FAAC 460P User Manual

para la naturaleza |

100% papel reciclado |

460-P |

|

|

||||

|

|

|

|

|

|

|

||

ist umweltfreundlich |

100% Altpapier |

|

|

|

|

|

|

|

pour la nature |

papier recyclé 100% |

|

|

|

|

|

|

|

for nature |

recycled paper 100% |

|

|

|

|

|

|

|

per la natura |

carta riciclata 100% |

|

|

RM |

|

|

||

C |

E |

|

|

E |

||||

|

|

T |

||||||

|

|

|

|

|

A |

|||

A |

|

|

|

|

||||

Z |

|

|

|

|

T |

|||

I |

|

|

|

|

||||

E |

|

|

|

C |

A |

|||

N |

|

|

|

|||||

|

D |

|

|

|

|

|||

|

|

|

I |

|

||||

|

A |

|

IF |

|

|

|||

|

T |

|

|

|||||

|

|

|

C ER |

|

|

|

||

UNI EN ISO 9001-085 |

||||||||

|

|

|

|

|

|

|

||

ENGLISH |

|

ENGLISH |

|

|

|

EC MACHINE DIRECTIVE COMPLIANCE DECLARATION

Manufacturer: FAAC S.p.A.

Address: |

Via Benini, 1 |

|

40069 - Zola Predosa |

|

BOLOGNA - ITALY |

Hereby declares that: The electronic control unit model 460P

•complies with the essential safety requirements of the following directives :

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Additional note:

These products have undergone tests in a typical uniform configuration (all products manufactured by FAAC S.p.A.).

Bologna, 1 January 1997

Managing

Director

1 5

ENGLISH |

|

ENGLISH |

|

|

|

IMPORTANTNOTICEFORTHEINSTALLER

GENERAL SAFETY REGULATIONS

1)WARNING! FAAC strongly recommends to follow these instructions literally for the safety of persons. Improper installation or misuse of the product will cause very serious damages to persons.

2)Packaging material (plastic, polystyrene etc.) is a potential hazard and must be kept out of reach of children.

3)Read the instructions carefully before installing the product.

4)Keep these instructions for future reference.

5)This product has been designed and manufactured only for the use stated in this manual. Any other use not expressly set forth will affect the reliability of the product and/or could be source of hazard.

6)FAAC S.p.A. cannot be held responsible for any damage caused by improper use or different from the use for which the automation system is destined to.

7)Do not use this device in areas subject to explosion: the presence of flammable gas or fumes is a serious hazard.

8)Mechanical constructive elements must comply with UNI8612, CEN pr EN 12604 and CEN pr EN 12605 standards.

Countries outside the EC shall follow the regulations above besides their national normative references in order to offer the utmost safety.

9)FAAC cannot be held responsible for failure to observe technical standards in the construction of gates and doors, or for any deformation of the gates which may occur during use.

10)Installation must comply with UNI8612, CEN pr EN 12453 and CEN pr EN 12635. The degree of safety of the automation must be C+E.

11)Before carrying out any operations, turn off the system’s main switch.

12)An omnipower switch shall be provided for the installation with an opening distance of the contacts of 3 mm or more. Alternatively, use a 6A thermomagnetic breaker with multi-pole switching.

13)Ensure that there is a differential switch up-line of the electrical system, with a trip threshold of 0.03A.

14)Check that the earthing plant is in perfect condition and connect it to the metallic parts. Also earth the yellow/green wire of the operator.

15)The automation is fitted with an anti-crush safety system that is a torque control device. In any case, further safety devices shall be installed.

16)The safety devices (e.g. photocells, safety edges etc.) protect areas wherethere is a mechanical movement hazard, e.g. crushing, entrapment and shearing.

17)Each installation must be fitted with at least one flashing light (e.g. FAAC LAMP, MINILAMP etc.) as well as a warning plate suitably fixed to the gate, besides the safety devices as per point 16. above.

18)FAAC cannot be held responsible regarding safety and correct functioning of the automation in the event that parts other than FAAC original parts are used.

19)Use only FAAC original spare parts for maintenance operations.

20)Do not carry out any modifications to automation components.

21)The installer must supply all information regarding manual operation of the system in the event of an emergency and provide the end-user with the “End-user Guide” attached to the product.

22)Keep out of persons when the product is in operation.

23)Keep out of reach of children the remote radio controls and any control devices. The automation could be operated unintentionally.

24)The end-user must avoid any attempt to repair or adjust the automation personally. These operations must be carried out exclusively by qualified personnel.

25)What is not explicitly stated in these instructions is not permitted.

1 6

ENGLISH |

|

ENGLISH |

|

|

|

1. DESCRIPTION

The 460P is a microprocessor-based programmable electronic control unit for hydraulic operators constructed in SMT technology. It is supplied in a standard configuration which can be modified using the FAACTOTUM programmer.

1.1 |

TECHNICAL SPECIFICATIONS |

|||

Table 1 460P hardware characteristics |

||||

|

|

|

||

Power supply |

230 V ~ (+6% -10%) - 50 Hz |

|||

Max. absorbed power |

35 W |

|

||

Max. motor load |

800 W |

|

||

Accessories power supply |

24 Vdc |

|

||

Max. accessories load |

0.5 A |

|

||

Warning light power supply |

24 Vdc |

|

||

Max. warning light load |

3 W |

|

||

Temperature range |

-20°C +55°C |

|

||

Fuses |

|

|

Motors power supply |

|

|

|

|

Accessories power supply |

|

|

|

|

Logic power supply |

|

Mains |

filter |

Integrated in card |

|

|

Quick |

connector |

For decoding cards/RP Receiver |

|

|

Connector |

For FAACTOTUM and optional modules |

|

||

Terminal |

block outputs |

Motor 1 |

|

|

|

|

|

Motor 2 |

|

|

|

|

Flashing light |

|

|

|

|

Warning light power supply |

|

|

|

|

Accessories power supply |

|

Terminal |

block |

Removable |

|

|

Table 2 Default programming characteristics |

||||

|

|

|

||

Terminal block inputs |

Open |

|||

|

|

|

Open single leaf |

|

|

|

|

Stop |

|

|

|

|

Closure safeties |

|

|

|

|

Opening safeties |

|

Operating logic |

Automatic |

|||

Opening/closing time |

25 seconds |

|||

Pause time |

25 seconds |

|||

Closing leaf delay time |

5 seconds |

|||

Opening leaf delay time |

2 seconds |

|||

Table 3 Accessories for 460P |

||||

|

|

|

||

FAACTOTUM |

for card programming |

|||

GATECODER |

deceleration/anti-crushing safety |

|||

Optional |

modules |

MEI (input expansion module) |

||

|

|

|

MEL1 (electric lock management 1) |

|

|

|

|

MEL2 (electric lock management 2) |

|

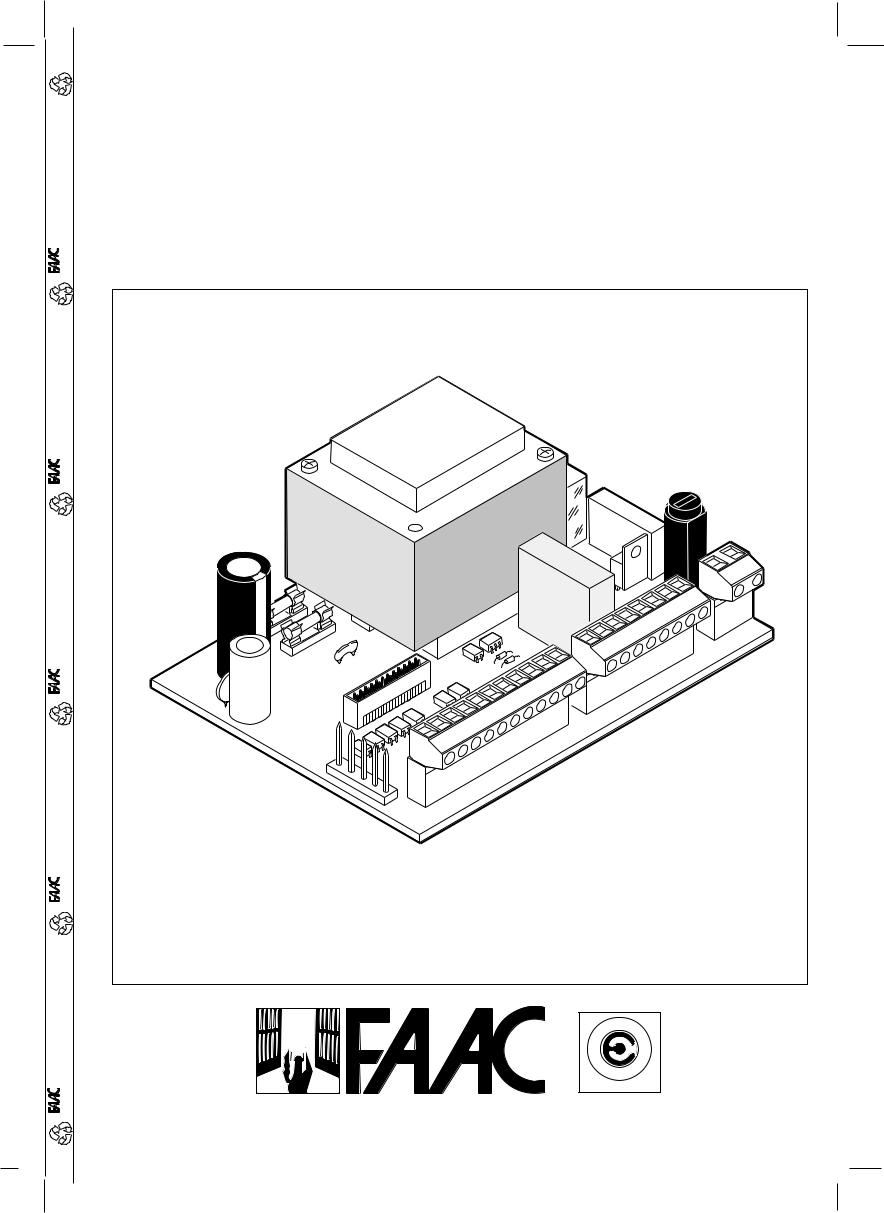

1.3 LAYOUT

5

6

8 7

9

4

1 |

2 |

3 |

Fig. 1

1.2 PROGRAMMABLE PARAMETERS

Table 4 Parameters that can be programmed with FAACTOTUM

Operating logics: |

A-E-S-EP-P-B-C-B/C or customised |

Safety operating logics |

|

Warning light operating logics |

|

Programmable warning light output |

|

Available configurable outputs: Single leaf opening / Complete opening Stop

Close Opening/closing safeties Panic device Opening/closing safety edge

Leaf 1 and leaf 2 opening/closing limit switch Gatecoder

Programming for operation with TIMER

Pre-flashing for opening and/or closing

Independent opening/closing times for each motor

Pause times

Opening/closing leaf delay

Failsafe on safeties

Electric lock opening/closing management

Over pushing stroke during opening and/or closing

Inversion stroke during opening and/or closing

Electronic deceleration: |

timed |

with limit switches |

|

with |

Gatecoder |

The 460P electronic control unit can be installed using the standard configuration and settings the card is supplied with (characteristics are given in Table 2).

The FAACTOTUM programmer must be used if the default configuration requires modification. By using FAACTOTUM it is possible to modify an extremely wide range of parameters to customise card operation according to the requirements and characteristics of the automation.

FAACTOTUM also has a diagnostic function (signalling on the display the state of the gate and inputs in real time and the voltage levels on the card) and verifies operation of the automation and the cycle counts performed.

For details on operation and programming of the FAACTOTUM refer to its instruction manual.

aLow-tension terminal block J2 is used to connect the activating devices and the accessories.

bHigh-tension terminal block J3 is used to power the motors and the flashing light.

c High-tension terminal block J4 is used for line voltage input.

dFuse F1 5x20 5A/250V rapid powers motors and transformer primary coil.

e Fuse F2 5x20 1.6A/250V delayed powers accessories. f Fuse F3 5x20 315mA/250V delayed powers logic

gLED DL1 indicates the card power supply (lights up) and any variations in the state of each input (goes out momentarily)

hConnector J1 for inserting optional modules and/or cable for connection to FAACTOTUM.

iConnector J5 forquickconnectionofDECODER,MINIDEC,RP receiver.

1 7

ENGLISH |

|

ENGLISH |

|

|

|

2. ELECTRICAL CONNECTIONS USING STANDARD CONFIGURATION

OPEN-A |

OPEN-B |

STOP |

FSW CL |

FSW OP |

|

|

WARNING |

LIGHT |

|

460P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J3 |

|

|

|

|

|

J4 |

|||||||

J2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IN1 |

IN2 |

IN3 |

IN4 |

IN5 |

- |

- |

W-L F-TX |

+ |

+ |

LAMP |

C |

OP1 CL1 |

C OP2 CL2 |

L |

N |

|||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 16 |

|

17 |

18 |

19 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

BLU |

C1 |

|

BLU |

|

C2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

BLUE |

|

BLUE |

|

|

|

|

||

|

|

|

|

|

|

|

24 Vdc |

|

|

FAAC LAMP |

|

M1 |

|

|

|

M2 |

230 Vac |

|||

|

|

|

|

|

|

|

|

|

MINILAMP |

|

|

|

|

|||||||

|

|

|

|

|

|

|

3 W max |

|

|

|

|

|

|

|

50 Hz |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 2 |

Terminal block J2 (low tension)

1 - IN1 = OPEN-A command - complete opening (N.O.)

This means any device (pushbutton, detector, etc.) which can give an opening/closing pulse for both gate leaves through the closure of a contact.

To install more than one OPEN - A device connect the N.O. contacts in parallel.

2 - IN2 = OPEN-B command - single leaf opening (N.O.)

This means any device (e.g. pushbutton) which can give an opening/closing pulse for the gate leaf driven by motor M1 through the closure of a contact.

To install more than one OPEN-B device connect the N.O. contacts in parallel.

3 - IN3 = STOP command (N.C.)

This means any device (e.g. pushbutton) which stops the movement of the gate by opening a contact.

To install more than one stop device connect the N.C. contacts in series.

ÜIf Stop devices are not connected jumper the input with the common contact (terminal 6 or 7).

Opening/closing photocells |

|

|

|

A |

A |

|

|

|

A |

|

|

B |

B |

|

Closing photocells |

Opening |

|

Fig. 3 |

|

photocells |

|

|

|

Note about safety devices

These are all devices (photocells, safety edges, magnetic coils, etc.) with an N.C. contact which are activated if an obstacle obstructs the area protected by the safety devices and stop the movement of the gate leaves (fig. 3).

ÜIf the opening safety devices are activated when the gate is closed, they prevent the leaves from opening.

If the closing safety devices are activated when the gate is open, they prevent the leaves from closing.

4 - IN4 = FSW-CL Closing safety device contact (N.C.)

During closure, activation of the safety devices causes the gate leaves to reverse their direction of movement. They are not activated during opening.

ÜIf closure safety devices are not connected, jumper this input to the common contact (terminal 6 or 7).

The function of the closure safety devices is to safeguard the area affected by the movement of the leaves during closure (B, fig. 3).

5 - IN5 = FSW-OP Opening safety device contact (N.C.)

During opening the safety devices stop the movement of the gate leaves. When released they reverse the direction of movement.

ÜIf opening safety devices are not connected, jumper this input with the common contact (terminal 6 or 7).

The function of the opening safety devices is to safeguard the area behind the gate leaves (A, fig. 3).

It is possible to connect devices which operate simultaneously as opening and closing safety devices (see example of safety device connection).

The gate leaves stop if these safety devices are activated during opening, then carry on opening when they are released. The leaves stop moving if these safety devices are activated during closure, then change direction and open when they are released.

Fig.3showsarecommendedexampleofsafetydeviceinstallation.

1 8

Loading...

Loading...