Dewalt DW090, DW092 User Manual

WorldWide Web at www.dewalt.com |

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO |

|

|

|

|

|

|

||

ANTES DE USAR EL PRODUCTO. |

|

|

|

|

|

|

|

||

Questions? See us in the |

INSTRUCTION MANUAL |

GUIDE D'UTILISATION MANUAL DE INSTRUCCIONES |

|

|

|

|

DW090 Builder’s Level DW092 Transit Level |

Niveau de chantier DW090 Niveau théodolite DW092 |

DW090 Nivel para constructor DW092 Nivel de tránsito |

|

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 |

|

|||||||

|

(DEC03-CD-1) Form No. 621277-00 |

DW090, DW092 Copyright © 2003 |

|

||||||

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

Safety Instructions for Levels and Transits

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

DANGER: Do not operate during storms or near high voltage. NEVER attempt to use a grade rod in a storm or near overhanging electric wires.

DANGER: Do not operate during storms or near high voltage. NEVER attempt to use a grade rod in a storm or near overhanging electric wires.

DANGER: Do not use optical tools such as a telescope or transit to view a laser beam. Serious eye injury could result.

DANGER: Do not use optical tools such as a telescope or transit to view a laser beam. Serious eye injury could result.

DANGER: Always be sure to set up optical instruments so that any user will not intentionally or accidentally look through the instrument at the sun or any other source of bright light, keeping in mind that the sun moves throughout the day.

DANGER: Always be sure to set up optical instruments so that any user will not intentionally or accidentally look through the instrument at the sun or any other source of bright light, keeping in mind that the sun moves throughout the day.

•Store level and transit out of reach of children and other untrained persons.

•Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one level and transit, may create a risk of injury when used on another level and transit.

•Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel may result in injury. To locate your nearest DEWALT service center call 1-800-4-DEWALT (1-800-433-9258) or go to http://www.dewalt.com on the Internet.

•Do not operate the level and transit around children or allow children to operate the level and transit. Serious eye injury may result.

•Do not remove or deface warning labels.

•Position the level and transit securely on a level surface. Damage to the level and transit or serious injury could result if the level and transit fall.

WARNING: This product contains chemicals, including lead, known to the State of California to cause cancer, and birth defects or other reproductive harm. Wash hands after handling.

WARNING: This product contains chemicals, including lead, known to the State of California to cause cancer, and birth defects or other reproductive harm. Wash hands after handling.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

Components

BUILDER’S LEVEL DW090 (FIG. 1) |

TRANSIT LEVEL DW092 (FIG. 2, 3) |

A. Rubber Eyepiece Cap |

A. Rubber Eyepiece Cap |

B. Focusing Knob |

B. Focusing Knob |

C. Telescope Level Vial |

C. Telescope Level Vial |

D. Horizontal Circle |

D. Horizontal Circle |

E. Leveling Screws |

E. Leveling Screws |

F. Horizontal Tangent Drive |

F. Horizontal Tangent Drive |

G. Base Plate |

G. Base Plate |

|

H. Vertical Arc |

|

I. Vertical Index Pointer |

|

J. Vertical Tangent Screw |

|

K. Lock Lever |

To ensure the accuracy of your instrument, check to make sure it is calibrated often. See the

Field Calibration Check section of this manual.

ASSEMBLY

DEWALT Builder’s and Transit Levels are fully assembled at the factory. No further assembly is necessary. See the following instructions regarding the tripod.

DW090

FIG. 1 |

|

B |

FIG. 2 |

A |

J |

B |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

A |

C |

|

|

|

|

C |

|

|

|

|

|

|

|

F |

|

|

K |

|

D |

|

|

F |

|

|

|

|

|

|

|

||

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

E |

G |

|

G |

|

E |

|

|

|

|

|

DW092 |

FIG. 3 |

FIG. 4 |

P |

|

L |

||

|

|

N |

|

|

|

M |

Q |

|

|

|

|

|

|

H |

|

|

|

I |

O |

|

|

|

Tripod Setup

1.Loosen the straps (L) around the tripod legs (M). Lift the extension quick-release clamps

(N).

2.With the tripod closed, extend the legs so the tripod head is approximately eye level. Tighten the quick-release clamps.

3.Position the legs in a triangular position. Fix the legs firmly into the ground by pressing on the tripod shoes (O).

4.Gently remove the level from the carrying case. Note how the level is packed so that it can be placed back in the same position.

5.Carefully position the instrument in the approximate center of the tripod head (Q). Insert the tripod centering screw (Q) into the base plate (G), taking care to align the threads properly. Tighten the screw until the instrument fits snug on the tripod. Do not overtighten or strip the threads.

Leveling

1.If using the DW092 Transit Level, make sure the lock lever (K) is engaged.

2.Turn the telescope so that it is aligned with two of the leveling screws.

3.Holding the two leveling screws on one side of the the telescope, turn both knobs in opposite directions (moving both thumbs simultaneously toward or away from you), until the bubble is centered in the vial. (This loosens one screw while tightening the other.)

NOTE: If the instrument rocks, it is not securely mounted to the tripod or the tripod is not securely situated. You will NOT be able to level the instrument until it is secure.

4.Rotate the telescope 90˚ then only turn the third knob until the bubble is level again.

5.Rotate the telescope 90˚ again to make sure the bubble is still centered.

NOTE: If the instrument is properly leveled, the bubble should stay centered throughout the 360˚ rotation. If the instrument cannot be properly leveled, it needs to be checked by a qualified technician.

OPERATION

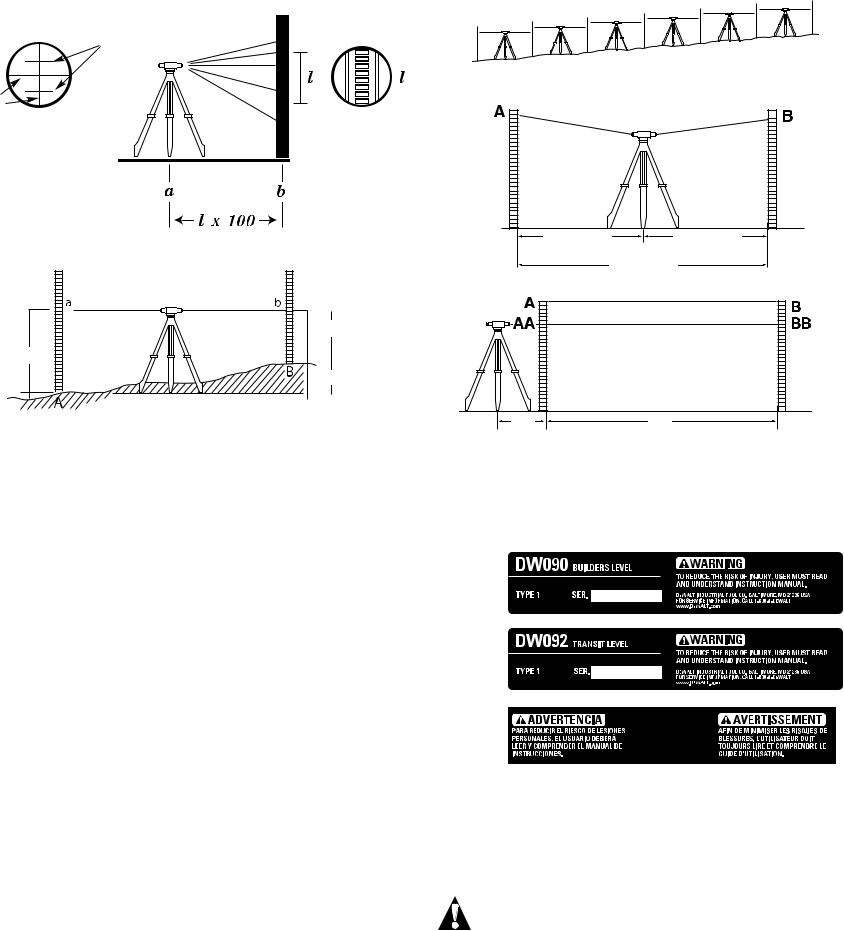

Stadia Measurement

The Builder’s and Transit Levels are equipped with a stadia reticle so you can make simple distance estimates. The stadia lines are located in the reticle (Figure 5). Sight the rod, read the two observations at the stadia lines, take the difference of these observations and multiply by 100 to estimate the distance between the rod and the center of the instrument.

Measuring Height Difference (Fig. 5, 6)

1.Set up the instrument at a point approximately halfway between points A and B (Fig. 6). NOTE: The reticle stadia lines can be used to optically compare the distances.

2.Position the rod vertically at point A. Take reading (a) [back sight] on the rod at point A.

3.Then sight the rod at point B and take reading (b) [foresight].

4.The difference (a – b) is the height difference (h) of B from A (Fig. 6).

Example: a – b = h

5.25 ft. – 3.25 ft. = 2.00 ft.

Therefore point B is 2.00 ft. higher than point A (the value of h will be negative if point B is lower than point A).

WHEN THE DISTANCE BETWEEN POINTS A AND B IS LARGE OR IF THE HEIGHT DISTANCE IS GREAT

1.Divide the distance into a number of sections and determine the height difference of each section (Fig. 7).

2.The height difference between points A and B is the total of the height differences of all the sections.

The general formula is:

altitude of known point + total of back sight values – total of foresight values = altitude of the required point

NOTE: This simple leveling technique has no error check. It is better to measure from A to B and then measure back to A so that the error of closure can be calculated.

Horizontal Circle and Reading (Fig. 1, 2)

Your instrument is equipped with an easy-to-read horizontal circle (D) for simple angle turning. This horizontal circle is turntable and is used for laying out or estimating rough angles. The horizontal circle is graduated in single degrees. The index line is located above the horizontal circle.

Use the plumb bob provided and set up the instrument directly above the surveying point. Sight the objective and use the horizontal tangent screw to bring crosshairs precisely on line with tangent objective. Using the index line of horizontal circle, take the angle reading. The vernier can be used for reading the circle in increments finer than single degrees. With the DW092 Transit Level, the vertical index pointer (I) is used to read your vertical angles.

PLEASE READ BELOW BEFORE USING YOUR NEW INSTRUMENT Although this instrument has gone through various checks and adjustments at the factory, instruments may come out of calibration during shipping. Because of this, we recommend that you have this instrument checked for calibration by a qualified instrument technician or follow the procedure described below.

Field Calibration Check (Fig. 8, 9)

1.Place two rods facing each other at points A and B at a distance of 50 - 80m apart (Fig. 8). Set up your instrument about halfway between A and B. If you are using a transit level, be sure that the lock lever is engaged.

2.Sight the rods and take readings on point A as A and on point B as B.

3.Set the instrument at point D which is about 2m from point A (Fig. 9).

4.Sight the rods at point A, take reading as AA. Then, sight the rod at point B, take reading as BB.

5.Use the following equation to calculate:

BB’ = AA – (A – B)

The instrument is in its perfect condition if BB’ = BB, otherwise, it needs adjustment.

FIG. 5 |

STADIA LINES |

TRAITS STADIMÉTRIQUES

LÍNEAS ESTADIMÉTRICAS

CROSSHAIRS |

FILS CROISÉS

HILOS DE

CRUZ FILAR

FIG. 6

3.25 ft.

5.25 ft.

2.00 ft.

Additional Operational Instructions for the Transit Level

The Transit Level has all the same functions and capabilities as the Builder’s Level. By disengaging the lock lever (K), the instrument is capable of measuring and working with vertical applications.

The vertical arc (H) is attached to the telescope axis and is read through the use of a vertical index pointer (I). Vertical angles can generally be read with a transit level to 45˚ above or below horizontal. This can be accomplished by using the vertical tangent screw (J) to set the crosshairs on the object being measured. Once this is set, do no move the instrument and take your vertical measurement.

Instruments with telescope tilting capabilities can be used in various applications such as fence posts, setting points in a line, plumbing building walls and setting columns.

TO PLUMB A VERTICAL COLUMN

1.Set up and level this instrument.

2.Sight a point at the bottom of the object that you are setting or checking and set your crosshairs on that point.

3.Raise the telescope so that it tracks along the intended line. If the object stays aligned with the vertical crosshair, the object that you are looking at is plumb.

4.To accurately complete this procedure, move and set up the instrument at a 90˚ angle from your original point and repeat the above procedure.

Specifications

|

Builder’s Level |

Transit Level |

|

DW090 |

DW092 |

TELESCOPE |

|

|

Magnification |

20x |

20x |

Objective Aperture |

22mm |

22mm |

Minimum Focus |

5 feet |

5 feet |

Stadia Ratio |

1:100 |

1:100 |

Transit Capabilities |

No |

Yes |

Leveling Head |

3 screws |

3 screws |

Tripod Thread |

5/8" x 11" |

5/8" x 11" |

Approximate Weight |

|

|

Instrument |

3 lbs. |

4 lbs. |

Instrument with case |

6 lbs. |

7 lbs. |

Horizontal Circle Accuracy |

±1˚ |

±1˚ |

Vertical Scale Accuracy |

±1˚ |

±1˚ |

MAINTENANCE

The Builder’s and Transit Levels are designed to be used generally in construction as well as for agriculture, mining and forestry industries. With the appropriate care, your instrument will need only minimal routine maintenance and minor adjustments under normal field use.

In case your instrument is damaged or abused, it should be taken to a qualified instrument repair facility or returned to DEWALT for repair.

1.The instrument should always be kept properly encased when not in use, for maximum protection.

2.Keep the instrument clean and free of dirt and moisture. After use, clean every part of the instrument completely before putting it back in its case.

3.Do not attempt to clean, oil or repair interior parts. Do not remove any lenses. The interior parts are not user serviceable.

4.After working in dusty locations, remove all dust from the lenses with a clean, soft tissue or cloth and brush the leveling and tangent screws threads with a small brush.

5.When working near moving equipment, never leave your instrument unattended.

6.Make sure not to over tighten the leveling screw, clamp screw or adjusting screw.

7.Always spread the tripod legs to insure a stable setup. When setting up your tripod on an incline, make sure two of the three legs are on the lower side of the incline. When setting up on a pavement or other hard surface, try to protect the legs from slipping by either making holes for the legs to sit in or blocking the legs.

8.It is recommended that a qualified service technician check the instrument periodically.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory for your tool, contact: DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286.

CAUTION: The use of any other accessory not recommended for use with this tool could be hazardous.

CAUTION: The use of any other accessory not recommended for use with this tool could be hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by authorized service centers or other qualified service personnel, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We will repair, without charge, any defects due to faulty materials or workmanship. For warranty repair information, call 1-800-4-DEWALT. This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

FIG. 7

|

|

|

|

F |

G |

B |

|

|

|

E |

|

||

|

|

D |

|

|

||

|

C |

|

|

|

||

A |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

FIG. 8 |

|

1/2 (L) |

1/2 (L) |

|

L = 50 - 80m |

FIG. 9 |

|

D |

|

L |

L |

2m |

|

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your DEWALT heavy duty industrial tool, simply return it to the participating seller within 30 days for a full refund. Please return the complete unit, transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT for a free replacement.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ SANS FRAIS LE : 1 800 4-DEWALT (1 800 433-9258)

Consignes de sécurité concernant les niveaux et les théodolites

AVERTISSEMENT ! Lire, comprendre et suivre toutes les directives précisées ci-dessous, y compris les consignes de sécurité, afin d’éviter les risques de choc électrique, d’incendie ou de blessure grave.

CONSERVER CES DIRECTIVES

DANGER : Ne pas utiliser pendant un orage ni près de lignes à haute tension. NE JAMAIS utiliser le tube jaugeur pendant un orage ni près de fils électriques suspendus.

DANGER : Ne pas utiliser pendant un orage ni près de lignes à haute tension. NE JAMAIS utiliser le tube jaugeur pendant un orage ni près de fils électriques suspendus.

DANGER : Ne pas utiliser un dispositif optique, tel qu’un télescope ou un théodolite, pour examiner le faisceau laser afin d’éviter de blesser grièvement les yeux.

DANGER : Ne pas utiliser un dispositif optique, tel qu’un télescope ou un théodolite, pour examiner le faisceau laser afin d’éviter de blesser grièvement les yeux.

DANGER : Toujours s’assurer d’installer les instruments optiques de manière à empêcher l’utilisateur de regarder, volontairement ou accidentellement, le soleil ou toute autre source de lumière intense à travers ceux-ci, étant donné que le soleil se déplace toute la journée.

DANGER : Toujours s’assurer d’installer les instruments optiques de manière à empêcher l’utilisateur de regarder, volontairement ou accidentellement, le soleil ou toute autre source de lumière intense à travers ceux-ci, étant donné que le soleil se déplace toute la journée.

•Ranger le niveau et le théodolite hors de la portée des enfants ou des personnes non qualifiées.

•N’utiliser que les accessoires recommandés par le fabricant pour le modèle concerné; un accessoire destiné à un niveau ou à un théodolite particulier peut devenir dangereux lorsqu’il est utilisé avec un autre.

•L’outil ne doit être réparé ou entretenu par le personnel qualifié seulement; toute maintenance effectuée par une personne non qualifiée pourrait entraîner des risques de blessure. Pour obtenir le numéro du centre de service DEWALT le plus près, composer le 1 800 4-DEWALT (1 800 433-9258) ou consulter le site Internet http://www.dewalt.com.

•Ne pas utiliser le niveau ou le théodolite en présence d’un enfant, ni autoriser les enfants à utiliser ces instruments afin d’éviter les blessures graves aux yeux.

•Ne pas retirer ni abîmer les étiquettes d’avertissement.

•S’assurer de bien déposer l’instrument sur une surface de niveau afin de l’empêcher de tomber et de s’endommager ou de blesser l’utilisateur.

AVERTISSEMENT : Ce produit contient des produits chimiques, y compris le plomb, qui, dans l’État de la Californie, sont reconnus comme étant susceptibles de causer le cancer, d’entraîner des malformations congénitales ou d’être nocifs pour le système reproductif.

AVERTISSEMENT : Ce produit contient des produits chimiques, y compris le plomb, qui, dans l’État de la Californie, sont reconnus comme étant susceptibles de causer le cancer, d’entraîner des malformations congénitales ou d’être nocifs pour le système reproductif.

Se laver les mains après chaque utilisation.

•Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils électriques. Porter des vêtements de protection et nettoyer les parties exposées du corps à l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

Composants

NIVEAU DE CHANTIER DW090 (FIG. 1)

A.Capuchon d’oculaires en caoutchouc

B.Bouton de mise au point

C.Fiole de niveau du télescope

D.Cercle horizontal

E.Vis de mise de niveau

F. Entraînement tangentiel horizontal G. Plaque de fixation

NIVEAU THÉODOLITE DW092 (FIG. 2, 3)

A.Capuchon d’oculaires en caoutchouc

B.Bouton de mise au point

C.Fiole de niveau du télescope

D.Cercle horizontal

E.Vis de mise de niveau

F.Entraînement tangentiel horizontal

G.Base

H.Arc vertical

I.Indicateur d’index vertical

J.Vis tangente verticale

K.Levier de verrouillage

Loading...

Loading...