FAAC E024 S User Manual

E024S |

|

|

|

INDEX |

|

|

|

|

|

|

0 |

BOX LAYOUT..................................................................................................................................... |

2 |

||

1 |

WARNINGS |

........................................................................................................................................ |

3 |

|

2 |

LAYOUT AND CONNECTIONS............................................................................................................ |

3 |

||

3 |

TECHNICAL SPECIFICATIONS ............................................................................................................ |

4 |

||

|

3.1 |

DESCRIPTION .........................................................................................................OF COMPONENTS |

4 |

|

|

3.2 |

DESCRIPTION ..................................................................................................OF TERMINAL-BOARDS |

4 |

|

4 |

PROGRAMMING THE LOGIC.............................................................................................................. |

4 |

||

5 |

PROGRAMMING THE SPEED.............................................................................................................. |

4 |

||

6. |

START-UP........................................................................................................................................... |

|

5 |

|

|

6.1 |

LEDS ......................................................................................................................................CHECK |

5 |

|

|

6.2 |

PROGRAMMING ......................................................................................................THE DIPS-SWITCH |

5 |

|

|

6.3 |

TIME .....................................................................................................................- SETUP LEARNING |

5 |

|

|

|

6.3.1 ................................................................................................................................................. |

AUTOMATIC SET - UP |

5 |

|

|

6.3.2 ...................................................................................................................................................... |

MANUAL SET - UP |

5 |

|

|

6.3.3 .............................................................................................................................PROGRAMMING OF THE LOGIC |

6 |

|

|

|

6.3.4 ....................................................................................Second level programming - ADVANCED FUNCTIONS |

6 |

|

7 |

INSTALLATION OF BUS ACCESSORIES................................................................................................ |

7 |

||

|

7.1 |

ADDRESSING ...................................................................................................THE BUS PHOTOCELLS |

7 |

|

|

7.2 |

MEMORY .......................................................................................STORAGE OF BUS ACCESSORIES |

8 |

|

8 |

MEMORY STORING THE RADIO CODE................................................................................................ |

8 |

||

|

8.1 |

MEMORY ....................................................................................STORAGE OF DS RADIO CONTROLS |

8 |

|

|

8.2 |

MEMORY ..................................................................................STORAGE OF SLH RADIO CONTROLS |

8 |

|

|

8.3 |

MEMORY ....................................................................................STORAGE OF LC RADIO CONTROLS |

9 |

|

|

|

8.3.1 ..................................................REMOTE MEMORY STORAGE OF LC RADIO CONTROLS |

9 |

|

|

8.4 |

RADIO .........................................................................................CONTROLS DELETION PROCEDURE |

9 |

|

9 |

CONNECTION OF BUFFER BATTERIES (OPTIONAL).............................................................................. |

9 |

||

10 |

AUTOMATED SYSTEM TEST................................................................................................................. |

9 |

||

11 |

S700H ADDRESSING BUS ENCODER ............................................................................................... |

10 |

||

12 |

LOGIC TABLES................................................................................................................................. |

10 |

||

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY Declares that: Control board mod. E024S,

• conforms to the essential safety requirements of the following EEC directives:

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

Additional information:

This product underwent a test in a typical, uniform configuration. (all products made by FAAC S.p.A)

Bologna 01-03-2009. |

The Managing Director |

|

A. Marcellan |

WARNINGS

•Important! For the safety of people, it is important that all the instructions be carefully observed.

•Incorrect installation or incorrect use of the product could cause serious harm to people.

•Carefully read the instructions before beginning to install the product and keep them for future reference.

•The symbol  indicates notes that are important for the safety of persons and for the good condition of the automated system.

indicates notes that are important for the safety of persons and for the good condition of the automated system.

•The symbol

draws your attention to the notes on the characteristics and operation of the product.

draws your attention to the notes on the characteristics and operation of the product.

ENGLISH

ENGLISH

ELECTRICAL BOX E024S

0 BOX LAYOUT

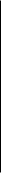

The box contains the E024S electronic unit and the devices to power it. It must therefore be handled with care during all installation stages, to avoid damaging its components.

The box contains the E024S electronic unit and the devices to power it. It must therefore be handled with care during all installation stages, to avoid damaging its components.

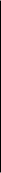

The dimensions of the box are shown in Fig.A:

The lid hinges can be moved upward to allow opening the box housing (Fig. C); they can also be removed and re-positioned in order to enable the lid to open to the right or left.

Fig. C

When you have secured the box in the selected position, cover the securing holes (ref.a Fig.B) and the screws with the supplied plugs as shown in Fig.D.

306

64 |

225 |

|

Dimensions in mm |

||

130 |

||

Fig. A |

||

|

Fig. B shows the four 5 mm diam. holes for securing the box (ref.a) to the wall, the three fittings M16/M20/M25 for installing the cable grippers (ref.b) and the two lid hinges (ref.c).

Fig. D

After you have finished the operations to connect the control board with the various parts of the automated system, close the box, positioning the lid in its seat with seal.

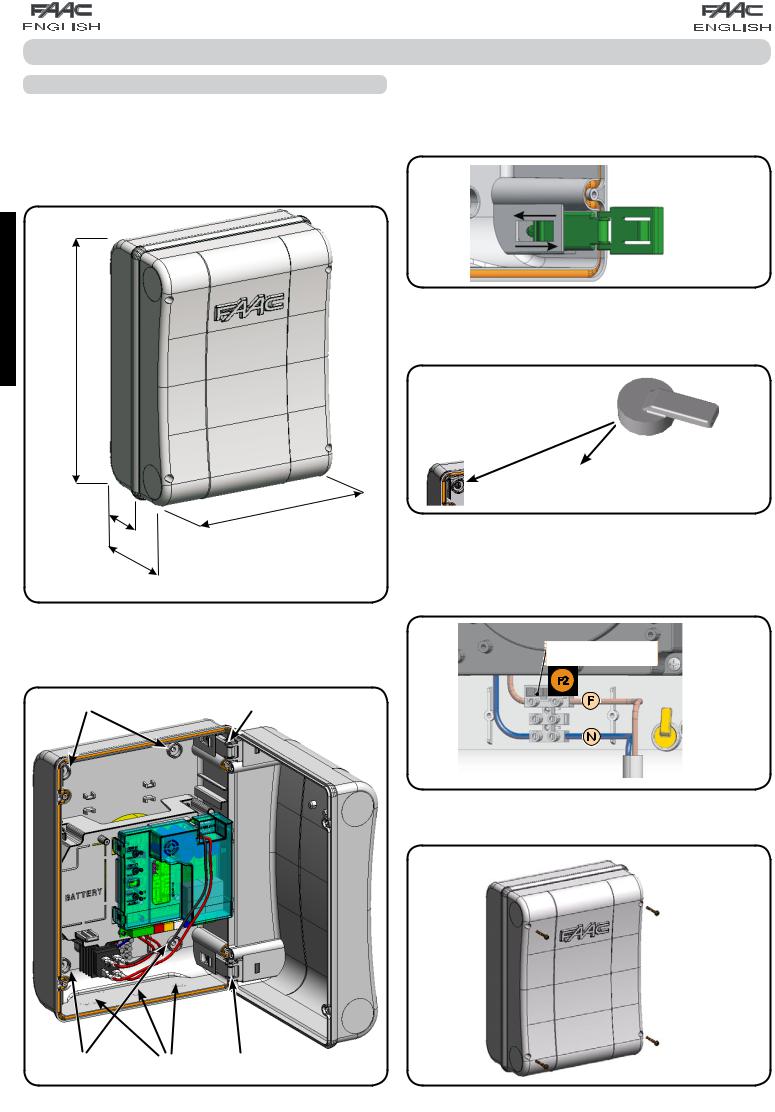

Connect the supply as shown in Fig. E.

230V -> 2,5A - 250V

115V -> 4A - 120V

a |

c |

Fig. E

Next, tighten the four supplied screws to guarantee the degree of protection against external agents (Fig.F).

a |

b |

c |

Fig. B |

Fig. F |

CONTROL UNIT E024S

1 WARNINGS

Before attempting any work on the control unit (connections, maintenance), always turn off power.

-Install, upstream of the system, a differential thermal breaker with adequate tripping threshold,

-Always separate power cables from control and safety cables (push-button, receiver, photocells, etc.).

-To avoid any electrical disturbance, use separate sheaths or a screened cable (with the screen earthed).

2 LAYOUT AND CONNECTIONS

|

ENGLISH |

230 Vac 50Hz |

|

or |

*1 |

115 Vac 60Hz |

|

(TOTAL OPENING) |

|

(PARTIAL OPENING) |

|

|

Fig. 1 |

*1 The power supply is related to the E024S purchased version.

|

|

3 |

|

TECHNICAL SPECIFICATIONS |

|

|

|

|

|||

|

|

Power supply voltage *2 |

230Vac (+6% -10%) - 50Hz |

||

|

|

or |

|||

|

|

|

|

|

115Vac (+6% -10%) - 60Hz |

|

|

|

|

|

|

|

|

Absorbed power |

4W |

||

|

|

|

|

|

|

|

|

Motor max. load |

150W x 2 |

||

|

|

|

|

|

|

|

|

Accessories max. current |

250 mA |

||

|

|

(+24V) |

|||

|

|

|

|||

|

|

|

|

|

|

|

|

BUS Accessories max.current |

400 mA |

||

|

|

|

|

|

|

|

|

Operating ambient tempera- |

-20°C... +55°C |

||

|

|

||||

|

|

ture |

|||

|

|

|

|||

|

|

|

|

|

|

|

|

Fuses *2 |

F1 = self-resetting; |

||

ENGLISH |

|

F2 = T2A-250V or T4A-120V |

|||

|

|

|

|

||

|

|

|

|

|

|

Function logics |

Varies according to learning |

||||

|

|

A, E, AP, EP,A1,B,C |

|||

|

|

Work time (time-out) |

5 minute (fixed) |

||

|

|

Pause time |

(max. 10 min.) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terminal board inputs |

Open A, Open B, Stop, BUS |

||

|

|

(I/O) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connector inputs |

Power supply, battery |

||

|

|

module XF 433 or XF 868 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motors, flashing lamp, power |

|

|

Terminal board outputs |

supply to accessories, |

||

|

|

electric lock, service light |

|||

|

|

|

|

|

|

|

|

|

|

|

contact (90 sec fixed) |

|

|

|

|

|

|

|

|

Programmable functions |

Logic (A, E, AP, EP,A1,B,C), |

||

|

|

Speed (High - Low) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Learning functions |

Pause time, |

||

|

|

leaf closing delay |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Integrated radio channels |

DS, SLH (max 250 channels) |

||

|

|

type |

LC (max 250 channels - |

||

|

|

|

|

|

|

|

|

*2 |

The power supply and the fuse are related to the purchased |

||

|

|

|

version. |

|

|

3.1DESCRIPTION OF COMPONENTS

J1 |

POWER SUPPLY connector |

|

|

J2 |

SERVICE LIGHT command terminal-board |

|

|

J3 |

FLASHING LAMP terminal-board |

|

|

J4 |

ELECTRIC LOCK terminal-board |

|

|

J5 |

COMMANDS terminal-board |

|

|

J7 |

MOTOR 1 terminal-board |

|

|

J8 |

MOTOR 2 terminal-board |

|

|

J9 |

Rapid connection for XF MODULE |

|

|

J10 |

BUS terminal-board |

|

|

J11 |

BATTERY connector |

|

|

SW1 |

SET UP push-button |

|

|

SW2 |

SPEED push-button |

|

|

SW3 |

LOGIC push-button |

|

|

DS1 |

Programming Dip-switch |

|

|

F1 |

Accessories protective fuse |

|

|

F2 |

Fuses protecting transformers and motors |

|

|

LED |

Signalling LEDs |

|

|

3.2DESCRIPTION OF TERMINAL-BOARDS

Terminal |

and/or |

Description |

Device connected |

||

terminal-board |

|||||

|

|

||||

|

|

|

|

|

|

1 |

|

|

+24V |

Power supply for |

|

|

|

accessories |

|||

|

|

|

|

||

2 |

|

|

GND |

Negative |

|

|

|

|

|

|

|

|

|

|

|

Device with NC |

|

3 |

|

J5 |

STOP |

contact which causes |

|

|

|

|

|

the automated |

|

|

|

|

|

system to shut down |

|

4 |

|

|

OPEN B |

Device with N.O |

|

|

|

|

|

contact (see chap. |

|

5 |

|

|

OPEN A |

||

|

|

FUNCTION LOGICS) |

|||

|

|

|

|

|

|

|

J10 |

BUS |

Safety devices with |

||

RED terminal |

BUS technology |

||||

|

|||||

|

|

|

|

|

|

|

|

|

|

Service Light control |

|

|

J2 |

SERVICE |

output (connect a |

||

GREY terminal |

LIGHT |

relay coil at 24Vdc- |

|||

|

|

|

|

100mA max) |

|

|

J3 |

LAMP |

Flashing lamp 24Vdc |

||

ORANGE terminal |

- 15W |

||||

|

|||||

|

J4 |

LOCK |

Electric lock 12Vac or |

||

|

24 Vdc (to be installed |

||||

BLUE terminal |

|||||

|

on leaf 1) |

||||

|

|

|

|

||

|

J7 |

MOT1 |

Motor 1 (leaf 1) |

||

|

|

|

|

||

|

J8 |

MOT2 |

Motor 2 (leaf 2) |

||

|

|

|

|

|

|

Leaf 1 means the leaf which opens first during

Leaf 1 means the leaf which opens first during

the opening operation.

the opening operation.

The service light control is active during the

The service light control is active during the

entire gate opening or closing movement and for the successive 90 seconds.

entire gate opening or closing movement and for the successive 90 seconds.

3.3ANTI-CRUSHING FUNCTION

The electronic anti-crushing function is obtained by controlling the current consumption or the encoder of the motors connected to the E024S equipment.

If the gate detects an obstacle during the opening or closing movement, the anti-crushing function activates and reverses the sense of direction of the operator, thus increasing the safety degree of the automated system.

4 PROGRAMMING OF THE LOGIC

Repeatedly press the SW3 LOGIC push-button to select one of the 7 programming logics available.

The selected logic is signaled by the LD7 LED: the number of blinkings corresponds to the number of the selected logic.

See paragraph 6.3.3.

5 PROGRAMMING THE SPEED

The function SPEED can be adjusted at any time by pressing push-button SW2.

The selected speed is then displayed on LED LD8:

LED on |

= HIGH speed |

LED off |

= LOW speed |

Loading...

Loading...