FAAC 724 D 24V User Manual

voor de natuur |

kringlooppapier |

|

100% |

para la naturaleza |

100% papel reciclado |

ist umweltfreundlich |

100% Altpapier |

pour la nature |

papier recyclé 100% |

for nature |

recycled paper 100% |

per la natura |

carta riciclata 100% |

724D - 24V

ISTRUZIONI PER L’USO - NORME DI INSTALLAZIONE INSTRUCTIONS FOR USE - DIRECTIONS FOR INSTALLATION

INSTRUCTIONS - REGLES D’INSTALLATION

INSTRUCCIONES PARA EL USO - NORMAS PARA LA INSTALACION

GEBRAUCHSANLEITUNG - ANWEISUNGEN ZUR INSTALLATION GEBRUIKSAANWIJZINGEN – INSTALLATIEVOORSCHRIFTEN

|

|

|

EC DECLARATION OF CONFORMITY |

|

Manufacturer : |

FAAC S.p.A. |

|

||

Address: |

Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY |

|

||

Declares that: |

724D control board, |

|

||

|

|

|

• conforms to the essential safety requirements of the following directives: |

|

|

|

|

73/23/EEC and subsequent amendment 93/68/EEC. |

|

|

|

|

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC |

|

|

|

|

Additional note: |

|

|

|

|

This product underwent tests in a typical uniform configuration |

|

|

|

|

(all products manufactured by FAAC S.p.A.). |

|

|

|

|

Bologna, 01 January 2004 |

|

|

|

|

Director |

|

|

|

|

Bassi |

|

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1)ATTENTION! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people.

2)Carefully read the instructions before beginning to install the product.

3)Do not leave packing materials (plastic, polystyrene, etc.) within reach of children as such materials are potential sources of danger.

4)Store these instructions for future reference.

5)This product was designed and built strictly for the use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good condition/ operation of the product and/or be a source of danger.

6)FAAC declines all liability caused by improper use or use other than that for which the automated system was intended.

7)Do not install the equipment in an explosive atmosphere: the presence of inflammable gas or fumes is a serious danger to safety.

8)The mechanical parts must conform to the provisions of Standards EN 12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Standards mentioned above must be observed, in addition to national legal regulations.

9)FAACisnotresponsibleforfailuretoobserveGoodTechnique in the construction of the closing elements to be motorised, or for any deformation that may occur during use.

10)The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Standards mentioned above must be observed, in addition to national legal regulations.

11)Before attempting any job on the system, cut out electrical power and disconnect the batteries (if provided).

12)The mains power supply of the automated system must be fitted with an all-pole switch with contact opening distance of 3mm or greater. Use of a 6A thermal breaker with all-pole circuit break is recommended.

13)Make sure that a differential switch with threshold of 0.03 A is fitted upstream of the system.

14)Make sure that the earthing system is perfectly constructed, and connect metal parts of the means of the closure to it.

15)The automated system is supplied with an intrinsic anticrushing safety device consisting of a torque control. Nevertheless, its tripping threshold must be checked as specified in the Standards indicated at point 10.

16)The safety devices (EN 12978 standard) protect any danger areas against mechanicalmovementRisks,suchascrushing, dragging, and shearing.

17)Use of at least one indicator-light (e.g. FAACLIGHT 12VDC) is recommended for every system, as well as a warning sign adequately secured to the frame structure, in addition to the devices mentioned at point “16”.

18)FAAC declines all liability as concerns safety and efficient operation of the automated system, if system components not produced by FAAC are used.

19)For maintenance, strictly use original parts by FAAC.

20)Do not in any way modify the components of the automated system.

21)The installer shall supply all information concerning manual operation of the system in case of an emergency, and shall hand over to the user the warnings handbook supplied with the product.

22)Do not allow children or adults to stay near the product while it is operating.

23)Keep remote controls or other pulse generators away from children, to prevent the automated system from being activated involuntarily.

24)Transit is permitted only when the automated system is idle.

25)The user must not attempt any kind of repair or direct action whatever and contact qualified personnel only.

26)Do not short-circuit the poles of the batteries and do not try to recharge the batteries with power supply units other than those provided with the equipment (if provided).

27)Do not throw exhausted batteries into containers for other waste but dispose of them in the appropriate containers to enable them to be recycled. Disposal costs have already been paid for by the manufacturer (if provided).

28)Maintenance: check at least every 6 months the efficiency of the system, particularly the efficiency of the safety devices (including, where foreseen, the operator thrust force) and of the release devices.

29)Anything not expressly specified in these instructions is not permitted.

9

724D ELECTRONIC CONTROL UNIT FOR 24 Vdc SLIDING GATES WITH ENCODER AND

LIMIT-SWITCH

USE INSTRUCTIONS - INSTALLATION INSTRUCTIONS

1. GENERAL CHARACTERISTICS

This control unit for 24 Vdc sliding gates with encoder offers high performance and a wide range of adjustments: opening and closing decelerations, motor control and a facility for managing the opening and closing limit-switches.

A sophisticated electronic control constantly monitors the power circuit and disables the control unit in the event of malfunctions that could impair efficiency of the electronic clutch.

The parameter settings and the operating logic are shown on a handy display, which, indicates gate status during normal operation. The 24V operators 740 are designed to directly house 2 12Vdc-1,2Ah buffer batteries (optional). Alternatively, 2 larger external 12Vdc-4Ah batteries (optional) can be used with support for fastening in suitable enclosure.

2. TECHNICAL SPECIFICATIONS

Supply voltage of transformer |

115 / 230 V~ (+6 -10%) - 50 / 60 Hz. |

|

Supply voltage of control unit |

24 V~ (+6 -10%) - 50 / 60 Hz. |

|

Absorbed power |

3 W |

|

Motor max load |

70 W |

|

Accessories max load |

24Vdc 500mA |

|

Flashing lamp max. load |

24Vdc 15W max. |

|

Operating ambient temperature |

-20°C +50°C |

|

Protection fuses |

3 |

|

|

Automatic / Stepped Automatic / Semiautomatic / Stepped |

|

Function logics |

Semiautomatic / |

|

|

Condo type |

|

Opening / closing time |

Through self-learning during programming |

|

Pause time |

Through self-learning during programming |

|

Thrust force |

Four levels adjustable on display |

|

Decelerations |

Through self-learning during opening and closing |

|

|

Power supply 22V~ / Battery supply / Encoder / Total opening / |

|

Terminal board inputs |

Pedestrian opening / Opening-closing safety devices / Stop / |

|

|

Opening-closing limit-switch |

|

Radio connector |

Rapid 5-pin connector |

|

Terminal board outputs |

24Vdc power supply to accessories / 24Vdc Motor / Flashing lamp |

|

24Vdc |

||

|

||

|

|

|

Board dimensions |

127 x 145 mm. |

|

Characteristics of 230V~ toroidal transformer |

prim. 230V~ - sec. 22V~ / 80VA |

|

|

|

|

Characteristics of 115V~ toroidal transformer |

prim. 115V~ - sec. 20V~ / 80VA |

|

|

|

|

Characteristics of optional indoor batteries |

12V - 1.2 Ah / dimens. 96 x 46 x 50 mm. |

|

Characteristics of optional outdoor batteries |

12V - 4 Ah / dimens. 90 x 70 x 108 mm. |

|

Characteristics of outdoor enclosure |

305 x 225 x 125 mm. - IP55 |

Attention: different output values on voltage 24V~ are possible according to the mains voltage. Before starting, always check the transformer output voltage. It shall not exceed 26V~ both for the 230V~ power supply and 115V~ power supply. Voltage is to be measured loadless, i.e. when the transformer is supplied with power but disconnected from the board.

3. PRELIMINARY SETTING-UP

Attention: To ensure people's safety, all warnings and instructions in this booklet must be carefully observed. Incorrect installation or incorrect use of the product could cause serious harm to people.

Make sure there is an adequate differential switch upstream of the system as specified by current laws, and install a thermal breaker with all-pole switching on the electrical supply line.

To lay electric cables, use adequate rigid and/or flexible pipes. Always separate the connection cables of low voltage accessories from the 115/230 V~ power cables.

In the version with control unit installed on the gearmotor, some connections and installations described in |

|

|

these instructions (motor, transformer, encoder, etc) are factory wired. |

|

|

In the version with control unit in the watertight outdoor enclosure, maximum length of connection cables |

|

|

between control unit and motor/encoder must not exceed 3 m., using 2x2.5mm² cables for the motor and |

$ |

% |

3x0.5mm² cables for the encoder and for the limit-switches (optional). |

||

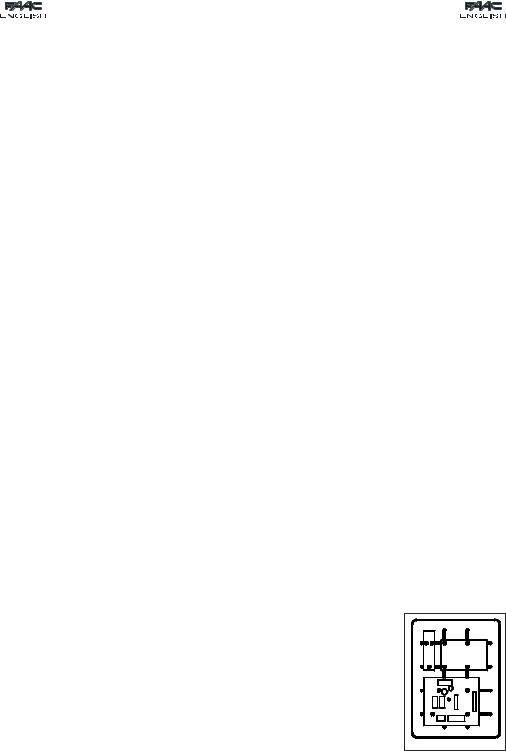

Procedure for securing components in the waterproof enclosure, referring to fig. 1: |

||

1) Secure the support for the toroidal transformer in position A, using 3 Ø4.2x13 self-tapping screws (supplied), |

|

|

placing the spacers between the support and the guides of the watertight enclosure. |

|

|

NB.: the support is sized to house a transformer with the characteristics and dimensions specified on the |

|

& |

table in paragraph 2. |

|

|

2) Secure the transformer to the support with 2 clamps (supplied). |

|

|

3) If using buffer batteries, secure the relevant support in position B with 4 Ø3.5x9.5 self-tapping screws |

|

|

(supplied) in the crossover holes of the guides of the watertight enclosure. |

|

|

NB.: the support is sized to house 2 batteries (not supplied) with the characteristics and dimensions |

|

Fig. 1 |

specified on the table in paragraph 2. |

|

10

Loading...

Loading...