BMW K1200LT 1999 User Manual [ru]

Repair Manual

K 1200 LT

BMW AG Motorcycle Division

After Sales

Published by: |

© BMW AG Motorcycle Division |

|

After Sales |

|

UX-VS-2 |

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written permission.

Errors and omissions excepted; subject to technical amendment.

Produced in Germany 7/99

Introduction

This repair manual will help you to perform all the main maintenance and repair work correctly and efficiently. If it is consulted regularly by workshop personnel it will form a useful addition to the theoretical and practical knowledge acquired at the BMW Training Centre. It is a contribution towards achieving even higher Service quality.

A new issue of this repair manual will be published if amendments or additions (supplements) are needed.

All information in both text and illustrations refers to motorcycles in standard condition or with genuine BMW accessories installed, and not to motorcycles which have been modified in any way to depart from the manufacturer’s specification.

•The repair manual is structured in the logical sequence of the work to be performed: Removal, Disassembly, Repair, Assembly, Installation.

•The entire contents are divided into individual chapters, corresponding to the Construction Groups.

|

|

|

|

11 . 10 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chapter |

|

|

|

|

Page number within chapter |

|

|||||

|

|

|||||||||||

|

|

|

||||||||||

An arrow symbol followed by the chapter and page numbers is a reference to another chapter, e.g. Ób ............................................See Group 46

•Work to be performed during an Inspection is described in Group “00”. The various inspection routines are numbered I, II, III and IV. This numbering is repeated in the work descriptions which follow, so that work can take place without interruption.

•Use of the BMW special tools needed for certain tasks is described in the work instructions.

If the need arises, repair instructions are also issued in the form of Service Information. This information is of course incorporated into the next issue of the repair manual. We also recommend, as an additional source of information, the Electronic Parts Catalogue (ETC), which contains clear and easy-to-follow illustrations.

If the work described here is restricted to a particular equipment specification, for instance if a specific optional extra (OE) is fitted, this is stated in square brackets at the start of the item concerned, e.g. [With heated handlebar grips].

Please refer to the following pages as well for a description of other symbols used and how to work with it.

BMW AG Motorcycle Division

After Sales

Published by: |

BMW AG Sparte Motorrad |

|

After Sales |

|

UX-VS-2 |

|

D - 80788 München |

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written permission.

Errors and omissions excepted; subject to technical amendment.

Produced in Germany

Usage

Each chapter starts with the list of contents.

The list of contents is followed by the Technical Data table.

Chapter 00 “Maintenance and general instructions” details the handover checklist and lists all tightening torques and operating fluids.

Key to symbols

In this Workshop Manual for the K 1200 LT model, the following symbols are used; their meanings are explained in the table.

Special instructions aimed at improving the work procedures

L Note:

Specific information on operating, inspecting and adjusting work for the motorcycle as well as maintenance procedures.

e Caution:

Instructions and precautions specifically intended to prevent damage to the motorcycle. Failure to comply with them could invalidate the warranty.

d Caution:

This symbol stands for precautions and measures which are essential in order to protect the rider or other persons from possibly severe or fatal injury.

Contents

Headlines for the work described in the chapter........................................... |

with the relevant page number |

Activities

•Activities

•The bullet symbol means that work steps are described in greater detail under another headline

–Preceding activities

–A line indicates work steps described in greater detail under another headline or in another chapter

If the term “release” or “remove” is used:

the fastener (e.g. screw) must be slackened off and taken out or

a component (e.g. fuel rail) must be removed to the extent that other components which it conceals (e.g. throttle-valve rail) are accessible

If the term “loosen” or “slacken” is used:

the fastener (e.g. screw) must only be slackened off but not taken out

X Tightening torques:

Values are stated if they differ from DIN EN 24 014 or DIN 912 ISO industrial standards.

Contents

Group / Chapter |

|

|

|

|

|

00 |

Maintenance and general instructions |

00.1 |

|

|

|

|

|

|

|||

11 |

Motor |

11.1 |

|

|

|

|

|

|

|||

12 |

Engine electrics |

12.1 |

|

|

|

|

|

|

|||

13 |

Fuel preparation and control |

13.1 |

|

|

|

|

|

|

|||

16 |

Fuel tank and lines |

16.1 |

|

|

|

|

|

|

|||

|

|

|

|||

|

|

|

|||

17 |

Radiator |

17.1 |

|

|

|

|

|

|

|||

18 |

Exhaust system |

18.1 |

|

|

|

|

|

|

|||

21 |

Clutch |

21.1 |

|

|

|

|

|

|

|||

23 |

Gearbox |

23.1 |

|

|

|

|

|

|

|||

31 |

Front fork |

31.1 |

|

|

|

|

|

|

|||

32 |

Steering |

32.1 |

|

|

|

|

|

|

|||

|

|

|

|||

|

|

|

|

|

|

Group / Chapter |

|

|

|

33 |

Rear wheel drive |

33.1 |

|

|

|||

34 |

Brakes |

34.1 |

|

|

|||

36 |

Wheels and tyres |

36.1 |

|

|

|||

46 |

Frame |

46.1 |

|

|

|||

51 |

Equipment |

51.1 |

|

|

|||

52 |

Seat |

52.1 |

|

|

|||

61 |

General electrical equipment |

61.1 |

|

|

|||

62 |

Instruments |

62.1 |

|

|

|||

63 |

Lights |

63.1 |

|

65 |

Radio and optional extras |

65.1 |

|

|

|||

|

|

|

|

BMW AG Motorcycle Division

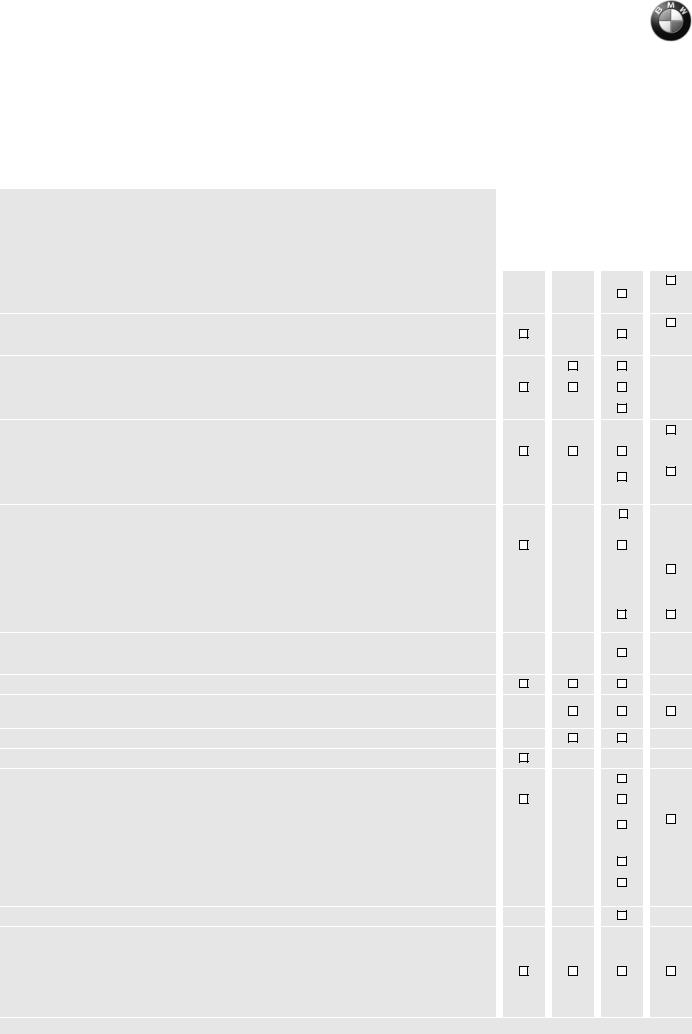

Maintenance schedule

K 1200 LT

|

|

|

|

|

|

Customer |

Licence plate No. |

||

|

|

|

|

|

|

Order No. |

Mechanic’s signature |

||

|

|

|

|

|

Read out the fault memory with the BMW MoDiTeC unit

Check throttle cable play, adjust if necessary

Change engine oil while at operating temperature

If the motorcycle is ridden only for short distances or at outside temperatures below 0 °C (32 °F), this work must be done every 3 months or at least every 3,000 km (1,800 miles) *)

BMW Inspection at 1,000 km (600 miles) |

|

BMW Service every 10,000 km (6,000 miles) |

|

BMW Inspection every 20,000 km (12,000 miles) |

|

BMW Annual Service |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Change oil in gearbox while at operating temperature at least every 2 years *)

Change oil in rear wheel drive while at operating temperature at least every 2 years *)

Examine brake pads and discs for wear, replace if necessary *)

Check the front/rear brake fluid level

Check operation of brake system and freedom from leaks; repair/replace items if necessary *)

Replace the brake fluid at least once a year

Check clutch operating fluid level

Change clutch fluid

every 40,000 km (24,000 miles) or at least every 2 years *)

Replace fuel filter *)

generally every 40,000 km (24,000 miles), if the fuel is of poor quality, every 20,000 km (12,000 miles)

Check and top up, where necessary, coolant level and concentration

Replace the coolant at least every 2 years*)

Check battery acid level, if necessary add distilled water

Clean/grease battery terminals if necessary

Replace intake air cleaner element

If severe dirt and dust are encountered, replace the intake air cleaner every 10,000 km (6,000 miles) or even more frequently *)

Check function of side stand contact switch

Grease side stand bearing, check that the centre stand moves freely, and grease it if necessary *)

Check the steering damper

Check tightness of rear wheel studs

Check rear wheel bearing play by rocking wheel

Check swinging arm bearings (free of play), adjust if necessary *)

Clean the inductive sensor on the rear wheel every 40,000 km (24,000 miles) or at least every 2 years *)

Check valve clearances, adjust if necessary

Replace the lining of the chain tensioning rail and chain guide rail every 60,000 km (36,000 miles)*)

Replace spark plugs

Final inspection with road safety and functional check:

–Condition of tires and wheels, tyre pressure

–Clutch, gearshift mechanism, hand and foot brake, ABS, steering system

–Lighting and signalling equipment, telltale lights, instruments, horn

–Reversing aid, radio with remote contro, optional equipment fitted

–Trial run if necessary

*) Charged as an additional item

every 2 years

every 2 years

40,000

every 2 years

40,000

every 2 years

40,000

every 2 years

60,000

Order No. 01 71 9 799 278 |

UX-VS-2, 01/99 |

Printed in Germany |

BMW AG Motorcycle Division

Pre-delivery check

K 1200 LT

|

|

|

|

|

Customer |

Licence plate No. |

|||

|

|

|

|

|

Order No. |

Mechanic’s signature |

|||

|

|

|

|

|

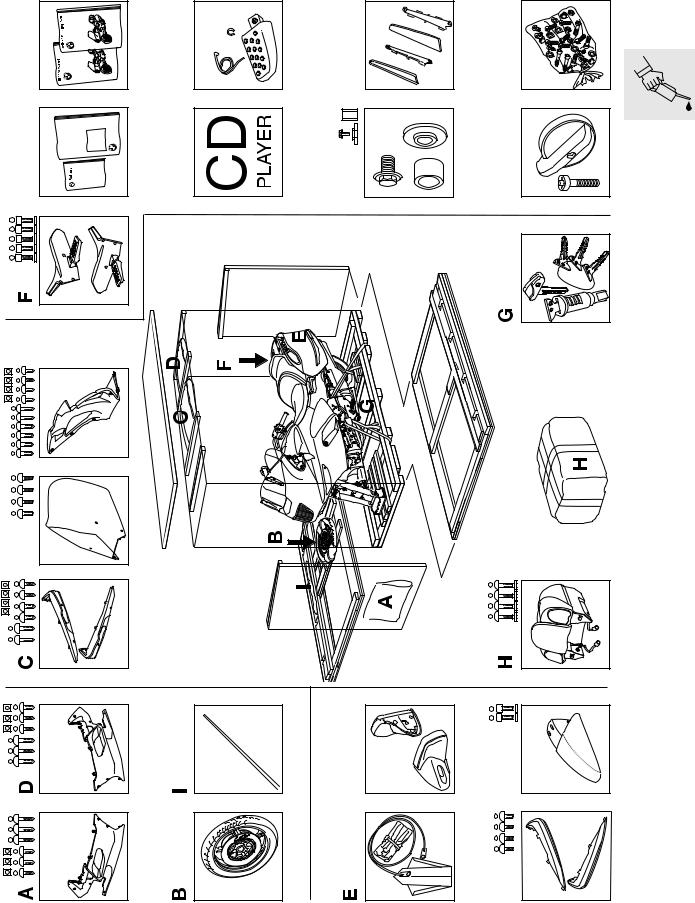

Check the shipping crate for damage

Unpacking the motorcycle

– |

unpack |

|

– |

inspect for damage |

|

– |

check that delivery is complete |

Motorcycle keys |

|

|

Top case lock cylinder |

|

|

Toolkit and helmet lock |

Documentation

Top case (packed separately)

Optional extras

Installing remaining items on motorcycle

–Fit front wheel and mudguard

–Fit the mirror

–Fit the right-hand side footrest and passenger footrest plate

–Fit engine spoiler, reversing aid actuation, bumpers

–Install the top case

Fill and charge the battery (mark with charging date)

Check the front/rear brake fluid level

Check clutch fluid level

Check tyre pressures

Check rear wheel studs for tightness (note correct tightening torque)

Fit antenna, windshield

Checking and adjusting the motorcycle

–Check function of side stand contact switch

–Seat

–Top case

–Headlight, spring strut

Add fuel

Final inspection and function check

–Check engine oil when engine is cold

–Clutch, gearshift mechanism, reversing aid

–Lighting and signalling equipment, telltale lights, instruments

–Check radio for operation

–Hand brake and foot brake, ABS

–Check optional equipment for operation

CD player, on-board computer, cruise control

–Trial run if necessary

Confirm pre-delivery check in Service and Technical Booklet

Final cleaning

Motorcycle handed over on:

BMW

Pre-delivery check

Order No. 01 71 9 799 278 |

UX-VS-2, 01/99 |

Printed in Germany |

00 Maintenance and general instructions

Tightening torques and Table of operating fluids Pre-delivery check

Maintenance

Contents |

Page |

Tightening torques ...................................................................................................................... |

7 |

Table of operating fluids ......................................................................................................... |

19 |

00.1

Contents - Pre-delivery check |

Page |

Overview: K1200LT packing materials ........................................................................... |

21 |

Checking the shipping crate for damage ..................................................................... |

22 |

Damage discovered in Germany ............................................................................................ |

22 |

Damage discovered in importer markets ........................................................................... |

22 |

Unpacking the motorcycle .................................................................................................... |

23 |

Installing the front wheel ....................................................................................................... |

24 |

General instructions ................................................................................................................. |

26 |

Pushing the motorcycle onto a workshop platform ....................................................... |

26 |

Inspecting motorcycle for damage .................................................................................. |

26 |

Checking that delivery is complete .................................................................................. |

26 |

Installing remaining items on motorcycle .................................................................... |

27 |

Installing the front mudguard ................................................................................................... |

27 |

Installing the mirrors .................................................................................................................... |

27 |

Installing the footrests ................................................................................................................. |

28 |

Installing the rear left footrest plate .................................................................................................... |

28 |

Installing the rear right footrest and footrest plate ............................................................................. |

28 |

Installing the engine spoilers ................................................................................................... |

29 |

Installing the reverser control .................................................................................................. |

29 |

Installing the skirts ........................................................................................................................ |

29 |

Installing the top case ................................................................................................................. |

30 |

Additional instructions for moving the backrest ................................................................................. |

30 |

Filling and charging the battery ......................................................................................... |

31 |

Checking brake fluid level ..................................................................................................... |

32 |

Front brake ....................................................................................................................................... |

32 |

Rear brake ........................................................................................................................................ |

33 |

Checking clutch fluid level .................................................................................................... |

34 |

Checking tyre pressures ........................................................................................................ |

34 |

Checking tightness of rear wheel studs ........................................................................ |

34 |

Installing the aerial .................................................................................................................... |

34 |

Installing the windscreen ....................................................................................................... |

35 |

00.2

Contents - Pre-delivery check |

Page |

Installing the windscreen cover .............................................................................................. |

35 |

Checking and adjusting the motorcycle ........................................................................ |

35 |

Checking the function of side stand contact switch ..................................................... |

35 |

Adjusting the seat ......................................................................................................................... |

35 |

Adjusting the top case ................................................................................................................ |

35 |

Checking headlight beam angle, adjusting if necessary ............................................. |

36 |

Vertical adjustment ............................................................................................................................ |

36 |

Lateral adjustment ............................................................................................................................. |

36 |

Final inspection and function check ............................................................................... |

37 |

Final cleaning ................................................................................................................................ |

37 |

00.3

Contents - Maintenance |

Page |

Key to maintenance intervals .............................................................................................. |

38 |

General instructions ................................................................................................................. |

39 |

Pushing the motorcycle onto a workshop platform ....................................................... |

39 |

High idle speed .............................................................................................................................. |

39 |

Removing the aerial ..................................................................................................................... |

39 |

Reading the fault code memory with the MoDiTeC ................................................ |

40 |

(Inspections I, II, III and IV) ................................................................................................................. |

40 |

Checking throttle cable play, adjusting if necessary ............................................. |

40 |

(Inspections I and III) ......................................................................................................................... |

40 |

Models without cruise control ................................................................................................. |

40 |

Models with cruise control ........................................................................................................ |

40 |

Throttle-opener cable, throttle-closer cable ...................................................................................... |

40 |

Cruise-control system cable .............................................................................................................. |

41 |

Turning the throttle twist grip relative to the throttle valve shaft .............................. |

41 |

Cruise control system does not switch off ......................................................................................... |

41 |

Cruise control system cannot be set, or continually shuts down ....................................................... |

41 |

Changing engine oil, replacing oil filter element ...................................................... |

42 |

(Inspections I, II, III and IV) ................................................................................................................. |

42 |

Changing gearbox oil ............................................................................................................... |

43 |

Change the gearbox oil every two years at the latest ......................................................................... |

43 |

(Inspection III) .................................................................................................................................... |

43 |

Changing the oil in the rear wheel drive ........................................................................ |

44 |

Change the oil in the rear wheel drive every two years at the latest ................................................... |

44 |

(Inspections I and III) ......................................................................................................................... |

44 |

Brake pads/brake discs .......................................................................................................... |

45 |

Checking brake pads and discs for wear and replacing if necessary ................................................. |

45 |

(Inspections II and III) ......................................................................................................................... |

45 |

Checking brake pads for wear ................................................................................................ |

45 |

Front brake pads ............................................................................................................................... |

45 |

Rear brake pads ................................................................................................................................ |

45 |

Replacing brake pads ................................................................................................................. |

46 |

Front brake ........................................................................................................................................ |

46 |

Rear brake ........................................................................................................................................ |

47 |

Checking the brake discs ......................................................................................................... |

48 |

00.4

Contents - Maintenance |

Page |

Checking the front/rear brake fluid level ...................................................................... |

48 |

(Inspections I, II and III) ...................................................................................................................... |

48 |

Checking the front brake fluid level ...................................................................................... |

48 |

Checking the fluid level with brake fluid |

|

reservoir open ................................................................................................................................... |

49 |

Checking the rear brake fluid level ........................................................................................ |

50 |

(Inspections I, II and III) ...................................................................................................................... |

50 |

Checking operation of brake system and freedom from leaks, repairing/repla- |

|

cing if necessary ............................................................................................................................ |

50 |

(Inspection III) .................................................................................................................................... |

50 |

Changing brake fluid and bleeding brake system ................................................... |

51 |

Change the brake fluid once a year at the latest ................................................................................ |

51 |

(Inspection IV) .................................................................................................................................... |

51 |

Front brake ....................................................................................................................................... |

51 |

Forcing back the brake pistons ......................................................................................................... |

51 |

Opening the brake fluid reservoir ....................................................................................................... |

51 |

Bleeding the front brake pressure modulator .................................................................................... |

52 |

Bleeding the left brake calliper .......................................................................................................... |

52 |

Bleeding the front right brake calliper ................................................................................................ |

53 |

Rear brake ........................................................................................................................................ |

54 |

Bleeding the rear brake pressure modulator ..................................................................................... |

54 |

Forcing back the brake pistons ......................................................................................................... |

54 |

Bleeding the brake calliper ................................................................................................................ |

55 |

Checking clutch fluid level .................................................................................................... |

55 |

(Inspections I, II and III) ...................................................................................................................... |

55 |

Changing the clutch fluid (every 40,000 km/24,000 miles) .................................. |

56 |

Change the clutch fluid every 2 years at the |

|

latest ................................................................................................................................................. |

56 |

(Inspection III) .................................................................................................................................... |

56 |

Replacing fuel filter (every 40,000 km/24,000 miles) ............................................... |

58 |

(Inspection III) .................................................................................................................................... |

58 |

Removing the fuel pump unit ................................................................................................... |

58 |

Removing and installing fuel filter .......................................................................................... |

59 |

Installing the fuel-pump unit ..................................................................................................... |

59 |

Checking and topping up, if necessary, coolant level and concentration .60 |

|

(Inspections I and III) ......................................................................................................................... |

60 |

Changing coolant ....................................................................................................................... |

61 |

(Inspection IV) .................................................................................................................................... |

61 |

Draining coolant ............................................................................................................................. |

61 |

Filling coolant system .................................................................................................................. |

62 |

00.5

Contents - Maintenance |

Page |

Battery .............................................................................................................................................. |

63 |

(Inspections III and IV) ....................................................................................................................... |

63 |

Check battery acid level and add distilled water if necessary; inspect battery terminals and clean and |

|

grease them if necessary .................................................................................................................. |

63 |

Checking battery acid level ...................................................................................................... |

63 |

Adding distilled water .................................................................................................................. |

63 |

Installing the battery ..................................................................................................................... |

63 |

Replacing intake air filter element .................................................................................... |

64 |

(Inspection III) .................................................................................................................................... |

64 |

Checking function of side stand contact switch ...................................................... |

64 |

(Inspections I, II and III) ...................................................................................................................... |

64 |

Greasing the side stand .......................................................................................................... |

65 |

(Inspections II, III and IV) .................................................................................................................... |

65 |

Checking the centre stand, greasing if necessary .................................................. |

65 |

(Inspections II, III and IV) .................................................................................................................... |

65 |

Checking the centre stand

Greasing the centre stand

.......................................................................................................65

........................................................................................................65

Checking the steering damper ........................................................................................... |

67 |

(Inspections II and III) ......................................................................................................................... |

67 |

Checking tightness of rear wheel studs ........................................................................ |

67 |

(Inspection I) ...................................................................................................................................... |

67 |

Checking rear wheel bearing play by tilting wheel .................................................. |

67 |

(Inspection III) .................................................................................................................................... |

67 |

Checking swinging arm bearings, adjusting if necessary ................................... |

67 |

(Inspections I and III) ......................................................................................................................... |

67 |

Cleaning the inductive sensor on the rear wheel (every 40,000 km/ |

|

24,000 miles) ................................................................................................................................. |

67 |

Clean the inductive sensor on the rear wheel every two years at the latest ....................................... |

67 |

(Inspection III) .................................................................................................................................... |

67 |

Checking valve clearances, adjusting if necessary ................................................ |

68 |

(Inspection III) .................................................................................................................................... |

68 |

Checking valve clearances

Adjusting valve clearances

.......................................................................................................68

.......................................................................................................68

Replacing the chain tensioning rail lining and chain guide rail ........................ |

70 |

(every 60,000 km/36,000 miles) ........................................................................................................ |

70 |

Replacing spark plugs ............................................................................................................. |

71 |

(Inspection III) .................................................................................................................................... |

71 |

Final inspection with road safety and functional check ....................................... |

71 |

(Inspections I, II, III and IV) ................................................................................................................. |

71 |

00.6

00

Tightening torques

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

|

|

11 Engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder head |

|

|

|

|

|

|

|

|

|

|

|

Cylinder head bolts |

|

|

|

|

|

Joint torque |

|

20 |

Oiled before installation |

|

|

|

|

|

|||

Wrench angle |

90° |

|

|

|

|

|

|

|

|

|

|

Cylinder head cover |

|

9 |

|

|

|

|

|

|

|

|

|

Heat shield for cylinder-head cover |

|

5 |

|

|

|

|

|

|

|

|

|

Coolant stub pipe |

|

9 |

|

|

|

|

|

|

|

|

|

Intake stub pipe |

|

9 |

|

|

|

|

|

|

|

|

|

Split conrods |

|

|

|

|

|

|

|

|

|

|

|

Split-conrod bearing |

|

20 |

|

|

|

Wrench angle |

80° |

|

|

|

|

|

|

|

|

|

|

Crankshaft |

|

|

|

|

|

|

|

|

|

|

|

Rotor flange |

|

50 |

|

|

|

|

|

|

|

|

|

Main bearing |

|

50 |

|

|

|

|

|

|

|

|

|

Cover, crankcase |

|

9 |

|

|

|

|

|

|

|

|

|

Freewheel |

|

|

|

|

|

|

|

|

|

|

|

Cover plate |

|

10 |

|

|

|

|

|

|

|

|

|

Engine block |

|

|

|

|

|

|

|

|

|

|

|

Collared bearing, output shaft |

|

40 |

|

|

|

|

|

|

|

|

|

Needle bearing, output shaft |

|

20 |

|

|

|

|

|

|

|

|

|

Lower section of crankcase |

|

10 |

|

|

|

|

|

|

|

|

|

Oil sump |

|

10 |

|

|

|

|

|

|

|

|

|

Oil drain plug |

|

30 |

|

|

|

|

|

|

|

|

|

Oil filter cover |

|

10 |

|

|

|

|

|

|

|

|

|

Oil filter |

|

11 |

|

|

|

|

|

|

|

|

|

Oil mesh strainer |

|

10 |

|

|

|

|

|

|

|

|

|

00.7

|

|

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

11 Engine |

|

|

|

|

|

|

|

|

|

Camshafts |

|

|

|

|

|

||

|

|

|

|

|

|

|

Bearing cap |

|

10 |

|

|

|

|

|

|

|

Chain sprockets |

|

56 |

|

|

|

|

|

|

|

Intermediate flange |

|

|

|

|

|

||

|

|

|

|

|

|

|

Thrust plate, driver to intermediate flange |

|

9 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Driver to auxiliary shaft |

|

50 |

|

|

|

|

|

|

|

Intermediate flange to engine block |

|

9 |

|

|

|

|

|

|

|

Timing case |

|

|

|

|

|

|

|

|

|

Chain tensioner to cover of timing case |

|

9 |

|

|

|

|

|

|

|

Screw plug for chain tensioner |

|

9 |

|

|

|

|

|

|

|

Timing case cover |

|

9 |

|

|

|

|

|

|

|

Oil/water pump |

|

|

|

|

|

|

|

|

|

Water-pump impeller to pump shaft |

|

33 |

|

|

|

|

|

|

|

Water-pump temperature sensor |

|

9 |

|

|

|

|

|

|

|

Oil pressure switch |

|

35 |

|

|

|

|

|

|

|

Oil pressure relief valve screw plug |

|

35 |

|

|

|

|

|

|

|

Pump housing to crankcase |

|

10 |

|

|

|

|

|

|

|

Cover, pump housing |

|

10 |

|

|

|

|

|

00.8

Model |

K 1200 LT |

|

|

|

|

|

|

Connection |

Nm |

|

|

|

|

|

|

12 Engine electrics |

|

|

|

|

|

|

|

Spark plugs |

20 |

|

|

|

|||

|

|

|

|

Ignition coil |

|

|

|

|

|

|

|

Ignition coil to mounting plate |

8 |

|

|

|

|

|

|

Mounting plate to intermediate flange |

9 |

|

|

|

|||

|

|

|

|

Cover, shield housing |

5 |

|

|

|

|

|

|

Ignition signal sensor |

|

|

|

|

|

|

|

Rotor |

4 |

|

|

|

|

|

|

Magnetic gate |

6 |

|

|

|

|

|

|

Cover, ignition sensor |

9 |

|

|

|

|

|

|

Alternator |

|

|

|

|

|

|

|

Mount to intermediate flange |

20 |

|

|

|

|

|

|

Driver housing to alternator shaft |

50 |

|

|

|

|

|

|

Connector, lead B+ |

10 |

|

|

|

|

|

|

Connector, lead D+ |

2 |

|

|

|

|

|

|

Starter motor |

|

|

|

|

|

|

|

Starter motor to gearbox |

6 |

|

|

|

|

|

|

Pinch bolt, starter-motor housing |

6 |

|

|

|

|

|

|

Positive lead to starter motor |

6 |

|

|

|

|

|

|

Earth (ground) lead to cross-tube |

6 |

|

|

|

|

|

|

13 Fuel preparation and control |

|

|

|

|

|

|

|

Air intake connection to cylinder head |

9 |

|

|

|

|

|

|

Hose clips |

Hand-tight |

|

|

|

|

|

|

Fuel lines to engine |

9 |

|

|

|

|

|

|

Injection rail to cylinder head |

9 |

|

|

|

|

|

|

Retaining plate for cruise control system to |

|

|

|

fairing bracket |

8 |

|

|

|

|

|

|

Throttle-valve actuator to throttle-valve rail |

5 (clean thread + Loctite 270) |

|

|

|

|

|

|

Throttle-valve potentiometer to throttle- |

|

|

|

valve rail |

2 |

|

|

|

|

|

|

Temperature sensor to intake air silencer |

15 |

|

|

|

|

|

|

00.9

|

|

Model |

K 1200 LT |

|

|

|

|

|

|

Connection |

Nm |

|

|

|

|

|

|

16 Fuel tank and lines |

|

|

|

|

|

|

|

Union nut, fuel-pump unit |

30 |

|

|||

|

|

|

|

|

|

Roll-over valve |

3 |

|

|

|

|

|

|

Immersion-tube sensor |

6 |

|

|

|

|

|

|

Fuel tank to frame M 8 |

21 |

|

|||

|

|

|

|

|

|

Bridge to frame M 8 |

21 |

|

|

|

|

|

|

Bridge to frame M 6 |

9 |

|

|

|

|

|

|

17 Radiator |

|

|

|

|

|

|

|

Hose clips |

Hand-tight |

|

|

|

|

|

|

Fan to radiator |

2 (clean thread + Loctite 2701) |

|

|

|

|

|

|

Water pump temperature sensor |

9 |

|

|

|

|

|

|

Coolant stub pipe to cylinder head |

9 |

|

|

|

|

|

|

18 Exhaust system |

|

|

|

|

|

|

|

Oxygen sensor to exhaust system |

45 |

|

|

|

|

|

|

Exhaust system to cylinder head |

22 |

|

|

|

|

|

|

Exhaust mountings |

|

|

|

|

|

|

|

Retaining plate to pivot mount |

41 |

|

|

|

|

|

|

Stirrup to retaining plate |

30 (clean thread + Loctite 243) |

|

|

|

|

|

|

Stirrup to silencer |

21 |

|

|

|

|

00.10

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

21 Clutch |

|

|

|

|

|

|

|

|

|

Clutch-lever fitting to handlebar |

|

5 |

|

|

|

||||

|

|

|

|

|

Grub screw in filler adapter |

|

10 |

|

|

|

|

|

|

|

Filler adapter to breather line |

|

18 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Clutch housing to output shaft |

|

|

|

|

|

|

|

|

|

initial torque |

|

140 |

|

|

release |

|

|

|

|

second torque |

|

50 |

|

|

wrench angle |

60° |

|

|

|

|

|

|

|

|

Cover to clutch housing |

|

18 |

|

|

|

|

|

|

|

Lines to clutch slave cylinder |

|

7 |

|

|

|

|

|

|

|

Clutch slave cylinder to gearbox |

|

9 |

|

|

|

|

|

|

|

Pressure line to clutch fitting |

|

18 |

|

|

|

|

|

|

|

Connector, pressure line |

|

10 |

|

|

|

|

|

|

|

23 Transmission |

|

|

|

|

|

|

|

|

|

Oil drain plug |

|

55 |

|

|

|

|

|

|

|

Oil filler plug |

|

30 |

|

|

|

|

|

|

|

Speed sensor for reverser to gearbox |

|

|

|

|

housing |

|

6 |

|

|

|

|

|

|

|

Housing cover to housing |

|

9 |

|

|

|

|

|

|

|

Gearshift linkage |

|

|

|

|

|

|

|

|

|

Selector lever to selector shaft |

|

9 |

|

|

|

|

|

|

|

Relay lever to transverse tube |

|

9 |

|

|

|

|

|

|

|

Ball head to gearshift pedal |

|

8 (clean thread + Loctite 2701) |

|

|

|

|

|

|

|

Gearbox mounts |

|

|

|

|

|

|

|

|

|

Gearbox to intermediate flange |

|

24 |

|

|

|

|

|

|

|

Clamp, rubber mount |

|

9 |

|

|

|

|

|

|

|

Gearbox to frame |

|

70 |

|

|

|

|

|

|

|

Reverser |

|

|

|

|

|

|

|

|

|

Link from actuator for reverser to |

|

|

|

|

intermediate flange |

|

24 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Actuator, reverser to link |

|

24 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Reverse gear switch to actuating shaft |

|

9 |

|

|

|

|

|

|

|

Switch unit, reverser to gearbox |

|

9 |

|

|

|

|

|

|

|

Actuator lever, reverser |

|

6 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Cover, reverser to gearbox housing |

|

10 |

|

|

|

|

|

|

|

Cover plate, reverser |

|

10 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Threaded pin M 6 in cover, reverser |

|

5 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

00.11

|

|

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

31 Front forks |

|

|

|

|

|

|

|

|

|

Fork bridge to frame |

|

|

|

|

(nut micro-encapsulated) |

|

130 (clean thread + new nut or Loctite 2701) |

|

|

|

|

|

|

|

Fork stanchion to fork bridge |

|

45 |

|

|

|

|

|

|

|

Steering damper to slider tube bridge |

|

|

|

|

|

||

|

|

(screw micro-encapsulated) |

|

21 (clean thread + new screw or Loctite 243) |

|

|

|

|

|

|

|

Steering damper to leading link |

|

21 (clean thread + new screw or Loctite 243) |

|

|

|

|

|

|

|

Leading link to fork slider bridge |

|

|

|

|

(nut micro-encapsulated) |

|

130 (clean thread + Loctite 2701) |

|

|

|

|

|

|

|

Ball joint to fork slider bridge |

|

230 |

|

|

|

|

|

|

|

Leading link to fork slider bridge |

|

130 (clean thread + Loctite 2701) |

|

|

|

|

|

|

|

Leading link to frame |

|

107 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Clamp, leading link M 8 |

|

21 |

|

|

|

|

|

|

|

Spring strut to leading link |

|

43 |

|

|

|

|

|

|

|

Suspension strut to frame |

|

43 |

|

|

|

|

|

|

|

Slider tube bridge to slider tube |

|

21 (clean thread + new screw or Loctite 243) |

|

|

|

|

|

|

|

Brake distributor to holder, sliding tube right |

|

9 |

|

|

|

|

|

|

|

Oil drain plug in slider tube |

|

12 |

|

|

|

|

|

|

|

Vent screw, stanchion |

|

3 |

|

|

|

|

|

|

|

32 Steering |

|

|

|

|

|

|

|

|

|

Brake-lever fitting to handlebar |

|

5 |

|

|

|

|

|

|

|

Clutch-lever fitting to handlebar |

|

5 |

|

|

|

|

|

|

|

Handlebar to fork bridge |

|

21 |

|

|

|

|

|

|

|

Bearing screw, brake and clutch levers |

|

5 (clean thread + Loctite 2701) |

|

|

|

|

|

00.12

Model |

K 1200 LT |

|

|

|

|

|

|

Connection |

Nm |

|

|

|

|

|

|

33 Rear wheel drive |

|

|

|

|

|

|

|

Oil drain plug |

23 |

|

|

|

|||

|

|

|

|

Oil filler plug |

23 |

|

|

|

|

|

|

Speed sensor mount |

5 |

|

|

|

|

|

|

Threaded ring |

118 (clean thread + Hylomar SQ 32) |

|

|

|

|||

|

|

|

|

Nut, bevel drive pinion |

200 (clean thread + Loctite 270) |

|

|

|

|

|

|

Housing cover to housing |

35 |

|

|

|

|

|

|

Rear wheel drive to swinging arm |

|

|

|

|

|

|

|

Reaction link to rear wheel drive |

43 |

|

|

|

|

|

|

Reaction link to frame |

43 |

|

|

|

|

|

|

Free bearing stud |

7 |

|

|

|

|

|

|

Fixed bearing stud |

160 |

|

|

|

|

|

|

Locknut |

160 |

|

|

|

|

|

|

Swinging arm to frame |

|

|

|

|

|

|

|

Fixed bearing stud |

160 |

|

|

|

|

|

|

Lock ring |

160 |

|

|

|

|

|

|

Threaded ring, right |

200 |

|

|

|

|

|

|

Threaded ring, left |

10 |

|

|

|

|

|

|

Suspension strut |

|

|

|

|

|

|

|

Handwheel to rear frame |

21 |

|

|

|

|

|

|

Suspension strut to swinging arm |

50 |

|

|

|

|

|

|

Suspension strut to frame |

43 |

|

|

|

|

|

|

00.13

|

|

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

34 Brakes |

|

|

|

|

|

|

|

|

|

Front brake |

|

|

|

|

|

||

|

|

|

|

|

|

|

Brake calliper to fork tube |

|

40 |

|

|

|

|

|

|

|

Brake disc to front wheel |

|

21 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

ABS sensor |

|

4 |

|

||||

|

|

|

|

|

|

|

Grubscrew in filler adapter |

|

10 |

|

|

|

|

|

|

|

Filler adapter in brake calliper |

|

18 (clean thread + new filler adapter or |

|

|

|

|

Loctite 243) |

|

|

|

|

|

|

|

Vent screw in brake calliper |

|

10 |

|

|

|

|

|

|

|

Brake-lever fitting to handlebar |

|

5 |

|

|

|

|

|

|

|

Holder for brake line to sliding tube |

|

4 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Brake lines to frame/slider tube M 6 |

|

9 |

|

|

|

|

|

|

|

Banjo bolts for brake line |

|

18 |

|

|

|

|

|

|

|

Rear brake |

|

|

|

|

|

|

|

|

|

Brake calliper to rear-wheel drive |

|

40 |

|

|

|

|

|

|

|

Brake disc to rear wheel drive |

|

21 (clean thread + new screws) |

|

|

|

|

|

|

|

ABS sensor ring to brake-disc carrier |

|

4 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

ABS sensor |

|

4 |

|

|

|

|

|

|

|

Vent screw in brake calliper |

|

10 |

|

|

|

|

|

|

|

Footbrake lever to footrest plate |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Holder, stop-lamp switch to footrest plate |

|

5 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Locknut for stop screw, foot brake lever |

|

7 |

|

|

|

|

|

|

|

Locknut on piston rod |

|

9 |

|

|

|

|

|

|

|

Brake line to brake cylinder |

|

18 |

|

|

|

|

|

|

|

Brake cylinder to footrest plate |

|

9 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Banjo bolts for brake line |

|

18 |

|

|

|

|

|

|

|

Brake line to frame M 5 |

|

4 |

|

|

|

|

|

|

|

Retaining plate for brake line to battery |

|

|

|

|

carrier |

|

4 |

|

|

|

|

|

|

|

ABS pressure modulator |

|

|

|

|

|

|

|

|

|

Bleed screw in ABS pressure modulator |

|

10 |

|

|

|

|

|

|

|

Brake line to ABS pressure modulator |

|

18 |

|

|

|

|

|

|

|

ABS II control unit to battery holder M 5 |

|

4 |

|

|

|

|

|

|

|

ABS II control unit to battery holder M 6 |

|

9 |

|

|

|

|

|

|

|

Battery holder to frame M 6 |

|

9 |

|

|

|

|

|

|

|

Battery holder to frame M 8 |

|

21 |

|

|

|

|

|

00.14

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

36 Wheels and tyres |

|

|

|

|

|

|

|

|

|

Rear wheel mount |

|

|

|

|

Initial tightening |

|

50 |

|

|

Final tightening |

|

105 |

|

|

|

|

|

|

|

Quick-release axle, front wheel |

|

|

|

|

Initial tightening |

|

19 |

|

|

|

||||

Final tightening |

|

30 |

|

|

|

|

|

|

|

Pinch bolt, quick-release axle |

|

21 |

|

|

|

|

|

|

|

46 Frame |

|

|

|

|

|

|

|

|

|

Frame |

|

|

|

|

|

|

|

|

|

Engine cross members to main frame |

|

74 |

|

|

|

|

|

|

|

Engine cross members to engine |

|

41 |

|

|

|

|

|

|

|

Transverse tube to main frame |

|

41 |

|

|

|

|

|

|

|

Torsion stop, swinging-arm bushings |

|

Fitted flush with bushing (clean thread + |

|

|

|

|

Loctite 243) |

|

|

|

|

|

|

|

Skirt bracket M 8 |

|

21 |

|

|

|

|

|

|

|

Crash bar to skirt bracket |

|

9 |

|

|

|

|

|

|

|

Lifter handle to rear frame M 6 |

|

9 |

|

|

|

|

|

|

|

Rear frame to main frame, top |

|

41 |

|

|

|

|

|

|

|

Rear frame to main frame, bottom |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Radiator holder to frame/engine cross |

|

|

|

|

member M 6 |

|

10 |

|

|

|

|

|

|

|

Radiator holder to fairing bracket/skirt |

|

|

|

|

bracket M 8 |

|

21 |

|

|

|

|

|

|

|

Fairing bracket |

|

|

|

|

|

|

|

|

|

Fairing bracket to main frame M 8 |

|

21 |

|

|

|

|

|

|

|

Windscreen adjuster to fairing bracket at |

|

|

|

|

side |

|

9 |

|

|

|

|

|

|

|

Windscreen adjuster to fairing bracket at |

|

|

|

|

centre |

|

3 |

|

|

|

|

|

|

|

Fasteners for retaining plates M 5 |

|

4 |

|

|

|

|

|

|

|

Fasteners for retaining plates M 6 |

|

11 |

|

|

|

|

|

|

|

Fasteners for retaining plates M 8 |

|

21 |

|

|

|

|

|

|

|

Threaded fasteners, mirror plate M 6 |

|

9 |

|

|

|

|

|

|

|

00.15

|

|

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

46 Frame |

|

|

|

|

|

|

|

|

|

Footrests |

|

|

|

|

|

||

|

|

|

|

|

|

|

Footrest system front to frame |

|

21 |

|

|

|

|

|

|

|

Footrest system rear to frame |

|

21 |

|

|

|

|

|

|

|

Footrest rubber to footrest |

|

4 |

|

||||

|

|

|

|

|

|

|

Shift lever to footrest plate |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Footbrake lever to footrest plate |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Stop, footbrake lever |

|

7 |

|

|

|

|

|

|

|

Stop screw, return spring for footbrake lever |

|

5 |

|

|

|

|

|

|

|

Rear section, side cases and top case |

|

|

|

|

|

|

|

|

|

Rear carrier to rear frame |

|

9 |

|

|

|

|

|

|

|

Cover, rear carrier to rear frame |

|

9 |

|

|

|

|

|

|

|

Cover, rear carrier to case |

|

1 |

|

|

|

|

|

|

|

Side case to rear frame |

|

9 |

|

|

|

|

|

|

|

Strap to top of case |

|

2 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Case trimmer to rear frame |

|

5 |

|

|

|

|

|

|

|

Case trimmer to case |

|

2 |

|

|

|

|

|

|

|

Top case to rear frame |

|

9 |

|

|

|

|

|

|

|

Armrest to top case |

|

1 |

|

|

|

|

|

|

|

Stands |

|

|

|

|

|

|

|

|

|

Pivot mount to gearbox |

|

41 |

|

|

|

|

|

|

|

Main stand to pivot mount |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Side stand to pivot mount |

|

41 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Fairing |

|

|

|

|

|

|

|

|

|

Fairing screws |

|

2 |

|

|

|

|

|

|

|

Windscreen to windscreen adjuster |

|

2 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Cover of fork bridge. |

|

2 |

|

|

|

|

|

|

|

Front mudguard, front, to fork slider bridge |

|

|

|

|

M 6 |

|

4 |

|

|

|

|

|

|

|

Front mudguard, front section, to sliding |

|

|

|

|

tube M 6 |

|

6 |

|

|

|

|

|

|

|

Front mudguard, rear section, to fork slider |

|

|

|

|

bridge M 6 |

|

3 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Miscellaneous |

|

|

|

|

|

|

|

|

|

Intake air pipe to fairing bracket |

|

10 |

|

|

|

|

|

|

|

Intake air pipe to radiator holder |

|

10 |

|

|

|

|

|

00.16

Model |

|

K 1200 LT |

|

|

|

|

|

|

|

Connection |

|

Nm |

|

|

|

|

|

|

|

51 Equipment |

|

|

|

|

|

|

|

|

|

Non-removable screw for ignition/steering |

|

|

|

|

lock |

|

21 |

|

|

|

|

|

|

|

Lock, tank cover to bridge |

|

5 |

|

|

|

|

|

|

|

Locking mechanism, front seat to rear frame |

|

5 |

|

|

|

||||

|

|

|

|

|

52 Seat |

|

|

|

|

|

|

|

|

|

Bridge, seat to frame M 6 |

|

9 |

|

|

|

|

|

|

|

Bridge, seat to frame M 8 |

|

21 |

|

|

|

|

|

|

|

Front hinge, seat to bridge |

|

9 |

|

|

|

|

|

|

|

Seat, front, to carrier plate |

|

5 |

|

|

|

|

|

|

|

Gas-filled strut to carrier plate for seat, front |

|

21 |

|

|

|

|

|

|

|

Seat, rear, to rear frame |

|

9 |

|

|

|

|

|

|

|

Backrest, rear, to top case |

|

5 |

|

|

|

|

|

|

|

61 General electrical equipment |

|

|

|

|

|

|

|

|

|

Retaining plate for fanfare horn to fairing |

|

|

|

|

bracket |

|

21 |

|

|

|

|

|

|

|

Ignition lock to fork bridge |

|

21 |

|

|

|

|

|

|

|

Wiring harness to main frame |

|

6 |

|

|

|

|

|

|

|

Electronics box to main frame |

|

9 |

|

|

|

|

|

|

|

Holder for plug and socket connections |

|

|

|

|

behind battery panel, left |

|

9 |

|

|

|

|

|

|

|

Attachment, side-stand switch |

|

7 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Holder, stop-lamp switch to footrest plate |

|

5 (clean thread + Loctite 243) |

|

|

|

|

|

|

|

Locknut for stop screw, foot brake lever |

|

7 |

|

|

|

|

|

|

|

Temperature sensor, cylinder head |

|

30 |

|

|

|

|

|

|

|

Attachments, battery holder |

|

4 |

|

|

|

|

|

|

|

Speed sensor, rear wheel |

|

4 |

|

|

|

|

|

|

|

Socket to engine spoiler |

|

4 |

|

|

|

|

|

|

|

Socket to top case |

|

4 |

|

|

|

|

|

|

|

00.17

|

|

Model |

K 1200 LT |

|

|

|

|

|

|

Connection |

Nm |

|

|

|

|

|

|

62 Instruments |

|

|

|

|

|

|

|

Instrument cluster to fairing bracket |

6 |

|

|||

|

|

|

|

|

|

63 Lights |

|

|

|

|

|

|

|

Headlight to upper section of fairing |

2 |

|

|

|

|

|

|

Rear light cluster to case trimmer |

5 |

|

|

|

|

|

|

65 Radio and optional extras |

|

|

|

|

|

|

|

Clamping nut, stub aerial |

3 |

|

|

|

|

|

|

Aerial holder to frame |

9 |

|

|

|

|

|

|

Retaining plate for cruise control system to |

|

|

|

fairing bracket |

8 |

|

|

|

|

|

|

Holder for temperature sensor to upper |

|

|

|

section of fairing |

2 |

|

|

|

|

00.18

Table of operating fluids

Item |

Use |

Order number |

Quantity |

|

|

|

|

|

|

|

|

Lubricant |

|

|

|

|

|

|

|

|

|

|

|

Staburags NBU 30 PTM |

High-performance lubricating paste |

07 55 9 056 992 |

75 g tube |

|

|

|

|

|

|

|

|

Optimoly MP 3 |

High-performance lubricating paste |

07 55 9 062 476 |

100 g tube |

|

|

|

|

|

|

|

|

Optimoly TA |

High-temperature assembly paste |

18 21 9 062 599 |

100 g tube |

|

|

|

|

|

|

|

|

Silicone grease 300, heavy |

Damping grease |

07 58 9 058 193 |

10 g tube |

|

|

|

|

|

|

|

|

Retinax EP2 |

Wheel, steering head and taper roller |

83 22 9 407 845 |

100 g tube |

|

|

|

bearing grease |

|

|

|

|

|

|

|

|

|

|

Contact spray |

Contact spray |

81 22 9 400 208 |

300 ml spray |

|

|

|

|

|

|

|

|

Chain spray |

Drive chain |

72 60 2 316 676 |

50 ml spray |

|

|

72 60 2 316 667 |

300 ml spray |

|

|

||

|

|

|

|

||

|

|

|

|

|

|

Sealants |

|

|

|

|

|

|

|

|

|

|

|

3-Bond 1110 B |

Surface sealant |

07 58 9 056 998 |

5 g tube |

|

|

|

|

|

|

|

|

3-Bond 1209 |

Surface sealant |

07 58 9 062 376 |

30 g tube |

|

|

|

|

|

|

|

|