FAAC 844 T User Manual

EC DECLARATION OF CONFORMITY

Manufacturer : FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: 844 T control board,

• conforms to the essential safety requirements of the following directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Additional note:

This product underwent tests in a typical uniform configuration (all products manufactured by FAAC S.p.A.).

Bologna, 01 January 2005

The Managing Director

A. Bassi

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people.

2)Carefully read the instructions before beginning to install the product.

3)Do not leave packing materials (plastic, polystyrene, etc.) within reach of children as such materials are potential sources of danger.

4)Store these instructions for future reference.

5)This product was designed and built strictly for the use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good condition/operation of the product and/or be a sourceofdanger.

6)FAACdeclinesallliabilitycausedbyimproperuseoruseotherthanthatfor whichtheautomatedsystemwasintended.

7)Donotinstalltheequipmentinanexplosiveatmosphere:thepresenceof inflammablegasorfumesisaseriousdangertosafety.

8)ThemechanicalpartsmustconformtotheprovisionsofStandardsEN12604 andEN12605.

Fornon-EUcountries,toobtainanadequatelevelofsafety,theStandards mentioned above must be observed, in addition to national legal regulations.

9)FAAC is not responsible for failure to observe Good Technique in the constructionoftheclosingelementstobemotorised,orforanydeformation thatmayoccurduringuse.

10)TheinstallationmustconformtoStandardsEN12453andEN12445.

Fornon-EUcountries,toobtainanadequatelevelofsafety,theStandards mentioned above must be observed, in addition to national legal regulations.

11)Before attempting any job on the system, cut out electrical power .

12)Themainspower supplyoftheautomatedsystemmustbefittedwithanallpole switchwithcontactopeningdistanceof3mmorgreater.Useofa6A thermal breaker with all-pole circuit break is recommended.

13)Makesurethatadifferentialswitchwiththresholdof0.03Aisfittedupstream ofthesystem.

14)Makesurethattheearthingsystemisperfectlyconstructed,andconnect metal parts of the means of the closureto it.

15)The safety devices (EN 12978 standard) protect any danger areas against mechanical movement Risks, such as crushing, dragging, and shearing.

16)Useofatleastoneindicator-light(e.g.FAACLIGHT)isrecommendedfor everysystem,aswellasawarningsignadequatelysecuredtotheframe structure, in addition to the devices mentioned at point “15”.

17)FAAC declines all liability as concerns safety and efficient operation of the automated system, if system components not produced by FAAC areused.

18)For maintenance, strictly use original parts by FAAC.

19)Do not in any way modify the components of the automated system.

20)Theinstallershallsupplyallinformationconcerningmanualoperationof the system in case of an emergency, and shall hand over to the user the warningshandbooksuppliedwiththeproduct.

21)Do not allow children or adults to stay near the product while it is operating.

22)Keep remote controls or other pulse generators away from children, to prevent the automated system from being activated involuntarily.

23)Transit through the leaves is allowed only when the gate is fully open.

24)The user must not attempt any kind of repair or direct action whatever and contact qualified personnel only.

25)Maintenance:checkatleastevery6monthstheefficiencyofthesystem, particularly the efficiency of the safety devices (including, where foreseen, the operator thrust force) and of the release devices.

26)Anything not expressly specified in these instructions is not permitted.

7

CONTROL BOARD 844 T

These instructions apply to the following model:

844T Electronic control unit

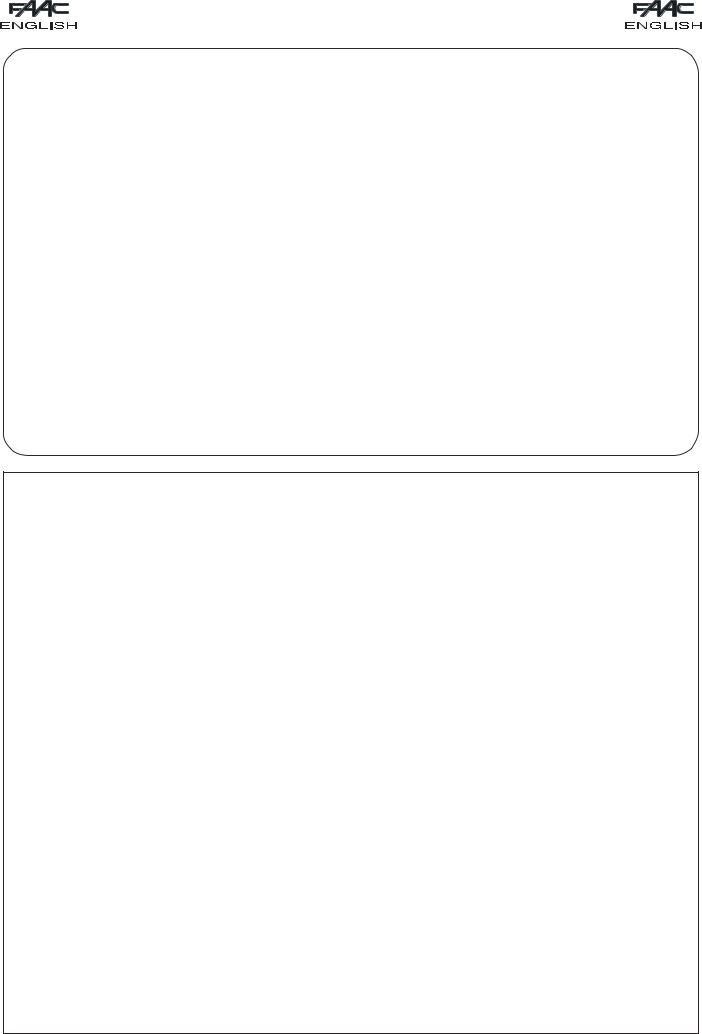

This appliance can be installed in containers mod. E, L and LM. Before securing the card in the container, fit the supplied support feet (long for mod. E, short for models L and LM) in the 3 S-holes (Fig.1).

1. TECHNICAL SPECIFICATIONS

Power supply |

230 Vac. 3ph (+6% -10% 50 Hz.) |

|

400 Vac. 3ph + N (+6% -10% 50 Hz.) |

||

|

||

Motor max load |

1,3 Kw. |

|

|

|

|

Accessories power supply |

24 Vdc. |

|

|

|

|

Accessories max load |

500 mA. |

|

|

|

|

Warninig light power supply |

24 Vac. (max 5 Watt.) |

|

|

|

|

Temperature range |

-20 °C + 55 °C |

|

|

|

|

Fuses |

F2, F5, F6, F7 (Tab. 1) |

|

Quick-fit plugs |

decoding cards or RP receivers |

|

|

|

|

Inputs |

OPEN/PARTIAL OPEN/ |

|

STOP/CLOSURE SAFETY DEVICE/ |

||

|

LIMIT-SENSORS |

|

|

warnig light |

|

Outputs |

flashlight |

|

motor |

||

|

||

|

power supply to 24 Vdc. accessories |

|

|

pause time (5 - 10 - 15 - 30 - 60 |

|

Programming |

120 - 180 sec.) |

|

logics A1/A2/S1/S2/E1/E2/B/C |

||

|

||

|

pre-flashing |

|

Motor braking |

fixed |

|

|

|

|

Safety timing |

255 sec. |

|

|

|

F7 |

F6 |

F5 |

|

|

|

TF1 |

|

|

|

RL7 |

RL6 |

SW1 |

|

|

F2 |

|

|

DS1 |

|

RL8 |

|

|

|

LK1 |

|

|

J1 |

|

|

LED |

J4 |

J5 |

J3 |

||

J2 |

|

|

Tab. 1 - 844 T CONTROL UNIT COMPONENTS

F5 - F6 - F7 |

Fuse F1 6,3x32 5A/250V rapid (power supply fuses) |

F2 |

Fuse F2 5x20 1,6A/250V rapid (accessories) |

SW1 |

RESET push-button |

DS1 |

Programming microswitches |

LED |

Input status signalling LEDs A, B, STOP, FSW, FCC, FCA |

J1 |

Quick-fit plug for decoding cards/RP receivers |

J2 |

Low voltage terminal board for inputs/accessories |

J3 |

Flashlight output terminal board (230V~ max 60W) |

J4 |

Motor output terminal board |

J5 |

Line power supply input terminal board |

LK1 |

Bridge for warning light free contact |

RL6 - RL7 |

Motor relay |

RL8 |

Braking relay |

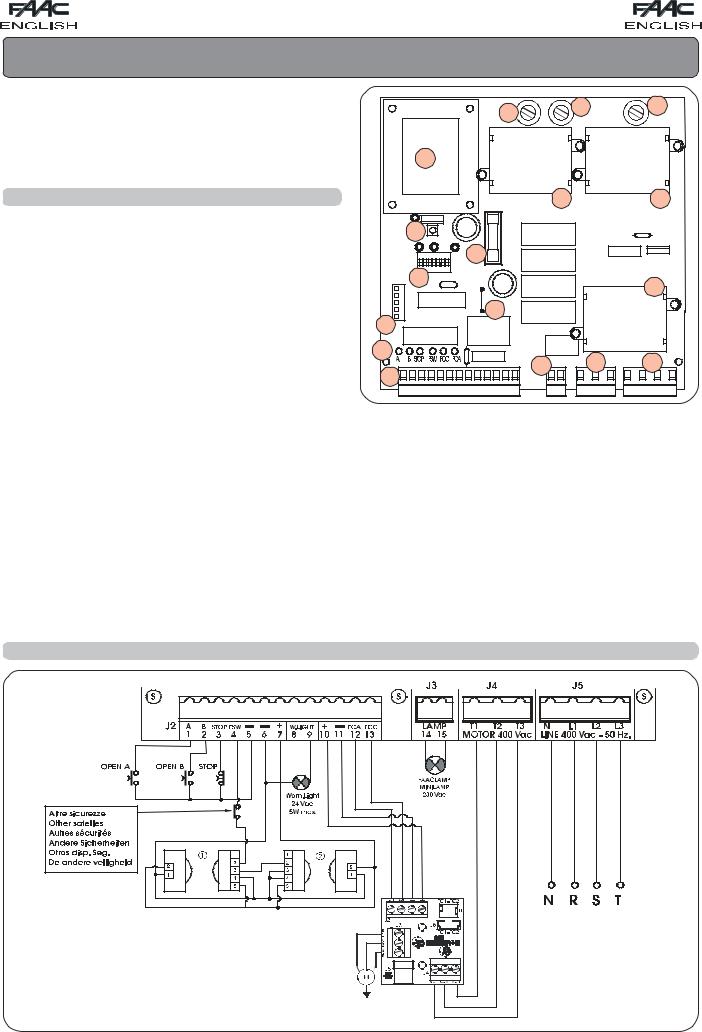

2. ELECTRICAL CONNECTIONS WITH 400V 3ph (N.B.: for connection to 230 V 3ph, see Chapter 8)

Fig. 1

8

Loading...

Loading...