Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 15i / 150i – Model A

Remote Buffer

Descriptions Manual

B-6322EN-1/01 1999

Page 2

Warnings and notices for

GFLE-003

this publication

Warning

In this manual we have tried as much as possible to describe all the various

matters. However, we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this

manual should be regarded as “impossible”.

Notice

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware or software, nor to provide every contingency in connection with

installation, operation, or maintenance. Features may be described herein which are not present in

all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to

holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall

apply.

The following are Registered Trademarks of GE Fanuc Automation

CIMPLICITY® Genius®

The following are Trademarks of GE Fanuc Automation

Alarm Master

CIMSTAR

Field Control

Genet

Helpmate

LogicMaster

Modelmaster

PowerMotion

ProLoop

PROMACRO

Series Five

Series 90

Series One

Series Six

Series Three

VuMaster

Workmaster

© Copyright 1998 FANUC Ltd.

Authorized Reproduction GE Fanuc Automation Europe S.A.

All Rights Reserved

No part of this manual may be reproduced in any form.

All specifications and designs are subject to change without notice.

Page 3

B-63322EN-1/01 PREFACE

PREFACE

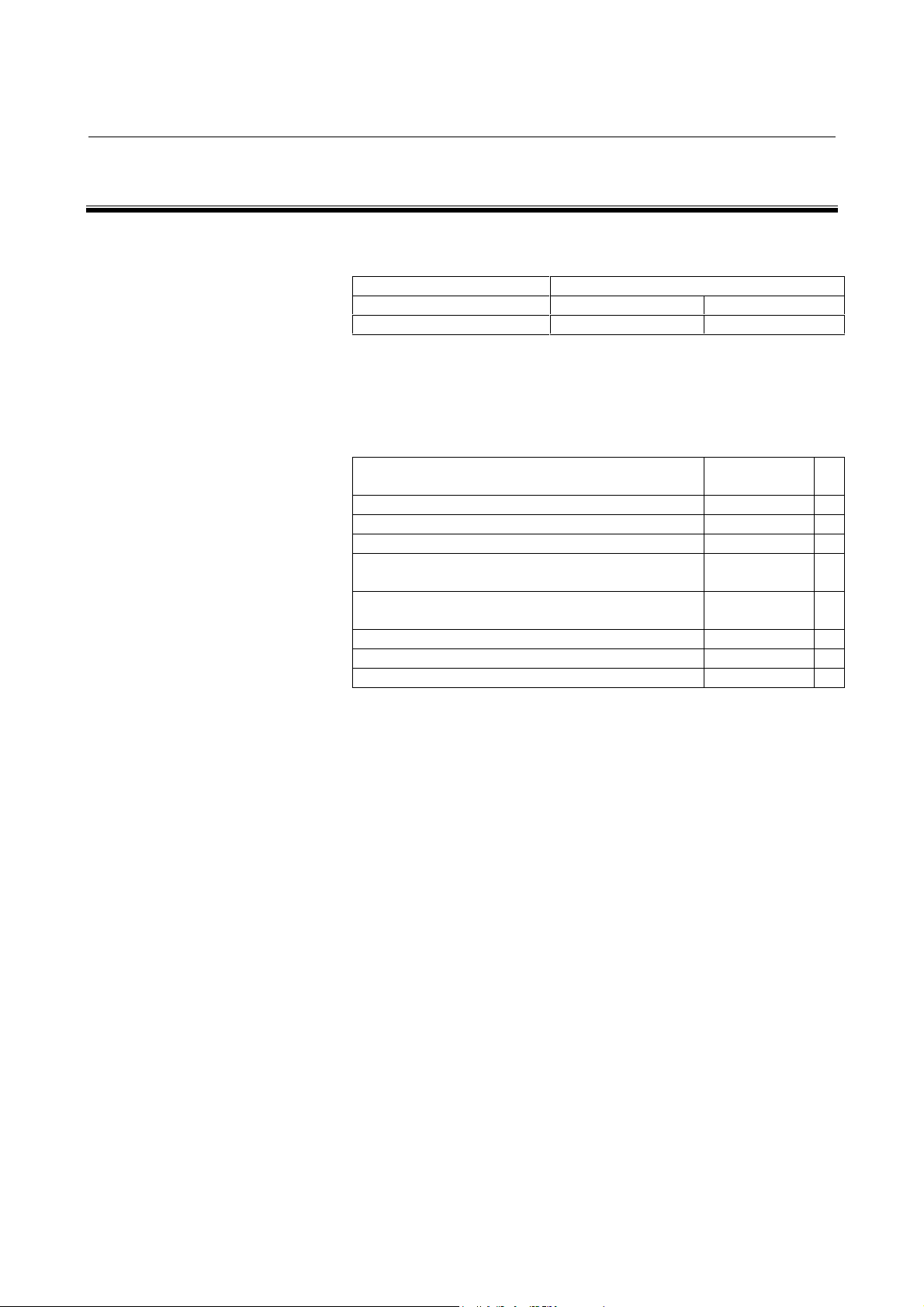

Applicable product name

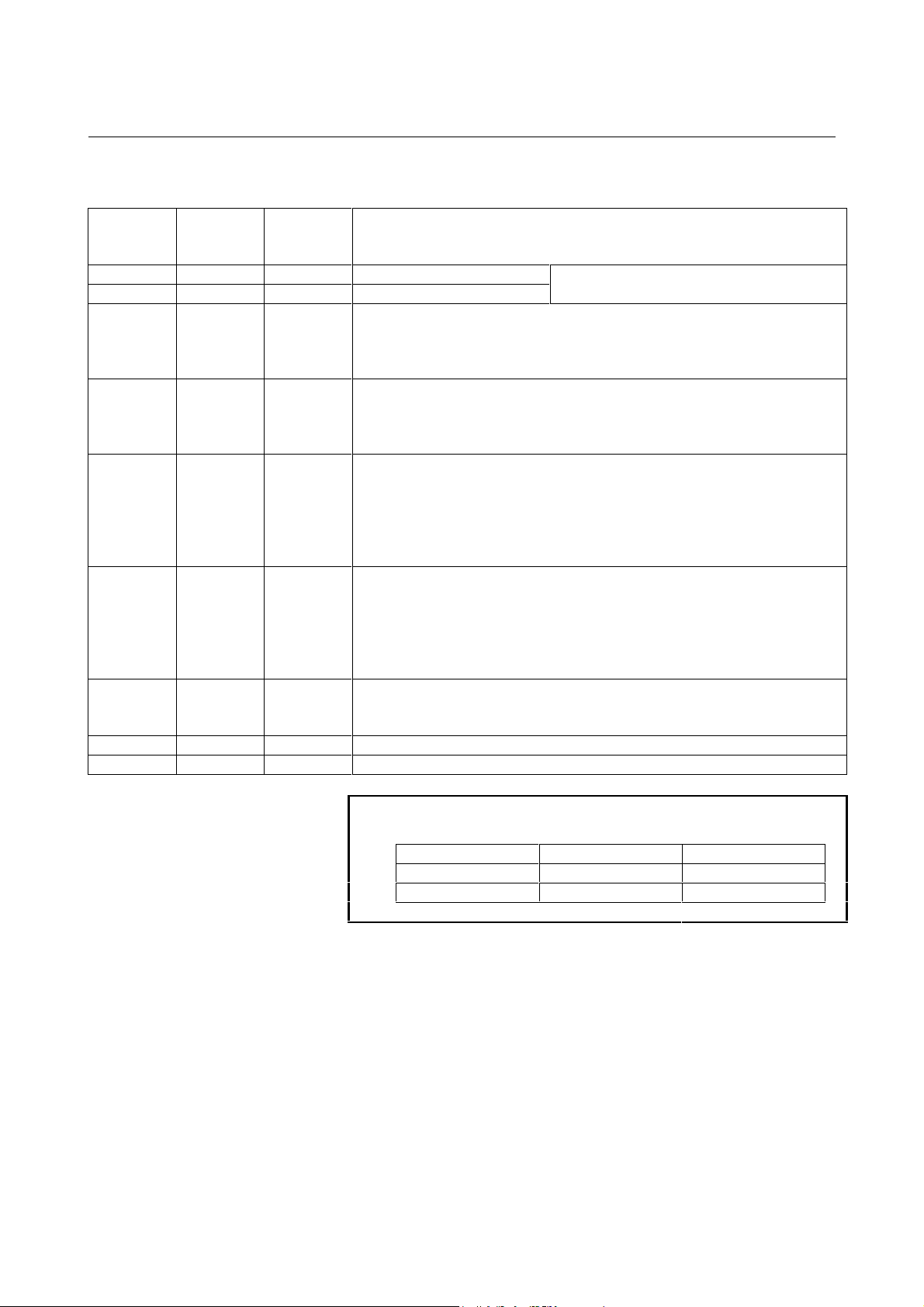

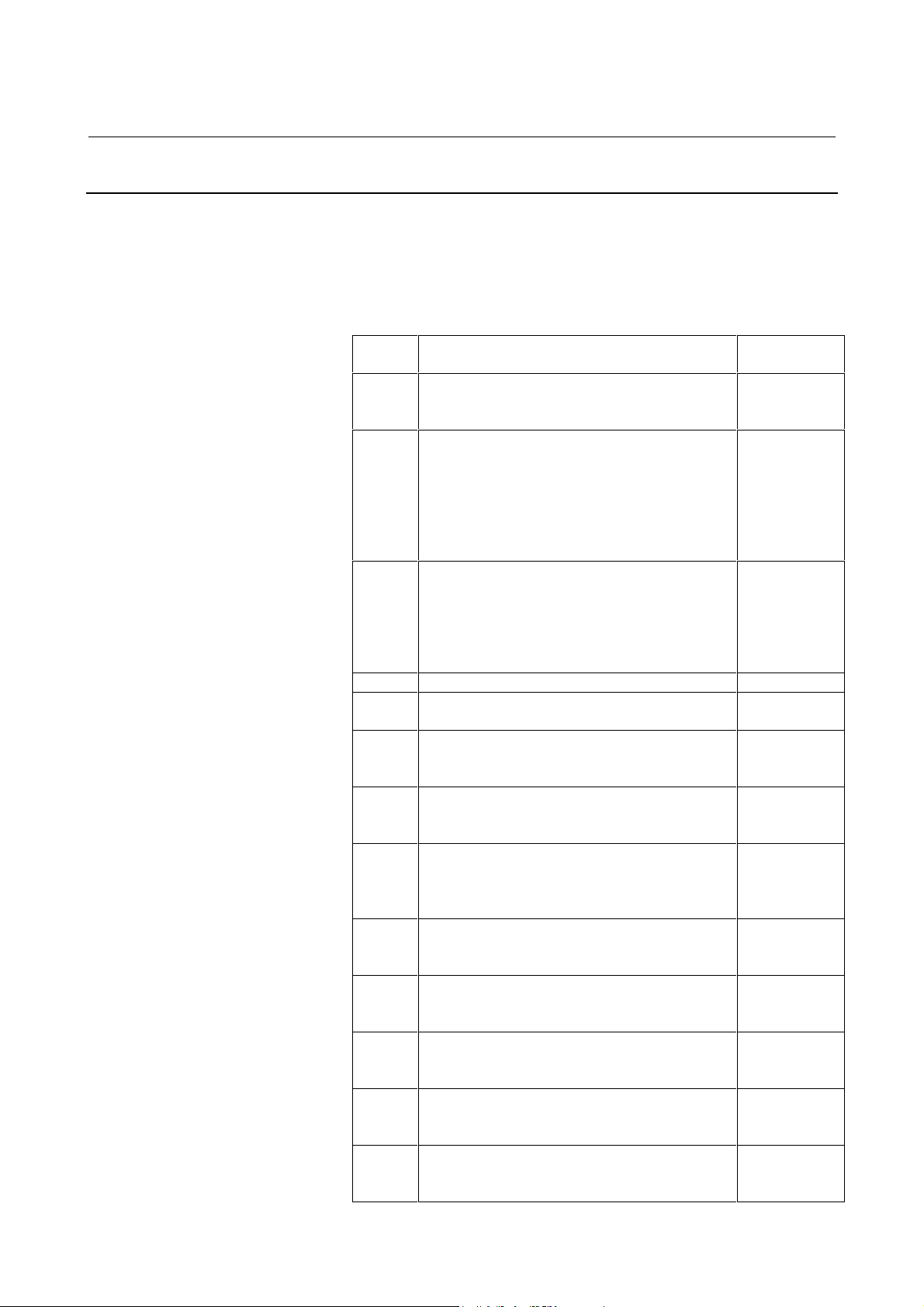

The models covered by this manual, and their abbreviations are:

Product name Abbreviations

FANUC Series 15i-MA 15i-MA Series 15i

FANUC Series 150i-MA 150i-MA Series 150i

Related manuals

The table below lists manuals related to MODEL A of Series 15i, and

Series 150i. In the table, this manual is marked with an asterisk (*).

Table 1 (a) Related manuals

Manual name

DESCRIPTIONS B-63322EN

CONNECTION MANUAL (Hardware) B-63323EN

CONNECTION MANUAL (Function) B-63323EN-1

OPERATOR’S MANUAL (PROGRAMMING)

for Machining Center

OPERATOR’S MANUAL (OPERATION)

for Machining Center

MAINTENANCE MANUAL B-63325EN

PARAMETER MANUAL B-63330EN

DESCRIPTIONS (Supplement for Remote Buffer) B-63322EN-1 *

Specification

number

B-63324EN

B-63324EN-1

p-1

Page 4

B-63322EN-1/01

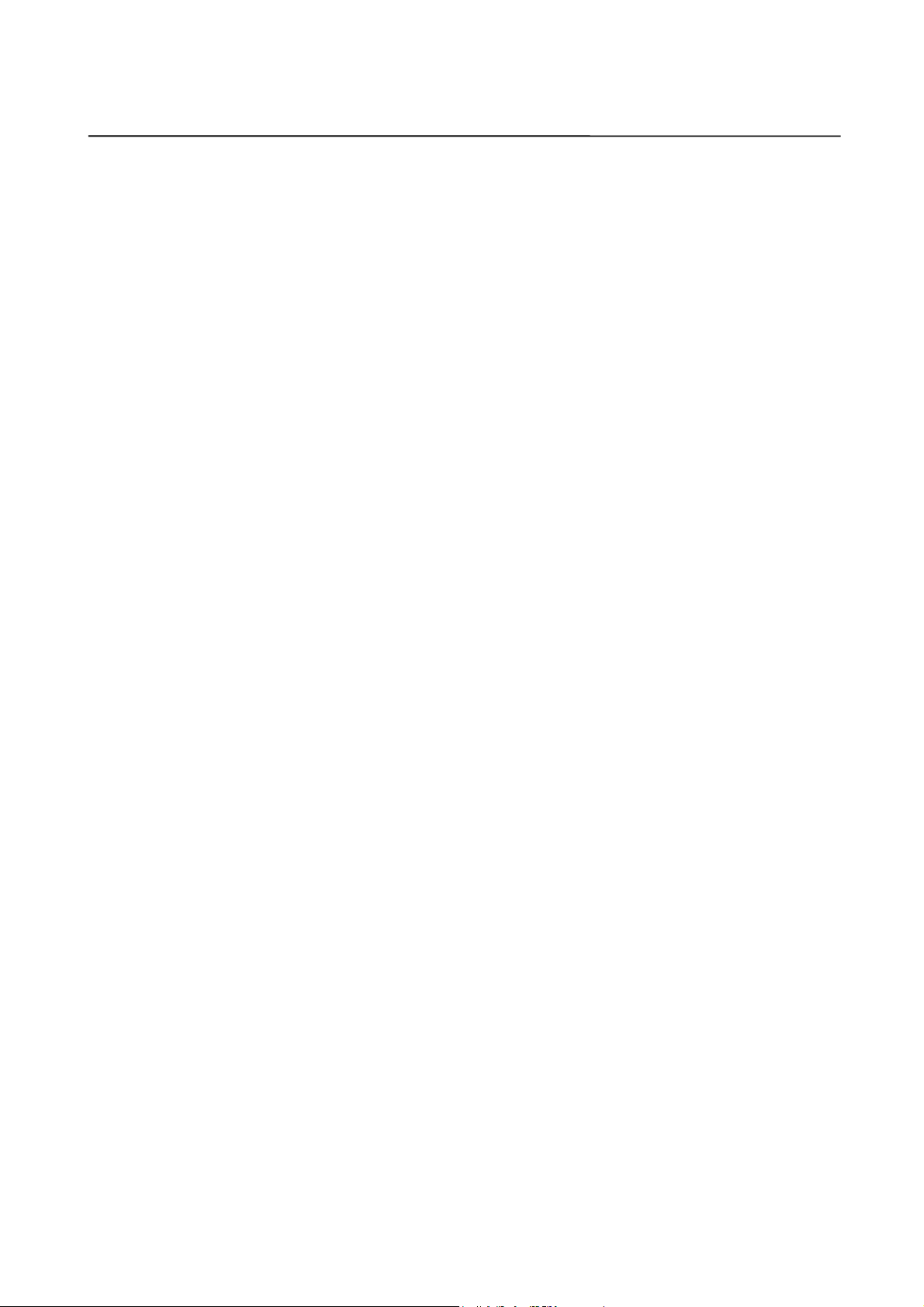

CONTENTS

PREFACE ................................................................................................................ p-1

1. GENERAL.............................................................................................................1

2. INTERFACE BETWEEN REMOTE BUFFER AND

HOST COMPUTER.............................................................................................2

2.1 ELECTRICAL INTERFACE ..................................................................................................... 3

2.2 SOFTWARE INTERFACE........................................................................................................ 4

3. ELECTRICAL INTERFACE.............................................................................5

3.1 TRANSMISSION SYSTEM....................................................................................................... 6

3.2 RS-232-C INTERFACE.............................................................................................................. 7

3.3 RS-422 INTERFACE................................................................................................................ 10

4. PROTOCOL A....................................................................................................13

4.1 MESSAGE FORMAT .............................................................................................................. 14

4.2 CODE SYSTEM....................................................................................................................... 14

4.3 COMMUNICATION SYSTEM............................................................................................... 15

4.4 COMMAND ............................................................................................................................. 17

4.4.1 Command Table.............................................................................................................................17

4.4.2 Description of Data Part.................................................................................................................19

4.5 PARAMETER TABLE............................................................................................................. 23

4.6 ERROR PROCESS................................................................................................................... 24

4.7 STATUS TRANSITION........................................................................................................... 25

5. EXPANSION PROTOCOL A...........................................................................26

5.1 COMMUNICATION SYSTEM............................................................................................... 27

5.2 DATA PACKET FORMAT ..................................................................................................... 28

5.3 MONITOR PACKET FORMAT.............................................................................................. 30

5.4 COMMUNICATION EXAMPLE............................................................................................ 32

6. PROTOCOL B....................................................................................................41

6.1 COMMUNICATION SYSTEM............................................................................................... 42

6.1.1 When the CNC Alarm/Reset is not Posted to the Host...................................................................42

6.1.2 When the CNC Alarm/Reset is Posted to the Host.........................................................................44

6.2 CONTROL CODE.................................................................................................................... 48

6.3 BUFFER CONTROL................................................................................................................ 48

6.4 ALARM AND RESET OF CNC.............................................................................................. 49

7. EXPANSION PROTOCOL B (RS-422)...........................................................50

c-1

Page 5

CONTENTS B-63322EN-1/01

8. DATA INTERFACE ..........................................................................................51

8.1 DATA PART ............................................................................................................................ 52

8.2 INTERFACE OF DATA PART ............................................................................................... 52

9. BINARY INPUT OPERATION FUNCTION .................................................53

9.1 FUNCTION EXPLANATION ................................................................................................. 54

9.2 TRANSFER RATE................................................................................................................... 57

9.3 NOTES......................................................................................................................................58

10. PARAMETER.....................................................................................................59

10.1 INPUT DEVICE NUMBER..................................................................................................... 60

10.2 EXCLUSIVE PARAMETER FOR REMOTE BUFFER......................................................... 61

10.3 PARAMETERS RELATED TO BINARY INPUT OPERATION.......................................... 67

11. ALARM ...............................................................................................................70

12. MAINTENANCE................................................................................................71

12.1 LED INDICATIONS ................................................................................................................ 71

12.1.1 Normal State ..................................................................................................................................71

12.1.2 System Errors.................................................................................................................................72

12.2 MATERIAL FOR REMOTE BUFFER TROUBLESHOOTING............................................ 74

12.3 DETERMINING THE LOGICAL SLOT NUMBER OF

THE REMOTE BUFFER BOARD .......................................................................................... 76

12.3.1 Determining the Logical Slot Number on the Screen Displayed

at the Time a System Alarm Occurs......................................................................................76

12.3.2 Determining the Logical Slot Number on the System Configuration Screen.........................77

c-2

Page 6

Page 7

B-63322EN-1/01 1. GENERAL

1 GENERAL

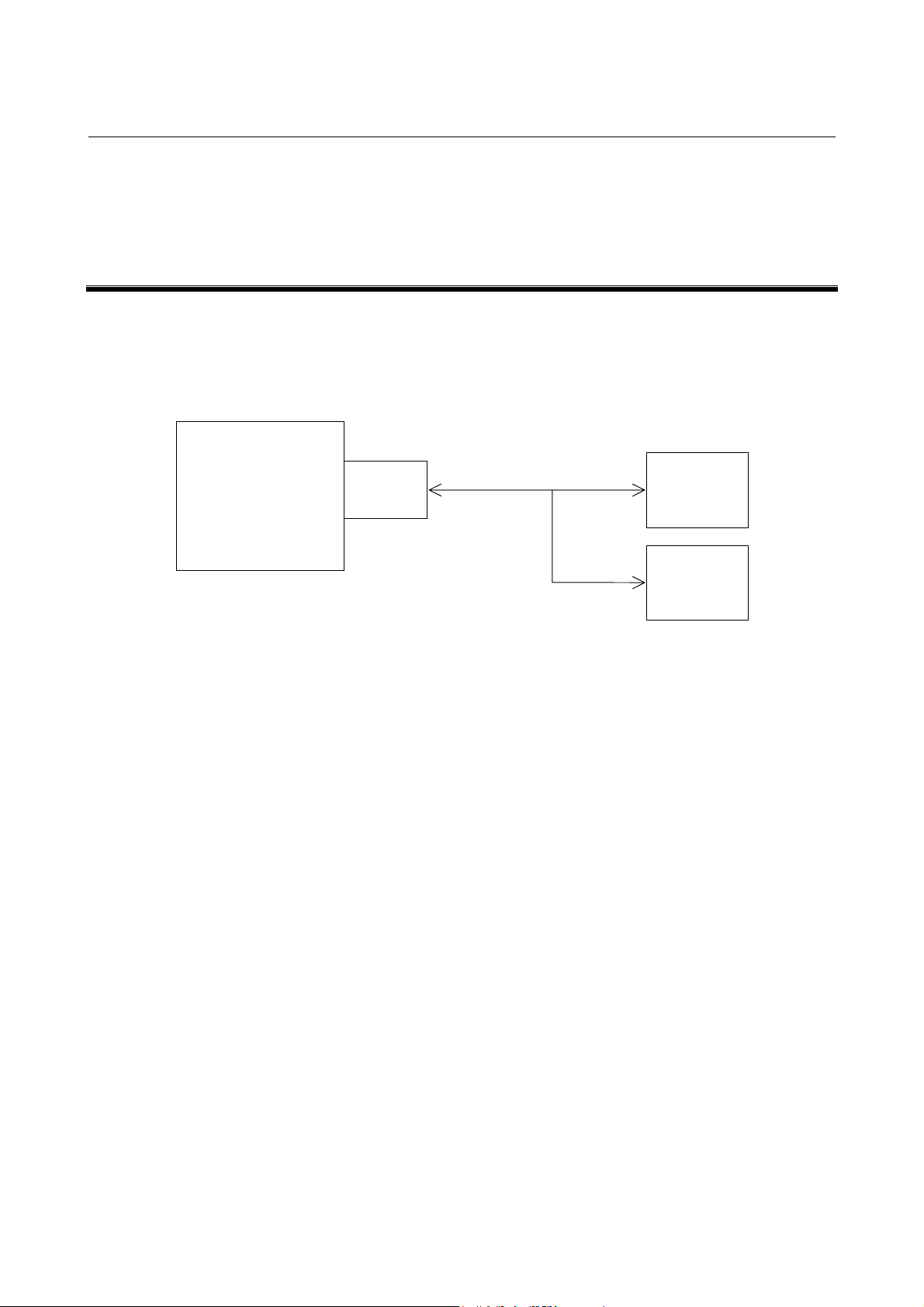

The remote buffer for FANUC Series 15i/150i-MODEL A is an

option and is used to allow a large number of data to be continuously

supplied to the CNC at high speed by connecting it to the host

computer or I/O device through a serial interface.

15i/150i-MA

Remote

buffer

The followings can be performed by the remote buffer.

1) It is used to perform DNC operation at high speed and with high

reliability by performing on-line connection to the host

computer.

2) It is used to download the NC program and parameters from the

host computer. When protocol B or expansion protocol B is

used, NC programs and parameters can also be uploaded to the

host computer.

3) It is used to perform DNC operation and download various kinds

of data by connecting to the I/O device. The following I/O

devices can be connected.

RS-232-C/RS-422

Host

computer

I/O device

(1) FANUC PROGRAM FILE Mate

(2) FANUC HANDY FILE

Hereafter, the destination where the remote buffer is connected to is

called “Host computer” for ease of explanation.

-1-

Page 8

2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER B-63322EN-1/01

2 INTERFACE BETWEEN REMOTE BUFFER

AND HOST COMPUTER

-2-

Page 9

B-63322EN-1/01 2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER

2.1

ELECTRICAL INTERFACE

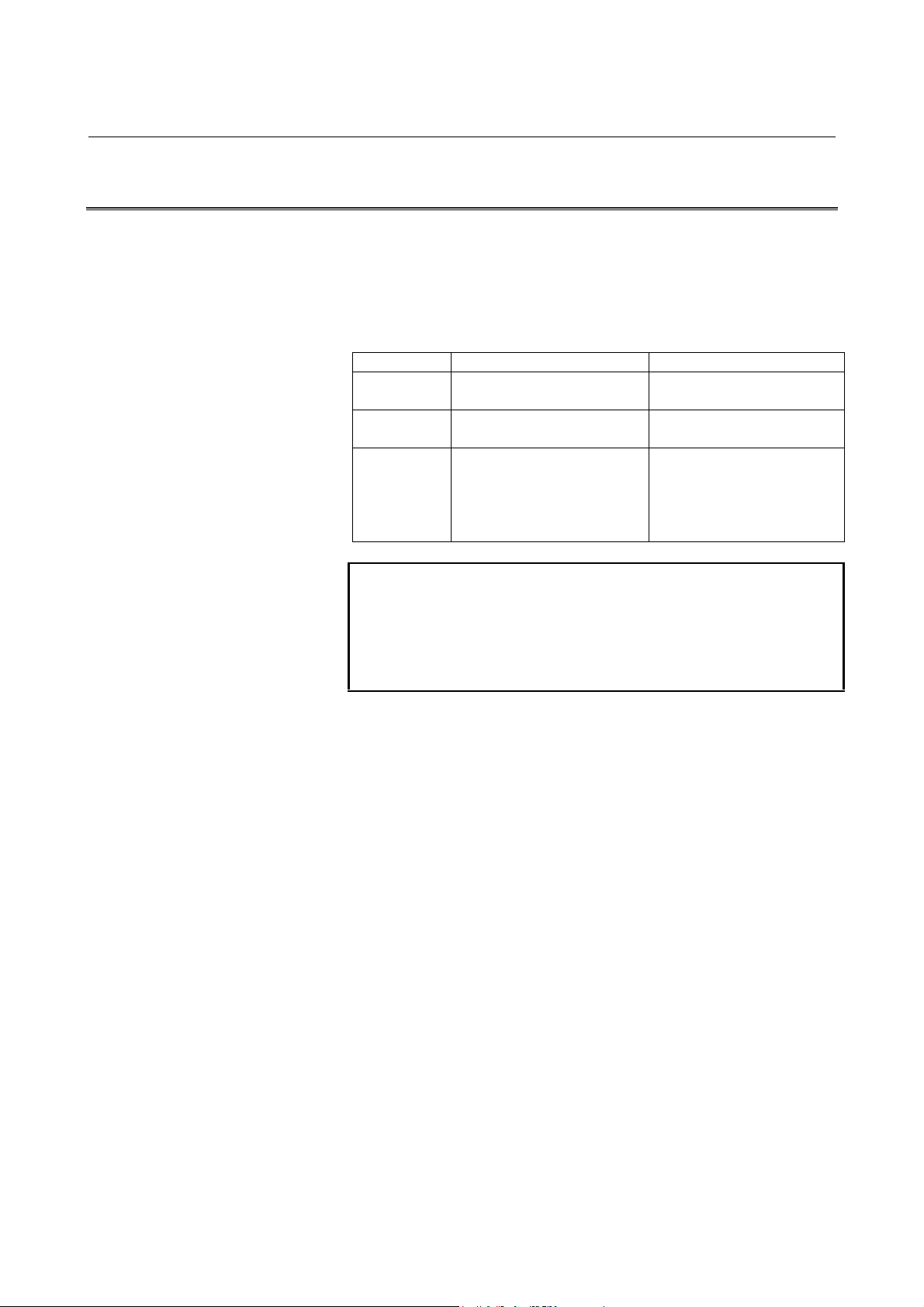

The following which interfaces are provided as standard

specifications.

1) RS-232-C interface

2) RS-422 interface (Note 1)

Interface Serial voltage interface

(start-stop system)

Baud rate 50 – 19200 baud rate

(Note 2)

Cable length

(MAX.)

NOTE

1 When the baud rate exceeding 38400 BPS is used, the

synchronization of reception clock is required. Prepare

the TT (*TT ) and RT (*RT) signals.

2 When t he baud r at e used is 19200 baud or more, use the

RS-422 interface.

100m (4800 baud or less)

50m (9600 baud)

15m (19200 baud)

It differs depending on I/O

devices.

RS-232-C RS-422

Balance transmission serial

interface (start-stop system)

50 – 86400 baud rate

(Note 1)

Approximately 800m

(9600 baud or less)

50m (19200 baud or more)

-3-

Page 10

2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER B-63322EN-1/01

2.2

SOFTWARE INTERFACE

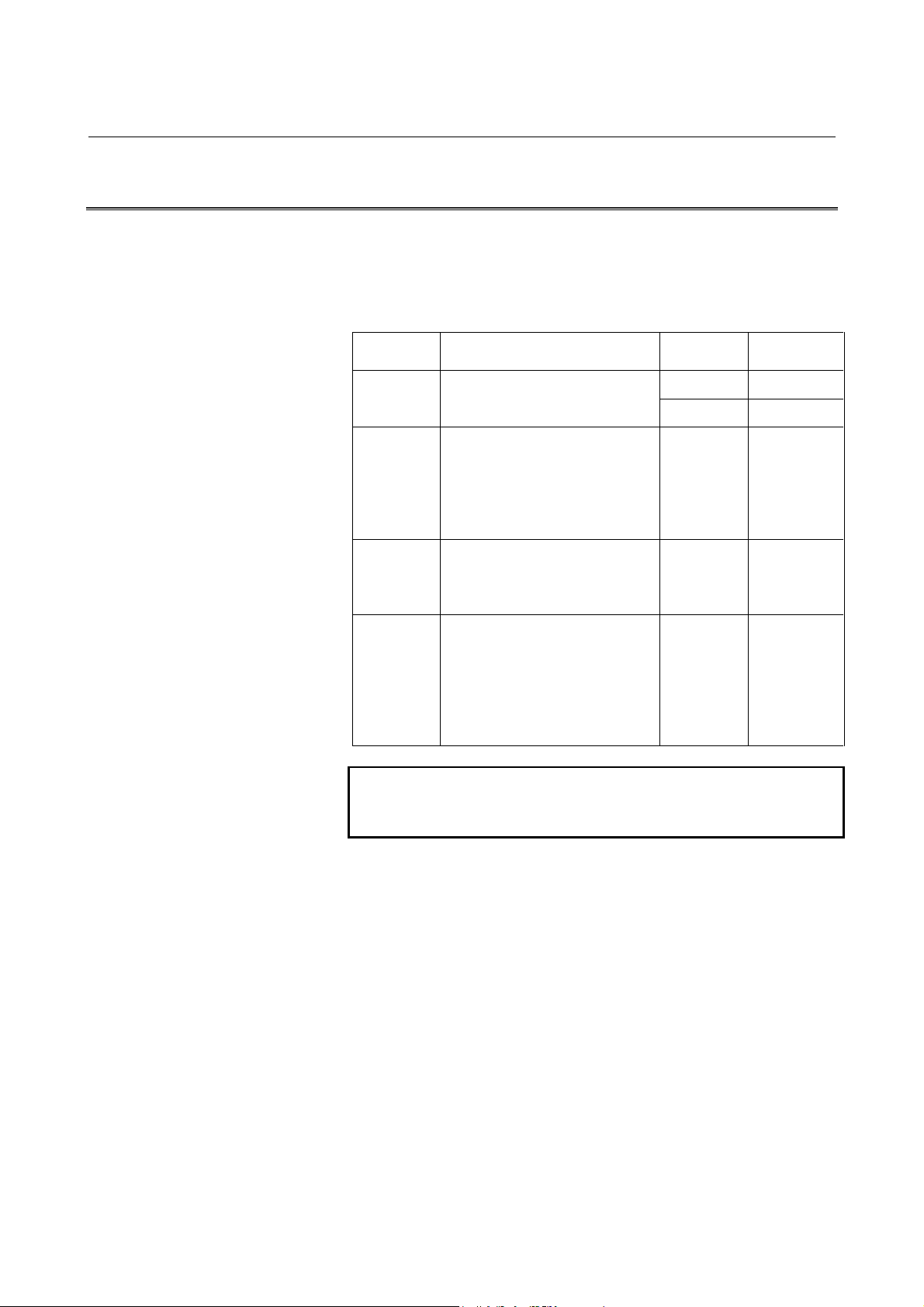

The following four protocols for communication between the remote

buffer and host computer are provided. The protocol meeting the

requirement of specifications of connection device can be selected by

setting a parameter.

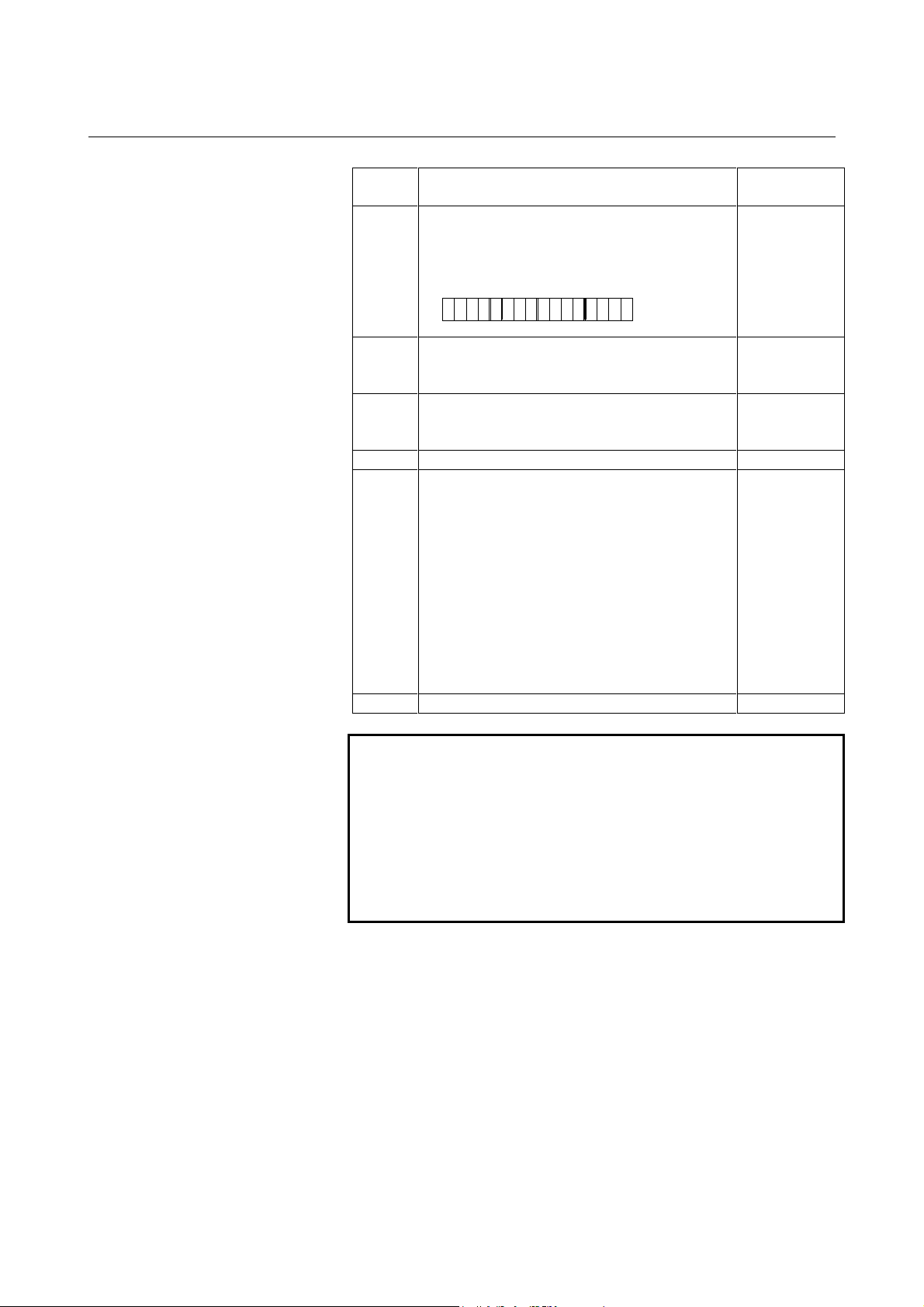

Protocol Features of protocol

where transmit/receive is

repeated between the both.

Expansion

protocol

A

ProtocolBIt is the system for controlling

Expansion

protocol

B

It is nearly the same as the

protocol A. However, the NC

program can be transferred at

high-speed so that it can be

applied to the high-speed DNC

operation.

the communication between the

both by the control code output

from the remote buffer.

The control system is the same

as that of protocol B. However,

it allows the transmission speed

to be increased. In this case, it

is required to receive the

reception synchronization clock

from the source.

Interface

used

RS-232-C 19200 BPSProtocolAIt is the handshake system

RS-422 86400 BPS

RS-422 86400 BPS

RS-232-C 19200 BPS

RS-422 86400 BPS

Transfer

rate (Max.)

NOTE

The average data transfer speed becomes smaller than

the maximum transfer speed.

-4-

Page 11

B-63322EN-1/01 3. ELECTRICAL INTERFACE

3 ELECTRICAL INTERFACE

-5-

Page 12

3. ELECTRICAL INTERFACE B-63322EN-1/01

3.1

TRANSMISSION SYSTEM

It is the start-stop system for adding the start bit before and stop bit

after the information bits, respectively.

The format for adding one parity bit to each byte of data to be

transmitted is also allowed.

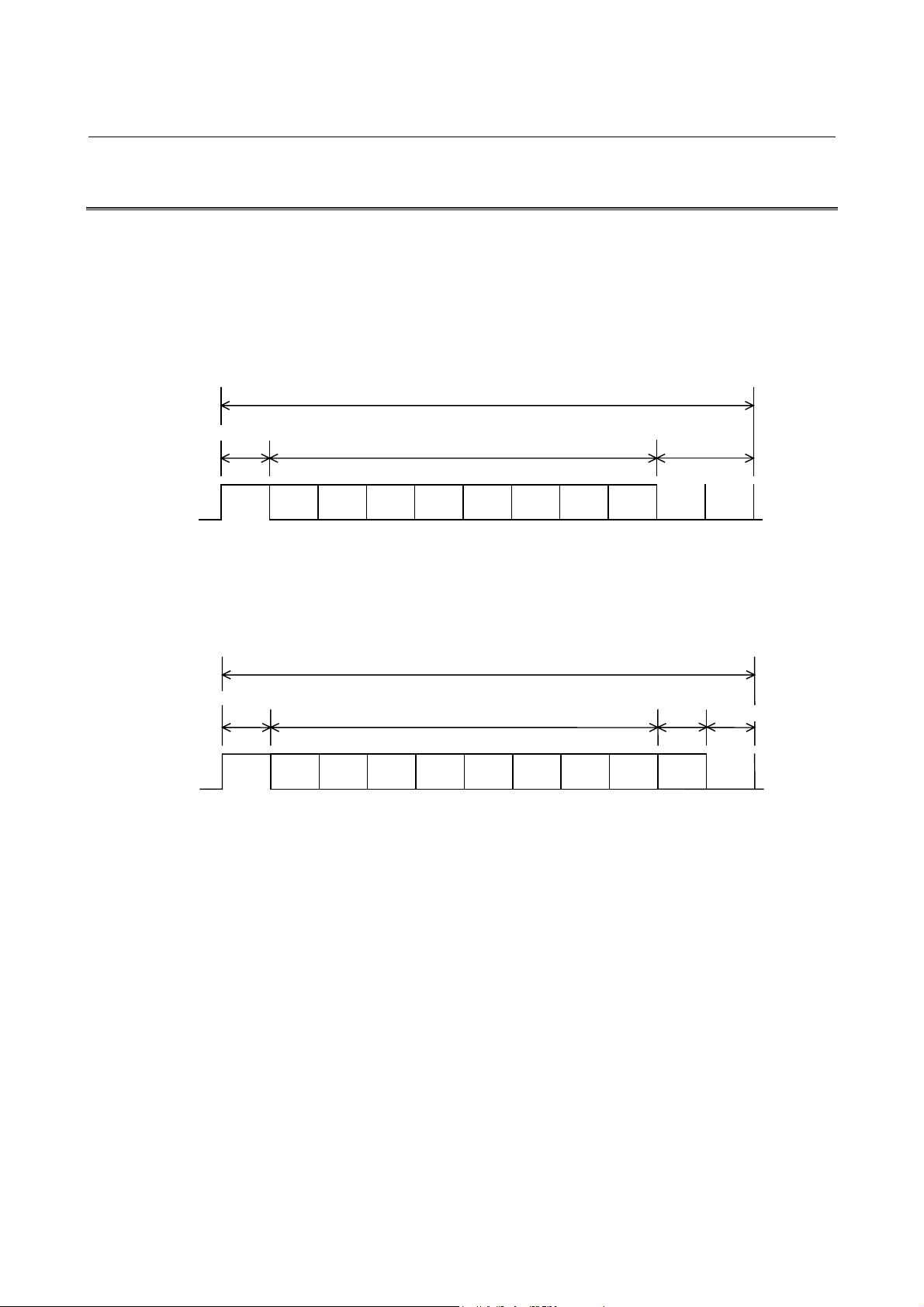

1) Format with no parity bit

1 character

Start bit Stop bit

ON

b1 b2 b5b4b3 b8b7b6

OFF

LSB MSB

Data bit is sent starting from the LSB.

2) Format with parity bit

Data bit

ON

OFF

Start bit

1 character

Data bit

LSB MSB

Data bit is sent starting from the LSB.

The format with parity bit becomes the even parity including a

parity bit. The number of stop bits of parameter determines

whether there is a parity bit or not.

Stop bit 1 → With parity bit

Stop bit 2 → With no parity bit

Parity bit

Stop bit

pb1 b2 b5b4b3 b8b7b6

-6-

Page 13

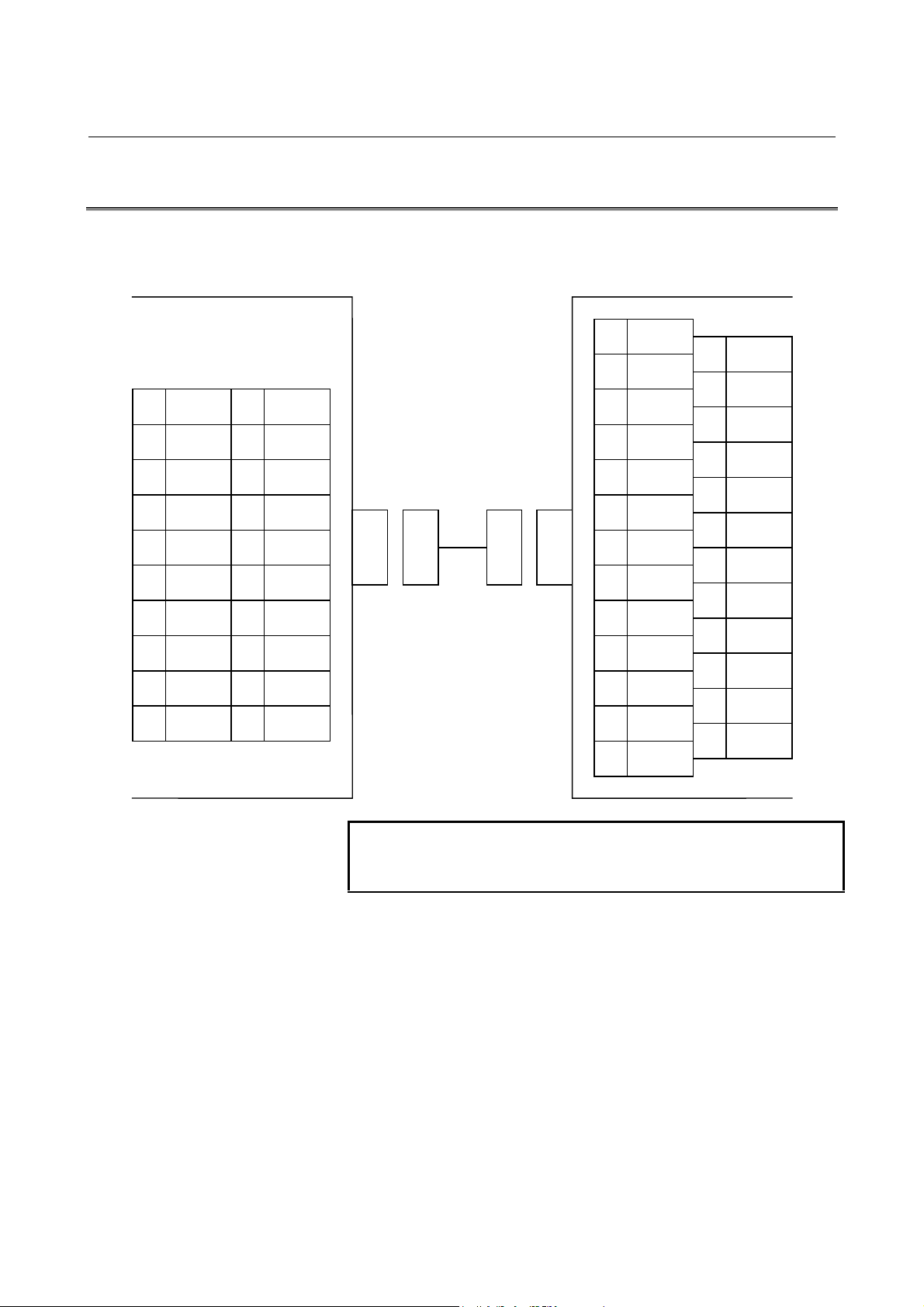

B-63322EN-1/01 3. ELECTRICAL INTERFACE

3.2

RS-232-C INTERFACE

remote buffer board

CNC

JD5L

(PCR-E20LMDETZ-SL)

1 RD

2 0V

3 DR

4 0V

5 CS

6 0V

7 CD

8 0V

9

10 (+24V)

11 SD

12 0V

13 ER

14 0V

15 RS

16 0V

17

18

19 (+24V)

20

1) Connection between devices

Host compute r (e xample)

(DBM-25S)

1 FG

14

2 SD

15

3 RD

16

4 RS

17

5 CS

18

6 DR

19

7 SG

20 ER

8 CD

21

9

22

10

23

11

24

12

25

13

NOTE

(+24V) is used as the power to FANUC RS-232-C

devices.

-7-

Page 14

3. ELECTRICAL INTERFACE B-63322EN-1/01

2) General diagram of signal connection

CNC

Output

Input

SD

RD

RS

CS

ER

DR

CD

0V

Host compute r

11

1

15

5

13

3

7

SD

RD

RS

CS

ER

DR

CD

SG

FG Note)

When no CS is used, short-circuit it with the RS. However,

when the protocol A or expansion protocol A is used, perform

connecting as shown in the figure above for use as busy control.

When DR is not used, short-circuit it with ER.

Always short-circuit CD to ER.

NOTE

Connect the FG pin to the FG pin of the relay connector

or to the protective grounding pin inside t he locker.

-8-

Page 15

B-63322EN-1/01 3. ELECTRICAL INTERFACE

3) Signal description

Signal

name

SD 103 Output Send data

RD 104 Input Receive data

RS 105 Output Request to send

CS 106 Input Clear to send

DR 107 Input Data set ready

ER 108.2 Output Data terminal ready

CD 109 Input Received line signal detector

SG 102 Grounding for signal

FG 101 Grounding for protection

RS-232-C

circuit

number

Input/

output

It is used to inform whether the remote buffer is ready to receive data or not.

When the ER signal is on and this signal is on, the remote buffer is ready to

receive data.

It is used to know the busy status at the host computer. When the DR signal

is on and this signal is on, the host computer is regarded as being ready to

receive data.

When this signal is on, it is considered that the preparation at the host

computer has been completed. Generally, it is connected to the ER signal of

the host computer. When this signal is off during data transmission, an

alarm occurs.

Always connect it to the ER signal of CNC side when this signal is not used.

When this signal is on, it is considered that the remote buffer is in ready

condition.

In general, it is connected to the ER signal at the host computer. If it is

turned off during transmission of data, an alarm occurs. If this signal is not

used, always connect this to the ER signal at the CNC side.

This signal is not used for connection to the host computer. Thus, connect it

to the ER signal of remote buffer side.

Description

See “3.1” for the bit configuration.

NOTE

Turn on or off signal according to the following:

-3 V or less +3 V or more

Function OFF ON

Signal Condition Marking Spacing

-9-

Page 16

3. ELECTRICAL INTERFACE B-63322EN-1/01

3.3

RS-422 INTERFACE

remote buffer board

CNC

JD6L

(PCR-E20LMDETZ-SL)

1 RD

2 *RD

3 RT

4 *RT

5 CS

6 *CS

7 RR

8 0V

9 *RR

10 (+24V )

11 SD

12 *SD

13 TT

14 *TT

15 RS

16 *RS

17 TR

18 *TR

19 (+24V)

20

1) Connection between devices

Host compute r (e xample)

1 FG

20

2

21

3

22 *SD

4 SD

23

5

24 *RD

6 RD

25 *RS

7 RS

26 *RT

8 RT

27 *CS

9 CS

28

10

29 *RR

11 RR

30 *TR

12 TR

31

13

32

14

33

15

34

16

35 *TT

17 TT

36

18

37

19 SG

NOTE

Do not connect anything to the (+24V) pin.

-10-

Page 17

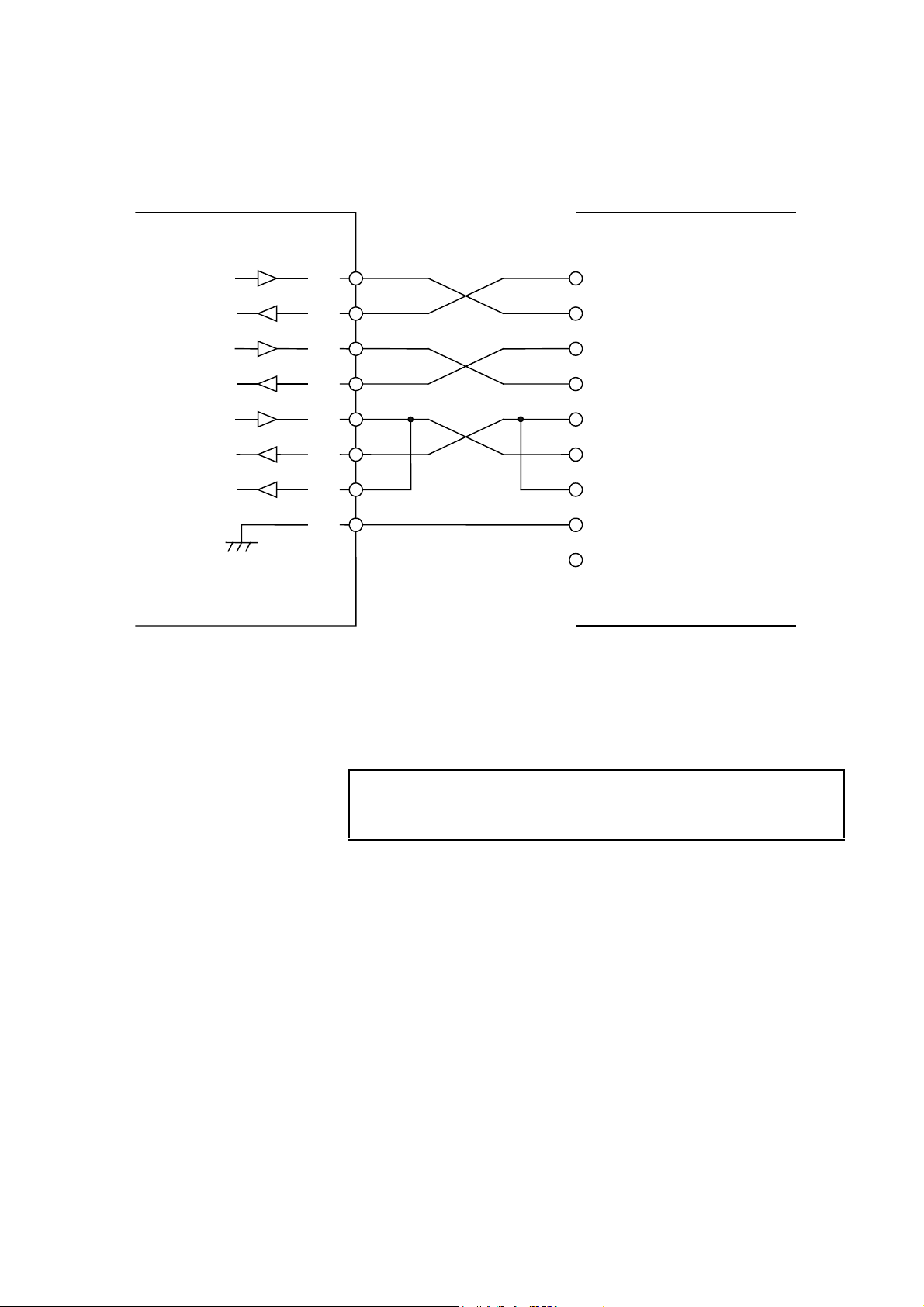

B-63322EN-1/01 3. ELECTRICAL INTERFACE

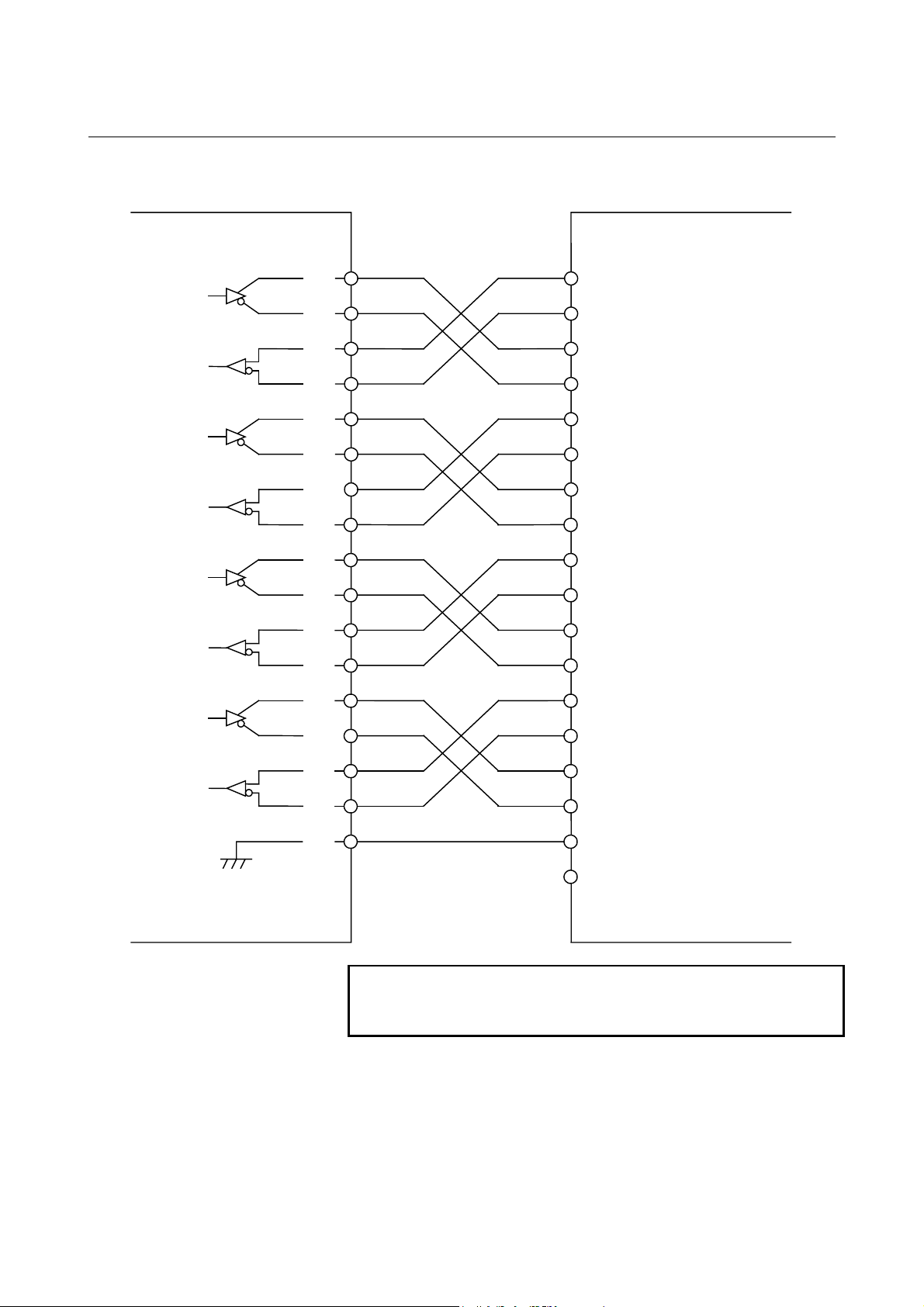

2) General diagram of signal connection

CNC

Output

Input

SD

*SD

RD

*RD

RS

*RS

CS

*CS

TR

*TR

RR

*RR

TT

*TT

RT

*RT

0V

11

12

15

16

17

18

13

14

Host compute r

SD

*SD

1

RD

2

*RD

RS

*RS

5

CS

6

7

9

3

4

8

*CS

TR

*TR

RR

*RR

TT

*TT

RT

*RT

SG

FG Note)

NOTE

Connect the FG pin to the FG pin of the relay connector

or to the protective grounding pin inside t he locker.

-11-

Page 18

3. ELECTRICAL INTERFACE B-63322EN-1/01

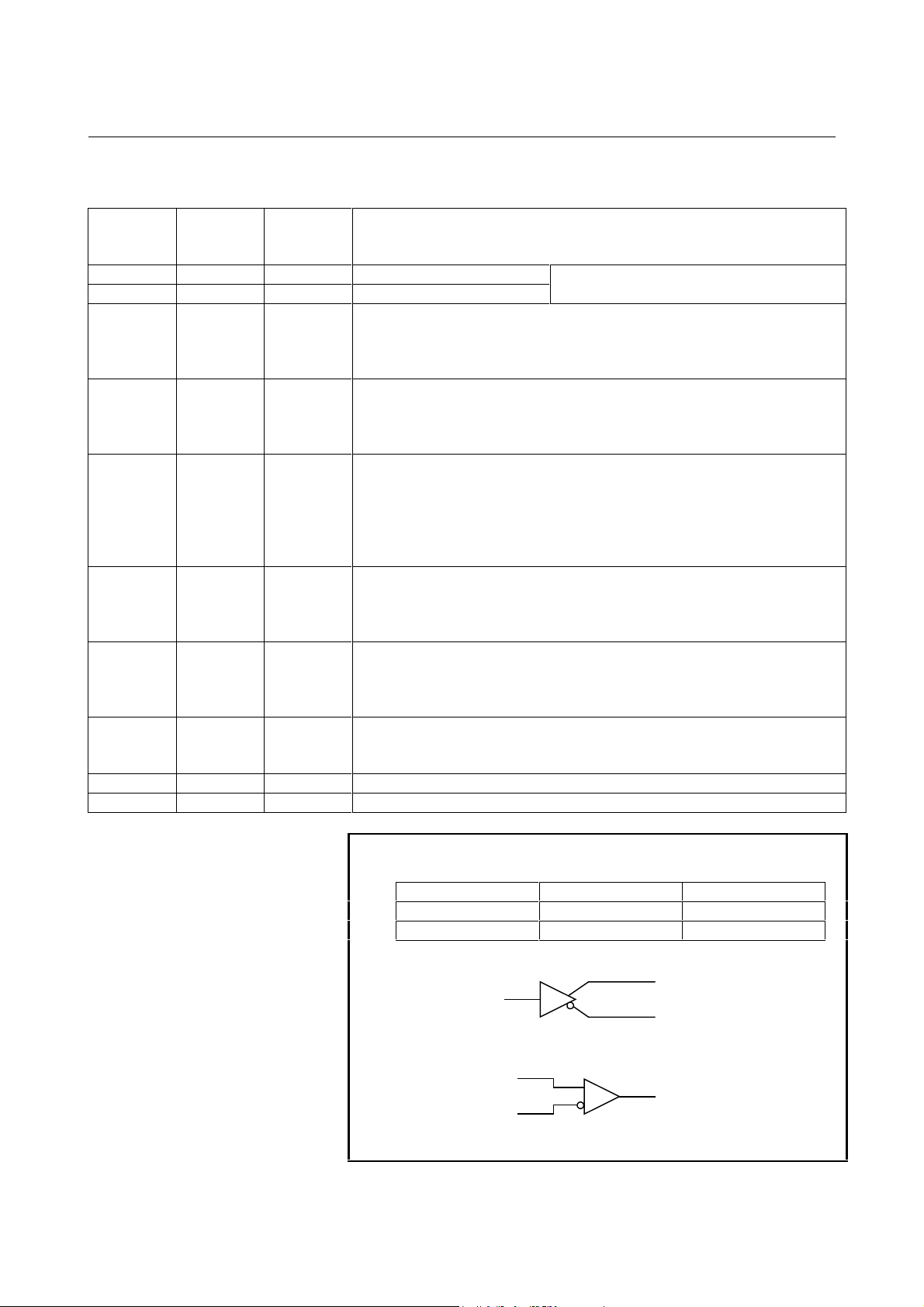

3) Signal description

Signal

name

SD 103 Output Transmission data

RD 104 Input Reception data

RS 105 Output Transmission request

CS 106 Input Clear to send

TR

(ER)

RR

(DR)

TT 113 Output Transmission timing

RT 115 Input Reception timing

SG 102 Grounding for signal

FG 101 Grounding for protection

RS-232-C

circuit

number

108.2 Output Terminal Ready

109 Input Receiver Ready

Input/

output

It is used to inform whether the remote buffer is ready to receive data or not.

When the TR signal is on and this signal is on, the remote buffer is ready to

receive data.

It is used to know the busy status at the host computer. When the RR signal

is on and this signal is on, the host computer is regarded as being ready to

receive data.

When this signal is on, it is considered that the operation of remote buffer

has been completed.

In general, it is connected to the ER signal at the host computer. If it is

turned off during transmission of data, an alarm results. If this signal is not

used, always connect this to the ER signal at the CNC side.

When this signal is on, it indicates that the host computer is ready to transmit

data to the remote buffer. If this signal is not used, always connect it to the

TR signal at the remote buffer side.

Transmission clock transmission terminal at the remote buffer side. When

38400 baud or more is used, always connect it to the RT signal at the host

computer side.

Reception clock input terminal at the remote buffer side. When 38400 baud

or more is used, always connect it to the TT signal at the host computer side.

Description

See “3.1” for the bit configuration.

NOTE

The signal turn on/of f according to the following:

A < B A > B

Function OFF ON

Signal Condition Marking Spacing

Driver

Receiver

A

B

A

B

-12-

Page 19

B-63322EN-1/01 4. PROTOCOL A

4 PROTOCOL A

It is used for the handshake system where the communication between

the remote buffer and host computer repeats transmission/reception

each other.

-13-

Page 20

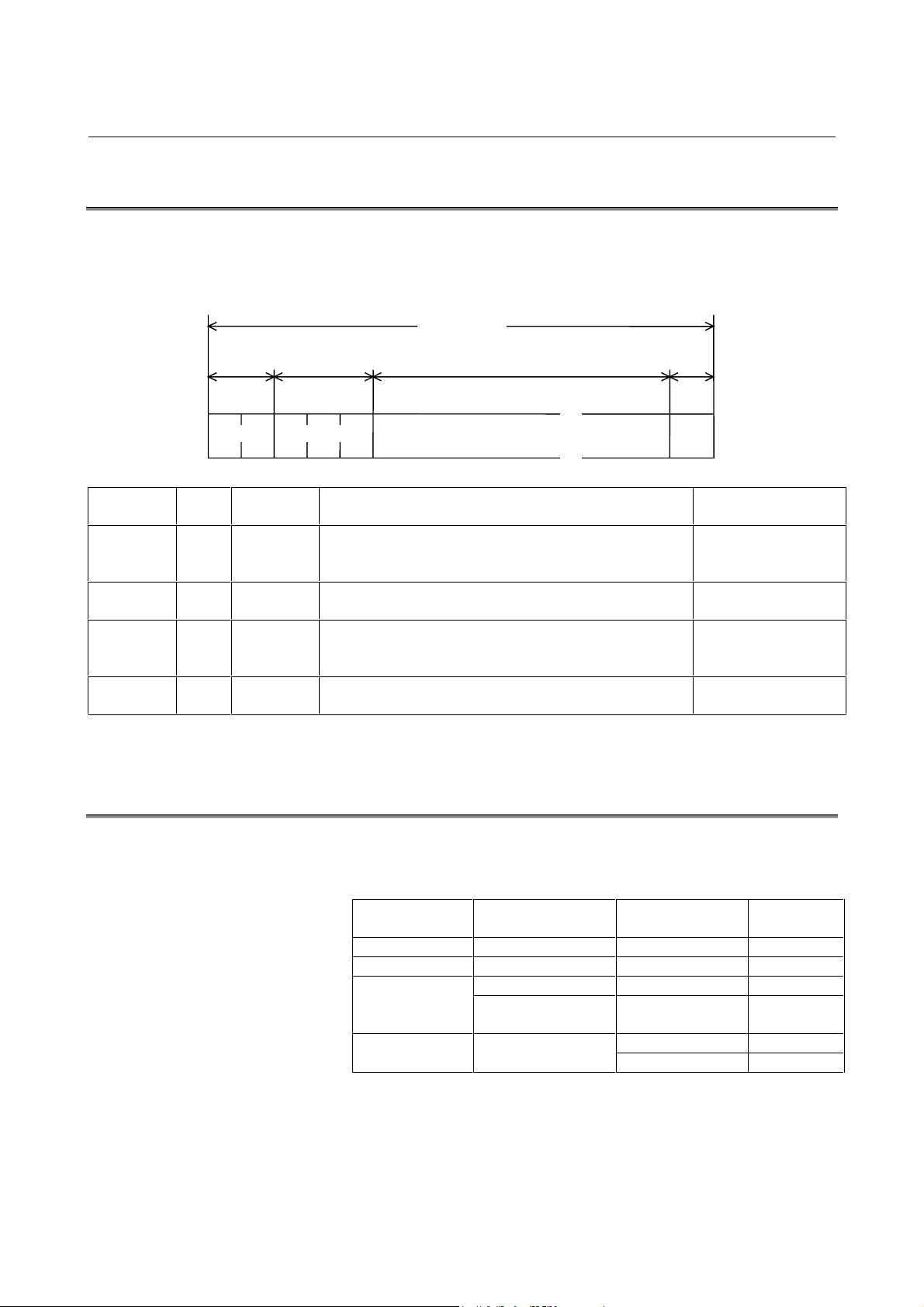

4. PROTOCOL A B-63322EN-1/01

4.1

MESSAGE FORMAT

The information (character-string) exchanged between the remote

buffer and host computer is called “message”. The general type of

message is shown as below:

Message

Variable length (it can be omitted.)3 byte2 byte

/

Sum Command Data part

/

Field

Checksum 2 No It is used to indicate the lower 8 bits of binary sum of all

Command 3 No It is used to display the type of message (functions) and

Data 0 – n Yes It is the data part corresponding to a command.

End code

(ETX)

Byte

length

Abbreviation Meaning Remarks

bytes from the command field to end code by two-digit

hexadecimal number (0 – 9 and A – F).

to specify the operation and response of the partner.

Abbreviate it when a command without data part is used.

Details are described later.

1 No It indicates the end of message. Not transmit a code

which is the same as an end code to data part.

1 byte

ETX

Transmit the MSB

before the LSB.

SAT, SET, DAT, RTY

SDI, SDO

4.2

CODE SYSTEM

The communication codes between the remote buffer and host

computer are described below:

Field Command Code

Checksum --- ISO/ASCII 5000#2

Command name --- ISO/ASCII 5000#2

DAT ISO/ASCII/EIA/Bin 0000#2Data part

Commands other

than DAT

ISO/ASCII 5000#2

ISO/ASCII 5000#2End code --CR/ETX 5000#3

Related

parameters

-14-

Page 21

B-63322EN-1/01 4. PROTOCOL A

4.3

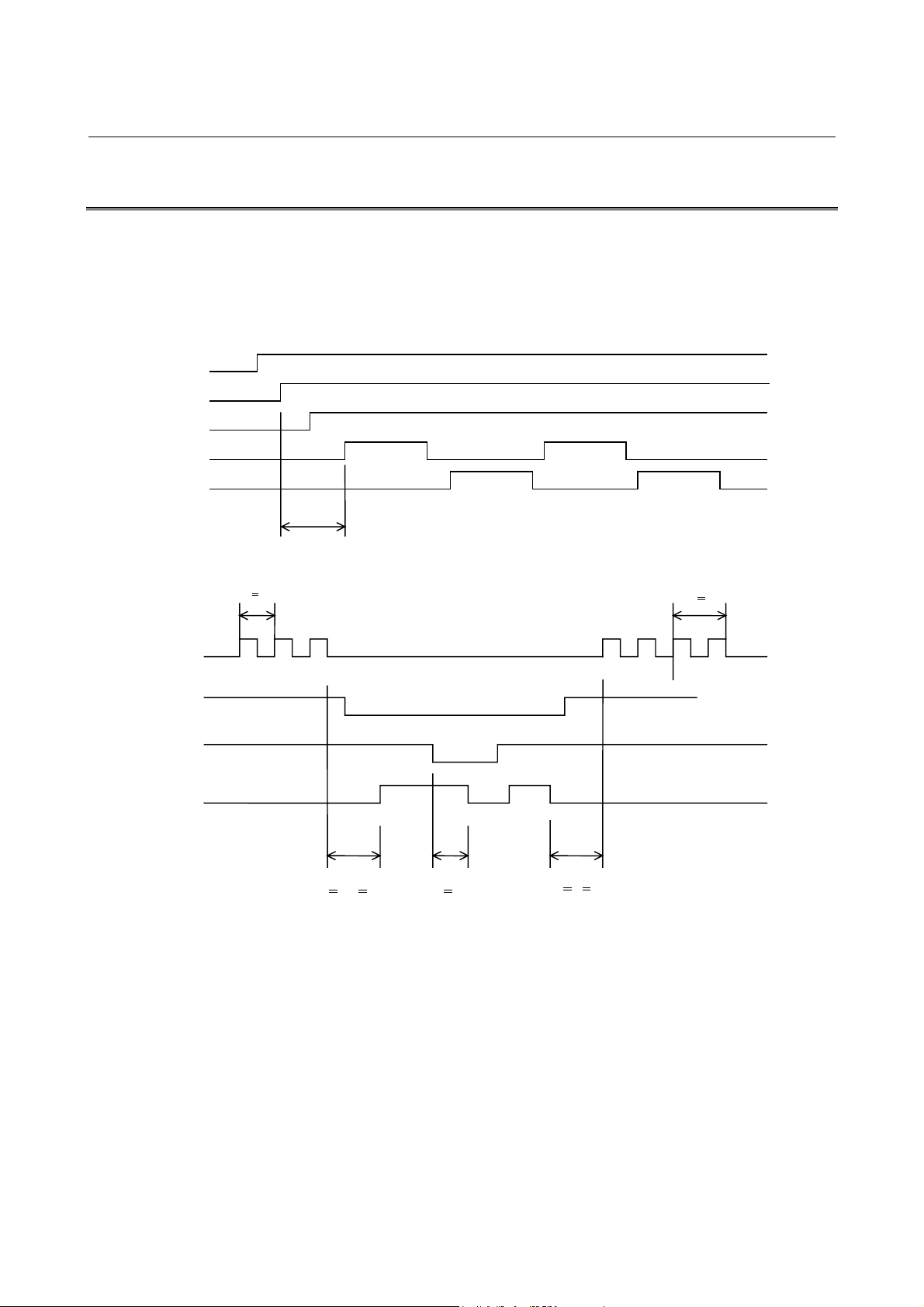

COMMUNICATION SYSTEM

It is used to perform communication between the remote buffer and

host computer. When the both are ready to operate after power on,

the communication starts from the transmission of remote buffer and

reception of host computer and then the transmission/reception is

repeated.

ER

RS

CS

SD

RD

Approximately 2 seconds

t1 > ti

n1 < 3

SD

CS

RS

RD

n2t2 t3

0 < t2 < To n2 < No

Tx<t3<tp

(1) Approximately two seconds are required for the first request

after both of remote buffer and host computer are ready.

However, when the CS signal is off, the first transmission is

performed after turning on the CS signal.

(2) The minimum time period between bytes is determined by the

parameter Ti (msec) of SET command. There is no prescription

of minimum time period between reception bytes.

(3) Switching from transmission to reception

Immediately the remote buffer side can be ready to receive

signal. Start transmission within the parameter setting time (To

sec) at the host computer side. When no response is obtained for

the time period (To or more), an error occurs in the host

computer. (Overtime)

-15-

Page 22

4. PROTOCOL A B-63322EN-1/01

(4) Switching from reception to transmission

The remote buffer waits for Tx msec (parameter setting time)

and moves to the transmission process after completion of

reception. When there is no transmission after waiting another

parameter (Tp seconds), it is considered that an error occurred in

the remote buffer.

(5) Overrun on reception

When the RS signal is turned off by the remote buffer on

reception of signal, stop the transmission within the overrun

parameter number bytes by the host computer.

(6) Overrun on transmission

When the CS is turned off on transmission of remote buffer, the

transmission is suspended within 3 bytes including that which is

currently being transmitted.

-16-

Page 23

B-63322EN-1/01 4. PROTOCOL A

4.4

4.4.1

COMMAND

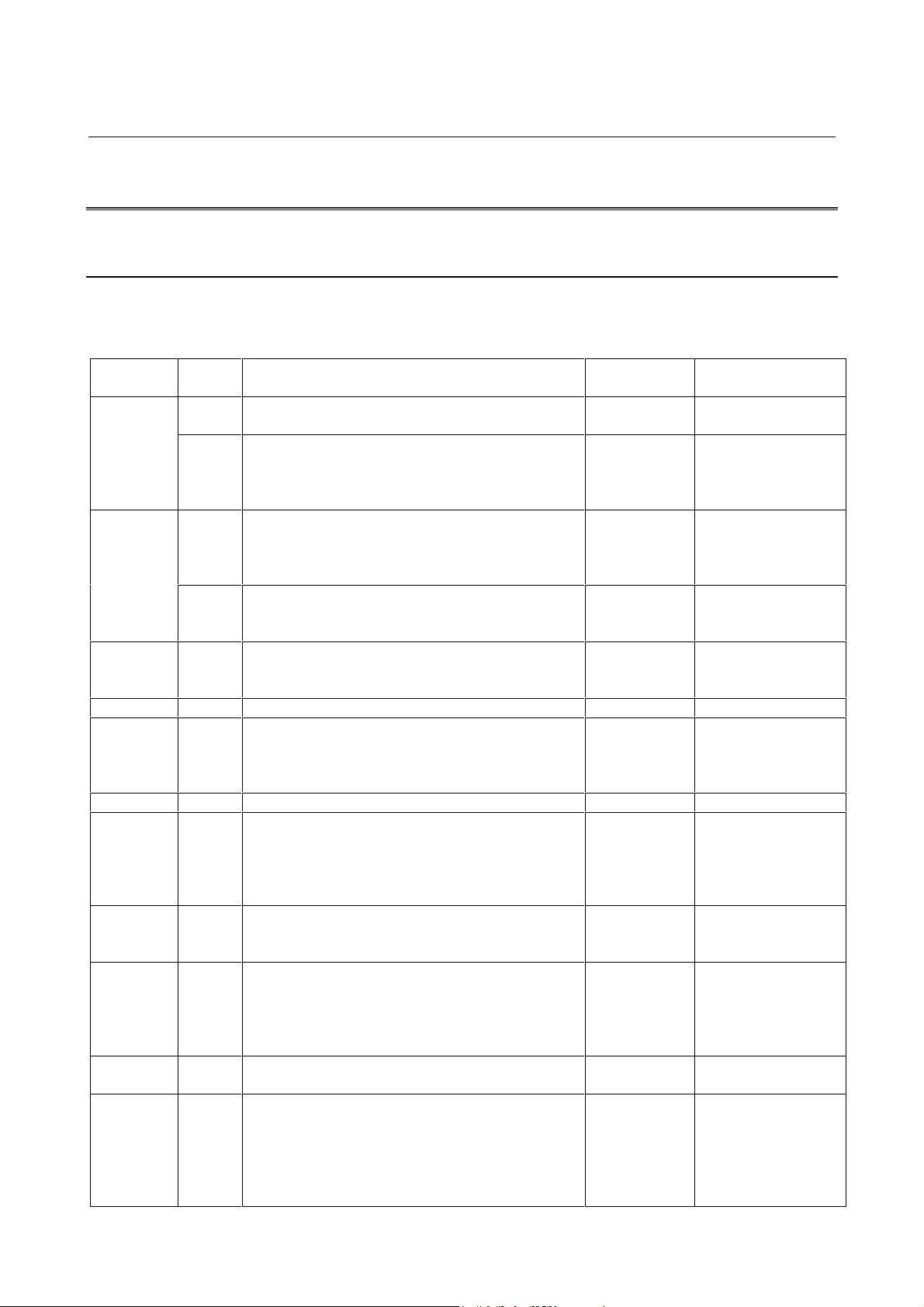

Command Table

Commands used in the protocol A are described below:

Origin station R: Remote buffer H: Hoast computer

Command

RDY

RST R Notice of CNC reset

ARS H Response corresponding to the RST Meaningless

ALM R Notice of CNC alarm occurrence

AAL H Response corresponding to the ALM Meaningless

SAT R Notice of remote buffer status

SET H Response corresponding to the SAT

GTD R Transmit command of NC data

DAT H Response corresponding to the GTD

WAT H Response corresponding tot he GTD

Origin

station

R Initialization command

It is used to command the initialization of host.

H Response of SYN

Response when the initialization does not end yet

Initialization command

It is command to initialize the remote buffer.

R Notice of initialization end

The host should respond the RDY in the case of end

of initialization or the SYN when the initialization has

not ended.

H Notice of initialization end

It is used to notice that the initialization of host has

ended.

Immediately after the CNC is res et, transmit this

command when it is possible to transmit signal.

When an alarm occurs in CNC, trans mit this

command when it is possible to transmit immediately

after that.

It is used to notice the status of remote buffer by

transmitting it when there is no data to be especially

transmitted while the Tp sec has passed after

receiving the command.

It is used to modify the setting parameter of remote

buffer by specifying the data part.

Transmit this command when the space of remote

buffer exceeds Nb bytes of parameter setting value

in the remote operation status.

Transmit this command with the NC data.

Transmit this command if the NC data cannot be

transmitted within To when the GTD has been

received.

The GTD is transmitted again by the remote buffer

after a parameter setting time of Tw.

Functions Data part

Meaningless SYNSYN

Meaningless

Meaningless RDY, SYN

Meaningless

Meaningless ARS

Meaningless AAL

Status SET......... Normal

Modification

parameter

Meaningless DAT ........ Normal

NC data

Meaningless

Executed command

at CNC side

CLB

RDI

SDO

SYN

EOB........ End

WAT ....... Busy

RDI

SDO

-17-

Page 24

4. PROTOCOL A B-63322EN-1/01

Command

EOD H Response corresponding to GTD

CLB H Buffer clear

RDI H DI reading request

SDI R Notice of DI

SDO H DO output request

RTY R/H Request of retransmission

Origin

station

Transmit this command when the GTD has been

received while the transmission of NC data has

been completed.

It can be transmitted as the response of SAT when

the buffer at the remote buffer side is to be cleared.

It is used to request transmission of image of

specified 8-bit DI.

The DI image at that time is responded by the SDI

command in the remote buffer.

This command can be transmitted as responses of

SAT and GTD.

It is used to transmit the signal status of DI as the

response of RDI command.

The host should transmit the response of command

received immediately before transmitting the RDI

after receiving this command.

It is used to command that the 8-bit image of data

part should be output to the DO.

It can be transmitted as responses of SAT, GTD,

and SDI.

It is used to request the retransmission of the same

message as before.

Immediately transmit this command when a

transmit error is detected during reception of

messages.

Functions Data part

Executed command

at CNC side

Meaningless

Meaningless

Meaningless

DI image Response

corresponding to the

GTD/SAT

DO image

Reason for

retransmission

Command

transmitted

immediately before

-18-

Page 25

B-63322EN-1/01 4. PROTOCOL A

4.4.2

Description of Data Part

Data part of message is of variable length. Up to 4096 and 72 bytes

can be received/transmitted in the case of <DAT> and the others,

respectively.

1) Data part of SAT

Byte

position

1 Switching of remote/tape operations

According to parameter (Data No. 5000, #1)

setting. (*C)

2 Status of remote buffer

0: Non-completion status of operation

1: Reset status

2: Operation status

3: Alarm status

4: Open line

3 Causes of shift to alarm status

0: NC alarm

1: Checksum error (retry over)

6: Reception of unexpected response

A: Overrun error (retry over)

4 Not used ---

5 - 8 Number of bytes currently stored in the buffer

(Four-digit hexadecimal number)

9 - 12 Current value of parameter Nb

Empty area limit of buffer

(Four-digit hexadecimal number)

13 - 16 Current value of parameter No

Amount of maximum overrun on reception

(Four-digit hexadecimal number)

17 - 20 Current value of parameter No

Number of times of retry on detecting a

transmission error (Four-digit hexadecimal

number)

21 - 24 Current value of parameter Tp

Polling time interval (second)

(Four-digit hexadecimal number)

25 - 28 Current value of parameter To

Time-out time (second)

(Four-digit hexadecimal number)

29 - 32 Current value of parameter Ti

Minimum time interval between bytes

transmitted (Four-digit hexadecimal number)

33 - 36 Current value of parameter Tx

Minimum switching time from reception to

transmission (Four-digit hexadecimal number)

37 - 40 Current value of parameter Tw

Waiting time on reception of (WAT)

(Four-digit hexadecimal number)

Meaning and code

preparation

(command error)

Default value

(hexadecimal)

0

0

0

0000

07D0

0032

000A

0005

0014

000A

0064

0005

-19-

Page 26

4. PROTOCOL A B-63322EN-1/01

2

Byte

position

41 - 44 Unit for the boring time (four digits in

hexadecimal)

Setting parameter P

boring time to 0.1 seconds.

15 0

0000000000000P

45 - 46 Note)

Code to be converted (two-digit hexadecimal

number)

47 - 78 Note)

Code after conversion (two-digit hexadecimal

number)

49 - 54 Rese rve --55 - 56 Packet length parameter n of expansion

protocol A (two-digit hexadecimal number)

00: Normal protocol A

01: Expansion protocol A

02: Expansion protocol A

04: Expansion protocol A

57 - 72 Not used ---

Meaning and code

to 1 sets the unit for the

2

00

NC data length = 256 bytes

Packet length = 260 bytes

NC data length = 512 bytes

Packet length = 516 bytes

NC data length = 1024 bytes

Packet length = 1028 bytes

Default value

(hexadecimal)

0000

00

00

00

NOTE

Bytes 45, 46, 47, and 48 of SAT

These bytes contain the parameters necessary for the

remote buffer t o convert the protocol A <DAT > command

data and expansion protocol A data in the specified

section. Specify the code to be converted in bytes 45

and 46. Specify the code to which conversion is to be

performed in bytes 47 and 48. For details, refer to

Section 4.4.2 (3).

-20-

Page 27

B-63322EN-1/01 4. PROTOCOL A

a) Protocol A

Section to be converted

//

SUM

DAT

Data

//

ETX

b) Expansion protocol A

Section to be converted

//

Data

//

No

ETXSUM

<Example of use>

The host computer handles an EOB code in an NC program as “;” and

transmits it to the CNC as is. When ‘3’ and ‘B’ (= 3BH) are specified

in SET command bytes 45 and 46, and ‘ ’ and ‘A’ (= 0AH) are

specified in bytes 47 and 48, “;” is converted to “LF” which is then

transmitted to the CNC.

2) Data part of SET

The format of data part of command <SET> is the same as that

of data part of <SAT> except the following points.

Data part can be abbreviated when no parameter is modified.

Byte

position

1 Switching request of remote/tape operations

2 Status of host computer Ignore

3 - 8 Not used

9 - 48 Modified value of parameter

49 - 54 Not used

55 - 56 Parameter for expansion protocol

57 - 72 Not used

Meaning and code Remarks

3) Data part of DAT

Up to 4096 bytes of NC data can be received at the data part of

command <DAT>.

Transmit the NC data depending on the specifications of NC

since no data process is performed in the remote buffer other

than the conversion code set by the parameter.

Also, always add the EOR code to the end of NC program.

-21-

Page 28

4. PROTOCOL A B-63322EN-1/01

4) Data part of SDI

Byte

position

1 - 2 2-byte hexadecimal display of 8-bit contents of DI

(PMC address: G152)

3 - 72 Not used (it can be omitted.)

Meaning

1) Data part of SDO

Byte

position

1 - 2 2-byte hexadecimal display of 8-bit contents of DO

(PMC address: F152)

3 - 72 Not used (it can be omitted.)

Meaning

6) Data part of RTY

Byte

position

1 Reason for requesting retransmission

1: Checksum error

3: Overrun error (Data received after RS has been turned off)

2 - 72 Not used (it can be omitted.)

Meaning

7) Data part of other commands

Byte

position

1 - 72 Not used (it is generally omitted.)

Meaning

-22-

Page 29

B-63322EN-1/01 4. PROTOCOL A

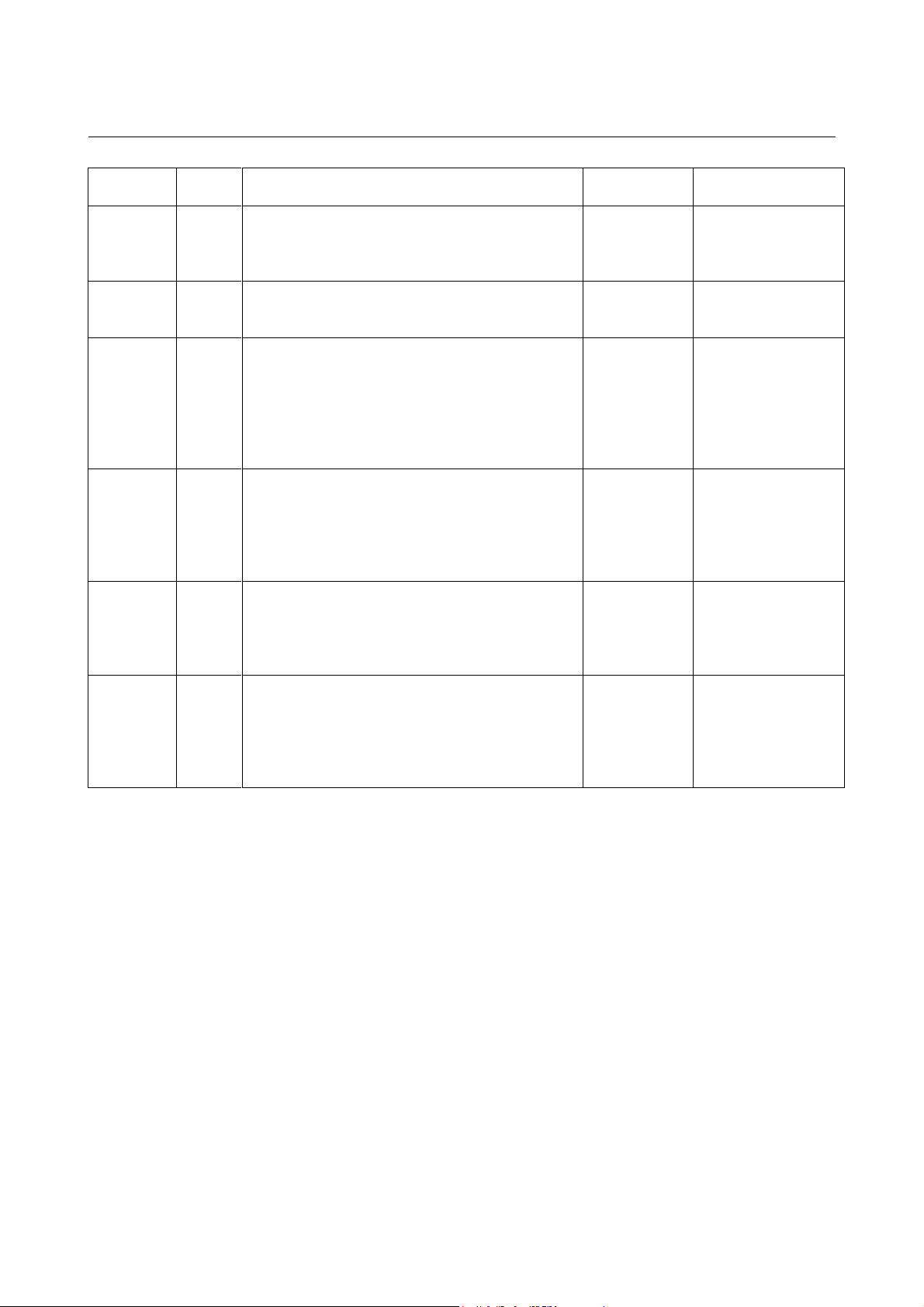

4.5

PARAMETER TABLE

Parameters which can be set in the data part of SET command are

shown as below:

Parameter Meaning Unit Range

Nb Number of bytes of minimum buffer empty area on transmission of

GTD

(Note 1)

No Maximum amount of overrun on reception of data Byte 2 - 2000 50

Ne Number of retry times on detection of transmission error Times 0 - 100 10

Tp Polling time interval Sec 1 - 99 5

To Time-out time Sec 1 - 999 20

Ti Minimum time interval between transmission bytes msec 0 - 10

Tx Minimum switching time from reception to transmission msec 0 - 100 100

Tw Wait time on reception of WAT Sec 0 - Tp 5

Byte 1 - 4000 2000

(Note 2)

NOTE

1 Setting value l+No≤Nb≤4000 (l : Data length for DAT

command)

2 2 msec step

On turning

on power

10

-23-

Page 30

4. PROTOCOL A B-63322EN-1/01

4.6

ERROR PROCESS

1) Open-line error

When the following error occurs, it may be an open line error.

Restart the initialization of remote buffer for recovering the line.

When the line is recovered, it waits for transmission of SYN and

is SYN wait status.

The procedures are the same as those of initialization on power

on other than continuation or SYN of host computer.

(1) Framing error

(2) Overrun error

(3) Parity error

(4) Data Set Ready off

(5) Buffer full (the transmission stop request is unacceptable.)

(6) Time out

(7) Number of retry times has been exceeded.

2) Reception error

Ignore the reception data and restart the reception of SAT

command at the remote buffer side when the following errors

occurs.

(1) Number of retry times exceeded

Number of RTY reception times + Number of

retransmission by checksum error > Ne

(2) Command error

Message format error

Reception of undefined command

Reception of unexpected command

(3) Overrun

This results if the transmission stop request is not accepted

and the reception buffer is overflown.

3) Reception during transmission

Data received during transmission is ignored.

-24-

Page 31

B-63322EN-1/01 4. PROTOCOL A

4.7

STATUS TRANSITION

The status transition diagram of remote buffer is shown as below:

Turning on power

Non-completed status of

operation preparation

SYN

reception

NC reset

EOD reception

0

Reset status

1

RDY reception

GTD

transmission

Line error Note 1

Reception error

NC alarm

Line error

After 2 msec

Open line status

4

NC reset

Line error

(Note 1)

Remote operation

status

2

Reception error

NC alarm (Note 2)

NOTE

1 Causes of line error

(1) DR off

(2) Number of retry times over

(3) Time out

(4) Buffer full

2 Reception error

(1) Undefined command

(2) Unexpected command

(3) Number of retry times over by sum error

(4) Overrun

Alarm status

3

-25-

Page 32

5. EXPANSION PROTOCOL A B-63322EN-1/01

5 EXPANSION PROTOCOL A

It allows the NC data between the remote buffer and host computer to

be efficiently transferred by adding the high-speed reception function

to the protocol A.

-26-

Page 33

B-63322EN-1/01 5. EXPANSION PROTOCOL A

5.1

COMMUNICATION SYSTEM

The expansion protocol A is the same as the protocol A excluding the

transmission of NC data.

The expansion protocol A mode is initiated after the <GTD> is output

to the host computer by the remote buffer according to the data

request from the CNC side.

The communication system is performed in the full duplex mode in

the expansion protocol A. The NC data transmitted is packeted and is

transmitted to the remote buffer by the host computer. Also, perform

the reception process of monitor packet from the remote buffer.

GTD transmission

Protocol

A

mode

End packet

Mode transition

Expansion

protocol A

mode

Packet transmission/

reception

-27-

Page 34

5. EXPANSION PROTOCOL A B-63322EN-1/01

5.2

DATA PACKET FORMAT

The NC data is transferred to the remote buffer using the following

format by the host computer after receiving the <GTD>.

When the NC data transmitted becomes multiple packets, the packets

can be transmitted in order without waiting the response from the

remote buffer by the host computer.

NC data

( "256*n" byte )

Calculation range of checksum

1) NC data

The NC data is the fixed length of “256*n” bytes and the n is

specified with the parameter (byte position 55 to 56) by the

<SET> command.

The default value of n is 0. In the case of “n = 0”, the normal

protocol A is used.

n = 0 : Normal protocol A

n = 1, 2, 4 : Expansion protocol A

Packet

No.

(1 byte)

Checksum

(2 byte)

End code

(1 byte)

NOTE

Note that n is set to 0 automatically even if n is set to t he

values other than listed above.

2) Packet No.

a) Effective packet : 30h – 39h (ASCII code)

Be sure to assign packet No. 30h to the first packet. If there

is only one effective packet, assign FFh to the packet, since

it is not only the first but also the last packet.

If there is more than one effective packet, packet No. 30h is

transmitted to the host computer by the remote buffer, along

with the monitor packet <NAK> of retransfer request.

Hereafter, the value incremented by 1 should be the packet

No.

However, the value next to 39h becomes 30h.

If there is only one packet, the packet is both the first and

the last; be sure to assign FFh.

Also, when the loss or improper order of packet No. is

detected, the improper packet No. is transmitted to the host

computer along with the monitor packet No. <NAK>.

When the checksum error is detected, the improper packet

No. is transmitted to the host computer with the monitor

packet <NAK> of retransfer request by the remote buffer.

-28-

Page 35

B-63322EN-1/01 5. EXPANSION PROTOCOL A

b) End packet : FFh

The end packet is transmitted by setting the packet No. to

FFh. The data part of end packet is considered to be the

effective data. However, the end packet received after

transmitting <CAN> ignores the data part.

This allows the expansion protocol A mode to be ended and

the normal protocol A mode is initiated.

However, when the checksum error is detected at the end

packet, the before packet No. +1 is transmitted as the end

packet No. to the host computer with monitor packet

<NAK> of retransmission request. (Note)

The host computer should shift to the protocol A when the

command of protocol A is received after transmitting the

end packet.

NOTE

If FFh is assigned to the first packet, packet No. 0 is

transmitted to the host computer with <NAK>, since this

packet is the last packet.

c) Invalid packet : Other than above

Transmit this invalid packet with the dummy data of

“256*n” bytes when the time out may occur since time is

required for editing of NC data transmitted by the host

computer.

The remote buffer is processed as an invalid packet.

3) Checksum

The checksum is obtained by adding the NC data to the packet

No. in units of byte and then expressing the 1 byte data produced

by neglecting the overflow above 8 bits out of the total value

above using ASCII 2-byte code.

4) End code

The end code should be the ASCII code CR (0Dh).

-29-

Page 36

5. EXPANSION PROTOCOL A B-63322EN-1/01

5.3

MONITOR PACKET FORMAT

The monitor packets transmitted from the remote buffer to the host

computer are shown as below. All packets have the fixed length

consisting of 5 bytes.

1) Stop request

CAN

(18h )

The stop request is transmitted to the host computer by the

remote buffer when resetting the NC and stopping data reception

by an alarm.

Transmit the end packet (the NC is dummy) after transmitting

the packet which is currently being transmitted and move to the

normal protocol A mode when this packet is received by the host

computer.

If the end packet was being transmitted when the CAN packet

was received, the end packet need not be retransmitted in

response to CAN.

Transmit the end packet even in the DC3 reception status.

Meaningless

(20h )

Checksum

( 2 b y t e )

End code

( 0Dh )

2) Retransmission request

NAK

( 15h )

Packet No.

(1 byte)

Checksum

( 2 b y t e )

When a check sum error is detected in the received packet, the

retransmission request corresponding to the packet is transmitted

by the remote buffer.

The host computer should perform retransmission from the

corresponding packet immediately after ending the transmission

of packet which is currently being transmitted when it receives

this packet.

End Code

(0Dh )

-30-

Page 37

B-63322EN-1/01 5. EXPANSION PROTOCOL A

3) Interruption request

DC3

(93h )

Meaningless

( 20h )

Checksum

( 2 b y t e )

The interruption request is transmitted to the host computer by

the remote buffer when the reception buffer may become

overflown.

The host computer should interrupt the transmission and wait

until the next monitor packet is received after completing the

transmission of packet which is currently being transmitted when

it receives this packet.

4) Restart request

DC1

( 11h )

Meaningless

( 20h )

Checksum

( 2 b y t e )

The restart request is transmitted to the host computer by the

remote buffer when there is space in the reception buffer after

requesting interruption.

The host computer should restart the transmission from the next

packet following the interrupted one when this packet is

received.

End code

(0Dh )

End code

(0Dh )

-31-

Page 38

5. EXPANSION PROTOCOL A B-63322EN-1/01

5.4

COMMUNICATION EXAMPLE

1) Normal

Remote buffer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

Host computer

)

h

F

F

0

(

t

e

k

c

a

p

d

n

E

<

S

A

T

>

>

T

E

S

<

-32-

Page 39

B-63322EN-1/01 5. EXPANSION PROTOCOL A

2) Stop request

Remote buffer

RESET

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

2

(

et

k

c

a

P

"

C

A

N

"

)

h

F

F

0

(

t

e

k

ac

P

d

n

E

m

u

D

(

)

a

t

a

d

y

m

<

R

S

T

>

>

S

R

A

<

<

S

A

T

>

>

T

E

S

<

-33-

Page 40

5. EXPANSION PROTOCOL A B-63322EN-1/01

3) Retransmission (i)

Remote buffer

Checksum error

detection

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

"

N

A

K

"

(

1

)

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

)

h

F

F

0

(

t

e

k

c

a

p

d

n

E

Retransmit from

the packet (1)

<

S

A

T

>

>

T

E

S

<

-34-

Page 41

B-63322EN-1/01 5. EXPANSION PROTOCOL A

3) Retransmission (ii)

Remote buffer

Checksum error

detection

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

)

h

F

F

0

(

t

e

k

ac

P

d

n

E

"

N

A

K

"

(

4

)

)

h

F

F

0

(

t

e

k

c

a

P

d

n

E

<

S

A

T

>

>

T

E

S

<

-35-

Page 42

5. EXPANSION PROTOCOL A B-63322EN-1/01

3) Retransmission (iii)

Remote buffer

Packet No.

Out-of-order

detection

Packet No.

Out-of-order

detection

Host computer

<

G

T

D

>

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

"

N

A

K

"

(

0

)

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

)

h

F

F

0

(

t

e

k

c

a

p

d

n

E

"

N

A

K

"

(

2

)

)

2

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

)

h

F

F

0

(

t

e

k

c

a

p

d

n

E

<

S

A

T

>

>

T

E

S

<

-36-

Page 43

B-63322EN-1/01 5. EXPANSION PROTOCOL A

4) Interruption → Restart

Remote buffer

Empty buffer

Remaining

less than

2 Packet s

Empty buffer

Remaining

more than

3 Packet s

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

2

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

"

D

C

3

"

"

D

C

1

"

)

h

F

F

0

(

t

e

k

c

a

P

d

n

E

<

S

A

T

>

>

T

E

S

<

-37-

Page 44

5. EXPANSION PROTOCOL A B-63322EN-1/01

5) Interruption → Start

Remote buffer

Empty buffer

Remaining

one block

RESET

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

)

3

(

t

e

k

c

a

P

"

D

C

3

"

"

C

A

N

"

)

H

F

F

0

(

t

e

k

ac

P

nd

E

m

u

D

(

)

a

t

a

d

y

m

Transmit the end

packet for ending

the expansion

protocol A although

the DC3 is

currently being

received.

<

R

S

T

< ARS >

<

S

A

T

T

E

S

<

>

>

>

-38-

Page 45

B-63322EN-1/01 5. EXPANSION PROTOCOL A

6) Interruption → Retransmission

Remote buffer

Empty buffer

Remaining

one block

Checksum error

detection

Empty buffer

Remaining

two blocks

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

)

1

(

t

e

k

c

a

P

"

D

C

3

"

)

2

(

t

e

k

c

a

P

"

N

A

K

"

(

2

)

)

2

(

t

e

k

c

a

P

Transmit only an

error packet since

the DC3 is receiving

data.

Restart transmission

of packets following

this after receiving

DC1.

"

D

C

1

"

)

3

(

t

e

k

c

a

P

)

h

F

F

0

(

t

e

k

c

a

P

d

n

E

<

S

A

T

>

>

T

E

S

<

-39-

Page 46

5. EXPANSION PROTOCOL A B-63322EN-1/01

7) Time-out detection

Remote buffer

Time-out

detection

Host computer

<

G

T

D

>

)

0

(

t

e

k

c

a

P

<

S

Y

N

>

>

N

Y

S

<

<

R

D

Y

>

>

Y

D

R

<

<

S

A

T

>

>

T

E

S

<

NOTE

The time-out monitoring period lasts until the next one

packet is received immediately after output of <GTD>.

After that, it is t he time between reception of one pack et

and that of another.

-40-

Page 47

B-63322EN-1/01 6. PROTOCOL B

6 PROTOCOL B

The protocol B is used to control the communication between the

remote buffer and host computer by the control code.

-41-

Page 48

6. PROTOCOL B B-63322EN-1/01

6.1

6.1.1

ER (output)

RS (output)

SD (output)

COMMUNICATION SYSTEM

The communication system can be in either of two settings, one in

which the CNC reset/alarm state is posted to the host and the other in

which it is not posted. When ETX (bit 3 of parameter No. 5000) is 1,

the system is in the setting in which the state is posted.

When the CNC Alarm/Reset is not Posted to the Host

1) When the remote buffer receives data

The remote buffer requests the host computer to send data.

10 ms or more 100 ms or more

DC3DC1DC3DC1

ER code

RD (input)

DR (input)

CS (input)

Overrun

1 ms or more

(1) The remote buffer transmits the DC1 code.

(2) The host computer starts to transmit the DC3 code to the

remote buffer by the DC1 code.

(3) When the empty area of remote buffer area becomes the

value specified, the DC3 code is transmitted.

(4) T he host computer should stop transmission to the remote

buffer by the DC3 code. The overrun value is specified

later.

(5) The remote buffer transmits the DC1 code when the

remainder of buffer data becomes less than the level

specified and requests the host computer to start

transmitting data.

(6) The host computer should start transmitting data again by

the DC1 code. The transmission data is a continuation of

previous data.

-42-

Page 49

B-63322EN-1/01 6. PROTOCOL B

(7) The remote buffer transmits the DC3 code when the data

read is completed. The end of data read is indicated by the

detection of ER or NC reset.

(8) The host computer stops transmission of data.

2) When the remote buffer sends data (punch-out)

(Fig. A)

10 ms or more 100 ms or more

ER (output)

RS (output)

SD (output)

DR (input)

CS (input)

ER (output)

RS (output)

DC4DC2

1 ms or more

2 characters or less

(Fig. B)

10 ms or more 100 ms or more

DC4DC2

SD (output)

RD (input)

DR (input)

CS (input)

DC3 DC1

Overrun

1 ms or more

-43-

Page 50

6. PROTOCOL B B-63322EN-1/01

(1) The remote buffer transmits the DC2 code.

(2) The remote buffer then transmits punch-out information.

(3) If the processing speed of the host computer is not high

enough to handle arriving data, perform one of the

following:

(a) Turn the CS signal of the remote buffer off. The

remote buffer stops data transmission within two

characters including the character being sent. (See Fig.

A.)

(b) Send a DC3 code to the remote buffer. The remote

buffer stops data transmission within the overrun,

which will be explained later, from the point when

DC3 is sent. To make the remote buffer resume data

transmission, send a DC2 code to the remote buffer.

(See Fig. B.)

(4) When the host computer completes data processing, turn

the CS signal of the remove buffer on. Then, the remote

buffer sends the data following the previous data.

(5) When data transmission is completed, the remote buffer

sends the DC4 code.

6.1.2

When the CNC Alarm/Reset is Posted to the Host

When the remote buffer becomes ready after the power is turned on,

the remote buffer turns the ER signal on, and keeps the ER signal on

until the power is turned off. When an alarm occurs in the NC, the

NAK code is sent to the host computer, and when the NC is reset, the

SYN code is sent to the host computer. This is not performed,

however, if the host computer is not ready for reception (each of the

DR, CD, and CS signals is on).

-44-

Page 51

B-63322EN-1/01 6. PROTOCOL B

1) When the remote buffer is neither receiving nor transmitting data

CNC power-on Reset or alarm Reset or alarm Reset or alarm

ER (output)

RS (output)

SD (output)

RD (input)

DR (input)

CD (input)

CS (input)

SYN or NAK

Ignored period Valid period Ignored period

The “SYN” or “NAK” code is output upon reset of the CNC or the

detection of a CNC alarm, but only during the valid period shown in

the above figure.

2) When the remote buffer is receiving or transmitting data

ER (output)

RS (output)

SD (output)

RD (input)

DR (input)

CD (input)

CS (input)

ON

ON

(1)

<When the remote buffer is receiving data>

Reset or alarm

DC1

(2) (4) (6) (8)

(3)

DC3

(5)

DC1

-45-

(7)

DC3

SYN or

NAK

Page 52

6. PROTOCOL B B-63322EN-1/01

(1) The remote buffer transmits the DC1 code.

(2) Upon receiving the DC1 code, the host computer shall start

transmitting data to the remote buffer.

(3) Once the amount of free space in the remote buffer falls below

the specified value, the remote buffer transmits the DC3 code.

(4) Upon receiving the DC3 code, the host computer shall stop

transmitting data to the remote buffer.

(5) Once the amount of data in the remote buffer falls below the

specified value, the remote buffer transmits the DC1 code to

request that the host computer restart data transmission.

(6) Upon receiving the DC1 code, the host computer shall restart

data transmission, picking up from the data immediately after

that transmitted last.

(7) When the CNC has been reset or an alarm has been issued in the

CNC, the remote buffer transmits, to the host computer, the DC3

code, followed by the SYN code (for reset) or NAK code (for an

alarm). Thus, data reading is terminated.

(8) The host computer shall stop data transmission.

<When the remote buffer is transmitting data (punch-out)>

ER (output)

ON

ON

RS (output)

SD (output)

DR (input)

CS (input)

DC2

(1)

(2)

(3)

(Fig. A)

Reset or alarm

DC4

(4)

If a CNC reset or CNC alarm occurs during

this period, DC4

transmitted.

(5)

SYN or

NAK

, SYN, or NAK is not

-46-

Page 53

B-63322EN-1/01 6. PROTOCOL B

(Fig. B)

Reset or alarm

ON

ER (output)

ON

RS (output)

SD (output)

RD (input)

DR (input)

CS (input)

DC2

SYN or

(2)(1)

DC4

DC3 DC1

(4)(3)

(5)

NAK

(1) The remote buffer transmits the DC2 code.

(2) The remote buffer starts transmitting punch-out data.

(3) If data processing in the host computer cannot keep pace with

the rate of data transmission from the remote buffer:

(a) Turning off the CS signal for the remote buffer causes the

remote buffer to stop data transmission after transmitting a

maximum of most two characters, including the character

currently being transmitted. (See Fig. A.)

(b) Transmitting a DC3 code to the remote buffer causes the

remote buffer to stop data transmission, such that the

amount of data transmitted after transmission of the DC3

code does not exceed the overrun. (See Fig. B.)

NOTE

If the RBETX bit of parameter No. 5000 is set to 1,

method (a) cannot be used because, while the CS signal

is off, a SYN/NAK or DC4 code is not transmitted even if

CNC reset or a CNC alarm occurs. In such a cause, use

method (b).

(4) For method (a) in step (3)

Once data processing by the host computer terminates, turning

on the CS signal for the remote buffer causes the remote buffer

to restart data transmission, picking up from the data

immediately after that transmitted last.

For method (b) in step (3)

Transmitting a DC1 code to the remote buffer causes the remote

buffer to restart data transmission.

(5) When the CNC has been reset or an alarm has been issued in the

CNC, the remote buffer transmits, to the host computer, a DC4

code, followed by a SYN code (for reset) or NAK code (for an

alarm).

-47-

Page 54

6. PROTOCOL B B-63322EN-1/01

6.2

6.3

CONTROL CODE

The control code is as shown below regardless of the ISO, EIA, and

Binary data:

Control

code

DC1 Starts host transmission. 11H 11H

DC3 Stops host transmission. 93H 13H

DC2 Starts punch-out. 12H 12H

DC4 Stops punch-out. 14H 14H

NAK Posts an NC alarm. 95H 15H

SYN Posts NC reset. 96H 16H

BUFFER CONTROL

The buffer control method of remote buffer is described in the

following:

Function

Code (hexadecimal)

Bit 2 of parameter

No. 5000 = 0

Bit 2 of parameter

No. 5000 = 1

Protocol Interface MAX baud rate

Protocol B RS-232-C 19200 Remaining characters <=

Expansion

protocol B

RS-422 86400 Remaining characters <=

DC3 transmission

conditions

512 characters

2560 characters

DC1 transmission

conditions

Vacant space >= 4096

characters

Vacant space >= 4096

characters

Allowable

overrun value

Less than 512

characters

Less than 2560

characters

-48-

Page 55

B-63322EN-1/01 6. PROTOCOL B

6.4

ALARM AND RESET OF CNC

Once an alarm has been issued in the CNC, or upon the CNC being

reset, the remote buffer transmits the DC3 code, then:

(1) When the CNC reset/alarm state is not to be posted to the host

(parameter No. 5003 bit 3 = 0)

Turns off the ER signal, then performs close processing.

(2) When the CNC reset/alarm state is to be posted to the host

(parameter No. 5003 bit 3 = 1)

Transmits the “SYN” or “NAK” code to the host, then performs

close processing.

NOTE

1 When the parameter is set to post the CNC reset/alarm

to the host, the CNC term inates comm unication upon the

occurrence of an alarm in the CNC during

communication in either of the following cases:

(1) For foreg r ound oper ation: The reset key or the STOP

key (soft key) is pressed.

(2) For background oper ation: The STOP k ey (soft key)

is pressed. (A reset does not cause communication

to terminate.)

2 When the remote buffer transmits data (for punch-out),

pressing the STOP soft key of the CNC cannot stop the

data transmission until all the buff ered data between the

CNC and remote buffer has been transmitted t o the host

computer.

To stop data transmission immediately, press the RESET

key.

-49-

Page 56

7. EXPANSION PROTOCOL B (RS-422) B-63322EN-1/01

7 EXPANSION PROTOCOL B (RS-422)

The expansion protocol B is a protocol used to enable high-speed

transmission with a simple protocol. The communication system is

the same as that of protocol B.

However, the overrun value after transmission of DC3 is limited to

1280 characters or less to enable high-speed transmission.

* When the remote buffer receives data

TR (output)

RS (output)

DC3DC1

DC1 DC3

SD (output)

RD (input)

RR (input)

CS (input)

TR (output)

RS (output)

SD (output)

DC2

ER code

2560 characters or less 2560 characters or less

* When the remote buffer transmits data

DC4

DC3

DC1

RD (input)

RR (input)

CS (input)

2560 characters or less

-50-

Page 57

B-63322EN-1/01 8. DATA INTERFACE

8 DATA INTERFACE

-51-

Page 58

8. DATA INTERFACE B-63322EN-1/01

8.1

DATA PART

Sum Command

Data received from the host computer is largely classified into two

parts, namely the control part and data part.

With the protocol B/expansion protocol B, all data received from the

host computer become the data part.

See the following figure for the data part of protocol A/expansion

protocol A.

1) Protocol A

Packet configuration of <DAT>

Data partControl part

/

Data

/

ETX

ETX

2) Expansion protocol A

Configuration of response packet for <GTD>

Data part Control part

/

Data

Sum

/

ETXNo.

8.2

INTERFACE OF DATA PART

The interface of data part is in conformity the provisions of data

which can be handled through the serial port by the CNC.

The end of data part is judged by the detection of EOR code. Also,

all data after EOR code is ignored.

In general, the data part configuration is as shown below. However,

in the case of DNC operation, the data already received will be lost by

the CNC reset.

Significant information

% ; Program-1 M02 ; Program-2 M02 ; .... ; Program-N M02 ; %

-52-

Page 59

B-63322EN-1/01 9. BINARY INPUT OPERATION FUNCTION

9 BINARY INPUT OPERATION FUNCTION

-53-

Page 60

9. BINARY INPUT OPERATION FUNCTION B-63322EN-1/01

9.1

FUNCTION EXPLANATION

Once a single "G05;" block is specified in normal NC command

format, operation can be performed by specifying desired move data

and auxiliary functions in the following format.

By specifying zero for all of the travel distances along all axes and the

auxiliary function, the system subsequently accepts commands in

normal NC command format again..

• Binary input operation on: G05;

• Binary input operation off: Zero specified for all of the travel

distances along all axes and the auxiliary function

Host computer

©

RS232Cª or

©

ª

RS422

CNC

(FS15i)

Remote buffer

High

byte

byte

First axis

Low

byte

• Data format for binary input operation

Second axis

High

byte

Order of data items

Low

byte

(1) In this format, the travel distance per unit time along each axis

(2) The unit time in msec can be specified with bits 0, 1, and 2 of

(3) All data must be in binary representation.

Auxiliary function

Fourth

byte

• • •

First

byte

Check

byte

• • •

High

byte

N-th axis

Low

byte

(two bytes) is arranged for all axes, starting with the first axis,

followed by an auxiliary function (four bytes. See (6).) and by

the check byte (one byte).

parameter No. 7618.

-54-

Page 61

B-63322EN-1/01 9. BINARY INPUT OPERATION FUNCTION

(4) The travel distance along each axis must be specified in the

following units. (Negative travel distances must be in two’scomplement form.)

IS_A IS_B IS_C IS_D IS_E Unit

Millimeter

machine

Inch

machine

Rotation

axis

0.01 0.001 0.0001 0.00001 0.000001 mm

0.001 0.0001 0.00001 0.000001 0.0000001 inch

0.01 0.001 0.0001 0.00001 0.000001 deg

(5) The following data formats can be selected for the travel

distance, using RDS (bit 2 of parameter No. 7609). (Specify the

travel distance per unit time using the bits marked with the

asterisk (*).)

• Special format (bit 2 of parameter No. 7609 = 0)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

*******0*******

0

• General format (bit 2 of parameter No. 7609 = 1)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

****************

(Example) If the travel distance per unit time is 700 microns

(Millimeter machine, unit: IS_B.)

• Special format (bit 2 of parameter No. 7609 = 0)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0000101

• General format (bit 2 of parameter No. 7609 = 1)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0000001010111100

NOTE

For the protocol A, the data format for the travel distance

must always be the special one.

0 01111000

(6) Whether to use auxiliary functions can be specified with RAX

(bit 3 of parameter No. 7609).

• Bit 3 of parameter No. 7609 = 0 …

Does not use auxiliary functions.

(The data length is [2 * N + 1] bytes.)

-55-

Page 62

9. BINARY INPUT OPERATION FUNCTION B-63322EN-1/01

• Bit 3 of parameter No. 7609 = 1 ...

Uses auxiliary functions.

(The data length is [2 * N + 5] bytes.)

(7) When the parameter is set to use auxiliary functions, specify the

auxiliary functions to be used, using parameter No. 2034, as

follows:

• "0"... Second auxiliary functions

• "1"... Miscellaneous functions

• "2"... S functions

• "3"... T functions

(8) The following data formats can be selected for the auxiliary

function, using RDS (bit 2 of parameter No. 7609). (Specify

data using the bits marked with the asterisk (*) and specify

whether the data is significant using the MSB.)

• Special format (bit 2 of parameter No. 7609 = 0)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

*******0*******

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

******0*******

0

0

MSB = 1: The data is signific ant.

MSB = 0: The data is not signifi cant.

• General format (bit 2 of parameter No. 7609 = 1)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

****************

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

***************

MSB = 1: The data is signific ant.

MSB = 0: The data is not signifi cant.

When the MSB is 1, the data specified with the bits marked with the

asterisk (*) is sent to the auxiliary function, described above.

After the time set for parameter No. 2010 has elapsed, a strobe signal

is sent for the time set for parameter No. 2012. The system does not,

however, wait for FIN.

(9) The check byte must be the result of adding together all the other

[2 * N + (0 or 4)] bytes in byte-by-byte basis, with any overflows

of 8 bits or more removed.

-56-

Page 63

B-63322EN-1/01 9. BINARY INPUT OPERATION FUNCTION

9.2

TRANSFER RATE

After every unit time set for the appropriate parameter, the CNC

extracts data of 2 * N + n bytes (where N is the number of axes, n is

equal to 1 when auxiliary functions are not used and 5 when they are

used.) from the remote buffer. To achieve smooth machining without

any interruption of pulse distribution during machining, the baud rate

of transfer between the host computer and the remote buffer must be

at least

(2 * N + n) * 11/T * 1000 (bps) (where T is the unit time.).

For example, when three axes are used, auxiliary functions are not

used, and the unit time is 2 msec,

the baud rate must be at least

(2 × 3 + 1) bytes × 11 bits/byte/2 msec × 1000 = 38500 bps.

-57-

Page 64

9. BINARY INPUT OPERATION FUNCTION B-63322EN-1/01

/

/

s

9.3

NOTES

NOTE

1 In binary input operation mode, any modal commands (such

as G00, G02, G03, and G90) before the G05 block are

disabled, and are executed as linear interpolation G01 based

on the command data format (equivalent to linear incremental

commands). Upon leaving binary input operation mode, the

system accepts modal commands as usual again.

2 An alarm is issued if G05; is specified in the following modes:

Cutter compensation, three-dimensional cutter compensation,

interrupt macro, canned cycle, three-dimensional coordinate

conversion, coordinate conversion, programmable mirror

image, scaling, polar coordinate interpolation, polar

coordinate command, normal direction control, hypothetical

axis interpolation, cylindrical interpolation, constant surface

speed control, spindle speed fluctuation detection

3 In binary input operation mode, single blocks are

disabled. By setting G5S (bit 3 of parameter No. 2007)

to 1, they are enabled.

4 Feed hold and interlocking are enabled.

5 Turning mirror images on and off is enabled even in

binary input operation.

6 Program restarts and block restarts cannot be used.

7 Registration in memory is not possible.

8 In binary input operation mode, acceleration/decelerat ion

after interpolation is subject to the acceleration

deceleration in cutting feed mode ( G01).

9 The action to be taken when manual intervention is

performed in binary input operation mode does not f ollow

ABS (bit 3 of parameter No. 2409), but the action in the

manual/absolute off state (the travel due to the

intervention is not regained at a restart) is always

assumed. In a mode other than binary input operation

mode, ABS (bit 3 of paramet er No. 2409) is effective.

10 If binary input operation is performed when acceleration

deceleration before look-ahead interpolation or fine HPCC i

enabled, acceleration/deceleration before look-ahead inter-

polation or fine HPCC remains enabled. In operation with the

unit time shorter than 8 msec, acceleration/deceler ation bef ore

look-ahead interpolation or fine HPCC must be enabled.