Dewalt D28065N, D28115, D28115N, D28065 User Manual

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENOIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

E ®

D28065, D28065N, D28115, D28115N

Heavy-Duty Angle Grinders

Meuleuses & renvoi d'angle de type industriel

Esmeriladoras de &ngulo para trabajo pesado

Definitions: Safety Guidelines

The definitions below describe the level of severity br each

signal word. Please read the manual and pay attention to these

symbols.

_DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

i_WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

i_,CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

_ ARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

_ WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool Distractions can cause you to lose control

2} ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a powertool in a damp location isunavoidable,

use a ground fault circuit interrupter (GFCI) protected

supply. Use of a GFC/ reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the power tool's operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

SAFETY INSTRUCTIONS FOR

ALL OPERATIONS

Safety Warnings Common for Grinding,

Sanding, Wire Brushing, Polishing or

Abrasive, Cutting-Off Operations

a) This power tool is intended to function as a grinder,

sander, wire brush, polisher or cut-off tooL Read all safety

warnings, instructions, illustrations and specifications

provided with this power tool Failure to follow a//instructions

listed below may result in electric shock, fire and/or serious

injury.

b) Do not use accessories which are not specifically

designed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power

tool, it does not assure safe operation.

c) The rated speed of the accessory must be at least

equal to the maximum speed marked on the power tool

Accessories running faster than their rated speed can break

and fly apart.

d) The outside diameter and the thickness of your accessory

must be within the capacity rating of your power tool

Incorrectly sized accessories cannot be adequately guarded or

controlled.

e) The arbor size of wheels, flanges, backing pads or

any other accessory must properly fit the spindle of

the power tool Accessories with arbor holes that do not

match the mounting hardware of the power too/wi//run out of

balance, vibrate excessively and may cause loss of control

Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage or install an

undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from

the plane of the rotating accessory and run the power

tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

g) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of

stopping small abrasive or workpiece fragments. The eye

protection must be capable of stopping flying debris generated

by various operations. The dust mask or respirator must be

capable of filtrating particles generated by your operation.

Prolonged exposure to high intensity noise may cause hearing

loss.

h) Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal

protective equipment. Fragments of workpiece or of a

broken accessory may fly away and cause injury beyond

immediate area of operation.

i) Hold power tool by insulated gripping surfaces only,

when performing an operation where the cutting

accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make exposed

metal parts of the power tool "live" and could give the operator

an electrical shock.

j) Position the cord clear of the spinning accessory./f you

lose control, the cord may be cut or snagged and your hand or

arm may be pulled into the spinning accessory.

k) Never lay the power tool down until the accessory has

come to a complete stop. The spinning accessory may grab

the surface and pull the power tool out of your control

I) Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag

your clothing, pulling the accessory into your body.

m) Regularly clean the power tool's air vents. The motor's

fan will draw the dust inside the housing and excessive

accumulation of powdered metal may cause electrical hazards.

n) Do not operate the power tool near flammable materials.

Sparks could ignite these materials.

o) Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in electrocution

or shock.

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or snagged rotating

wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be fomed in the

direction opposite of the accessory's rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or pinched by the

workpiece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel

to climb out or kick out. The wheel may either jump toward or

away from the operator, depending on direction of the wheel's

movement at the point of pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool misuse and/or incorrect

operating procedures or conditions and can be avoided by taking

proper precautions as given below."

a) Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up.

The operator can control torque reaction or kickback forces, if

proper precautions are taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool

in direction opposite to the wheel's movement at the point of

snagging.

d) Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of

control

Safety Warnings Specific for Grinding and

Abrasive Cutting-Off Operations

a) Use only wheel types that are recommended for your

power tool and the specific guard designed for the

selected wheel Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

b) The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. Theguard helps

to protect operator from broken wheel fragments, accidental

contact with wheel, and sparks that could ignite clothing.

c)Wheels must be used only for recommended applications.

For example: do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral grinding,

side forces applied to these wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are of correct

size and shape for your selected wheel. Proper wheel

flanges support the wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be different from

grinding wheel flanges.

e) Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the

higher speed of a smaller tool and may burst.

Additional Safety Warnings Specific for

Abrasive Cutting-Off Operations

a) Do not 'yam" the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive depth

of cut. Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut and

the possibility of kickback or wheel breakage.

b) Do not position your body in line with and behind the

rotating wheel. When the wheel, at the point of operation, is

moving away from your body, the possible kickback may propel

the spinning wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut for any

reason, switch off the power tool and hold the power

tool motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off wheel from

the cut while the wheel is in motion otherwise kickback

may occur. Investigate and take corrective action to eliminate

the cause of wheel binding.

d) Do not restart the cutting operation in the workpiece.

Let the wheel reach full speed and carefully reenter the

cut. The wheel may bind, walk up or kickback if the power tool

is restarted in the workpiece.

e) Support panels or any oversized workpiece to minimize

the risk of wheel pinching and kickback. Large workpieces

tend to sag under their own weight. Supports must be placed

under the workpiece near the line of cut and near the edge of

the workpiece on both sides of the wheel

Use extra caution when making a "pocket cut" into

existing walls or other blind areas. The protruding wheel

may cut gas or water pipes, electrical wiring or objects that can

cause kickback.

Safety Warnings Specific for Sanding

Operations

a) Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when selecting

sanding paper. Larger sanding paper extending beyond the

sanding pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

Safety Warnings Specific for Polishing

Operations

a) Do not allow any loose portion of the polishing bonnet

or its attachment strings to spin freely. Tuck away or

trim any loose attachment strings. Loose and spinning

attachment strings can entangle your fingers or snag on the

workpiece.

Safety Warnings Specific for Wire

Brushing Operations

a) Be aware that wire bristles are thrown by the brush even

during ordinary operation. Do not overstress the wires

by applying excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or brush

with the guard. Wire wheel or brush may expand in diameter

due to work load and centrifugal fomes.

Additional Safety Rules for Grinders

i_ WARNING: The grinding wheel or accessory may loosen

during coast-down of the tool when shut off. if grinding wheel

or accessory loosens, it may dismount from the machine and may

cause serious personal injury.

• Use of accessories not specified in this manual is not

recommended and may be hazardous. Use of power boosters

that would cause the tool to be driven at speeds greater than its

rated speed constitutes misuse.

• Use clamps or anotherpractical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body leaves it unstable and may lead to loss of

control

• Avoid bouncing the wheel or giving it rough treatment. If this

occurs, stop the tool and inspect the wheel for cracks or flaws.

• Always handle and store wheels in a careful manner.

• Never cut into area that may contain electrical wiring or

piping. Serious injury may result.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Do not use Type 11 (flaring cup) wheels on this tool. Using

inappropriate accessories can result in injury.

• Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the tool

at all times.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Minimum Gauge for Cord Sets

Volts

Ampere Rating

More Not More

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 NotRecommended

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Total Length of Cord

in Feet (meters)

AWG

i_,WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

i_ WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do thb type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

A WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure. Direct particles away from face and body.

i_ WARNING: Always wear proper personal hearing protection

that conforms to ANSI $12.6 ($3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ................... volts

Hz................. hertz

min ............... minutes

- -- or DC... direct current

_) ................. Class I Construction

(grounded)

[] ................. Class II Construction no .................... no load

(double insulated)

.../min .......... per minute

BPM ............. beats per minute

IPM ............... impacts per minute

RPM ............. revolutions per

minute

sfpm ............. surface feet per minute

A...................... amperes

W..................... watts

"_,or AC ..........alternating

current

or AC/DC... alternating or

direct current

speed

n ...................... rated speed

..................... earthing

terminal

_, ..................... safety alert

symbol

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

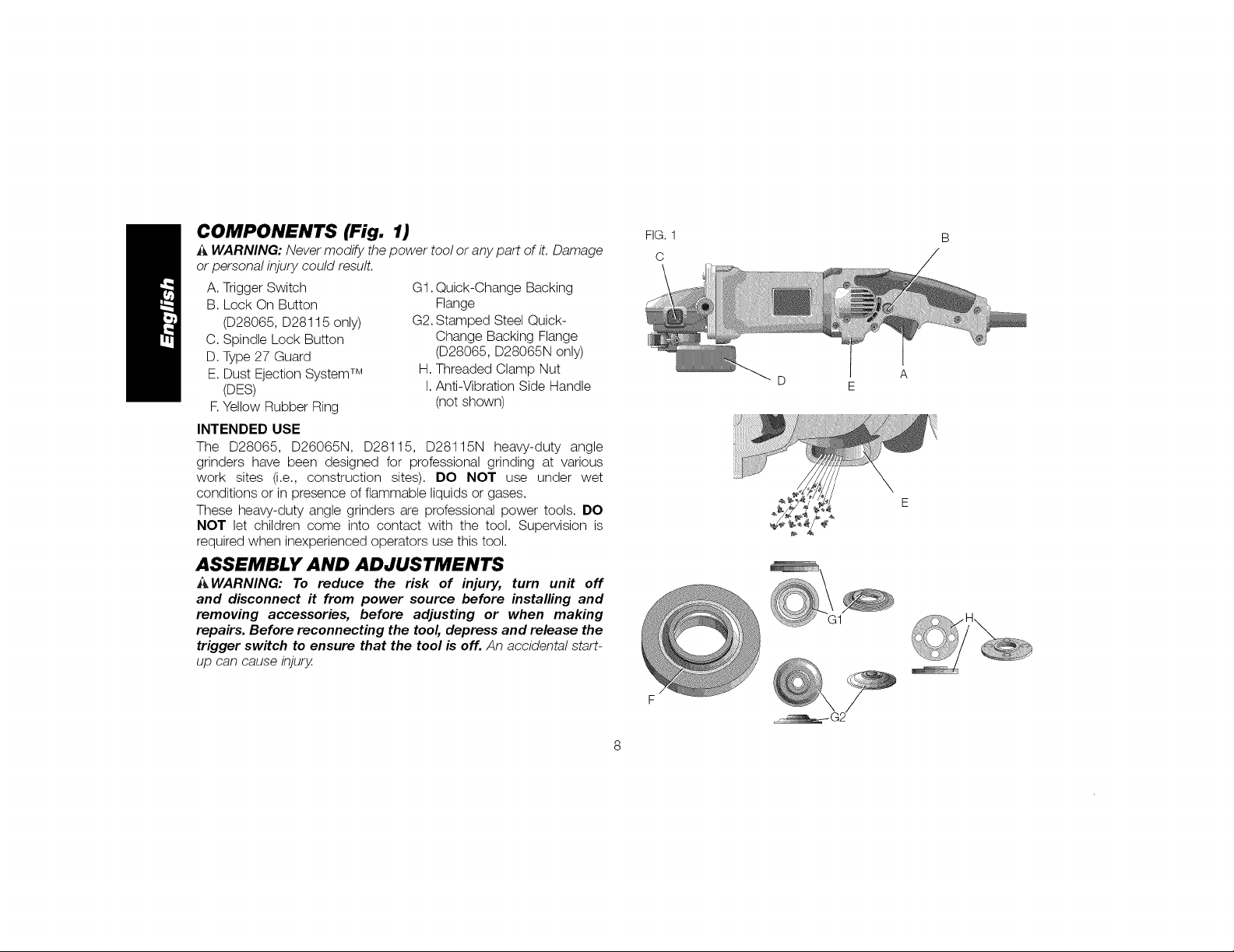

COMPONENTS (Fig. 1)

_ WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Trigger Switch

B. Lock On Button

(D28065, D28115 only)

C. Spindle Lock Button

D. Type 27 Guard

E. Dust Ejection SystemTM

(DES)

F.Yellow Rubber Ring

INTENDED USE

The D28065, D26065N, D28115,

grinders have been designed for professional grinding at various

work sites (i.e., construction sites). DO NOT use under wet

conditions or in presence of flammable liquids or gases.

These heavy-duty angle grinders are professional power tools. DO

NOT let children come into contact with the tool. Supervision is

required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

A WARNING: To reduce the risk of injury, turn unit off

and disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off. An accidental start-

up can cause injury.

G1. Quick-Change Backing

Flange

G2. Stamped Steel Quick-

Change Backing Flange

(D28065, D28065N only)

H. Threaded Clamp Nut

I.Anti-Vibration Side Handle

(not shown)

D28115N heavy-duty angle

FIG. 1

C

B

A

G1

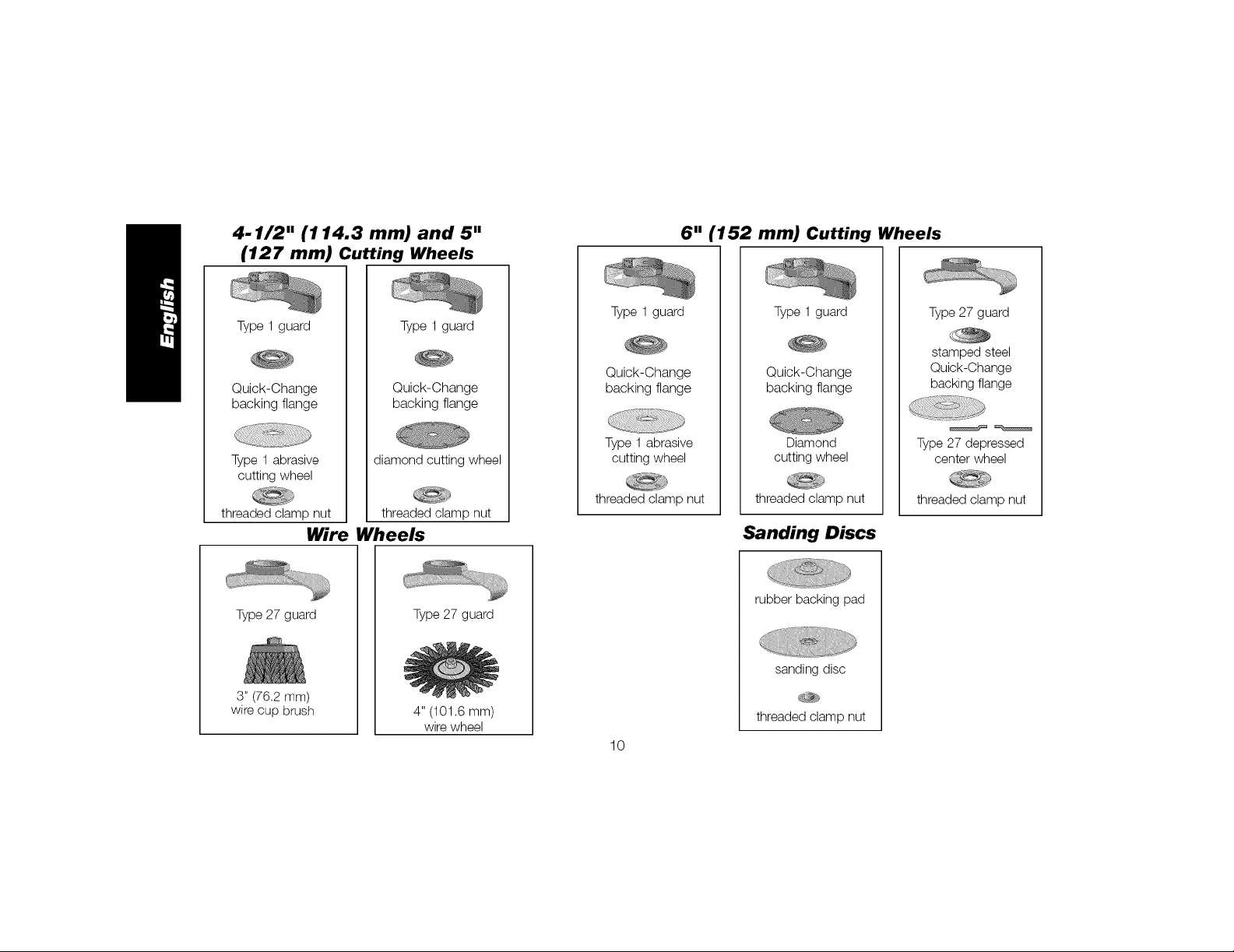

4-1/2" (114.3 mm) and 5" (127 mm)

Grinding Wheels

6" (152 mm) Grinding Wheels

Type 27 guard

Quick-Change

backing flange

Type 27 depressed

center wheel

threaded clamp nut

Type 27 guard

Type 27 hubbed wheel

Attaching Side Handle (FIG. 2)

The side handle (I)can be fitted to either side of the

gear case in the threaded holes, as shown. Before

using the tool, check that the handle is tightened

securely. Use a wrench to firmly tighten the side

handle.

FIG. 2

I

Type 27 guard

stamped steel

Quick-Change

backing flange

Type 27 depressed

center wheel

threaded clamp nut

Type 27 guard

Type 27 hubbed wheel

Rotating the Gear Case

1. Remove guard and flanges from tool.

2. Remove the four corner screws attaching the gear case to motor

housing.

3. Separating the gear case from motor housing not more than 1/4"

(6.35 mm), rotate the gear case head to desired position.

4-1/2" (114.3 mm) and 5"

(127 mm) Cutting Wheels

6" (152 mm) Cutting Wheels

Type 1guard

Quick-Change

backing flange

Type 1 abrasive

cutting wheel

threaded clamp nut

Wire Wheels

Type27 guard

3" (76,2 mm)

wire cup brush

Type 1guard

Quick-Change

backing flange

diamond cutting wheel

threaded clamp nut

Type27 guard

4" (101.6 mm)

wire wheel

Type 1guard

Quick-Change

backing flange

Type 1abrasive

cutting wheel

threaded clamp nut

10

Type 1 guard

Quick-Change

backing flange

Diamond

cutting wheel

threaded clamp nut

Sanding Discs

rubber backing pad

sanding disc

threaded clamp nut

Type27 guard

stamped steel

Quick-Change

backing flange

Type27 depressed

center wheel

threaded clamp nut

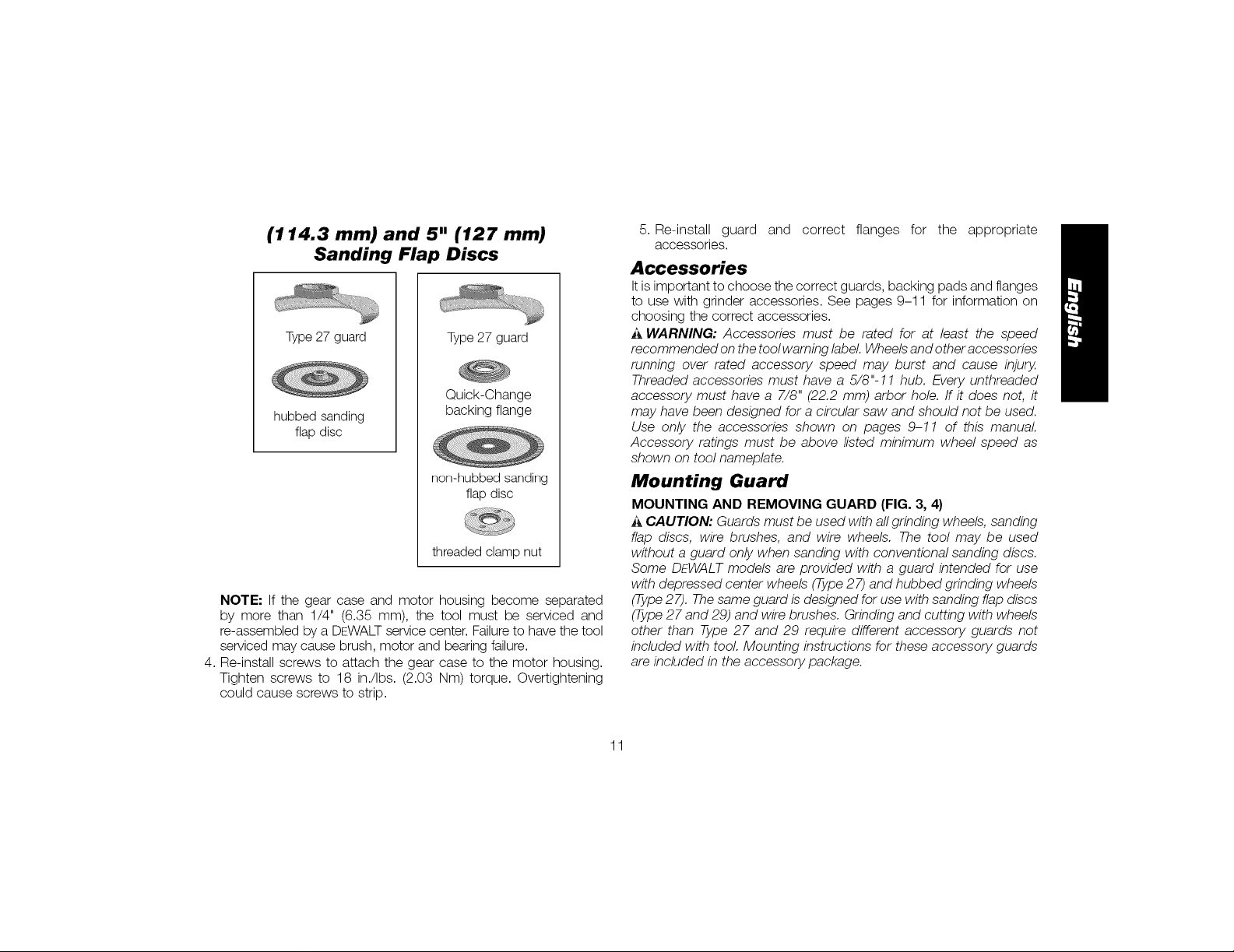

(114.3 mm) and 5" (127 mm)

Sanding Flap Discs

Type 27 guard

hubbed sanding

flap disc

NOTE: If the gear case and motor housing become separated

by more than 1/4" (6.35 mm), the tool must be serviced and

re-assembled by a DEWALTservice center. Failure to have the tool

serviced may cause brush, motor and bearing failure.

4. Re-install screws to attach the gear case to the motor housing.

Tighten screws to 18 in./Ibs. (2.03 Nm) torque. Overtightening

could cause screws to strip.

Type 27 guard

Quick-Change

backing flange

rlon-hubbedsanding

flap disc

threaded clamp nut

5. Re-install guard and correct flanges for the appropriate

accessories.

Accessories

Itis important to choose the correct guards, backing pads and flanges

to use with grinder accessories. See pages 9-11 for information on

choosing the correct accessories.

WARNING: Accessories must be rated for at least the speed

recommended on the toolwaming label Wheels and other accessories

running over rated accessory speed may burst and cause injury.

Threaded accessories must have a 5/8 "-11 hub. Every unthreaded

accessory must have a 7/8" (22.2 mm) arbor hole. If it does not, it

may have been designed for a circular saw and should not be used.

Use only the accessories shown on pages 9-11 of this manual

Accessory ratings must be above listed minimum wheel speed as

shown on tool nameplate.

Mounting Guard

MOUNTING AND REMOVING GUARD (FIG. 3, 4}

CAUTION: Guards must be used with all grinding wheels, sanding

flap discs, wire brushes, and wire wheels. The tool may be used

without a guard only when sanding with conventional sanding discs.

Some DEWALT models are provided with a guard intended for use

with depressed center wheels (Type 27) and hubbed grinding wheels

(Type27). The same guard is designed for use with sanding flap discs

(Type27 and 29) and wire brushes. Grinding and cutting with wheels

other than Type 27 and 29 require different accessory guards not

included with tool Mounting instructions for these accessory guards

are included in the accessory package.

11

1.Opentheguardlatch(J).Alignthelugs(K)on FIG.3

theguardwiththeslots(L)onthegear K.

case.

2.Pushtheguarddownuntiltheguardlugs

engageandrotatefreelyinthegrooveon

thegearcasehub.

3.Withtheguardlatchopen,rotatetheguard

(D)intothedesiredworkingposition.The J

guardbodyshouldbepositionedbetween

thespindleandtheoperatorto provide

maximumoperatorprotection.

4.Closetheguardlatchtosecuretheguard

onthegearcase.Youshouldnotbeable

torotatetheguardbyhandwhenthelatch D

isclosed.Donotoperatethegrinderwith

alooseguardortheclampleverinopenposition.

5.Toremovetheguard,opentheguardlatch,rotatetheguardso

thatthearrowsarealignedandpullupontheguard.

NOTE: The guard is pre-adjusted to the FIG.4

diameter of the gear case hub at the factory.

If, after a period of time, the guard becomes

loose, tighten the adjusting screw (M) with

clamp lever in the closed position.

A CAUTION: Do not tighten the adjusting screw with the clamp lever

in open position. Undetectable damage to the guard or the mounting

hub may result.

_ CAUTION: If guard cannot be tightened by adjusting clamp, do

not use tool and take the tool and guard to a service center to repair

or replace the guard.

OPERATION

WARNING: To reduce the risk of injury, turn unit off and

disconnect ff from power source before installing and removing

accessories, before adjusting or when making repairs. Before

reconnecting the tool, depress and release the trigger switch

to ensure that the tool is off. An accidental start-up can cause

injury.

Guards and Flanges

It is important to choose the correct guards and flanges to use with

the grinder accessories. See pages 9-11 for the correct accessories.

NOTE: Edge grinding and cutting can be performed with Type 27

wheels designed and specified for this purpose.

_ WARNING: Accessories must be rated for at least the speed

recommended on the toolwaming label Wheels and other accessories

running over rated accessory speed may burst and cause injury.

Every unthreaded accessory must have a 7/8" (22.2 mm) arbor hole.

flit does not, it may have been designed for a circular saw and should

not be used. Use only the accessories shown on pages 9-11.

Accessory ratings must be above listed minimum wheel speed as

shown on tool nameplate.

Trigger Switch (Fig. 1, 5, 6)

A CAUTION: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come to

a complete stop before laying the tool down.

NOTE: To reduce unexpected tool movement, do not switch the

tool on or off while under load conditions. Allow the grinder to run

up to full speed before touching the work surface. Lift the tool from

the surface before turning the tool off. Allow the tool to stop rotating

before putting it down.

12

ACAUTION: Before connecting the tool to a power source depress

and release the trigger switch (A)once without depressing the lock-on

button (B) to ensure that the switch is off. Depress and release the

trigger switch as described above after any interruption in power

supply to the tool, such as the activation of a ground fault interrupter,

throwing of a circuit breaker, accidental unplugging, or power failure.

To turn the tool on, depress the trigger switch (A). The tool will run

while the switch is depressed. Turn the tool off by releasing the

trigger switch.

LOCK-ON BUTTON (D28065, D28115} (FIG. 5}

The lock-on button (B)offers increased comfort FIG.5

in extended use applications. To lock the tool

on, depress the trigger switch (A), then push

the lock-on button (B).The tool will continue to

run after the trigger switch is released. To

unlock the tool, depress and release the trigger

switch. This will cause the tool to stop. B A

A CAUTION: Allow the tool to reach full

speed before touching tool to the work surface. Lift the tool from the

work surface before turning the tool off.

SPINDLE LOCK (FIG. 6)

The spindle lock (C) is provided to prevent the

spindle from rotating when installing or removing

wheels. Operate the spindle lock only when the

tool is turned off, unplugged from the power

supply, and has come to a complete stop. Do

not engage the spindle lock while the tool is

operating because damage to the tool will

result. To engage the lock, depress the spindle

lock button and rotate the spindle until you are

unable to rotate the spindle further.

FIG.6

Mounting and Using Depressed Center

Grinding Wheels and Sanding Flap Discs

MOUNTING AND REMOVING HUBBED WHEELS

Hubbed wheels install directly on the 5/8"-11 threaded spindle.

Thread of accessory must match thread of spindle.

1. Backing flange is retained to the grinder by an O-ring on the

spindle. Remove backing flange by pulling and twisting flange

away form the machine.

2. Thread the wheel on the spindle by hand.

3. Depress the spindle lock button and use a wrench to tighten the

hub of the wheel.

4. Reverse the above procedure to remove the wheel.

A CAUTION: Failure to properly seat the wheel before turning the

tool on may result in damage to the tool or the wheel

MOUNTING NON-HUBBED WHEELS (FIG. 7, 8)

Depressed center Type 27 grinding wheels must be used with

included flanges.

NOTE: The stamped steel quick-change FIG.7

backing flange (G2) is for use with D28065 G1,G2

and D28065N for Type 27 grinding wheels

only. Referto pages 9-11 for more information.

1. Install the stamped steel quick-change N

backing flange (G2) (D28065, D28065N

only) for Type 27 6" (152 mm) wheels or

the quick-change backing flange (G1) for

all other non-hubbed wheels on spindle

(N) with the raised section (pilot) against

the wheel. Be sure the backing flange

recess is seated onto the flats of the H _

spindle by pushing and twisting the flange

before placing wheel.

13

2.Placewheelagainstthebackingflange,centeringthewheelon

theraisedsection(pilot)ofthebackingflange.

3.Whiledepressingthespindlelockbutton,threadtheclamp

nut(H)onspindle.Ifthewheelyouareinstallingismore

than1/8"(3.17mm)thick,placethethreadedclampnut

onthespindlesothattheraisedsection(pilot)fitsintothe

centerof thewheel.Ifthewheelyouareinstallingis 1/8"

(3.17mm)thickorless,placethethreadedclampnutonthe

spindlesothattheraisedsection(pilot)isnotagainstthewheel.

4.Whiledepressingthespindlelockbutton, FIG.8

tightentheclampnutwithawrench. 1/4"wheels

5.Toremovethewheel,depressthespindle (6.35mm)

lockbuttonandloosenthethreaded

clampnutwithawrench, threadedclampnut

NOTE"Ifthewheelspinsaftertheclamp

nutistightened,checktheorientationofthe

threadedclampnut.Ifathinwheelisinstalled

withthepilotontheclampnutagainstthe Quick-Change

wheel,itwillspinbecausetheheightofthe backingflange

pilotpreventstheclampnutfromholdingthe 1/8"wheels

wheel. (3.17mm)

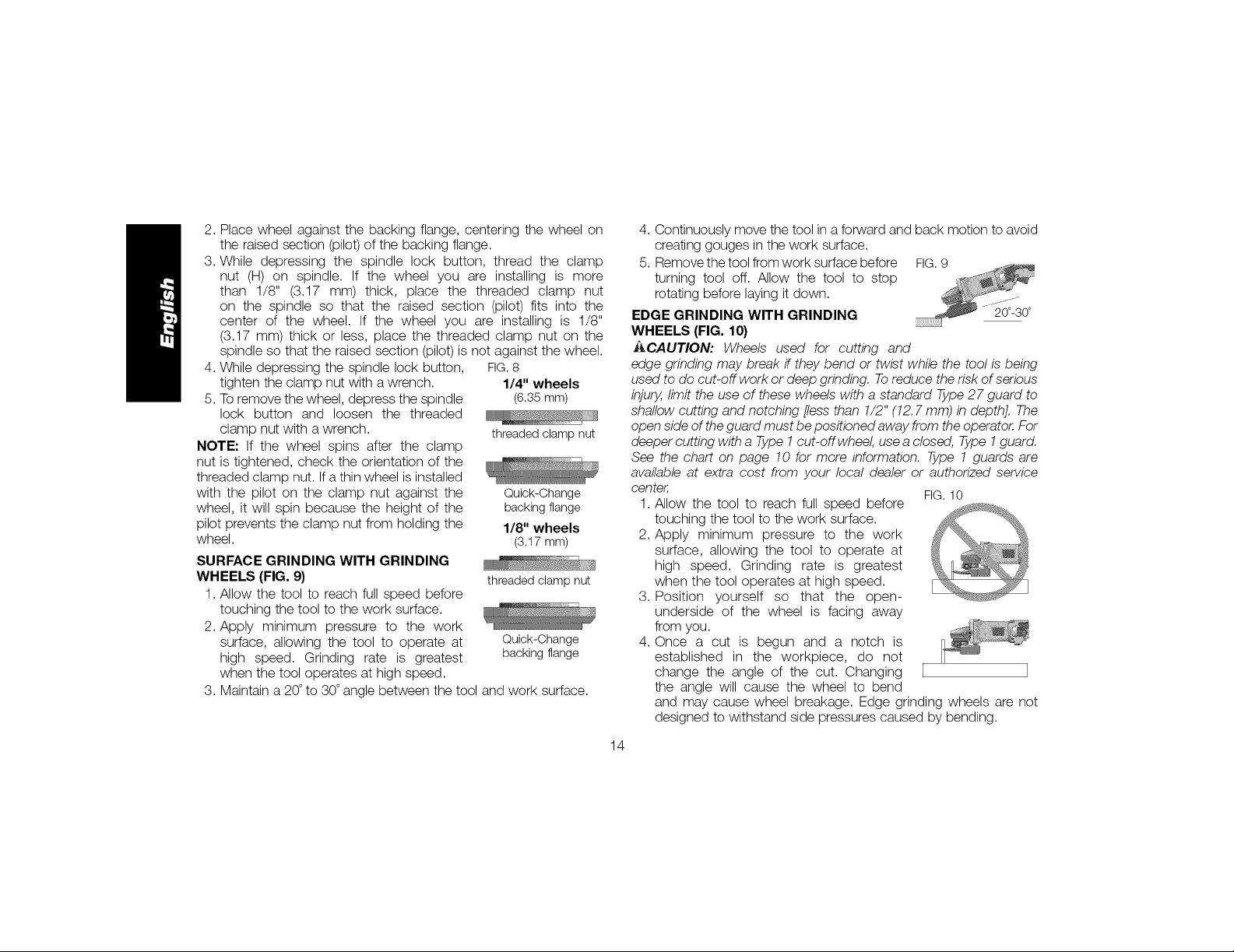

SURFACE GRINDING WITH GRINDING

WHEELS (FIG. 9) threadedclamp nut

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate at

high speed. Grinding rate is greatest

when the tool operates at high speed.

3. Maintain a 20°to 30°angle between the tool and work surface.

Quick-Change

backing flange

14

4. Continuously move the tool in a forward and back motion to avoid

creating gouges in the work surface.

5. Remove the tool from work surface before FIG.9

turning tool off. Allow the tool to stop

rotating before laying it down.

EDGE GRINDING WITH GRINDING 20°-30°

WHEELS (FIG. 10)

i_CAUTION: Wheels used for cutting and

edge grinding may break if they bend or twist while the tool is being

used to do cut-off work or deep grinding. To reduce the risk of serious

injury,limit the use of these wheels with a standard Type 27 guard to

shallow cutting and notching [less than 1/2" (12.7 mm) in depth]. The

open side of the guard must be positioned away from the operator. For

deeper cutting with a Type 1 cut-off wheel, use a closed, Type 1guard.

See the chart on page 10 for more information. Type 1 guards are

available at extra cost from your local dealer or authorized service

center. FIG.10

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate at

high speed. Grinding rate is greatest

when the tool operates at high speed.

3. Position yourself so that the open-

underside of the wheel is facing away

from you.

4. Once a cut is begun and a notch is

established in the workpiece, do not

change the angle of the cut. Changing

the angle will cause the wheel to bend

and may cause wheel breakage. Edge grinding wheels are not

designed to withstand side pressures caused by bending.

5.Removethetoolfromtheworksurfacebeforeturningthetooloff.

Allowthetooltostoprotatingbeforelayingitdown.

WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for side

pressures encountered with surface grinding. Wheel breakage and

injury may result.

SURFACE FINISHING WITH SANDING FLAP DISCS (FIG. 11)

3. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5° to 10° angle between FIG.11

the tool and work surface.

4. Continuously move the tool in a

forward and backward motion to

avoid creating gouges in the work

surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

MOUNTING SANDING BACKING PADS (FIG. 12}

CAUTION: Proper guard must be reinstalled for grinding wheel,

sanding flap disc, wire brush or wire wheel applications after

sanding applications are complete.

1. Place or appropriately thread backing pad (O) on the spindle.

2. Place the sanding disc (P) on the backing pad.

3. While depressing spindle lock, thread FIG.12

clamp nut (H) on spindle, piloting the H

raised hub on the clamp nut into the

center of sanding disc and backing pad. i

4. Tighten the clamp nut by hand. Then

depress the spindle lock button while \

turning the sanding disc until the sanding

disc and clamp nut are snug.

5. To remove the wheel, grasp and turn

the backing pad and sanding pad while

depressing the spindle lock button.

USING SANDING BACKING PADS (FIG. 13}

Choose the proper grit sandpaper for your application. Sandpaper

is available in various grits. Coarse grits yield faster material removal

rates and a rougher finish. Finer grits yield slower material removal

and a smoother finish.

Begin with coarse grit discs for fast, rough material removal. Move

to a medium grit paper and finish with a fine grit disc for optimal

finish.

Coarse 16 - 30 grit

Medium 36 - 80 grit

Fine Finishing 100 - 120 grit

Very Fine Finishing 150 - 180 grit

1. Allow the tool to reach full speed before touching tool to the work

surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5° to 15° angle between the tool and work surface.

The sanding disc should contact approximately one inch of work

surface.

15

4.Movethetoolconstantlyinastraightline FIG.13

topreventburningandswirlingofwork

surface.Allowingthetooltorestonthe

worksurfacewithoutmoving,ormoving

thetoolina circularmotioncauses

burningandswirlingmarksonthework

surface.

5.Removethetoolfromworksurfacebeforeturningtooloff.Allow

thetooltostoprotatingbeforelayingitdown.

Mounting and Using Wire Brushes

and Wire Wheels

Wire cup brushes or wire wheels screw directly on the grinder

spindle without the use of flanges. Use only wire brushes or wheels

provided with a 5/8"-11 threaded hub. A Type 27 guard is required

when using wire brushes and wheels.

_ CAUTION: Wear work gloves when handling wire brushes and

wheels. They can become sharp.

_ CAUTION: Wheel or brush must not touch guard when mounted

or while in use. Undetectable damage could occur to the accessory,

causing wires to fragment from accessory wheel or cup.

MOUNTING WIRE BRUSHES AND WIRE WHEELS

1. Thread the wheel on the spindle by hand.

2. Depress spindle lock button and use a wrench on the hub of the

wire wheel or brush to tighten the wheel.

3. To remove the wheel, reverse the above procedure.

_ CAUTION: Failure to properly seat the wheel hub before turning

the tool on may result in damage to tool or wheel.

USING WIRE CUP BRUSHES AND WIRE WHEELS

(FIG. 14, 15)

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

1. Allow the tool to reach full speed before FIG.14

touching the tool to the work surface.

2. Apply minimum pressure to work

surface, allowing the tool to operate

at high speed. Material removal rate is

greatest when the tool operates at high

speed.

3. Maintain a 5°to 10° angle between the tool and work surface for

wire cup brushes.

4. Maintain contact between the edge of the wheel and the work

surface with wire wheels.

5. Continuously move the tool in a forward and FIG.15

backward motion to avoid creating gouges in

the work surface. Allowing the tool to rest on

the work surface without moving, or moving the

tool in a circular motion causes burning and

swirling marks on the work surface.

6. Remove the tool from the work surface before

turning the tool off. Allow the tool to stop

rotating before setting it down.

i_ CAUTION: Use extra care when working over an edge, as a

sudden sharp movement of grinder may be experienced.

16

Mounting and Using Cutting

(Type 1) Wheels (Fig. 1)

Cutting wheels include diamond wheels and abrasive discs. Abrasive

cutting wheels for metal and concrete use are available. Diamond

blades for concrete cutting can also be used.

NOTE" All grinders that use Type 1 wheels use the quick-change

backing flange (G1).

_ WARNING: A closed, 2-sided cutting wheel guard is not included

with this tool and is required when using cutting wheels. Failureto use

proper flange and guard can result in injury resulting from wheel

breakage and wheel contact. See page 10 for more information.

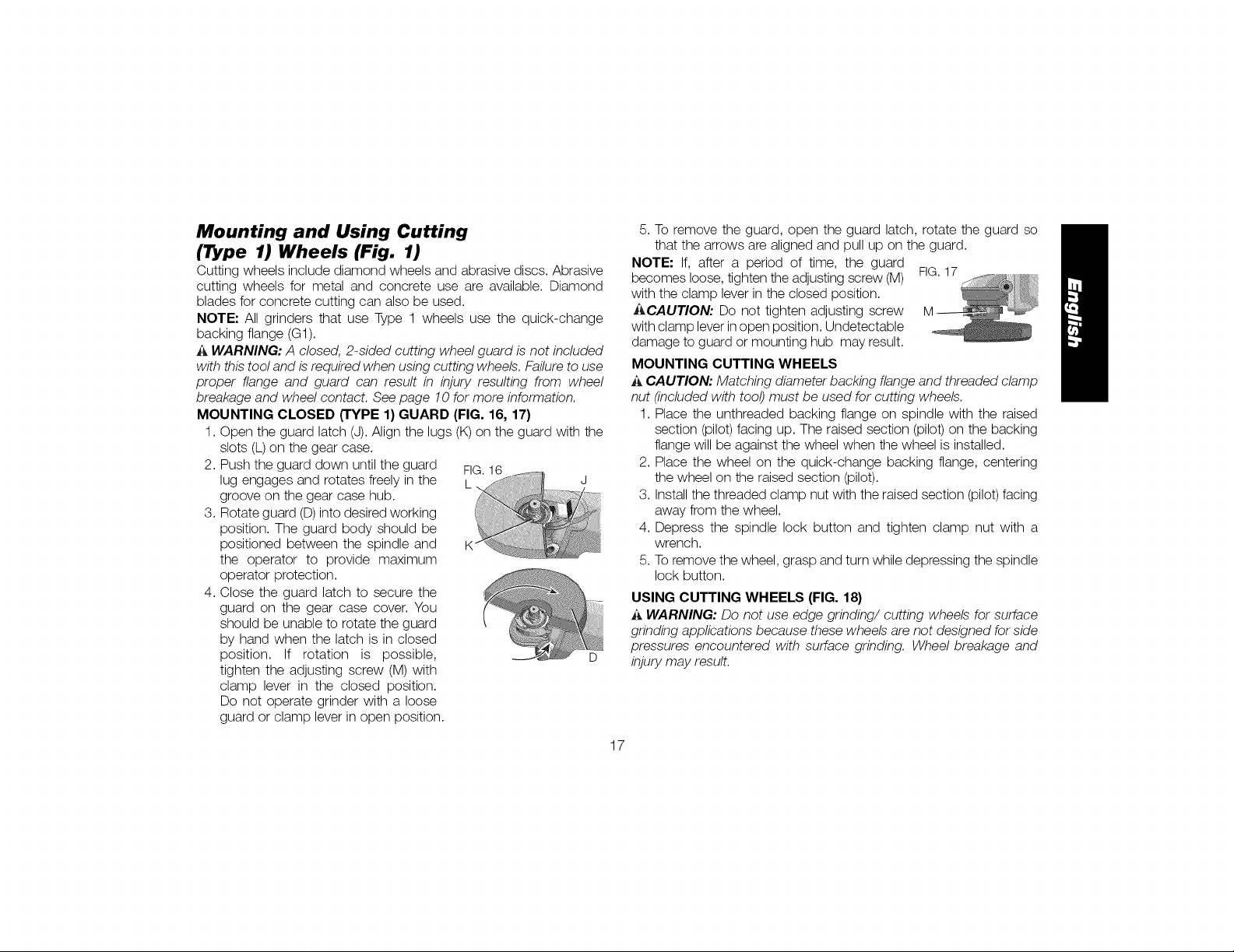

MOUNTING CLOSED (TYPE 1) GUARD (FIG. 16, 17)

1. Open the guard latch (J). Align the lugs (K)on the guard with the

slots (L) on the gear case.

2. Push the guard down until the guard FIG.16

lug engages and rotates freely in the I J

groove on the gear case hub.

3. Rotate guard (D) into desired working

position. The guard body should be

positioned between the spindle and

the operator to provide maximum

operator protection.

4. Close the guard latch to secure the

guard on the gear case cover. You

should be unable to rotate the guard

by hand when the latch is in closed

position. If rotation is possible,

tighten the adjusting screw (M) with

clamp lever in the closed position.

Do not operate grinder with a loose

guard or clamp lever in open position.

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

NOTE" If, after a period of time, the guard

becomes loose, tighten the adjusting screw (M) FIG.17

with the clamp lever in the closed position.

._CAUTION: Do not tighten adjusting screw M

with clamp lever inopen position. Undetectable

damage to guard or mounting hub may result.

MOUNTING CUTTING WHEELS

CAUTION: Matching diameter backing flange and threaded clamp

nut (included with tool) must be used for cutting wheels.

1. Place the unthreaded backing flange on spindle with the raised

section (pilot) facing up. The raised section (pilot) on the backing

flange will be against the wheel when the wheel is installed.

2. Place the wheel on the quick-change backing flange, centering

the wheel on the raised section (pilot).

3. Install the threaded clamp nut with the raised section (pilot) facing

away from the wheel.

4. Depress the spindle lock button and tighten clamp nut with a

wrench.

5. To remove the wheel, grasp and turn while depressing the spindle

lock button.

USING CUTTING WHEELS (FIG. 18)

i_ WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for side

pressures encountered with surface grinding. Wheel breakage and

injury may result.

17

1.Allowtooltoreachfullspeedbeforetouching

FIG. 18

tooltoworksurface.

2.Applyminimumpressureto worksurface,

allowingtooltooperateathighspeed.Cutting

rateisgreatestwhenthetooloperatesathigh

speed.

3.Onceacutisbegunandanotchisestablished

intheworkpiece,donotchangetheangle

of thecut.Changingtheanglewillcause

thewheelto bendandmaycausewheel

breakage.

I I

4.Removethetoolfromworksurfacebefore

turningtooloff.Allowthetooltostoprotating

beforesettingitdown.

MAINTENANCE

_ WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. Before

reconnecting the tool, depress and release the trigger switch

to ensure that the tool is off. An accidental start-up can cause

injury.

Cleaning

i_ WARNING: Blow dirt and dust out of all air vents with clean, dry

air at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

A WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

Accessories

WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALT recommended accessories should be used with

this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-DEiWALT (1-800-433-9258) or visit our website: www.

dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by a DEiWALTfactory service center, a DEWALT

authorized service center or other qualified service personnel. Always

use identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

18

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA" This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

DXXXXX,E,._ "]

ATLEA_r_i_ ALWAYSUSEP_0PE_R_S_I_ATORY_OTEml0N.

f

DEBE LEER Y COMPDENDE$_ EL MANUAL DE INST$_UCCiONES ANTES DE

UTBLJZAR EL PROUUET0. UTiLJCE DIEMPRE LAD GUARDAE APROPiADAS.

UTJLJDE MEMPRE LA PROTECDiDN ADECUADA PARA LA VISTA Y PARA

LAD VIAD RESPIRATOMAG. UTILICE SOLAMENTE LOS ACCEDO_IO$

CALIFICADOS DOMO MiNiM0 PAPA XXXXX RPM/MIN.

EUTILMATEUD DOlT UDE ET COMPDENDRE LE GUIDE D'UTILMATION.

TOUJOUDS UTitJGE_ LEDPROTECTEURS APPGOPRIES, TOUJDU_D

PODTED NE L'_UUJPEM E_T NEPDOTECTIO_ OCULAIRE ET _EDPiDATOJRE

APPM_PRJE. UT_LJDERSENLEMEt,_T DES ACCESS01RES CON_US POUR

UNE DEGJME DE _(XXXTPJMIN.

U_OE_STAN_ INSTHUCTION NNUAL ALWAYS USE P_0_R

D_WALT INDUSTRIP, L TOOL 80_ BALTIMORE, MI) 212_6 USA

F01_SERVICEINFOP,M_TU0_r CALLI-S0_-_Wt, LT www,_WALT_D_

PARA REDUCZGEL MESGO DE

LEMONED PERSONALES. SIEMP_E DE

AFiN DE D_DUIDE LED

19

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. Lire le mode d'emploi et

porter une attention particuliere a.ces symboles.

ADANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

,_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

_ATTENTION : indique une situation potentie//ement

dangereuse qui, si el/en'est pas evitee, pourrait entra_nerdes

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est fair

pour /'eviter, pourraff poser des risques de dommages

materiels.

J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL DEWALT, COMPOSE LE

NUMFt:ROSANS FRAIS : 1-800-4-DEWALT (1-800-433-9258}.

AVERTISSEMENT afin de reduire le de life

le mode d'emploi de I'outil.

risque

blessures,

Avertissements de sdcuritd gdndraux

pour les outils dlectriques

s_curit_ et toutes les directives. Le non-respect des

_k AVERTISSEMENT! life tous les avertissements de

avertissements et des directives pourrait se solder par un

choc dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUSLES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Le terme _outil dectrique _ cite dans les avertissements se rapporte

votre outil electrique a alimentation sur secteur (avec ill) ou par piles

(sansfi/).

1) SI_CURITI_ DU LIEU DE TRAVAIL

a) Ten#" I'aire de travail propre et bien _clair_e. Les Iieux

encombres ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d'outils _lectriques clans un

milieu d_flagrant, tel qu'en presence de liquides, de

gaz ou de poussi_res inflammables. Les outi/s e/ectriques

produisent des etincelles qui pourraient enflammer la poussiere

ou les vapeurs.

c) E-Ioignerles enfants et les personnes a proximit_ pendant

I'utilisation d'un outil _lectrique. Une distraction pourrait en

faire perdre la ma_trise a I'utilisateur.

2) SI_CURITI_ EN MATI#RE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre

la prise. Ne jamais modifier la fiche d'aucune faqon.

Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera

reduit par I'utilisation de fiches non modifiees correspondant

la prise.

2O

Loading...

Loading...