Page 1

Service Manual

Fuller Automated Transmissions

TRSM0020

October 2007

RT-11109A-AT

RT-11109A-ATR

RT-11109A-ATS

RT-12109A-AT

RT-14109A-ATS

RTO-11109A-AT

RTO-11109A-ATS

RTO-11109B-AT

RTO-11109B-ATE

RTO-11109B-ATR

RTO-11109B-ATS

RTO-12109A-AT

RTO-12109B-AT

RTO-13109A-ATE

RTO-13109B-AT

RTO-13109B-ATE

RTO-14109A-ATE

RTO-14109A-ATS

RTO-14109B-AT

RTO-14109B-ATE

RTO-14109B-ATS

RTO-16109A-AT

RTO-16109A-ATE

RTO-16109B-AT

RTO-16109B-ATE

RTO-9109A-AT

RTO-9109B-AT

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Warnings & Precautions

General Information

Model/Assembly Reference

External Parts

Shift Bar Housing

Front Section

Auxiliary Section

Options

Page 5

Page 6

Section 1: Warnings and Precautions

Warning

WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Precautions

Disassemble

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Snap Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

When using Tools to Move Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Warning & Precautions

Inspection

Autoshift Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Bearing Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Gray Iron Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

O-Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Power Synchronizer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Rear Oil Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Reverse Idler Gear Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Shift Bar Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Sliding Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Synchronizer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Assemble

Axial Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Capscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Initial Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

O-Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Universal Joint Companion Flange or Yoke . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

9

Page 7

Page 8

WARNING

Before starting a vehicle always be

seated in the drivers seat, place the

transmission in neutral, set the

Warning & Precautions

parking brakes.

Before working on a vehicle place

the transmission in neutral, set the

parking brakes and block the wheels.

Before towing the vehicle place

the transmission in neutral and lift the

drive wheels off the ground or

disconnect the driveline to avoid

damage to the transmission during

towing.

11

Page 9

Precautions

Disassemble

It is assumed in the detailed assembly instructions that the lubricant has

been drained from the transmission, the necessary linkage, cooler lines,

and air lines disconnected, and the transmission has been removed from

vehicle chassis. Removal of the gear shift cable and electrical harness is

included in the detailed instructions; however, they MUST be detached

from the transmission before they can be removed from the chassis. For

in shop disassembly, holding the transmission in the vertical position can

be done securely by fastening a compatible companion flange to a large

base, forming a holder for the output shaft splines. Use extreme caution

when handling heavy equipment.

Follow closely each procedure in the detailed instructions, make use of

the text, illustrations, and photographs provided.

The electronic control unit (ECU is a non-serviceable

component. Follow the instructions in the "External Parts"

section, careful to remove and protect the unit from damage.

Assemblies

When disassembling the various assemblies, such as the reverse

idler, countershafts, and auxiliary section, lay all parts on a clean

bench in the same sequence as removed. This procedure will

simplify assembly and reduce the possibility of losing parts.

Bearings

Carefully wash and lubricate all usable bearings as removed and

protectively wrap until ready for use. Remove bearings planned to

be reused with pullers designed for this purpose.

Cleanliness

Provide a clean place to work. It is important that no dirt or foreign

material enters the unit during repairs. Dirt is an abrasive and can

damage bearings. It is always good practice to clean the outside of

the unit before starting the planned disassembly.

Snap Rings

Remove snap rings with pliers designed for this purpose. Snap

rings removed in this manner can be reused, if they are not sprung

or loose.

12

When Using Tools to Move Parts

Always apply force to shafts, housings, etc., with restraint.

Movement of some parts is restricted. Never apply force to driven

parts after they stop solidly. The use of soft hammers, soft bars,

and mauls for all disassembly work is recommended.

Page 10

Inspection

Before assembling the transmission, check each part carefully for

abnormal or excessive wear and damage to determine reuse or

replacement. When replacement is necessary, use only genuine Eaton

Fuller Transmission parts to assure continued performance and

extended life from your unit.

Since the cost of a new part is generally a small fraction of the total cost

of downtime and labor, avoid reusing a questionable part which could

lead to additional repairs and expense soon after assembly. To aid in

determining the reuse or replacement of any transmission part,

consideration should also be given to the unit’s history, mileage,

application, etc.

Precautions

Warning & Precautions

Recommended inspection procedures are provided in the following

checklist.

Autoshift Assembly

1. Autoshift finger should move side to side, fore and aft with frictional

resistance only.

Bearings

1. Wash all bearings in clean solvent. Check balls, rollers, and

raceways for pitting, discoloration, and spalled areas. Replace

bearings that are pitted, discolored, spalled, or damaged during

disassembly.

2. Lubricate bearings that are not pitted, discolored, or spalled and

check for axial and radial clearances.

3. Replace bearings with excessive clearances.

4. Check bearing fit. Bearing inner races should be tight to shaft; outer

races slightly tight to slightly loose in case bore. If bearing spins

freely in bore, case should be replaced.

Bearing Covers

1. Check covers for wear from thrust of adjacent bearing. Replace

covers damaged from thrust of bearing outer race.

2. Check cover bores for wear. Replace those worn or oversized.

continued on next page

13

Page 11

Precautions

Inspection

Gears

1. Check gear teeth for frosting and pitting. Frosting of gear teeth

faces presents no threat of transmission failure. Often in continued

operation of the unit, frosted gears “heal” and do not progress to

the pitting stage. In most cases, gears with light to moderate pitted

teeth have considerable gear life remaining and can be reused, but

gears in the advanced stage of pitting should be replaced.

2. Check for gears with clutching teeth abnormally worn, tapered, or

reduced in length from clashing during shifting. Replace gears

found in any of these conditions.

3. Check axial clearance of gears.

Gray Iron/Torque Converter Housing Parts

1. Check all gray iron parts for cracks and breaks. Replace parts

found to be damaged.

Hydraulic Valve

1. Should be clean and free of contamination.

O-Rings

1. Check all O-rings for cracks or distortion. Replace if worn.

Oil Pump

1. Free from damage with no apparent leaks.

Power Synchronizer/Inertia Brake Assembly

1. Check the splined shaft and drive gear for free rotation.

2. No visual damage to band or disc and free of contamination.

Rear Oil Seals

1. Check oil seal in rear bearing cover. If sealing action of lip has

been destroyed, replace the seal. Check the mating flange for

damage.

14

Reverse Idler Gear Assemblies

1. Check for excessive wear from action of roller bearings.

continued on next page

Page 12

Inspection

Shift Bar Housing Assembly

1. Check for wear on shift yokes and blocks at pads and lever slot.

Replace excessively worn parts.

2. Check yokes for correct alignment. Replace sprung yokes.

3. Check lockscrews in yoke and blocks. Tighten and rewire those

found loose.

4. If housing has been disassembled, check neutral notches of shift

bars for wear from interlock balls.

Sliding Clutches

1. Check all shift yokes and yoke slots in sliding clutches for extreme

wear or discoloration from heat.

Precautions

Warning & Precautions

2. Check engaging teeth of sliding clutches for partial engagement

pattern.

Splines

1. Check splines on all shafts for abnormal wear. If sliding clutch

gears, companion flange, or clutch hub has worn marks in the spline

sides, replace the specific shaft affected.

Range Synchronizer Assembly

1. Check synchronizer for burrs, uneven and excessive wear at contact

surface, and metal particles.

2. Check blocker pins for excessive wear or looseness.

3. Check synchronizer contact surfaces on the synchronizer cups for

wear.

Washers

1. Check surfaces of all washers. Washer scored or reduced in

thickness should be replaced.

Wiring Harnesses

1. Should have no abrasions, connector pins should be firmly seated.

15

Page 13

Precautions

Assemble

Make sure that case interiors and housings are clean. It is important that

dirt and other foreign materials are kept out of the transmission during

assembly. Dirt is an abrasive and can damage polished surfaces of

bearings and washers. Use certain precautions, as listed below, during

assemble.

Axial Clearances

Maintain original axial clearances of .006" to .015" for mainshaft

gears.

Bearings

Use a flange-end bearing driver for bearing installation. These

special drivers apply equal force to both bearing races, preventing

damage to balls/rollers and races while maintaining correct

bearing alignment with bore and shaft. Avoid using a tubular or

sleeve-type driver, whenever possible, as force is applied to only

one of the bearing races.

Capscrews

To prevent oil leakage and loosening, use Eaton/Fuller sealant

#71211 or equivalant on all capscrews. For torque ratings, use the

torque recommendations through out the service manual.

Gaskets

Use new gaskets throughout the transmission as it is being rebuilt.

Make sure all gaskets are installed. An omission of any gasket can

result in oil leakage or misalignment of bearing covers.

Initial Lubrication

Coat all limit washers and shaft splines with Lubriplate during

assembly to prevent scoring and galling of such parts.

O-Rings

Lubricate all O-rings with silicon lubricant.

Universal Joint Companion Flange or Yoke

Pull the companion flange or yoke tightly into place with the output

shaft nut, using 450-500 Lbf·ft of torque. Make sure the

speedometer drive gear or a replacement spacer of the same width

has been installed. Failure to pull the companion flange or yoke

tightly into place can result in damage to the mainshaft rear

bearing.

16

IMPORTANT: See the appropriate Illustrated Parts Lists (specified by

model series) to ensure that proper parts are used during assemby of the

transmission.

Page 14

Section 2: General Information

How to Use This Manual 3

Model Designation 5

Lubrication

Maintain Proper Oil Level 6

Draining Oil 7

Refilling 7

Flush Procedure 8

Maintenance Interval Chart 9

Recommended Lubricant Chart 9

Transmission Operating Angles 10

Operating Temperatures with Oil Coolers 11

Power Flow

General Information

Torque Converter Mode: LO Range 12

Torque Converter Mode: Lockup Mode 14

Auxiliary Section: HI Range 15

Timing

Front Section 16

Auxiliary Section 17

Tool Reference 18

Preventive Maintenance 19

Checks Before Transmission Removal 20

Checks with Drive Line Dropped 21

Checks With Universal Joint Companion Flange or Yoke Removed 21

Transmission appearance may differ, procedure is the same.

1

Page 15

Page 16

This manual is designed to provide detailed information

necessary to service and repair the Eaton Fuller

transmissions listed on the front.

As outlined on the first page, the manual has been

divided into its main components: external parts, shift

bar housing, front section, auxiliary section, and

options (if applicable). Each component has its own

tabbed section. Each tabbed section has its own table

of contents and procedural flow charts. The table of

contents lists the procedures. The flow charts

represent the order in which the transmission should

be disassembled or assembled. The procedures have

two parts, disassembly or removal and reassembly or

installation.

How to Use This Manual

General Information

The following is the general layout with descriptions.

1. Heading

Gives a general description of the topic covered.

2. Subhead

Gives a more specific description of the topic covered.

3. Special Instructions

Procedures that need to be done before performing the

topic covered. Hints that will make the procedure

easier to preform.

4. Special Tools

For most procedures typical service mechanic tools are

all that is required, but sometimes a "special" tool is

needed to prevent damaging the transmission.

5. The "How to"

The actual procedure to be performed.

6. Illustrations and pictures

To further help explain and illustrate the procedures.

How to Install the Air Supply Hoses for LO and HI Range

Special Instructions

Make sure air hoses are not damaged.

Install the air hoses at their proper locations.

All externally threaded

with pre-applied thread sealant must be coated with

Eaton sealing material #71209 or equivalent for at least

3 complete and consecutive threads.

For the

To install the hoses, the air filter/regulator must be in

position.

Special Tools

Typical service mechanic tools

To Install

1. Connect one air supply hose end to the range

2. Connect the other end to the slave valve HI range

3. Connect one air supply hose end to the range

4. Connect the other end to the slave valve LO range

Final Check

Make sure air lines are not kinked.

3

1

⁄4" air fittings that are not coated

4

1

⁄4" I.D. air hoses, install the fixed nut end first.

5

cylinder HI range supply port.

supply port.

cylinder LO range supply port.

supply port.

7

Air System

1

2

1

6

H/45-4

External Parts

2

H/45-3

3

H/45-2

7. Final Check

Must do's for proper performance.

8. Page Number/Section

Tells what page your on and in what section.

Transmission appearance may differ, procedure is the same.

Transmission appearance may differ, procedure is the same.

4

H/45-1

8

6

3

Page 17

How to Use This Manual

3

Synchronizer

Assembly

Rear Bearing

Cover

DS/AS-3

1

2

Auxiliary

Section

Range

Cylinder

Assembly

Countershaft

Assemblies

Output

Shaft

Assembly

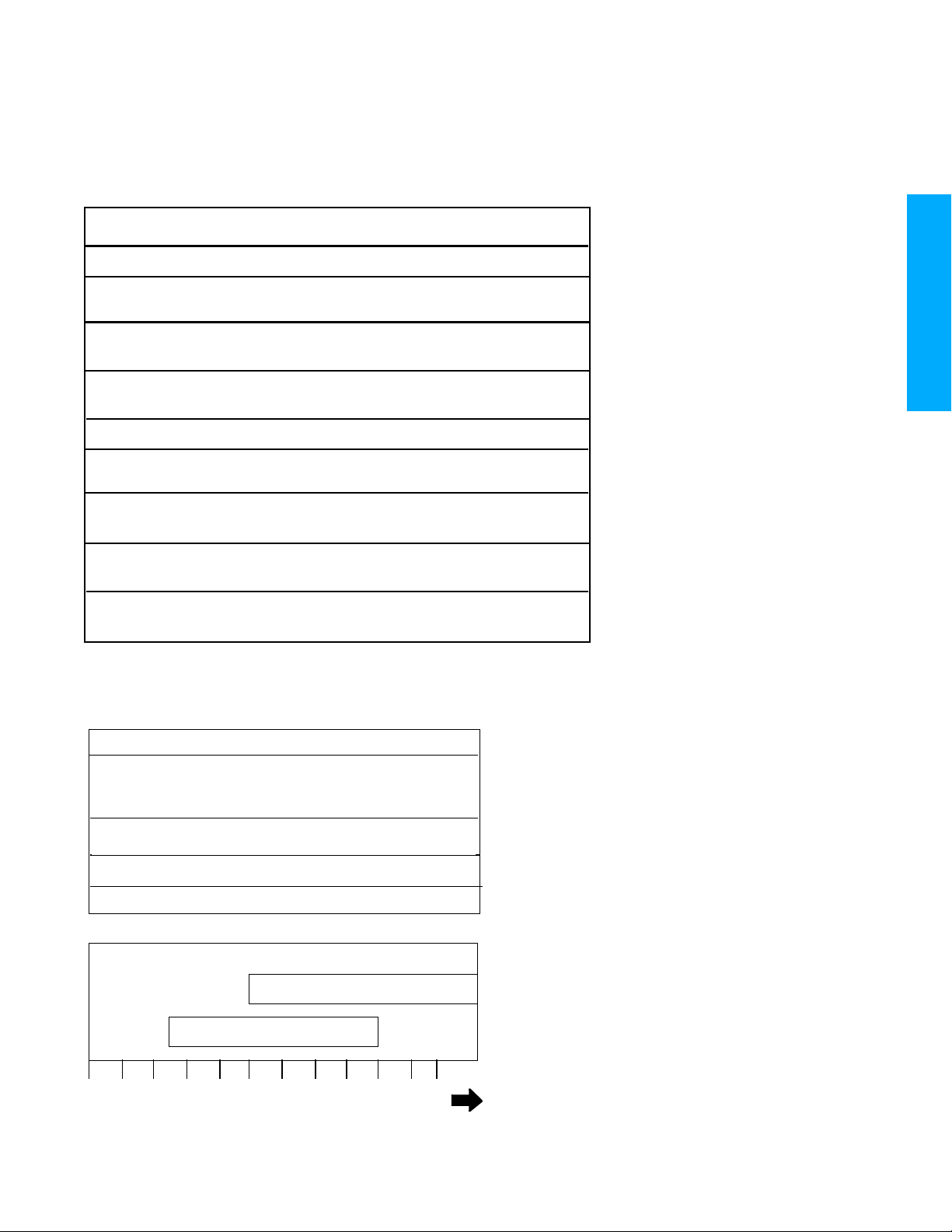

As mentioned on the previous page, the flow charts

represent the order in which the transmission should

be disassembled or assembled.

The following is an example of how to disassemble the

auxiliary section, specifically the synchronizer

assembly.

Follow the flow chart "How to Disassemble the

Auxiliary Section".

1. Remove the auxiliary section from the front box.

2. Remove the range cylinder assembly.

3. Disassemble the synchronizer.

AS/AS-4

2

3

Output

Shaft

Assembly

Countershaft

Assemblies

Range

Cylinder

Assembly

Auxiliary

Section

1

Assemble

Synchronizer

Assembly

Rear Bearing

Cover

Once the synchronzier parts have been replaced,

assemble the auxiliary section according to the "How

to Assemble the Auxiliary Section".

1. Assemble the synchronizer assembly.

2. Install the countershaft assemblies, if they were

removed.

3. Install the range cylinder assembly.

4

Transmission appearance may differ, procedure is the same.

Page 18

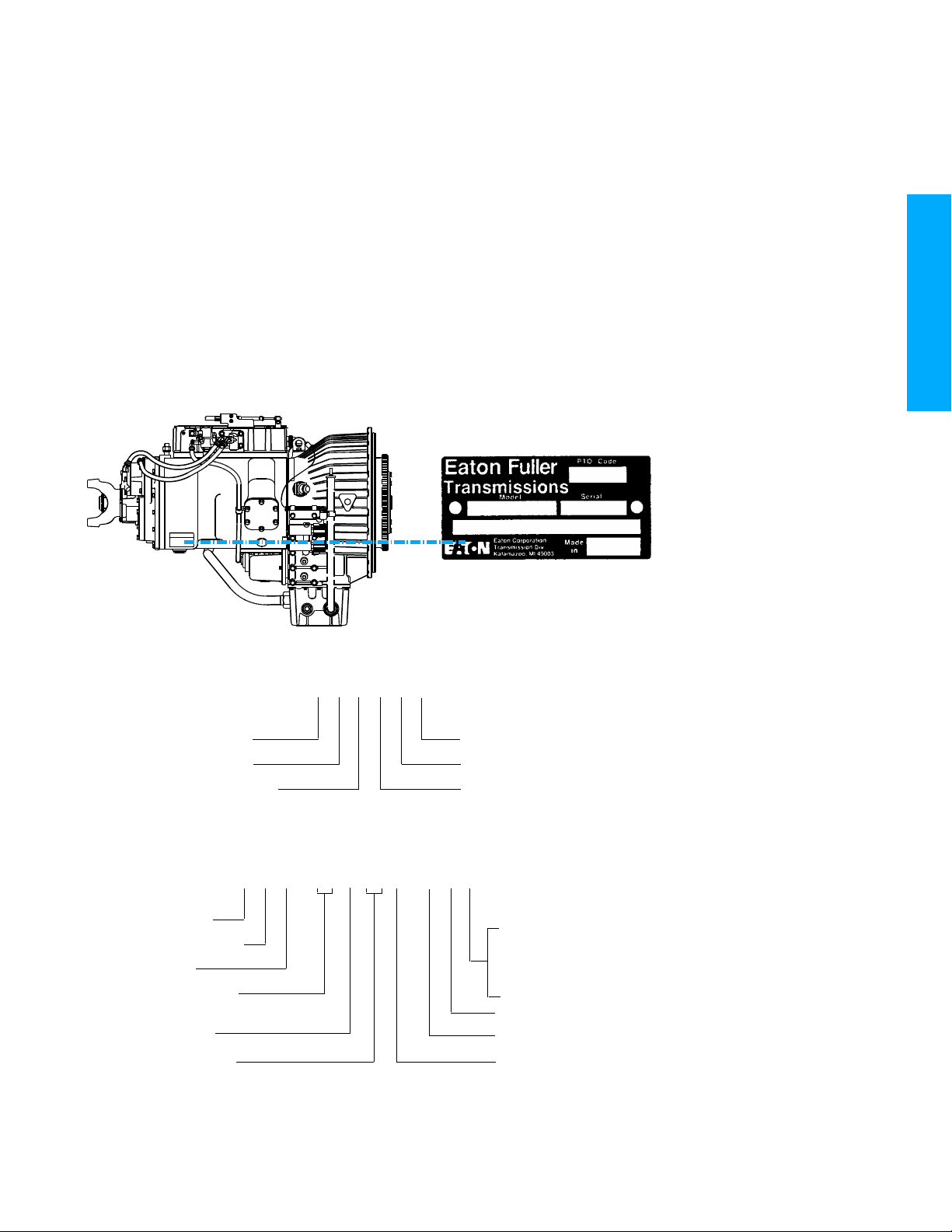

Transmission model designation and other

transmission identification information are stamped on

the transmission tag. To identify the transmission

model designation and serial number, locate the tag on

the transmission and then locate the numbers as

shown.

Do not remove or destroy the transmission

identification tag.

Model Designation

General Information

Converter

Enhanced

Electronically

Roadranger

Twin Countershaft

Overdrive

X 100 = Nominal

Torque Capacity

Design Level

Forward Speeds

BYPASS

INTERRUPT

MAIN

LUBE

C E E M A T

R T O - 11 1 09 A - A T E

Transmission

Automatic

Managed

S—Special Duty

R—Regular Duty

E—Electronic

Governed Engines

Torque Converter

Automatic

Gear Ratio

Transmission appearance may differ, procedure is the same.

5

Page 19

Lubrication

Proper lubrication procedures are the key to a good all-around

maintenance program. If the oil is not doing its job, or if the oil level is

ignored, all the maintenance procedures in the world are not going to

keep the transmission running or assure long transmission life.

Eaton Fuller Transmissions are designed so that the internal parts

operate in an oil bath circulated by the motion of the gears and shafts.

Thus, all parts are amply lubricated if these procedures are closely

followed:

1. Maintain oil level. Inspect regularly.

2. Change oil and filters regularly.

• Use the correct grade and type of oil.

• Buy oil from a reputable dealer.

Additives and friction modifiers are not recommended for use in Eaton

Fuller Transmissions.

20053-7/93

1. Maintain Proper Oil Level

Different Views of the Oil Dipstick

Make sure oil is within dipstick marks for the corresponding oil temperature. Oil

should be checked at idle speed in the neutral position using the corresponding

temperature band. Cold checks can be performed when the oil temperature is 60–

120°F. The oil level should be within the dipstick “cold” band. Additional checks can

be made with the transmission at operating temperature by using the “hot” band on

the opposite side of the dipstick. The “hot” band temperature range is 180–220°F.

6

Transmission appearance may differ, procedure is the same.

Page 20

2. Draining Oil

Drain transmission while oil is at ambient temperature (65°F ± 20). To

drain oil, remove the main case drain plug and the converter housing oil

pan drain plug. Clean the drain plugs and flush the cooler circuit before

re-installing.

A complete hydraulic circuit flush should be completed

when:

• changing oil types and brands.

• changing oil viscosity grades from or to Arctic oil.

• a catastrophic failure has occurred.

3. Refilling

The operational level should always be within the limit marks on the

dipstick. The exact amount of oil depends on the transmission

inclination and model. Insufficient oil damages the pump and other

components, and can affect the function and reduce the life of the

transmission.

Lubrication

General Information

DO NOT OVERFILL! This causes overheating and loss of fuel economy.

When adding oil, types and brands of oil should not be mixed because of

possible incompatibility.

When changing oil viscosity to Arctic oil or alternate viscosity ranges,

follow the recommended transmission oil flush procedure.

Use clean oil and clean containers when filling transmssion. Containers

that have been used for anti-freeze or water should not be used for

transmission oil.

1. Remove the dipstick and slowly add seven (7) gallons of the

prescribed oil through the filltube.

2. Place the transmission in the neutral position and apply the parking

brakes. Start the engine and let it idle for 5 minutes, (this allows oil

to fill the converter, main case, and cooling system), add oil as

needed to obtain a level at the proper temperature range, (cold

band under 120°F, hot band between 180 and 220°F). Total oil

quantity needed at this time should be approximately 10 gallons;

this varies depending on the cooling system.

3. Increase the engine idle slowly to 1500 RPM for two (2) minutes.

Now recheck the oil level at normal idle speed in neutral, again

adding oil to obtain a level at the proper temperature range (cold

band under 100°F, hot band between 180 and 220°F).

4. Replace the dipstick and tighten securely.

Transmission appearance may differ, procedure is the same.

7

Page 21

Lubrication

4. Flush Procedure

1. Disconnect the transmission cooler supply line between the

transmission outlet and the oil cooler, (not between the cooler and the

transmission oil pan).

2. With clean dry air from a hose and nozzle (20 psi), use a rubber

stopper or clean rag to seal the air hose to the converter outlet hose.

3. Apply air to the converter outlet for approximately 2 minutes to

backflush oil into the transmission oil pan.

4. Connect the hose between the transmission and cooler. Tighten to

vehicle manufacturers specifications.

5. Install the transmission converter housing oil pan drain plug, tighten to

14-20 Lbf·ft of torque.

6. Install the transmission main case drain plug (rear @ bottom), tighten

to 45-50 Lbf·ft of torque.

7. Remove the transmission dipstick and slowly pour 7 gallons of the

appropriate oil into the transmission.

8. Apply the vehicle parking brakes and place the transmission lever in

neutral. Start the engine and let it idle for 5 minutes. Check the

dipstick periodically while the engine is idling, adding oil as needed to

obtain a level that is in the Cold Band on the dipstick. Total quantity

added at this time should be approximately 10 gallons.

9. With the transmission still in neutral, increase the engine idle speed to

1500 rpm and retain at this speed for 5 minutes. Now recheck the oil

level at normal engine idle speed in neutral, again adding oil as required

on the dipstick. Total oil quantity added at this time should be ≈11

gallons.

Transmission Temperature (°F)

180 to 220 Oil level between the add-

hot and full-hot marks.

Below 120 Oil level at the cold fill

mark.

8

Transmission appearance may differ, procedure is the same.

Page 22

5. Maintenance Interval Chart

Lubrication Change and Inspection

HIGH WAY USE

First 1,000 to 1,500 miles Change transmission oil, filter,

and strainer on new units.

Every 2,500 miles Inspect lubrication level.

Check for leaks.

Every 50,000 miles or 1 year Change transmission lubricant and filter.

Check the strainer for dirt.

OFF-HIGHWAY USE

First 30 hours Change transmission oil, filter,

and strainer on new units.

Every 40 hours Inspect lubrication level.

Check for leaks.

Lubrication

General Information

Every 500 hours Change transmission lubricant and filter

where severe dirt conditions exist.

Every 1,000 hours Change transmission lubricant and filter.

(Normal off-highway use.)

6. Recommended Lubricant Chart

Recommended Lubricant

Type Grade Fahrenheit (Celsius)

(SAE) Ambient

Temperature

C4 Type 10W Above 0°F (-32°C)

Dexron II Above 0°F (-32°C)

MIL-L-2104E

C4Type 10W Above 0°F (-32°C)

Dexron

II Above 0°F (-32°C)

MIL-L-2104E

Arctic Oil 0W-20 Below 0

0°F

-17.78

°C

SAE 10W or Dexron II

°F (-32°C)

-25

°F

-31.67

°C

-50 -40 -30 -20 -10 0 10 20 30 40 50 Above

SAE 0W-20

(Degrees F)

50

Minimum Temperature For Operating Transmission

Transmission appearance may differ, procedure is the same.

9

Page 23

Lubrication

7. Buy from a reputable dealer

For a complete list of approved and reputable dealers,

write to:

Eaton Corporation

Truck Component Marketing Headquarters

P.O. Box 4013

Kalamazoo, MI 49003

Transmission Operating Angles

If the transmission operating angle is more than 12

degrees, improper lubrication can occur. A special kit

may be required for sustained operation on grades

greater than 12 degrees.

10

Transmission appearance may differ, procedure is the same.

Page 24

Operating Temperatures with Oil Coolers

An external oil cooler is required on the automatic

transmission in order to maintain proper operating

temperatures*. Transmission oil temperature is sensed

from the torque converter outlet port before the oil

enters the cooler.

Normal operating temperature, when sensed from the

torque converter outlet port, should be below 250°F;

however, intermittent operating temperatures to 300°F

do not harm the transmission.

On vehicles equipped with two transmission oil

temperature gauges, one gauge (required) senses

torque converter oil as mentioned above, while the

other gauge (optional) reads oil temperature from the

transmission sump. The sump temperature represents

oil that has circulated through the cooler. This

temperature is normally below 225°F; however,

intermittent sump temperatures to 250°F do not harm

the transmission.

Lubrication

General Information

When the average temperature of the transmission oil

exceeds the temperature limits as stated above, more

frequent oil changes may be needed.

The following conditions in any combination can cause

the recommended transmission oil temperatures to be

exceeded: (1) operating the transmission in a "stall"

condition; i.e., extended operation while in gear with the

vehicle stopped or slowly moving, (2) high density of

starts and stops at slow operating speed, (3) minimal

cooler capacity and/or restricted air flow to the

transmission oil cooler, (4) exhaust system too close to

the transmission, (5) improper oil level/incorrect oil.

*Engineering approval is required for cooler sizing on

all new CEEMAT

TM

applications.

Transmission appearance may differ, procedure is the same.

11

Page 25

Power Flow

The transmission must efficiently transfer the engine's

power to the vehicle's driveline. Knowledge of what

takes place in the transmission is helpful when

troublshooting and making repairs.

Torque Converter Mode: LO Range

1. Power (torque) from the vehicle's engine is

transferred to the torque converter's splined

cover.

2. The impeller spins directing oil through the

torque converter.

3. The oil flow hits the turbine causing the turbine to

rotate. The power is related to the speed

difference between the impeller and the turbine.

4. The turbine is connected to the interrupt clutch

housing. The interrupt clutch inner hub is

splined directly to the transmission input shaft.

5. When the interrupt clutch is activated, the

housing and the innner hub are connected to

1

3

2

complete the mechanical link and transfers power

to the input shaft.

4

5

12

5004A-8/92

Transmission appearance may differ, procedure is the same.

Page 26

6. Input shaft splines engage the internal splines in

the main drive gear hub.

7. Torque is split between the two countershaft drive

gears.

8. Torque is delivered along both countershafts to

mating countershaft gear of the "engaged"

mainshaft gear (1st gear in this example).

9. The internal clutching teeth in the engaged

mainshaft gear hub transfers torque to the

mainshaft through the sliding clutch.

10. The mainshaft transfers torque directly to the

auxiliary drive gear.

11. The auxiliary drive gear splits torque between the

two auxiliary countershaft drive gears.

Power Flow

General Information

12. Torque is delivered along both countershafts to

the "engaged" LO range gear on the range

mainshaft or output shaft.

13. Torque is transferred to the output shaft through a

sliding clutch.

14. Torque is delivered to the driveline as LO range

1st.

7

6

8

9

10

13

14

5004A-8/92

Transmission appearance may differ, procedure is the same.

11

12

13

Page 27

Power Flow

Torque Converter Mode: Lockup Mode

1. Power (torque) from the vehicle's engine is

transferred to the torque converter's splined

cover.

2. The splined cover is connected to the lockup

clutch.

3. The lockup clutch is splined directly to the

interrupt clutch outer hub. When the lockup

clutch is activated, the interrupt clutch is driven

directly from the engine.

4. The interrupt clutch inner hub is splined directly

to the transmission input shaft.

5. When the interrupt clutch is activated, the torque

is transmitted directly from the engine to the

input shaft from the lockup clutch. The losses

from the slippage in the torque converter are

eliminated in this manner.

1

2

3

4

5

5004B-8/92

14

Transmission appearance may differ, procedure is the same.

Page 28

Auxiliary Section: HI Range

6. Input shaft splines engage the internal splines in

the main drive gear hub.

7. Torque is split between the two countershaft drive

gears.

8. Torque is delivered along both countershafts to

mating countershaft gear of the "engaged"

mainshaft gear.

9. The internal clutching teeth in the engaged

mainshaft gear hub transfers torque to the

mainshaft through the sliding clutch.

10. The mainshaft transfers torque directly to the

auxiliary drive gear.

Power Flow

General Information

11. The auxiliary drive gear transfers torque directly to

the range mainshaft or output shaft through the

"engaged" sliding clutch.

12. Torque is delivered through the output shaft to the

driveline as HI range 6th.

6

7

8

9

10

11

12

5004C-8/92

Transmission appearance may differ, procedure is the same.

15

Page 29

Timing

Timing Procedures

It is essential that both countershaft assemblies of the

front and auxiliary sections are "timed." This assures

proper tooth contact is made between mainshaft gears

seeking to center on the mainshaft during torque

transfer and mating countershaft gears that distribute

the load evenly. If not properly timed, serious damage

to the transmission is likely to result from unequal

tooth contact causing the mainshaft gears to climb out

of equilibrium.

Timing is a simple procedure of marking the

appropriate teeth of a gear set prior to installation and

placing them in proper mesh while in the

transmission. In the front section, it is necessary to

time only the drive gear set. And depending on the

model, only the LO range, deep reduction, or splitter

gear set is timed in the auxiliary section.

Front Section

A. Marking countershaft drive gear teeth.

1

1

2

1. Prior to placing each countershaft assembly into

the case, clearly mark the tooth located directly

over the drive gear keyway as shown. This tooth

is stamped with an "O" to aid identification.

B. Marking main drive gear teeth.

1. Mark any two adjacent teeth on the main drive

gear.

2. Mark the two adjacent teeth located directly

opposite the first set marked on the main drive

gear. As shown to the left, there should be an

equal number of unmarked gear teeth on each

side between the marked sets.

16

Transmission appearance may differ, procedure is the same.

Page 30

Timing Procedures (cont)

C. Meshing marked countershaft drive gear teeth with

marked main drive gear teeth.

(After placing the mainshaft assembly into the case, the

countershaft bearings are installed to complete

installation of the countershaft assemblies.)

1. When installing the bearings on the left

countershaft, mesh the countershaft drive gear

marked tooth with either set of main drive gear

two marked teeth.

2. Repeat the procedure when installing the bearings

on the right countershaft, make use of the

remaining set of main drive gear two marked teeth

to time assembly.

Auxiliary Section

Timing

2

1

General Information

Standard Auxiliary Section

1. Mark any two teeth on the LO range gear. Then

mark two teeth located directly opposite the first

marked.

2. Prior to placing each auxiliary countershaft

assembly into housing, mark the tooth on each

auxiliary countershaft assembly LO range gear

stamped with the "O".

3. Follow the assembly procedures in the "Auxiliary

Section".

Transmission appearance may differ, procedure is the same.

17

Page 31

Tool Reference

Some repair procedures pictured in this manual show

the use of specialized tools. Their actual use is

recommended as they make transmission repair

easier, faster, and prevent costly damage to critical

parts.

But for the most part, ordinary mechanic's tools such

as socket wrenches, screwdrivers, etc., and other

standard shop items such as a press, mauls and soft

bars are all that is needed to successfully disassemble

and reassemble any Eaton Fuller Transmission.

The specialized tools can be obtained from a tool

supplier or made from tool prints as required by the

individual user. Detailed Eaton Fuller Transmission

Tool Prints are available upon request by writing to:

Eaton Corporation

Transmission Division

Technical Service Dept.

P.O. Box 4013

Kalamazoo, Michigan 49003

18

Transmission appearance may differ, procedure is the same.

Page 32

Everyday there are countless vehicles operating over

the highways with transmissions in such a neglected

mechanical condition, they can be referred to as

failures looking for a place to break down. They lack a

proper and organized preventive maintenance program.

Preventive maintenance is a general term which applies

to all procedures necessary to have maximum life and

satisfactory service at the lowest possible cost, short of

removing and repairing the unit.

A number of conditions contrary to good preventive

maintenance can generally be pointed to when

inspecting a failed transmission. Taking a few minutes

every so many hours or miles to do a few simple

checks could help avoid eventual breakdown or reduce

the repair cost. If the transmission is not cared for, it

will breakdown.

Preventive Maintenance

General Information

Transmission appearance may differ, procedure is the same.

19

Page 33

Preventive Maintenance

Checks Before Transmission Removal

1 Air System and Connections (not shown)

Annually replace the filter/regulator element. If

excessive contamination is present, service

vehicle air/dryer system.

2 Lubricant and Filter

Change at specified service intervals.

Use only the types and grades as recommended.

See LUBRICANTS.

Check lubrication lines and cooling circuit for

leaks.

3 Dipstick (not shown)

Remove dipstick and check level of lubricant at

specificed intervals. Check oil in neutral at

engine idle.

4 Drain Plugs

Tighten the drain plugs securely. Tighten the

main case drain plug to 45-50 Lbf·ft of torque.

Tighten oil pan plugs to 14-20 Lbf·ft of torque.

5 Capscrews and Gaskets

Check all capscrews, especially those on PTO

covers and rear bearing covers for looseness

which would cause oil leakage. Use the torque

recommendations identified in this service

manual.

Check PTO opening, oil sump/strainer, hose

fittings, and rear bearing covers for oil leakage

due to faulty gaskets.

20

5

1

4

Transmission appearance may differ, procedure is the same.

Page 34

Preventive Maintenance

Checks with Drive Line Dropped

6 Universal Joint Companion Flange or Yoke Nut

Check for tightness. Tighten to recommended

torque.

Checks With Universal Joint Companion Flange

or Yoke Removed

NOTE: If necessary, use solvent and shop rag to clean

sealing surface of companion flange or yoke.

Do not use crocus cloth, emery paper, or

other abrasive materials that will mar sur-

face finish.

8 Splines on Output Shaft

Check for wear from movement and chucking

action of the universal joint companion flange or

yoke.

7 Output Shaft

Pry upward against output shaft to check radial

clearance in mainshaft rear bearing.

9 Mainshaft Rear Bearing Cover

Check oil seal for wear.

General Information

9

8

6

7

Transmission appearance may differ, procedure is the same.

21

Page 35

Page 36

Section 3: Model/Assembly Reference

CEEMAT-AT 2

CEEMAT-ATR 4

CEEMAT-ATS 6

CEEMAT-ATE 8

Model/Assembly Reference

1

Page 37

CEEMAT-AT

Remove/ Install/

Disassemble Assemble

(page numbers)

External Parts

Air System

Air Supply Hoses for the Power Synchronizer 4 5

Air Supply Hose for LO and HI Range 8 9

Air Filter/Regulator 10 11

Slave Valve 12 13

Lube System

Lube Supply Hose for the Power Synchronizer 14 15

Oil Pan/Strainer 18 19

Oil Filter 20 21

Synchronizer System

Power Synchronizer 22 23

Shift Bar Housing

Shift Bar Housing Cover 24 25

Autoshift Harness 26 27

Autoshift Assembly 28 29

Shift Bar Housing 30 31

Torque Converter

Torque Converter 32 33

Hydraulic Valve 34 35

Dip Stick 36 37

Torque Converter Housing 38 39

Oil Pump 40 41

Filter Bypass Valve 42 43

HI Pressure Relief Valve 42 43

Output Yoke/Companion Flange 44 45

Auxiliary Section

Auxiliary Section 46 47

Rear Bearing Cover Assembly 48 49

2

Page 38

Remove/ Install/

Disassemble Assemble

(page numbers)

Shift Bar Housing

Shift Bar Housing 4 6

CEEMAT-AT

Front Section

Auxiliary Drive Gear Assembly 4, 6 5, 7

Reverse Idler Gear Assembly 8 9

Countershaft Assembly

Countershaft Bearings 10 11

Countershaft Assembly 12, 14 13, 15

Mainshaft Assembly (may have 3 grooves) 16, 18 17, 19

Input Shaft Assembly 22 23

Auxiliary Section

Range Cylinder Assembly

Range Cylinder Assembly 4 5

Synchronizer Assembly 6 7

Countershaft Assembly 8 9

Output Shaft Assembly/Rear Bearing 12 13

Model/Assembly Reference

3

Page 39

CEEMAT-ATE

Remove/ Install/

Disassemble Assemble

(page numbers)

External Parts

Air System

Air Supply Hoses for theInertia Brake 6 7

Air Supply Hose for LO and HI Range 8 9

Air Filter/Regulator 10 11

Slave Valve 12 13

Lube System

Lube Supply Hose for the Inertia Brake 16 17

Oil Pan/Strainer 18 19

Oil Filter 20 21

Synchronizer System

Inertia Brake 22 23

Shift Bar Housing

Shift Bar Housing Cover 24 25

Autoshift Harness 26 27

Autoshift Assembly 28 29

Shift Bar Housing 30 31

Torque Converter

Torque Converter 32 33

Hydraulic Valve 34 35

Dip Stick 36 37

Torque Converter Housing 38 39

Oil Pump 40 41

Filter Bypass Valve 42 43

HI Pressure Relief Valve 42 43

Output Yoke/Companion Flange 44 45

Auxiliary Section

Auxiliary Section 46 47

Rear Bearing Cover Assembly 48 49

8

Page 40

Remove/ Install/

Disassemble Assemble

(page numbers)

Shift Bar Housing

Shift Bar Housing 4 6

CEEMAT-ATE

Front Section

Auxiliary Drive Gear Assembly 4, 6 5, 7

Reverse Idler Gear Assembly 8 9

Countershaft Assembly

Countershaft Bearings 10 11

Countershaft Assembly 12, 14 13, 15

Mainshaft Assembly (may have 3 grooves) 16, 18 17, 19

Input Shaft Assembly 22 23

Auxiliary Section

Range Cylinder Assembly

Range Cylinder Assembly 4 5

Synchronizer Assembly 6 7

Countershaft Assembly 8 9

Output Shaft Assembly/Rear Bearing 12 13

Model/Assembly Reference

9

Page 41

Page 42

Section 4: External Parts

Air System

How to Remove the Air Supply Hoses for the Power Synchronizer 4

How to Install the Air Supply Hoses for the Power Synchronizer 5

How to Remove the Air Supply Hose for the Inertia Brake 6

How to Install the Air Supply Hoses for the Inertia Brake 7

How to Remove the Air Supply Hoses for LO and HI Range 8

How to Install the Air Supply Hoses for LO and HI Range 9

How to Remove the Air Filter/Regulator 10

How to Install the Air Filter/Regulator 11

How to Remove a Slave Valve 12

How to Install a Slave Valve 13

Lube System

How to Remove the Lube Supply Hose for the Power Synchronizer 14

How to Install the Lube Supply Hose for the Power Synchronizer 15

How to Remove the Lube Supply Hose for the Inertia Brake 16

How to Install the Lube Supply Hoses for the Inertia Brake 17

How to Remove the Oil Tube and Oil Pan/Strainer 18

How to Install the Oil Tube and Oil Pan/Strainer 19

How to Remove the Oil Filter 20

How to Install the Oil Filter 21

External Parts

Synchronizer Systems

How to Remove the Power Synchronizer 22

How to Install the Power Synchronizer 23

How to Remove the Inertia Brake 22

How to Install the Inertia Brake 23

Transmission appearance may differ, procedure is the same.

1

Page 43

Shift Bar Housing

How to Remove the Shift Bar Housing Cover 24

How to Install the Shift Bar Housing Cover 25

How to Remove the Autoshift Harness 26

How to Install the Autoshift Harness 27

How to Remove the Autoshift Assembly 28

How to Install the Autoshift Assembly 29

How to Remove the Shift Bar Housing 30

How to Install the Shift Bar Housing 31

Torque Converter

How to Remove the Torque Converter 32

How to Install the Torque Converter 33

How to Remove the Hydraulic Valve 34

How to Install the Hydraulic Valve 35

How to Remove the Dip Stick 36

How to Install the Dip Stick 37

How to Remove the Torque Converter Housing 38

How to Install the Torque Converter Housing 39

How to Remove the Oil Pump 40

How to Install the Oil Pump 41

How to Remove the Filter Bypass Valve 42

How to Install the Filter Bypass Valve 43

How to Remove the HI Pressure Relief Valve 42

How to Install the HI Pressure Relief Valve 43

Output Yoke/Companion Flange

How to Remove the Output Yoke/Companion Flange 44

How to Install the Output Yoke/Companion Flange 45

Auxiliary Section

How to Remove the Auxiliary Section 46

How to Install the Auxiliary Section 47

How to Remove the Rear Bearing Cover Assembly 48

How to Install the Rear Bearing Cover Assembly 49

2

Transmission appearance may differ, procedure is the same.

Page 44

Page 45

Air System

How to Remove the Air Supply Hoses for the Power Synchronizer

Special Instructions

Before removing the air hoses, label or record their

location.

Special Tools

1

H/49-1

1

2

Typical service mechanic tools

To Remove

1. Remove the capscrew holding the air hose clamp

to the auxiliary housing.

2. Disconnect the air hose at the shift bar housing

power synchronizer disc port (labeled Port A).

3. Disconnect the air supply hose connected to the

power synchronizer disc port.

4. Disconnect the air hose at the shift bar housing

port air supply hose (labeled Port B).

2

1

1

5. Disconnect the air supply hose connected to the

power synchronizer band port.

H/45-5

6. Inspect the air supply fittings on the shift bar

housing and the power synchronizer, remove if

damaged.

3

H/49-2

5

4

H/45-8

4

H/45-9

Transmission appearance may differ, procedure is the same.

Page 46

How to Install the Air Supply Hoses for the Power Synchronizer

Special Instructions

Make sure air hoses are not damaged.

Air System

Install the air hoses at their proper locations.

All externally threaded 1⁄4" air fittings that are not coated

with pre-applied thread sealant must be coated with

Eaton sealing material #71209 or equivalent for at least

3 complete and consecutive threads.

For the 1⁄4" I.D. air hoses, install the fixed nut end first.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install new air fittings.

Tighten to 7-10 Lbf·ft of torque.

2. Connect one air supply hose end to the power

synchronizer band port. Tighten to 7-10 Lbf·ft of

torque.

3. Connect the other end to the shift bar housing

cover band port (labeled Port B). Tighten to 7-10

Lbf·ft of torque.

2

H/45-9

External Parts

2

3

1

H/45-8

4. Connect one air supply hose end to the power

synchronizer disc port. Tighten to 7-10 Lbf·ft of

torque.

5. Connect the other end to the shift bar housing

cover supply port (labeled Port A). Tighten to 710 Lbf·ft of torque.

6. Position the two (2) air supply hoses inside the

retaining clamp.

7. Position the clamp on the auxiliary housing by the

range cylinder and install the retaining capscrew.

Tighten to 35-45 Lbf·ft of torque.

Final Check

Make sure air lines are not kinked.

4

H/49-2

7

6

5

Transmission appearance may differ, procedure is the same.

H/45-5 H/49-1

5

Page 47

Air System

How to Remove the Air Supply Hose for the Inertia Brake

Special Instructions

Before removing the air hose, label or record its

location.

Special Tools

Typical service mechanic tools

2

To Remove

1. If necessary, remove the capscrew holding the air

H/51-3

hose to the auxiliary housing.

2. Disconnect the air hose at the shift bar housing

inertia brake port (labeled Port A).

3. Disconnect the air supply hose connected to the

inertia brake air port.

4. Inspect the air supply fittings on the shift bar

housing and the inertia brake, remove if

damaged.

3

H/51-4

6

Transmission appearance may differ, procedure is the same.

Page 48

How to Install the Air Supply Hoses for the Inertia Brake

Special Instructions

Make sure air hose is not damaged.

Install the air hose at its proper location.

All externally threaded 1⁄4" air fittings that are not coated

with pre-applied thread sealant must be coated with

Eaton sealing material #71209 or equivalent for at least

3 complete and consecutive threads.

For the 1⁄4" I.D. air hoses, install the fixed nut end first.

Air System

3

To install the hose, the air filter/regulator must be in

position.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install new air fittings.

Tighten to 7-10 Lbf·ft of torque.

2. The pipe plug in Port B is tighten to 7-10 Lbf·ft of

torque.

3. Connect the air supply hose to the inertia brake

air port. Tighten to 7-10 Lbf·ft of torque.

4. Connect the other end to the shift bar houisng

inertia brake port (labeled Port A). Tighten to 7-10

Lbf·ft of torque.

5. When necessary, position the air supply hose

inside the retaining clamp.

H/51-4

External Parts

4

H/51-3

2

6. Position the clamp on the 6 bolt PTO cover and

install the retaining capscrew. Tighten to 35-45

Lbf·ft of torque.

Final Check

Make sure air lines are not kinked.

Transmission appearance may differ, procedure is the same.

1

7

Page 49

Air System

How to Remove the Air Supply Hoses for LO and HI Range

Special Instructions

Before removing the air hoses, label or record their

location.

Special Tools

Typical service mechanic tools

1

To Remove

1. Disconnect the slave valve LO range supply port

H/45-1

air hose.

2. Disconnect the air supply hose connected to the

range cylinder LO range supply port.

2

3. Disconnect the slave valve HI range supply port

air hose.

4. Disconnect the air supply hose connected to the

range cylinder HI range supply port.

5. Inspect the air supply fittings on the shift bar

housing and the range cylinder, remove if

damaged.

H/45-2

3

H/45-3

4

H/45-4

8

Transmission appearance may differ, procedure is the same.

Page 50

How to Install the Air Supply Hoses for LO and HI Range

Special Instructions

Air System

Make sure air hoses are not damaged.

Install the air hoses at their proper locations.

All externally threaded 1⁄4" air fittings that are not coated

with pre-applied thread sealant must be coated with

Eaton sealing material #71209 or equivalent for at least

3 complete and consecutive threads.

For the 1⁄4" I.D. air hoses, install the fixed nut end first.

To install the hoses, the air filter/regulator must be in

position.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install new air supply

fittings. Tighten to 7-10 Lbf·ft of torque.

2. Connect one air supply hose end to the range

cylinder HI range supply port. Tighten to 7-10

Lbf·ft of torque.

3. Connect the other end to the slave valve HI range

supply port. Tighten to 7-10 Lbf·ft of torque.

2

H/45-4

External Parts

3

H/45-3

4. Connect one air supply hose end to the range

cylinder LO range supply port. Tighten to 7-10

Lbf·ft of torque.

5. Connect the other end to the slave valve LO range

supply port.

Final Check

Make sure air lines are not kinked.

Transmission appearance may differ, procedure is the same.

4

H/45-2

5

H/45-1

9

Page 51

Air System

How to Remove the Air Filter/Regulator

Special Instructions

1

The air filter/regulator has two (2) O-rings located

between the filter/regulator and the shift bar housing

cover.

Special Tools

Typical service mechanic tools needed

To Remove

H/49-3

1. From the air filter/regulator, remove the two (2)

capscrews.

2. From the shift bar cover, remove the two (2) O-

rings.

3. Inspect the O-rings for cracks or distortion.

4. Inspect the air fittings on the air filter/regulator,

remove if damaged.

2

H/04-4

10

Transmission appearance may differ, procedure is the same.

Page 52

How to Install the Air Filter/Regulator

Special Instructions

The air filter/regulator has two (2) O-rings located

between the filter/regulator and the shift bar housing.

Use a small amount of grease to hold the O-rings in

place, if the shift bar housing is installed on the

transmission.

Air System

Special Tools

Typical service mechanic tools needed

To Install

1. If previously removed, install new air supply

fittings. Tighten the larger fitting to 14-20 Lbf·ft

of torque and the smaller to 7-10 Lbf·ft of torque.

2. On the shift bar cover, position the two (2) O-

rings.

3. Over the O-rings, position the air filter/regulator.

4. Apply Eaton/Fuller Sealant #71205 or equivalent

to the two (2) retaining capscrews.

5. Install the two (2) retaining capscrews, tighten to

8-12 Lbf·ft of torque.

Final Check

Make sure the capscrews are properly torqued.

2

H/04-4

4, 5

External Parts

3

H/49-3

Transmission appearance may differ, procedure is the same.

11

Page 53

Air System

How to Remove a Slave Valve

Special Instructions

1

The air lines should be removed.

Special Tools

Typical service mechanic tools needed

To Remove

1. Remove the retaining capscrews.

2. From the shift bar cover, remove the slave valve

H/49-4

and gasket. You may need to use a plastic

hammer to remove.

3. Thoroughly clean gasket area. Do not get gasket

2

material or dirt in the shift bar housing ports or

valve ports.

4. If the insert valves have been damaged, remove

the plugs and insert valves.

H/49-5

12

4

4

4

Range Valve

Transmission appearance may differ, procedure is the same.

Page 54

How to Install a Slave Valve

Special Instructions

Make sure gasket mounting areas are clean.

Air System

1

Special Tools

Typical service mechanic tools needed

To Install

1. If previously removed, install new insert valves.

Tighten to 20-25 Lbf·ft of torque.

2. Position the corresponding new gasket on the

slave valve mounting surface.

3. Position the slave valve over the gasket.

4. Apply Eaton/Fuller Sealant #71205 or equivalent

to the retaining capscrews.

5. Install the retaining capscrews. Tighten to 8-12

Lbf·ft of torque.

Final Check

Make sure the retaining capscrews are properly

torqued.

4

1

Range Valve

2

External Parts

H/49-6

3

Transmission appearance may differ, procedure is the same.

H/49-5

4, 5

H/49-4

13

Page 55

Lube System

How to Remove the Lube Supply Hose for the Power Synchronizer

Special Instructions

2

Before removing the lube hose, label or record its

location.

1

Special Tools

Typical service mechanic tools

To Remove

1. Disconnect the lube hose from the power

H/49-7

synchronizer.

2. To ease in removal, remove the capscrew and

clamp holding the hose to the auxiliary section.

3

3. Disconnect the lube supply line connected to the

converter housing.

4. Inspect the fitting and connector, remove if

damaged.

5. Inspect the oil restrictor behind the connector,

remove if damaged.

H/43-5

14

Transmission appearance may differ, procedure is the same.

Page 56

How to Install the Lube Supply Hose for the Power Synchronizer

Special Instructions

Lube System

Make sure lube hose is not damaged.

Install the lube hose at its proper location.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install a new oil restrictor.

Tighten to 20-30 Lbf·in of torque.

2. If previously removed, install a new connector

and/or fitting. Tighten to 14-20 Lbf·ft of torque.

3. Connect one lube supply hose end to the

converter housing lube port. Tighten to 15-20

Lbf·ft of torque.

4. Connect the other end to the power synchronizer

lube port. Tighten to 15-20 Lbf·ft of torque.

5. Install the capscrew and clamp to hold the hose

to the auxiliary section. Tighten to 35-45 Lbf·ft of

torque.

2, 3

H/43-5

5

External Parts

4

1, 2

H/49-7

Final Check

Make sure air hoses are not kinked or twisted.

Transmission appearance may differ, procedure is the same.

15

Page 57

Lube System

How to Remove the Lube Supply Hose for the Inertia Brake

Special Instructions

Before removing the lube hose, label or record its

location.

Special Tools

Typical service mechanic tools

1

To Remove

1. Disconnect the lube supply hose connected to the

H/51-5

inertia brake.

2. Disconnect the lube supply hose at the torque

converter housing lube port.

2

3. Inspect the fittings, remove if damaged.

4. Inspect the oil restrictor behind the torque

converter fitting, remove if damaged.

H/43-5

16

Transmission appearance may differ, procedure is the same.

Page 58

How to Install the Lube Supply Hoses for the Inertia Brake

Special Instructions

Lube System

Make sure lube hose is not damaged.

Install the lube hose at its proper location.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install a new oil retrictor.

Tighten to 20-30 Lbf·in of torque.

2. If previously removed, install new connectors.

Tighten to 15-20 Lbf·ft of torque.

3. Connect one lube supply hose end to the

converter housing lube port.

4. Connect the other lube supply hose end to the

inertia brake.

Final Check

Make sure air hoses are not kinked.

1, 2

3

H/43-5

External Parts

4

H/51-5

Transmission appearance may differ, procedure is the same.

17

Page 59

Lube System

How to Remove the Oil Tube and Oil Pan/Strainer

Special Instructions

Special Tools

1

H/49-8

3

H/50-1

2

Typical service mechanic tools

5

⁄16" - 12 Point socket

To Remove

H/49-9

1. Disconnect the return tube from the oil pan and

transmission.

2. From the oil pan, remove the retaining capscrews.

4

3. Remove the oil pan.

4. Remove the retaining capscrews, oil transfer tube,

and oil pan gasket.

5. Inspect the oil return adapter tube, remove if

damaged.

6. Inspect the dip stick adaptor fitting, remove if

damaged.

H/50-2

7. Inspect the cooler back pressure valve, if

damaged replace.

8. Clean the oil pan magnet.

18

6

5

9. Clean and inspect the strainer. Replace, if

damaged.

10. Inspect the return tube fitting on the transmission,

remove if damaged.

7

H/50-4

7

8

H/50-3

Transmission appearance may differ, procedure is the same.

Page 60

How to Install the Oil Tube and Oil Pan/Strainer

Special Instructions

If the magnet needs to be replaced, use adhesive

#71210 or equivalent and cover the entire mating

surface.

Special Tools

Lube System

2

Typical service mechanic tools

To Install

1. If previously removed, install the strainer

capscrews. Tighten to 5-7 Lbf·ft of torque.

2. Position a new oil pan gasket and the oil transfer

tube.

3. Install the two (2) retaining capscrews. Tighten

the screws to 14-20 Lbf·ft of torque.

4. Position the oil pan.

5. Install the retaining capscrews. Tighten the

screws to 14-20 Lbf·ft of torque.

6. If previously removed, install the dip stick adaptor

O-ring and fitting. Tighten to 34-48 Lbf·ft of

torque.

7. If previously removed, install the oil return

adaptor O-ring and adaptor. Tighten to 34-48

Lbf·ft of torque.

8. If previously removed, install a new return tube

fitting on the transmission. Tighten to 60-75

Lbf·ft of torque.

1

3

H/50-2

4

H/50-1

External Parts

6

5

9. Install the return tube on the sump pan. Tighten

to 60-75 Lbf·ft of torque.

Final Check

Make sure all connector are properly torqued.

Transmission appearance may differ, procedure is the same.

H/49-9

7

8, 9

H/49-8

19

Page 61

Lube System

How to Remove the Oil Filter

Special Instructions

1

Special Tools

Typical service mechanic tools

To Remove

1. Remove the three (3) retaining capscrews.

2. Remove the oil filter housing and O-ring seal.

H/50-5

3. Remove the oil filter by pulling it straight off.

4. Inspect the oil filter nipple, remove if damaged.

2

H/50-6

20

3

H/50-7

4

H/50-8

Transmission appearance may differ, procedure is the same.

Page 62

How to Install the Oil Filter

Special Instructions

Depending on the orientation (vertical or horizontal),

grease may be needed to hold the seal ring on the filter

housing.

Special Tools

Typical service mechanic tools

To Install

Lube System

1

1. If removed, apply hydraulic sealant and replace

the oil filter nipple. Tighten to 34-48 Lbf·ft of

torque.

2. Install the oil filter on the oil filter nipple.

3. Position the O-ring seal on the oil filter housing.

4. Position the oil filter housing over the oil filter.

5. Install the three (3) capscrews. Tighten to 26-32

Lbf·ft of torque.

Final Check

Make sure the capscrews are properly torqued.

H/50-8

External Parts

2

H/50-7

3

Transmission appearance may differ, procedure is the same.

H/50-6

4, 5

H/50-5

21

Page 63

Synchronizer Systems

1

How to Remove the Power Synchronizer

Special Instructions

There are different capscrew lengths, note their

location.

The hoses need to be disconnected.

1

Special Tools

Typical service mechanic tools

To Remove

H/28-2

1. From the power synchronizer, remove the

mounting capscrews.

2

2. Remove the power synchronizer and gasket.

3. Inspect the roll pin in the middle mounting

position.

3

H/28-3

How to Remove the Inertia Brake

Special Instructions

1

H/51-6

There are different capscrew lengths, note their

location.

The hoses need to be disconnected.

The removal/replacement procedure is "typical". Your

inertai brake may be installed in a "6 bolt" or "rotated 6

bolt" PTO configuration. The process for the removal/

replacement is the same. Refer to the Illustrated Parts

Lists for further pictures.

22

Special Tools

Typical service mechanic tools

2

To Remove

1. From the inertia brake, remove the mounting

capscrews.

2. Remove the inertia brake and gasket.

3. Inspect the fittings, remove if damaged.

H/51-7

Transmission appearance may differ, procedure is the same.

Page 64

Special Instructions

Synchronizer Systems

How to Install the Power Synchronizer

There are different capscrew lengths, make sure they

are in their proper location.

Special Tools

Typical service mechanic tools

To Install

1. If previously removed, install a new roll pin in the

middle mounting position.

2. Position the power synchronizer and gasket.

3. Install the power synchronizer mounting

capscrews. Tighten to 35-45 Lbf·ft of torque. The

middle capscrew uses a washer.

Final Check

Make sure the capscrews are properly torqued.

2

1

H/28-3

3

External Parts

3

H/28-2

How to Install the Inertia Brake

Special Instructions

There are different capscrew lengths, note their

location.

Special Tools

Typical service mechanic tools

To Remove

1. If previously removed, install new fittings.

Tighten the 1/8" elbow to 7-10 Lbf·ft of torque.

Tighten the 90° elbow to 14-20 Lbf·ft of torque.

2. Position the inertia brake and gasket with

washers.

3. Install the inertia brake mounting capscrews.

Tighten to 35-45 Lbf·ft of torque.

Final Check

Make sure the capscrews are properly torqued.

Transmission appearance may differ, procedure is the same.

2

H/51-7

3

H/51-6

23

Page 65

Shift Bar Housing

How to Remove the Shift Bar Housing Cover

Special Instructions

1

Before removing the shift bar housing cover, the air

hoses must be disconnected.

Removal of the air filter/regulator and the slave valve

can be done before removing the shift bar cover.

There are different capscrew lengths, note their

location.

The shift bar housing cover is a non-serviceable

assembly.

H/42-8

CAUTION: Do not touch the electronic components.

Cover and set aside in a clean area.

Special Tools

Typical service mechanic tools needed

2

To Remove

1. Disconnect the torque converter wire harness.

2. Remove the shift bar housing cover capscrews

and shift cable bracket.

H/46-7

3. Lift the shift bar housing cover up vertically past

the alignment pins.

5

4. Carefully tip the cover on its side.

24

6

5. Disconnect the internal autoshift harness

connector.

4

6. Remove the shift bar housing cover.

7

7. Remove the shift bar housing cover gasket.

8. On the shift bar housing back side, inspect the

breather, bushing, and pipe plug, remove if

H/51-1

damaged.

Transmission appearance may differ, procedure is the same.

Page 66

How to Install the Shift Bar Housing Cover

Shift Bar Housing

Special Instructions

Be careful when lowering the shift bar housing cover

that the harness wires do not get pinched between the

cover and housing or autoshifter.

There are different capscrew lengths, install in the

correct location.

Special Tools

Typical service mechanic tools needed

To Install

1. Position a new gasket on the shift bar housing.

2. Carefully set the shift bar cover on its side on the

shift bar housing top.

3. Connect the internal autoshifter harness

connector.

4. Use the alignment pins and set the shift bar

housing cover in place.

3

2

4

1

H/51-1

External Parts

7

5, 6

8

5. Apply Eaton/Fuller Sealant #71205 or equivalent

to the retaining capscrews or use dyna sealsTM.

6. Install the retaining capscrews with washers.

Tighten to 23-30 Lbf·ft of torque.

7. Install the shift cable bracket with washers.

Tighten to 23-30 Lbf·ft of torque.

8. If previously remove, install the shift cable lever

nut. Tighten to 23-30 Lbf·ft of torque.

9. Connect the converter wire harness to the shift

bar housing cover.

10. If previously removed, install a new bushing and

breather. Tighten to 5-7 Lbf·ft of torque.

11. If previously removed, install a new pipe plug.

Tighten to 14-20 Lbf·ft of torque.

Final Check

Make sure the converter wire harness is connected.

H/46-7

9

H/42-8

Transmission appearance may differ, procedure is the same.

25

Page 67

Shift Bar Housing

How to Remove the Autoshift Harness

Special Instructions

1

Make sure all labels are in the right place.

Note locations and positions of terminals and

connectors.

Use the removal tool included on the harness to

disconnect the in-line connectors.

2

Special Tools

Typical service mechanic tools needed

H/46-9

H/47-1

To Remove

1. Disconnect the 2 pin in-line connector from the

input shaft speed pick-up using the removal tool

located on the autoshifter harness. Slide the tool

along the wire into the insert cavity until it

3

engages the contact and resistance is felt. The

contact retaining clip will be in the unlocked

position.

4

2. Pull the contact wire assembly out of the

connector.

H/47-2

H/51-2

3. Repeat steps 1 and 2 to disconnect the output

shaft speed pick-up.

26

4. On the shift bar housing, loosen the four (4) ball

switch screws on the range ball switches and

remove the autoshift harness terminals.

6

5. Remove the four (4) hex head screws retaining

3

the autoshifter and remove the autoshifter, gasket

and O-ring.

6. Remove the four (4) nuts from the four (4)

H/47-6

H/09-1

autoshift solenoids.

7. Remove the brackets, retainers, and coils.

8. Loosen the six (6) screws that hold the harness

on the three (3) autoshifter ball switches and

remove the harness terminals.

7

8

H/09-2

H/09-3

Transmission appearance may differ, procedure is the same.

Page 68

How to Install the Autoshift Harness

Special Instructions

Make sure all labels are in the right place.

Note locations and positions of terminals and

connectors.

When connecting the in-line connectors, make sure the

wire locks into position. To check, pull gently on the

wires; if the wires resist they are locked.

Special Tools

Typical service mechanic tools needed

To Install

1. Install the three harness (3) ball switch terminals

(labeled S1, S2, and S3) mounted on the autoshift

housing end. Tighten to 14-20 Lbf·ft of torque.

2. Install the four (4) brackets (with square end out)

and coils.

3. Install the four (4) nuts on the solenoids. Tighten to

15-20 Lb

4. Install autoshifter gasket and O-ring.

5. Install the autoshifter with four (4) hex head bolts

with washers. Tighten to 20-30 Lb

6. Position the autoshift harness S4 lead ends under

the washers in the HI range ball switch.

·in of torque.

f

·ft of torque.

f

Shift Bar Housing

2

1

H/09-3

3

H/09-1

5

H/09-2

External Parts

4

H/47-6

7. Tighten the screws to 15-20 Lb

·in of torque.

f

8. Position the autoshift harness S5 lead ends under

the washers in the LO range ball switch.

9. Tighten the screws to 15-20 Lb

·in of torque.

f

10. Connect the 2 pin in-line connector for the input

shaft speed pick-up by inserting the contact wire

inside the insert cavity. Check that they are locked.

11. Connect the 2 pin in-line connector for the output

shaft speed pick-up by inserting the contact wire

inside the insert cavity. Check that they are locked.

Final Check

Make sure the autoshift harness is connected exactly

like the line drawing shown for "How to Install the

Autoshifter Assembly".

Transmission appearance may differ, procedure is the same.

10

H/47-5

H/48-4

8, 9

6, 7

H/51-2

11

H/47-2

27

Page 69

Shift Bar Housing

How to Remove the Autoshift Assembly

S6

S2

S4

S3

KEEP

WIRES

OUT

OF

THIS

AREA

S 6

S1 S7 P2

1

S 3

S 4

TIE WRAP ALL WIRES - EXCEPT S2

S 2

S 1

P4

P3S5

Special Instructions

Make sure all labels are in the right place.

S 5

P 4

P 3

Note locations and positions of terminals and

connectors.

Use the removal tool included on the harness to

disconnect the in-line connectors.

P 2

S 7

P 1

The air hoses, shift bar cover assembly, and autoshift

harness connectors must be disconnected.

P1

Line drawing

Special Tools

Typical service mechanic tools needed

To Remove

2

1. Disconnect the 2 pin in-line connector from the

input shaft speed pick-up using the removal tool.

Slide the tool along the wire into the insert cavity

until it engages the conact and resistance is felt.

The contact retaining clip will be in the unlocked

position.

H/46-9

H/47-1

6

2. Pull the contact wire assembly with tool out of

the connector.

3. Repeat steps 1 and 2 to disconnect the output

shaft speed pick-up.

4. On the shift bar housing, loosen the two switch

screws on the range switches and remove the

3

autoshift harness lead ends.

5. Remove the four (4) allen head screws and

washers from the autoshift assembly.

4

6. Remove the autoshift assembly and harness.

H/47-2

H/51-2

7. Remove the air supply O-ring and gasket.