Burkert 8694 User Manual [en, de, fr]

Type 8692 / 8693 / 8694

Exchange of an 8630 positioner with an ELEMENT positioner

Austausch eines 8630-Positioners gegen einen ELEMENT-Positioner

Remplacement d’un positionneur 8630 par un positionneur ELEMENT

Conversion Instructions

Umbauanleitung

Instructions de transformation

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2009 - 2012 Bürkert Werke GmbH

Operating Instructions 1206/01_EU-ML_00805949 / Original DE

Types 8692, 8693, 8694

Conversion Instructions Positioner

Table of Contents:

1. CONVERSION INSTRUCTIONS ...............................................................4

1.1. Symbols ..............................................................................................4

2. BASIC SAFETY INSTRUCTIONS .............................................................5

3. GENERAL INFORMATION ...........................................................................6

3.1. Contact Addresses .......................................................................... 6

3.2. Warranty ............................................................................................. 6

3.3. Information on the Internet ............................................................. 6

4. INSTALLATION

4.1. Safety instructions ...........................................................................6

4.2. Disassembly of Type 8630 ............................................................7

4.3. Assembling the exchange kit ......................................................... 9

4.4. Install positioner ..............................................................................10

4.5. Pneumatic connection to actuator .............................................11

5. ORDER TABLE FOR EXCHANGE KITS ............................................. 12

..................................................................................................6

english

3

Types 8692, 8693, 8694

Conversion Instructions

1. CONVERSION INSTRUCTIONS

The conversion instructions describe the exchange of a Type 8630

positioner with an ELEMENT positioner (Types 8692, 8693, 8694) on

a Type 27xx control valve. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available

to every new owner of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

For further information on the application, the authorized

use, the technical specifications, start-up and functions as

well as the provisions for packaging, transport, storage and

disposal, please refer to the operating instructions for the

type concerned.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning will result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or

minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Types 8692, 8693, 8694

Basic Safety Instructions

2. BASIC

SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

DANGER!

Danger – high pressure!

• Before dismounting pneumatic lines and valves, turn off the

pressure and vent the lines.

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

Risk of burns/risk of fire if used continuously through hot

device surface!

• Keep the device away from highly flammable substances and

media and do not touch with bare hands.

The positioners Type 8692, 8693 and 8694 were developed

with due consideration given to the accepted safety rules

and are state-of-the-art. Nevertheless, dangerous situations

may occur.

WARNING!

General Hazardous Situations.

To prevent injury, ensure that:

• the system cannot be activated unintentionally.

• installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

• after an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

• the device may be operated only when in perfect condition and

in consideration of the operating instructions.

• the general rules of technology apply to application planning

and operation of the device.

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario, they will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1

and 5-2 to minimize or avoid the possibility of damage caused

by sudden electrostatic discharge!

• Also, ensure that you do not touch electronic components when

the power supply voltage is present!

english

5

Types 8692, 8693, 8694

General Information

3. GENERAL INFORMATION

3.1. Contact Addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

3.2. Warranty

The warranty is only valid if the positioners are used as intended in

accordance with the specified application conditions.

3.3. Information on the Internet

The operating instructions and data sheets for Types 8692, 8693 and

8694 can be found on the Internet at:

www.burkert.com

4. INSTALLATION

4.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before dismounting pneumatic lines and valves, turn off the

pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

6

english

Types 8692, 8693, 8694

Installation

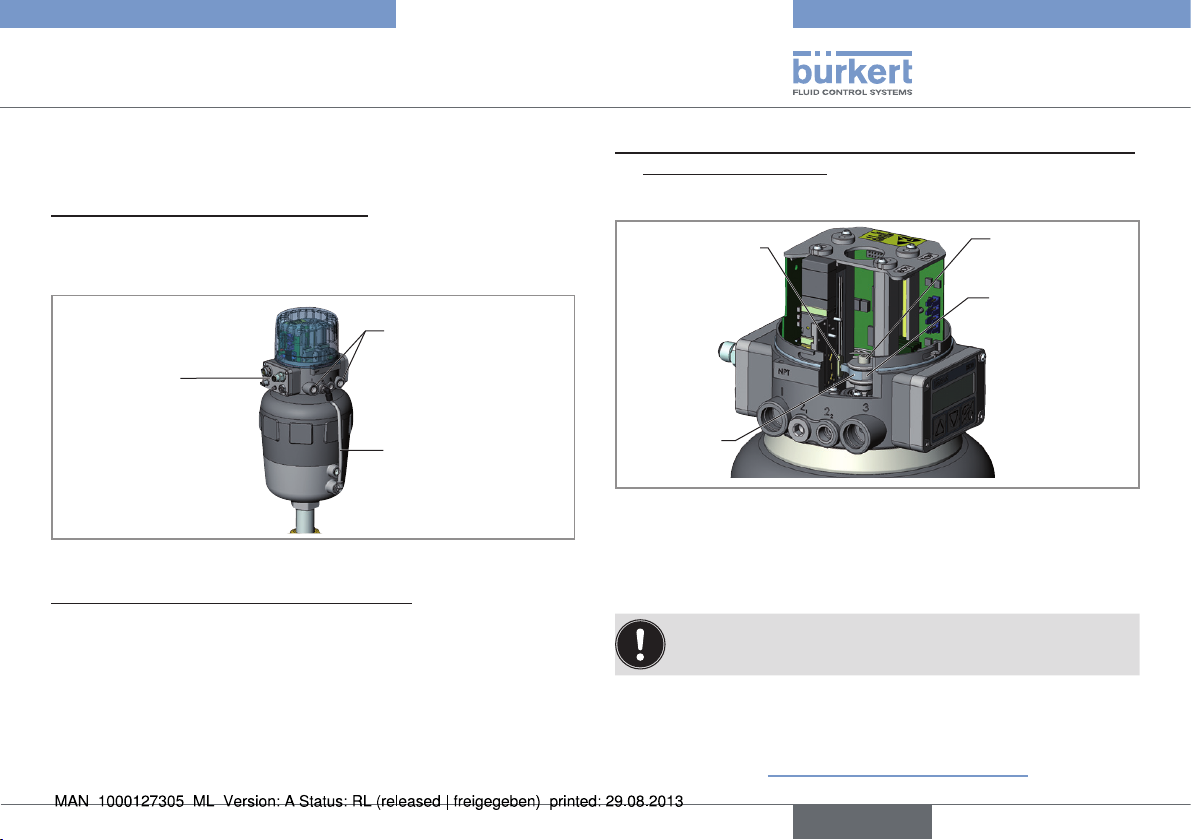

4.2. Disassembly of Type 8630

Procedure:

1. Disconnecting pneumatic connection:

→ Remove supply pressure connection and exhaust air connection

(if installed).

→ Loosen pneumatic connection between positioner and actuator.

Supply pressure and

exhaust air connection

Electrical

connection

(multi-pole variant)

Pneumatic

connection

Fig. 1: Disconnecting supply

2. Disconnecting electrical supply connection:

Multi-pole variant:

→ Pull out the round plug.

Cable gland:

→ Loosen the four screws of the cover together with the cable

glands and remove cover.

→ Unscrew the screw terminals and pull out cables.

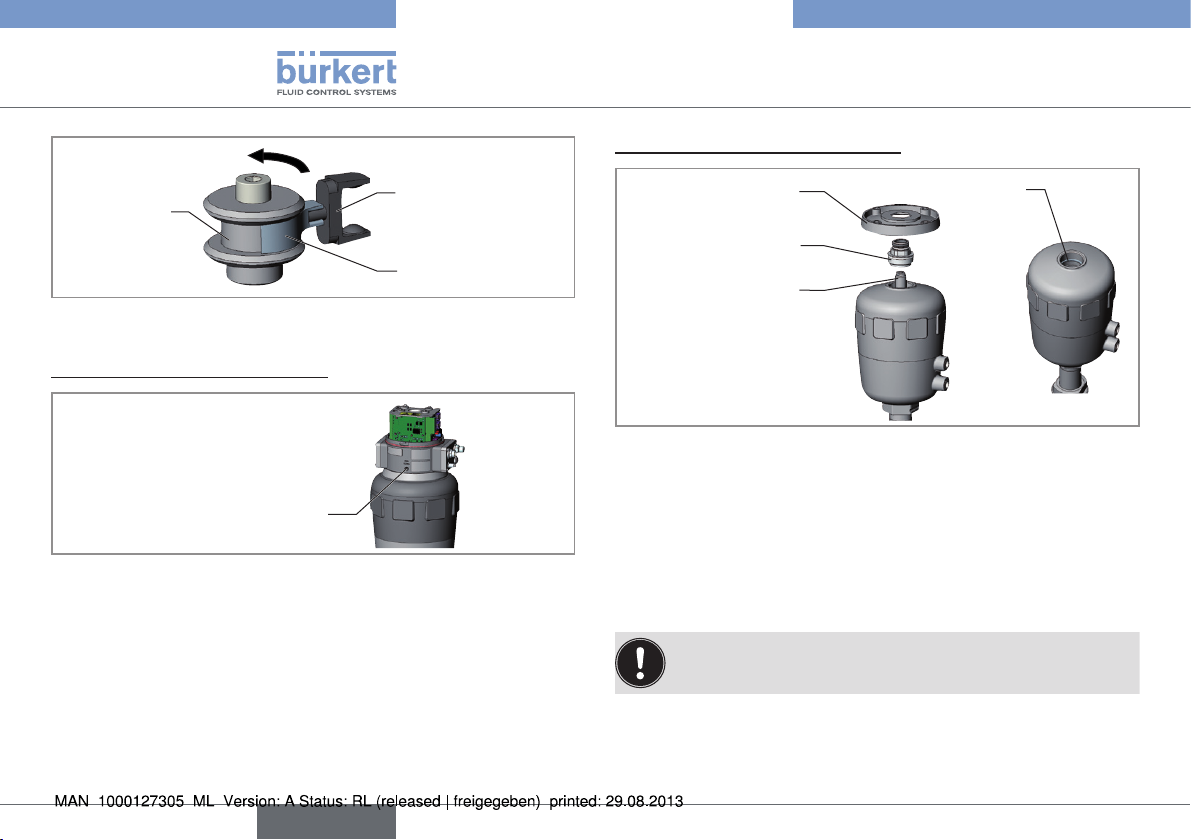

3. Removing the mechanical coupling between position measuring

system and switch cam:

→ Open the transparent hood of the positioner.

Coupling element

position measuring

system

Driving fork

Fig. 2: Coupling position measuring system

The driving fork is clipped onto the coupling element and there are

two options to remove this coupling:

Hexagonal socket

head screw

Switch cam

→ Loosen hexagonal socket head screw and remove switch cam.

The switch cam is secured with screw locking paint. As a

result, increased effort may be required to remove it.

or

→ Remove the driving fork from the coupling element of the

position measuring system by turning a screw driver counterclockwise (see "“Fig. 3: Removing the driving fork”").

english

7

Types 8692, 8693, 8694

Installation

5. Disassembling adaption set 8630

Switch cam

Fig. 3: Removing the driving fork

4. Removing positioner Type 8630:

Fastening screw

Fig. 4: Fastening screw

Coupling element position measuring

system

Driving fork

→ Remove fastening screw (hexagon socket WAF 3) of the

positioner.

→ Remove positioner from actuator.

Spacer ring

Guide piece

Spindle extension

Fig. 5: Disassembling adaption set 8630

O-ring

→ Remove spacer ring

→ Unscrew guide piece

→ Actuator size H (125) and more:

Unscrew spindle extension

→ Remove the O-ring from the cover of the actuator.

The spindle extension is secured with screw locking paint.

As a result, increased effort may be required to remove it.

8

english

Types 8692, 8693, 8694

Installation

4.3. Assembling the exchange kit

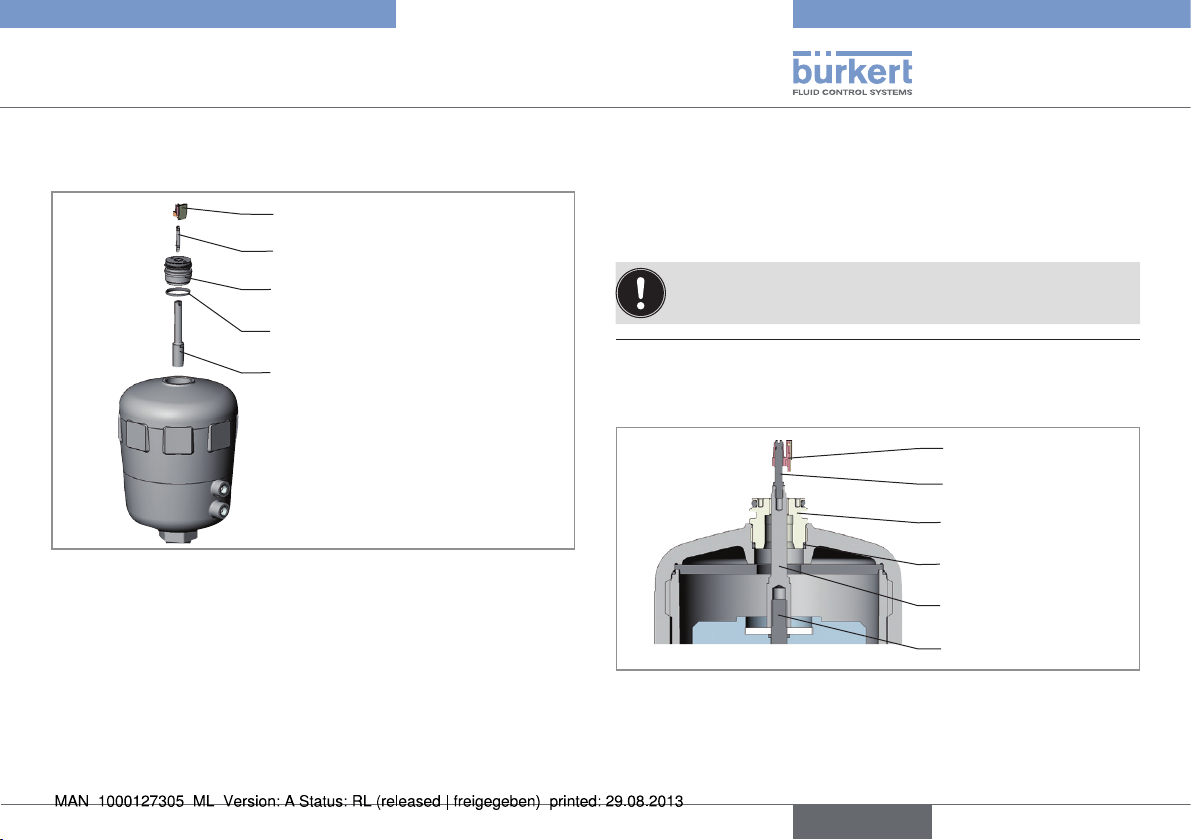

Puck holder

Switch spindle

Guide piece

O-ring

Spindle extension

(only with actuator size H (125)

and more)

Fig. 6: Exchange set 869x

→ Actuator size H (125) and more:

Apply some screw locking paint (Loctite 290) in the tapped bore

of the spindle extension and screw to the spindle in the actuator

(torque: 20 ± 3 Nm).

→ Press the O-ring downwards into the cover of the actuator.

→ Screw guide piece into the cover of the actuator using a face

wrench 1) (torque: 8.0 Nm).

→ To secure the switch spindle, apply some locking paint (Loctite

290) to the thread of the switch spindle.

→ Screw switch spindle onto the spindle extension. To do this,

there is a slot on the upper side.

→ Push the puck holder onto the switch spindle until it engages.

The puck holder is not a component of the upgrade kit; it is

enclosed with the control.

1)

Journals : ∅ 3 mm; journal gap: 23.5 mm

Puck holder

Switch spindle

Guide piece

O-ring

Spindle extension

Fig. 7: Exchange set 869x assembled

Spindle (actuator)

english

9

4.4. Install positioner

→ Attach moulded seal from accessories set to positioner.

→ Push the positioner onto the actuator. At the same time, align the

puck holder until it is inserted into the guide rail of the positioner.

Guide rail

Puck holder

Types 8692, 8693, 8694

Installation

Fastening

screws

Moulded seal

Fig. 8: Aligning the puck holder

→ Press the positioner all the way down to the actuator and turn it

into the required position.

Ensure that the pneumatic connections of the positioner

and those of the valve actuator are situated preferably vertically one above the other.

If they are positioned differently, longer hoses may be

required other than those supplied in the accessory kit.

10

english

Fig. 9: Install positioner

NOTE!

Too high torque when screwing in the fastening screw does

not ensure protection class IP65 / IP67!

• The fastening screws may be tightened to a maximum torque of

0.5 Nm only.

→ Attach positioner to the actuator using the two side fastening

screws. In doing so, tighten the screws only hand-tight (max.

torque: 0.5 Nm).

Types 8692, 8693, 8694

Installation

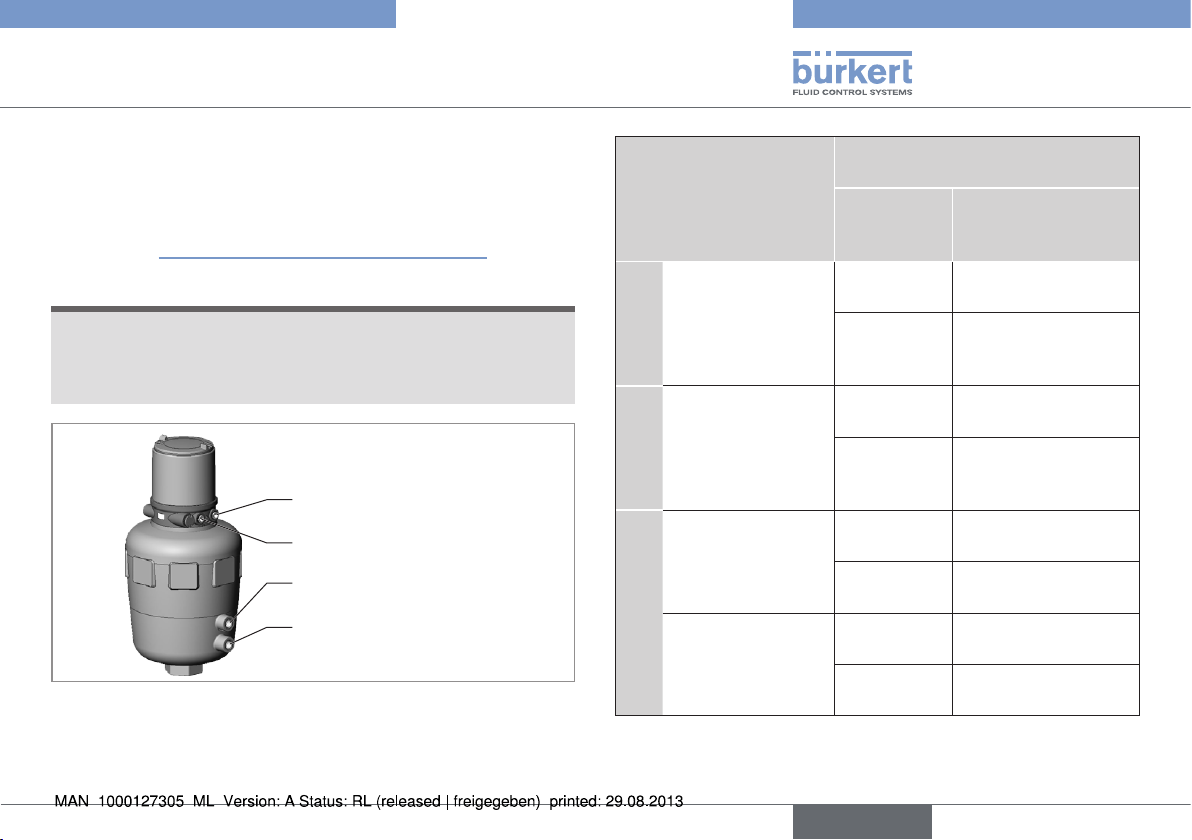

4.5. Pneumatic connection to

actuator

→ Using the hoses supplied in the accessory kit, make the pneu-

matic connection between the positioner and actuator with the

following "“Tab. 1: Pneumatic connection to actuator”".

NOTE!

Damage or malfunction due to ingress of dirt and moisture!

• To comply with protection class IP65 / IP67, connect the control air connection (for CF A und CF B) which is not required to

the free chamber of the actuator or seal with a plug.

Control air connection 2

Control air connection 2

upper chamber

lower chamber

Fig. 10: Pneumatic connection to actuator

1

2

Control function Pneumatic connection

Type 869x to actuator

Control air

Actuator input

connection

Type 869x

Process valve

closed in rest

A

position

(by spring force)

Process valve open

in rest position

B

(by spring force)

Process valve

closed in rest

position

I

Process valve open

in rest position

2

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

lower chamber of the

actuator

Should be connected

to the upper chamber

of the actuator

upper chamber of the

actuator

Should be connected

to the lower chamber

of the actuator

lower chamber of the

actuator

upper chamber of the

actuator

upper chamber of the

actuator

lower chamber of the

actuator

Tab. 1: Pneumatic connection to actuator

english

11

Loading...

Loading...