FAAC 452 MPS1, 452 MPS User Manual

ENGLISH

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: 452 MPS control board,

•conforms to the essential safety requirements of the following directives:

73/23/CEE and subsequent amendment 93/68/CEE.

89/336/CEE and subsequent amendment 92/31/CEE and 93/68/CEE

Additional note:

This product underwent tests in a typical uniform configuration (all products manufactured by FAAC S.p.A.).

Bologna, 01 January 2001

The Managing Director

A. Bassi

INSTALLATION WARNINGS

GENERAL SAFETY OBLIGATIONS

1)CAUTION! It is important for personal safety to follow all the instructions carefully. Incorrect installation or misuse of the product may cause people serious harm.

2)Read the instructions carefully before starting to install the product.

3)Packaging material (plastic, polystyrene, etc.) must not be left within reach of children as it is a potential source of danger.

4)Keep the instructions in a safe place for future reference.

5)This product was designed and manufactured strictly for the use indicated in this documentation. Any other not expressly indicated use may damage the product and/or be a source of danger.

6)FAAC accepts no responsibility due to improper use of the automated system or use other than that intended.

7)Do not install the equipment in an area subject to explosion hazard: inflammable gases or fumes are a serious safety hazard.

8)Mechanical construction elements must meet the provisions of UNI8612, EN 12604 and EN 12605 Standards.

To obtain an adequate level of safety in non EU countries, the above mentioned Standards must be observed in addition to national Standards.

9)FAAC will not accept responsibility if the principles of Good Workmanship are disregarded in constructing the closing elements to be motorised, and if any deformation occurs during use of the said elements.

10)Installation must meet the following Standards: UNI8612, EN 12453 and EN 12445.

11)Before carrying out any work on the system, switch off the power supply.

12)The mains power supply of the automated system must be fitted with a allpole switch with contact opening distance of 3mm or greater. Use of a 6A thermal breaker with all-pole circuit break is recommended.

13)Make sure there is a differential switch with 0.03A threshold upstream of the system.

14)Check that theearthing system is correctly made and connectthe closure metal parts to it. Also connect the Yellow/Green wire of the automated system to the earthing system.

15)Theautomatedsystemincludesanintrinsicanti-crushingdeviceconsisting of a torque control which, however, must be installed together with other safety devices.

16)The safety devices (EN 12978 Standard) protect any dangerous areas against Mechanical movement risks, such as crushing, dragging, and shearing.

17)Use of at least one indicator-light (e.g. FAAC LAMP MINILAMP, etc.) is recommended for every system, as well as a warning sign adequately fixed to the frame structure, in addition to the devices mentioned at point "16".

18)FAAC accepts no responsibility regarding safety and correct operation of the automated system, should components made by manufacturers other than FAAC be used in the system.

19)Use only FAAC original spare parts for maintenance.

20)Donotmakeanyalterationstothe componentsoftheautomated system.

21)The installer must supply full information regarding manual operation of the system in case of an emergency and hand to the user of the system the “User’s Guide” included with the product.

22)Do not allow children or other persons to stand near the product while in operation.

23)Keep remote controls or any other pulse generator well away from children, to prevent the automated system from being activated accidentally.

24)The user must refrain from attempting to repair or adjust the system personally and should contact qualified personnel only.

25)Anything not expressly provided for in these instructions is not permitted.

10

ENGLISH

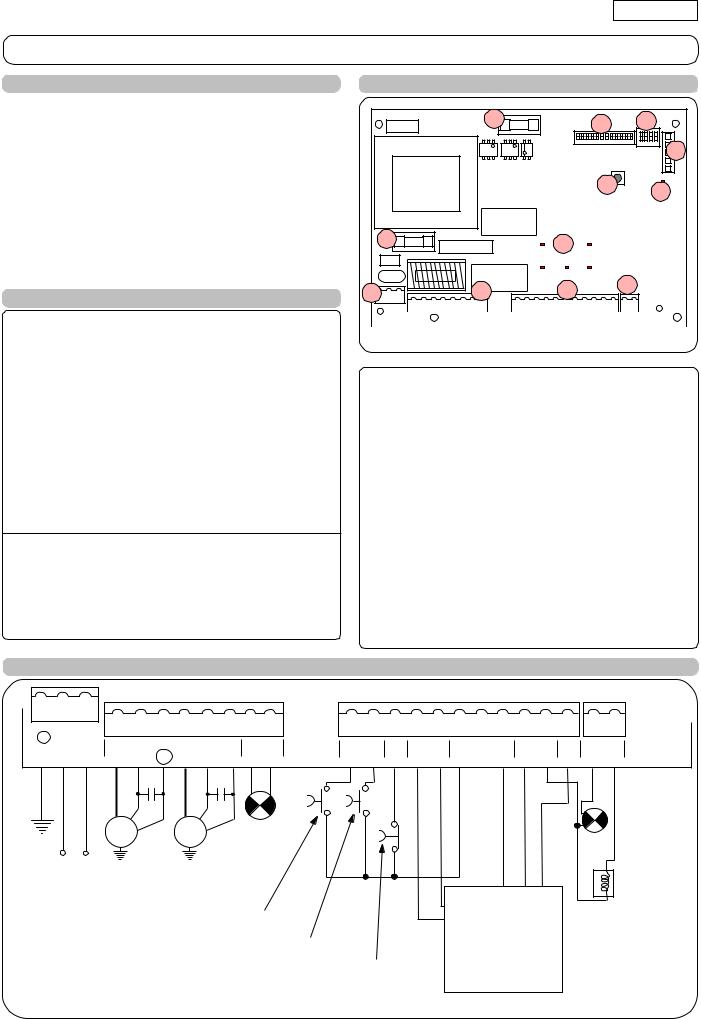

CONTROL BOARD 452 MPS

1. WARNINGS |

3. LAYOUT AND COMPONENTS OF 452 MPS |

Important: Before attempting any work on the control board (connections, maintenance), always turn off power.

-Install, upstream of the system, a differential thermal breaker with adequate tripping threshold.

-Connect the earth cable to the appropriate terminal on the J3 connector of the equipment (see fig.2).

-Always separate power cables from control and safety cables (push-button, receiver, photocells, etc.). To avoid any electric noise, use separate sheaths or a shielded cable (with earthed shield).

2.TECHNICAL SPECIFICATIONS

Power supply |

|

230 V~ ( +6% -10%) - 50 Hz |

Absorbed power |

|

10 W |

Motor max. load |

|

800 W |

Accessories max. load |

|

0,5 A |

Electric lock max. load |

|

15 VA |

Operating ambient temperature |

-20 °C +55 °C |

|

Protection fuses |

|

2 (see fig. 1) |

Function logics |

Automatic / Semi-automatic / Safety devices / |

|

Semi-automatic B / Dead-man C / "Stepped" semi-automatic |

||

Opening/closing time |

|

Programmable (from 0 to 120 s) |

Pause time |

|

0, 10, 20, 30, 60, 120 s |

Closing leaf delay |

|

0, 5, 10, 20 s |

Opening leaf delay |

|

2 s (Can be disabled with the dip-switch) |

Thrust force |

Dip-switch adjustable on 8 levels for each motor |

|

Terminal board inputs |

|

Open / Open free leaf / Stop / |

Opening safety devices / Closing safety devices / Power supply + Earth

Terminal board outputs Flashing lamp - Motors - 24 Vdc accessories

|

power supply - 24 Vdc indicator-light - Fail safe - |

|

12 Vac electric lock power supply |

Rapid connector |

To connect Minidec, Decoder or RP cards |

Selectable functions |

Logics and pause times - Thrust force - |

|

Opening and closing leaf delay - Reversing stroke - |

|

Fail safe - Closing safety devices logic - Pre-flashing |

Programming key |

work time learning |

4.ELECTRIC CONNECTIONS

|

F2 |

F2 |

|

|

|

DS1 |

|

|

|

DS2 |

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 12 |

1 |

2 |

3 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J2 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

DL10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DL10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F1 |

|

OP_A |

Led |

|

OP_B |

|

|

|

|

|

|

|

|

|

|

|

|

|

F1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STOP |

FSWCL |

FSWOP |

|

|

|

|

|

|

|

|

|

|

|||

J3 |

J4 |

|

J1 |

|

|

|

|

|

|

|

|

J5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J5 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J3 |

|

|

|

|

|

|

|

|

|

|

J4 |

J1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PE N |

L |

1 |

2 |

4 |

5 |

6 |

|

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

|

|

|

|||

|

|

OP |

|

OP |

CL |

|

LAMP |

|

|

A |

B |

STP |

CL |

OP |

- |

- |

- |

+ |

+ |

-TX |

|

LOCK |

|

|

|||||

|

MAIN |

|

|

COM M1 |

COM M2 |

|

|

|

OPEN |

FSW |

+24V |

FSW |

W.L. |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 1 |

|

LedOP_A |

|

TOTALLYOPENLED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

LedOP_B |

|

LED:OPENLEAF1/CLOSE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

LedSTOP |

|

LEDSTOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

LedFSWCL |

LED:CLOSINGSAFETYDEVICES |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

LedFSWOP |

LED:OPENINGSAFETYDEVICES |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

DL10 |

|

|

|

LED:TIMELEARNINGSIGNALLING |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

J1 |

|

|

|

LOWVOLTAGETERMINALBOARD |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

J2 |

|

|

|

CONNECTORFORDECODER/MINIDEC/RPRECEIVER |

|

||||||||||||||||||||||||

J3 |

|

|

|

230VACPOWERSUPPLYTERMINALBOARD |

|

|

|

|

|

|

|||||||||||||||||||

J4 |

|

|

|

MOTORSANDFLASHINGLAMPCONNECTIONTERMINALBOARD |

|

||||||||||||||||||||||||

J5 |

|

|

|

INDICATOR-LIGHTANDELECTRICLOCKTERMINALBOARD |

|

||||||||||||||||||||||||

F1 |

|

|

|

MOTORSANDTRANSFORMERPRIMARYWINDINGFUSE(F5A) |

|

||||||||||||||||||||||||

F2 |

|

|

|

LOWVOLTAGEANDACCESSORIESFUSE(T800mA) |

|

||||||||||||||||||||||||

F |

|

|

|

TIMELEARNING PUSH-BUTTON |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

DS1 |

|

|

|

1STGROUPOFMICROSWITCHPROGRAMMING |

|

|

|

|

|||||||||||||||||||||

DS2 |

|

|

|

2NDGROUPOFMICROSWITCHPROGRAMMING |

|

|

|

|

|||||||||||||||||||||

J5

J3

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

J4 |

J1 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

PE N |

L |

8 |

9 |

|||||||||||||||||||

COM |

OP |

|

COM |

OP |

CL |

LAMP |

A |

B |

STP |

CL |

OP |

- |

- |

- |

+ |

+ |

-TX |

W.L. |

LOCK |

|||

MAIN |

|

M1 |

|

M2 |

OPEN |

FSW |

+24V |

FSW |

|

|||||||||||||

|

|

BLUE |

C1 |

|

BLUE |

|

C2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

M1 |

|

|

M2 |

|

|

230 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

max.60W |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For connection of |

|

|

|

||||

|

|

|

|

|

|

|

TOTALLY OPEN |

|

|

|

|

|

the photocells |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

and safety |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

OPEN LEAF 1 |

|

|

|

|

|

devices, see |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

STOP |

|

|

paragraph 4.1 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(page 12). |

|

|

|

|

||||

NB.: Capacitors are supplied with the operators.

Fig. 2

11

ENGLISH

4.1. Connection of photocells and safety devices

Before connecting the photocells (or other devices) we advise you to select the type of operation according to the movement area they have to protect (see fig.3):

Opening safety devices: they operate only during the gate opening movement and, therefore, they are suitable for protecting the area between the opening leaves and fixed obstacles (walls, etc) against the risk of impact and crushing.

Closing safety devices: they operate only during the gate closing movement and, therefore, they are suitable for protecting the closing area against the risk of impact.

Opening/closing safety devices

|

|

|

|

Closing safety devices |

|

|

|

Opening |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Fig. 3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

safety devices |

|||||

Connection of a pair of closing photocells, a pair of |

||||||||||||||||||||

opening |

|

photocells and a pair of opening/closing |

||||||||||||||||||

|

|

photocells (recommended lay-out) |

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

10 |

|

11 |

|

12 |

13 |

|

14 |

15 |

16 |

|

|

17 |

18 |

|

19 |

20 |

21 |

|

|

|

|

|

|

|

|

||||||||||||||

|

A |

B |

|

STP |

|

CL |

OP |

|

- |

- |

- |

|

|

+ |

+ |

|

-TX |

|

LOCK |

|

|

OPEN |

|

|

FSW |

|

|

|

+24V |

|

FSW |

W.L. |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

1 |

|

|

2 |

|

1 |

3 |

- |

|

+ |

|

|

4 |

2 |

|

- |

|

|

5 |

+ |

|

|

|

1 |

2

1

3

3

2

4

5

1 |

|

|

2 |

|

1 |

3 |

- |

|

+ |

|

|

4 |

2 |

|

- |

|

|

5 |

+ |

|

Fig. 4

Opening/closing safety devices: they operate during the gate opening and closing movements and, therefore, they are suitable for the opening and closing areas against the risk of impact.

FAAC recommends use of the lay-out in fig. 4 (in the event of fixed obstacles at opening) or in fig. 5 (no fixed obstacles).

N.B. If two or more devices have the same function (opening or closing), they should be connected to each other in series (see fig. 12). N.C. contacts must be used.

Connection of a pair of closing photocells and a pair of opening/closing photocells (recommended lay-out)

9 |

10 |

|

11 |

|

12 |

13 |

|

14 |

15 |

16 |

|

17 |

18 |

|

19 |

20 |

21 |

|

|

|

|

|

|||||||||||||

A |

B |

|

STP |

|

CL |

OP |

|

- |

- |

- |

|

+ |

+ |

|

-TX |

|

LOCK |

OPEN |

|

|

FSW |

|

|

+24V |

|

FSW |

W.L. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||

1 |

|

|

|

2 |

- |

1 |

|

3 |

|||

+ |

|

||

4 |

2 |

||

- |

|

||

5 |

+ |

|

|

|

|

1 |

2

1

3

3

2

4

5

Fig. 5

Connection of a closing safety device and an opening safety device

9 |

10 |

|

11 |

|

12 |

13 |

|

14 |

15 |

16 |

|

17 |

18 |

|

19 |

20 |

21 |

|

|

|

|

|

|

||||||||||||||

A |

B |

|

STP |

|

CL |

OP |

|

- |

- |

- |

|

+ |

+ |

|

-TX |

|

LOCK |

|

OPEN |

|

|

FSW |

|

|

|

+24V |

|

FSW |

W.L. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 6

Connection of no safety device

9 |

10 |

|

11 |

|

12 |

13 |

|

14 |

15 |

16 |

|

17 |

18 |

|

19 |

20 |

21 |

|

|

|

|

|

|||||||||||||

A |

B |

|

STP |

|

CL |

OP |

|

- |

- |

- |

|

+ |

+ |

|

-TX |

|

LOCK |

OPEN |

|

|

FSW |

|

|

+24V |

|

FSW |

W.L. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||

Fig. 7

12

Loading...

Loading...