3M Dynapro Series B ET 3170 Guide

Installing the NEMA 4X Hatch

ET 350 Monitor (Models ET 350R and ET 350L3) and ET 3170 Terminal

Intended Use

When properly installed using the materials provided, and according to these instructions, the NEMA 4X hatch is intended to provide a NEMA 4X/IP66 seal on all sides for

the 3M DynaproTM ET 350 monitor (specifically, ET 350R and ET 350L3 monitors) and the ET 3170 terminal. The ET 350L3 monitor is also UL Listed for use in Pollution Degree 3 environments.

Product safety information

Read and understand all safety information in this document before installing and using the NEMA 4X hatch.

WARNING

WARNING

To reduce the risks associated with electric shock or fire which, if not avoided, may result in death or serious injury and/or property damage:

!Follow all product and accessory installation instructions.

!Any servicing or other procedures not described in this document are to be performed only by 3M Touch Systems service personnel.

WARNING

WARNING

To reduce the risks associated with electric shock or fire which, if not avoided, could result in death or serious injury and/or property damage.

!Wiring installation should be done by a journeyman electrician and must comply with federal and local electrical codes.

!Properly install the ET unit with a NEMA 4X gasket that is undamaged and effective.

!Properly install the ET unit so that it is environmentally sealed to the NEMA 4X/IP66 standard. Do not use an ET unit that is not rated for NEMA 4X/IP66 in environments that require such a seal.

WARNING

WARNING

To reduce the risks associated with electric shock or fire which, if not avoided, could result in death or serious injury and/or property damage.

!Choose fittings and a power cable that provide adequate strain relief for communications and power cables.

!A cable/fitting combination will have to be found that meets local electrical requirements and the requirements for a NEMA 4X seal.

!When connecting power with fixed field wiring, the power cable must be double insulated. A clear, flexible insulator (supplied) must cover the portion of the cable that is not double insulated when connecting to a terminal strip connector.

!When closing the hatch of the ET unit, make sure that it closes flush and that the hatch screws do not bind when they are attached. If the hatch is not closed properly, the NEMA 4X seal may be compromised and the warranty invalidated.

CAUTION

CAUTION

To reduce the risk associated with electric shock or fire that may result in personal injury or property damage:

!After making an opening for cables, make sure that there are no metal shavings in the hatch.

!Use round cables that fit the diameter range of the cable fitting, as shown in Table A, to meet local electrical requirements and the requirements for a NEMA-4X/IP66 seal.

3M Touch Systems Proprietary Information

1

Installing the NEMA 4X Hatch

Equipment

Materials supplied

The following materials are supplied for installing the NEMA 4X hatch:

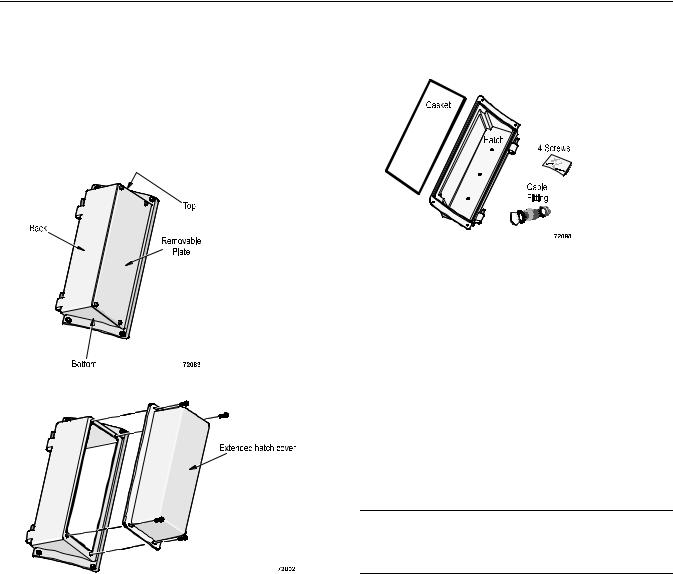

!1 NEMA 4X hatch (with removable plate attached).

!1 NEMA 4X extended hatch cover

!1 gasket

!4 #6-32 Phillips screws

!Cable fitting components (3 large sizes and 3 small sizes of each component are provided):

!Locking nut

!O-ring

!Body hex with compression sleeve

!Sealing nut

For details about the supplied cable fitting components, see Table A.

Tools required

To install the NEMA 4X hatch, you will need the following:

!Horizontal work surface with a padded cover or foam pads to protect the front bezel and the display of the unit.

!Flat blade screwdriver with 3/16-inch blade

!No. 1 Phillips torque screwdriver

!1 19/32" (15 mm) open-end wrench

!1 15/16" (24 mm) open-end wrench

Attaching the gasket

Important

If you ordered the ET 350L3 monitor, the hatch gasket was attached at the factory. Proceed to “Preparing the hatch for cables”.

1.Place the ET unit face down on a horizontal work surface (covered with foam pads or other material to protect the unit’s bezel and touch screen), with the access hatch facing you.

2.Before removing the gasket backing, position the gasket over the recessed edge of the access hatch opening so that you know which way it fits.

3M Touch Systems Proprietary Information

2

Loading...

Loading...