Dewalt DW713-XE User Manual

Questions? See us on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

DW713-XE

254 mm (10") COMPOUND MITER SAW

TABLE OF CONTENTS |

|

|

|

DOUBLE INSULATION ....................................................................................................................................... |

|

|

2 |

SAFETY INSTRUCTIONS FOR ALL TOOLS ......................................... |

…………………………………………2 |

||

ADDITIONAL SAFETY RULES ....................................... |

|

|

……………………………………………………….2 |

ELECTRICAL SAFETY................................................ |

|

|

…………………………………………………………4 |

UNPACKING YOUR SAW ....................................... |

|

|

……………………………………………………………4 |

FAMILIARIZATION.................................. |

|

………………………………………………………………………4 |

|

SPECIFICATIONS................................... |

|

………………………………………………………………………4 |

|

ACCESSORIES.................................................................................................................................................. |

|

|

5 |

OPTIONAL ACCESSORIES..................................... |

|

|

……………………………………………………………5 |

BENCH MOUNTING ................................... |

|

……………………………………………………………………6 |

|

CHANGING OR INSTALLING A NEW SAW BLADE.................. |

…………………………………………………6 |

||

TRANSPORTING THE SAW........................................ |

|

|

…………………………………………………………6 |

ADJUSTMENTS................................. |

|

…………………………………………………………………………6 |

|

MITER SCALE ADJUSTMENT ............................... |

|

………………………………………………………6 |

|

MITER POINTER ADJUSTMENT................................ |

|

……………………………………………………6 |

|

BEVEL SQUARE TO TABLE |

....................................................................................................................... |

|

6 |

BEVEL POINTER ...................................................................................................................................... |

|

|

7 |

BEVEL STOP............................................................................................................................................ |

|

|

7 |

FENCE ADJUSTMENT .......................... |

|

…………………………………………………………………7 |

|

GUARD ACTUATION AND VISIBILITY ................................ |

………………………………………………7 |

||

AUTOMATIC ELECTRIC BRAKE......................................................................................................................... |

|

7 |

|

MITER LOCK ADJUSTMENT ............................................................................................................................. |

|

8 |

|

BRUSHES ................................. |

………………………………………………………………………………8 |

||

OPERATION .................................. |

……………………………………………………………………………8 |

||

SWITCH................................................................................................................................................... |

|

|

8 |

CUTTING WITH YOUR SAW ..................................................................................................................... |

|

8 |

|

CROSSCUTS ..................................................................................................................................................... |

8 |

BEVEL CUTS...................................................................................................................................................... |

8 |

QUALITY OF CUT............................................................................................................................................... |

8 |

BODY AND HAND POSITION.............................................................................................................................. |

8 |

CLAMPING THE WORKPIECE................................................................................................................... |

9 |

SUPPORT FOR LONG PIECES................................................................................................................... |

9 |

CUTTING PICTURE FRAMES, SHADOW BOXES AND OTHER FOUR SIDED PROJECTS ............................. |

9 |

CUTTING TRIM MOLDING AND OTHER FRAMES...................................................................................... |

9 |

CUTTING COMPOUND MITERS .............................................................................................................. |

10 |

MITER SCALE........................................................................................................................................ |

10 |

VERNIER SCALE.............................................................................................................................................. |

10 |

WHEN MITERING TO THE RIGHT ........................................................................................................... |

10 |

WHEN MITERING TO THE LEFT.............................................................................................................. |

10 |

CUTTING BASE MOLDING...................................................................................................................... |

11 |

CUTTING CROWN MOLDING.................................................................................................................. |

12 |

SPECIAL CUTS ............................................................................................................................................... |

13 |

MAINTENANCE ............................................................................................................................................... |

13 |

REPAIRS......................................................................................................................................................... |

13 |

WARRANTY .................................................................................................................................................... |

13 |

TROUBLESHOOTING GUIDE............................................................................................................................ |

14 |

COMPOUND MITER CUT REFERENCE CHART................................................................................................. |

15 |

1

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

WARNING: Read all instructions before operating product. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers of electrical insulation or one double thickness of insulation between you and the tool’s electrical system. Tools built with this insulation system are not intended to be grounded.

NOTE: Double insulation does not take the place of normal safety precautions when operating this tool. The insulation system is for added protection against injury resulting from a possible electrical insulation failure within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Repair or replace damaged cords.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Repair or replace damaged cords.

Safety Instructions For All Tools

This miter saw accepts the DEWALT worklight and laser attachments.

WARNING: To reduce the risk of eye injury, ALWAYS use eye protection when operating the miter saw.

WARNING: To reduce the risk of eye injury, ALWAYS use eye protection when operating the miter saw.

•KEEP GUARD IN PLACE and in working order.

•REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from spindle before turning tool on. Tools, scrap pieces, and other debris can be thrown at high speed, causing injury.

•KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

•DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power tools in damp or wet locations or in rain can cause shock or electrocution. Keep your work area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

•KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area. Your shop is a potentially dangerous environment.

•MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing starter keys. The unauthorized start-up of a machine by a child or visitor may result in injury.

•DON’T FORCE TOOL. It will do the job better and be safer at the rate for which it was designed.

•USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed. Using the incorrect tool or attachment may result in personal injury.

•WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair. Air vents may cover moving parts and should also be avoided.

•ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

•ANSI Z87.1 eye protection (CAN/CSA Z94.3)

•ANSI S12.6 (S3.19) hearing protection

•NIOSH/OSHA/MSHA respiratory protection

•SECURE THE WORKPIECE. Use clamps or a vise to hold the workpiece on the table and against the fence or when your hand will be dangerously close to the blade (within 6"). It is safer than using your hand and it frees both hands to operate tool.

•DON’T OVERREACH. Keep proper footing and balance at all times. Loss of balance may cause personal injury.

•MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories. Poorly maintained tools and machines can further damage the tool or machine and/or cause injury.

•TURN THE MACHINE “OFF”, AND DISCONNECT THE MACHINE FROM THE POWER SOURCE before installing or removing accessories, before adjusting or changing set-ups, when making repairs or changing locations. An accidental start-up can cause injury. Do not touch the plug’s metal prongs when unplugging or plugging in the cord.

•REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is in the “OFF” position before plugging in the power cord.

•USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. If your product is equipped with a cordset, use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool’s plug. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

|

|

|

|

MINIMUM GAUGE FOR CORD SETS |

|

|||

For Cable length (m): |

7.5 |

15 |

25 |

30 |

45 |

60 |

||

Use Cable with minimum rating (Amperes) |

|

|

|

|

||||

Tool Amperes |

|

|

|

|

|

|

||

0 |

- |

3.4 |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

3.5 |

- |

5.0 |

7.5 |

7.5 |

7.5 |

7.5 |

10 |

15 |

5.1 |

- |

7.0 |

10 |

10 |

10 |

10 |

15 |

15 |

7.1 |

- 12.0 |

15 |

15 |

15 |

15 |

20 |

20 |

|

12.1 |

- 20.0 |

20 |

20 |

20 |

20 |

25 |

– |

|

•CHECK for DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function—check for alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced. Do not use tool if switch does not turn it on and off.

•USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool may be hazardous when used on another tool. Consult the instruction manual for recommended accessories. The use of improper accessories may cause risk of injury to persons.

•NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

•NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool until it comes to a complete stop. Serious injury can result.

•DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors in these tools may spark and ignite fumes.

•STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE OF DRUGS or ALCOHOL. A moment of inattention while operating power tools may result in injury.

Additional Safety Rules For Miter Saws

WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace safety rules. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace safety rules. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

•DO NOT OPERATE THIS MACHINE until it is completely assembled and installed according to the instructions. A machine incorrectly assembled can cause serious injury.

•OBTAIN ADVICE from your supervisor, instructor, or another qualified person if you are not thoroughly familiar with the operation of this machine. Knowledge is safety.

•STABILITY. Make sure the miter saw is placed on a secure supporting surface and does not slip or move during use. If the mobility kit is installed, raise the moveable caster(s) so saw is in its stationary position.

•FOLLOW ALL WIRING CODES and recommended electrical connections to prevent shock or electrocution. Protect electric supply line with at least a 15 ampere time-delay fuse or a circuit breaker.

•MAKE CERTAIN the blade rotates in the correct direction. The teeth on the blade should point in the direction of rotation as marked on the saw.

•TIGHTEN ALL CLAMP HANDLES, knobs and levers prior to operation. Loose clamps can cause parts or the workpiece to be thrown at high speeds.

2

•BE SURE all blade and blade clamps are clean, recessed sides of blade clamps are against blade and arbor screw is tightened securely. Loose or improper blade clamping may result in damage to the saw and possible personal injury.

•ALWAYS USE A SHARP BLADE. Check the blade to see if it runs true and is free from vibration. A dull or a vibrating blade can cause damage to the machine and/or serious injury.”

•DO NOT OPERATE ON ANYTHING OTHER THAN THE DESIGNATED VOLTAGE for the saw. Overheating, damage to the tool and personal injury may occur.

•DO NOT WEDGE ANYTHING AGAINST THE FAN to hold the motor shaft. Damage to tool and possible personal injury may occur.

•DO NOT force cutting action. Stalling or partial stalling of motor can cause damage. To the machine or blade and/or serious injury.

•ALLOW THE MOTOR TO COME TO FULL SPEED prior to starting cut. Starting the cut too soon may cause damage to the machine or blade and/or serious injury.”

•NEVER CUT FERROUS METALS (Those with any iron or steel content) or masonry. Either of these can cause the carbide tips to fly off the blade at high speeds causing serious injury.

•DO NOT USE ABRASIVE WHEELS. The excessive heat and abrasive particles generated by them may damage the saw and cause personal injury.

•NEVER have any part of your body in line with the path of the saw blade. Personal injury will occur.

•NEVER apply blade lubricant to a running blade. Applying lubricant could cause your hand to move into the blade resulting in serious injury.

•DO NOT place either hand in the blade area when the saw is connected to the power source. Inadvertent blade activation may result in serious injury.

•DO NOT PERFORM FREE-HAND OPERATIONS (workpiece not supported by table and fence). Hold the work firmly against the fence and table. Free-hand operations on a miter saw could cause the workpiece to be thrown at high speeds, causing serious injury.

•NEVER REACH AROUND or behind the saw blade. A blade can cause serious injury.

•DO NOT reach underneath the saw unless it is unplugged and turned off. Contact with saw blade may cause personal injury.

•SECURE THE MACHINE TO A STABLE SUPPORTING SURFACE. Vibration can possibly cause the machine to slide, walk, or tip over, causing serious injury.

•USE ONLY CROSSCUT SAW BLADES recommended for miter saws. For best results, use only zero-degree or negative hook angles when using carbide-tipped blades. Do not use blades with deep gullets. These can deflect and contact the guard, and can cause damage to the machine and/or serious injury.

•USE ONLY BLADES OF THE CORRECT SIZE AND TYPE specified for this tool to prevent damage to the machine and/or serious injury.

•INSPECT BLADE FOR CRACKS or other damage prior to operation. A cracked or damaged blade can come apart and pieces can be thrown at high speeds, causing serious injury. Replace cracked or damaged blades immediately.

•CLEAN THE BLADE AND BLADE CLAMPS prior to operation. Cleaning the blade and blade clamps allows you to check for any damage to the blade or blade clamps. A cracked or damaged blade or blade clamp can come apart and pieces can be thrown at high speeds, causing serious injury.

•DO NOT use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the plastic guard. The polycarbonate material used in the guard is subject to attack by certain chemicals.

•ALWAYS USE THE KERF PLATE AND REPLACE THIS PLATE WHEN DAMAGED. Small chip accumulation under the saw may interfere with the saw blade or may cause instability of workpiece when cutting.

•USE ONLY BLADE CLAMPS specified for this tool to prevent damage to the machine and/or serious injury.

•CLEAN THE MOTOR AIR SLOTS of chips and sawdust. Clogged motor air slots can cause the machine to overheat, damaging the machine and possibly causing a short which could cause serious injury.

•KEEP ARMS, HANDS, AND FINGERS away from the blade to prevent severe cuts. Clamp all workpieces that would cause your hand to be within 6" of the saw blade.

•NEVER LOCK THE SWITCH in the “ON” position. Severe personal injury may result.

•TURN OFF THE MACHINE and allow the blade to come to a complete stop before raising the arm and prior to cleaning the blade area, removing debris in the path of the blade, before servicing or adjusting tool. A moving blade can cause serious injury.

•PROPERLY SUPPORT LONG OR WIDE WORKPIECES. Loss of control of the workpiece can cause injury.

•Never cross arms in front of blade while using tool. Always make a dry run (unpowered) before making a finish cut so that you can check the path of the blade or severe personal injury may result.

•ADDITIONAL INFORMATION regarding the safe and proper operation of power tools (i.e. a safety video) is available from the Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 (www. powertoolinstitute.com). Information is also available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201. Please refer to the American National Standards Institute ANSI 01.1 Safety Requirements for Woodworking Machines and the U.S. Department of Labor OSHA 1910.213 Regulations.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE TABLE AND AGAINST THE FENCE.

WARNING: NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE TABLE AND AGAINST THE FENCE.

CAUTION: Do not connect unit to electrical power source until complete instructions are read and understood.

CAUTION: Do not connect unit to electrical power source until complete instructions are read and understood.

CAUTION: Wear appropriate personal hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: Wear appropriate personal hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated timber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW. WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

ALWAYS WEAR EYE PROTECTION.

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

ON MOVING FENCE:

ALWAYS ADJUST FENCE PROPERLY BEFORE USE. Clamp small pieces before cutting. See manual.

ON GUARD:

DANGER – KEEP AWAY FROM BLADE.

ON UPPER GUARD:

PROPERLY SECURE BRACKET WITH BOTH SCREWS BEFORE USE.

ON TABLE: (2 PLACES)

WARNING: FOR YOUR OWN SAFETY READ INSTRUCTION MANUAL BEFORE OPERATING MITER SAW.

KEEP HANDS OUT OF PATH OF SAW BLADE. DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE. CHECK LOWER GUARD FOR PROPER CLOSING BEFORE EACH USE.

ALWAYS TIGHTEN ADJUSTMENT BEFORE USE. DO NOT PERFORM ANY OPERATION FREEHAND.

NEVER REACH IN BACK OF SAW BLADE. NEVER CROSS ARMS IN FRONT OF BLADE. TURN OFF TOOL AND WAIT FOR SAW BLADE TO STOP BEFORE MOVING WORKPIECE, CHANGING SETTINGS OR MOVING HANDS.

DISCONNECT POWER BEFORE CHANGING BLADE OR SERVICING.

TO REDUCE THE RISK OF INJURY, ALLOW SAW TO RETURN TO THE FULL UP POSITION AFTER EACH OPERATION. THINK! YOU CAN PREVENT ACCIDENTS.

3

Electrical Safety

The electric motor has been designed for one voltage only. Always check that the power supply corresponds to the voltage on the rating plate. 230 V AC means your tool will operate on alternating current. As little as 10% lower voltage can cause loss of power and can result in overheating. All DEWALT tools are factory tested; if this tool does not operate, check the power supply. Your DEWALT tool is double insulated, therefore no earth wire is required.

•Young children and the infirm. This appliance is not intended for use by young children or infirm persons without supervision. Young children should be supervised to ensure that they do not play with this appliance.

•Replacement of the supply cord. If the supply cord is damaged, it must be replaced by the manufacturer or an authorised DEWALT Service Centre in order to avoid a hazard.

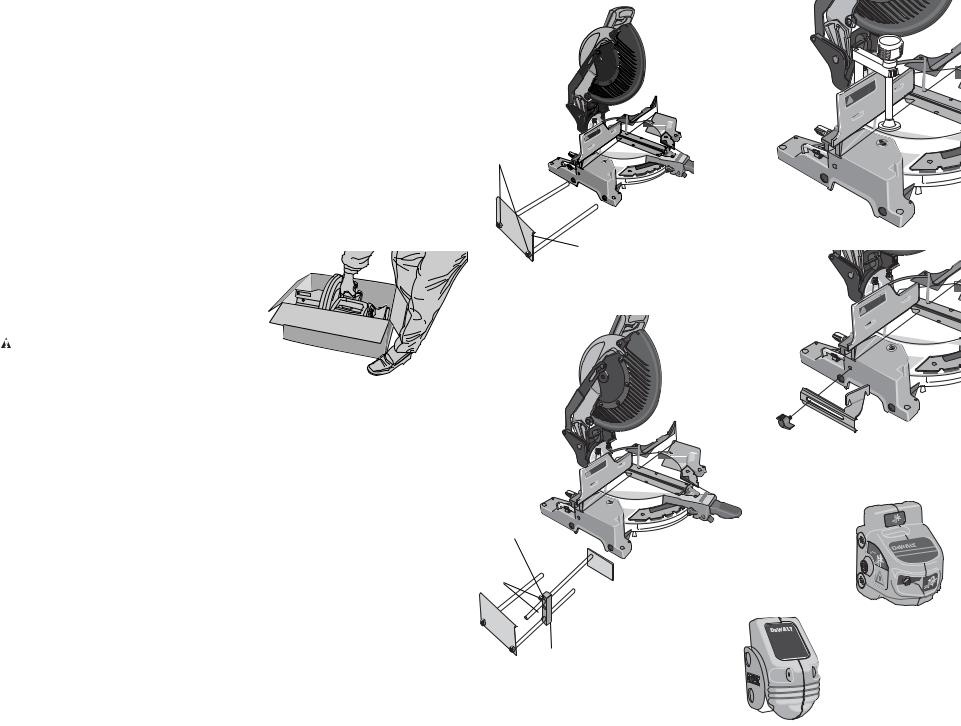

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have received all parts. In addition to this instruction manual, the carton should contain:

1.One No. DW713 miter saw with blade.

2.One blade wrench in wrench pocket shown in Figure 2.

3.One No. DW7053 Dust Bag.

Familiarization

Your miter saw is fully assembled in the carton.Open the box |

FIG. 1 |

and lift the saw out by the convenient carrying handle, as |

|

shown in Figure 1. |

|

Place the saw on a smooth, flat surface such as a workbench |

|

or strong table. |

|

Examine Figures 2 and 3 to become familiar with the saw and |

|

its various parts. The section on adjustments will refer to these |

|

terms and you must know what and where the parts are. |

|

CAUTION: Pinch Hazard. To reduce the risk of injury, keep |

|

thumb underneath the handle when pulling the handle down. |

|

The lower guard will move up as the handle is pulled down |

|

which could cause pinching. |

|

Press down lightly on the operating handle and pull out the lock down pin, as shown in Figure 4. Gently release the downward pressure and allow the arm to rise to its full height. Use the lock down pin when carrying the saw from one place to another. Always use the carrying handle to transport the saw or the hand indentations shown in Figure 3.

Specifications

DW7080

LOCKNUTS

END PLATE

DW7051

CAPACITY OF CUT |

|

50 degree miter left and right |

|

48 degree bevel left: 3 degree right |

|

0 degree miter |

|

Max. Height 88.9 mm (3.5") |

Result Width 88.9 mm (3.5") |

Max. Width 154.9 mm (6.1") |

Result Height 31.8 mm (1.25") |

45 degree miter |

|

Max. Height 88.9 mm (3.5") |

Result Width 61.0 mm (2.4") |

Max. Width 106.7 mm (4.2") |

Result Height 31.8 mm (1.25") |

45 degree bevel |

|

Max. Height 58.4 mm (2.3") |

Result Width 88.9 mm (3.5") |

Max. Width 154.9 mm (6.1") |

Result Height 19.0 mm (0.75") |

31.62 degree miter and 33.85 bevel |

|

Max. Width 33.4 mm (5.25") |

Result Height 22.9 mm (0.9") |

DRIVE |

|

230 Volt Motor |

|

1600 Watts |

Cut Helical Gears with Roller and Ball Bearings |

5000 RPM |

Automatic Electric Brake |

Carbide Tooth Blade |

|

TOP HOLE

(USE IF ON LEFT

SIDE)

KNOBS

BOTTOM HOLE

(USE IF ON RIGHT SIDE)

(USE IF ON RIGHT SIDE)

BRACKET

MATERIAL

CLAMP

DW7084

DW7187

DWS7085

4

Loading...

Loading...