Danfoss S67, S113, S155 Data sheet

Data sheet

Gasketed Plate Heat Exchangers (DN 250 / 10”) S67 / S113 / S155

Description

SONDEX® gasketed plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments.

We have the largest plate portfolio in the world, and we customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our gasketed plate heat exchangers a stellar investment.

Benefits:

•Individually customized solution that perfectly matches your requirements and lowers your energy consumption.

•High performance and a low pressure drop eliminate unnecessary burdens on your system and optimize overall system performance.

•The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Common applications:

•HVAC industry

•Marine/offshore industry

•Dairy/food/beverage industry

•Sugar industry

•Biogas industry

•Pulp and paper industry

•Heavy industry

•Mining industry

•Petrochemical industry

•Chemical industry

Main data:

•Min. temperature −10 °C

•Max. temperature 180 °C

•Max. working pressure 16 / 25 bar (10 bar on request)

•Water and different fluids, steam

•Connection size DN 250 or 10”

Approvals:

•Please contact your local Danfoss/SONDEX® sales representative for an overview of the available approvals in your region

Construction standard:

•EN13445 (PED 2014/68/EU)

•ASME sec VIII, Div. 1

| 2019.07 |

VD.JQ.S1.02 | 1 |

Data sheet |

S67 / S113 / S155 (DN 250) |

|

|

Naming of units |

S67-IS16-21-TKTL89 |

TKTL89 - Plate grouping 3)

21 - Number of plates in the heat exchanger

16 - Design pressure of the heat exchanger IS - Frame type 2)

67 – Type of heat exchanger 1)

S – Gasketed heat exchanger

1)

2)

Type of heat exchanger:

67 - …

Letter S67 shows type of the attachment of gasket to plate: e.g. 67 (without A) – SonderLock

67A (with A) – Hang-on

Description of frame types:

There are few different frame types which can be offered for different applications and duties. IS – with suspension roller,

IG – without suspension roller,

FS – food/sanitary with suspension roller, FG - food/sanitary,

ST – simple design of frame with threaded connections

3) Channel grouping:

In this example, the heat exchanger combines TK and TL channels. The share of TL channels equals 89% of the total number of channels.

The number of channels is defined as “the number of plates - 1”. TK - short thermal length

TM - medium thermal length TL - long thermal length

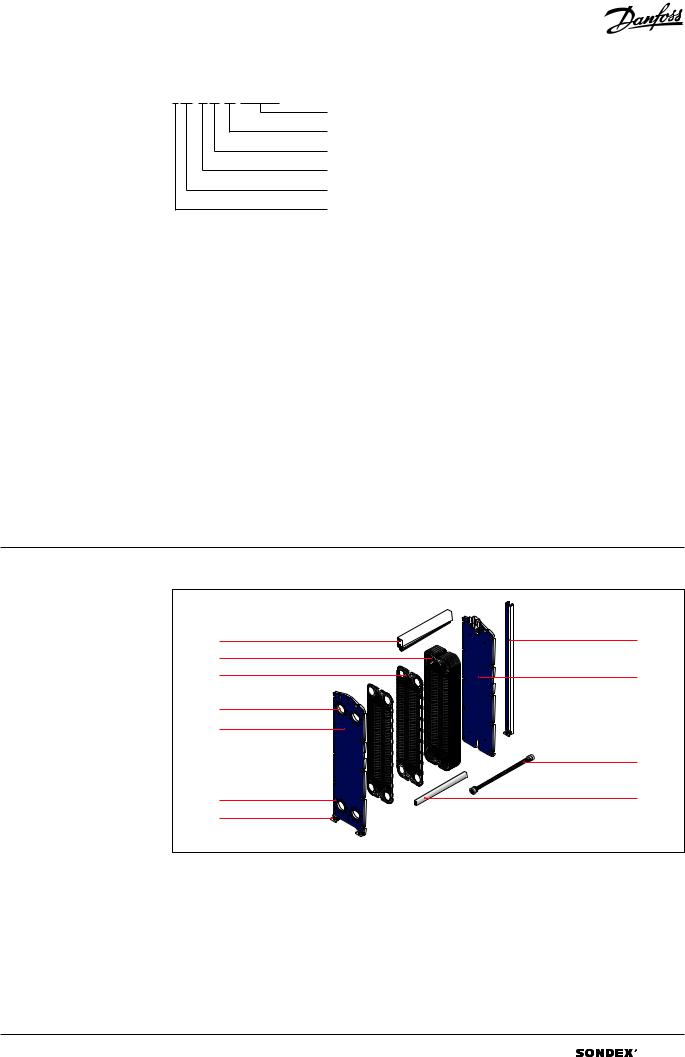

Heat exchanger design |

Gasketed heat exchangers consist of |

Carrying Bar

Plate Pack

Plate

Connections

Head

Flange Connections

Foundation Feet

Column

Follower

Tie Bolt

Guiding Bar

Anatomy of a SONDEX® plate heat exchanger - IS frame.

2 | VD.JQ.S1.02 |

| 2019.07 |

Data sheet |

S67 / S113 / S155 (DN 250) |

|

|

|

|

Heat exchanger design |

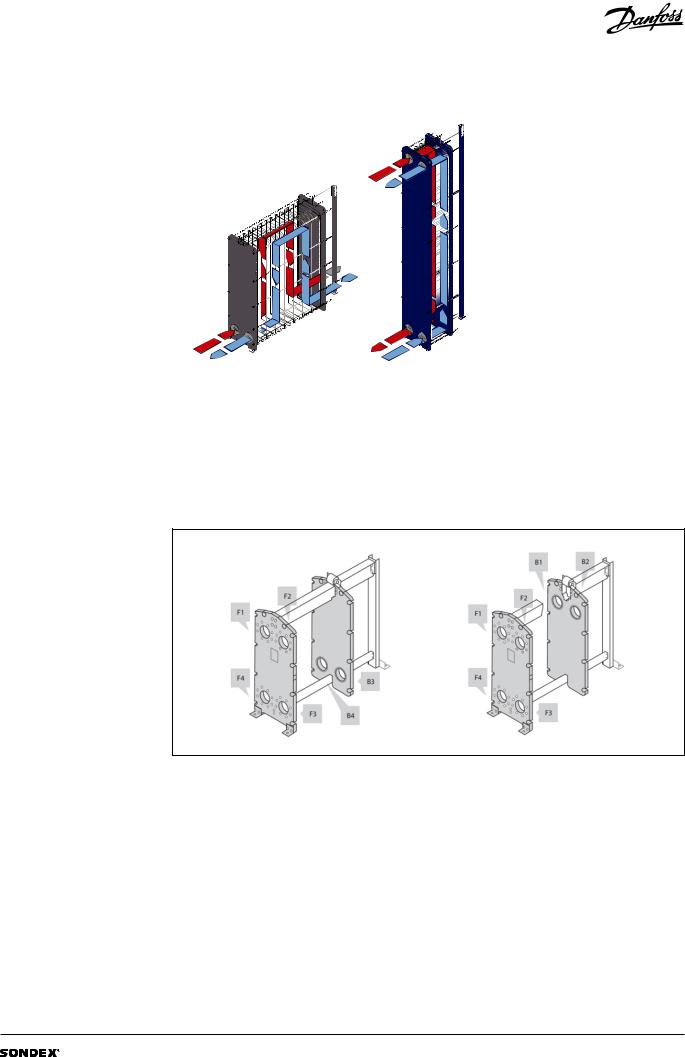

Multi-pass design |

|

(continued) |

|

|

To the left: A multi-pass solution with connections |

|

|

|

|

|

|

on the follower and the head. |

|

|

To the right: A single-pass solution with |

|

|

all connections on the head. |

|

|

|

|

Connections

The heat exchanger may have connections on both front and back-end sides of the unit.

Connections on the front-end plate are marked with F and connections on the back-end plate are marked with B. The numbers 1, 2, 3 and 4 designate the position of the connection on the end-plate from the top-left port clockwise.

| 2019.07 |

VD.JQ.S1.02 | 3 |

Loading...

Loading...