Danfoss SONDEX, SAW Data sheet

Data sheet

SONDEX® Fully welded plate heat exchangers (SAW)

Description

SONDEX® Fully welded plate heat exchangers (SAW) are designed to handle extremely aggressive and demanding media and achieve very close temperature approaches with a true counter-current design. Very small and compact, they are the perfect solution for applications and duties that require a fully welded product, such as a plate and shell or block-type heat exchanger, but do not need their substantial capacities. A product that perfectly matches the specifications of the task will always be the optimal solution.

In their class, the fully welded series outperform shell and tube heat exchangers in every aspect and offer all the benefits of a gasketed heat exchanger as well as increased durability.

Benefits:

•Very compact, cost-effective units that take up minimal floor space are light in weight, while providing very efficient heat transfer, through the courtesy of a true countercurrent flow.

•The gasket-free solutions feature a fully welded plate pack that enable them to work with very high pressure and temperatures. The risks of leaks are severely diminished with a completely welded heat exchanger.

•The plates in the completely welded plate pack are made from highly resistant materials guaranteed to withstand even the most extreme working conditions.

Common applications:

•HVAC industry

•Refrigeration industry

•Pulp and paper industry

•Heavy industry

•Mining industry

•Petrochemical industry

•Chemical industry

Main data:

•Min. temperature −10 °C (14°F)

•Max. temperature 300 °C (572°F)

•Max. working pressure 25 bar (360 psi)

•Clean fluids, steam, gases

•Connections DN50

•Diagonal flow

Approvals:

•Please contact your local Danfoss/Sondex sales representative to provide you with exact approvals availability on your region

Pressure vessel code:

•EN13445 (PED 2014/68/EU)

•ASME sec VIII, Div. 1

•Other standards available on request

Naming of units |

SAW23-IS25-30 |

30 - Number of plates

25 - Design pressure of heat exchanger (bar)

IS - Frame type

23 - Type of heat exchanger

SAW - SONDEX® fully welded heat exchanger

| 2020.10 |

AI351128197836en-010101 | 1 |

Data sheet |

SONDEX® Fully welded plate heat exchangers (SAW) |

|

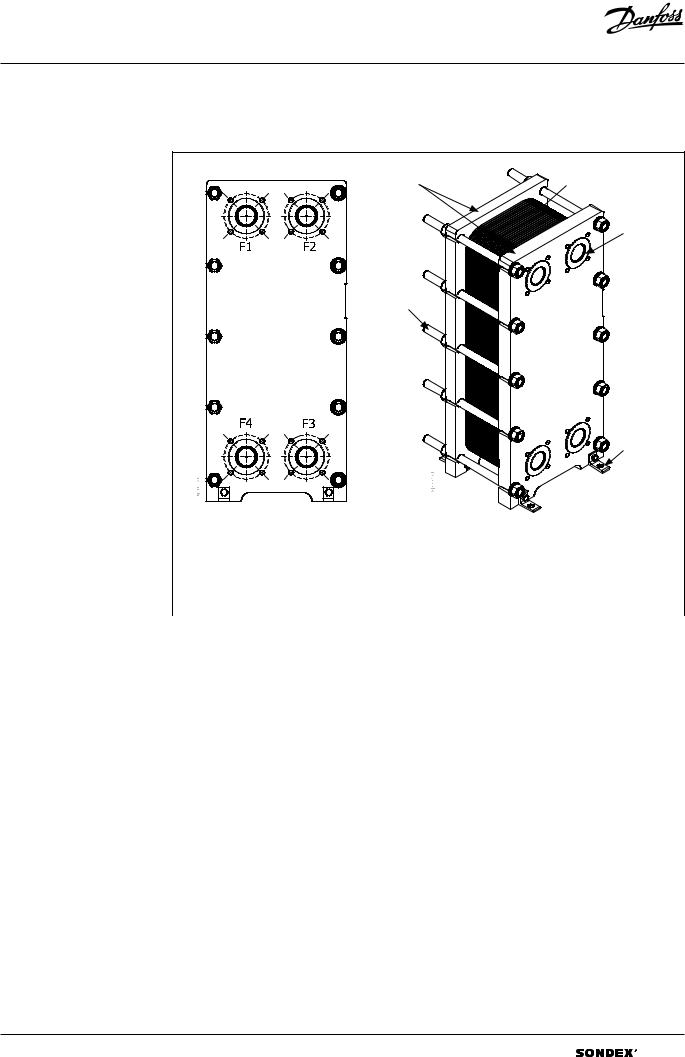

Heat exchanger design |

SONDEX® fully welded heat exchangers (SAW) contain a number of welded plates forming a gasket-free |

|

|

plate pack which is placed between two frame plates made from carbon steel and tightened with tie bolts. |

|

|

SONDEX® fully welded heat exchanger SAW23 |

|

|

Frame plates |

Welded plate pack |

|

|

Connection |

Tie bolt

Feet

|

The SAW23 unit has a diagonal flow. |

|

||

|

F1 – hot side inlet, |

|

|

|

|

F2 – cold side outlet |

|

|

|

|

F3 – hot side outlet |

|

|

|

|

F4 – cold side inlet |

|

|

|

|

|

|

|

|

|

|

|

|

|

Connections |

• DN50 flange. According to all known standards. |

|||

|

Please contact your local Danfoss or Sondex sales |

|||

|

representative to provide you with design for |

|||

|

SONDEX® fully welded heat exchangers. |

|

||

|

|

|

|

|

Technical data |

SONDEX® fully welded heat exchanger (SAW) |

|

||

|

|

|

|

|

|

Type |

|

|

SAW23 |

|

Max. working pressure |

bar / psi |

|

25 / 360 |

|

Min. operating temperature |

°C / °F |

|

−10 / 14 |

|

Max. operating temperature |

|

300 / 572 |

|

|

|

|

||

|

Connection |

|

|

DN50 flange. According to all known standards. |

|

Number of plates |

|

|

10, 16, 20, 26, 30, 36, 40, 46, 50, 56, 60, 64 |

|

Plate material |

|

|

Stainless steel EN 1.4404 (AISI 316L) |

|

|

|

Other materials available on request |

|

|

|

|

|

|

|

Frame material |

|

|

Carbon Steel P355GH |

|

|

|

Other materials available on request |

|

|

|

|

|

|

|

Frame painting specification |

|

|

Painting available for corrosion categories C2L, C4M, C5M |

2 | AI351128197836en-010101 |

| 2020.10 |

Loading...

Loading...