Page 1

aCAUTION

Never touch the rear brake pedal after removing the wheel. If you do, the caliper

pistons may be pushed o ut of thei r seats,

and brake fluid wil l be spilled. Should

you accidentally do this, take your vehicle to your Local APRILIADealer who will

know how to repair this damage.

REASSEMBLY

◆

Apply a thin film of grease to the outer

seals of the rear wheel hub.

aCAUTION

While reassembling the wheel, be careful not to damage the brake line, the

disc and the pads.

◆

Position the wheel centrally in the swinging arm, on the support (1).

aWAR NING

Keep your fing ers well away from the

chain and sprocket. You could ea sily

lose a finger if it becomes pinched between thes e two pa rts. Us e heavy work

gloves while installing the rear wheel.

Never attempt to line the rear wheel up

using your fingers. Failure to heed this

warning can result in serious personal

injury.

◆

Move the wheel as f ar for war d as po ssible, to install the drive chain (6) on the

rear sprocket (7).

◆

Pull the rear wheel backwards until the

bearing holes are lined up with the holes

in the swinging arm.

◆

Lightly grease the outside of the axle (2).

◆

Install the washer (5) on the axle (2).

NOTE To facilitate the insertion of the

axle (2), slightly raise the wheel.

◆

Install the axle (2) completely through

the wheel from the left side.

NOTE Ensure that the ax le (2) is pushe d

all the way home with the head in the appropriate seat on the left chain tightener.

◆

Install the washer (4) and tighten the nut

(3) finger tight.

◆

Remove the support (1) from under the

rear tire.

◆

Check the chain tension, see p. 78

(DRIVE CHAIN).

◆

Tighten the nut (3).

Wheel nut (3) tightening torque:

72.33 ftlb (100 Nm).

aWARNING

After servicing t he brakes, always

check them for function. If the stroke of

the lever or pedal is excessive, or if you

detect that the effect iveness of the

brakes is reduced in any way, have y our

vehicle serviced by your Local APRILIA

Dealer. It may be necessary to ha ve

your dealer bleed the sy stem, or ther e

may be some other problem with the

brake system.

Never ride your veh i c le in traffic immediately after servicing the brakes.

Always apply the brake pedal or lever

several times before riding your vehicle .

Then, try yo ur v eh i cl e in a park ing lo t or

other safe area with little t raff ic to ens ure

that the brakes are working properly.

Failure to observe this warning can lead

to a serious accident with subsequent serious injury or death.

Check the wheel centering.

Have the t ightening torques, centerin g

and balancing of the wheel checked by

your Local APRILIA Dealer. These are

critical safety operations, and failure to

observe this warning could lead to an

upset with subsequent serious injury or

death.

use and maintenance Pegaso 650

-

77

Page 2

$2)6%#(!).

Carefully read p. 61 (MAINTENANCE).

Every 312 mi (50 0 km) check the conditions, the wear, the play (tension) and the

lubrication of the drive chain.

The vehicle is equipped with an endle ss

chain. There is no master link used.

aWARNING

An excessively loose cha in can come

off the sprocket which can result in a

serious accident and serio us dama ge to

the vehicle from the upset and subsequent serious injury or even death.

Do not ride your vehicle with an improperly adjusted chain, see p. 79 (ADJUSTMENT).

To inspect the conditio n of the chain,

grasp the chain where it goes around

the sprocket and try to pull it away from

the sprocket. If you can move it more

than one-eighth of a n inch away from

the sprocket, the chain is worn out and

the chain and both front and rear

use and maintenance Pegaso 650

78

-

sprockets must be replaced. See your

Local APRILIADealer.

aCAUTION

Lack of maintenance can cause premature wear of the chain an d damage to

the sprockets.

Maintain your chain more often if your

vehicle is used on dusty or muddy roads.

aWAR NING

Before carring out the following operations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

aWAR NING

Keep your fingers well clea r of the chain

and sprocket, especially if you are turning the rear wheel while working on the

vehicle. You can easily be seriously injured if a finger is caught between the

chain and sprocket. Use work-gloves to

carrying out these operation.

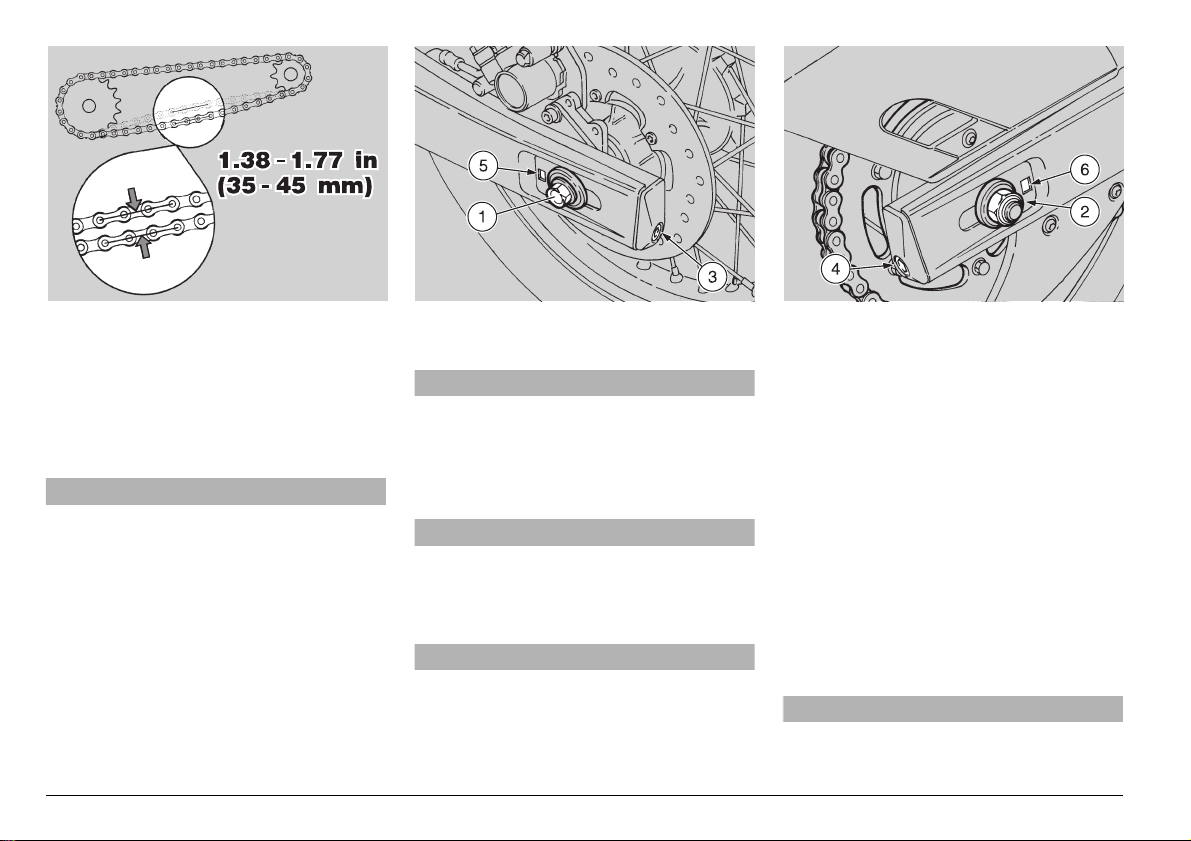

CHECKING THE PLAY

To check the play:

◆

Stop the engine.

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Shift to neutral.

◆

Check the chain p lay. It shoul d be 1 .38 –

1.77 in (35 – 45 mm) at mid-bottom span

as shown abov e.

◆

Move the vehicle forward or backward,

or support the rear wheel in the air and

turn the wheel to several positions, to

check the chain slack at several locations. If the slack is markedly different

with the wheel in different positions, the

chain and sprockets must be replaced.

aWARNING

Do not ever operate your vehicle with a

damaged chain. This could cause

wheel seizure which could lead to an

Page 3

upset with subsequent serious injury or

death. Lubricate your chain frequently

to minimize the possibility of this kind

of damage, see p. 79 (CLEANING AND

LUBRICATION).

If the play is the same at several locati ons, but

is more or less than 1.38 – 1.77 in (35 – 45

mm), adjust it, see p. 79 (ADJUSTMENT).

ADJUSTMENT

To adjust the chain tension:

◆

Place the vehicle on the center

stand,see p. 59 (POSITIO NING THE

VEHICLE ON THE STAND).

◆

Hold the axle (1) from rotating with an

appropriate Allen wrench.

Wheel nut (2) tightening torque:

72.33 ftlb (100 Nm).

◆

Loosen the nut (2) to several turns.

NOTE In order to facilitate whe el c en ter-

ing, numbered reference mark s are prov ided on the swinging arm, which correspond

with marks on the adjusters (3) and (4).

These marks may be seen through the

slots (5) and (6).

◆

Adjust the left (3) and right (4) tension

adjusters to obtain the appropriate chain

play, ensuring that the slot (5) and (6) coincide with the same reference marks on

each side of your vehicle.

◆

Hold the axle (1) from rotating with an

appropriate Allen wrench.

◆

Tighten the nut (2).

Wheel nut (2) tightening torque:

72.33 ftlb (100 Nm).

◆

Check the chain play again, see p. 78

(CHECKING THE PLAY).

CHECKING THE WEAR OF THE CHAIN

AND SPROCKETS

In addition to the check, see p. 78 (CHECKING THE PLAY), inspect the chain an d

sprockets to make sure that there are no:

– damaged rollers; – loose pins; – dry,

rusty, crushed or seized links; – excessive wear; – missing “O” rings; – sprock-

et or teeth excessively worn or damaged.

You may check the wear of the chain and

sprocket by grasping the chain where it con-

tacts the rear sproc ket, and pull ing it away

from the sprocket as far as you can. If you

are able to pul l the chai n far enough away

from the sprocket so that you can see light

between the side plates of the chain and the

sprocket teeth, the chain and sprocket are

worn out and should be replaced.

NOTE Always replace both sprockets

and the chain wh en any of these co mponents are replaced.

aCAU TION

If chain rollers are d amaged, the pins

and/or the O rings are loose or missing,

both sprockets as well as the chain

must be replaced.

aCAU TION

Lubricate the chain frequently, especially if it displays any rust or if it is dry to

the touch. If, after lubricating the chain,

it still has li nks which ca nnot be tu rned

easily, the chain must be replaced.

◆

Finally, check the wear of the rear fork

protection shoe.

CLEANING AND LUBRICATION

aCAUTION

The drive chain is provided with O ri ngs

among the links, in order to keep the

grease inside them.

Carry out chain adjustment, lubrication,

cleaning and replacement with great

care. Remember to keep your fingers

clear of the chain and sprocket.

Never wash the chain with water jets,

steam jets, high-pressure water jets and

highly inflammable solvents.

◆

Wash the chain with a non-flammable

solvent. If your chain rusts quickly, lubricate it more often.

Lubricate the chain every 312 mi (500 km)

or whenever it appears dry.

After washing the chain and letting it dry,

lubricate it exclusively with spray grease

for chains provided with sealing rings, see

p. 104 (LUBRICANT CHART).

aCAUTION

Make sure that the chain lubric ant you

use is appropriate for “O” ring chains.

There are some lub ricants available

which contain subst ances which will

destroy the “O” rings in your chain.

If you have any question, contact your

Local APRILIADealer.

NOTE Do not use the vehicle immedi-

ately after lubricat ing the ch ain , gi ve the lubricant a chance to dry, otherwise the

chain will spray the lubricant all over you

and your vehicle.

use and maintenance Pegaso 650

-

79

Page 4

2%-/6).'4(%&5%,4!.+

Carefully read p. 35 (FUEL) and p. 61

(MAINTENANCE).

aWARNING

Risk of fire.

Wait until the engine and th e exhau st silencer have completely cooled down.

Fuel vapors are noxious for your health .

Make sure that the room in which you

are working is properly ventilated.

Do not inhale fuel vapours.

Do not smoke and do not use naked

flames.

DISPOSE OF UNWANTED FUEL PROPERLY.

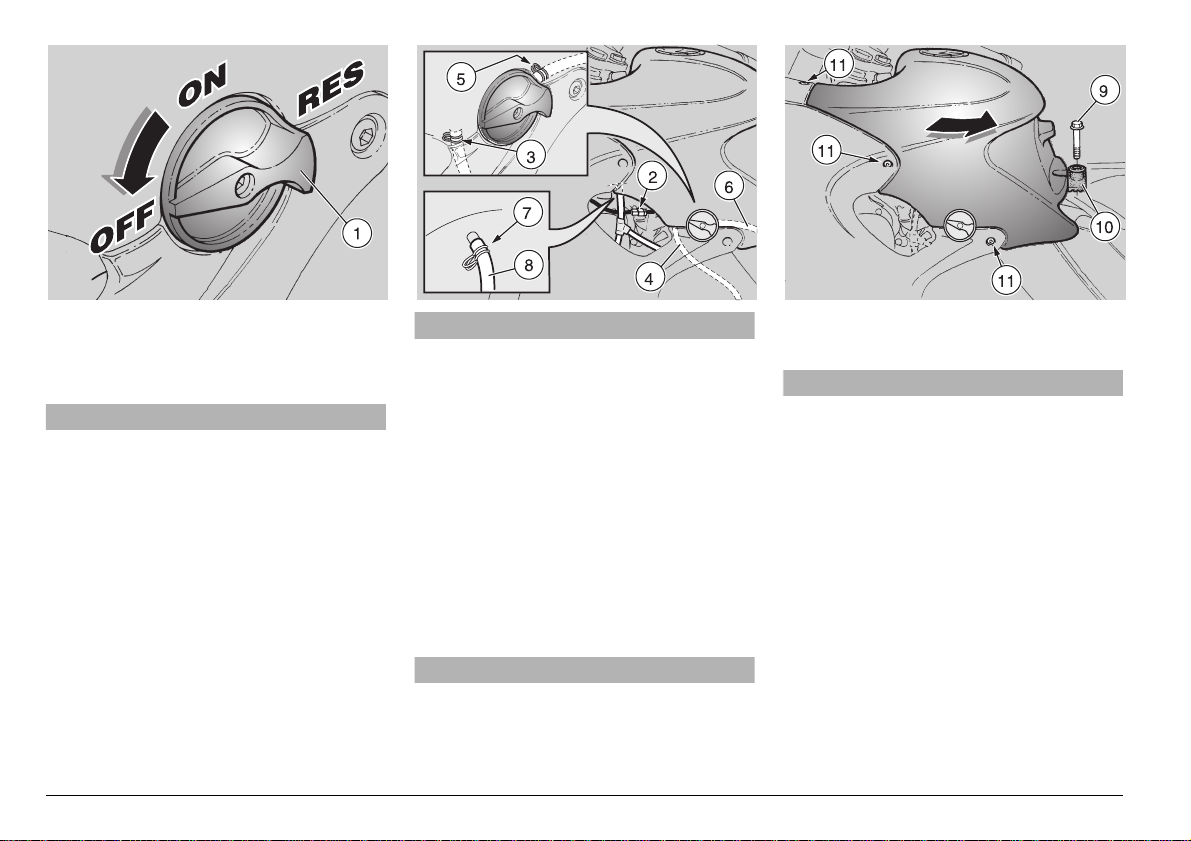

◆

Remove the saddle, see p. 81 (REMOVING THE SADDLE).

◆

Drain the fuel tank completely, see p. 97

(DRAINING THE FUEL TANK).

◆

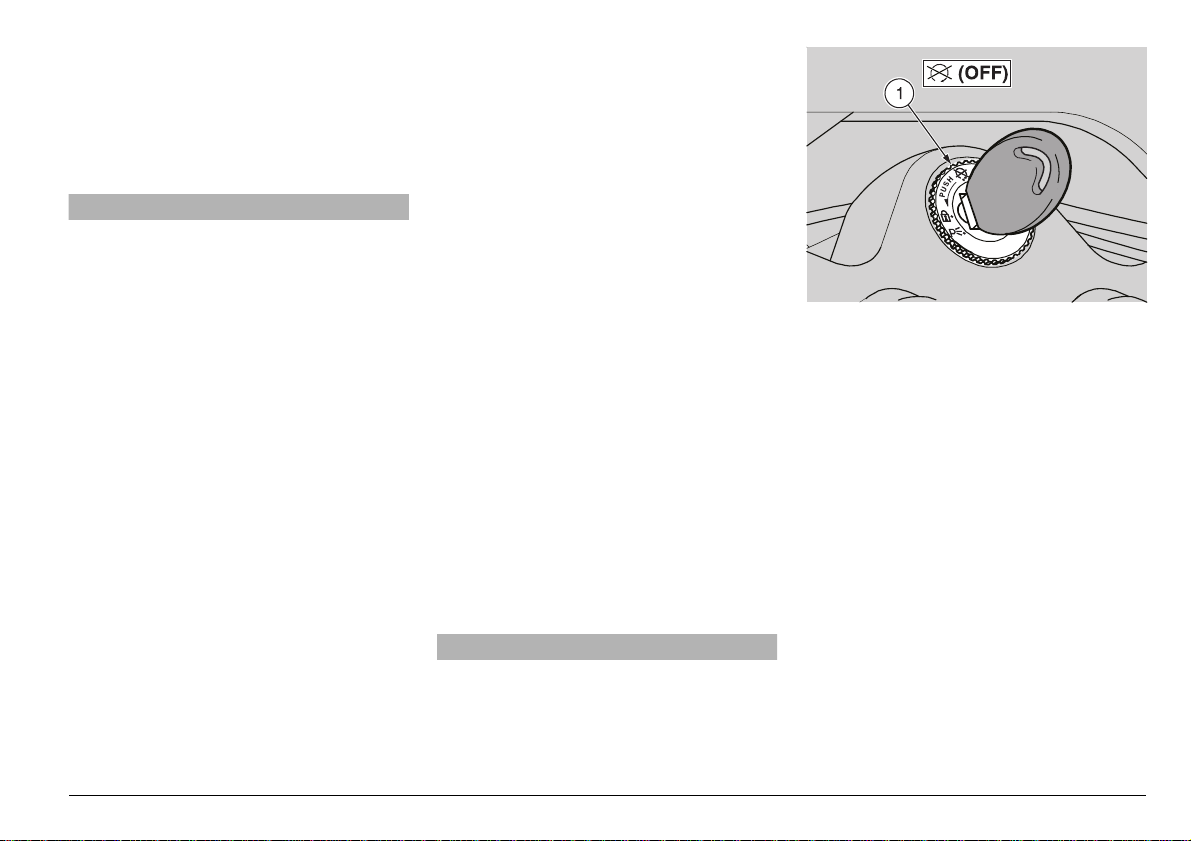

Move the fuel valve leve r (1) to the “OFF”

position.

use and maintenance Pegaso 650

80

-

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

Be careful do n ot damage the electric

cables.

NOTE To release th e clam ps , us e a p air

of pliers.

Working from the left side of the vehicle:

◆

Disconnect the electric connector (2) of

the low fuel sensor.

◆

Release the clamp (3) and disconnect

the water drain line (4 ) from the fuel tank.

◆

Release the clamp (5) and remove the

fuel line (6) from the fuel valve.

aWAR NING

Danger! Some fuel may spill.

◆

Plug the free end of the fuel line (6) and

attach it to the vehicle with a wire or ta pe

in the vertical position.

◆

Release the clamp (7) and remove the

breather line (8) from the fuel tank.

aCAU TION

Upon reassem bly, be sure that the line s (4)

and (8), the cl amp (3) and (7) and, m ost im portant the fuel line (6) and clamp (5), are

properly in stal led.

◆

Unscrew and remove the central screw (9).

◆

Take the rubber element (10) complete

of the washer and the bush.

◆

★ Unscrew and remove the three

screws (11).

◆

Slightly raise the rear part o f the fuel t ank

and at the same time withdraw it from its

two seats (i n the front part), by pulling it

backwards.

NOTE Upon reassembly, make sure

that the fuel tank fits correctly into the relative seats in the front part.

Page 5

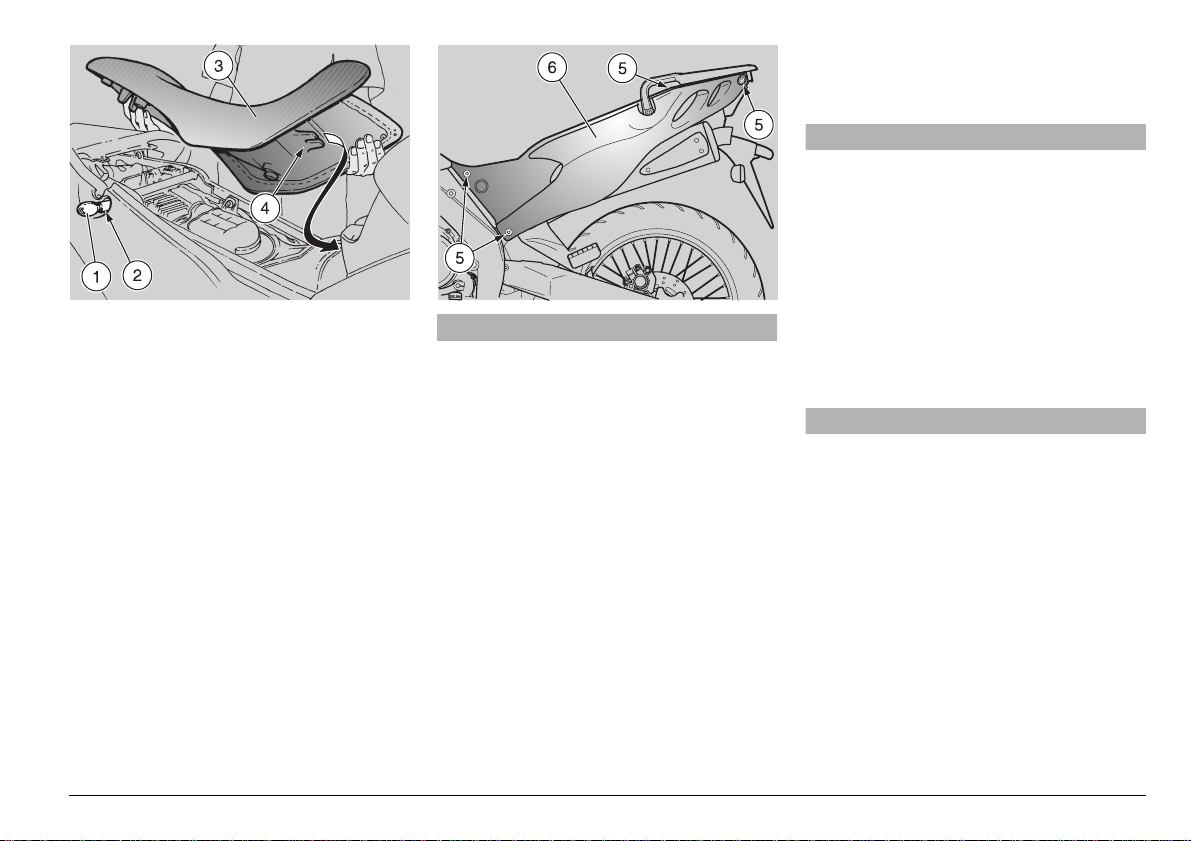

2%-/6).'4(%3!$$,%

Carefully read p. 61 (MAINTENANCE).

◆

Place the vehicle on the center or side

stand, see p. 59 (POSIT IONING THE

VEHICLE ON THE STAND).

◆

Insert the key (1) in the lock (2).

◆

Turn the key (1) clockwise.

◆

Raise and remove the saddle (3).

Upon reassembly:

NOTE Before l owering and locking the

saddle, make sure that you have not left

the key in the glove/tool kit compart ment.

◆

Insert the tang (4) of th e saddle in the appropriate seats (see figure).

◆

Lower the saddle and press the its rear

part.

aCAUTION

Do not leave you r vehicle unatte nded

without ensuring that the saddle (3) is

properly positioned and l ocked. Should

you forget and ride away with the saddle loose, you could be injured.

2%-/6).'4(%2)'(4!.$ ,%&4

3)$%0!.%,3

Carefully read p. 61 (MAINTENANCE).

aWAR NING

Before carrying out the following operations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

◆

Remove the saddle, see beside (REMOVING THE SADDLE).

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Unscrew and remove the four screws

(5).

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

◆

Remove the side panel (6).

use and maintenance Pegaso 650

-

81

Page 6

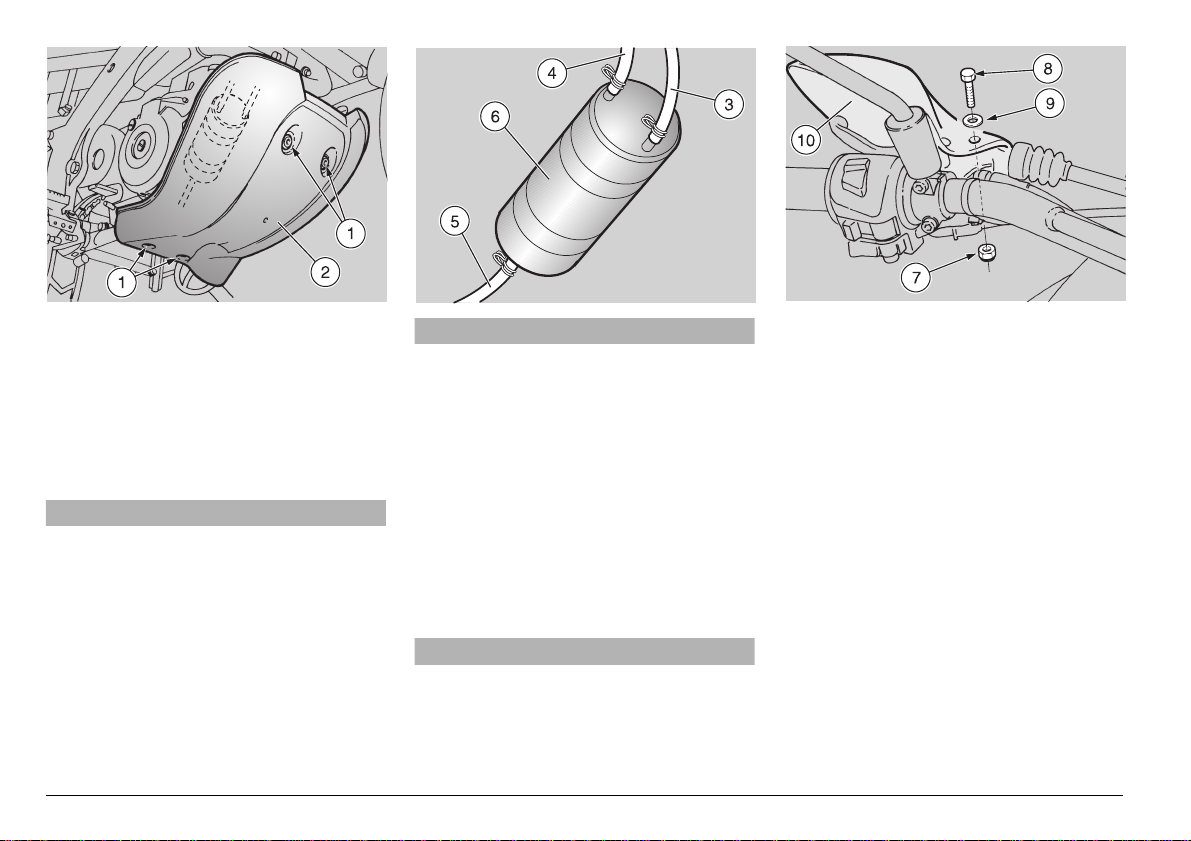

2%-/6).'4(%/),0!.'5!2$

Carefully read p. 61 (MAINTENANCE).

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Unscrew and remove the four screws

(1).

aCAUTION

While removing the oil pan guard (2),

pay extra care not to pull, force or damage the three lines (3), (4), (5) of the carbon canister (6).

◆

Remove the oil pan guard (2) only as

much as necessary to disconnect the

three lines (3), (4), (5) of the carbon canister.

aCAUTION

WHILE REASSEMBLING, PA Y EXTRA

CARE NOT TO INVERT THE LIN ES OF

THE CARBON CANISTER.

◆

Mark the lines and the relevant couplings, in order to be able to reassemble

them correctly.

NOTE To release th e clam ps , us e a p air

of pliers.

◆

Release the clamps and remove the

lines (3), (4), (5).

◆

Remove completely the oil pan guard

(2).

aCAUTION

While reassembling the oil pan guard

(2), pay extra care and ensure not to

crash the lines (3), (4), (5).

2%-/6).'4(%(!.$'5!2$3

Carefully read p. 61 (MAINTENANCE).

◆

Hold the nut (7) from rotating with an appropriate Allen wrench.

◆

Remove the screw (8) the washer (9).

◆

Remove the hand-guard (10).

use and maintenance Pegaso 650

82

-

Page 7

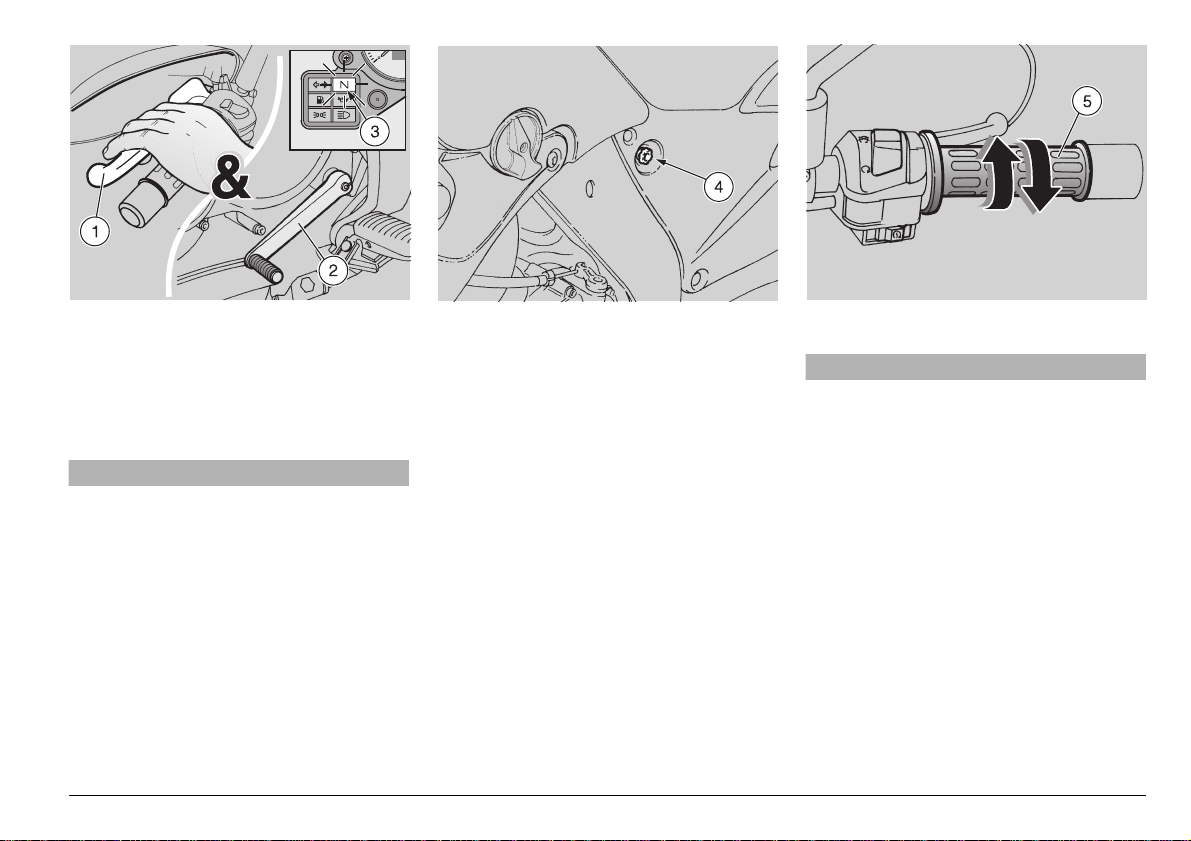

)$,).'!$*534-%.4

Carefully read p. 61 (MAINTENANCE).

If the idle becomes irregular, too fast, or

too slow, it must be adjusted.

To adjust the idle:

aWAR NING

Exhaust gases co ntain carbon monoxide, which is extremely poisonous if inhaled.

Do not start the engine in closed or badly-ventilated rooms.

Failure to observe this warning may

cause loss of consciousness or even

lead to death by asphyxia.

◆

Ride for a few miles until the engine

reaches normal running temperature,

see p. 15 (Coolant temperature indicator

h”).

“

◆

Pull in the clutch lever (1) c ompletely an d

put the shift lever (2) in neutral so that

the green “

◆

Keep the vehicle in vertical position, with

both wheels resting on the ground.

◆

Observe the tachometer.

The engine must idle 1,400 ± 100 rpm, CO

1% [+ 1% – 0.5% (total range from 0.5%

to 2%)].

q” light (3) is on.

If it does not:

aWAR NING

Do not adjust the air adjusting screw.

Doing so will upset t he idling performance of your engine, as well as increasing exhaust emissions.

◆

Adjust the knob (4) positioned on the left

side of the vehicle.

Rotate the knob clockw ise to increase

engine rpm.

Rotate the knob counterclockwise to decrease the engine rpm.

◆

Accelerate and decelerate the engine a

few times to make sure, when the throt tle

returns to idle, that the engine idle speed

is still correct.

NOTE If necessary, contact your Local

aprilia Dealer.

use and maintenance Pegaso 650

-

83

Page 8

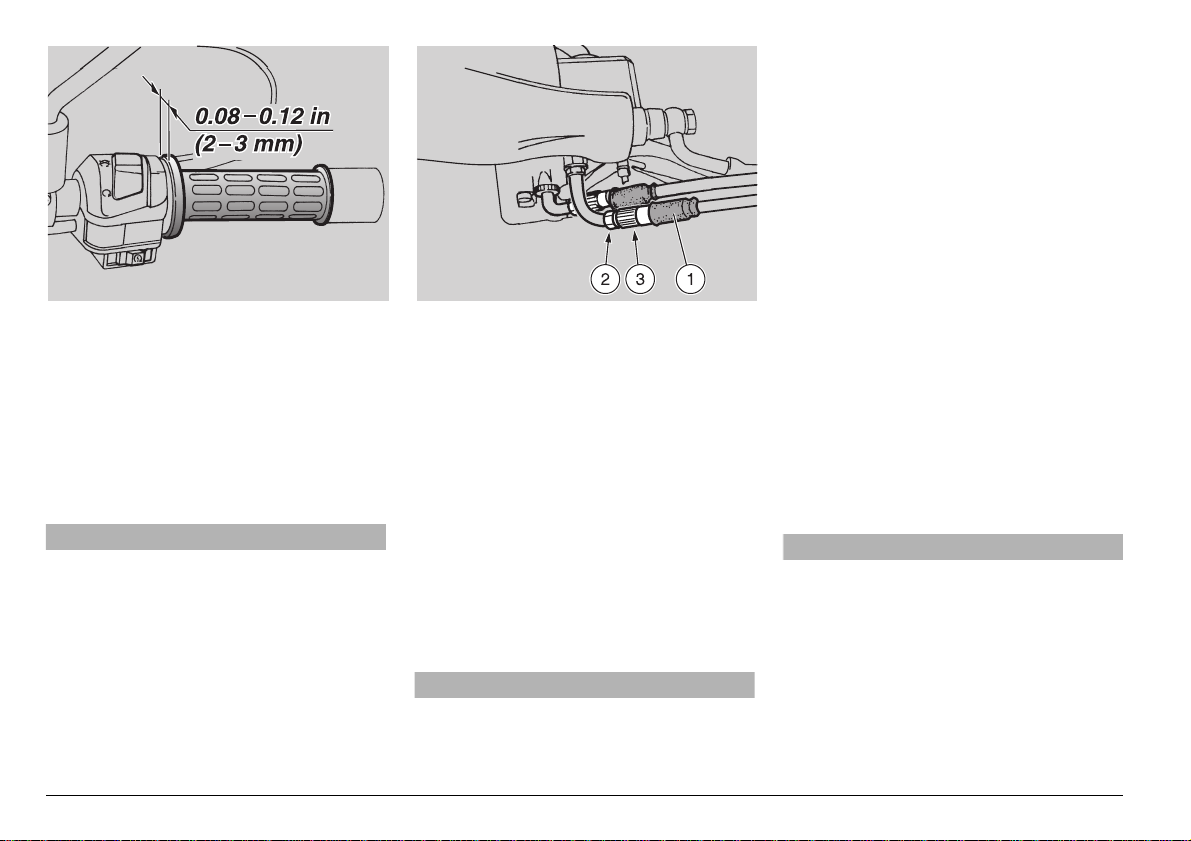

!$*534).'

4(%4(2/44,%#/.42/,

Carefully read p. 61 (MAINTENANCE).

This vehicle is equipped with two throttle

cables.

The following information may refer to just

one throttle cable but should be observed

with regard to both throttle cables.

aWARNING

If the throttle sticks open, it may cause

a collision with another ve hicle, or an

upset.

If the throttle sticks, kill the engine with

the engine stop switch located on the

right handlebar.

Do not attempt to restart the engine until the throttle has been repaired and

works perfectly. Failure to obey this

warning can lead to a runaway with se riously injuries or even death.

If any fastener in the throttle system becomes loose, likewise you w ill lose control of your vehicle.

Either si tuation c an lead to an upset or

collision with subsequent serious injury

or death.

Your vehicle is equipped with a double cable throttle. One cable opens the throttle

when you rotate the throttle grip toward

you; the other closes the throttle when you

rotate th e gr ip aw ay from y ou. I t i s es sen tial, when you release the throttle grip, that

it automatically return to the idle position.

This double cable arrangement enhances

safety by providing for positive closing of

the throttle.

aWAR NING

In the event of a throttle sticking emergency, always kill the engine using the

engine stop switch located ne ar the

throttle grip on the right handlebar.

Never use your vehicle if the throttle

does not automatically fully return to

the idle position whe n the throttle gr ip

is released. Contact your Local APRILIA

Dealer for repairs. Failure to heed this

warning can lead to a serious accident

and subsequent injury or even death.

The play of the throttle cable must be between 0.08 – 0.12 in (2 – 3 mm), measured at the edge of the grip, see the illustration above.

To adjust the cable:

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Pull back the rubber boot (1).

◆

Loosen the lock nut (2).

◆

Rotate the adjuster (3) in such a way as

to restore the prescribed value.

◆

After the adjustment, tighten the lock nut

(2) and check the play again.

◆

Replace the rubber boot (1).

◆

Repeat the adjustment for the second

cable.

aWARNING

Exhaust gases contain carbon monoxide, which is extremely poisonous if inhaled.

Do not start the engine in c losed or badly-ventilated rooms.

Failure to observe this warning may

cause loss of consciousness or even

lead to death by asphyxia.

use and maintenance Pegaso 650

84

-

Page 9

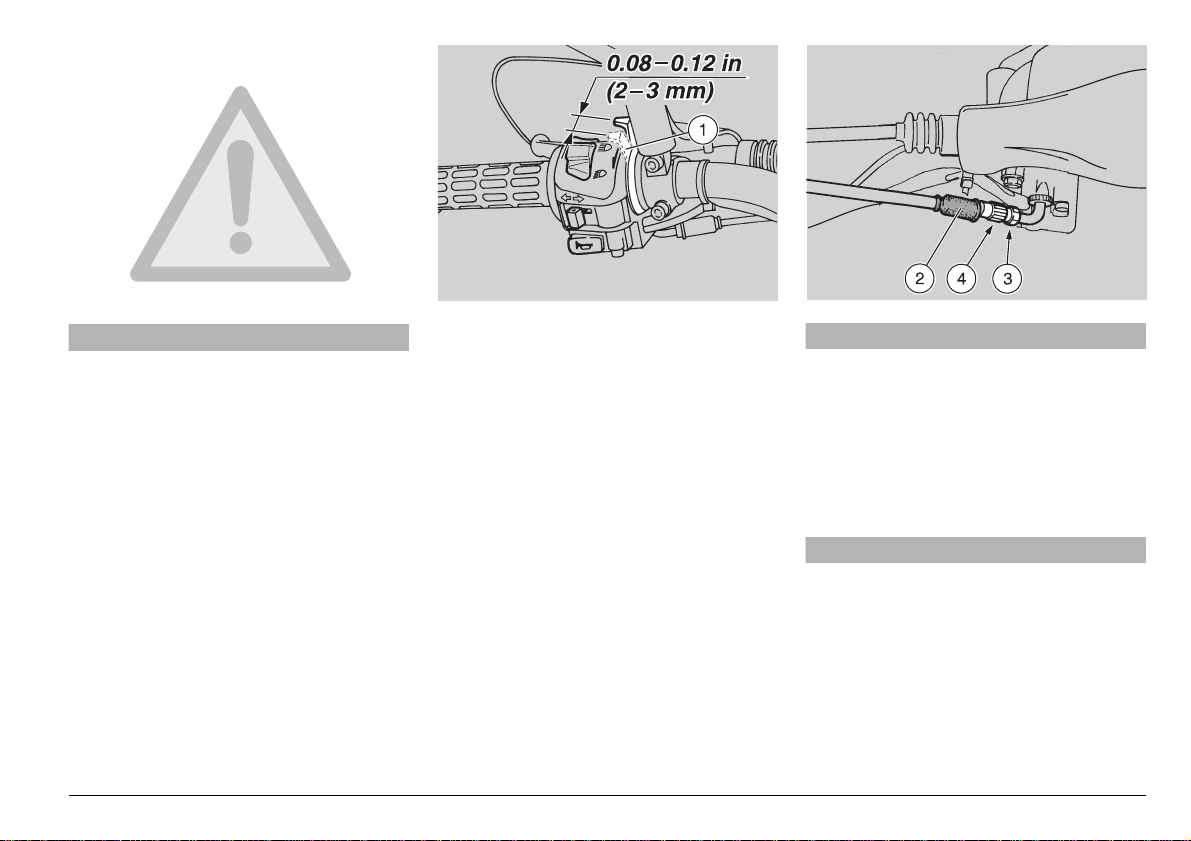

aWAR NING

After you have adjusted the throttle, rotate the handlebars full left and full right

with the engine idling. Check to ensure

that the idle sound is not affected by

this. Also check that the throttle

smoothly and fully closes when released.

!$*534).'4(%#/,$34!24

#(/+%#/.42/,

Carefully read p. 61 (MAINTENANCE).

The play of the c old s tart ca ble m ust b e between 0.08 – 0.12 in (2 – 3 mm), measured on the lever (1).

To adjust the cable:

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Pull back the rubber boot (2).

◆

Loosen the lock nut (3).

◆

Rotate the adjuster (4) in such a way as

to restore the prescribed value.

◆

After the adjustment, tighten the lock nut

(3) and check the play again.

◆

Replace the rubber boot (2).

e

aWAR NING

Exhaust gases co ntain carbon monoxide, which is extremely poisonous if inhaled.

Do not start the engine in closed or badly-ventilated rooms.

Failure to observe this warning may

cause loss of consciousness or even

lead to death by asphyxia.

aWAR NING

After you have adjus ted the cold start,

rotate the handlebars full left and full

right with the engine idling. Check to

ensure that the idle sound is not affected by this.

use and maintenance Pegaso 650

-

85

Page 10

30!2+0,5'

Carefully read p. 61 (MAINTENANCE).

Clean the spark plug every 3,750 mi

(6,000 km); change it every 7,500 mi

(12,000 km).

Periodically remo ve the spark plug and

clean it carefully, removing carbon deposits; change it if necessary.

To reach the spark plug:

◆

Remove the fuel tank, see p. 80 (REMOVING THE FUEL TANK).

To remove and clean the spark plug:

aWARNING

Before carrying out the following ope rations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

◆

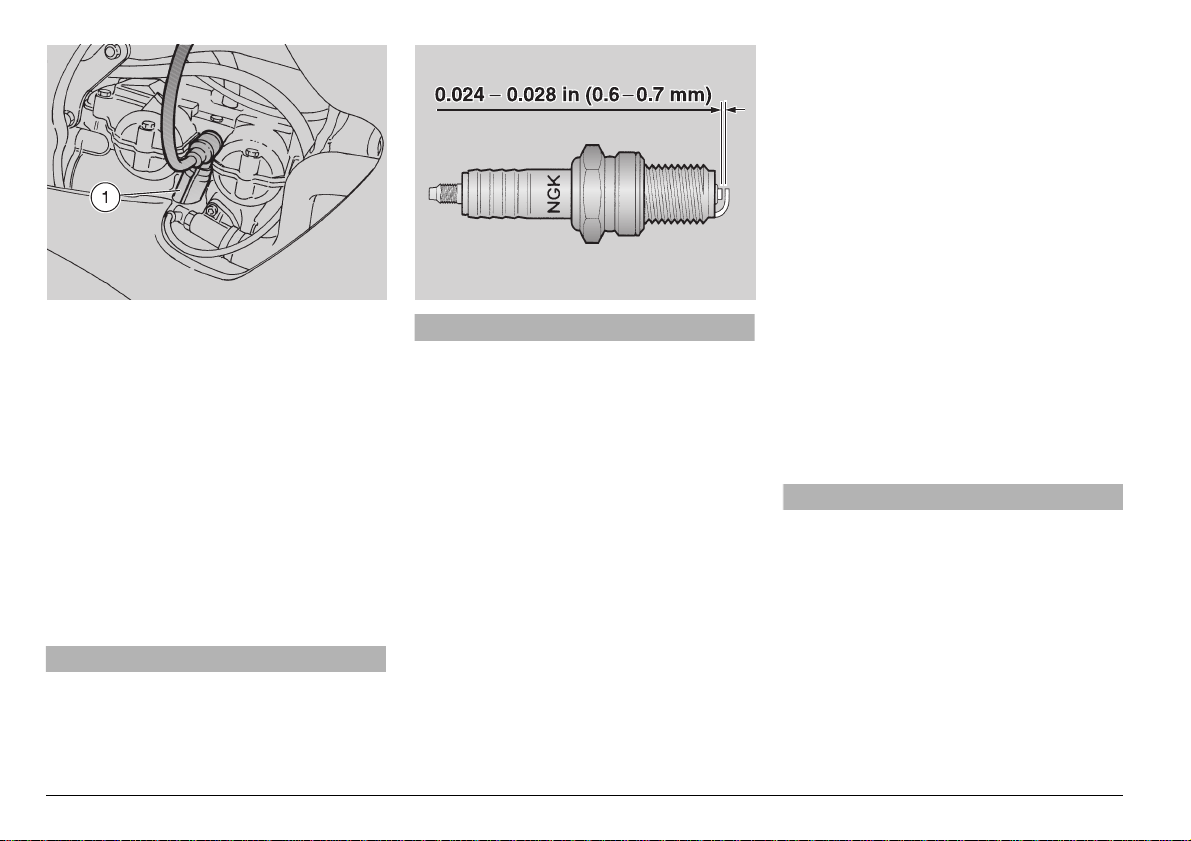

Remove the spark plug cap (1).

use and maintenance Pegaso 650

86

-

aWARNING

During this operation, always wear goggles which provide your eyes with 360°

protection. Be very careful using compressed air jets, they can cause serious

personal injury if directed towards your

body.

◆

Using compressed air, blow all the dirt

away from the base of the spark plug.

Using the special spark plug wrench

from the tool kit, unscrew the spark plug.

Make sure that no dirt falls into the cylinder through the spark plug hole.

◆

Inspect the spark plug, and insure that

there are no carbon deposits nor corrosion marks on either electrode or the ceramic nose that surrounds the center

electrode. If necessary, clean the spark

plug with a proprietary spark plug cleaner, and a stainless steel brush.

◆

Using compressed air, carefully blow out

the spark plug after you have cleaned it.

Inspect for cracks on the insulating mate rial, electrode corrosion or erosion, or

deposits that you cannot remove.

If the spark plug shows any of these defects, it must be replaced.

◆

Check the spark plug gap with a thickness gauge.

◆

The gap must be 0.024 – 0.028 in (0.6 –

0.7 mm); if necessary adjust it, carefully

bending the ground (outside) electrode.

◆

Make sure the gasket is in good condition. With the gaske t on, screw th e spark

plug into the head by hand.

◆

Tighten the spark plug with the spark

plug wrench, approxim ately one-ha lf tur n

after it first snugly contacts the cylin der

head.

Spark plug tightening torque:

14.47 ftlb (20 Nm).

aCAU TION

The spark plug must be well tightened,

otherwise the engine may overheat and

be seriously damag ed.

Use the recommended type of spark

plug only, see p. 100 (TECHNICAL DATA), in order not to compromise the life

and performance of the engine.

◆

Position the spark plug cap (1) properly,

so that it does not come off du e to the vi brations of the engine.

◆

Replace the fuel tank, see p. 80 (REMOVING THE FUEL TANK).

Page 11

"!44%29

Carefully read p. 61 (MAINTENANCE).

Check the electrolyte level and the tightness of the terminals after the first 62 5 mi

(1,000 km) and su ccessively every 3 ,750

mi (6,000 km) or 8 months.

aWAR NING

Batteries, when charged, give off hydrogen gas, which is highly explosive.

Therefore, do not smoke while working

on or around the battery, and keep naked

flames or sparks away from the battery.

Keep gasoli ne and o ther flammabl e substances well away from the battery, since

a battery spa rk could easi ly ignit e them

and cause a devastating fire.

Battery electro lyte is toxic and cau stic

and can seve rely burn your eyes or

skin. Always wear tight fitting goggles

and protective clothing when handling

battery electrolyte. It is particularly important for you to protect your eyes

since even a minuscule amount of battery acid could destroy your vision.

Should you accidentally get even the

smallest amount of battery electrolyte

on your skin or eyes, immediately flush

with large quantities of clear cool water

and immediately seek professional

medical attention.

If someone should accidentally swallow

battery electrolyte, drink a large quantity of milk or cool cle ar water a nd conti nue with milk of magnesia or vegetable

oil. Seek pro fessional medi cal assistance immediately.

Since the battery gives off exp losive hy drogen gas, especially when it is being

charged, when you are charging a battery, make sure that the room is properly ventilated. Do not inhale the gases

released during charging. Do not permit any open flames , sparks or cigarettes or any other source of heat anywhere near the battery while it is

charging.

Do not tip the vehicle too much, or tip

the battery too much , to avoid electrolyte leaking out. Should you accid entally spill battery electrolyte on any part of

your vehicle, immediately wa sh it off

with lots of cool clear water. Spills may

be neutralized with a mixture of baking

soda and water, as we ll. Th is is particularly important, as the battery electrolyte will severely corrode metallic parts

and destroy t he finish of plas tic and

painted parts.

aCAU TION

Never invert the battery cables. Observe the proper polarity of the battery.

Incorrectly attaching the battery to your

vehicle will irreparably destroy the electrical system of your vehicle.

Connect and disc onnect the battery

only with the ignition switch (1) in the

m” (OFF) position.

“

First connect the positive cable red (+),

then the negative (–).

Disconnect the negative cabl e (–) first,

then the positive red (+).

If your battery needs to be charged, use

a constant voltage, or “taper” charger,

with a current rating no greater than

1/10th the capacity of the battery (i.e.,

for a 50 amp hour battery, th e ma xim um

charging current should be 5 amps).

Use of a more powerful charger can not

only damage the battery irrepara bly, but

could cause it to overheat and explode.

If your battery is equipped with an overflow tube, always ensure that it is properly installed, and properly routed. Failure

to adhere to this instruction can cause

corrosive fumes from the battery to cause

serious damage to your vehicle.

use and maintenance Pegaso 650

-

87

Page 12

"!44%2934/2!'%

Carefully read p. 87 (BATTERY).

If your vehicle remains unused for more

than a couple of weeks, it will be necessary to “trickle charge” th e battery, to prevent battery damage, see p. 89 (RECHARGING THE BA TTE RY ) .

◆

Remove the battery, see beside (REMOVING THE BATTERY), and put it in a

cool, dry place.

◆

The best way to p revent battery det erioration is to constantly leave a “trickle”

charger with a capa city of about 1/10 th

amp attached. These chargers are very

economically available from your Local

aprilia Dealer, and will ensure that your

battery always remains in t ip top condition.

◆

If this cannot be don e, charge the ba ttery

for about 30 minutes using a ba ttery

charger with a current capacity of no

greater than 1/10th the capacity of the

battery, see p. 89 (RECHA RGING THE

BATTERY).

◆

While we recommend removing the battery from t he v eh i cl e, i f yo u mu st l eav e it

in your vehicle, disconnect bo th battery

cables.

use and maintenance Pegaso 650

88

-

#(%#+).'!.$#,%!.).'

4(%4%2-).!,3

Carefully read p. 87 (BATTERY).

◆

Remove the left side panel, see p. 81

(REMOVING THE RIGHT AND LEFT

SIDE PANELS).

◆

Remove the red protection rubber (1).

◆

Make sure that the cable terminals (2)

and the battery terminals (3) are:

– in good conditions (and not corroded or

covered with deposits);

– covered with neutral grease or Vaseline.

If it is necessary to clean the battery terminals:

◆

Remove the battery, see beside (REMOVING THE BATTERY).

◆

Brush with a wire brush to eliminate any

sign of corrosion.

◆

Check the electrolyte level, see p. 89

(CHECKING THE ELECTROLYTE LEVEL).

◆

Install the battery, see p. 89 (INSTALLING

THE BATTERY).

2%-/6).'4(%"!44%29

Carefully read p. 87 (BATTERY).

◆

Make sure that the ignition switch (4) is

m” (OFF) position.

in “

◆

Remove the left side panel, see p. 81

(REMOVING THE RIGHT A ND LEFT

SIDE PANELS).

◆

Unscrew and remove the screw (5).

◆

Remove the battery cover (6).

◆

Remove the red protection rubber (1).

◆

Disconnect first t he negati ve (–) and the n

the positive cable red ( +).

◆

Remove the battery breather tube (7).

◆

Remove the battery from its compartment and put it on a flat s urface , in a coo l

and dry place.

aWARNING

Once it has been removed, the battery

must be stored in a safe place and kept

away from children: risk of serious injuries or even death.

Page 13

◆

Replace the battery cover (6).

◆

Screw the screw (5).

◆

Replace the left side panel, see p. 81

(REMOVING THE RIGHT AND LEFT

SIDE PANELS).

#(%#+).'

4(%%,%#42/,94%,%6%,

Carefully read p. 87 (BATTERY).

To check the electrolyte level, proceed as

follows:

NOTE Carry out these checks only on a

firm, flat surface such as a co ncrete gara ge

floor.

◆

Remove the left side panel, see p. 81

(REMOVING THE RIGHT AND LEFT

SIDE PANELS).

◆

Unscrew and remove the screw (5).

◆

Remove the battery cover (6).

◆

Make sure that the fluid level falls between the “MIN” and “MAX” notches

stamped on the side of the battery. If it

does not:

◆

Remove the battery, see p. 88 (REMOVING THE BATTERY).

◆

Remove the battery plugs.

aCAUTION

Top up with distilled water only. Do not

exceed the “MAX” mark, since the electrolyte le vel increases du ring the recharge.

◆

Top up by adding distilled water.

2%#(!2').'4(%"!44%29

Carefully read p. 87 (BATTERY).

◆

Remove the battery, see p.88 (REMOVING THE BATTERY).

◆

Remove the battery plugs.

aWARNING

The battery gives off noxio us and expl osive gases; keep it away from flames,

sparks, cigarettes and any other source

of heat.

During recharging or use, make sure

that the room is properly ventilated and

avoid inhali ng the gases re leased during the recharging.

◆

Check the electrolyte level, see beside

(CHECKING THE ELECTROLYTE LEVEL).

◆

Connect the battery charger to the battery.

◆

Charge the battery u sing a battery charger with a curre nt capacity of no greater

than 1/10th the capacity of the battery,

see p. 100 (TECHNICAL DATA).

◆

After the recharging op era tion, check the

electrolyte level again and if necessary

top up with distilled water.

aCAU TION

Do not replace the battery plugs until 10

minutes after disconnecting the charger, since the battery continues to produce gas after the charger is removed.

◆

Replace the battery plugs.

).34!,,).'4(%"!44%29

Carefully read p. 87 (BATTERY).

◆

Check the charge of the battery, see beside (RECHARGING THE BATTERY).

◆

Make sure that the ignition switch (4) is

in the “m” (OFF) position.

◆

Remove the left side panel, see p. 81

(REMOVING THE RIGHT AND LEFT

SIDE PANELS).

◆

Unscrew and remove the screw (5).

◆

Remove the battery cover (6).

◆

Put the battery in its container.

◆

Connect the battery breather tube (7).

aCAUTION

Reconnect the battery breather tube (7),

see p. 87 (BATTERY).

◆

Connect, in order, the positive red (+)

and negative (–) cable .

◆

Cover the terminals of the cables and of

the battery with neutral grease or Vaseline.

◆

Replace the red protection rubber (1).

◆

Replace the battery cover (6).

◆

Screw and tighten the screw (5).

◆

Replace the left side panel, see p. 81

(REMOVING THE RIGHT AND LEFT

SIDE PANELS).

use and maintenance Pegaso 650

-

89

Page 14

#(!.').'&53%3

Carefully read p. 61 (MAINTENANCE).

aCAU TION

Do not repair faulty fuses.

Use only recommended fuses.

Using fuses of an improper capacity

can cause damage to the electrical system or an electrical fire, which could result in total destruction of your vehicle

as well as injury to you.

NOTE If a fuse blows frequently, there

probably is a short circuit or an overload in

the electrical system. If this occurs, take the

vehicle to your Local aprilia Dealer.

If an electric component does not work or

works irregularly, or if the vehicle fails to

start, it is necessary to check the fuses.

To check the fuses:

◆

Turn the ignition switch (1) in the “m”

(OFF) position.

◆

Remove the sa dd l e, s ee p . 81 (REMOVING THE SADDLE).

aCAUTION

Extract the fuses one by one, in such a

way as to avoid positioning them incorrectly during reassembly.

NOTE Check the fuses in the order:

– first the 7.5A fuse (2);

– second the 15A fuse (3);

– third the 20A fuse (4).

◆

Remove, one by one, the fuse and inspect the filam ent (5). If it is open, t he

fuse must be r eplaced.

◆

Replace the blown fuse with the relevant

spare fuse (6) (7), (8) or with a new fuse

having the same amperage rating.

aWARNING

If you replace the fuse and it blows

again immediately, there is a serious

problem with the electrical system of

your vehicle. Do not attempt to continue using your vehicle. Take it to your

Local APRILIADealer for repair and service.

NOTE If you use the spare fuse (6) (7),

(8), replace it as soon as convenien t.

FUSE CIRCUIT

7.5 A fuse (2) - From the key switch to:

ignition.

15 A fuse (3) - From the key switch to:

all light loads.

20 A fuse (4) - From the battery to:

key switch, regulator, fan.

use and maintenance Pegaso 650

90

-

Page 15

!$*534).'4(%(%!$,)'(4

"%!-6%24)#!,,9

aWAR NING

Do not use the vehicle if the lights are

not functioning properly.

Do not use the vehicle if the hea dlight is

adjusted incorrectly. This could temporarily blind oncoming cars, and also reduce the rider’s ability to see any obstacle along the road while riding at night.

It is always ad visable to red uce speed

when riding during the night, in such a

way as to have the time necessary to

avoid any obstacle and to adapt to the

poorer visibility that inevitably results

from darkness. Failure to observe this

warning can cause you to collide with

another object, with consequent risk of

serious injury or even death.

NOTE The procedure described here is

in compliance with the Italian standard that

establishes the maximum height of the

headlight beam.

For vehicles used in other countries, you

must conform with the local regulations.

To quickly check the correct adjustment of

the beam, place the vehicle on flat ground,

32.81 ft (10 m) away from a wall.

Turn on the low beam, sit on the vehicle

and make sure that the beam projected on

the wall is slightly under the horizontal line

of the headlight (about 9/10th of the total

height).

To adjust the headlight beam:

◆

Working from the left underside of the

front part of the f airing, adjust manually

the knob (1).

By SCREWING IT clockwise, you adjust

the beam higher.

By UNSCREWING IT counterclockwise,

you adjust the beam lower.

◆

Make sure that the vertical adjustement

of the headlight beam is correct.

use and maintenance Pegaso 650

-

91

Page 16

!$*534).'4(%(%!$,)'(4

"%!-(/2):/.4!,,9

NOTE The terms “right” and “left” are re-

ferred to the rid er seated on th e vehicle in

the normal riding position.

It is possible to adjust the horizontal position both to the right and to the left.

To adjust the headlight beam:

◆

Working from the right underside of the

front part of the f airing, adjust manually

the knob (1).

By SCREWING IT clockwise, you adjust

the beam to the left.

By UNSCREWING IT counterclockwise,

you adjust the beam to the right.

◆

Make sure that the hori zo nta l a dju stm en t

of the headlight beam is correct.

use and maintenance Pegaso 650

92

-

Page 17

"5,"3

Carefully read p. 61 (MAINTENANCE).

aWARNING

Risk of fire.

Keep fuel and o ther flammable sub-

stances away from the electrical components.

aCAU TION

Before changing a bulb, turn th e ignition switch (1) to the “

and wait a few m inutes so that t he bulb

cools down.

Change the bulb wearing clean gloves

or using a clean and dry cloth.

Do not leave fing erprints on the bu lb,

since these may cause its overheating

and consequent breakage.

If you touch the bulb with your bare fingers, remove any fingerprints w ith alc ohol in order to avoid any damage.

TAKE CARE TO AVOID DAMAGING THE

ELECTRIC CABLES.

NOTE Befor e changing a bulb, ch eck

the fuses, see p.90 (CHANGING FUSES).

m” (OFF) position

use and maintenance Pegaso 650

-

93

Page 18

#(!.').'

4(%(%!$,)'(4"5,"3

Carefully read p. 93 (BULBS).

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

NOTE Before changing a bulb, check

the fuses, see p. 90 (CHANGING FUSES).

The headlight contains:

– one low / high beam bulb (1) (right side);

– one parking light bulb (2) (lower position);

– one high beam bu lb (3) (l ef t si de ).

To change the bulbs:

PARKING LIGHT BULB (LOWER POSI-

TION)

aCAU TION

While removing a bulb socket, do not

pull on the wires.

use and maintenance Pegaso 650

94

-

◆

Working from the central underside of

the front part of the fairing, pull back the

rubber boot (4) with your fingers.

◆

Grasp the b ulb sock et (5), pull it an d remove it from its seat.

◆

Remove the parking light b ulb (2) and replace it with an identical bulb.

LOW / HIGH BEAM BULB (RIGHT SIDE)

NOTE Remove the bulb sockets one by

one in such a way as to avoid replacing

them incorrectly during reassembly.

If the bulb sockets must all be removed at

the same time, take great care to reassemble them in the proper position.

◆

Working from the right underside of the

front part of the fairing, pull back the rubber boot (6) with your fingers.

aCAU TION

To extract the bulb electric connector,

do not pull its electric wires.

◆

Grasp the bulb electric connector (7),

pull it and disconnect it from the bulb (1).

◆

Rotate the bul b socket (8) coun terclockwise and extract it from the reflector.

◆

Remove the bulb (1) from the seat.

NOTE Be sure to maintain the same ori-

entation as the old bulb when you install

the new bulb. Do not force the bulb, it will

go easily if it is properly oriented.

◆

Insert the new bulb (1) into the reflector,

by aligning the two tabs (9) on the bulb

with the respective guides (10) in the reflector.

◆

Position the bulb socket (8) in the reflector and rotate it clockwise.

◆

Connect the bulb electric connector (7).

◆

Replace the rubber boot (6).

Page 19

LOW BEAM BULB (LEFT SIDE)

NOTE Remove the bulb sockets one by

one in such a way as to avoid replacing

them incorrectly during reassembly.

If the bulb sockets must all be removed at

the same time, take great care to reassemble them in the proper position.

◆

Working from the left underside of the

front part of the fairing, pull back the rubber boot (11) with your fingers.

◆

Grasp the electric terminal (12) pull it

and disconnect it from the bulb (3).

◆

Release the clip (13) positioned at the

rear of the bulb socket (14).

◆

Remove the bulb (3) from the seat.

NOTE Be sure to maintain the same ori-

entation as the old bulb when you install

the new bulb. Do not try to force the bulb,

it will go easily if it is properly oriented.

◆

Insert the new bulb into its socket (14),

ensuring tha t t h e t a bs a re c or re ct l y po s itioned.

◆

Replace the clip (13).

◆

Connect the bulb electric terminal (12).

◆

Replace the rubber boot (11).

#(!.').'4(%&2/.4!.$2%!2

$)2%#4)/.).$)#!4/2"5,"3

Carefully read p. 93 (BULBS).

NOTE Before changing a bulb, check

the fuses, see p.90 (CHANGING FUSES).

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Unscrew and remove the screw (15).

NOTE While removing the lens, use ex-

tra care to be sure that you do not break

the key.

◆

Remove the lens (16).

NOTE Upon reassembly, position the

lens correctly in its seat.

aCAUTION

Tighten the screw (15) moderately and

with care to avoid damaging the lens.

◆

Push the bulb (17) in s lig htl y a nd rot ate it

counterclockwise.

◆

Extract the bulb from its seat.

NOTE Insert the bulb in the bulb socket,

carefully aligning the two bulb pins with

their guides in the socket.

◆

Correctly install a new bulb of the same

type.

NOTE If the bulb socket (18) has fallen

out of its seat, repla ce it c orre ctl y, ens uri ng

that the slot in the reflector aligns with the

screw hole in the body of the turn signal

lamp.

use and maintenance Pegaso 650

-

95

Page 20

#(!.').'

4(%2%!2,)'(4"5,"

Carefully read p. 93 (BULBS).

aWARNING

Do not ride your vehicle if the tail light

and the stoplight are not working properly. The stoplight is particularly imp ortant to preve nt other vehicles from

rearending yo u. Obviously, fail ure to

comply with these instructions could

lead to a serious accident with subsequent injuries or even death.

NOTE Befor e changing a bulb , check

the fuses, see p. 90 (CHANGING FUSES),

also check the operation of t he stoplight

switches, see p. 71 (CHECKING THE

SWITCHES).

The rear light contains:

– two parking light / stoplight bulbs (1).

use and maintenance Pegaso 650

96

-

To change the bulb:

◆

Place the vehicle on the center stand.

◆

Unscrew and remove the two screws (2).

◆

Remove the lens (3).

NOTE Upon reassembly, make sure

that the lens seats properly.

aCAUTION

Upon reassembly, do not overtighten

the two screws (2). Overtightening will

crack the lens.

◆

To remove the bulb (1), push the bulb

slightly forward and rotate it counterclockwise.

◆

Pull it from its seat.

◆

Correctly install a new bulb of the same

type.

NOTE Ensure that the orientation of

your replacement bulb is identical to that of

the original bulb. Do not try to force the

bulb, it will fit easily i f it is prop erly ori ented.

#(!.').'

4(%,)#%.3%0,!4%"5,"

Carefully read p. 93 (BULBS).

NOTE Befor e changing a bulb, ch eck

the fuses, see p. 90 (CHANGING FUSES)

To change the bulb:

◆

Unscrew and remove the screw (4).

aCAU TION

Upon reassembly, do not overtighten

the screw (4). Overtightening will crack

the light unit.

◆

Remove the light unit (5) from its seat.

aCAU TION

While removing a bulb socket, do not

pull on the wires.

◆

Grasp the bulb socket (6), pull it and remove it from its seat.

◆

Remove the bulb (7) and replace it with

an identical bulb.

Page 21

42!.30/24

Do not inhale fuel vapours.

aWAR NING

Before tran sporting your vehi cle, you

must empty the fuel tank and drain the

carburetors completel y, ensuring that

both are completely dry.

While your vehicle is being transpo rted,

it must be kept in a vertical position,

firmly tied down, an d with the wheels

blocked.

Transport your vehicle in neutral gear

only.

Failure to heed this warning could

cause serious damage to the transmission due to vibration of the transport

truck.

aWAR NING

Never attempt to tow your vehic le with

another vehicle.

$2!).).'4(%&5%,4!.+

Carefully read p. 35 (FUEL) and p. 61

(MAINTENANCE).

aWAR NING

Risk of fire.

Wait until the engine and the exh aus t silencer have completely cooled down.

Fuel vapours are noxio us for your

health.

Before proceed ing, make sure that th e

room in which you are working is properly ventilated.

Do not smoke or allow open flames near

the vehicle while you are draining the

fuel.

DISPOSE OF UNWANTED FUEL PROPERLY.

◆

Place the vehicle on the center stand.

◆

Stop the engine and wait until it has

cooled down.

◆

Prepare a container with capacity exceeding the fuel qu antity present in the

tank and put it on the ground on the left

side of the vehicle.

◆

Open the fuel filler cap, see p. 35 (FUEL).

◆

Empty the fuel t ank b y means of a manu al pump or a similar system.

aWARNING

After draining the fuel tank, correctly

close the fuel filler cap.

To drain the carburetors comp letely,

proceed as follows:

NOTE This vehicle is equipped with two

carburetors. Both carburetor float chambers must be completely draine d.

NOTE To drain the carburetor float

chamber, get a flexible pipe (1) with inner

diameter Ø 0.16 in (Ø 4 mm) and lenght

1 1 .81 in (300 mm).

◆

Introduce a flexible pipe (1) into the

draining union of the chamber (2).

◆

Put the free end of the flexible pipe (1)

into the container.

◆

Move the fuel valve (3) to reserve position “RES”.

◆

Working through the hole (4) positioned

on left side of the frame, open the carburetor outlet by loosening the drain screw

(5) positioned under the float cham ber.

When all the fuel has flowed out of the carburetor:

◆

Tighten the drain screw (5) completely.

aWARNING

Tighten the drain screw (5) with care, to

avoid fuel leakages from the carburetor

during the refueling. Do not overtighten

the drain screws.

Do not hesit ate to contact your Local

APRILIADealer for help.

use and maintenance Pegaso 650

-

97

Page 22

#,%!.).'

Clean your vehicle regularly. Your vehicle

will look better and work better if you keep

it clean. You will find you will need to

clean it more frequentl y if it is used in t he

following conditions:

– Polluted areas (cities and industrial areas).

– Areas characterize d by a high percent-

age of salinity and humidity (sea areas,

hot and humid climates ).

– Partic ular conditions (use of salt and

anti-ice chemical products on the roads

during the winter).

◆

Do not allow contaminants such as industrial dus t, tar spot s, d ead i nsect s, bird

droppings, etc. to remain on the painted

portions of your vehicle. They will very

quickly etch into and damage the paint.

◆

Do not park your vehicle under trees,

since some trees ooze resins that contain

chemicals which can damage the paint.

aWARNING

After your vehicle has been w ashed, th e

brake functioning will b e temporarily

impaired because of the wetness of the

discs and pads. Do not ride in tr affic

until after you have dried the brakes by

repeated braking from slow speed.

Always after washing your vehicle, carry out the pre liminary chec king operation, see p. 49 (PRELIMINARY CHECKING OPERATIONS).

use and maintenance Pegaso 650

98

-

To remove dirt and mud from the painted

surfaces, use a low pressure water hose.

Carefully wet the dirty parts and remove

mud and dirt with a soft ca r sponge. You

may use proprietary c ar shampoos (2-4%

parts of shampoo i n clear w ater), to make

this easier.

Carefully flush so that no dirt or girt remains on the paintwork, and dry with a

clean chamois or clean terry towel.

To clean the engine and other non-painted

parts, use a mild solvent and a bristle

brush, along with plenty of rags.

aCAUTION

Polish with silicone wax only after having carefully washed your vehicle. Do

not wash the vehicle in direct sunlight,

especially during the summer, w hen the

paintwork is still warm, since if the

shampoo dries be fore being rinsed

away, it can damage the paint.

Do not use solvents or water hotter than

40°C to clean the plastic components of

the vehicle.

Never use a high pressure washer, a

steam cleaner, or an air augmented water jet to clean your vehicle, espe cially

the wheel hubs, handlebar controls,

brake reservoirs and cylinders, instruments, electrical compo nents or exhaust silencer.

Such cleani ng machiner y will force water into critical portions of your vehicle,

which could damage your vehicle

through corrosion or short circuiting.

Do not use alcohol or other solvents to

clean the rubber or plastic parts, or the

seat, use only cle ar water with a mild

soap.

aWARNING

Do not apply any prot ective coating to

the seat, such coatings tend to make

the seat too slippery.

After washing the vehicle, always:

◆

Place the vehicle on the center stand,

see p. 59 (POSITIONING THE VEHICLE

ON THE STAND).

◆

Remove the plug (1) to ensure that any

water or other impurity that may have accumulated inside the air cleaner case is

drained.

Page 23

,/.'0%2)/$3/&).!#4)6)49

If the vehicle is to be stored for a relatively

long period of time, such as over t he winter, some simple precautions will make

putting the vehicle back into service much

easier.

It is much less difficult to prepare the vehicle for storage properly than it is to restore

the vehicle to proper working condition after a storage peri od if you have forgott en

or neglected to do this preparation.

To prepare the vehicle for storage:

◆

Empty the fuel tank and carburetors , see

p. 97 (DRAINING THE FUEL TANK).

◆

Remove the spark plug, see p.86

(SPARK PLUG).

◆

Pour a teaspoon [0.17 – 0.34 US fl oz (5-

3

)] of engine oil into the cylinder.

10 cm

NOTE Cover the spark plug hole with a

clean cloth in order t o protect th e rest of the

bike from sprayed oil.

◆

Rotate the ignition key (1) to the “n”

(ON) position.

◆

Pull in the clutch lever (2) completely and

put the shift lever (3) in neutral so that

the green “

◆

Move the engine stop switch (4) to the

n” (ON) position.

“

◆

Press the starter button “r” (5) for a few

seconds to distr ibute the oil evenly on

the surfaces of the cylinder.

◆

Move the engine stop switch (4) to the

m” (OFF) position.

“

◆

Rotate the key (1) to the “m” (OFF) posi-

tion.

q” light is on.

◆

Remove the cloth.

◆

Replace the spark plug, see p. 86

(SPARK PLUG).

◆

Remove the battery, see p.88 (REMOVING THE BATTERY) and p. 88 (BAT TERY STORAGE).

◆

Wash and dry the vehicle, see p. 98

(CLEANING).

◆

Polish the painted surfaces with wax.

◆

Inflate the tires, see p. 46 (TIRES).

◆

By means of a suitable support, position

the vehicle so that both tires are raised

from the ground.

◆

Place the vehicle in an a cool, dry room,

away from direct sunlight, with minimum

temperature variation s.

◆

Place a plastic bag ov er the outle t pipe of

the muffler, and tape or tie it tight.

◆

Cover the vehicle with an old sheet or a

light canvas, do not u se a sheet of plastic

or other waterpr oof material. This will

cause condens ation which wil l result in

corrosion.

PUTTING THE VEHICLE BACK INTO

SERVICE

◆

Uncover and clean th e v eh ic le, see p.98

(CLEANING).

◆

Check the charge of the battery, see

p. 89 (RECHARGING THE BATTERY)

and install it, see p. 89 (INSTALLING

THE BATTERY).

◆

Refill the fuel tank, see p. 35 (FUEL).

◆

Carry out the preliminary checking operations, see p. 49 (PRELIMINARY

CHECKING OPERATIONS).

aWAR NING

Test ride the veh icle at mod erat e s peed

in a low traffic area before you ride in

heavy traffic.

use and maintenance Pegaso 650

-

99

Page 24

4%#(.)#!,$!4!

DIMENSIONS Max. length .................................................. 85.83 in (2,180 mm)

Max. width.................................................... 34.65 in (880 mm)

Max. height

(front part of the fairing included)................. 49.80 in (1,265 mm)

Seat height................................................... 33.07 in (840 mm)

Wheelbase................................................... 58.27 in (1,480 mm)

Min. ground clearance................................. 7.87 in (200 mm)

Curb weight ................................................. 440.53 lb (199.82 kg)

ENGINE Type............................................................. one-cylinder, 4-stroke with 5 valves, 2 camshafts at the head, dry

Number of cylinders..................................... 1

Total displace men t....................................... 39.78 cu in (651.88 cm #)

Bore / stroke................................................. 3.94 in / 3.27 in (100 mm / 83 mm)

Compression ratio........................................ 9.0 ± 0.5 : 1

Starting......................................................... electric

Engine idling rpm......................................... 1,400 ± 100 rpm CO 1%

Valve clearance (with engine cold) ............. 0.004 in (0.1 mm) [intake] - 0.006 in (0.15 mm) [exhaust]

Clutch........................................................... multidisc in oil bath, with manual control on the left side

Cooling......................................................... liquid-cooled

use and maintenance Pegaso 650

100

-

crankcase lubrication.

[+ 1% – 0.5% (total range from 0.5% to 2%)]

of the handlebar.

Page 25

CAPACITY Fuel (reserve included)................................. 5.81 US gal (22 L )

Fuel reserve ................................................. 1.32 US gal (5 L ) [mechanical reserve] –

1.59 US gal (6 L ) [electrical reserve]

Engine oil..................................................... oil change 2.27 US qt (2150 cm#) –

oil and oil filter change 2.32 US qt (2200 cm#)

Coolant......................................................... 0.37 US gal (1.4

L )

(50% water + 50% antifreeze with ethylene glycol)

Seats............................................................ 2

Vehicle max. load

(driver+passenger+luggage)........................ 396.47 lb (180 kg)

Gross weight limit (GVWR) (*)...................... 837.00 lb (379.66 kg)

Permissible wheel lo ads (GAWR) (*)

– front........................................................... 279.73 lb (126.88 kg)

– rear............................................................ 557.27 lb (252.77 kg)

(*) These two weights: Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Rating (GAWR); are stamped on the certification

plate positioned on the front part of the frame, see p. 7 (VEHICLE IDENTIFICATION NUMBER (V.I.N.) (FRAME NUMBER)).

TRANSMISSION Type.............................................................. mechanical, 5 gears with foot control on the left side of the engine

GEAR RATIOS Ratio Primary Secondary

st

1

nd

2

rd

3

th

4

th

5

37/72 = 1 : 1.946 12/33 = 1 : 2.750

16/28 = 1 : 1.750

16/21 = 1 : 1.312

22/23 = 1 : 1.045

24/21 = 1 : 0.875

Final ratio Total ratio

16 / 47 = 1 : 2,937 1 : 15.720

1 : 10.003

1 : 7.502

1 : 5.976

1 : 5.001

CARBURETOR Number......................................................... 2

Model............................................................ Mikuni BST 33 B424

Choke tube................................................... Ø 1.24 in (Ø 31.5 mm)

FUEL SUPPLY Fuel .............................................................. unleaded petrol minimum octane rating (R+M) / 2 method 90

use and maintenance Pegaso 650

-

101

Page 26

FRAME Type............................................................. composite structure made of steel and alloy, with removable cradle

Rake............................................................. 28°

Trail.............................................................. 4.29 in (109 mm)

SUSPENSIONS Front............................................................. hydraulically operated telescopic fork

Wheel stroke................................................ 7.09 in (180 mm)

Rear............................................................. hydraulic adjustable mono-shock absorber

Wheel stroke................................................ 1.93 in (49 mm)

BRAKES Front............................................................. disc brake - Ø 11.81 in (Ø 300 mm) - with hydraulic actuation

Rear............................................................. disc brake - Ø 8.66 in (Ø 220 mm) - with hydraulic actuation

WHEEL RIMS Type............................................................. aluminium with spokes

Front............................................................. 2.15 x 19”

Rear............................................................. 3.00 x 17”

TIRES FRONT

Type............................................................. Pirelli; Metzeler; Bridgestone

Size.............................................................. 100 / 90 - 19” 57 H

- alternative.................................................. 100 / 90 - R19” 57 H; 100 / 90 - 19” 57 S; 100 / 90 - 19” 57 T

Inflation pressure for solo rider

- off-road ...................................................... 26.10 ± 1.45 psi [(180 ± 10 kPa) (1.8 ± 0.1 bar )]

- asphalted road........................................... 26.10 ± 1.45 psi [(180 ± 10 kPa) (1.8 ± 0.1 bar )]

Inflation pressure for rider and passenger

- off-road ...................................................... 26.10 ± 1.45 psi [(180 ± 10 kPa) (1.8 ± 0.1 bar )]

- asphalted road........................................... 26.10 ± 1.45 psi [(180 ± 10 kPa) (1.8 ± 0.1 bar )]

and saddle pillar

use and maintenance Pegaso 650

102

REAR

Type............................................................. Pirelli; Metzeler; Bridgestone

Size.............................................................. 130 / 80 - R17” 65 H

- alternative.................................................. 140 / 70 - 17” 66 H; 130 / 80 - 17” 65 S;

130 / 80 - 17” 65 T; 130 / 80 - 17” 65 H

-

Page 27

Inflation pressure for solo rider

- off-road....................................................... 27.55 psi [(190 kPa) (1.9 bar)]

- asphalted road........................................... 27.55 psi [(190 kPa) (1.9 bar)]

Inflation pressure for rider and passenger

- off-road....................................................... 27.55 psi [(190 kPa) (1.9 bar)]

- asphalted road........................................... 31.9 ± 1.45 psi [(220 ± 10 kPa) (2.2 ± 0.1 bar)]

IGNITION Type.............................................................. CDI - Nippon Denso

Ignition timing............................................... 10° ± 2° at 3,000 rpm

SPARK PLUG Standard....................................................... (M12 x 1.25) NGK DR8 EA - NGK DR8 ES

Spark plug gap............................................. 0.024 – 0.028 in (0.6 – 0.7 mm)

ELECTRIC Battery.......................................................... 12 V - 12 Ah

SYSTEM Fuses............................................................ 7.5 A; 15A; 20A

Generator .................................................... 12 V - 280 W

BULBS Low / high beam........................................... 12 V - 55/60 W H4

High beam.................................................... 12 V - 55 W H1

Parking light.................................................. 12 V - 5 W

Direction indicators....................................... 12 V - 10 W

Rear parking light / stoplight......................... 12 V - 5 / 21 W

License plate light......................................... 12 V - 3 W

Speedometer................................................ 12 V - 3 W

Revolution counter....................................... 12 V - 2 W

Coolant temperature indicator...................... 12 V - 1.2 W

WARNING LIGHTS Neutral.......................................................... 12 V - 3 W

Direction indicators....................................... 12 V - 3 W

Low fuel ....................................................... 12 V - 3 W

Engine oil pressure....................................... 12 V - 3 W

Low beam and parking light ......................... 12 V - 3 W

High beam.................................................... 12 V - 3 W

use and maintenance Pegaso 650

-

103

Page 28

,5"2)#!.4#(!24

Engine oil (recommended): 0 SUPERBIKE 4, SAE 5W-40 or 4T FORMULA RACING, SAE 5W-40.

As an alternative to the recommended oil, it is possible to use high-quality oils with characteristics in compliance with or superior to the

CCMC G-4, A.P.I. SG specifications.

Fork oil (recommended):

If you need an oil with intermediate characteristics in comparison with the

FORK 20W, these can be mixed as indicated below:

SAE 10W =

SAE 15W =

Bearings and other lubrication points (recommended):

As an alternative t o the recom mende d produ ct , use hi gh-qual ity g rease for rol ling b ear ings, working temp erature range -30 °C…+140 °C,

dripping point 150 °C…230 °C, high protection against corrosion, good resistance to water and oxidation.

Protection of the battery poles: neutral grease or vaseline.

Spray grease for chains (recommended):

0 F.A. 5W 67% of the volume, + 0 F.A. 20W 33% of the volume or

0 F.A. 5W 33% of the volume, + 0 F.A. 20W 67% of the volume or

0 F.A. 5W or 0 F.A. 20 W fork oil;

an alternative FORK 5W or FORK 20W fork oil.

0 F.A. 5W and 0 F.A. 20 W or FORK 5W and

FORK 5W 67% of the volume + FORK 20W 33% of the volume.

FORK 5W 33% of the volume + FORK 20W 67% of the volume.

0 AUTOGREASE MP or GREASE 30.

0 CHAIN SPRAY or CHAIN LUBE.

aWARNING

Use new brake fluid only.

Brake fluid (recommended):

0 F.F., DOT 5 (DOT 4 compatible) or BRAKE 5.1, DOT 5 (DOT 4 compatible).

aWARNING

Use only antifreeze and anticorrosive without nitrite, ensuring protection at -35 °C at least.

Engine coolant (recommended):

0 ECOBLU -40 °C or COOL.

use and maintenance Pegaso 650

104

-

Page 29

./4%

!3+&/2'%.5).%30!2%0!243/.,9

use and maintenance Pegaso 650

-

105

Page 30

)MPORTERS

use and maintenance Pegaso 650

106

-

Page 31

)MPORTERS

use and maintenance Pegaso 650

-

107

Page 32

7)2).'$)!'2!-0EGASO

-

use and maintenance Pegaso 650

108

-

Page 33

7)2).'$)!'2!-+%90EGASO

1) Direction indicator warning light

2) High beam warning light

3) Parking light warning light

4) Engine oil pressure warning light

5) Dashboard bulbs

6) Neutral indicator warning light

7) Low fuel warning light

8) Coolant temperature indicator

9) Dashboard

10) Left dimmer switch

11) Right dimmer switch

12) Ignition switch

13) Flasher

14) Rear right direction indicat or

15) Rear light

16) Rear left direction indicator

17) Neutr al switch

18) Rear stoplight switch

19) Front stoplight switch

20) Coolant temperature thermistor

21) Cooling electrofan thermal switch

22) Starter

23) Start relay

24) Battery

25) Voltage regulator

26) Generator

27) CDI

28) Ignition coil

29) Safety start relay

30) Front left direction indicator

31) Pick up

32) Low/high beam bulb

33) Front parking light

34) Front right direction indicator

-

35) Horn

36) Headlight

37) Cooling electrofan

38) Spark plug

39) Fuses

40) Engine oil pressure sensor

41) Multiple connectors

42) Diode

43) Dashboard resistanc e

44) Switch on the clutch lever

45) Spark advance resistance

46) Low fuel sensor

47) Side stand switch

48) High beam bulb

49) Light relay

50) Number license light

51) Stoplight/parking light bulb

#!",%#/,/523

Ar Orange

Az Light blue

B Blue

Bi White

G Yellow

Gr Grey

M Brown

N Black

R Red

V Green

Vi Violet

Ro Pink

use and maintenance Pegaso 650

-

109

Page 34

./4%

use and maintenance Pegaso 650

110

!3+&/2'%.5).%30!2%0!243/.,9

-

Page 35

./4%

!3+&/2'%.5).%30!2%0!243/.,9

use and maintenance Pegaso 650

-

111

Page 36

aprilia s.p.a. wishes to thank its customers for the purchase of this vehicle.

– Do not dispose of oil, fuel, polluting substances and components in the envi-

ronment.

– Do not keep the engine running if it isn’t necessary.

– Avoid disturbing noi s es.

– Respect nature.

use and maintenance Pegaso 650

112

-

Loading...

Loading...