DeWalt D25980 User Manual

D25980

2 1

2

4 3

A1

5

6

7

8

9

10

10

11

11  12

12

A2 |

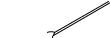

B1 |

1

3

3

13

4

B2

4

3

3

B3

2

14 |

E |

15 |

|

|

16 |

C

3

E N G L I S H

PAVEMENT BREAKER D25980

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make DEWALT one of the most reliable partners for professional power tool users.

Technical data

|

|

D25980 |

Voltage |

V |

220 |

|

|

|

Frequency |

Hz |

50-60 |

Power input |

W |

2,000 |

Impact rate |

min-1 |

870 |

Impact energy |

J |

68 |

Tool holder |

|

28 mm hex |

Weight |

kg |

31 |

The following symbols are used throughout this manual:

Denotes risk of personal injury, loss of life or damage to the tool in case of non-observance of the instructions in this manual.

Denotes risk of electric shock.

4

E N G L I S H

EC-Declaration of conformity

D25980 PAVEMENT BREAKER

DEWALT declares that these power tools have been designed in compliance with: 98/37/EC, 89/336/EEC, 73/23/EEC, 86/188/EEC, 2000/14/EC-Annex VIII, EN 60745-1, EN 60745-2-6, EN 55014-1, EN 55014-2, EN 61000-3-2 & EN 61000-3-3.

For more information, please contact DEWALT at the address below, or refer to the back of the manual.

Level of acoustic power according to 2000/14/EC (Article 12, Annex III No. 10):

|

|

|

D25980 |

LWA |

(measured) |

dB(A) |

104 |

LWA |

(guaranteed) |

dB(A) |

110 |

Tool specifications |

31 kg, 2,000 W (220 V) no = 870/min |

||

|

|

|

|

Laboratory report |

AB04C012 |

|

|

|

|

||

Notified body, delivering the certificate |

TÜV Rheinland Product and Safety GmbH (TRPS) |

||

Am Grauen Stein 1

D-51105 Köln, Germany

Level of sound pressure measured according to EN 60745-1 & EN 60745-2-6:

|

|

|

D25980 |

L |

pA |

dB(A)1) |

93 |

1) at the operator's ear

Take appropriate measures for the protection of hearing.

Weighted root mean square acceleration value:

|

|

D25980 |

Measured according to EN 50144 |

m/s2 |

5.4 |

Measured according to EN 60745-1 & EN 60745-2-6 |

m/s2 |

6.6 1) |

1) measurement uncertainty according to EN 12096: 1.5 m/s2 |

|

|

Director Engineering and Product Development

Horst Großmann

DEWALT, Richard-Klinger-Straße 11

D-65510, Idstein, Germany

5

E N G L I S H

Safety instructions

General power tool safety warnings

@Warning! Read all safety warnings and all instructions. Failure to follow the

warnings and instructions listed below may result in electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below refers to your mains operated (corded) power tool or battery operated (cordless) power tool.

1 Work area safety

a Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

bDo not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust.

Power tools create sparks which may ignite the dust or fumes.

cKeep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2 Electrical safety

aPower tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce risk of electric shock.

b Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is earthed or grounded.

cDo not expose power tools to rain or wet conditions.

Water entering a power tool will increase the

risk of electric shock.

dDo not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

eWhen operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

3 Personal safety

aStay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication.

A moment of inattention while operating power tools may result in serious personal injury.

bUse safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

cAvoid accidental starting. Ensure the switch is in the off position before plugging in.

Carrying power tools with your fi nger on the switch or plugging in power tools that have the switch on invites accidents.

d Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

eDo not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situations.

fDress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

gIf devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4 Power tool use and care

aDo not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

6

E N G L I S H

bDo not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

cDisconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

dStore idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

eMaintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

fKeep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

gUse the power tool, accessories and tool bits etc., in accordance with these instructions, taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous situation.

5 Service

aHave your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

Additional safety instructions for pavement breakers

•Ensure the chisel is secured in place before operating the tool.

•In cold-weather conditions or when the tool has not been used for a longer period of time, let the tool run with no load for several minutes before use.

•Always hold the tool firmly with both hands and ensure a secure stance. Always operate the tool with the side handle properly mounted.

•When working above ground level ensure the area below is clear.

•To prevent electric shock, check the working area for live wires before operation.

•Do not touch the chisel or the parts close to the chisel immediately after operation, as they may be extremely hot and cause burns to the skin.

•Always direct the power cable to the rear, away from the chisel.

•Keep the power cable away from the accessory. A power cable wrapped around the bit may cause electric shock.

•Do not wrap the power cable around your body.

•Do not allow children under 16 years of age to use this tool.

•Wear ear protectors. Exposure to noise can cause hearing loss.

•Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

•Do not strike jammed accessories with a hammer to dislodge them. Fragments of metal or material chips could dislodge and cause injury.

•Always switch off the tool when work is finished and before unplugging.

•Do not recondition accessories yourself. Chisel reconditioning should be done by a qualified specialist. Improperly reconditioned accessories could cause injury. Only sligthly worn accessories can be resharpened by grinding.

Residual risks

The following risks are inherent to the use of pavement breakers:

-injuries caused by touching the rotating parts or hot parts of the tool

In spite of the application of the relevant safety regulations and the implementation of safety devices, certain residual risks cannot be avoided. These are:

-Impairment of hearing.

-Risk of squeezing fingers when changing the accessory.

-Health hazards caused by breathing dust developed when working in concrete and/or masonry.

7

E N G L I S H

-Physical trauma due to inappropriate lifting and carrying of heavy equipment.

Package contents

The package contains: 1 Pavement breaker 1 Instruction manual 1 Exploded drawing

•Check for damage to the tool, parts or accessories which may have occurred during transport.

•Take the time to thoroughly read and understand this manual prior to operation.

Description (fig. A1 & A2)

D25980 pavement breaker has been designed for professional heavy duty demolition, chipping and chasing applications in concrete, brick, stone and other masonry materials.

Fig. A1

1On/off switch

2Side handle

3Tool retainer

4Tool holder

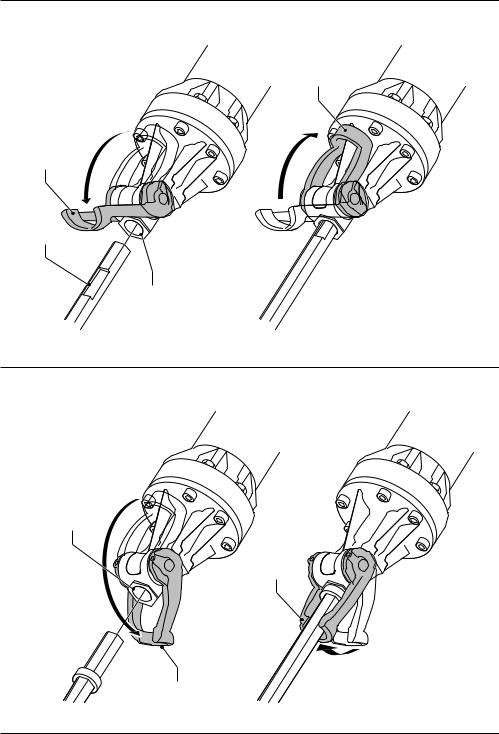

Optional accessories (fig. A2)

Various types of 28 mm hex. chisels are available as an option.

Consult your dealer for further information on the appropriate accessories.

5Pointed chisel

6Cold chisel

7Scaling tool

8Spade chisel

9Asphalt cutter

10Driver ground rod

11Shank tamper

12Plate tamper

Soft start feature

The soft start feature allows the impact rate to build up more slowly, thus preventing the chisel or point from "bouncing" around on the masonry when starting up.

Fully vibration-dampened handles

The dampers in the handles (2) absorb the vibrations transmitted to the user. This improves user comfort during the operation.

Active vibration control

The active vibration control neutralises rebound vibration from the hammer mechanism. Lowering hand and arm vibration, it allows more comfortable use for longer periods of time and extends the life of the unit.

Electrical safety

The electric motor has been designed for a limited voltage range. Always check that the power supply falls within the voltage range on the rating plate.

Your DEWALT tool is double insulated in accordance with EN 60745; therefore no earth wire is required.

Using an extension cable

If an extension cable is required, use an approved extension cable suitable for the power input of this tool (see technical data). The minimum conductor size is 1.5 mm2.

When using a cable reel, always unwind the cable completely.

Also refer to the table below.

Conductor size (mm2) |

Cable rating (amperes)) |

|

|

||||||

0.75 |

|

|

|

6 |

|

|

|

|

|

1.00 |

|

|

|

10 |

|

|

|

|

|

1.50 |

|

|

|

15 |

|

|

|

|

|

2.50 |

|

|

|

20 |

|

|

|

|

|

4.00 |

|

|

|

25 |

|

|

|

|

|

|

|

|

|

Cable length (m)) |

|

|

|

||

|

|

|

|

7.5 |

15 |

25 |

30 |

45 |

60 |

|

|

|

|

|

|||||

oltage |

Amperes |

Cable rating (amperes |

|

|

|||||

115 |

0 |

- |

2.0 |

6 |

6 |

6 |

6 |

6 |

10 |

|

2.1 |

- |

3.4 |

6 |

6 |

6 |

6 |

15 |

15 |

|

3.5 |

- |

5.0 |

6 |

6 |

10 |

15 |

20 |

20 |

|

|

|

|

|

|

|

|

|

|

|

5.1 |

- |

7.0 |

10 |

10 |

15 |

20 |

20 |

25 |

|

7.1 |

- 12.0 |

15 |

15 |

20 |

25 |

25 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

12.1 |

- 20.0 |

20 |

20 |

25 |

- |

- |

- |

|

230 |

0 |

- |

2.0 |

6 |

6 |

6 |

6 |

6 |

6 |

|

|

|

|

|

|

|

|

|

|

|

2.1 |

- |

3.4 |

6 |

6 |

6 |

6 |

6 |

6 |

|

3.5 |

- |

5.0 |

6 |

6 |

6 |

6 |

10 |

15 |

|

|

|

|

|

|

|

|

|

|

|

5.1 |

- |

7.0 |

10 |

10 |

10 |

10 |

15 |

15 |

|

7.1 |

- 12.0 |

15 |

15 |

15 |

15 |

20 |

20 |

|

|

12.1 |

- 20.0 |

20 |

20 |

20 |

20 |

25 |

- |

|

8

Loading...

Loading...