–axis

tracing control.

Setting Maximum displacement (mm) Resolution (mm)

1 "2 0.001

2 "4 0.002

3 "6 0.003

4 "8 0.004

5 "10 0.005

44

Page 50

B–63200EN/02

4.19

SETTING RELATED TO TRACING (DISPLAY)

[Data type] Bit

4. DESCRIPTION OF PARAMETERS

#7

15505

#6

TRS

#5

TRA

#4

EBS

#3 #2 #1 #0

EBS The process of establishing the tracing displacement amount standard:

0 : Is of the conventional type. (Data is processed one word at a time.)

1 : Can be expanded. (Data is processed two words at a time.)

TRA The trace setting screen displays the current position using:

0 : The relative coordinate system.

1 : The absolute coordinate system.

TRS TRS Except in tracing mode, the TRERS signal is output if:

0 : The tracing displacement amount > parameter No. 15537.

1 : The tracing displacement amount > (parameter No. 15537 + No.

15539) or the tracing displacement amount < –(parameter No.

15537).

#7

15507

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit

PCH The G codes for tracing control are:

0 : Of the normal type.

1 : Not of the normal type. G13 is a G code dedicated to changing gap

amounts and G14 is a G code with no function.

PCH

45

Page 51

4. DESCRIPTION OF PARAMETERS

4.20

SETTINGS RELATED TO TRACING (INTEGRATION)

15510 Integral time constant

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

[Standard setting] 0

15511 Integral calibration zero width

[Data type] Word

[Unit of data] 0.001 mm

B–63200EN/02

The integral time constant is used for displacement integration in Z–axis

tracing control.

[Valid data range] 0 to 32767

[Standard setting] 0

The setting is used as a displacement to disable integration in Z–axis

tracing control. The integration is not performed when |(displacement

specified as a reference value)| x (integral calibration zero width).

15512 Integral clamp value

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 0

The setting is the integral clamp value for displacement integration in

Z–axis tracing control.

46

Page 52

B–63200EN/02

4.21

SETTINGS RELA TED TO TRACING (PHASE COMPENSATION)

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

[Standard setting] 0 (A value lower than 2 is invalid.)

[Data type] Word

[Unit of data]

4. DESCRIPTION OF PARAMETERS

15520 Phase compensation time constant

This setting is the time constant for displacement phase compensation in

Z–axis tracing control.

15521 Phase compensation gain

[Valid data range] 0 to 32767

[Standard setting] 0 (A value lower than 2 is invalid.)

Specify a gain for displacement phase compensation in Z–axis tracing

control.

47

Page 53

4. DESCRIPTION OF PARAMETERS

4.22

SETTINGS RELATED TO TRACING (DISPLACEMENT)

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] Parameter No. 15531 to parameter No. 15532

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] –32768 to 32767

[Standard setting] 0

15530 Reference displacement

15531 Lower limit on reference displacement

B–63200EN/02

The setting determines the reference distance from the tip of the quill to

the workpiece to be controlled in Z–axis tracing control.

NOTE

This parameter can be set on the tracer setting screen.

Specify the minimum value that can be specified as the reference

displacement for Z–axis tracing control.

15532 Upper limit on reference displacement

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] –32768 to 32767

[Standard setting] 1000

Specify the maximum value that can be specified as the reference

displacement for Z–axis tracing control.

15533 Displacement causing large displacement alarm

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 1200

When a value specified as the reference displacement exceeds this setting

in Z–axis tracing control, a large displacement alarm is raised.

15534 Tracing displacement on workpiece surface

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

This setting indicates the displacement from the surface of the workpiece

to the zero point in tracing control.

48

Page 54

B–63200EN/02

4. DESCRIPTION OF PARAMETERS

15535 Lower limit on gap

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

Specify the minimum value that can be specified for the gap in tracing

control.

15536 Upper limit on gap

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

Specify the maximum value that can be specified for the gap in tracing

control.

15537 Tracing range over alarm

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 1000

When the absolute value of the value obtained by subtracting the reference

displacement from the detected displacement exceeds this setting in

Z–axis tracing control, an alarm is raised.

15538 Mask time of tracing range over alarm

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

[Standard setting] 1000

When the reference displacement amount is changed, an alarm is

suppressed in the transition state for the specified mask time.

15539 Calibration amount of tracing range over alarm

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 0

The calibration amount can be added to the detected value of the

approaching side to give the setting of parameter No. 15537.

49

Page 55

4. DESCRIPTION OF PARAMETERS

4.23

SETTINGS RELATED

TO TRACING

(VELOCITY

15540 Velocity control voltage conversion factor of Z–axis tracing control

COMMAND)

15541 Velocity control voltage conversion factor of W–axis tracing control

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

B–63200EN/02

Use the following expression to calculate the conversion factor to be

specified:

Conversionfactor + G

G : Tracing control loop gain (second

P 4

1000 Le

2 10*3 4096

–1

)

Le : Amount of machine movement per motor revolution (mm/rev)

P : Number of pulses detected by the pulse coder per motor revolution

(P/rev) (2048 for the serial A or α motor)

15544 Permissible approach acceleration

[Data type] Word

[Unit of data] mm/min

[Valid data range] 0 to 32767

A limit may be imposed on the tracing acceleration (speed increase per 2

msec) to prevent a servo overcurrent alarm from being raised at the start of

tracing. Specify this permissible value.

15545 Displacement amount at which an acceleration limit is imposed during approach

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] –32768 to 32767

A limit is imposed on the acceleration if the absolute value of the

displacement amount is larger than this setting during tracing approach.

50

Page 56

B–63200EN/02

4.24

SETTINGS RELATED TO TRACING (APPROACH)

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 50

4. DESCRIPTION OF PARAMETERS

15550 Approach completion detection range

This setting is the displacement at which the completion of approach is

assumed in Z–axis tracing control. When the displacement stays within

this approach completion detection range for the approach completion

interval time or longer, the system assumes that the approach has been

completed.

15551 Approach completion interval

[Data type] Word

[Unit of data] Millisecond

[Valid data range] 0 to 32767

[Standard setting] 500

When a displacement in Z–axis tracing control stays within the approach

completion detection range for the specified time or longer, the system

assumes that the approach has been completed.

15552 Approach completion detection displacement

[Data type] Word

[Unit of data] 0.001 mm

[Valid data range] 0 to 32767

[Standard setting] 50

Specify the approach completion displacement for approach feed.

15553 Upper limit on feedrate for the approaching side

[Data type] Word

[Unit of data] mm/min

[Valid data range] 0 to 32767

[Standard setting] 1200

Specify an upper limit on the feedrate in an approach.

51

Page 57

4. DESCRIPTION OF PARAMETERS

15554 Constant for clamping Z–axis tracing speed

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

15555 Upper limit on feedrate for the withdrawing side

[Data type] Word

[Unit of data] mm/min

B–63200EN/02

The setting is used as the constant for clamping the tracing speed. Specify

the value obtained using the following expression:

Tracing speed clamp constant +

P 4

Le

P : Number of pulses detected by the pulse coder per motor revolution

(P/rev) (2048 for the serial A or α motor)

Le : Amount of machine movement per motor revolution (mm/rev)

[Valid data range] 0 to 32767

[Standard setting] 1200

Specify an upper limit on the feedrate for the withdrawing side.

15556 Constant for clamping W–axis tracing speed

[Data type] Word

[Unit of data]

[Valid data range] 0 to 32767

This setting is used as the constant for clamping the tracing speed. Specify

the value obtained using the following expression:

Tracing speed clamp constant +

P : Number of pulses detected by the pulse coder per motor revolution

(P/rev) (2048 for the serial A or α motor)

Le : Amount of machine movement per motor revolution (mm/rev)

P 4

Le

52

Page 58

B–63200EN/02

4.25

SETTINGS RELATED TO THREE–DIMENSIONA L AXIAL MOVEMENT (ANGULAR AXIS)

4. DESCRIPTION OF PARAMETERS

#7

TDA15600

#6

NFX

#5

NCT

#4

RNC

#3

MIA

#2

NPC

#1 #0

[Data type] Bit

NPC During a stroke check before movement, movement in the G31 block is:

0 : Checked.

1 : Not checked.

MIA During attitude control B, the G53 mode is:

0 : Tip fix mode.

1 : Independent axis mode. (A program containing G53 cannot execute a

neighboring point search and program resumption.)

RNC During movement along an angular axis in manual reference position

return, the X, Y , and Z workpiece coordinates and relative coordinates are:

0 : Updated.

1 : Not updated.

NCT When no command is specified for an intermediate point around the

fourth and fifth axes in spatial circular interpolation (G12),

0 : The attitude does not change from the start point to the intermediate

point.

1 : The intermediate attitude of the attitudes at the start point and the end

point is specified for the intermediate point.

NFX A non–tip–fix command is allowed in memory operation for adjusting the

machine.

0 : The tip–fix operation is performed in memory operation.

1 : The non–tip–fix operation is performed in memory operation.

NOTE

When NFX is set to 1, the value (end point) specified by a

program does not match the coordinates. After adjusting the

machine, reset NFX to 0.

TDA When the attitude around a rotation axis exceeds a point of software

overtravel after three–dimensional conversion:

0 : Rotation in the opposite direction is performed.

1 : The software overtravel is not checked.

53

Page 59

4. DESCRIPTION OF PARAMETERS

B–63200EN/02

#7

OFC15601

#6 #5

RAT

#4

PCK

#3

RDC

#2

RFD

#1

PA5

[Data type] Bit

PA4 The rotation around the fourth axis is:

0 : Counterclockwise.

1 : Clockwise.

PA5 The rotation around the fifth axis is:

0 : Counterclockwise.

1 : Clockwise.

RFD When only the fourth and fifth axes are specified with G01, the feedrate is:

0 : That of parameter No. 15612 or 15613, whichever is lower.

1 : The program–specified feedrate in deg/min.

RDC In three–dimensional conversion, the rotation around the fourth and fifth