Page 1

Overview

The LB1922 is a single-chip drive circuit that provides the

direct PWM drive output appropriate for the power

brushless motors used in office automation equipment. It

provides a variety of peripheral circuits on chip, including

a speed control circuit and an FG amplifier. It is optimal

in systems that use a 12-V power supply.

Package Dimensions

unit: mm

3147A-DIP28HS

Monolithic Digital IC

Ordering number : EN5679

63097HA(OT) No. 5679-1/10

SANYO: DIP28HS

[LB1922]

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

Three-Phase Brushless Motor Driver

for Office Automation Applications

LB1922

Parameter Symbol Conditions Ratings Unit

Supply voltage

V

CC

20 V

V

M

20 V

Output current I

O

T ≤ 100 ms 3.1 A

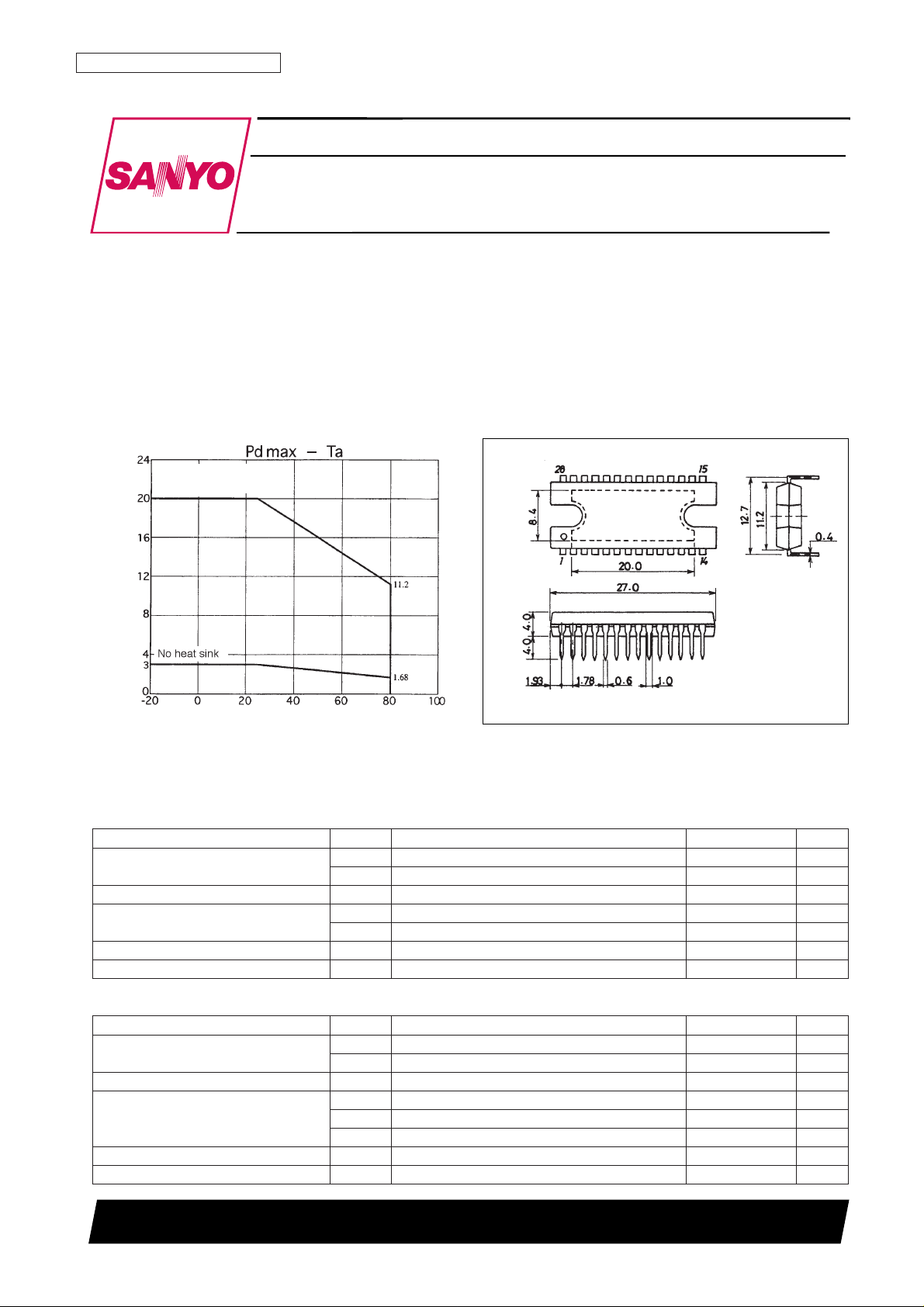

Allowable power dissipation

Pd max1 Independent IC 3 W

Pd max2 With an arbitrarily large heat sink 20 W

Operating temperature Topr –20 to +80 °C

Storage temperature Tstg –55 to +150 °C

Specifications

Absolute Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Supply voltage range

V

CC

9.5 to 18 V

V

M

9 to 18 V

FG Schmitt output applied voltage V

FGS

0 to 8 V

I

O

1 7 V output 0 to –20 mA

Fixed-voltage output current I

O

2 5 V output 0 to –20 mA

I

O

3 4 V output 0 to –15 mA

FG Schmitt output current I

FGS

0 to 5 mA

Lock detection output current I

LD

0 to 20 mA

Allowable Operating Ranges at Ta = 25°C

With an arbitrarily

large heat sink

Allowable power dissipation, Pd max – W

Ambient temperature, Ta – °C

Page 2

No. 5679-2/10

LB1922

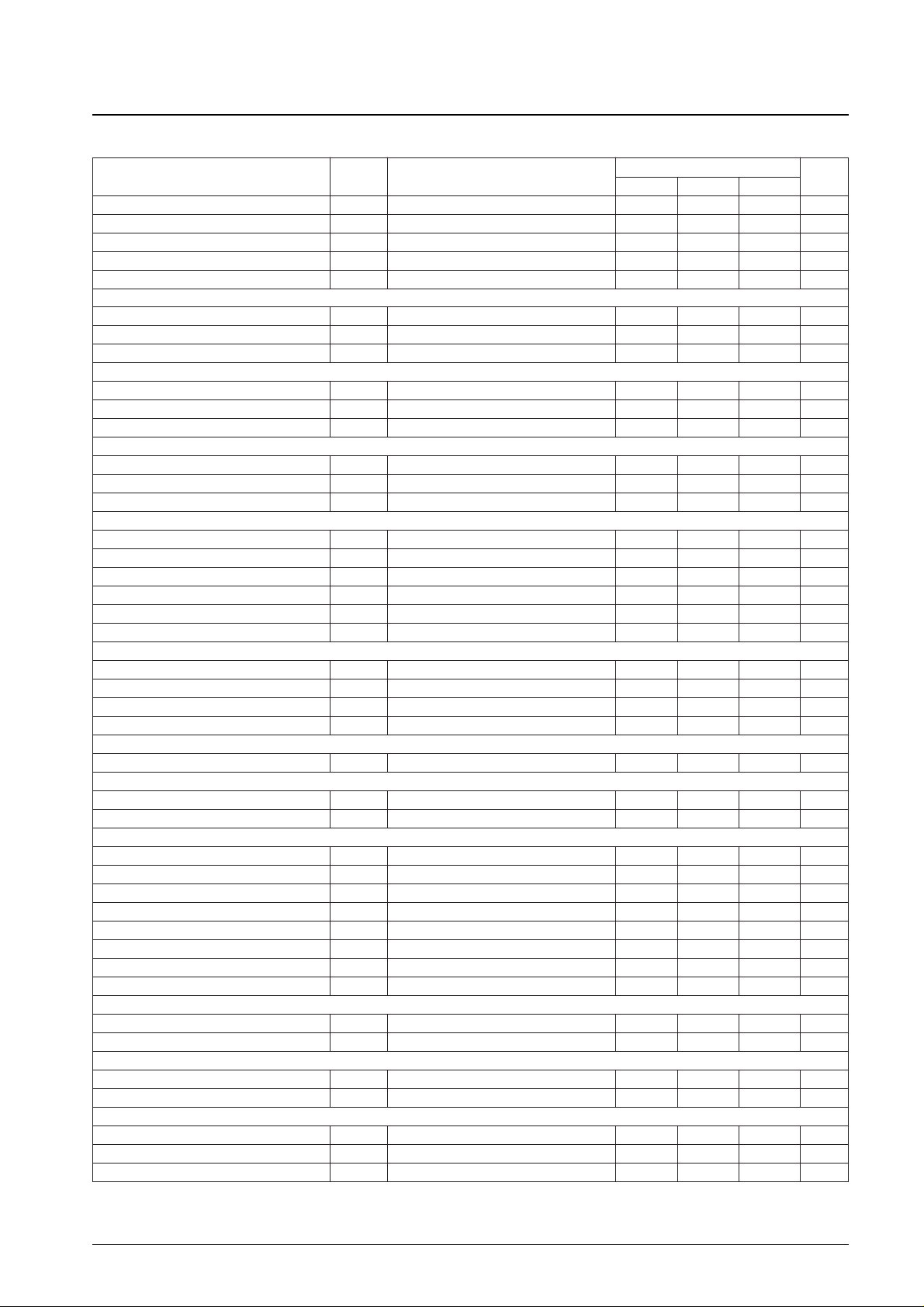

Parameter Symbol Conditions

Ratings

Unit

min typ max

Current drain 1 I

CC

1 34 50 mA

Current drain 2 I

CC

2 In stop mode 8 11 mA

Output saturation voltage 1 V

O

(sat)1 IO= 1 A, VCC= VM= 10.5 V 2.0 3.0 V

Output saturation voltage 2 V

O

(sat)2 IO= 2 A, VCC= VM= 10.5 V 2.7 4.2 V

Output leakage current I

O

leak 100 µA

[7-V Fixed-Voltage Output]

Output voltage V

HIO

= –10 mA 6.65 7.0 7.35 V

Line regulation ∆V

H

1 VCC= 9.5 to 18 V 50 200 mV

Load regulation ∆V

H

2 IO= –5 to –20 mA 40 200 mV

[5-V Fixed-Voltage Output]

Output voltage V

XIO

= –5 mA 4.45 4.80 5.15 V

Line regulation ∆V

X

1 VCC= 9.5 to 18 V 50 200 mV

Load regulation ∆V

X

2 IO= –5 to –20 mA 5 200 mV

[4-V Fixed-Voltage Output]

Output voltage V

FGIO

= –5 mA 3.65 4.0 4.35 V

Line regulation ∆V

FG

1 VCC= 9.5 to 18 V 40 200 mV

Load regulation ∆V

FG

2 IO= –5 to –15 mA 110 200 mV

[Hall Amplifier]

Input bias current I

HB

–4 –1 µA

Common-mode input voltage range V

ICM

1.5 5.1 V

Hall input sensitivity 60 mVp-p

Hysteresis ∆V

IN

8 14 24 mV

Input voltage (low

→ high) V

SLH

7 mV

Input voltage (high → low) V

SHL

–7 mV

[Oscillator]

Output high-level voltage V

OH(CR)

2.8 3.1 3.4 V

Output low-level voltage V

OL(CR)

0.8 1.1 1.4 V

Oscillator frequency f

(CR)

R = 56 kΩ, C = 1000 pF 15 kHz

Amplitude V

(CR)

2.0 Vp-p

[Current Limiter Operation]

Limiter V

CC-VM

0.4 0.5 0.6 V

[Thermal Shutdown Operation]

Thermal shutdown operating temperature TSD Design target value 150 180 °C

Hysteresis ∆TSD 50 °C

[FG Amplifier]

Input offset voltage V

IO(FG)

–10 +10 mV

Input bias current I

B(FG)

–1 +1 µA

Output high-level voltage V

OH(FG)IFG

= –2 mA 5.5 6 V

Output low-level voltage V

OL(FG)IFG

= 2 mA 1 1.5 V

FG input sensitivity Gain: 100 × 3 mV

Following stage Schmitt amplitude 100 180 250 mV

Operating frequency range 2 kHz

Open-loop gain f

(FG)

= 2 kHz 45 51 dB

[FGS Output]

Output saturation voltage 1 V

O(FGS)IO(FGS)

= 2 mA 0.1 0.5 V

Output leakage current I

L(FGS)VO

= 5 V 10 µA

[Speed Discriminator]

Output high-level voltage V

OH(D)

4.0 4.3 V

Output low-level voltage V

OL(D)

0.8 1.1 V

[PLL Output]

Output high-level voltage V

OH(P)

3.2 3.5 3.8 V

Output low-level voltage V

OL(P)

1.2 1.5 1.8 V

[Number of Counts] 512

Electrical Characteristics at Ta = 25°C, VCC= VM= 12 V

Continued on next page.

Page 3

No. 5679-3/10

LB1922

Parameter Symbol Conditions

Ratings

Unit

min typ max

[Lock Detection]

Output low-level voltage V

OL(LD)ILD

= 10 mA 0.15 0.5 V

Lock range 6.25 %

[Integrator]

Input bias current I

B(INT)

–0.4 +0.4 µA

Output high-level voltage V

OH(INT)

3.7 4.3 V

Output low-level voltage V

OL(INT)

0.8 1.2 V

Open-loop gain 60 dB

Gain-bandwidth product 1.6 MHz

Reference voltage –5% V

X

/2 +5% V

[Crystal Oscillator]

Operating frequency range f

OSC

1 10 MHz

[Start/Stop Pin]

Input high-level voltage V

IH(S/S)

4.0 V

Input low-level voltage V

IL(S/S)

1.5 V

Pull-down resistance R

D(S/S)

30 50 70 kΩ

[Forward/Reverse Pin]

Input high-level voltage V

IH(F/R)

4.0 V

Input low-level voltage V

IL(F/R)

1.5 V

Hysteresis ∆V

IN

0.5 V

Pull-down resistance R

D(F/R)

30 50 70 kΩ

Continued from preceding page.

Truth Table

Pin Assignment

Note: A high input is defined as IN+> IN–.

Source → sink

F / R = L F / R = H

IN1 IN2 IN3 IN1 IN2 IN3

1 OUT2 → OUT1 H L H L H L

2 OUT3 → OUT1 H L L L H H

3 OUT3 → OUT2 H H L L L H

4 OUT1 → OUT2 L H L H L H

5 OUT1 → OUT3 L H H H L L

6 OUT2 → OUT3 L L H H H L

Page 4

No. 5679-4/10

LB1922

Pin Functions

Pin No. Pin Function

1 5 V 5-V power supply.

2 7 V 7-V power supply

3 V

CC

Power supply for all blocks other than the output block

4 FG

IN

+

FG pulse input (4-V power supply pin)

5 FG

IN

–

FG pulse input

6 FG

OUT

FG amplifier output

7 CR PWM oscillator frequency setting

8 OUT1 Output 1

9 OUT2 Output 2

10 OUT3 Output 3

11 GND2 Ground for the output block

12 F/R

Forward/reverse control

Forward: low, reverse: high

13 S/S

Start/stop control

Start: low, stop: high

14 V

M

Output block power supply. This pin is also used for output current detection. The output current is converted to a

voltage and detected by inserting a resistor (Rf) between this pin and V

CC

.

20, 19 IN1

+

, IN1–Hall input for OUT1

18, 17 IN2

+

, IN2–Hall input for OUT2

16, 15 IN3

+

, IN3–Hall input for OUT3

21 X’tal Crystal oscillator. Connect a crystal oscillator to this pin.

22 GND1 Ground for all circuits other than the output block.

23 LD

Lock detection

Outputs a low level when the motor speed is within the lock range, i.e. within ±6.25% of the set speed.

24 D

OUT

Speed discriminator output

Outputs a high level on overspeed.

25 INT

IN

Integrator input

26 INT

OUT

Integrator output (speed control pin)

27 P

OUT

PLL output

28 FGS

OUT

FG amplifier output (After the Schmitt circuit)

The following formula gives the relationship between the crystal oscillator frequency (f

OSC

) and the FG frequency fFC.

fFC(servo)= f

OSC

/(ECL divided by 16 times the number of counts)

= f

OSC

/8192

External Crystal Oscillator Circuit

External Constants (Provided for reference only.)

However, a crystal with a ratio between the impedance at the crystal

fundamental frequency fo and the impedance at the third harmonic

frequency (3fo) of at least 1:5 must be used.

Xtal (MHz) C1 (pF) C2 (pF) R (kΩ)

3 to 4 39 82 0.82

4 to 5 39 82 1.0

5 to 7 39 47 1.5

7 to 10 39 27 2.0

Page 5

LB1922 Functional Description and Notes on External Components

1. Speed control circuit

Speed control in this IC is implemented with the combination of a speed discriminator circuit and a PLL circuit. The

speed discriminator circuit outputs an error output once every two FG periods using a charge pump technique. The

PLL circuit outputs a phase error once every FG period, also using a charge pump technique. As compared to the

earlier technique of only using a speed discriminator circuit, the combination of a speed discriminator circuit and a

PLL circuit is better able to suppress speed fluctuations when used in situations where large load variations are

applied to the motor. Since the FG servo frequency is determined by the following formula, applications must

determine the motor speed by setting the number of FG pulses and the crystal oscillator frequency.

fFG(servo) = f

OSC

/8192

f

OSC

: The crystal oscillator frequency

2. Direct PWM drive

To minimize power loss in the output, this IC adopts a direct PWM drive technique. The output transistors are always

saturated when on, and motor drive is adjusted by changing the duty with which the output transistors are on. Since

the output switching is performed by the lower side transistors, Schottky diodes (D1, D2, and D3) or similar devices

must be connected between OUT and VCC. (This is because if the devices used do not have a short reverse recovery

time, through currents will flow at the instant the lower side transistors turn on.) Normal rectifying diodes can be used

between OUT and ground.

3. Current limiter circuit

The current limiter circuit operates at a current determined by the formula I = 0.5/Rf, and operates as a peak current

limiter. Its current limiting operation consists of reducing the duty with which the output is on to suppress the current

drawn. No phase compensation capacitors are required.

4. Speed lock range

The speed lock range is ±6.25% of the set speed. When the motor speed is in the lock range the LD pin goes low.

(The LD pin is an open-collector output.) If the motor speed goes out of the lock range, the motor drive output on

duty is modified according to the speed error. This controls the motor speed to be in the lock range.

5. PWM frequency

The PWM frequency is determined by the resistor (R3) and the capacitor (C6) connected to the CR pin.

• If R3 is connected to the 4-V fixed-voltage supply:

f

PWM

≈ 1/(1.2 × C × R)

• If R3 is connected to the 7-V fixed-voltage supply:

f

PWM

≈ 1/(0.5 × C × R)

Do not use a value of 30 kΩ or less for R3. A PWM frequency of about 15 kHz is desirable. If the PWM frequency is

too low, the motor may resonate at the PWM frequency during motor constraint, and if the PWM frequency is in the

audible range result in noise. Inversely, if the PWM frequency is too high, the loss in the output transistors during

switching will increase.

6. Ground leading

GND1 (pin 22) --- Ground for all circuits other than the output block

GND2 (pin 11) --- Output block ground (the sink transistor emitter)

D4, D5, and D6 must be connected to GND2. All other external components must be connected to GND1. A single

ground point must be taken for GND1 and GND2 at the connector. Since GND2 carries large currents, the GND2

lines must be kept as short as possible.

7. Parasitic effects in the output

Parasitic effects occur when the output pin voltage falls –0.7 V below the GND1 and GND2 potential. (Note that the

actual value may become smaller than –0.7 V due to device temperature characteristics.) Also, applications must be

designed so that the output pin voltage never exceeds VCCby 1 V or more. If a parasitic effect occurs, at first speed

control will be lost intermittently. If the parasitic effects increase, the output transistors may be destroyed. Since D1,

No. 5679-5/10

LB1922

Page 6

D2, and D3 are for through current prevention, use Schottky diodes with a small Vf. This will prevent the potential

difference between the output pins and VCCfrom becoming a problem. Although normal rectifying diodes can be

used for D4, D5, and D6, design the ground lines carefully as described in item 6, “Ground leading”, so that parasitic

effects do not occur.

8. External interface pins

• LD pin

Output type: open collector

Voltage handling capacity: 20 V (absolute maximum)

Saturation voltage sample-to-sample variation reference value (ILD= 10 mA)

0.0 to 0.5 V

• FGS pin

Output type: open collector

Voltage handling capacity: 20 V (absolute maximum)

Saturation voltage sample-to-sample variation reference value (I

FGS

= 2 mA)

0.12 to 0.18 V

The FGS pin output is the FG amplifier output converted to a pulse output by a hysteresis comparator. It is used

as a speed monitor. If the FGS pin is not used, the pull-up resistor is not required.

• Start/Stop pin

Input type: PNP transistor base with a 50-kΩ pull-down resistor connected to ground

Threshold level (typical): About 2.6 V

The 4-V, 5-V, and 7-V fixed-voltage supplies are turned off in stop mode.

• F/R pin

Input type: PNP transistor base with a 50-kΩ pull-down resistor connected to ground

Threshold level (typical): About 2.2 V (high → low), about 2.7 V (low → high)

Hysteresis: about 0.5 V

F/R switching must only be performed in stop mode when the motor is stopped.

9. Fixed-voltage supply temperature characteristics

• 4-V supply: about –0.5 mV/°C

• 5-V supply: about –0.6 mV/°C

• 7-V supply: about –2.5 mV/°C

10. FG amplifier

The FG amplifier gain is determined by R1 and R2, and the DC gain, G, will be R2/21. The FG amplifier frequency

characteristics are determined by C4 and C5. (R1 and C4 form a high-pass filter and R2 and C5 form a low-pass

filter.) Since the FG amplifier output is input to a Schmitt comparator, set up values for R1, R2, C4, and C5 so that

the FG amplifier output has an amplitude of at least 250 mV p-p. (It is desirable to set up the FG amplifier so that its

output has an amplitude of between 1 and 3 V p-p during steady state motor operation.)

11. External capacitors

• C3

C3 is required to stabilize the FG

IN

+

pin fixed-voltage supply and to generate the initial reset pulse for the IC

internal logic. Although a relatively small capacitance suffices for power supply stabilization, a larger capacitance

(about 4.7 µF) is required to generate the reset pulse. The reset pulse is generated at the time when the FG

IN

+

pin

goes from 0 V to about 1.3 V. If the reset function does not operate, the LD pin may go on briefly at startup. If this

phenomenon is not a problem, a capacitance of around 0.1 µF can be used for C3. After C3 is charged to 4 V, if

VCCis turned off (or the IC is set to stop mode), the capacitor will be discharged by an IC-internal load of about

10 kΩ that is connected to this capacitor.

• C1 and C2

C1 and C2 are required for fixed-voltage supply stabilization. Since this IC adopts a direct PWM technique and

switches large currents in the outputs, it is extremely easy for noise to be generated. Therefore, adequate powersupply stabilization is required to prevent that noise from causing incorrect circuit operation. C1 through C3 must

be connected to GND1 with lines that are as short as possible. In particular, C1 can easily influence system

characteristics and requires care.

No. 5679-6/10

LB1922

Page 7

12. External resistors

• R4 and R5

R4 and R5 are used to apply the high-level input to the F/R pin. Since the F/R pin has a built-in pull-down resistor

which is about 50 kΩ, it will be at the low level when left open. A voltage of between 4.0 and 6.3 V must be

applied to input a high level to the F/R pin.

• R15

R15 is used to apply the high-level input to the S/S pin. Since the S/S pin has a built-in pull-down resistor which is

about 50 kΩ, it will be at the low level when left open. (A voltage of between 4.0 and 6.3 V must be applied to

input a start-state high level to the S/S pin.) As is the case with the F/R input, using a two-resistor voltage divider

to apply a voltage to the S/S pin provides better noise immunity since a lower input impedance can be set up.

However, in applications where noise is not a problem, the high level may be applied with a single resistor, as is

done with R15 in this circuit.

When VCCis first applied, if VCCcomes up slowly (around 10 mV/ms or slower) the motor may turn somewhat

even though the circuit is in stop mode. This is because the S/S pin input voltage is provided through a tworesistor voltage divider and when VCCis still relatively low, the S/S pin input voltage will be below 2.6 V, which

is the start mode input level. If it is impossible to increase the speed with which the power voltage is brought up

and this is a problem, a capacitor may be inserted between VCCand the S/S pin to resolve the problem.

13. Through currents due to the direct PWM technique

In the direct PWM technique, through currents may flow in the output due to the switching. (This occurs in both

discrete component implementations as well as with the LB1822.) This is due to the delay and parasitic capacitors in

the output transistors. Earlier application used capacitors to deal with this problem if it occurred. However, since this

IC includes circuits designed to deal with this phenomenon, there is no need for external components to deal with

these currents. During switching, whiskers of up to about 10 ns may appear in the RF waveform, but they will not

cause problems in applications.

14. Oscillators

Normally, applications using this IC will use a crystal oscillator. However, it may be possible to use a ceramic

oscillator in applications in which the requirements on the speed control characteristics are not demanding. To avoid

problems, always consult the manufacturer of the oscillator element concerning the values of the external capacitors

and resistors used.

15. IC internal power dissipation calculation (calculated for VCC= 12 V with typical specifications)

• Power dissipation due to the supply current (ICC)

Stop mode:

P1 = VCC× ICC1 = 12 × 34 m = 0.41 W

Start mode:

P2 = VCC× ICC2 = 12 × 8 m = 0.08 W

• Power dissipation when a –10-mA load current is drawn from the 7-V fixed voltage output.

P3 = (VCC– 7) × 10 m = 5 × 10 m = 0.05 W

• Power dissipation due to the output drive current (when the output duty is 100%)

P4 = {(VCC–1)2/8k} + {(VCC– 2)2/10k} = (112/2k) + (102/4k) = 0.09 W

• Power dissipation in the output transistors (when IO= 2 A, the output duty is 100%)

P5 = VO(sat)2 × IO= 2.7 × 2 = 5.4 W

Therefore, the IC overall power dissipation will be:

Start mode:

P = P2 = 0.08 W

Stop mode:

P = P1 + P3 + P4 + P5 = 5.95 W

(For an output duty of 100%)

No. 5679-7/10

LB1922

Page 8

16. Techniques for measuring IC internal temperature increases

• Thermocouple measurement

When using a thermocouple for temperature measurement, the thermocouple is attached to a fin on the heat sink.

While this measurement technique is simple, it suffers from large measurement errors when the thermal

generation process is not at steady state.

• Measurement using IC internal diode properties

We recommend using the properties of the parasitic diode that exists between INT.IN and ground for measuring

the temperature of this IC. (Sanyo data: For ID = 1 mA, the temperature characteristic is about 1.8 mV/°C.) The

external resistor must be disconnected when measuring the temperature.

17. Servo constants

The servo constant calculations depend strongly on the characteristics of the motor used and require special expertise.

Normally, the motor manufacturer will set up these constants. Sanyo can provide the data required for the servo

constant calculations. This data includes both the characteristics data for this IC as well as the frequency

characteristics simulation data for the filter characteristics set up by the motor manufacturer.

If the resistor (R10) between DOUT and INT.IN is too small, then C8 and C9 will become excessively large, and if

R10 is too large, then speed errors due to the speed discriminator shutoff current and the integrator input current will

become more likely to occur. Therefore, this resistor should have a value in the range 10 to 100 kΩ. If the resistor

(R8) between P

OUT

and INT.IN is too small, the influence of the PLL system will become excessive and the lock

state pull-in characteristics will be degraded. Thus the value of this resistor must not be made too small. We

recommend a value of around 1 MΩ when R10 is 75 kΩ. Applications must be designed by first setting up only the

speed discriminator system (R9, R10, C8, and C9) and only then setting up the PLL system resistor R8.

No. 5679-8/10

LB1922

Page 9

Equivalent Circuit Block Diagram

No. 5679-9/10

LB1922

Speed

discriminator

2.5 V

Page 10

No. 5679-10/10

LB1922

Sample Application Circuit

This catalog provides information as of June, 1997. Specifications and information herein are subject to change

without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀ Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁ Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

Loading...

Loading...