Quantum 270-11AC3-134, 150-08ACW-134, 340-17ACW-134, 340-11AC3-134 User Manual

Owner’s Manual Quantum Energy Technologies

OWNER'S MANUAL

Document number: QDC0030PD-11 Page 1 of 40

Including Installation Instructions And Warranty Information

TO SUIT HEAT PUMP STORAGE WATER HEATER

MODELS

Compact:

150-08ACW-134

270-11AC3-134

340-11AC3-134

340-17ACW-134

Titan Split:

340TIH-134

FOR ADVICE, REPAIRS AND SERVICE

1800 644 705

Document Number: QDC0030PD-11

Date Of Revision: 01 Mar. 2008

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 2 of 40

Contents

Section 1: APPLIANCE DETAILS ................................................................................................. 5

1a: Owner’s Details ...................................................................................................................... 5

1b: Installer’s Details .................................................................................................................... 5

1c: Service History ....................................................................................................................... 5

Section 2: INTRODUCTION .......................................................................................................... 6

2a: One Of The Worlds Most Energy Efficient Methods Of Water Heating ............................... 6

2b: Time Delay On Start ............................................................................................................... 7

2c: Features Of Your Quantum Water Heater .............................................................................. 7

Section 3: INSTALLATION DETAILS .......................................................................................... 7

3a: General Installation Requirements ......................................................................................... 7

3a.1: Location ............................................................................................................................ 7

3a.2: Corrosion Protection......................................................................................................... 8

3b: Air Flow.................................................................................................................................. 8

3c: Evaporator Drain..................................................................................................................... 8

3d: Pressure & Temperature Relief Valve (PTR)......................................................................... 8

3e: Expansion Control Valve (ECV) ............................................................................................ 8

3f: Cold Water Connection ........................................................................................................... 9

3g: Pressure Reducing Valve........................................................................................................ 9

3h: Caution Regarding Glass Lining Of Tank .............................................................................. 9

3i: Suitability For Installation In Frost Areas ............................................................................... 9

3j: Draining Of Tank .................................................................................................................... 9

3k: Hot Water Connection ............................................................................................................ 9

3l: Tempering Valves ................................................................................................................... 9

3m: Electrical Connection .......................................................................................................... 10

3m.1: Safety Notes .................................................................................................................. 10

3n: Refrigeration Connections (Split Models Only)................................................................... 10

3n.1: Refrigeration Tube Sizes ................................................................................................ 11

3o: Caution Regarding Drilling Metal Jacket ............................................................................. 11

Section 4: OPERATING INSTRUCTIONS .................................................................................. 14

4a: Filling The Water Heater ...................................................................................................... 14

4b: Water Quality ....................................................................................................................... 14

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 3 of 40

4c: Caution When Left Operating But Unused........................................................................... 14

Section 5: SAFETY INFORMATION .......................................................................................... 14

5a: Safety Devices ...................................................................................................................... 14

5b: Important Note Regarding PTR Valve ................................................................................. 15

Section 6: MAINTAINANCE & SERVICE INFORMATION...................................................... 15

6a: The Water Tank .................................................................................................................... 15

6b: Air Evaporator Coils............................................................................................................. 15

6c: Sacrificial Anode .................................................................................................................. 15

6d: Service Caution – Before Any Work Is Carried Out ............................................................ 16

6e: Thermal Overload (Incorporated in Digital Controller) ....................................................... 16

6f: Routine Service ..................................................................................................................... 16

6f.1: Six Month Service (By Owner)....................................................................................... 16

6f.2: Five Year Service (By Authorized Personnel Only) ....................................................... 17

6f.3: Access & Removal Of Sacrificial Anode ....................................................................... 17

6f.4: Flushing Of Water Tank ................................................................................................. 18

6f.5: Refrigeration & Thermostat Servicing ........................................................................... 18

Section 7: RECOGNITION OF ABNORMAL OPERATION...................................................... 19

7a: Pressure & Temperature Relief Valve Running ................................................................... 19

7a.1: Continuous Trickle ......................................................................................................... 19

7a.2: Steady Flow .................................................................................................................... 19

7b: No Hot Water........................................................................................................................ 19

7c: High Electricity Bills ............................................................................................................ 19

Section 8: WARRANTY CERTIFICATE ...................................................................................... 21

8a: Terms Of Warranty ............................................................................................................... 22

8b: Items Not Covered By Warranty .......................................................................................... 22

8c: Before Phoning For Service.................................................................................................. 22

Section 9: SPECIFICATIONS ....................................................................................................... 23

Section 10: OPERATION & ADJUSTMENT OF THE DIGITAL CONTROLLER .................... 25

10a: The Buttons ......................................................................................................................... 25

10a.1: SET BUTTON.............................................................................................................. 25

10a.2: UP BUTTON................................................................................................................ 25

10a.3: DOWN BUTTON ........................................................................................................ 25

10b: Restore Factory Programming ............................................................................................ 25

10b.1: First Level: Press SET+UP for 6 seconds....................................................................... 26

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 4 of 40

10b.2: Second Level: Press SET+DOWN for 6 seconds.......................................................... 26

10b.3: Third Level: Press UP+DOWN for 6 seconds........................................... 26

10c: Error Codes ......................................................................................................................... 26

10d: De-Icing........................................................................................................................ 27

10e: Operating Principle............................................................................................................ 27

10f: Adjusting............................................................................................................. 27

Appendix A: TROUBLE SHOOTING GUIDE ON QUANTUM WATER HEATERS .............. 31

A.1: No Hot Water; Compressor Not Running .......................................................................... 31

A.2: Thermal Cut Out Trips Off Repeatedly .............................................................................. 32

A.3: No Hot Water; Compressor Running ................................................................................. 33

A.4: Shortage Of Hot Water ....................................................................................................... 33

A.5: Testing Undercharge Or Overcharge Of Refrigerant ......................................................... 34

A.6: Water Temperature, Condensing Pressure & Amperage – R134a Units............................ 34

A.7: Suction Pressure – R134a Units ......................................................................................... 34

A.8: Signs Of Correct Charge..................................................................................................... 35

A.9: Signs Of Undercharge......................................................................................................... 35

A.10: Signs Of Overcharge......................................................................................................... 35

A.11: Technical Data For Service Personnel – SIAM Compressors – R134a ........................... 36

WARRANTY CARD .................................................................................................................. 37

NOTES (Owner’s Use) .................................................................................................................. 39

List of Figures

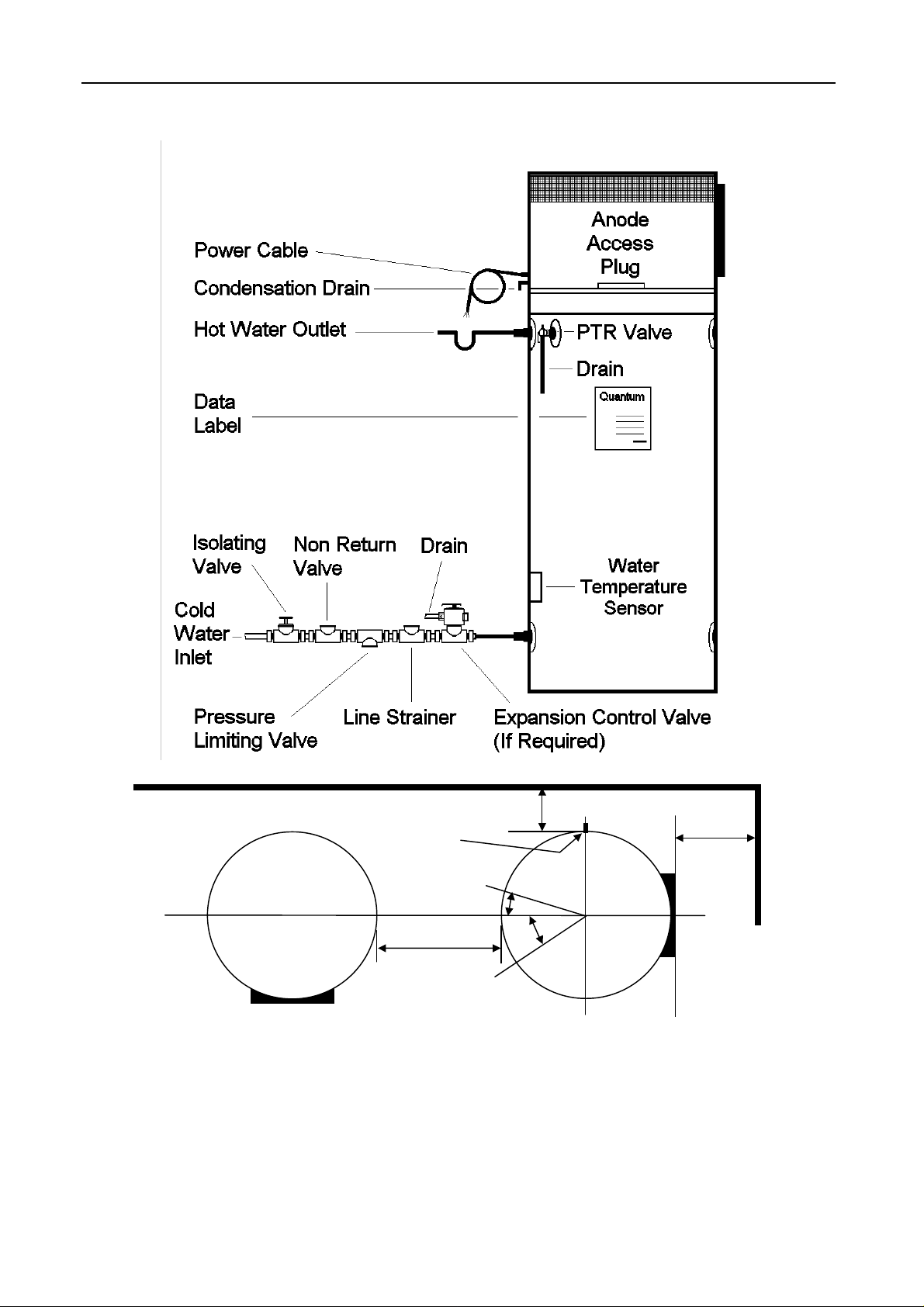

Figure 1: Installation Diagram (Compact Systems)....................................................................... 12

Figure 2: Installation Diagram (Split Systems) ............................................................................. 13

Figure 3: Specifications & Dimensions ......................................................................................... 23

Figure 4: Split Fin Coil Evaporator – 340 TIH-134 ....................................................................... 24

Figure 5: Layout Of Digital Controller Programming Buttons ..................................................... 28

Figure 6: Wiring Diagram –150-08ACW-134 270/340-11AC3-134 & 340-17ACW-134.......... 29

Figure 7: Wiring Diagram – 340 TIH-134……............................................................................ 30

Owner’s Manual Quantum Energy Technologies

Section 1: APPLIANCE DETAILS

For future convenience, please fill in the following details and retain with your original invoice.

1a: Owner’s Details

Surname: …………………………………… Given Name(s): ….………………………....

Address: ……………………………………………………………………………...…………

Town/Suburb: ……………………………………………………………………..……………

State/Territory:……………………………… Postcode: ……………………………………

Date of Purchase: .….……….………………

Purchased From: ………………………………………..………………………………….……

Model: ..…………………………………….. Serial Number: ………………..…………….

Date of Manufacture: .……………………………………………………………….………….

(Details on Data Plate on water heater)

1b: Installer’s Details

Date of Installation: ………………………… Installer’s Name: ……………………………

Address:…………………………………….……………………………….…………….……

Installer’s Signature: …………………………………….………………….……………….….

1c: Service History

Date of Service: ............................................. Serviced By: …………….………………….

Work Carried Out: …………………….………………………………………………….…….

Signature of Service Agent: .……………………………….…………………………………..

Date of Service: ............................................. Serviced By: ……………….……………….

Work Carried Out: …………………………………………………………….……………….

Signature of Service Agent: .……………………………...……….………….………………..

Document number: QDC0030PD-11 Page 5 of 40

Owner’s Manual Quantum Energy Technologies

Section 2: INTRODUCTION

Quantum Energy Technologies

2a:

One Of The Worlds Most Energy

Efficient Methods Of Water Heating Production

We thank you for your decision to purchase a Quantum Energy Technologies Heat Pump Water

Heater, which will reward you with many years of low energy hot water production.

QUANTUM ENERGY TECHNOLOGIES Pty Ltd designs and manufactures energy efficient Heat

Pump water heaters. The simple way to explain the advantage of this heater is that it saves energy

in any weather, even at night.

The Compact models use 1kW of electrical energy, however, they are able to put up to 3.6kW of

heat energy into the water @ 20°C ambient. The system can save up to 75% of conventional hot

water energy utilization; greatly assisting in the worldwide greenhouse gas reduction campaign.

As the name indicates, a Heat Pump is a machine that pumps heat from a low temperature source

to a high temperature reservoir. It has a cold side to absorb heat at low temperatures and a hot side

to deliver heat at high temperatures.

The Quantum compact model has an air conditioning coil as the cold side of the refrigeration

circuit. This coil absorbs the heat from air that is forced through it by means of the fan. The

Compact design is installed like a conventional electric water heater i.e. the electrical and

plumbing is completed in the same manner.

There is also a Split Air Sourced design, which can be used to recover heat from the roof space or

a warm area like a kitchen. The remote fan coil (energy collector) operates like a passive solar

collector, for instance, absorbing the heat energy from the warm air in the roof space (which has

been heated by the sun). Alternatively, the waste heat from the building can be used as the heat

source.

QUANTUM water heaters are designed and manufactured in Australia and can save energy in

countries all around the world. They are used in all weather conditions for domestic, commercial

and industrial applications, and are regarded as one of the most energy efficient water heaters

available.

This is your assurance that you have purchased one of the highest quality water heaters on the

market, one that will provide continuous hot water for all your needs – safely, economically, and

for many years to come.

2b: Time Delay On Start

NOTE: The system has a 10-minute time delay on start or restart. When the power is first

connected or after a disconnection then re connection, the time delay on start will commence. The

compressor and fan will not operate until the completion of this delay period.

Document number: QDC0030PD-11 Page 6 of 40

Owner’s Manual Quantum Energy Technologies

2c: Features Of Your Quantum Water Heater

1. Fully welded steel tank with class X vitreous enamel lining for superior corrosion

resistance and longer life.

2. Indirect heat transfer eliminates tank hot spots.

3. One of the most energy efficient Heat Pump systems in the world.

4. Able to save more money, especially in cold weather, than any other solar system on the

market.

Warranty Return Card

Enclosed you will find a warranty card – please fill in the details and return immediately. This will

ensure prompt service under warranty, if required (see Section 8 for terms of warranty).

Section 3: INSTALLATION DETAILS

3a: General Installation Requirements

This water heater must be installed by a licensed tradesperson, and in accordance with

1. AS 3500.4, National Plumbing And Drainage Code, Part 4: Hot Water Supply Systems.

2. AS 3500.4.2, National Plumbing And Drainage Code, Part 4.2: Hot Water Supply Systems

– Acceptable Solutions.

3. Other relevant Australian Standard, Industry or Local Water Supply regulations or codes

for mains pressure storage tanks.

Note: This water heater is not suitable for pool heating or building heating.

3a.1: Location

The water heater should be located as close as possible to the most frequently used hot water

outlets. Adequate access must be made for service to the evaporator, water temperature thermostat,

relief valve and anode. Ensure that the specification label is clearly visible. The front service cover

of the heat pump section (on top of tank) must be accessible from the front of the heater; this must

NOT face the wall. The fan MUST NOT be up against a wall (minimum clearance 500mm).

The Compact model has a noise level similar to an air conditioner (52dBA @ 1.5 metre); therefore

locating the unit away from bedrooms or living areas is recommended (both the owners & any

neighbours). Obviously installing near a bedroom window may be annoying to the occupants.

Note: All models are equipped with a sacrificial anode, accessible through the top cover. We

recommend allowing 400mm above the top of the water heater (if possible) for clearance to

replace the anode.

The water heater should be placed on a 650mm x 650mm plinth if installed on a floor subject to

wet conditions or outdoors. A properly drained overflow tray should be used where property

damage could occur from water spillage. (See AS3500.4 for further details.)

Note: The warranty does not cover damage due to leakage of the water heater

Document number: QDC0030PD-11 Page 7 of 40

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 8 of 40

3a.2: Corrosion Protection

Fittings and the Shell Surface in contact with the water are to be galvanically compatible. Sealants

and / or Teflon plumbing tape should be used on potentially galvanically incompatible fittings.

This is to protect against possible electrolytic corrosion between the metals (where moisture

penetration could occur due to incorrectly or poorly sealed fittings).

3b: Air Flow

The Compact and Split Air models extract the required heat from air being drawn through their Fin

Coil Evaporator. This produces cold exhaust air as a by-product. In order for the heaters to operate

efficiently, good ventilation of the proposed location for the Compact model or the Titan models

separate evaporator is required. This is to provide warm air as a heat source and to remove the cold

air being produced. The Compact therefore is best located externally, however a large double

garage (minimum of 120 cubic meters) may also be suitable. The Titans separate evaporator could

be located externally or in a large well-ventilated ceiling space or garage, however being a more

powerful system, more ventilation is required.

3c: Evaporator Drain

During operation considerable amounts of condensate water will flow from the evaporator drain. If

allowed to simply flow out of the outlet, this water may pool below the unit and can cause

problems to both the water heater and area around it. The evaporator drain on both the Compact

and Split Air units should be drained to a suitable location. This can be accomplished with a length

of hose or pipe but must not be connected directly to the PTR valve or expansion valve drain.

3d: Pressure & Temperature Relief Valve (PTR)

The Pressure and Temperature relief valve (see tank data plate for rating), which is supplied with

the unit, must be fitted and made accessible so that the release mechanism can be operated and, if

required, the valve replaced. The outlet of the PTR valve must be suitably drained to remove the

water discharged during the normal heating cycle. The valve thread is RP ½” / 15mm and must be

installed into the top front socket.

Warning: A separate drain line must be run for this relief valve. It is not permitted to couple the

drain lines from the relief valve and evaporator into a single common line. The use of a tundish

under the evaporator drain with this then connected to the drain of the PTR valve is acceptable.

3e: Expansion Control Valve (ECV)

Where an Expansion Control Valve is fitted to the cold water supply, the ECV should be rated at

150kPa lower than the Pressure & Temperature Relief valve (PTR). It is a State requirement for

SA & QLD that an ECV be fitted on the cold water supply line between the non- return valve

and the water heater.

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 9 of 40

3f: Cold Water Connection

An approved isolating valve, approved non-return valve, line strainer (optional but recommended),

and union must be fitted between the supply main and the RP ¾ / 20mm socket in the water heater.

All fittings must be approved by the relevant Authority (refer to Figures 1 & 2).

3g: Pressure Reducing Valve

This water heater is designed for direct connection to a maximum water supply pressure of 500

kPa. Where the mains pressure can exceed or fluctuate beyond this pressure, a pressure-limiting

device (complying with AS1357) must be fitted in the cold-water supply line. This device must be

installed after the isolating valve and set at or below 500 kPa (350 kPa if ECV fitted). With a water

supply pressure of 700 kPa, as the tank temperature reaches 55°C, the internal pressure climbs to

1100 kPa (well above the PTR valve rating). Given this 400 kPa rise, even with a 500 kPa supply,

the internal pressure could still reach 900 kPa.

3h: Caution Regarding Glass Lining Of Tank

When making the hot and cold water connections to the tank care should be taken not to apply

excessive strain as damage to the tank spigots or glass lining may occur.

3i: Suitability For Installation In Frost Areas

The R134a refrigerant used has a boiling point of –26°C so there is no risk of damage to the heat

pump from frost. Performance may be reduced in very low temperatures but the system will not be

damaged by such climatic conditions.

3j: Draining Of Tank

Consideration should be given to the possible necessity of draining the tank at some point.

Draining of the tank can be accomplished by the connection of a hose to the cold water inlet and

running to a suitable drain. It will be necessary to disconnect the hot water outlet or PTR valve to

relieve any partial vacuum created as the water flows out.

3k: Hot Water Connection

The hot water pipe should be connected to the RP ¾ / 20mm socket as shown in the Installation

Diagram (Figures 1 & 2). If desired a thermo siphon trap can be installed at the hot water outlet to

further reduce heat loss (a “U” shaped loop will form such a trap– see Figures 1 & 2). For the most

economical operation of the water heater, it is recommended that all hot water lines be insulated.

NOTE: Plugs are supplied with the water heater to plug off the inlet / outlet entries that are not

required. Ensure that adequate sealing tape is applied to the plugs for a tight, leak proof seal.

3l: Tempering Valves

Where a tempering valve is fitted on the hot water outlet of a Quantum (to reduce water

temperature to 50°C as per the plumbing code) ONLY high performance valves suitable for

“Solar” type water heaters are recommended to be used. Standard tempering valves may not

function correctly.

Owner’s Manual Quantum Energy Technologies

Document number: QDC0030PD-11 Page 10 of 40

3m: Electrical Connection

Quantum water heaters are designed for single-phase 220/240V A.C supply only. A certified

electrician must carry out all electrical work according to the local supply authority regulations and

AS3000. A 15-amp circuit breaker must be installed at the power supply for the hot water unit.

A separate circuit breaker is recommended for each unit in the case of multiple installations. The

power connection rating for all Quantum water heaters up to 1.7kW is 220-240VAC 50Hz 15A.

It is not recommended to wire the system to an earth leakage circuit breaker. There is lot of

moisture present while in operation and this can lead to nuisance tripping.

The connection will require an approved, standard 240V 15A On / Off switch or Junction Box in

close proximity to the heater. The unit should be connected to Standard Domestic tariff. Off Peak

connection is NOT recommended for Quantum heat pump units. If the unit is connected to an “Off

Peak” connection, the minimum power availability must be at least 18 hours per day.

The fitted power cord is not to be removed; this cord should be connected with the building wiring

in an On / Off switch enclosure or Junction Box. Faulty wiring may void the warranty if damage

has been sustained to the compressor or heat pump from such faulty or sub-standard wiring.

3m.1: Safety Notes

Note.1: This water heater is fitted with a thermostat and over-temperature energy cut-out (both

incorporated into the digital controller). Under no circumstances should the water heater be

operated without both of these devices being in the circuit. Only a qualified electrician or the

manufacturer should carry out replacement.

Note.2: If the supply cord is damaged, the manufacturer or its service agent or other similarly

qualified person must replace it in order to avoid hazard.

Caution: The water heater must be filled with water before turning on the electricity

3n: Refrigeration Connections (Split Models Only)

Refrigeration pipe work is very specialized and should only be completed by a licensed

tradesperson.

Maximum refrigeration pipe length from the tank connections to the evaporator is 10m.

If the evaporator is mounted below the tank connection point, then a suitable oil trap needs to be

installed on the suction line between the evaporator and the heat pump.

Owner’s Manual Quantum Energy Technologies

3n.1: Refrigeration Tube Sizes

Quantum Model Copper Tube Size - Inlet Copper Tube Size - Outlet

340 TIH-134

3

/

8

Inch (9.5mm)

5

/

8

Inch (15.9mm)

* When the evaporator is below the tank level on the Titan model use 12.7mm(1/2”) outlet tube.

3o: Caution Regarding Drilling Metal Jacket

This is extremely important and MUST be adhered to without exception!

DO NOT DRILL ANY HOLES IN OUTER METAL JACKET

DAMAGE TO REFRIGERATION LINES MAY RESULT

Document number: QDC0030PD-11 Page 11 of 40

Owner’s Manual Quantum Energy Technologies

Figure 1: Installation Diagram (Compact Systems)

Document number: QDC0030PD-11 Page 12 of 40

Orientation

if multiple

Compact units are

Condensation

Drain

Power Cord

100 mm Min

Wall

500 mm

Min

being installed.

i.e. fan to face out.

Water

Connections

15°

32°

200 mm Min

PTR Valve

NOTE

Front Access

If installing multiple Compact un its, the orientation of the tank will need to be at 90° to the normal arrangement

so that the fan points out from the wall rather than along it. This is so tha t cold air being discharged from one

unit is not drawn in by the one next to it. The space between multiple units should be a minimum of 200mm.

Tank Orientation Diagram for Compact Units

Loading...

Loading...