SIGMA-7

AC Servo Drives and Motors Technical Supplement

yaskawa.com

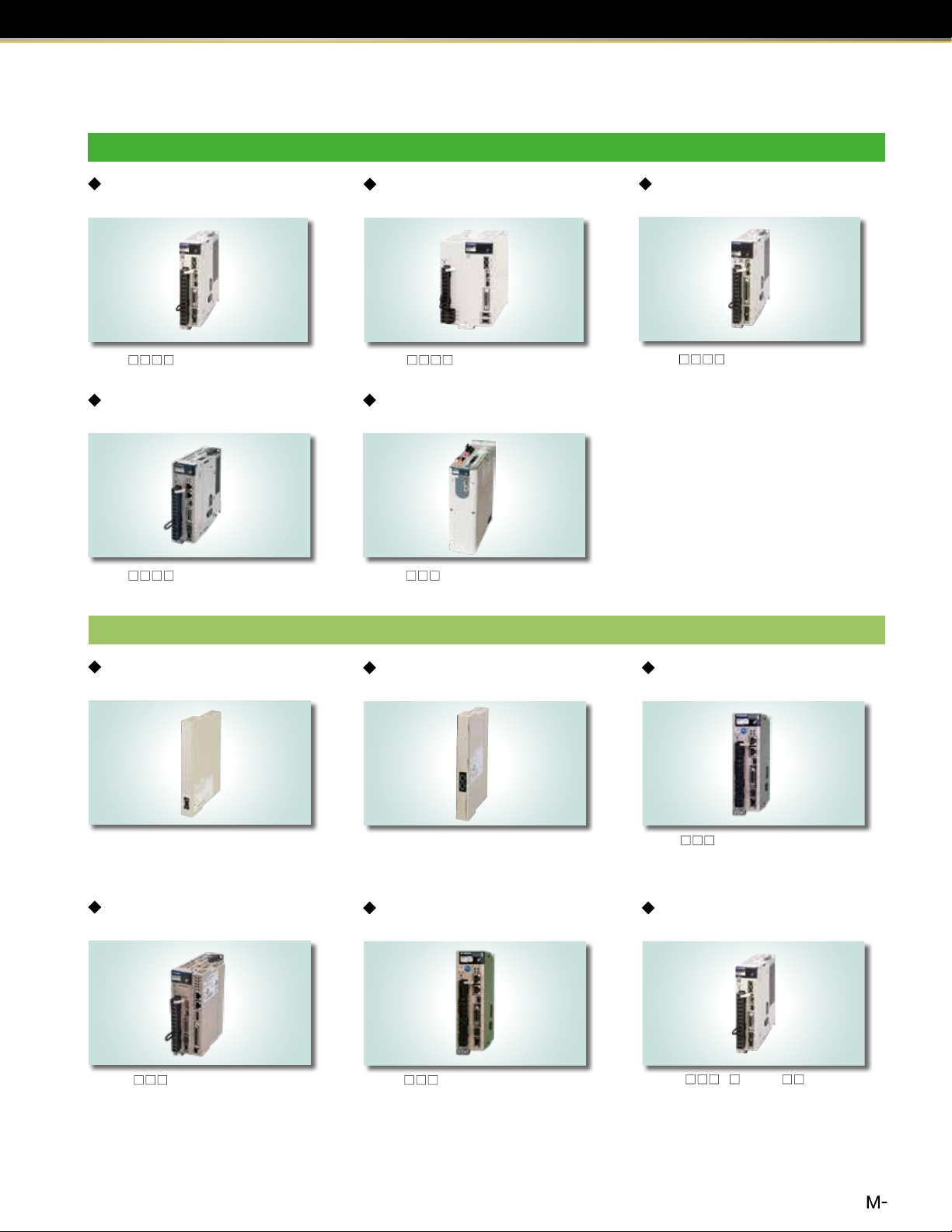

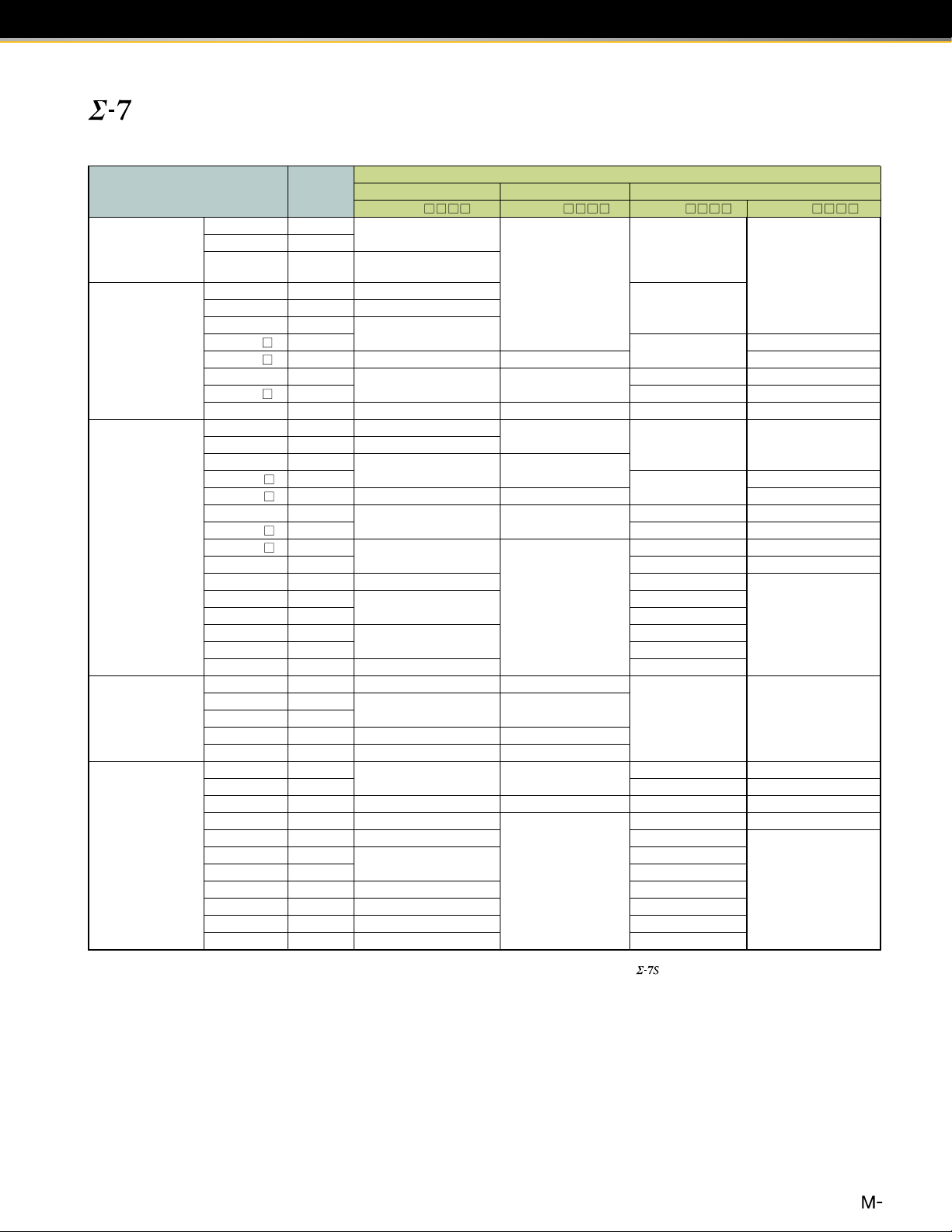

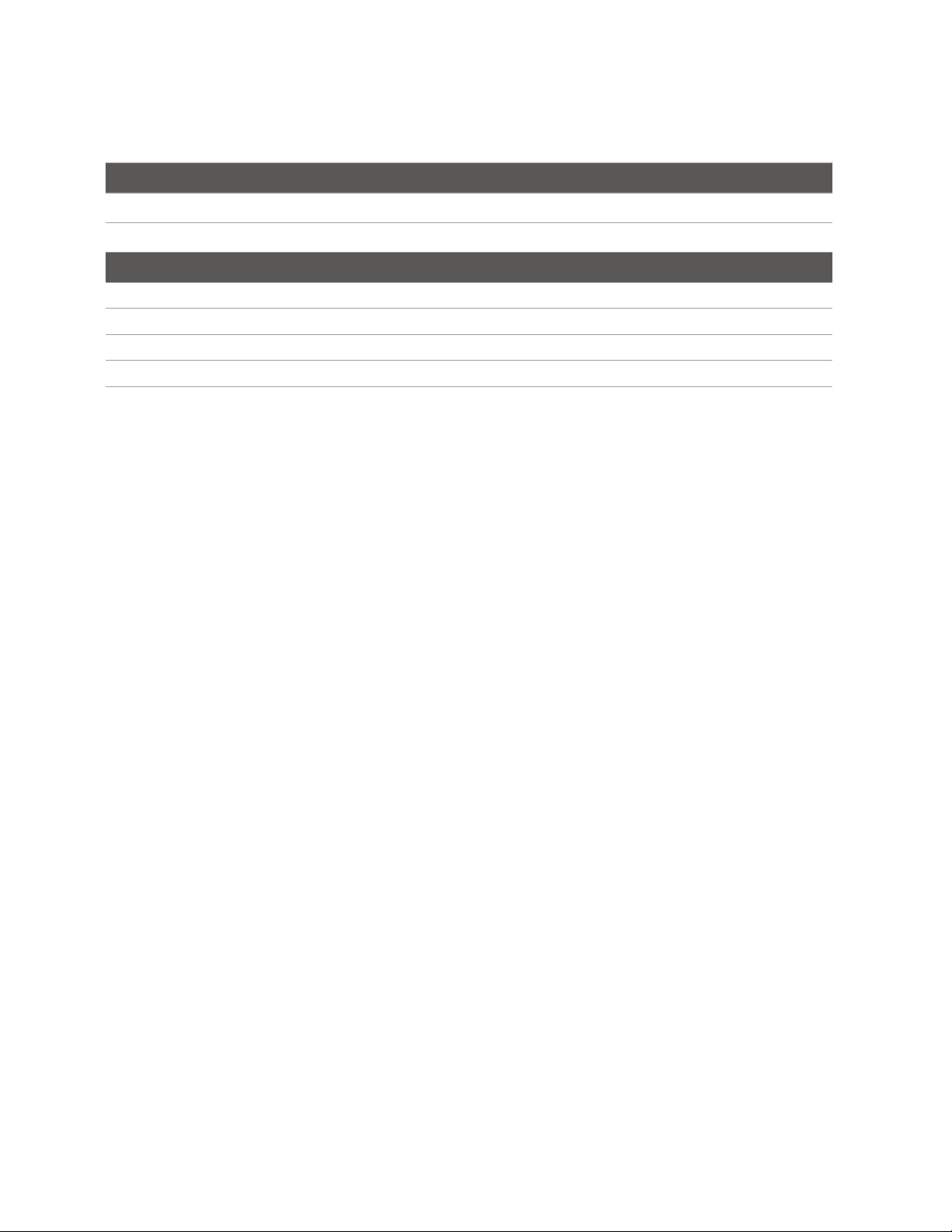

Product Lineup

Servomotors

Rotary Servomotors

SGMMV (Low inertia, ultra-small capacity)

10 W to 30 W

SGM7P (Medium inertia, at type)

100 W to 1.5 kW

SGM7J (Medium inertia, high speed)

50 W to 1.5 kW

SGM7G (Medium inertia, large torque)

300 W to 15 kW

Direct Drive Servomotors Linear Servomotors

Small capacity, with core, inner rotor (SGM7F)

2 Nm to 35 Nm

SGLG (Coreless model)

12.5 N to 750 N

SGM7A (Low inertia, high speed)

50 W to 7 kW

Linear Stages

ST2F Sigma Trac II

45 N to 180 N

Small and medium capacity, with core,

inner rotor (SGM7D), 1.3 Nm to 240 Nm

Small capacity, coreless (SGMCS)

2 Nm to 35 Nm

Medium capacity, with core (SGMCS)

45 Nm to 200 Nm

2

SGLFW2 (Model with F-type iron core)

45 N to 2520 N

SGLT (Model with T-type iron core)

130 N to 900 N

SERVOPACKs

Single-axis MECHATROLINK-III

Communications Reference

SGD7S- 30A

Single-axis EtherCAT

Communications Reference

SGD7S- A0A

Additional Options

Two-axis MECHATROLINK-III

Communications Reference

SGD7W- 30A

Two-axis EtherCAT

Communications Reference

SGD7W- DA0A (400V only)

Single-axis Analog Voltage/Pulse

Train Reference

SGD7S- 00A

Fully-Closed Module

Advanced Safety Module

+

SGDV-OFA01A

1.5 Axis Control Option

(MP2600iec)

SGDV-OSA01A

Network Indexer Option

(SigmaLogic7 Compact)

+

SGD7S AE0A000300 SGD7S- AQ0A000F51

Single-Axis Control Option

(Sigma-7Siec)

+

SGD7S AM0A000F50

Special Purpose Options

(FT Options)

+

SGD7S-

• FT19: Less Deviation Control

• FT79: Built-in Indexer

• FT81: Harmonic Drive SHA Actuators

• FT82/83: for SGM7D Direct Drive Motor

A 0A000F

3

Power supply

Three-phase 200 VAC

R S T

Linear Servomotor

Linear encoder

(Not provided by Yaskawa.)

Sensor Cable

Linear

Encoder

Cable

Linear Servomotor

Main Circuit Cable

Serial Converter Unit

Serial Converter Unit Cable

Noise Filter

Molded-case

circuit breaker

(MCCB)

Protects the power supply

line by shutting the circuit

OFF when overcurrent is

detected.

Used to eliminate

external noise from

the power line.

Magnetic

Contactor

Turns the servo

ON and OFF.

Install a surge

absorber.

Single-axis

MECHATROLINK-III

Communications Reference

SERVOPACK

CN8

External

Regenerative

Resistor

Connect an external

regenerative resistor to

terminals B1 and B2 if the

regenerative capacity is

insufficient.

Note: When not using the safety function, leave

the safety jumper connector connected to

the SERVOPACK.

Safety Function

Devices Cable

I/O Signal Cable

External devices such as

LED indicators

CN6

CN7

Computer Cable

MECHATROLINK Communications Cable

To next

MECHATROLINK-III station

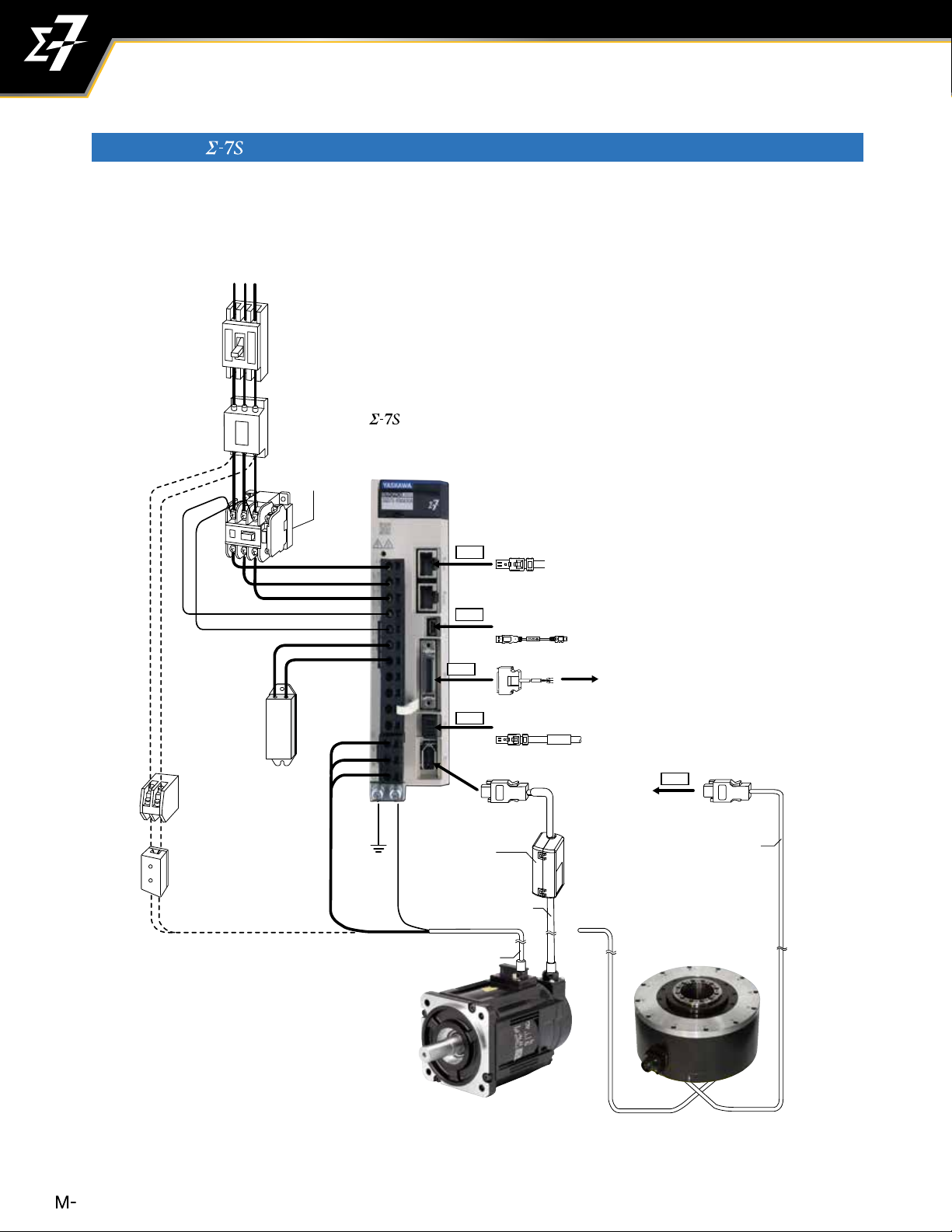

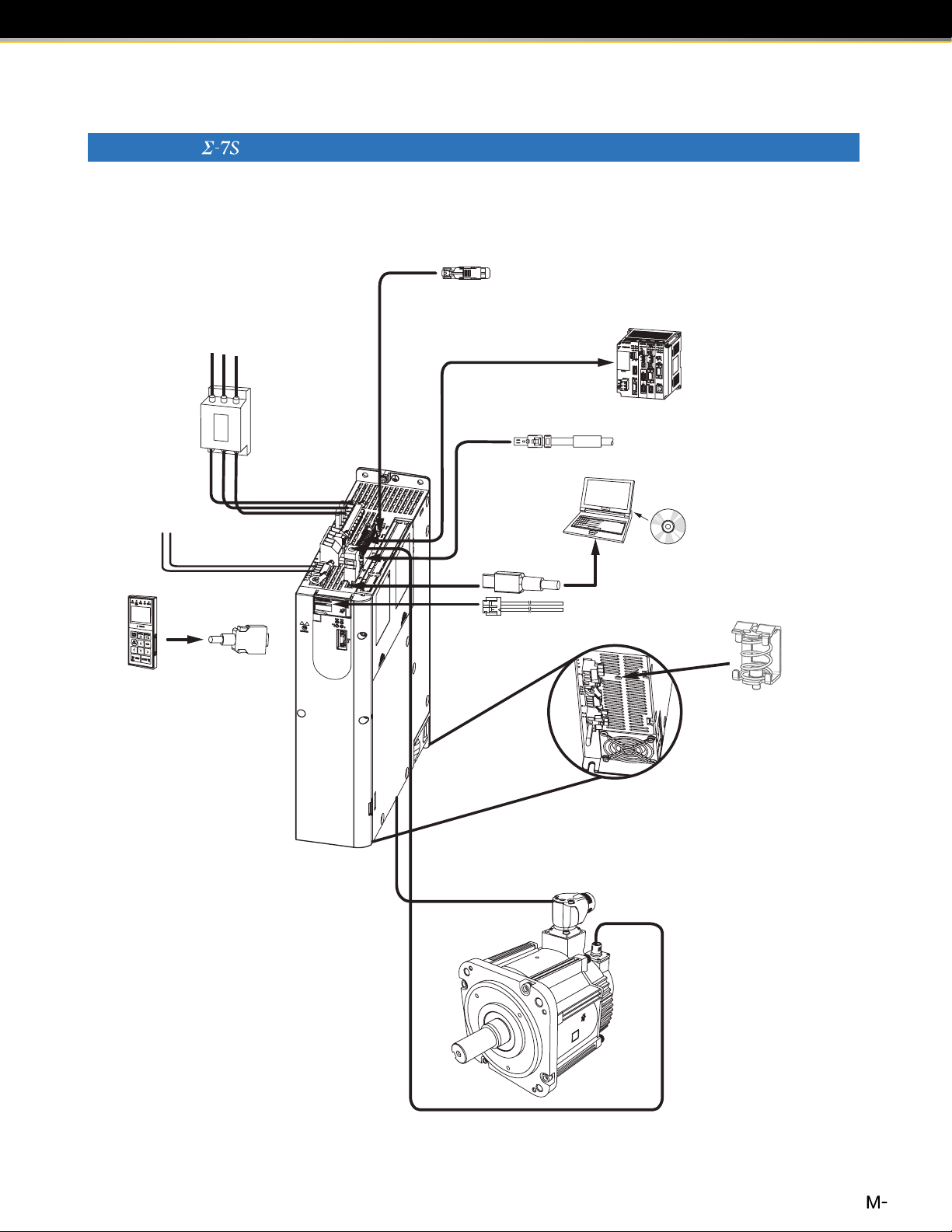

System Conguration Example

Combination of SERVOPACK and Rotary Servomotor/Direct Drive Servomotor (200V Power)

1For MECHATROLINK-III Communications

Three-phase 200 VAC

Power supply

Three-phase 200 VAC

Molded-case

circuit breaker

(MCCB)

Protects the power supply

line by shutting the circuit

OFF when overcurrent is

detected.

Noise Filter

Used to eliminate

external noise from

the power line.

R S T

Magnetic

Contactor

Turns the servo

ON and OFF.

Install a surge

absorber.

Single-axis

MECHATROLINK-III

Communications Reference

SERVOPACK

CN6

MECHATROLINK Communications Cable

To next

MECHATROLINK-III station

External

Regenerative

Resistor

Connect an external

regenerative resistor to

terminals B1 and B2 if the

regenerative capacity is

insufficient.

Magnetic

Contactor

Turns the brake

power supply

ON and OFF.

Install a surge

absorber.

Holding Brake

Power Supply Unit

Used for a

servomotor

with a brake.

(Wiring required for the brake)

Battery Case

(Required when an

absolute encoder is

used.)

Servomotor Main

Circuit Cable

CN7

Computer Cable

I/O Signal Cable

CN1

Safety Function

CN8

Devices Cable

Encoder Cable

External devices such as

LED indicators

Note: When not using the safety function, leave

the safety jumper connector connected to

the SERVOPACK.

CN2

To

Encoder Cable

Servomotor Main

Circuit Cable

Rotary Servomotor

Direct Drive Servomotor

4

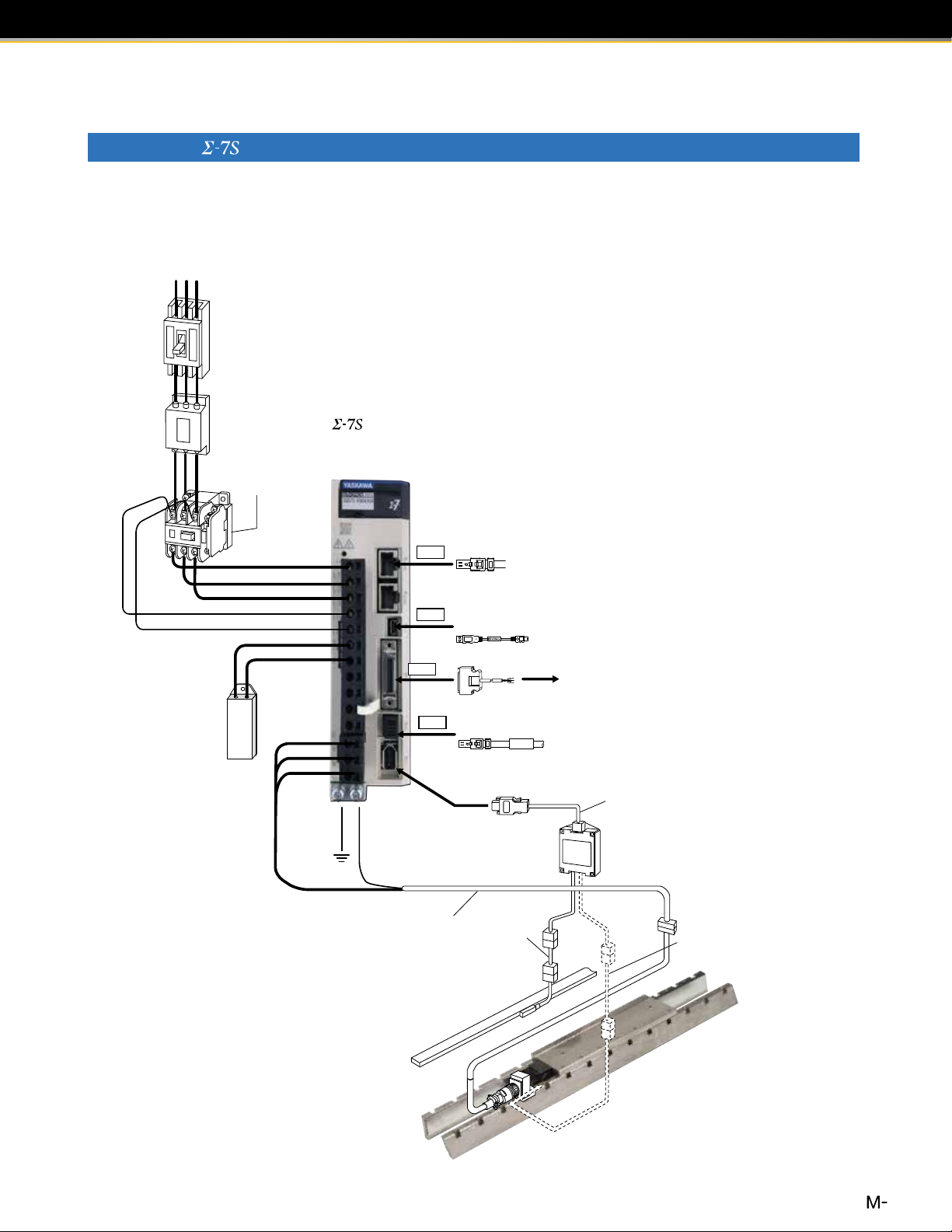

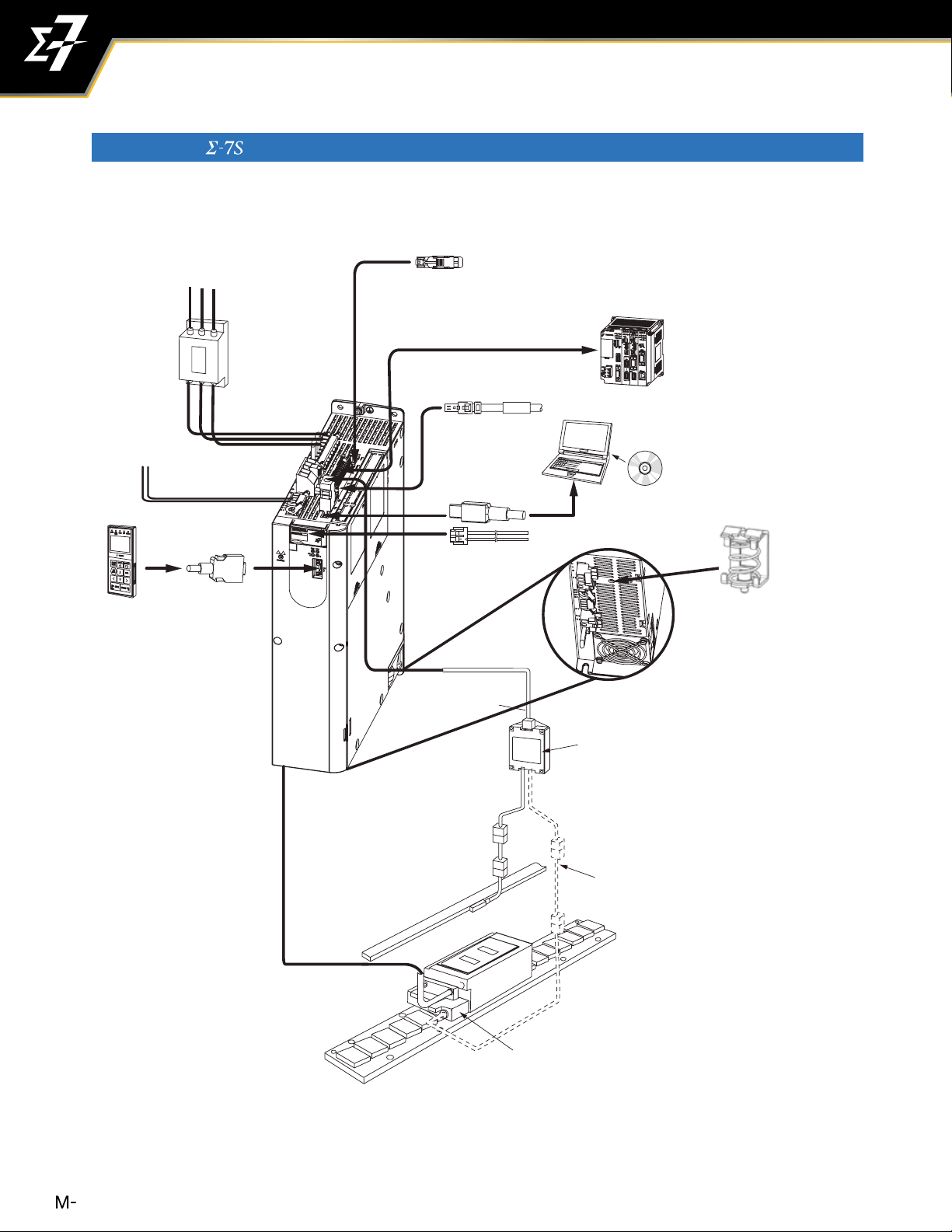

Combination of SERVOPACK and Linear Servomotor (200V Power)

1For MECHATROLINK-III Communications

Three-phase 200 VAC

Power supply

Three-phase 200 VAC

R S T

Molded-case

circuit breaker

(MCCB)

Protects the power supply

line by shutting the circuit

OFF when overcurrent is

detected.

Noise Filter

Used to eliminate

external noise from

the power line.

Magnetic

Contactor

Turns the servo

ON and OFF.

Install a surge

absorber.

Single-axis

MECHATROLINK-III

Communications Reference

SERVOPACK

MECHATROLINK Communications Cable

CN6

To next

MECHATROLINK-III station

External

Regenerative

Resistor

Connect an external

regenerative resistor to

terminals B1 and B2 if the

regenerative capacity is

insufficient.

CN7

CN8

Linear Servomotor

Main Circuit Cable

Linear encoder

(Not provided by Yaskawa.)

Computer Cable

I/O Signal Cable

Safety Function

Devices Cable

Linear

Encoder

Cable

External devices such as

LED indicators

Note: When not using the safety function, leave

the safety jumper connector connected to

the SERVOPACK.

Serial Converter Unit Cable

Serial Converter Unit

Sensor Cable

Linear Servomotor

5

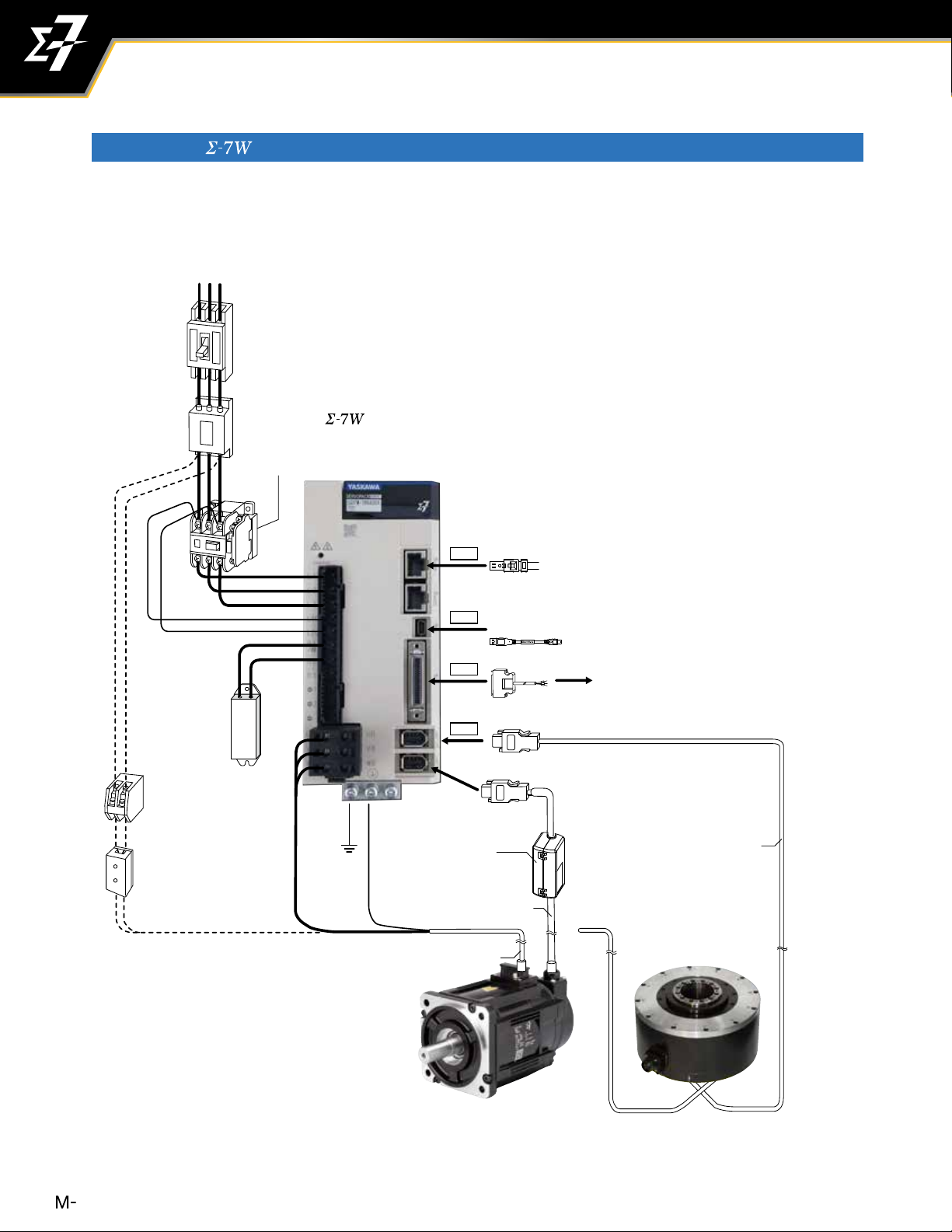

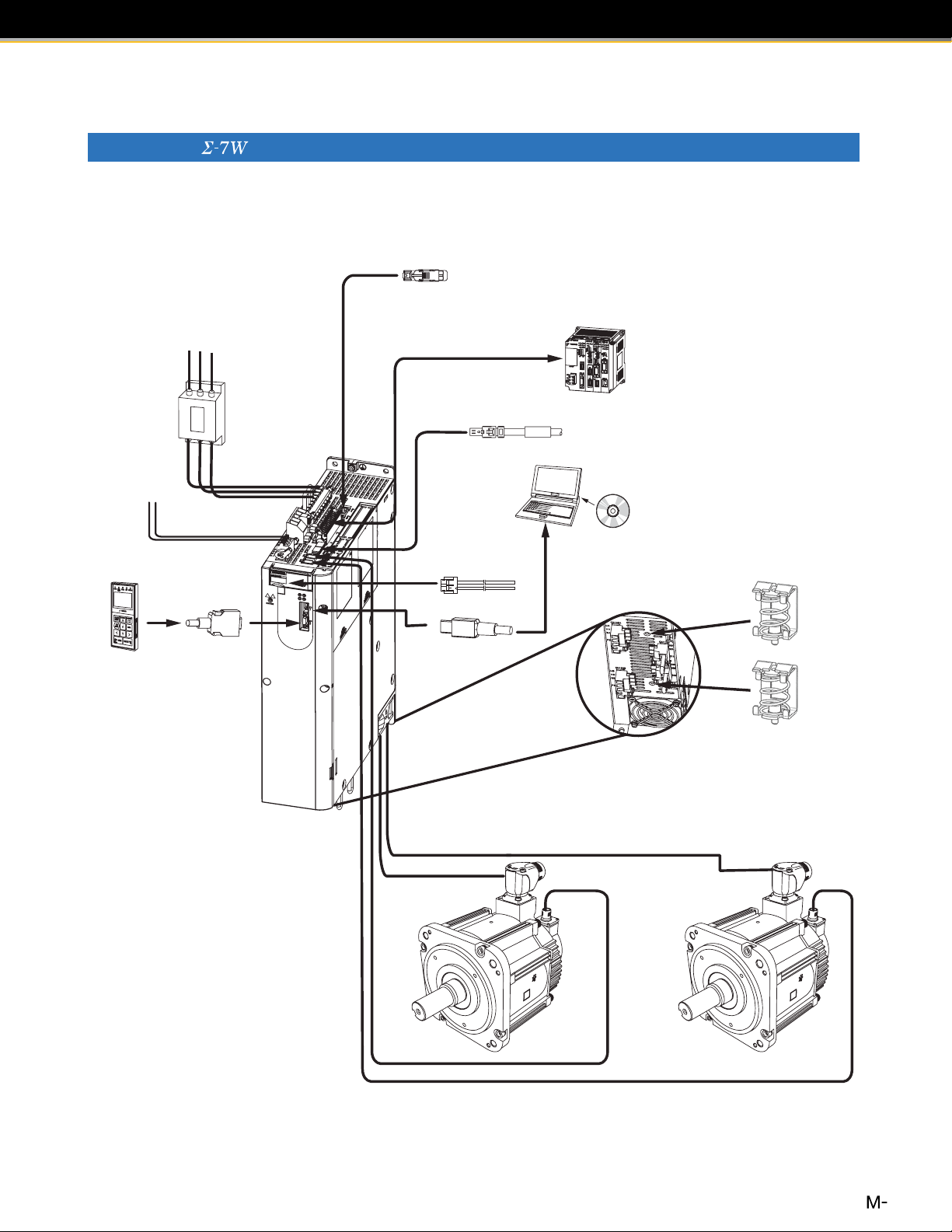

System Conguration Example

Combination of SERVOPACK and Rotary Servomotor/Direct Drive Servomotor (200V Power)

1For MECHATROLINK-III Communications

Three-phase 200 VAC

Power supply

Three-phase 200 VAC

R S T

Molded-case

circuit breaker

(MCCB)

Protects the power supply

line by shutting the circuit

OFF when overcurrent is

detected.

Noise Filter

Used to eliminate

external noise from

the power line.

External

Regenerative

Resistor

Connect an external

regenerative resistor to

terminals B1 and B2 if the

regenerative capacity is

insufficient.

Magnetic

Contactor

Turns the brake

power supply

ON and OFF.

Install a surge

absorber.

Holding Brake

Power Supply Unit

Used for a

servomotor

with a brake.

(Wiring required for the brake)

Magnetic

Contactor

Turns the servo

ON and OFF.

Install a surge

absorber.

Two-axis

MECHATROLINK-III

Communications Reference

SERVOPACK

CN6

CN7

CN1

CN2

Battery Case

(Required when an

absolute encoder is

used.)

Encoder Cable

Servomotor Main

Circuit Cable

MECHATROLINK Communications Cable

Computer Cable

I/O Signal Cable

To next

MECHATROLINK-III station

External devices such as

LED indicators

Servomotor Main

Circuit Cable

Encoder Cable

Rotary Servomotor

Direct Drive Servomotor

6

Combination of SERVOPACK and Rotary Servomotor (400V Power)

1For MECHATROLINK-III Communications

Three-phase 400 VAC

Communications Cable

Three-phase, 400 VAC

Noise Filter

Control Power Supply

Cable 24 VDC

L1 L2 L3

SERVOPACK

main circuit wires

Digital

Operator cable

Host controller

CN1 I/O Connector

Safety Function Device Cable

Computer

Support

Software

Computer Cable

Analog Monitor Cable

Motor Connection

Shielding Clamp

Bottom of SERVOPACK

7

System Conguration Example

Power supply

Communications Cable

Digital

Operato

Combination of SERVOPACK and Linear Servomotor (400V Power)

1For MECHATROLINK-III Communications

Three-phase 400 VAC

Three-phase, 400 VAC

L1 L2 L3

Noise Filter

SERVOPACK

main circuit wires

Control Power Supply

Cable 24 VDC

Digital

r

Operator cable

CN1 I/O Connector

Serial Converter Unit

Cable

Host controller

Safety Function Device Cable

Computer

Support

Software

Computer Cable

Analog Monitor Cable

Motor Connection

Shielding Clamp

Bottom of SERVOPACK

Serial Converter Unit

Linear Encoder Cable

Sensor Cable

(between Serial

Linear Encoder

(Not provided by Yaskawa.)

Polarity sensor

Linear Servomotor

Converter Unit and

polarity sensor)

8

Combination of SERVOPACK and Rotary Servomotors (400V Power)

1For MECHATROLINK-III Communications

Three-phase 400 VAC

Communications Cable

Power supply

Three-phase, 400 VAC

L1 L2 L3

CN1 I/O Connector

Host controller

Noise Filter

Digital

Operator

SERVOPACK

main circuit wires

Control Power Supply

Cable 24 VDC

Digital

Operator cable

Safety Function Device Cable

Computer

Analog Monitor Cable

Computer Cable

Support

Software

Bottom of SERVOPACK

Motor Connection

Shielding Clamps

9

Stock Status Definitions

The product selection tables in this catalog contain stock status codes, which are

subject to change. The codes are defined below:

S

LS

NS

Stock Item

Normally 3 to 5 days leadtime for most order quantities. 3 to 5 weeks maximum

if temporary outages occur. For critical lead time or large quantity shipments,

check with your Yaskawa sales representative.

Limited Stock Item

Typically small quantites are available from stock. Items may become stock

items as demand increases.

Non-Stock Item

Non-stock items typically carry a 12 - 16 week delivery time.

10

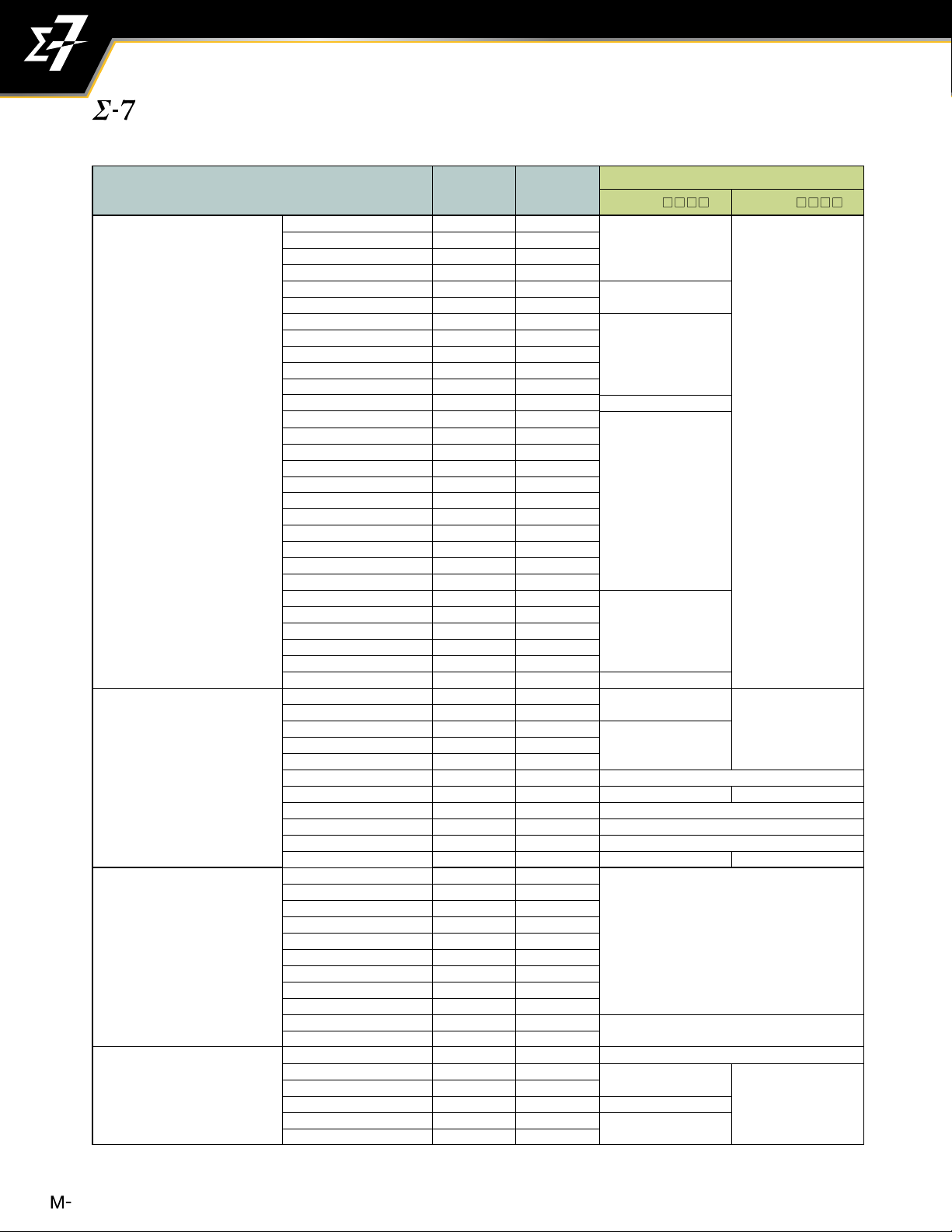

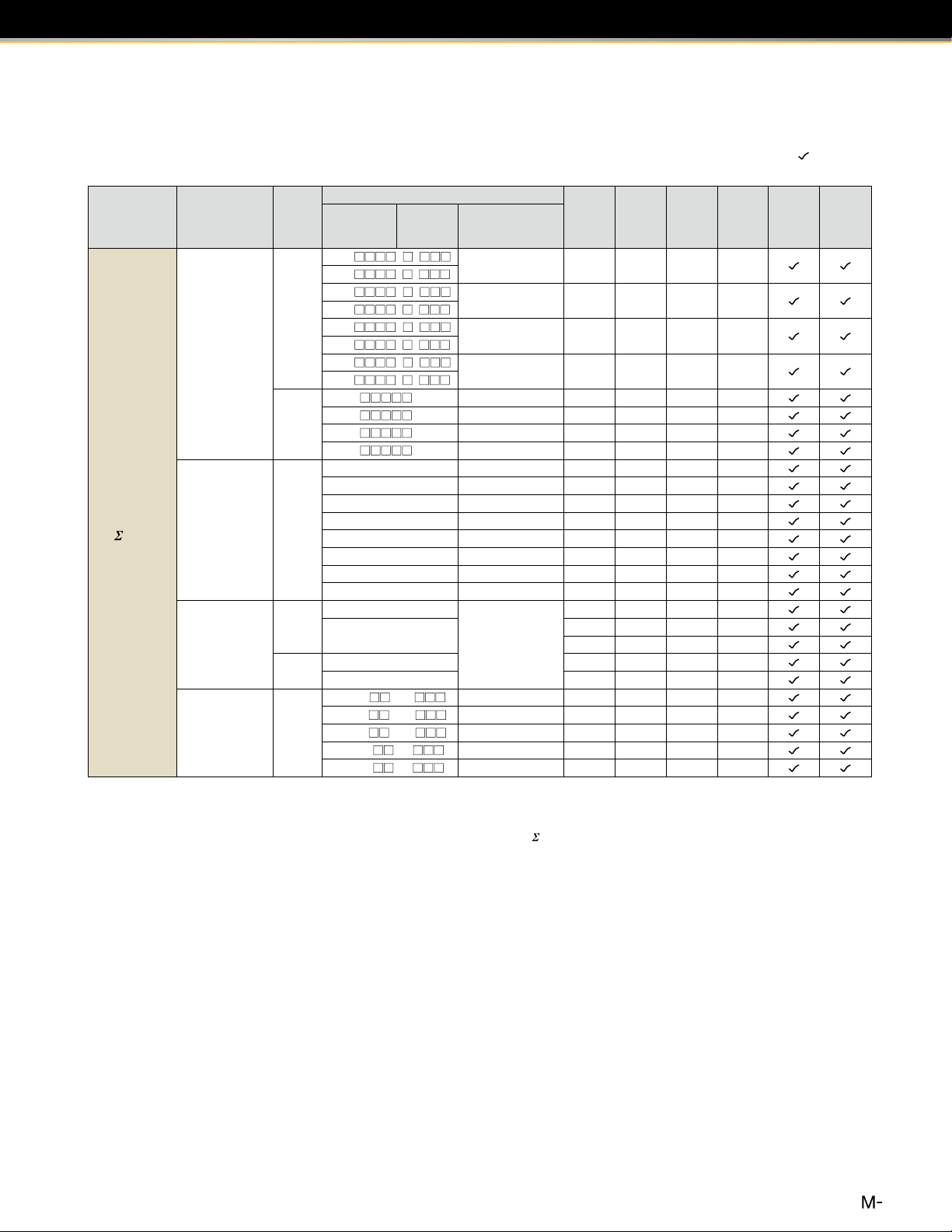

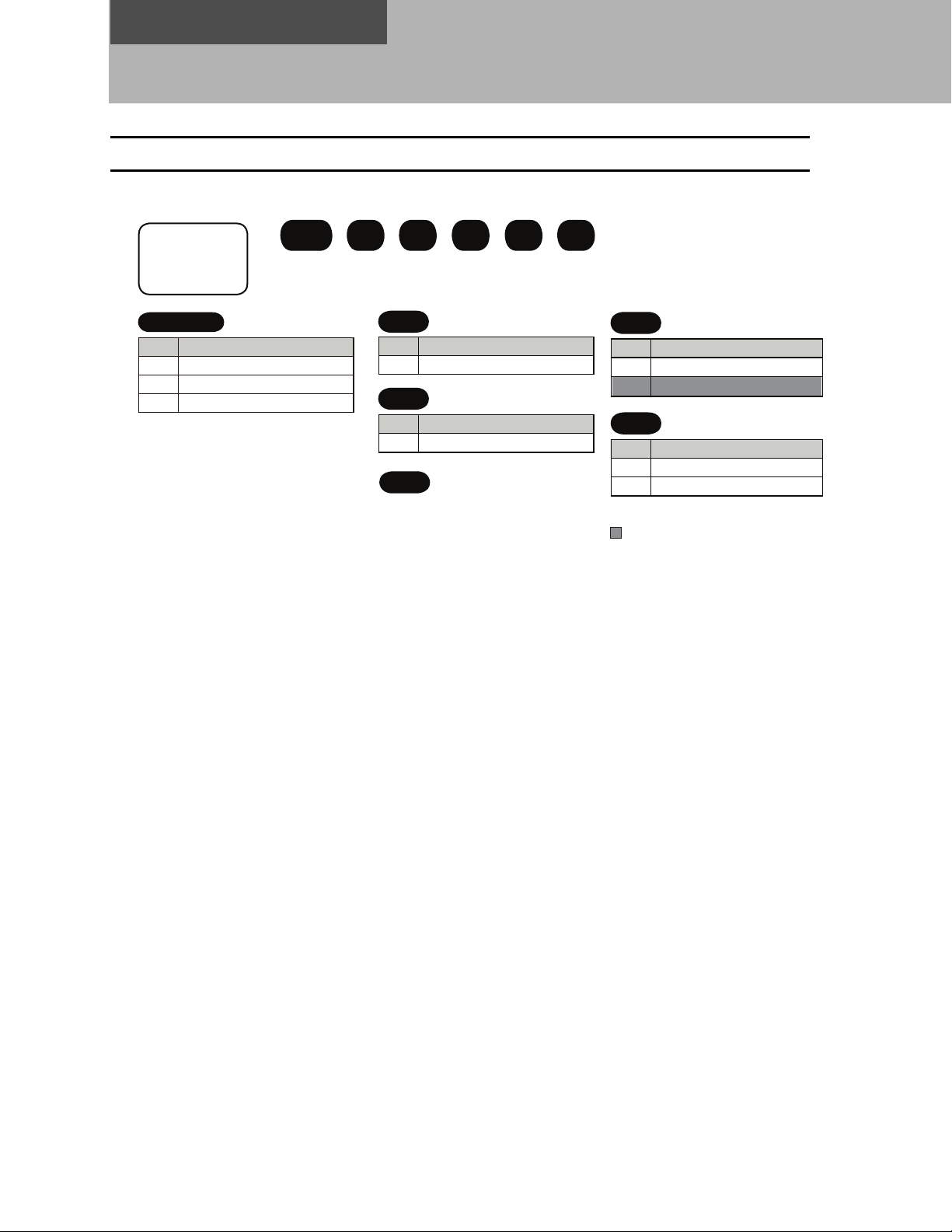

Series Combination

1Combination of Rotary Servomotors and SERVOPACKs

Rotary Servomotor Model

SGMMV

(Low inertia, ultra-

small capacity)

6000 RPM

SGM7J

(Medium inertia, high

speed)

3000 RPM

SGM7A

(Low inertia, high

speed)

3000 RPM

SGM7P

(Medium inertia, at

type)

3000 RPM

SGM7G

(Medium inertia,

large torque)

1500 RPM

Rated

Output

SGMMV-A1A 10 W

SGMMV-A2A 20 W

100V/200V 200V 400V

SGD7S-

R90A, R90F

SGMMV-A3A 30 W 1R6A, 2R1F

SGM7J-A5A 50 W R70A, R70F

SGM7J-01A 100 W R90A, R90F

SGM7J-C2A 150 W

SGM7J-02

SGM7J-04

200 W

400 W 2R8A, 2R8F 2R8A, 5R5A*1, 7R6A

SGM7J-06A 600 W

SGM7J-08

750 W 3R5D 2R6D or 5R4D*

1R6A, 2R1F

5R5A 5R5A, 7R6A

Sigma-7 SERVOPACK Model

SGD7W- SGD7S- SGD7W-

2R9E

*1

*1

, 2R8A

1R6A

−

*1

1R9D

2R6D*

2R6D* or 5R4D*

− −

−

SGM7J-15D 1.5 kW N/A N/A 5R4D 5R4D

SGM7A-A5A 50 W R70A, R70F

SGM7A-01A 100 W R90A, R90R

SGM7A-C2A 150 W

SGM7A-02 200 W

SGM7A-04

400 W 2R8A, 2R8F 2R8A, 5R5A*1, 7R6A

SGM7A-06A 600 W

SGM7A-08

SGM7A-10

750 W 3R5D 2R6D or 5R4D*

1.0 kW

SGM7A-15A 1.5 kW 5R4D 5R4D

1R6A, 2R1F 1R6A, 2R8A

5R5A 5R5A, 7R6A

120A

1R6A

*1

, 2R8A

*1

− −

*1

*1

1R9D

2R6D*

2R6D* or 5R4D*

− −

5R4D 5R4D*

SGM7A-20A 2.0 kW 180A 8R4D

SGM7A-25A 2.5 kW

SGM7A-30A 3.0 kW 120D

SGM7A-40A 4.0 kW

SGM7A-50A 5.0 kW 170D

SGM7A-70A 7.0 kW 550A

SGM7P-01A 100 W R90A, R90F 1R6A

SGM7P-02A 200 W

SGM7P-04A 400 W

200A

330A

*1

2R8A, 2R8F 2R8A, 5R5A

−

, 2R8A

*1

, 7R6A

*1

*1

120D

170D

−

− −

−

SGM7P-08A 750 W 5R5A 5R5A, 7R6A

SGM7P-15A 1.5 kW 120A

SGM7G-03A 300 W

SGM7G-05A 450 W 1R9D 2R6D or 5R4D*

3R8A 5R5A

−

*1

, 7R6A

*1

− −

SGM7G-09A 850 W 7R6A 7R6A 3R5D 5R4D*

SGM7G-13A 1.3 kW 120A

SGM7G-20A 1.8 kW 180A 8R4D

SGM7G-30A 2.9 kW

SGM7G-44A 4.4 kW 170D

SGM7G-55A 5.5 kW 470A 210D

*2

330A

−

5R4D 5R4D

120D

−

SGM7G-75A 7.5 kW 550A 260D

SGM7G-1AA 11 kW 590A 280D

SGM7G-1EA 15 kW 780A 370D

*1. If you use this combination, performance may not be as good, e.g., the control gain may not increase, in comparison with using a SERVOPACK.

*2. The rated output is 2.4 kW if you combine the SGM7G-30A with the SGD7S-200A.

11

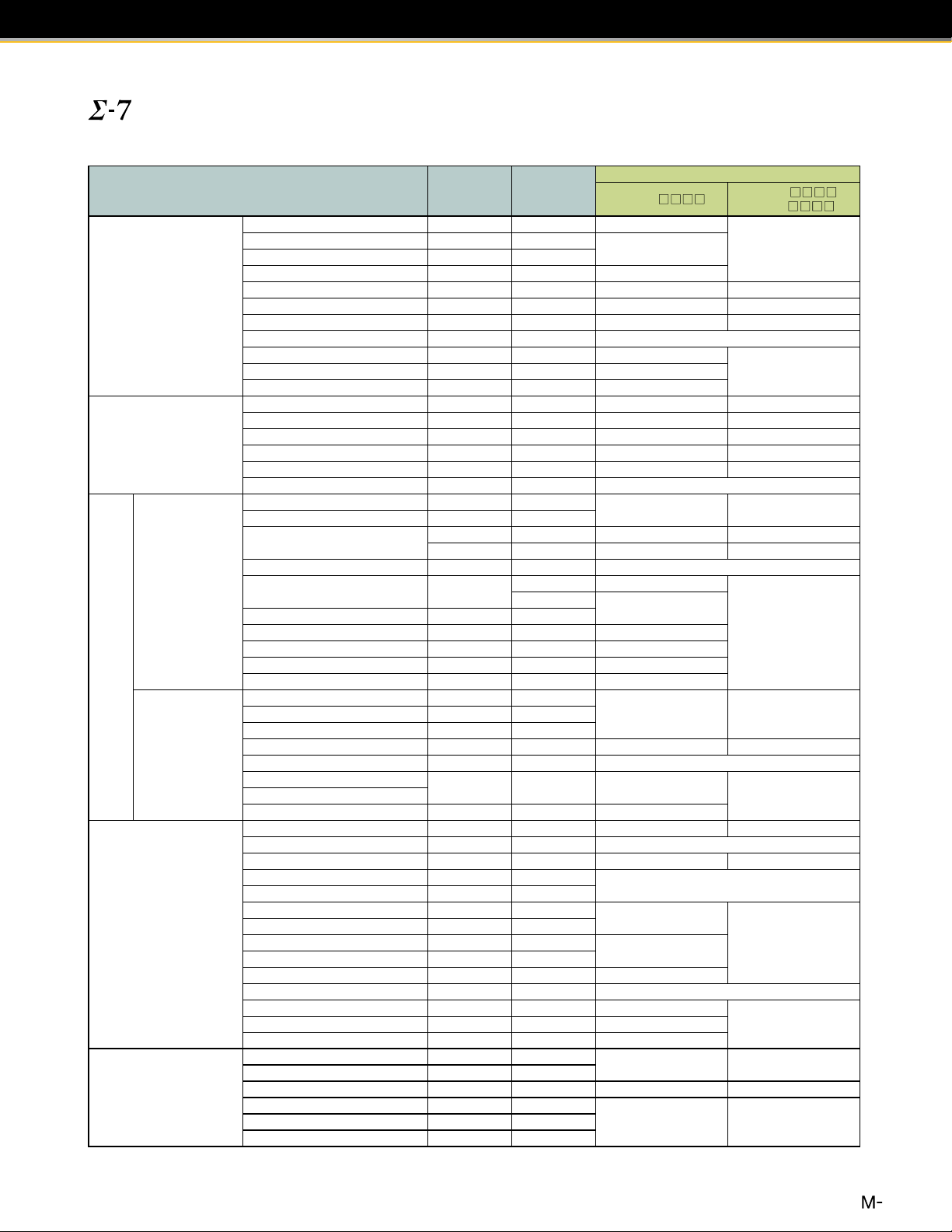

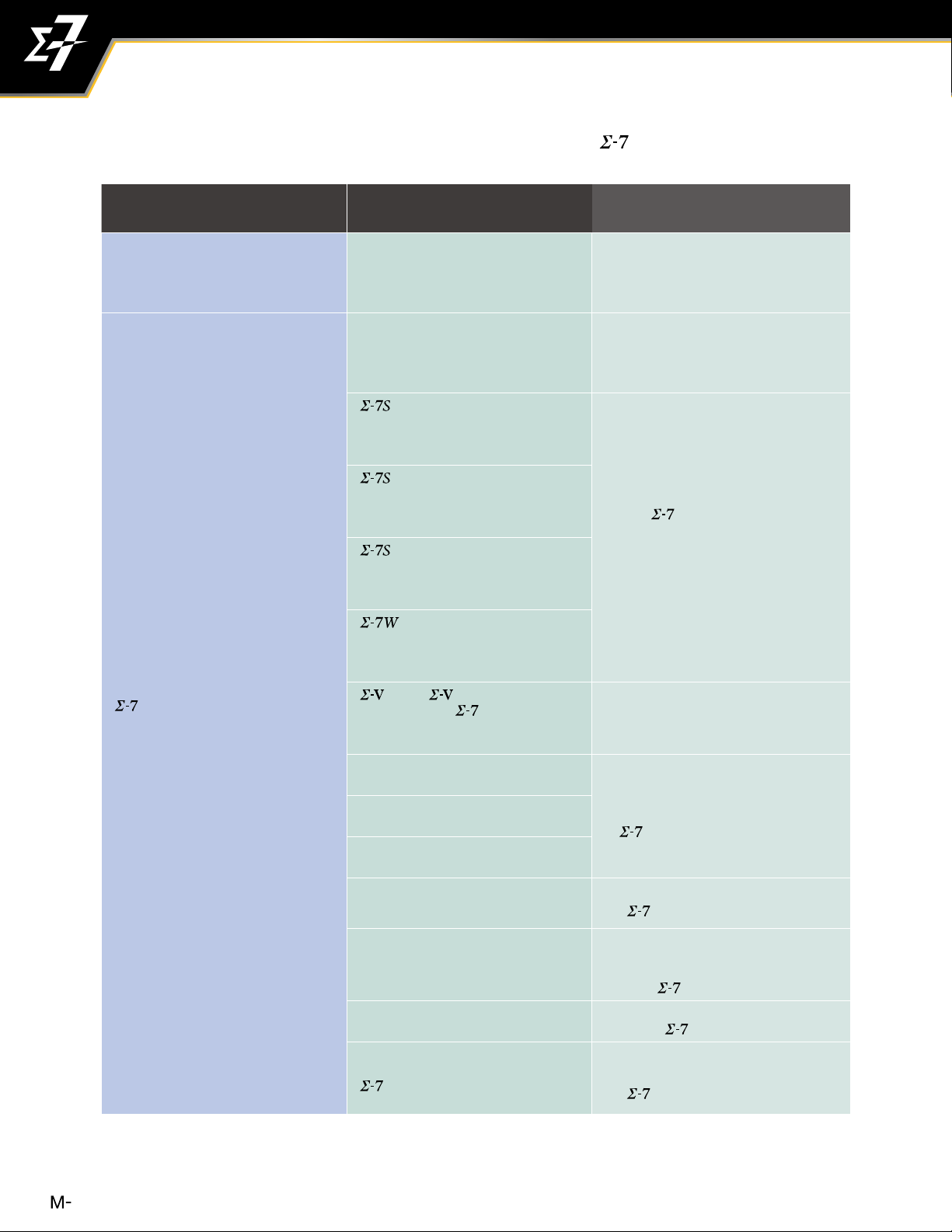

Series Combination

1Combination of Direct Drive Servomotors and SERVOPACKs

Direct Drive Servomotor Model

SGM7D

(With core, outer rotor)

SGM7F

(With core, inner rotor)

Small capacity, coreless

(SGMCS)

Medium capacity, with core

(SGMCS)

Rated Torque

Nm

SGM7D-30F 30.0 50.0

SGM7D-58F 58.0 100

SGM7D-90F 90.0 150

SGM7D-1AF 110 200

SGM7D-01G 1.30 4.00

SGM7D-05G 5.00 6.00

SGM7D-08G 8.00 15.0

SGM7D-18G 18.0 30.0

SGM7D-24G 24.0 45.0

SGM7D-34G 34.0 60.0

SGM7D-45G 45.0 75.0

SGM7D-03H 3.00 4.00 2R8A, 2R8F

SGM7D-28I 28.0 50.0

SGM7D-70I 70.0 100

SGM7D-1ZI 100 150

SGM7D-1CI 130 200

SGM7D-2BI 220 300

SGM7D-2DI 240 400

SGM7D-06J 6.00 8.00

SGM7D-09J 9.00 15.0

SGM7D-18J 18.0 30.0

SGM7D-20J 20.0 45.0

SGM7D-38J 38.0 60.0

SGM7D-02K 2.06 5.00

SGM7D-06K 6.00 10.0

SGM7D-08K 8.00 15.0

SGM7D-06L 6.00 10.0

SGM7D-12L 12.0 20.0

SGM7D-30L 30.0 40.0 120A

SGM7F-02A 2 6

SGM7F-05A 5 15

SGM7F-07A 7 21

SGM7F-10B 10 30

SGM7F-14B 14 42 5R5A

SGM7F-08C 8 24 2R8A, 2R8F 2R8A

SGM7F-17C 17 51 5R5A

SGM7F-25C 25 75 7R6A

SGM7F-16D 16 48 5R5A

SGM7F-35D 35 105 7R6A, 120A 7R6A

SGMCS-02B 2 6

SGMCS-05B 5 15

SGMCS-07B 7 21

SGMCS-04C 4 12

SGMCS-10C 10 30

SGMCS-14C 14 42

SGMCS-08D 8 24

SGMCS-17D 17 51

SGMCS-25D 25 75

SGMCS-16E 16 48

SGMCS-35E 35 105

SGMCS-45M 45 135 7R6A

SGMCS-80M 80 240

SGMCS-80N 80 240

SGMCS-1AM 110 330 180A

SGMCS-1EN 150 450

SGMCS-2ZN 200 600

Instantaneous

Max. Torque

Nm

SGD7S-

SERVOPACK Model

SGD7W-

120A

2R8A, 2R8F

120A

120A

2R8A, 2R8F

2R8A, 2R1F

2R8A

2R8A, 2R8FSGM7F-04B 4 12

2R8A

5R5A

120A

200A

−

−

12

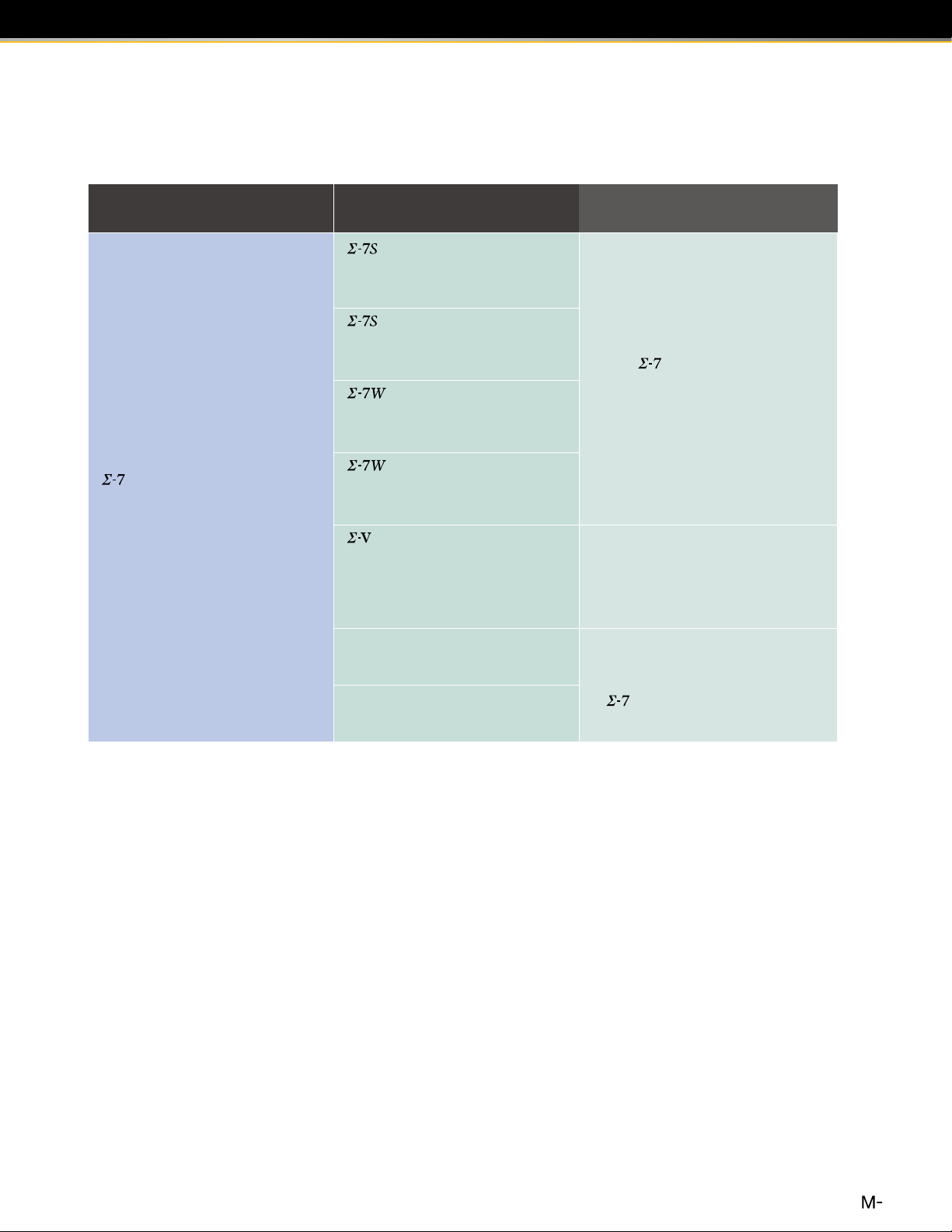

Series Combination

1Combination of Linear Servomotors and SERVOPACKs

Linear Servomotor Model

SGLGW-30A050C 12.5 40 R70A, R70F

SGLGW-30A080C 25 80

SGLGW-40A140C 47 140

SGLGW-40A253C 93 280 1R6A, 2R1F

SGLG

(Coreless model, with

standard magnetic way)

SGLG

(Coreless model, with high-

force magnetic way)

SGLFW2*

SGLF

(Model with F-type iron core)

SGLFW*

SGLT

(Model with T-type iron core)

ST2F

(Sigma Trac II

Linear Stages)

*: The SGLFW model is an earlier product. Select the SGLFW2 model when newly installing a linear servomotor to a machine.

SGLGW-40A365C 140 420 2R8A, 2R8F 2R8A

SGLGW-60A140C 70 220 1R6A, 2R1F 1R6A

SGLGW-60A253C 140 440 2R8A, 2R8F 2R8A

SGLGW-60A365C 210 660 5R5A

SGLGW-90A200C 325 1300 120A

SGLGW-90A535C 750 3000 200A

SGLGW-40A140C 57 230 1R6A, 2R1F 1R6A

SGLGW-40A253C 114 460 2R8A, 2R8F 2R8A

SGLGW-40A365C 171 690 3R8A 5R5A

SGLGW-60A140C 85 360 1R6A, 2R1F 1R6A

SGLGW-60A253C 170 720 3R8A 5R5A

SGLGW-60A365C 255 1080 7R6A

SGLFW2-30A070A 45 135

SGLFW2-30A120A 90 270

SGLFW2-30A230A

SGLFW2-45A200A 280 840 5R5A

SGLFW2-45A380A 560

SGLFW2-90A200A 560 1680

SGLFW2-90A380A 1120 3360 200A

SGLFW2-90A560A 1680 5040 330A

SGLFW2-1DA380A 1680 5040 200A

SGLFW2-1DA560A 2520 7560 330A

SGLFW-20A090A 25 86

SGLFW-35A120A 80 220

SGLFW-35A230A 160 440 3R8A 5R5A

SGLFW-50A200B 280 600 5R5A

SGLFW-50A380B

SGLFW-1ZA380B 1120 2400 200A

SGLTW-20A170A 130 380 3R8A 5R5A

SGLTW-20A320A 250 760 7R6A

SGLTW-20A460A 380 1140 120A −

SGLTW-35A170A 220 660

SGLTW-35A170H 300 600

SGLTW-35A320A 440 1320

SGLTW-35A320H 600 1200

SGLTW-35A460A 670 2000

SGLTW-40A400B 670 2600

SGLTW-40A600B 1000 4000 330A

SGLTW-50A170H 450 900 5R5A

SGLTW-50A320H 900 1800 120A

SGLTW-80A600B 2000 7500 550A

SGT2F-A1A 45 135

SGT2F-A2A 90 270

SGT2F-A3A 180 540 3R8A, 2R8A, 2R8F 2R8A, 2R8F

SGT2F-A1D 45 135

SGT2F-A3D 180 540

Rated ForceNMax. Force

N

180 540 3R8A −

170 500 2R8A, 2R8F 2R8A

1680 180A

1500

560 1200 120A

SERVOPACK Model

SGD7S-

R90A, R90F

1R6A, 2R1F 1R6A

120A

1R6A, 2R1F 1R6ASGLFW-20A120A 40 125

120A

180A

1R6A, 2R1F 1R6A

1R9D 2R6DSGT2F-A2D 90 270

SGD7WSGD7C-

5R5A

1R6A

−SGLGW-90A370C 550 2200 180A

−

−SGLFW-1ZA200B

−

−SGLTW-80A400B 1300 5000 330A

13

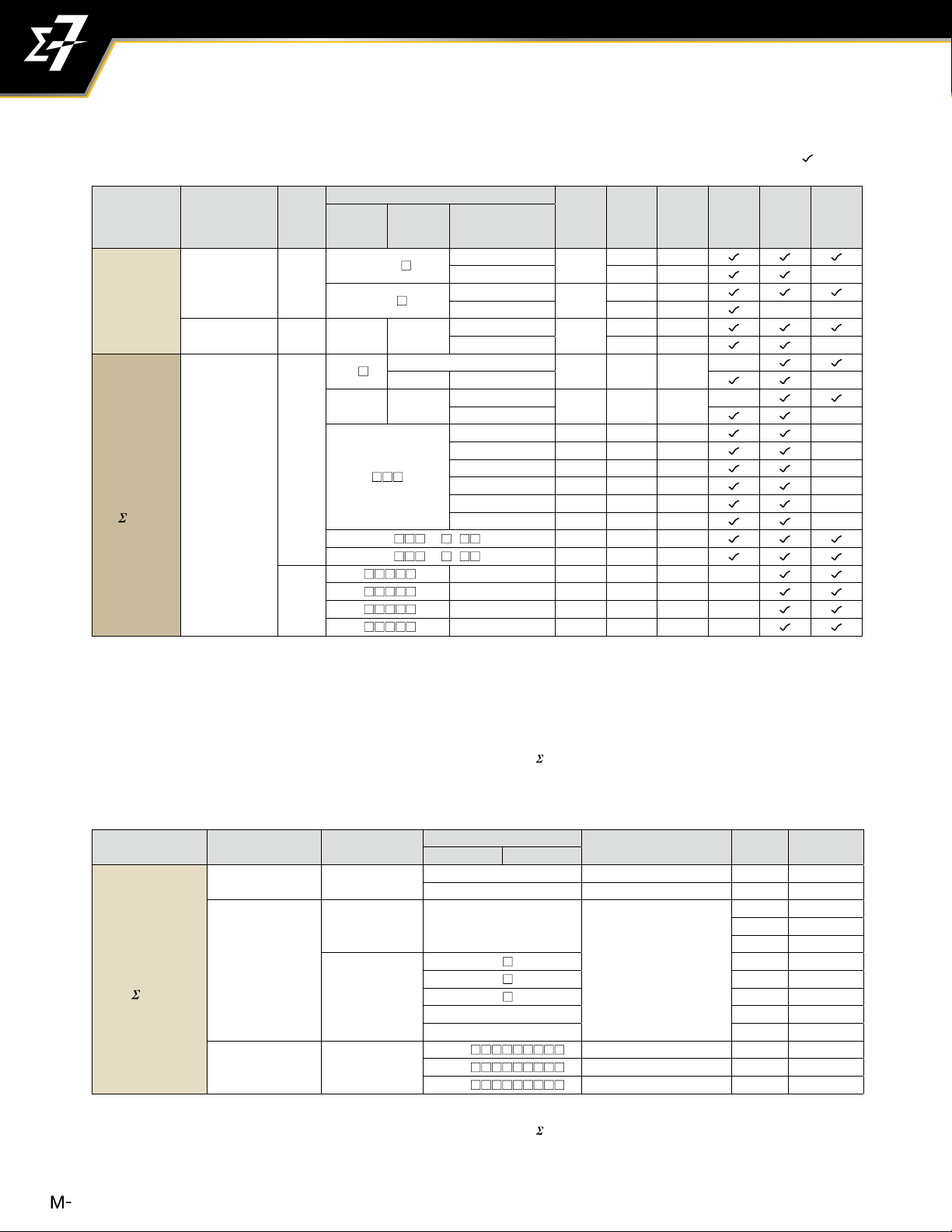

Recommended Encoders

1Incremental Linear Encoders

Output Signal Manufacturer

Heidenhain

1 Vp-p Analog

Voltage

*1

Corporation

Renishaw plc*4Exposed

Encoder

Type

Exposed

Scale

LIDA48

LIF48

RGS20 RGH22B

SL7 0

SQ10 PQ10

Linear

Encoder for

Yaskawa’s Serial

Interface

*2

Magnescale

Co., Ltd.

Exposed

BL57-

( -LINK)

BF1-

BF1- RY F

SR75-

Sealed

SR75- MF − 80 78.1 3.33 −

SR85- LF − 80 9.8 3.33 −

SR85- MF − 80 78.1 3.33 −

*1: You must also use a Yaskawa Serial Converter Unit. The output signal will be

multiplied by 8 bits (256 divisions) or 12 bits (4,096 divisions) in the Serial Converter

Unit.

*2: The multiplier (number of divisions) depends on the Linear Encoder. Also, you must

write the motor constant file to the Linear Encoder in advance.

*3: The maximum speeds given in the above table are the maximum applicable speeds

of the encoders when combined with a Yaskawa SERVOPACK. The actual speed

will be restricted by either the maximum speed of the Linear Servomotor or the

maximum speed of the Linear Encoder (given above).

Model

Sensor

Head

PL101 MJ620-T13

*8

RED

RY F

LF − 80 9.8 3.33 −

Linear

Interpolator (Serial

Encoder

Converter Unit)

JZDP-H003/-H006

JZDP-J003/- J006

JZDP-H003/-H006

JZDP-J003/- J006

JZDP-H005/-H008

JZDP-J005/- J008

PL101-RY

*5

*5

*5

*5

*5

*5

*6

*7 *8

MQ10-FLA

MQ10-GLA −

ResolutionnmMaximum

Pitch

μ

m

78.1 5

20

4

20

4.9 2

15.6 1

1.0 0.4

78.1 5

4.9 2

800 97.7 10

400 48.83 3

Speed

m/s

Support for

*3

Polarity

Sensor

Input

−

−

Application

to Linear

Motors

*8 *8

BD96-Y1051LC 0.4 0.78 0.8 −

BD96-Y1025LC 0.4 1.56 1.0

BD96-Y2051LC 0.4 0.78 0.8

BD96-Y2025LC 0.4 1.56 1.0

BD96-YJ051LC 0.4 0.78 0.8

BD96-YJ025LC 0.4 1.56 1.0

*8

*8

*4: If you use the origin signals with a Linear Encoder from Renishaw plc, the origin may

sometimes be falsely detected. If that occurs, use the BID/DIR signal to output the

origin signal only in one direction.

*5: Use this model number to purchase the Serial Converter Unit.

*6: Use this model number to purchase the Sensor Head with Interpolator.

*7: Use this model number to purchase the Interpolator.

*8: Contact your Yaskawa representative.

Note: 1. Confirm detailed specifications, such as the tolerances, dimensions, and

2.

0.25 0.49 1.77

0.25 0.98 1.8

operating environment, with the manufacturer of the Encoder before you use it.

-LINK is a registered trademark of YASKAWA ELECTRIC CORPORATION.

: Possible

Application to

Fully-Closed

Loop Control

*8

*8

−

−

−

−

−

1Absolute Rotary Encoder

The following Absolute Rotary Encoders are for fully-closed control. Can not use it to control the motor.

Output Signal Manufacturer

Magnescale

Co., Ltd.

Rotary Encoder

Type

Sealed

Exposed ECA4412

Encoder for Yaskawa’s

Serial Interface

-LINK)

(

Heidenhain

Corporation

Sealed

RA23Y-

Renishaw plc Exposed

RA26Y-

RA30Y-

*1: The maximum speeds given in the above table are the maximum applicable speeds

of the encoders when combined with a Yaskawa SERVOPACK. The actual speed

will be restricted by either the maximum speed of the Linear Servomotor or the

maximum speed of the Linear Encoder (given above).

*2: This is a single-turn absolute encoder.

Model

Scale Sensor Head

RU77-4096ADF

RU77-4096AFFT01

RCN2

RCN5

RCN8

ROC2310

ROC7310

*2

*2

*2

*2

10

*2

10

*2

10

*2

*2

Note: 1. Confirm detailed specifications, such as the tolerances, dimensions, and

operating environment, with the manufacturer of the Encoder before you use it.

2.

-LINK is a registered trademark of YASKAWA ELECTRIC CORPORATION.

Relay Device between Fully-Closed

*2

*2

*2

14

Module and Rotary Encoder

− 20 2000

− 22 2000

EIB3391Y

− 23 14600

− 26 3250

− 30 200

Resolution

Bits

27 1600

28 800

29 400

26 3000

28 800

29 400

26 3000

28 800

Maximum Speed*1

RPM

1Absolute Linear Encoder

: Possible

Model

Sensor

Head

S F

T F

A F

F F

S F

T F

A F

F F

LF − 80 9.8 3.33 −

Output Signal Manufacturer

Magnescale

Co., Ltd.

Linear

Encoder

Type

Exposed

Sealed

Scale

SQ47

-

SQ47

-

SQ47

-

SQ47

-

SQ57

-

SQ57

-

SQ57

-

SQ57

-

SR77-

SR77- MF − 80 78.1 3.33 −

SR87- LF − 80 9.8 3.33 −

SR87- MF − 80 78.1 3.33 −

ST781A − 256 500 5 −

Encoder for

Yaskawa’s Serial

Interface

*1

( -LINK)

Mitutoyo

Corporation

Exposed

ST782A − 256 500 5 −

ST783A − 51.2 100 5 −

ST784A − 51.2 100 5 −

ST788A − 51.2 100 5 −

ST789A

*4

ST1381 − 5.12 10 8 −

ST1382 − 0.512 1 3.6

LIC4100 Series

Heidenhain

Corporation

Exposed

Sealed

LIC2100 Series

LC115 40.96 10 3 −

LC415 40.96 10 3 −

EL36Y-050F

EL36Y

- 1

00F

Renishaw plc

Exposed

EL36Y

- 5

RL36Y-05

00F

0 − 12.8 50 100 −

RL36Y-001

*1: The multiplier (number of divisions) depends on the Linear Encoder. Also, you must

write the motor constant file to the Linear Encoder in advance.

*2: These are reference values for setting SERVOPACK parameters. Contact the

manufacturer for actual linear encoder scale pitches.

*3: The maximum speeds given in the above table are the maximum applicable speeds

of the encoders when combined with a Yaskawa SERVOPACK. The actual speed

will be restricted by either the maximum speed of the Linear Servomotor or the

maximum speed of the Linear Encoder (given above).

*4: Contact Mitutoyo Corporation for details on the Linear Encoders.

Interpolator (Serial

Converter Unit)

Linear

Encoder

*2

Pitch

μ

m

Resolution

nm

Maximum

Speed

m/s

Support for

*3

Polarity

Sensor

Input

− 20.48 5 3.33 −

− 40.96 10 3.33 −

− 20.48 5 3.33 −

− 40.96 10 3.33 −

− 25.6 50 5 −

*6

−

20.48 5 10 −

204.8 50 10 −

*5

EIB3391Y

409.6 100 10 −

− 12.8 50 100 −

− 25.6 100 100 −

− 128 500 100 −

− 0.256 1 3.6 −

*5: Use this model number to purchase the Interpolator.

*6: The speed is restricted for some SERVOPACKs.

Note: 1. Confirm detailed specifications, such as the tolerances, dimensions, and

operating environment, with the manufacturer of the Encoder before you use it.

2.

-LINK is a registered trademark of YASKAWA ELECTRIC CORPORATION.

Application

to Linear

Motors

Application to

Fully-Closed

Loop Control

15

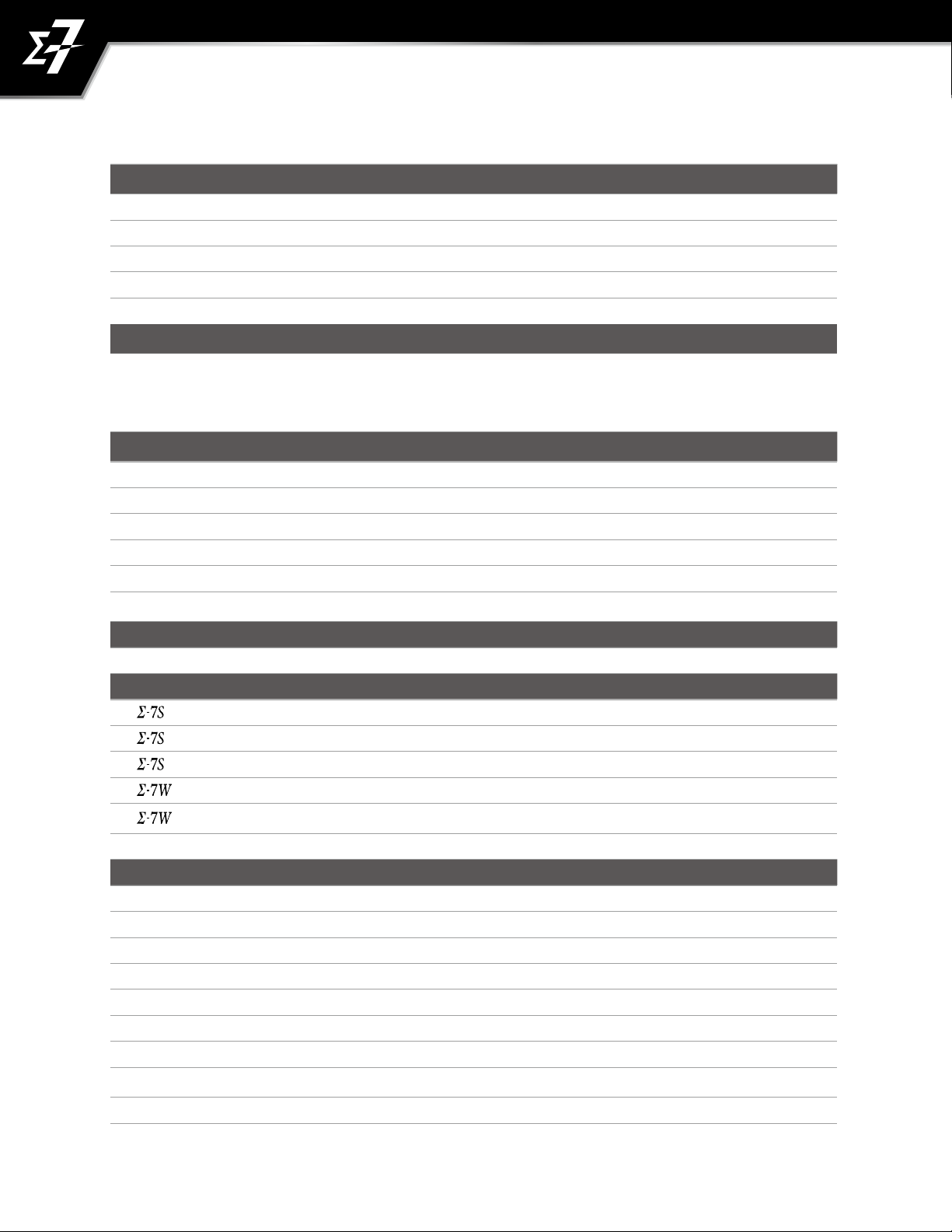

Related Documents

The documents that are related to the MP3300 Machine Controllers and series AC Servo Drives are

shown in the following table. Refer to these documents as required.

Brochure/Catalog Name

(Document No.)

Yaskawa Motion Product Brochure:

Condent, Consistent, Capable

(BL.MTN.01)

Series AC Servo Drives and Motors

Technical Supplement

(YAI-KAEPS80000123)

Manual Name

(Manual No.)

−

MP3300iec Machine Controller

Hardware Manual

(YAI-SIA-IEC-7)

SERVOPACK with

MECHATROLINK-3 Communications References

Product Manual

(SIEPS80000128)

SERVOPACK with Analog

Voltage/Pulse Train References

Product Manual

(SIEPS80000126)

SERVOPACK with EtherCAT (CoE)

Communication References

Product Manual

(SIEPS80000155)

SERVOPACK with

MECHATROLINK-3 Communications References

Product Manual

(SIEPS80000129)

-Series/ -Series for LargeCapacity Models/ -Series User’s

Manual Safety Module

(SIEPC72082906)

Rotary Servomotor Product Manual

(SIEPS80000136)

Linear Servomotor Product Manual

(SIEPS80000137)

Direct Drive Servomotor Product Manual

(SIEPS80000138)

Description of Document

This brochure presents an introduction to

Yaskawa America Motion Products and

services, with an emphasis on AC Servo,

Machine Controller, and IO products.

Provides detailed information on selection

and installation MP3300iec machine

controller components/accessories.

Provides detailed information on

selecting

and information on installing,

connecting, setting, performing

trial operation for, tuning, and monitoring the

Servo Drives.

Provides details information required for the

design and maintenance of a Safety Module.

Provide detailed information on

selecting, installing, and connecting

the

-Series SERVOPACKs

-Series Servomotors.

16

Peripheral Device Selection Manual

(SIEPS80000132)

MECHATROLINK-3 Communications

Standard Servo Prole Command Manual

(SIEPS80000131)

Digital Operator Operating Manual

(SIEPS80000133)

Engineering Tool

SigmaWin+ Online Manual

Component

(SIEPS80000148)

Describes the peripheral devices

for a

Provides detailed information on the

MECHATROLINK-3 communications

standard servo prole commands that are

used for a - Series Servo System.

Describes the operating procedures for a Digital

Operator for a -Series Servo System.

Provides detailed operating procedures

for the SigmaWin+ Engineering Tool

for a -Series Servo System.

-Series Servo System.

Brochure/Catalog Name

(Document No.)

Series AC Servo Drives and Motors

Technical Supplement

(YAI-KAEPS80000123)

Manual Name

(Manual No.)

SERVOPACK with 400V-Input

Power and EtherCAT (CoE) Communications References Product Manual

(SIEPS80000180)

SERVOPACK with 400V-Input

Power and MECHATROLINK III

Communications References Product

Manual (SIEPS80000214)

SERVOPACK with 400V-Input

Power and EtherCAT (CoE)

Communications References Product

Manual (SIEPS80000219)

SERVOPACK with

400V-Input Power and MECHATROLINK

III Communications References Product

Manual(SIEPS80000220)

-Series User Manual Safety Module

(SIEPC 72082906E)

Supplement for using with Sigma-7

SERVOPACKs (400 V-Input power

models) (900-200-100)

Rotary Servomotor with 400 V-Input

Power Product Manual

(SIEPS80000186)

Linear Servomotor with 400 V-Input

Power Product Manual

(SIEPS8000181)

Description of Document

Provides detailed information on

selecting

and information on installing, connecting,

setting, performing trial operation for, tuning,

and monitoring the Servo Drives.

Provides details information required for the

design and maintenance of a Safety Module.

Provide detailed information on

selecting, installing, and connecting

the

-Series SERVOPACKs

-Series Servomotors.

17

18

CONTENTS

Rotary Servo Motors

SGMMV 4

SGM7J 18

SGM7A 54

SGM7P 116

SGM7G 134

Direct Drive Servo Motors

SGM7F (With Core, Inner Rotor) 190

SGM7D (With Core, Outer Rotor) 206

SGMCS (Small Capacity, Coreless or Medium Capacity, with Core) 234

Linear Servo Motors

SGLFW2 (Models with F-type Iron Cores, 200V) 260

SGLFW2 (Models with F-type Iron Cores, 400V) 288

SGLG (Coreless Models) 308

SGLT (Models with T-type Iron Cores) 338

Recommended Linear Encoders and Cables 368

SGLFW (Earlier Models with F-type Iron Cores) 392

Linear Stages

ST2F Sigma Trac II Linear Stages 418

SERVOPACKs

Single-axis Analog Voltage/Pulse Train Reference SERVOPACKs

Single-axis MECHATROLINK-III Communications Reference SERVOPACKs

Single-axis EtherCAT Communications Reference SERVOPACKs

Two-axis MECHATROLINK-III Communications Reference SERVOPACKs

Two-axis EtherCAT Communications Reference SERVOPACKs

SERVOPACK External Dimensions 484

Option Modules

Feedback Option Module 500

Safety Option Module 506

Sigma-7Siec Option 510

MP2600iec Option 512

SigmaLogic7 Compact Option 520

FT19 Option - Less Deviation Control 522

FY79 Option - Built-in Indexer 524

424

434

448

464

478

FT81 Option - Support for Harmonic Drive SHA Series Actuators 526

FT82/83 Option - Support for SGM7D Direct Drive Motor 528

1

Cables and Peripheral Devices

Cables for SERVOPACKs 530

Peripheral Devices 540

Appendices

Capacity Selection for Servo Motors 572

Capacity Selection for Regenerative Resistors 582

International Standards 598

Warranty 600

2

Rotary Servo Motors

SGMMV .................................................................. 4

SGM7J .................................................................. 18

SGM7A ................................................................. 54

SGM7P ................................................................116

SGM7G ................................................................134

Rotary Servo Motors

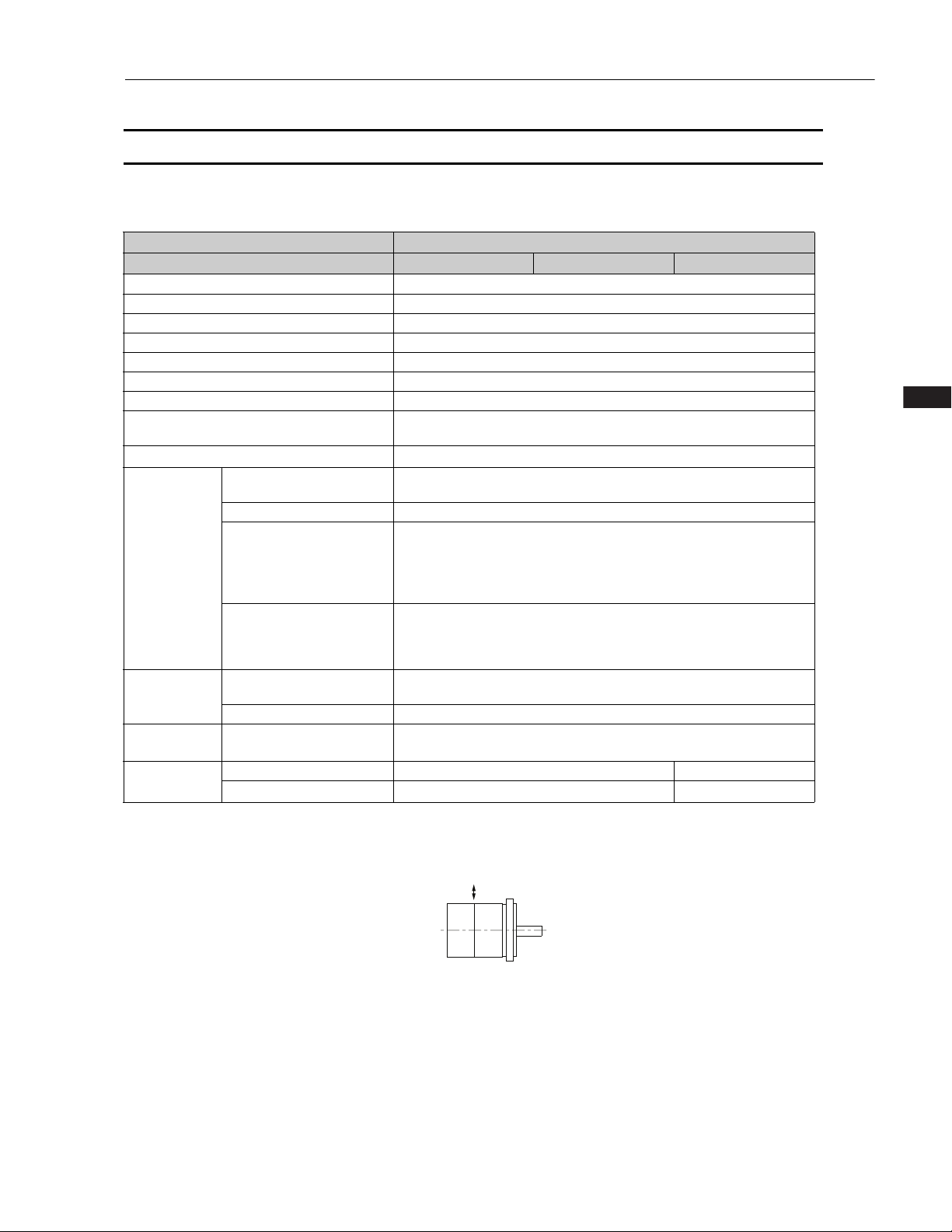

SGMMV

Model Designations

-

SGMMV

-V mini Series

Servo Motors:

SGMMV

A1

1st+2nd

digits

A 2 A

3rd

digit

4th

digit

5th

digit

21

6th

digit

7th

digit

1st+2nd digits

Code Specification

A1 10 W

A2 20 W

A3 30 W

Rated Output

3rd digit

Code Specification

4th digit

Code

5th digit

Power Supply Voltage

A 200 VAC

Serial Encoder

17-bit absolute

2

Design Revision Order

A

Specification

6th digit Shaft End

Code Specification

Straight

2

Straight with flat seats

A

7th digit Options

Code

1

C

Non Stock Items

Specification

Without options

With holding brake (24 VDC)

4

Rotary Servo Motors

Rotary Servo Motors

Vertical

Shock Applied to the Servo Motor

SGMMV

Specifications and Ratings

Specifications

Voltage 200 V

Model SGMMV- A1A A2A A3A

Time Rating Continuous

Thermal Class B

Insulation Resistance 500 VDC, 10 M min.

Withstand Voltage 1,500 VAC for 1 minute

Excitation Permanent magnet

Mounting Flange-mounted

Drive Method Direct drive

Rotation Direction

Vibration Class

*1

Surrounding Air Temperature

Surrounding Air Humidity 20% to 80% relative humidity (with no condensation)

Environmental

Installation Site

Conditions

Storage Environment

Shock

Resistance

Vibration

Resistance

Applicable

SERVOPACKs

Impact Acceleration Rate at

Flange

*2

Number of Impacts 2 times

Vibration Acceleration Rate

*3

at Flange

SGD7S- R90A, R90F 1R6A, 2R1F

SGD7W-

*1. A vibration class of V15 indicates a vibration amplitude of 15 m maximum on the Servo Motor without a load at the

rated motor speed.

*2. The shock resistance for shock in the vertical direction when the Servo Motor is mounted with the shaft in a horizontal

position is given in the above table.

Counterclockwise (CCW) for forward reference when viewed from the

load side

V15

0°C to 40°C

• Must be indoors and free of corrosive and explosive gases.

• Must be well-ventilated and free of dust and moisture.

• Must facilitate inspection and cleaning.

• Must have an altitude of 1,000 m or less.

• Must be free of strong magnetic fields.

Store the Servo Motor in the following environment if you store it with

the power cable disconnected.

Storage Temperature: -20°C to 60°C (with no freezing)

Storage Humidity: 20% to 80% relative humidity (with no condensation)

2

490 m/s

2

49 m/s

1R6A

*4

, 2R8A

*4

1R6A, 2R8A

*4

5

Rotary Servo Motors

Vertical

Horizontal direction

Vibration Applied to the Servo Motor

Front to back

Side to side

SGMMV

*3. The vertical, side-to-side, and front-to-back vibration resistance for vibration in three directions when the Servo Motor

is mounted with the shaft in a horizontal position is given in the above table. The strength of the vibration that the

Servo Motor can withstand depends on the application. Always check the vibration acceleration rate that is applied to

the Servo Motor with the actual equipment.

*4. If you use a S-7W SERVOPACK, the control gain may not increase as much as with a S-7S SERVOPACK and other

performances may be lower than those achieved with a S-7S SERVOPACK.

6

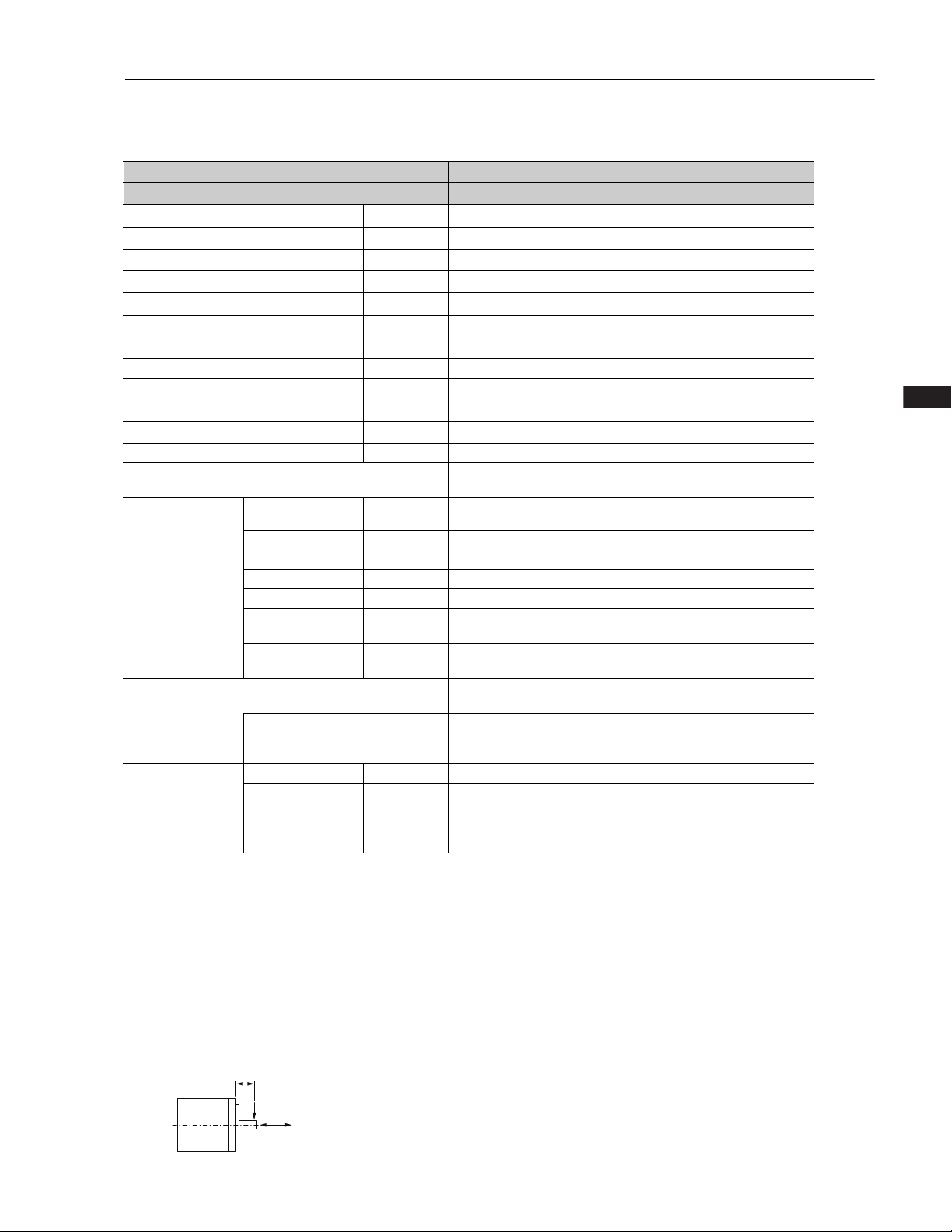

Rotary Servo Motors

Servo Motor Ratings

+10%

0

LF

Radial load

Thrust load

Vol tage 200 V

Model SGMMV

Rated Output

Rated Torque

Instantaneous Maximum Torque

Rated Current

Instantaneous Maximum Current

Rated Motor Speed

Maximum Motor Speed

*1

*1, *2

*1

*1

*1

-

W102030

N•m 0.0318 0.0637 0.0955

*1

*1

N•m 0.0955 0.191 0.286

Arms 0.70 0.66 0.98

Arms 2.0 1.9 2.9

-1

min

-1

min

Torque Constant N•m/Arms 0.0516 0.107

-7

Motor Moment of Inertia

Rated Power Rate

*1

Rated Angular Acceleration Rate

10

kW/s 3.72 8.71 13.7

*1

rad/s

kg•m

2

2

Heat Sink Size (Aluminum) mm 150 x 50 x 3 250 x 250 x 6

Protective Structure

*3

Rated Voltage V

Capacity W 2.0 2.6

Holding Torque N•m 0.0318 0.0637 0.0955

Holding Brake

Specifications

Coil Resistance (at 20°C) 320 221.5

*4

Rated Current A (at 20°C) 0.075 0.108

Time Required to

Release Brake

Time Required to

Brake

ms 40

ms 100

Allowable Load Moment of Inertia

(Motor Moment of Inertia Ratio)

With External Regenerative

Resistor and Dynamic Brake

Resistor

LF mm 16

Allowable Shaft

*5

Loads

Allowable Radial

Load

Allowable Thrust

Load

N34 44

N 14.5

A1A A2A A3A

3000

6000

2.72 (4.07) 4.66 (6.02) 6.68 (8.04)

117000 137000 143000

Totally enclosed, self-cooled, IP55

(except for shaft opening)

24 VDC

30 times

30 times

Rotary Servo Motors

SGMMV

*1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding is

20°C. These are typical values.

*2. The rated torques are the continuous allowable torque values with an aluminum or steel heat sink of the dimensions

given in the table.

*3. This does not apply to the shaft opening. Protective structure specifications apply only when the special cable is used.

*4. Observe the following precautions if you use a Servo Motor with a Holding Brake.

• The holding brake cannot be used to stop the Servo Motor.

• The time required to release the brake and the time required to brake depend on which discharge circuit is used.

Confirm that the operation delay time is appropriate for the actual equipment.

• The 24-VDC power supply is not provided by Yaskawa.

*5. The allowable shaft loads are illustrated in the following figure. Design the mechanical system so that the thrust and

radial loads applied to the Servo Motor shaft end during operation do not exceed the values given in the table.

Note: The values in parentheses are for Servo Motors with Holding Brakes.

7

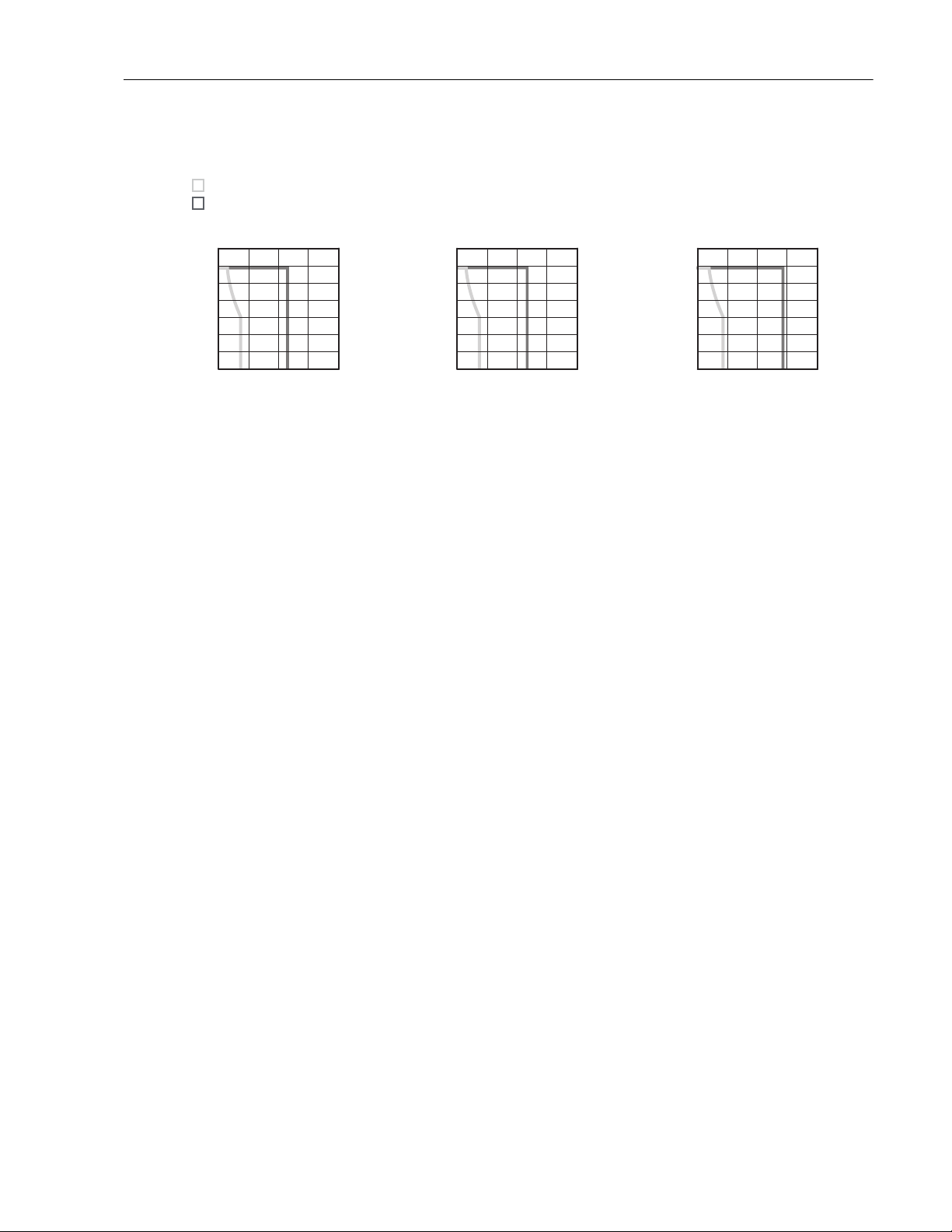

Rotary Servo Motors

SGMMV-A3A

A

B

4000

3000

2000

1000

0

5000

6000

7000

0 0.1 0.2 0.3 0.4

SGMMV-A1A

A

B

4000

3000

2000

1000

0

5000

6000

7000

0 0.04 0.08 0.12 0.16

SGMMV-A2A

A

B

4000

3000

2000

1000

0

5000

6000

7000

0 0.08 0.16 0.24 0.32

Continuous duty zone

Intermittent duty zone*

A

:

B

:

Motor speed (min

-1

)

Torque (N·m)

Motor speed (min

-1

)

Torque (N·m)

Motor speed (min

-1

)

Torque (N·m)

SGMMV

Torque-Motor Speed Characteristics

* The characteristics are the same for three-phase 200 V, single-phase 200 V, and single-phase 100 V input.

Note: 1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding

is 20°C. These are typical values.

2. The characteristics in the intermittent duty zone depend on the power supply voltage.

3. If the effective torque is within the allowable range for the rated torque, the Servo Motor can be used within the

intermittent duty zone.

4. If you use a Servo Motor Main Circuit Cable that exceeds 20 m, the intermittent duty zone in the torque-motor

speed characteristics will become smaller because the voltage drop increases.

8

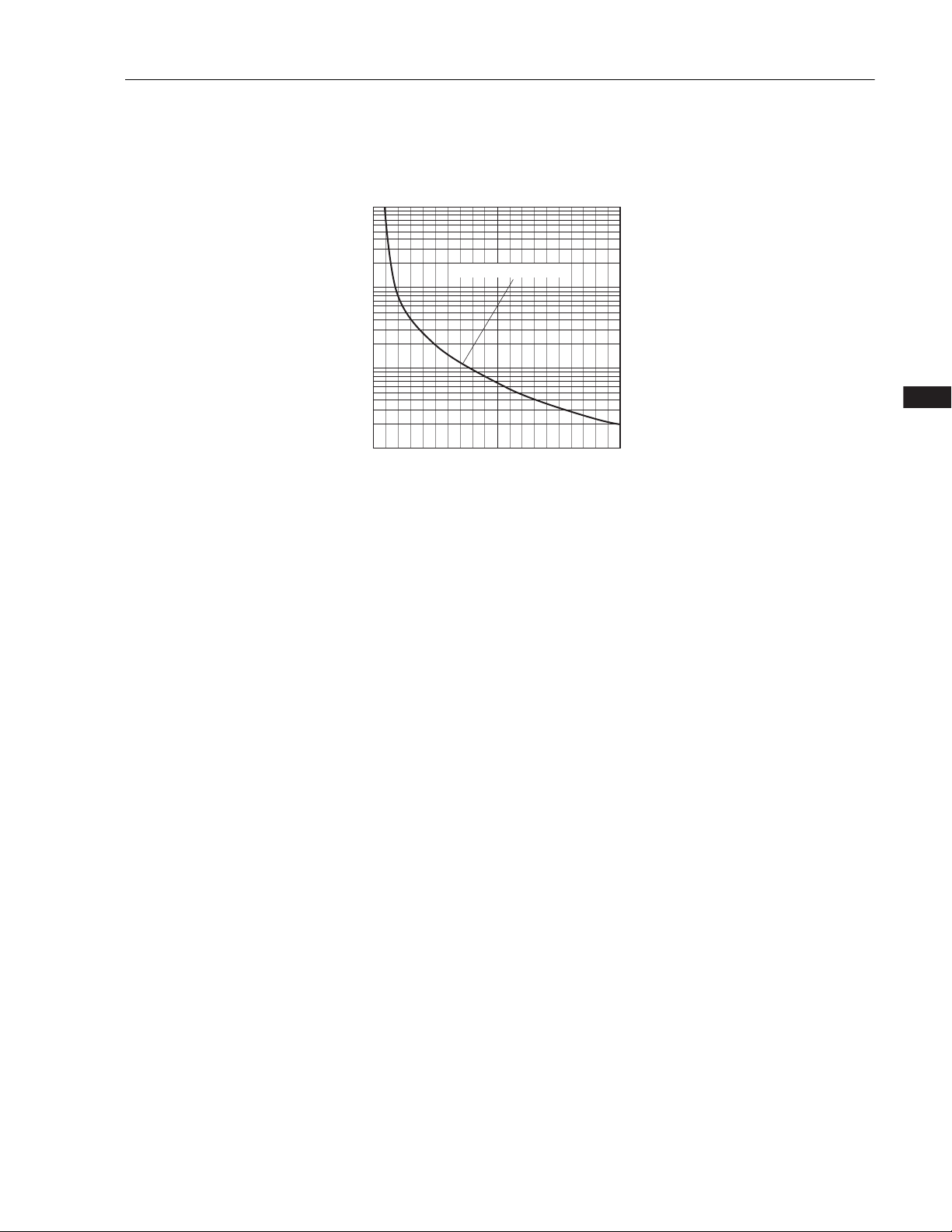

Rotary Servo Motors

Rotary Servo Motors

1000

100

10

1

100 200 300

SGMMV-A1 ,-A2 ,-A3

Detection time (s)

Torque reference (percent of rated torque)

(%)

SGMMV

Servo Motor Overload Protection Characteristics

The overload detection level is set for hot start conditions with a Servo Motor surrounding air temperature

of 40

°C.

Note: The above overload protection characteristics do not mean that you can perform continuous duty operation with an

output of 100% or higher. Use the Servo Motor so that the effective torque remains within the continuous duty zone

given in Torque-Motor Speed Characteristics (page 8).

Load Moment of Inertia

The load moment of inertia indicates the inertia of the load. The larger the load moment of inertia, the

worse the response. If the moment of inertia is too large, operation will become unstable.

The allowable size of the load moment of inertia (J

Motor Ratings (page 7). This value is provided strictly as a guideline and results depend on Servo Motor

driving conditions.

An Overvoltage Alarm (A.400) is likely to occur during deceleration if the load moment of inertia exceeds

the allowable load moment of inertia. SERVOPACKs with a built-in regenerative resistor may generate a

Regenerative Overload Alarm (A.320). Perform one of the following steps if this occurs.

• Reduce the torque limit.

• Reduce the deceleration rate.

• Reduce the maximum motor speed.

• Install an External Regenerative Resistor if the alarm cannot be cleared using the above steps.

Regenerative resistors are not built into SERVOPACKs for 400-W Servo Motors or smaller Servo Motors.

Even for SERVOPACKs with built-in regenerative resistors, an External Regenerative Resistor is

required if the energy that results from the regenerative driving conditions exceeds the allowable loss

capacity (W) of the built-in regenerative resistor.

) for the Servo Motor is restricted. Refer to Servo

L

9

Rotary Servo Motors

0

1000 2000 3000 4000 5000 6000 7000

0

35

30

25

20

15

10

5

Allowable load moment of inertia

scaling factor (times)

Motor speed (min-1)

SGMMV-A1A, -A2A, -A3A

SGMMV

Allowable Load Moment of Inertia Scaling Factor for SERVOPACKs

without Built-in Regenerative Resistors

The following graphs show the allowable load moment of inertia scaling factor of the motor speed for

SERVOPACKs* without built-in regenerative resistors when an External Regenerative Resistor is not

connected.

If the Servo Motor exceeds the allowable load moment of inertia, an overvoltage alarm may occur in the

SERVOPACK.

These graphs provide reference data for deceleration at the rated torque or higher.

* Applicable SERVOPACK models: SGD7S-R90A, -1R6A, -R90F, and -2R1F

10

Rotary Servo Motors

Rotary Servo Motors

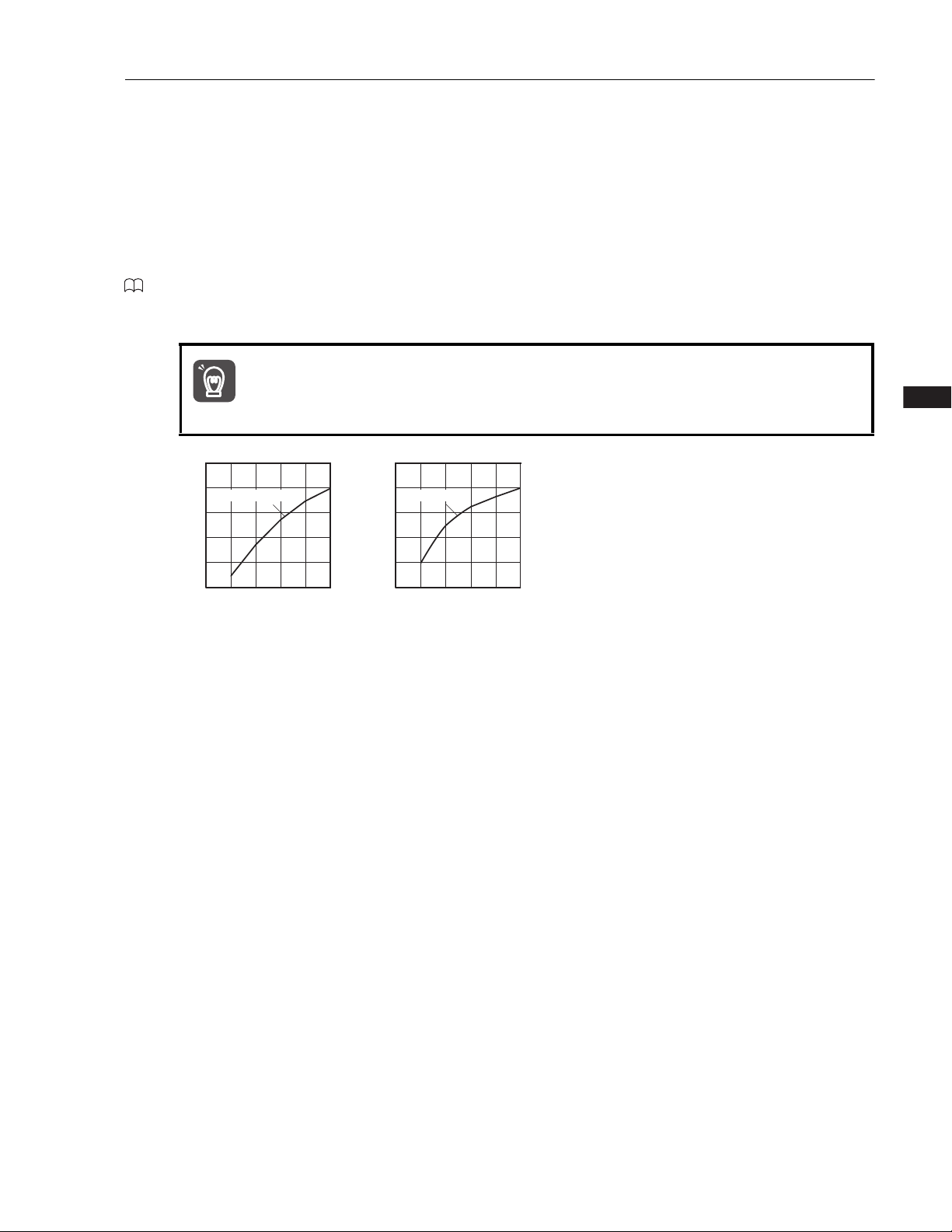

Important

90 150120

60

300 150 250200

100

500

100

80

60

40

20

100

80

60

40

20

SGMMV-A1, -A2

SGMMV-A3

Derating rate (%)

Heat sink size (mm)

Derating rate (%)

Heat sink size (mm)

SGMMV

Servo Motor Heat Dissipation Conditions

The Servo Motor ratings are the continuous allowable values when a heat sink is installed on the Servo

Motor. If the Servo Motor is mounted on a small device component, the Servo Motor temperature may

rise considerably because the surface for heat dissipation becomes smaller. Refer to the following graphs

for the relation between the heat sink size and derating rate.

When using Servo Motors with derating, change the detection timing of overload warnings and overload

alarms by referring to the motor overload detection level described in the following manual.

-7-Series AC Servo Drive Rotary Servo Motor Product Manual (Manual No.: SIEP S800001 36)

Note: The derating rates are applicable only when the average motor speed is less than or equal to the rated motor speed.

If the average motor speed exceeds the rated motor speed, consult with your Yaskawa representative.

The actual temperature rise depends on how the heat sink (i.e., the Servo Motor mounting

section) is attached to the installation surface, what material is used for the Servo Motor

mounting section, and the motor speed. Always check the Servo Motor temperature with the

actual equipment.

11

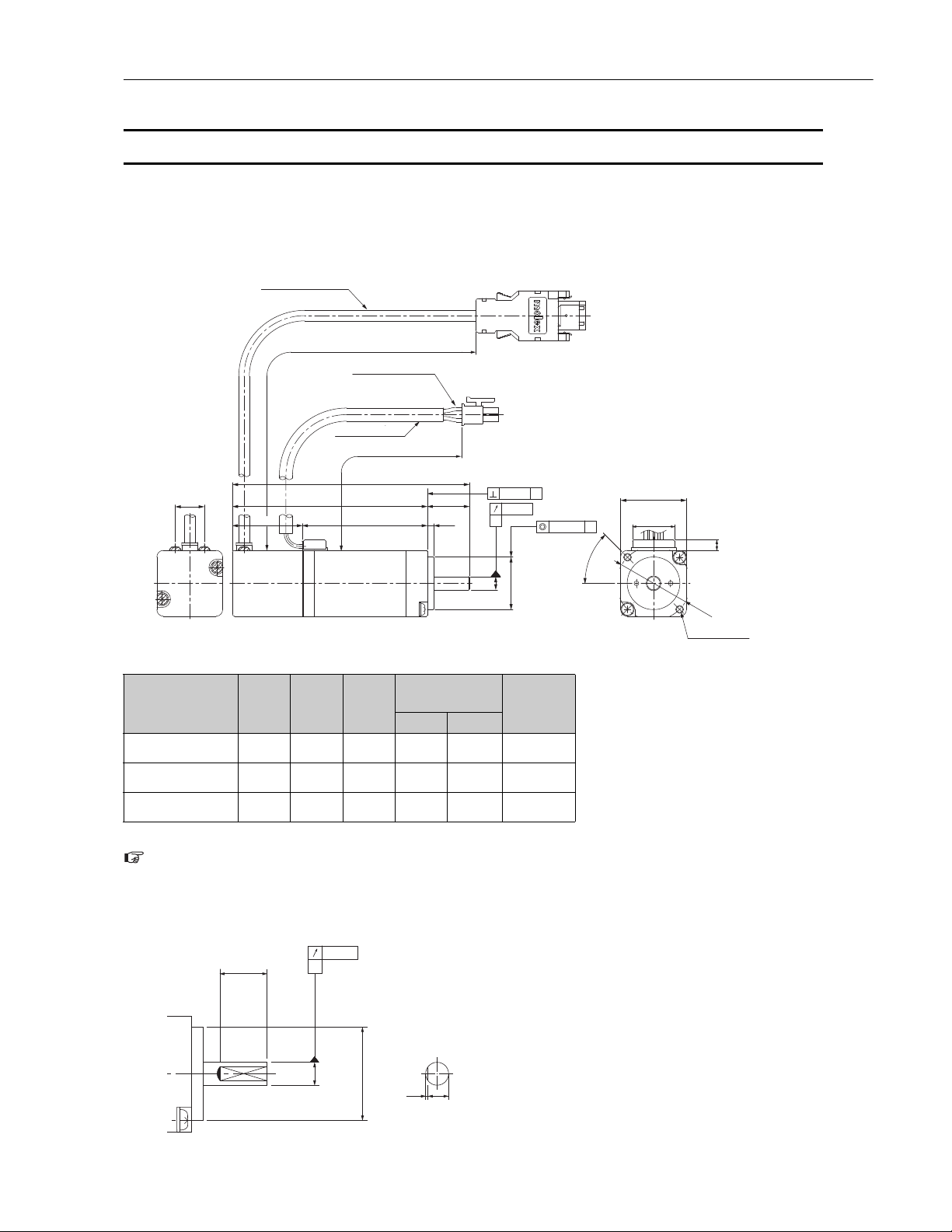

Rotary Servo Motors

300±30

Encoder Cable, 4 Dia.

UL

20276

Protective Tube

5

Dia., Black

Motor Lead

AWG

24

,UL

10095

or UL

3266

±

30300

28

Dia.

□

25

16

45

°

2.5

16

26

.

5

12

L

2

L

L

1

2-M3

Tapped

Holes, Depth

7

0.04

Dia.

A

A

0.02

0

.04A

4

LB Dia.

S Dia.

0

-0.008 0-0.021 0-0.008 0-0.021

0

-0.008 0-0.021

10

S Dia.

LB Dia.

0.5

4.5

A

0.02

SGMMV

External Dimensions

Servo Motors without Holding Brakes

SGMMV-A1, -A2 and -A3

Model

SGMMV-

1 70 54 27.5

A1A2A

1 80 64 37.5

A2A2A

A3A2A

1 90 74 47.5

L L1 L2

Flange

Dimensions

S LB

520

520

520

Approx.

Mass

[kg]

0.13

0.17

0.21

Refer to the following section for information on connectors.

SGMMV-A1, -A2, and -A3 without Holding Brakes (page 14)

Shaft End Specification

• Straight with Flat Seats

12

Rotary Servo Motors

Servo Motors with Holding Brakes

0

-0.008 0-0.021

0

-0.008

0

-0.021

0

-0.008 0-0.021

10

S Dia.

LB Dia.

0.5

4.5

A

0.02

SGMMV-A1, -A2 and -A3

Encoder Cable, 4 Dia.

20276

UL

Motor Lead

24,UL10095

AWG

3266

Protective Tube

5

Dia., Black

12

26.5

or UL

300±30

Rotary Servo Motors

SGMMV

±

30300

L

0

.04

S Dia.

0.02

A

°

45

2.5

16

A

L1

2

L

□

25

16

4

Model

SGMMV-

L L1 L2

A1A2A C 94.5 78.5 27.5

A2A2A C 108.5 92.5 37.5

A3A2A C 118.5 102.5 47.5

Flange

Dimensions

S LB

520

5

5

20

20

Approx.

Mass

[kg]

0.215

0.27

0.31

Refer to the following section for information on connectors.

SGMMV-A1, -A2, and -A3 with Holding Brakes (page 14)

Shaft End Specification

• Straight with Flat Seats

LB Dia.

0.04

Dia.

28

Dia.

A

2-M3 Tapped

Holes, Depth

7

13

Rotary Servo Motors

SGMMV

Connector Specifications

SGMMV-A1, -A2, and -A3 without Holding Brakes

• Encoder Connector Specifications

Model: 55102-0600

Manufacturer: Molex Japan LLC

Mating connector: 54280-0609

• Servo Motor Connector Specifications

Receptacle: 43025-0400

Manufacturer: Molex Japan LLC

SGMMV-A1, -A2, and -A3 with Holding Brakes

• Encoder Connector Specifications (24-bit Encoder)

Model: 55102-0600

Manufacturer: Molex Japan LLC

Mating connector: 54280-0609

• Servo Motor Connector Specifications

Receptacle: 43025-0600

Manufacturer: Molex Japan LLC

14

Rotary Servo Motors

Selecting Cables

Cable Configurations

The cables shown below are required to connect a Servo Motor to a SERVOPACK.

Encoder Cable of 20 m or Less Encoder Cable of 30 m to 50 m (Relay Cable)

Rotary Servo Motors

SGMMV

Servo Motor

Main Circuit Cable

Servo Motor Main

Circuit Cable

Servo Motor

SERVOPACK

Encoder Cable

Battery Case

(Required when an

absolute encoder is used.)

Encoder-end

Cable

Servo Motor Main

Circuit Cable

Servo Motor Main

Circuit Cable

Servo Motor

SERVOPACK

Relay Encoder Cable

Cable with a Battery

(Required when an

absolute encoder is used.)

Cable with Connectors

on Both Ends

Encoder-end Cable

Note: 1. If the cable length exceeds 20 m, be sure to use a Relay Encoder Cable.

2. If you use a Servo Motor Main Circuit Cable that exceeds 20 m, the intermittent duty zone in the torque-motor

speed characteristics will become smaller because the voltage drop increases.

3. Refer to the following manual for the following information.

• Cable dimensional drawings and cable connection specifications

• Order numbers and specifications of individual connectors for cables

• Order numbers and specifications for wiring materials

-7-Series AC Servo Drive Peripheral Device Selection Manual (Manual No.: SIEP S800001 32)

15

Rotary Servo Motors

L

SERVOPACK end

Motor end

L

SERVOPACK end Encoder end

SGMMV

Servo Motor Main Circuit Cables

Servo

Motor

Name

Model

For

Servo

Motors

without

SGMMV

-A1, -A2,

and -A3

10 W,

20 W,

30 W

*1. Use Flexible Cables for moving parts of machines, such as robots.

*2. The recommended bending radius (R) is 90 mm or larger.

Holding

Brakes

For

Servo

Motors

with

Holding

Brakes

Length

(L)

3 m JZSP-CF2M00-03-E JZSP-CF2M20-03-E

5 m JZSP-CF2M00-05-E JZSP-CF2M20-05-E

10 m JZSP-CF2M00-10-E JZSP-CF2M20-10-E

15 m JZSP-CF2M00-15-E JZSP-CF2M20-15-E

20 m JZSP-CF2M00-20-E JZSP-CF2M20-20-E

30 m JZSP-CF2M00-30-E JZSP-CF2M20-30-E

40 m JZSP-CF2M00-40-E JZSP-CF2M20-40-E

50 m JZSP-CF2M00-50-E JZSP-CF2M20-50-E

3 m JZSP-CF2M03-03-E JZSP-CF2M23-03-E

5 m JZSP-CF2M03-05-E JZSP-CF2M23-05-E

10 m JZSP-CF2M03-10-E JZSP-CF2M23-10-E

15 m JZSP-CF2M03-15-E JZSP-CF2M23-15-E

20 m JZSP-CF2M03-20-E JZSP-CF2M23-20-E

30 m JZSP-CF2M03-30-E JZSP-CF2M23-30-E

40 m JZSP-CF2M03-40-E JZSP-CF2M23-40-E

50 m JZSP-CF2M03-50-E JZSP-CF2M23-50-E

Standard Cable

Order Number

Flexible Cable

*1*2

SERVOPACK end

Appearance

L

Motor end

Encoder Cables of 20 m or Less

Servo

Motor

Name

Model

Cables with

Connectors on

Both Ends

(for incremen-

All

SGMMV

models

*1. Use Flexible Cables for moving parts of machines, such as robots.

*2. The recommended bending radius (R) is 68 mm or larger.

tal encoder)

Cables with

Connectors on

Both Ends

(for absolute

encoder: With

Battery Case)

Length

(L)

3 m JZSP-CMP00-03-E JZSP-CMP10-03-E

5 m JZSP-CMP00-05-E JZSP-CMP10-05-E

10 m JZSP-CMP00-10-E JZSP-CMP10-10-E

15 m JZSP-CMP00-15-E JZSP-CMP10-15-E

20 m JZSP-CMP00-20-E JZSP-CMP10-20-E

3 m JZSP-CSP19-03-E JZSP-CSP29-03-E

5 m JZSP-CSP19-05-E JZSP-CSP29-05-E

10 m JZSP-CSP19-10-E JZSP-CSP29-10-E

15 m JZSP-CSP19-15-E JZSP-CSP29-15-E

20 m JZSP-CSP19-20-E JZSP-CSP29-20-E

Standard Cable

Order Number

Flexible Cable

*1*2

SERVOPACK end Encoder end

Appearance

Battery Case

(battery included)

L

16

Rotary Servo Motors

Relay Encoder Cables of 30 m to 50 m

SERVOPACK

end

Encoder end

L

molex

Rotary Servo Motors

SGMMV

Servo Motor

Model

All SGMMV

Name

Cables with Connectors

on Both Ends (for incremental or absolute

encoder)

Length

(L)

Order Number for

Standard Cable

30 m JZSP-UCMP00-30-E

40 m JZSP-UCMP00-40-E

50 m JZSP-UCMP00-50-E

models

Cable with a Battery Case

(Required when an abso-

0.3 m JZSP-CSP12-E

lute encoder is used.)*

*This Cable is not required if a battery is connected to the host controller.

SERVOPACK

end

molex

Appearance

L

Battery Case

(battery included)

Encoder end

17

Rotary Servo Motors

SGM7J

SGM7J Servo Motors (without Gear Box)

Model Designations

-

SGM7J

-7 Series

Servo Motors:

SGM7J

01

A 7 D

1st+2nd

digits

3rd

digit

4th

digit

5th

digit

61

6th

digit

7th

digit

1st+2nd digits

Code

A5

50 W

01

100 W

C2

150 W

02 200 W

04 400 W

06 600 W

08 750 W

Rated Output

Specification

3rd digit

Code

4th digit

Code

5th digit

A: Global design revision for batteryless

D: Global design revision for battery

F: Global design revision for battery

Power Supply Voltage

Specification

A 200 VAC

D 400 VAC

Serial Encoder

Specification

6

24-bit batteryless absolute

7

24-bit absolute

F

24-bit incremental

Design Revision Order

absolute encoder (200 V)

type (200V)

type absolute encoder (400V)

6th digit

Code

7th digit

Code Specification

Shaft End

Specification

2

Straight without key

6

Straight with key and tap

B

With two flat seats

Options

1

Without options

C

With holding brake (24 VDC)

With oil seal and holding

E

brake (24 VDC)

S

With oil seal

Non Stock Items

18

Rotary Servo Motors

Rotary Servo Motors

1

2

3

4

5

03

05

50

Blank

C

050

090

070

A 200 VAC battery type

B 200 VAC batteryless type

D 400 VAC battery type

01

02 200 W

04 400 W

08 750 W

15 1.5 kW

100 W

VL

Code

Specification

5 arc-min backlash

3rd digit

4th digit

6th digit

-7 Series

Gear Motors:

SGM7J

Rated Output

Code

Specification

Code

Code

Specification

Specification

No brake

24 V Brake

Code

Code Specification

3:1 Ratio

5:1 Ratio

10

10:1 Ratio

25

25:1 Ratio

50:1 Ratio

Specification

50 mm

70 mm

90 mm

120

120 mm

155

155 mm

Power Supply Voltage

Brake Option

5th digit

Gear box backlash

Gear head frame size

7th digit

Gear Ratio

1st+2nd digits

S7J

-

01

A C VL

050 - 05

1st+2nd

digits

3rd

digit

4th

digit

5th

digit

6th

digit

7th

digit

SGM7J

SGM7J Gear Motors

The SGM7J gear motor product family pairs SGM7J servo motors with high precision, low backlash inline

planetary gear heads resulting in a portfolio of rotary actuators fit for a wide range of applications. The fam‐

ily of gear motors has been thoroughly tested and adheres to the high levels of quality and performance

expected from Yaskawa.

The high precision gear heads offer a variety of application advantages:

• Quiet operation – helical cut gears contribute toward reduced

vibration and noise

• High precision – a standard backlash of 5 arc-min make this gear

head ideal for the most accurate applications

• High rigidity and torque capacity – achieved with a design

which incorporates uncaged needle roller bearings

• Optimized adapter bushing – minimizes inertia allowing for more

output torque to be realized

• No leakage through the seal – high viscosity, anti-separation

grease does not liquefy and does not migrate away from the gears

• Maintenance-free – no need to replace the grease for the life of the

unit. The reducer can be positioned in any orientation

Model Designations

19

Rotary Servo Motors

Vertical

Shock Applied to the Servo Motor

SGM7J

Specifications and Ratings

Specifications (200 V Models)

Voltage 200 V

Model SGM7J- A5A 01A C2A 02A 04A 06A 08A

Time Rating Continuous

Thermal Class UL: B, CE: B

Insulation Resistance 500 VDC, 10 M min.

Withstand Voltage 1,500 VAC for 1 minute

Excitation Permanent magnet

Mounting Flange-mounted

Drive Method Direct drive

Rotation Direction

Vibration Class

*1

Surrounding Air

Temperature

Surrounding Air Humidity 20% to 80% relative humidity (with no condensation)

Environmental

Installation Site

Conditions

Storage Environment

Shock Resis-

*2

tance

Vibration

Resistance

Applicable

SERVOPAC Ks

Impact Acceleration Rate at

Flange

Number of Impacts 2 times

Vibration Acceleration Rate

*3

at Flange

SGD7S- R70A R90A 1R6A 2R8A 5R5A

SGD7W-

*1. A vibration class of V15 indicates a vibration amplitude of 15 m maximum on the Servo Motor without a load at the

rated motor speed.

*2. The shock resistance for shock in the vertical direction when the Servo Motor is mounted with the shaft in a horizontal

position is given in the above table.

Counterclockwise (CCW) for forward reference when viewed from the

load side

V15

0°C to 40°C (With derating, usage is possible between 40°C and

*4

60°C.)

• Must be indoors and free of corrosive and explosive gases.

• Must be well-ventilated and free of dust and moisture.

• Must facilitate inspection and cleaning.

• Must have an altitude of 1,000 m or less. (With derating, usage is

possible between 1,000 m and 2,000 m.)

*5

• Must be free of strong magnetic fields.

Store the Servo Motor in the following environment if you store it with

the power cable disconnected.

Storage Temperature: -20°C to 60°C (with no freezing)

Storage Humidity: 20% to 80% relative humidity (with no condensation)

2

490 m/s

2

49 m/s

2R8A

1R6A

*6

, 2R8A

*6

1R6A, 2R8A

*6

5R5A

7R6A

*6

*6

5R5A, 7R6A

20

Rotary Servo Motors

Rotary Servo Motors

*3. The vertical, side-to-side, and front-to-back vibration resistance for vibration in three directions when the Servo Motor

is mounted with the shaft in a horizontal position is given in the above table. The strength of the vibration that the

Servo Motor can withstand depends on the application. Always check the vibration acceleration rate that is applied to

the Servo Motor with the actual equipment.

Vertical

SGM7J

Front to back

Side to side

*4. If the surrounding air temperature will exceed 40°C, refer to the following section.

Applications Where the Surrounding Air Temperature of the Servo Motor Exceeds 40

*5. If the altitude will exceed 1,000 m, refer to the following section.

Applications Where the Altitude of the Servo Motor Exceeds 1,000 m (page 35)

*6. If you use the Servo Motor together with a S-7W SERVOPACK, the control gain may not increase as much as with a

Vibration Applied to the Servo Motor

Horizontal direction

C (page 34)

-7S SERVOPACK and other performances may be lower than those achieved with a -7S SERVOPACK.

21

Rotary Servo Motors

Vertical

Shock Applied to the Servo Motor

SGM7J

Specifications (400 V Models)

Voltage 400 V

Model SGM7J- 02D 04D 08D 15D

Time Rating Continuous

Thermal Class UL: B, CE: B

Insulation Resistance 500 VDC, 10 M min.

Withstand Voltage 1,800 VAC for 1 minute

Excitation Permanent magnet

Mounting Flange-mounted

Drive Method Direct drive

Rotation Direction

Vibration Class

*1

Environmental

Conditions

Shock Resis-

*2

tance

Vibration

Resistance

*3

Applicable

SERVOPAC Ks

Surrounding Air

Temperature

Surrounding Air Humidity 20% to 80% relative humidity (with no condensation)

Installation Site

Storage Environment

Impact Acceleration Rate at

Flange

Number of Impacts 2 times

Vibration Acceleration Rate

at Flange

SGDV-- 1r9 3R5 5R4

Counterclockwise (CCW) for forward reference when viewed from the

load side

V15

0°C to 40°C (With derating, usage is possible between 40°C and

*4

60°C.)

• Must be indoors and free of corrosive and explosive gases.

• Must be well-ventilated and free of dust and moisture.

• Must facilitate inspection and cleaning.

• Must have an altitude of 1,000 m or less. (With derating, usage is

possible between 1,000 m and 2,000 m.)

*5

• Must be free of strong magnetic fields.

Store the Servo Motor in the following environment if you store it with

the power cable disconnected.

Storage Temperature: -20°C to 60°C (with no freezing)

Storage Humidity: 20% to 80% relative humidity (with no condensation)

2

490 m/s

2

49 m/s

*1. A vibration class of V15 indicates a vibration amplitude of 15 m maximum on the Servo Motor without a load at the

rated motor speed.

*2. The shock resistance for shock in the vertical direction when the Servo Motor is mounted with the shaft in a horizontal

position is given in the above table.

22

Rotary Servo Motors

Rotary Servo Motors

*3. The vertical, side-to-side, and front-to-back vibration resistance for vibration in three directions when the Servo Motor

is mounted with the shaft in a horizontal position is given in the above table. The strength of the vibration that the

Servo Motor can withstand depends on the application. Always check the vibration acceleration rate that is applied to

the Servo Motor with the actual equipment.

Vertical

SGM7J

Front to back

Side to side

*4. If the surrounding air temperature will exceed 40°C, refer to the following section.

Applications Where the Surrounding Air Temperature of the Servo Motor Exceeds 40

*5. If the altitude will exceed 1,000 m, refer to the following section.

Applications Where the Altitude of the Servo Motor Exceeds 1,000 m (page 35).

Vibration Applied to the Servo Motor

Horizontal direction

C (page 34)

23

Rotary Servo Motors

SGM7J

Ratings of Servo Motors (200 V Models)

Voltage 200 V

Model SGM7J- A5A 01A C2A 02A 04A 06A 08A

Rated Output

Rated Torque

Instantaneous Maximum Torque

Rated Current

*1

*1, *2

*1

*1

Instantaneous Maximum Current

Rated Motor Speed

Maximum Motor Speed

*1

*1

Torque Constant N•m/Arms 0.316 0.413 0.321 0.444 0.544 0.493 0.584

Absolute encoder

Motor Moment of

Inertia

with battery

Batteryless absolute encoder

Rated Power Rate

*1

Rated Angular Acceleration Rate

Derating for Servo Motor with Oil Seal % 80 90 95

Heat Sink Size (Aluminum) mm 200 200 6 250 250 6

Protective Structure

*3

Rated Voltage V 24 VDC10%

Capacity W 5.5 6 6.5

Holding Torque N•m 0.159 0.318 0.477 0.637 1.27 1.91 2.39

Holding Brake

Specifications

Coil Resistance (at 20°C) 104.810% 9610% 88.610%

Rated Current A (at 20°C) 0.23 0.25 0.27

*4

Time Required to

Release Brake

Time Required to

Brake

Allowable Load Moment of Inertia

(Motor Moment of Inertia Ratio)

LF mm 20 25 35

Allowable Shaft

*5

Loads

Allowable Radial

Load

Allowable Thrust

Load

Note: The values in parentheses are for Servo Motors with Holding Brakes.

*1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding is

100°C. The values for other items are at 20°C. These are typical values.

*2. The rated torques are the continuous allowable torque values at a surrounding air temperature of 40°C with an alumi-

num heat sink of the dimensions given in the table.

*3. This does not apply to the shaft opening. Protective structure specifications apply only when the special cable is used.

*4. Observe the following precautions if you use a Servo Motor with a Holding Brake.

• The holding brake cannot be used to stop the Servo Motor.

• The time required to release the brake and the time required to brake depend on which discharge circuit is used.

Confirm that the operation delay time is appropriate for the actual equipment.

• The 24-VDC power supply is not provided by Yaskawa.

*5. The allowable shaft loads are illustrated in the following figure. Design the mechanical system so that the thrust and

radial loads applied to the Servo Motor shaft end during operation do not exceed the values given in the table.

W 50 100 150 200 400 600 750

N•m 0.159 0.318 0.477 0.637 1.27 1.91 2.39

N•m 0.557 1.11 1.67 2.23 4.46 6.69 8.36

Arms 0.55 0.85 1.6 1.6 2.5 4.2 4.4

*1

Arms 2.0 3.1 5.7 5.8 9.3 15.3 16.9

-1

min

-1

min

2

2

0.0395

(0.0475)

0.0410

(0.0490)

6.40

(5.32)

40200

(33400)

-4

10

kg•m

-4

10

kg•m

kW/s

*1

rad/s

2

0.0659

(0.0739)

0.0674

(0.0754)

15.3

(13.6)

48200

(43000)

0.0915

(0.0995)

0.0930

(0.1010)

24.8

(22.8)

52100

(47900)

3000

6000

0.263

(0.333)

0.264

(0.334)

15.4

(12.1)

24200

(19100)

0.486

(0.556)

0.487

(0.557)

33.1

(29.0)

26100

(22800)

0.800

(0.870)

0.801

(0.871)

45.6

(41.9)

23800

(21900)

Totally enclosed, self-cooled, IP67

ms 60 80

ms 100

35 times

15

times

10

times

20

times

N 78 245 392

N 54 74 147

LF

1.59

(1.77)

1.59

(1.77)

35.9

(32.2)

15000

(13500)

times

12

24

Radial load

Thrust load

Rotary Servo Motors

Rotary Servo Motors

Ratings of Servo Motors (400 V Models)

Voltage 400 V

Model SGM7J- 02D 04D 08D 15D

Rated Output

Rated Torque

Instantaneous Maximum Torque

Rated Current

*1

*1, *2

*1

*1

Instantaneous Maximum Current

Rated Motor Speed

Maximum Motor Speed

*1

*1

Torque Constant N•m/Arms 0.461 0.965 1.17 1.13

Motor Moment of Inertia

Rated Power Rate

*1

Rated Angular Acceleration Rate

Heat Sink Size (Aluminum) mm 250 250 6

Protective Structure

*3

Rated Voltage V 24 VDC10%

Capacity W 6.0 6.5 7.5

Holding Torque N•m 0.637 1.27 2.39 4.77

Holding Brake

Specifications

Coil Resistance (at 20°C) 9610%

Rated Current A (at 20°C) 0.25 0.27 0.31

*4

Time Required to

Release Brake

Time Required to

Brake

Allowable Load Moment of Inertia

(Motor Moment of Inertia Ratio)

LF mm 25 35

Allowable Shaft

*5

Loads

Allowable Radial

Load

Allowable Thrust

Load

Note: The values in parentheses are for Servo Motors with Holding Brakes.

*1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding is

100°C. The values for other items are at 20°C. These are typical values.

*2. The rated torques are the continuous allowable torque values at a surrounding air temperature of 40°C with an alumi-

num heat sink of the dimensions given in the table.

*3. This does not apply to the shaft opening. Protective structure specifications apply only when the special cable is used.

*4. Observe the following precautions if you use a Servo Motor with a Holding Brake.

• The holding brake cannot be used to stop the Servo Motor.

• The time required to release the brake and the time required to brake depend on which discharge circuit is used.

Confirm that the operation delay time is appropriate for the actual equipment.

• The 24-VDC power supply is not provided by Yaskawa.

*5. The allowable shaft loads are illustrated in the following figure. Design the mechanical system so that the thrust and

radial loads applied to the Servo Motor shaft end during operation do not exceed the values given in the table.

W 200 400 750 1500

N•m 0.637 1.27 2.39 4.77

N•m 2.23 4.46 8.36 14.3

Arms 1.5 1.4 2.2 4.5

*1

Arms 5.5 5.3 8.2 14.0

min

min

10

-1

-1

-4

kg•m

2

0.263

(0.333)

(0.556)

0.486

3000

6000

1.59

(1.77)

kW/s 15.4 (12,1) 33.1 (29.0) 35.9 (32.2) 56.6 (46.6)

*1

rad/s

2

24200

(19100)

26100

(22800)

15000

(13500)

Totally enclosed, self-cooled, IP67

88.610%

ms 60 80

ms 100

25 times 15 times 12 times

N 245 392 490

N 74 147

LF

4.02

(4.90)

11900

(9700)

300 300

12

76.810%

SGM7J

Radial load

Thrust load

25

Rotary Servo Motors

SGM7J-C2A

*2

AB

010.5 1.5 202.5

1000

2000

3000

4000

5000

6000

7000

SGM7J-04A

AB

102345

0

1000

2000

3000

4000

5000

6000

7000

SGM7J-06A

A

B

02 64810

0

1000

2000

3000

4000

5000

6000

7000

Continuous duty zone

Intermittent duty zone

A

(solid lines): With three-phase 200-V or single-phase 230-V input

(dotted lines): With single-phase 200-V input

(dashed-dotted lines): With single-phase 100-V input

:

B

:

SGM7J-A5A

*1

BA

0 0.15 0.3 0.45 0.6 0.75

0

1000

2000

3000

4000

5000

6000

7000

Torque (N

m)

Motor speed (min

-1

)

SGM7J-01A

BA

00.250.5 10.75

0

1000

2000

3000

4000

5000

6000

7000

Torque (N

m)

Motor speed (min

-1

)

Torque (N m)

Motor speed (min

-1

)

SGM7J-02A

AB

010.5 1.5 202.5

1000

2000

3000

4000

5000

6000

7000

Torque (N

m)

Motor speed (min

-1

)

Torque (N m)

Motor speed (min

-1

)

Torque (N m)

Motor speed (min

-1

)

SGM7J-08A

AB

0246810

0

1000

2000

3000

4000

5000

6000

7000

Torque (N

m)

Motor speed (min

-1

)

Important

SGM7J

Servo Motor Torque-Motor Speed Characteristics (200V Models)

* The characteristics are the same for three-phase 200 V and single-phase 200 V.

Note: 1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding

is 100°C. These are typical values.

2. The characteristics in the intermittent duty zone depend on the power supply voltage.

3. If the effective torque is within the allowable range for the rated torque, the Servo Motor can be used within the

intermittent duty zone.

4. If you use a Servo Motor Main Circuit Cable that exceeds 20 m, the intermittent duty zone in the torque-motor

speed characteristics will become smaller because the voltage drop increases.

The SERVOPACK speed control range is 5,000:1. If you use Servo Motors at extremely low

speeds (0.02 min-1 or lower at the gear output shaft), if you use Servo Motors with a one-pulse

feed reference for extended periods, or under some other operating conditions, the gear bearing lubrication may be insufficient. That may cause deterioration of the bearing or increase the

load ratio.

Contact your Yaskawa representative if you use a Servo Motor under these conditions.

* The moment of inertia for the Servo Motor and gear is the value without a holding brake. You can calculate the moment

of inertia for a Servo Motor with a Gear and Holding Brake with the following formula.

Motor moment of inertia for a Servo Motor with a Holding Brake from Ratings of Servo Motors (200 V Models)

(page 24) + Moment of inertia for the gear from the above table.

26

Rotary Servo Motors

Rotary Servo Motors

SGM7J-02D SGM7J-04D SGM7J-08D SGM7J-15D

0

0.5

1

1.5

2

2.5

B

A

0

1

2

3

4

5

A

B

0 1000 2000 3000 4000 5000 60000 1000 2000 3000 4000 5000 6000

0

2

4

6

8

10

B

A

0 1000 2000 3000 4000 5000 6000

0

3

6

9

12

15

B

A

0 1000 2000 3000 4000 5000 6000

Motor speed (min-1)

Torque (N·m)

Torque (N·m)

Torque (N·m)

Torque (N·m)

Motor speed (min-1) Motor speed (min-1) Motor speed (min-1)

Continuous duty zone

Intermittent duty zone

A

:

B

:

Servo Motor Torque-Motor Speed Characteristics (400V Models)

SGM7J

Note: 1. These values are for operation in combination with a SERVOPACK when the temperature of the armature winding

is 100°C. These are typical values.

2. The characteristics in the intermittent duty zone depend on the power supply voltage. The intermittent duty zones

in the graphs show the characteristics when a three-phase, 400-VAC power supply voltage is used.

3. If the effective torque is within the allowable range for the rated torque, the Servomotor can be used within the

intermittent duty zone.

4. If you use a Servomotor Main Circuit Cable that exceeds 20 m, the intermittent duty zone in the torquemotor

speed characteristics will become smaller because the voltage drop increases.

27

Rotary Servo Motors

Important

SGM7J

Ratings of Gear Motors (200 V Models: Abs. Encoder with Battery)

Gear Motor

Model Number

SJ7_____

01A -VL050-03

01A -VL050-05 5:1 600 1200 1.51 5.27 0.036

01A -VL050-10 10:1 300 600 3.02 10.5 0.030

01A -VL050-25 25:1

01A -VL070-50 50:1 60 120 14.3 50.0 0.051 1200 1100 5

02A -VL050-03

02A -VL050-05 5:1 600 1200 3.03 10.6 0.15

02A -VL050-10 10:1 300 600 6.05

02A -VL070-50 50:1 60 120 28.7

04A -VL050-03

04A -VL050-05 5:1 600 1200 6.03

04A -VL070-10 10:1 300 600 12.1

04A -VL070-25 25:1

04A -VL090-50 50:1 60 120 57.2

08A -VL070-03

08A -VL070-05 5:1 600 1200 11.4 39.7 0.46

08A -VL090-10 10:1 300 600 22.7 79.4 0.70

08A -VL090-25 25:1