Manual Tape Applicator MTA-2

3M™ Stamark™ Pavement Marking Tapes

Information Folder IF MTA-2 June 2010

Health and Safety Information

Precautions:

Wear safety shoes and appropriate gloves while handling

and using the Manual Tape Applicator.

Description

The 3M™ Manual Tape Applicator MTA-2 is intended

to be used for the application of 3M™ Stamark™

Pavement Marking Tapes. It is a simple-to-use, twowheeled, robust, push-type device. (Figure 1)

The usage of A 380ESD(high tack adhesive) demands

installation of the MTA-2 upgrade-kit DR995032239

to prevent roll blocking by the high tack adhesive

during the tape application.

The application rates depend on the individual

application conditions and environment. Typically tape is

being applied at walking speed.

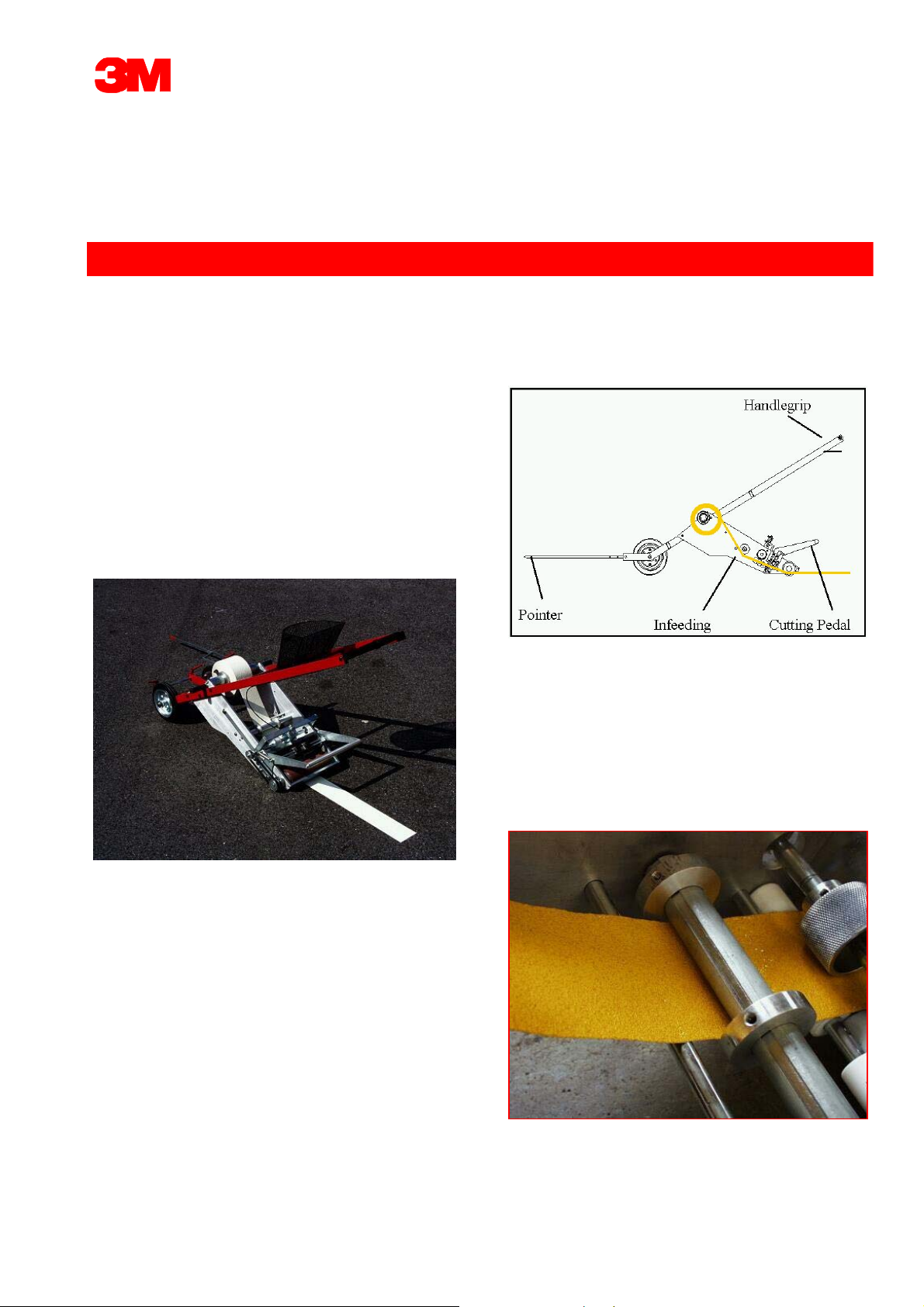

Figure 1: MTA-2 Tape applicator

The device is specifically designed to apply pavement

marking tapes precoated with pressure sensitive

adhesive.

The applicator weighs 75kg and can be partially

disassembled for transporting in a van, truck or station

wagon.

Product Width and Spacing

The MTA-2 can be used to apply all Stamark™

pavement marking tapes at all standard roll length.

Note: If special roll with larger length are being ordered,

the maximum roll diameter must not exceed 50cm, if the

material is to be applied with a Manual Tape Applicator.

Operation

The MTA-2 is operated by one person.

Note: Pavement Marking Roll changing should be

supported by a second person due to the weight of a tape

roll in order to avoid extensive workload for a single

operator.

Figure 2: Schematic drawing MTA-2

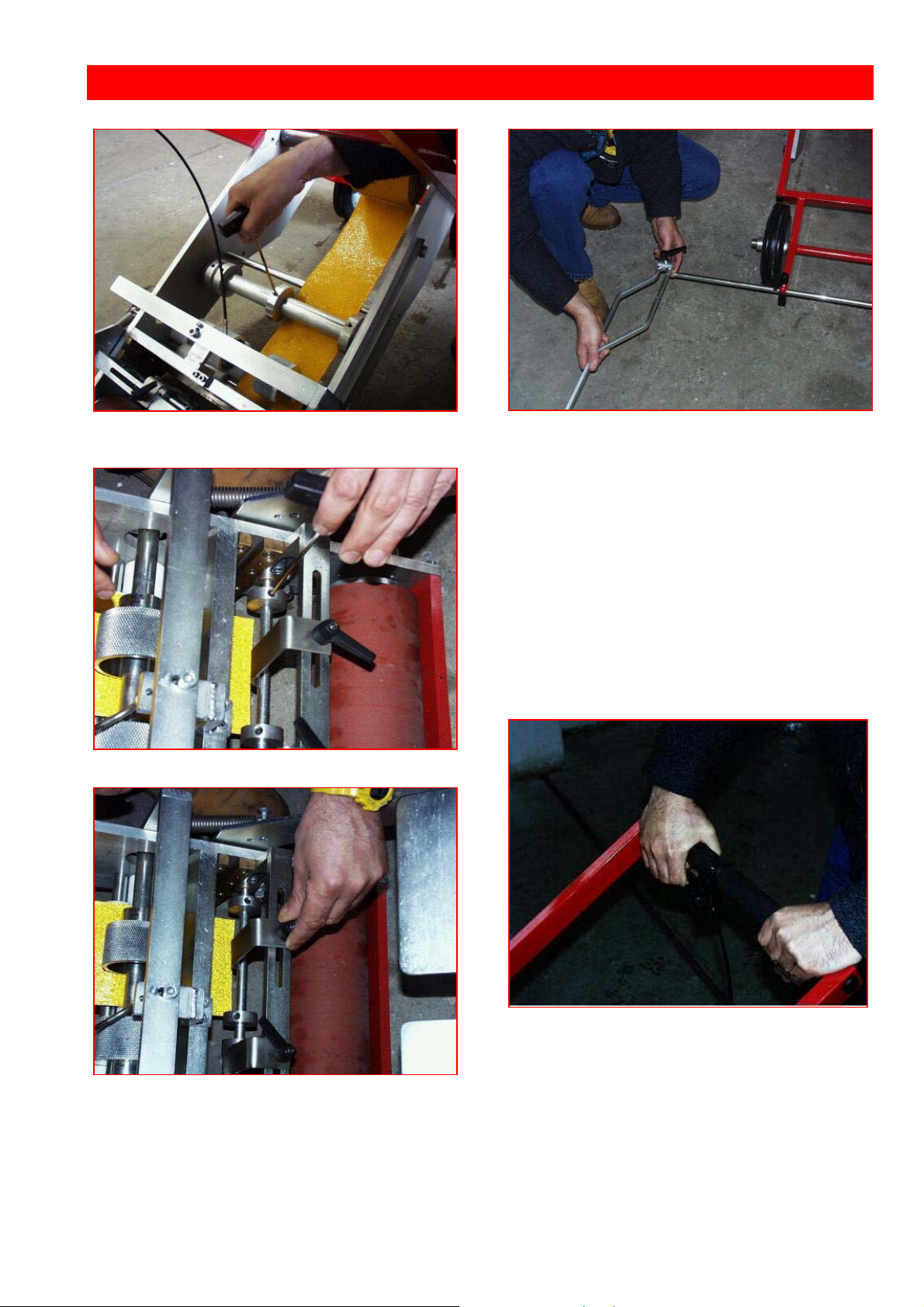

Procedure for Adjusting Machine and Tape

Load the tape roll, feed it in to the machine and do the

necessary adjustments, as shown in Figure 3 to 8. As

soon as these steps are done, the machine is ready for the

application.

Caution: Do not activate the cutting knife, while doing

adjustments!

Figure 3: Feeding of the Tape

Manual Tape Applicator MTA-2 Page 2

Figure 4: Adjustment of the upper tape guide rolls

Figure 5: Adjustment of the lower tape guide rolls

Figure 7: Adjustment of the pointer system

Tape Application

Determine where the first skip or long line starts by

measuring from the last existing skip or reference mark.

Adjust the pointer to the pre-marking. Best case is when

the pre-marking and the later tape position are in between

the wheels of the applicator. If primer is used apply tape

exactly on primer.

For starting the application pull handgrip and watch tape

being moved by infeeding-transportation roll. Position

tape start at start of pre-marking. Push applicator forward

and keep handle grip pulled u ntil tape appears on other

side of rubber application roll. Release handle-grip and

keep pushing applicator.

Figure 6: Adjustment of vertical guide plate

Figure 8: Infeeding Handle Grip

Tape Cutting

Bring the applicator to a complete stop. Keep tape under

slight tension.

Cut tape with one strong and fast movement of foot

pedal. Release the pedal slowly. Do not attempt to cut the

tape while moving. Cutting the tape in motion will

stretch and tear the tape, causing the n ext line to start off

center.

Manual Tape Applicator MTA-2 Page 3

Adjustments

The Knifes are pre-adjusted by the manufacturer to slide

across each other with a minimum of friction in a scissors

action. Adjustment is needed when the tape is not

properly cut.

Either the stationary knife or the sliding knife may be

adjusted. To adjust the stationary knife, untighten the

mounting screws slightly. Turn the setscrews to bring the

cutting edge down, and retighten the mounting screws.

The same procedure is followed to adjust the sliding

knife. Each knife has two cutting edges. The knives may

be removed and new cutting edges exposed. The knives

may be sharpened after the cutting edges are dull.

Figure 10: Cutting the tape

Tamping

After applying the pavement marking tape tamp it

thoroughly with the RTC-3 with a minimum 90kg

(200lb.) load.

When using the RTC-3 Roller Tamper Cart:

• Do not twist or turn the tamping device on the tape.

• Make three passes back and forth over each part of

the tape

• Move the RTC-3 slowly (4-5 km/h) over the tape

• Make sure all edges are firmly adhered

• If applying block markings or pedestrian crossings,

start in the center of the marking, then work towards

the edges to remove trapped air.

• Open road to traffic as soon as tamping is completed

Tamping is most important !

Maintenance

Keep all Fasteners Tight

Lubrication: The pivot points and sliding areas should

be kept lubricated with light oil.

Cleaning: The silicone application roller wheels and

cutting mechanism must be kept clean.

Mineral spirits, fuel oil or any other light oil cleaners

may be used on the wheels and knives.

Check knife blades from time to time to prevent adhesive

build-up.

Solvents may be used occasionally for difficult cleaning

problems. A spray bottle of cleaner or silicone spray is

useful to prevent asphalt and dirt pickup on the wheels

and adhesive buildup on the knives during operation.

Caution: Do not use solvents or petroleum products on

the silicone application roll when working on new, hot

asphalt surfaces.

To prevent asphalt buildup around the roller, untighten

the scraper mounting screws and move the scraper back.

Tighten the screws.

Trouble Shooting

Tape is not properly cut: The tape will no t cut cleanly if

cutting is done while the applicator is in motion. If the

knife edges are dull or out of alignment, the knives

should be sharpened and adjusted. (See Adjustments).

Clean adhesives build up from knives. (See

Maintenance).

MTA-2 - Spare Parts:

Spare parts can be ordered directly at the machine

manufacturer. Please contact your 3M representative for

further information.

Literature Reference

For additional information on 3M™ Stamark™ Tapes,

Application Instructions or 3M™ Application

Equipment, refer to the following publications:

IF OV Information Folder Overlay Application

IF AP Information Folder Inlay Application

IF BPlus Information Folder BitumenPlus Application

IF PS-98 Information Folder Adhesive Spray

Applicator PS-98

IF P50 Information Folder Surface Preparation

Adhesive 3M™ Stamark™ P50

IF RTC-3 Information Folder Tamper Cart RTC-3

PB A340 Product Bulletin 3M™ Stamark™ Durable

Tape Series A340

PB A380 Product Bulletin 3M™ Stamark™

High Performance Tape Series A380SD/ESD

PB A820 Product Bulletin 3M™ Stamark™

Wet Reflective Tape Series A820

PB A650 Product Bulletin 3M™ Stamark™ Temporary

Tape Series A650

PB A540 Product Bulletin 3M™ Stamark™ Temporary

Tape Series A540

PB A720 Product Bulletin 3M™ Stamark™ Temporary

Wet Reflective Tape Series A720

PB A750 Product Bulletin 3M™ Stamark™ Temporary

Wet Reflective Tape Series A750

Manual Tape Applicator MTA-2 Page 4

3M assumes no responsibility for any injury, loss or damage arising out of the use of a product that is not of our manufacture. Where

reference is made in literature to a commercially available product, made by another manufacturer, it shall be the user's responsibility to

ascertain the precautionary measures for its use outlined by the manufacturer.

Important Notice

All statements, technical information and recommendations herein are based on tests we believe to be reliable, but the accuracy or

completeness thereof is not guaranteed. 3M shall not be liable and no warranty shall be liable and no warranty shall apply for products not

applied according to our published information folder.

Before using, the user must determine the suitability of the product for its intended use, and the user assumes all risk and liability

whatsoever in connection therewith. All questions of warranty and liability relating to this product are governed by the terms of the sale

subject where applicable to the prevailing law. No statement or recommendation not contained herein shall have any force or effect unless

in an agreement signed by officers of us.

3M Deutschland GmbH

Display & Graphics Laboratory

Traffic Safety Systems Division

Carl-Schurz-Str. 1, 41453 Neuss, Germany

Tel: +49 (0) 21 31 / 14 0

Fax: +49 (0) 21 31 / 14 36 94

Loading...

Loading...