3M MICROFLUOR II Specifications

Microfluor® II Critical Sterilizing Grade PTFE Cartridge and Capsule Membrane Filters

Microfluor II PTFE membrane filters offer the ultimate in microorganism retention for air and gas streams while

providing superior air flow capacity.

New flow enhanced cartridge and capsule filter construction

provides lower differential pressure than competitive filters

CUNO’S Microfluor II filters with flow enhanced construction allow use of smaller, more economical air

filter assemblies compared to competitive air filters.

Microfluor II filters provide absolute retention based on liquid bacteria challenge and aerosol bacteriophage challenge.

Microfluor II filters are available in a wide range of cartridge and capsule configurations to provide the most economical solution to air, gas and aggressive liquid filtration applications.

Cartridge and Capsule Configurations to Meet Any Process Requirement

Microfluor II membrane filters are available in 5 through 40 inch cartridges, 2.5 and 5 inch Mini Cartridges and 2.5, 5, 10, 20 and 30 inch capsules. With the exceptionally high Microfluor II flow rates, smaller and more economical assemblies can provide the same air flow as larger, more costly competitive PTFE filters.

Feature |

Benefit |

|

|

|

|

Unique flow enhancing layer construction |

Higher air flow for fermenter aeration and smaller, |

|

|

more economical vent filter assemblies |

|

|

|

|

Liquid validation of B. diminuta retention |

Reliable sterilizing performance in wet or dry |

|

conditions |

||

|

||

|

|

|

Hydrophobic PTFE membrane |

Membrane will not become blocked with moisture |

|

|

|

|

21 CFR Materials of Construction, USP |

|

|

Biological Safety Test, Validation Guide |

Eases validation and regulatory submissions |

|

and Drug Master File Listing |

|

|

|

|

2

Microfluor® II Cartridge and Capsule Filter Applications

Microfluor II filters are optimized for applications requiring sterilization of air, gas, or aggressive solvents and chemicals. The hydrophobic PTFE filter membrane prevents wetting with aqueous liquids or moisture that can block free air flow. Some applications, however, may require filtration of aggressive fluids such as acids or bases. Depending on compatibility, Microfluor II filters can be used to provide sterile filtration of these fluids by prewetting the membrane with a low surface tension fluid such as alcohol. A list of Microfluor II filter applications includes:

Sterile venting of process tanks

Sterile filtration of process air and aseptic filling lines

Sterile venting of lyophilizers

Sterile venting of autoclaves

Sterile air filtration on blow, fill, and seal machines

Sterilizing filtration of fermentation inlet and exhaust air

Sterile filtration of aggressive liquids

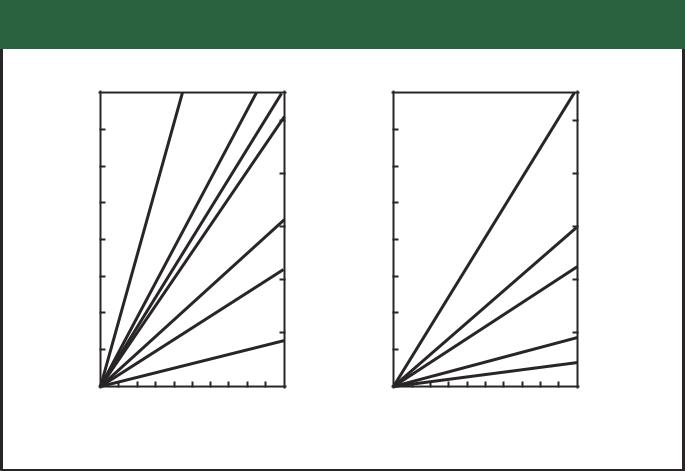

Microfluor II filters have been designed to provide exceptionally high flow rates with low differential pressures (Figure 1). Microfluor II filters are available in a range of cartridge and capsule filter configurations to meet any process requirement. Shown in Figure 1 are flow curves for cartridge and capsule filter assemblies at atmospheric (vent) and compressed air conditions. For details of sizing vent and compressed air assemblies, please ask for CUNO Automated Sizing Program assistance.

Figure 1. - Microfluor II Air Flow vs. Diffferential Pressure*

Microfluor II Filter |

Microfluor II Filter |

|

Air Flow @ Vent Conditions |

||

Air Flow @ 30 psi |

||

|

|

4.0 |

|

|

|

|

|

|

|

|

|

|

|

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

3.5 |

|

Capsules |

|

|

|

Cartridge |

0.25 |

|

|

3.5 |

|

|

|

|

|

|

|

|

Cartridge |

|

|||

DifferentialPressure(psid) |

3.0 |

|

& |

|

Mini |

|

Capsule |

|

DifferentialPressure(bar) |

DifferentialPressure(psid) |

3.0 |

|

|

|

|

|

Mini |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Cartridge |

5” |

|

|

5” |

|

|

0.20 |

|

|

|

|

|

5” |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

10” Capsule |

|

|

|

|

|

|

. |

|

|

Cartridge |

|

||||||||||

|

|

|

0.10 |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

Mini |

|

|

|

|

|

|

Cartridge |

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

5” |

|

|

|

|

|

5” |

|

0.15 |

|

|

|

|

|

|

|

|

|

|

|

|

Cartridge |

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

2.0 |

2 |

|

|

|

|

|

|

|

|

|

|

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1.5 |

|

|

|

|

|

|

|

|

|

|

|

1.5 |

|

|

|

|

5” |

Mini |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

Cartridge |

|

|

|

|

|

|

|

|

|

5” |

|

|

|

|

||||

|

1.0 |

|

|

|

|

|

|

|

1.0 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

10” |

|

|

|

|

0.05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 |

|

|

|

|

|

Cartridge |

|

|

|

0.5 |

|

|

10” |

Cartridge |

|

||||||||

|

|

|

20” |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cartridge |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20” |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

0 |

|

|

|

|

|

|

|

|

0 |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

20 |

40 |

60 |

|

|

|

80 |

100 |

|

|

0 |

20 |

40 |

60 |

|

|

|

|

|

80 |

100 |

||

0.25

0.20 |

(bar) |

|

Pressure |

||

0.15 |

||

Differential |

||

0.10 |

||

|

||

0.05 |

|

|

0 |

|

|

|

|

|

|

Air Flow (SCFM) |

|

|

|

|

|

Air Flow (SCFM) |

||||||||||||||||||

0 |

20 |

40 |

60 |

80 |

100 120 140 160 |

0 |

20 |

40 |

60 |

80 |

100 120 140 160 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Air Flow (Nm3/hr) |

|

|

|

|

|

Air Flow (Nm3/hr) |

||||||||||||||||||

* Cartridge airflow values with housing pressure loss subtracted (excluding capsules).

3

Loading...

Loading...