Page 1

MotionSuite™ MP940 Machine Controller

Reference Manual

Page 2

MotionSuite™ MP940 Machine Controller Reference Manual

WARNING

Yaskawa manufactures component parts that can be used in a wide variety of

industrial applications. The selection and application of Yaskawa products

remains the responsibility of the equipment designer or end user. Yaskawa

accepts no responsibility for how its products may be incorporated into the

final design.

Under no circumstances should any Yaskawa product be incorporated into

any product or design as the exclusive or sole safety control. Without exception, all controls should be designed to dynamically fault detect and fail safe

under all circumstances. All products designed to incorporate a component

part manufactured by Yaskawa must be supplied to the end user with appropriate warnings and instructions as to the safe use and operation. Any warnings provided by Yaskawa must be passed through to the end user.

Yaskawa offers an express warranty only as to the quality of its products to

conform to the catalog specifications. No other warranty, express or implied,

is offered. Yaskawa assumes no liability for any personal injury, property damage, losses or claims arising out of the mis-application of its products.

Page 3

Contents

Chapter 1: General Functions . . . . . . . . . . . . . . . . . . . . . . . 1-1

Outline of the MP940 . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Specifications and Functions . . . . . . . . . . . . . . . . . . 2-1

Chapter 3: Basic System Operation . . . . . . . . . . . . . . . . . . . 3-1

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Start, Stop Sequence . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Scan Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

User Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Symbol Management . . . . . . . . . . . . . . . . . . . . . . . 3-47

Chapter 4: MP940 Functions . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Outline of MP940 Functions . . . . . . . . . . . . . . . . . . . 4-1

Serial Transmission Function . . . . . . . . . . . . . . . . . . 4-4

LI/O Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

CNTR Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Mechatrolink Function . . . . . . . . . . . . . . . . . . . . . . 4-34

Chapter 5: System Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Handling Each Part . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Connection Method . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Connection with Peripheral Devices. . . . . . . . . . . . 5-27

Servo Amplifier Main Circuit Connection . . . . . . . . 5-34

Servo Amplifier I/O Signal . . . . . . . . . . . . . . . . . . . 5-38

Encoder Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Outline of the Start-up Procedure. . . . . . . . . . . . . . 5-49

Test Device Configuration . . . . . . . . . . . . . . . . . . . 5-50

Outline of Test Device Configuration . . . . . . . . . . . 5-51

Preparation of Devices Used . . . . . . . . . . . . . . . . . 5-52

Handling of the MP940 Module . . . . . . . . . . . . . . . 5-53

Mounting of Battery Holder . . . . . . . . . . . . . . . . . . . 5-56

Connection and Wiring . . . . . . . . . . . . . . . . . . . . . . 5-57

Chapter 6: Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parameter Outline . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parameter Details . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

i

Page 4

SGDH User Parameters . . . . . . . . . . . . . . . . . . . . . 6-54

Chapter 7: Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Outline of Absolute Encoder Functions . . . . . . . . . . 7-1

Starting the Absolute Encoder Function. . . . . . . . . . 7-7

Absolute Encoder Usage Method. . . . . . . . . . . . . . 7-16

Chapter 8: Maintenance Inspection . . . . . . . . . . . . . . . . . . . 8-1

Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MP940 Module Battery. . . . . . . . . . . . . . . . . . . . . . . 8-3

Chapter 9: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Troubleshooting Outline . . . . . . . . . . . . . . . . . . . . . . 9-1

System Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Motion Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Chapter 10: Servo Amplifier Maintenance and Inspection . 10-1

Servo Amplifier Maintenance/Inspection . . . . . . . . 10-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Chapter 11: Motion Control . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Outline of Motion Control . . . . . . . . . . . . . . . . . . . . 11-1

Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

Position Control . . . . . . . . . . . . . . . . . . . . . . . . . . 11-29

Position Control by Motion Commands . . . . . . . . 11-50

External Positioning (EX_POSING) . . . . . . . . . . . 11-58

Zero-point Return (ZRET). . . . . . . . . . . . . . . . . . . 11-63

Interpolation (INTERPOLATE) . . . . . . . . . . . . . . . 11-79

Interpolation with Position Detection (LATCH). . . 11-81

Set Speed Feed (FEED). . . . . . . . . . . . . . . . . . . . 11-82

Stepping (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . 11-85

Zero-point Setting (ZSET) . . . . . . . . . . . . . . . . . . 11-89

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

User Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Structure of User Parameters . . . . . . . . . . . . . . . . . . A-1

User Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Switch List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Input Signal Selection List . . . . . . . . . . . . . . . . . . . A-12

Output Signal Selection . . . . . . . . . . . . . . . . . . . . . A-14

Auxiliary Functions List. . . . . . . . . . . . . . . . . . . . . . A-15

Monitor Mode List . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Scan Processing . . . . . . . . . . . . . . . . . . . . . . . . . . A-32

ii

Page 5

SAFETY INFORMATION

PRECAUTIONS

1. Read this instruction manual in its entirety before using the MP940.

2. The following symbols are used to indicate precautions of which the user must be aware to

safely use this equipment.

CAUTION

The symbol above indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.”

WARNING

The symbol above indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.”

iii

Page 6

MotionSuite™ MP940 Machine Controller Reference Manual Outline of the MP940

Chapter 1: General Functions

This chapter describes the general functions and characteristics of the MP940.

Outline of the MP940

This section provides a general outline of theMP940.

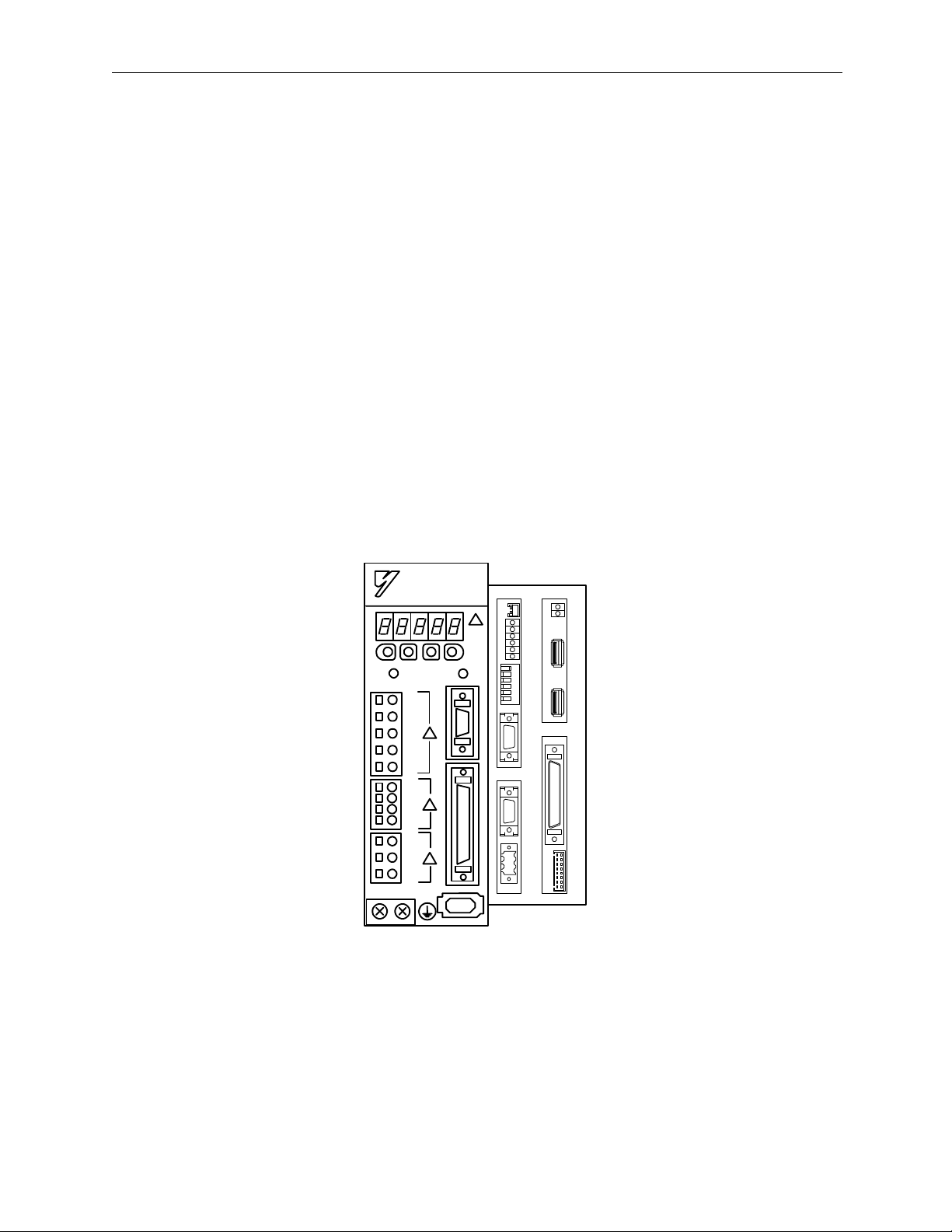

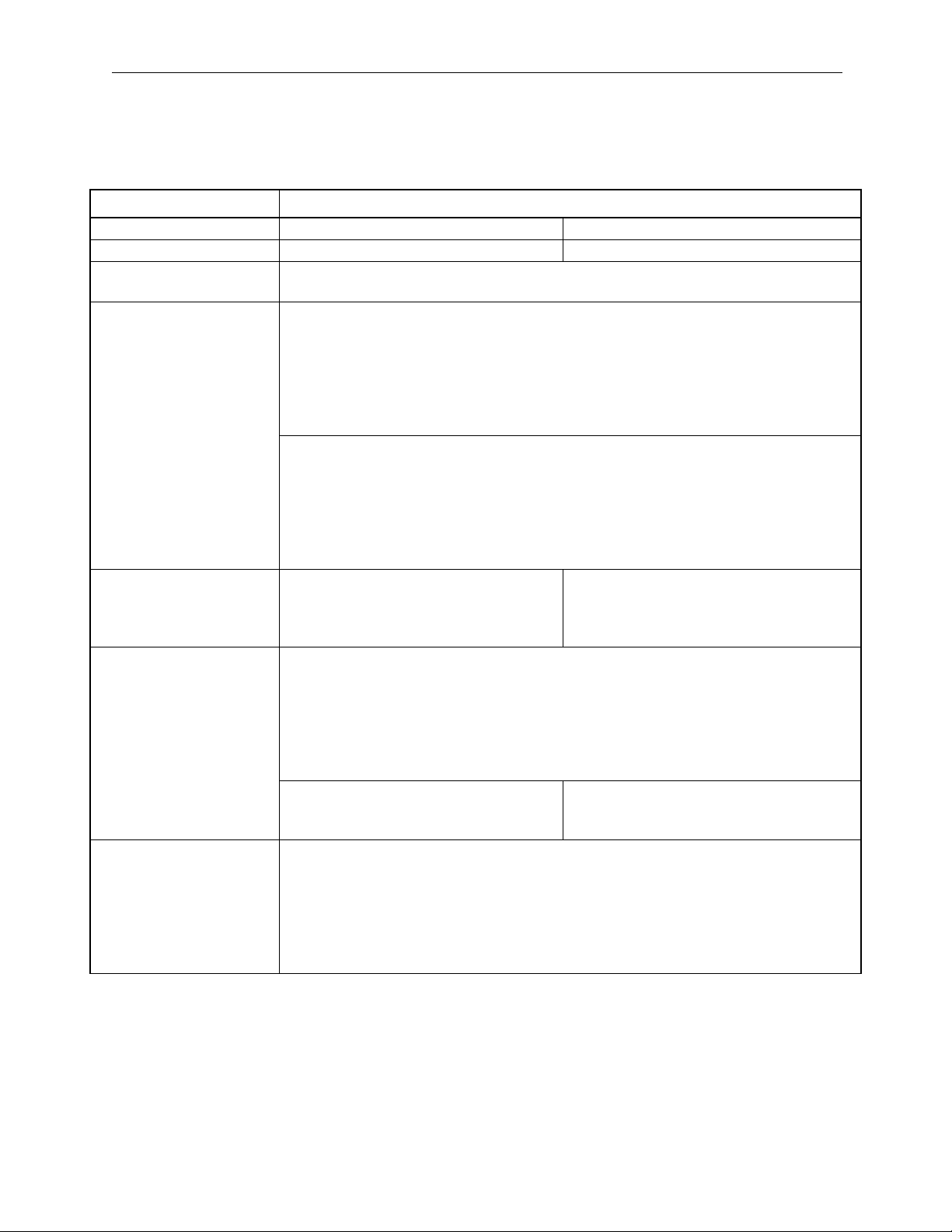

Exterior of the MP940 module

The MP940 is a single-axis controller with communication, local I/O,

external encoder, and motion functions bus connected with an SGDH servo

amplifier.

MP940

TX

BAT

R

X

RDY

RUN

ALM

1

BAT

L1

L2

L1C

L2C

B1

B2

PRT1

PRT2

RUN

654321

INIT

TEST

FLASH

PP

COPY

NO

・¨

PORT1

PORT2

POWER

+24V

GND

FG

M

E

C

H

A

T

R

2

O

L

I

N

K

I/O

LED

Figure 1.1: MP940 Machine Control and SGDH Servo Amplifier

1-1

Page 7

Outline of the MP940 MotionSuite™ MP940 Machine Controller Reference Manual

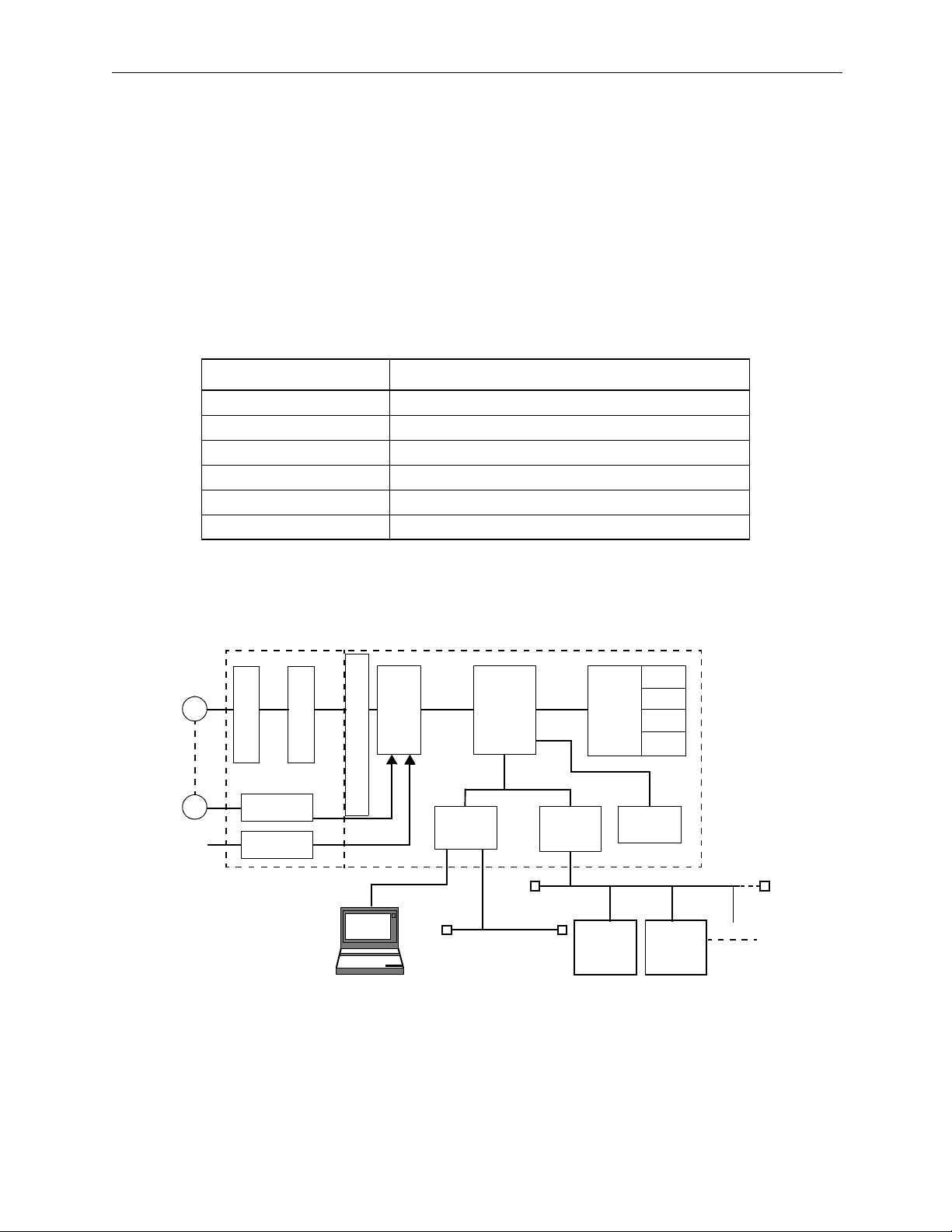

Features of the MP940

The MP940 machine controller functions in a variety of machine control

modes, from simple positioning to high-speed/high-precision synchronous

control.

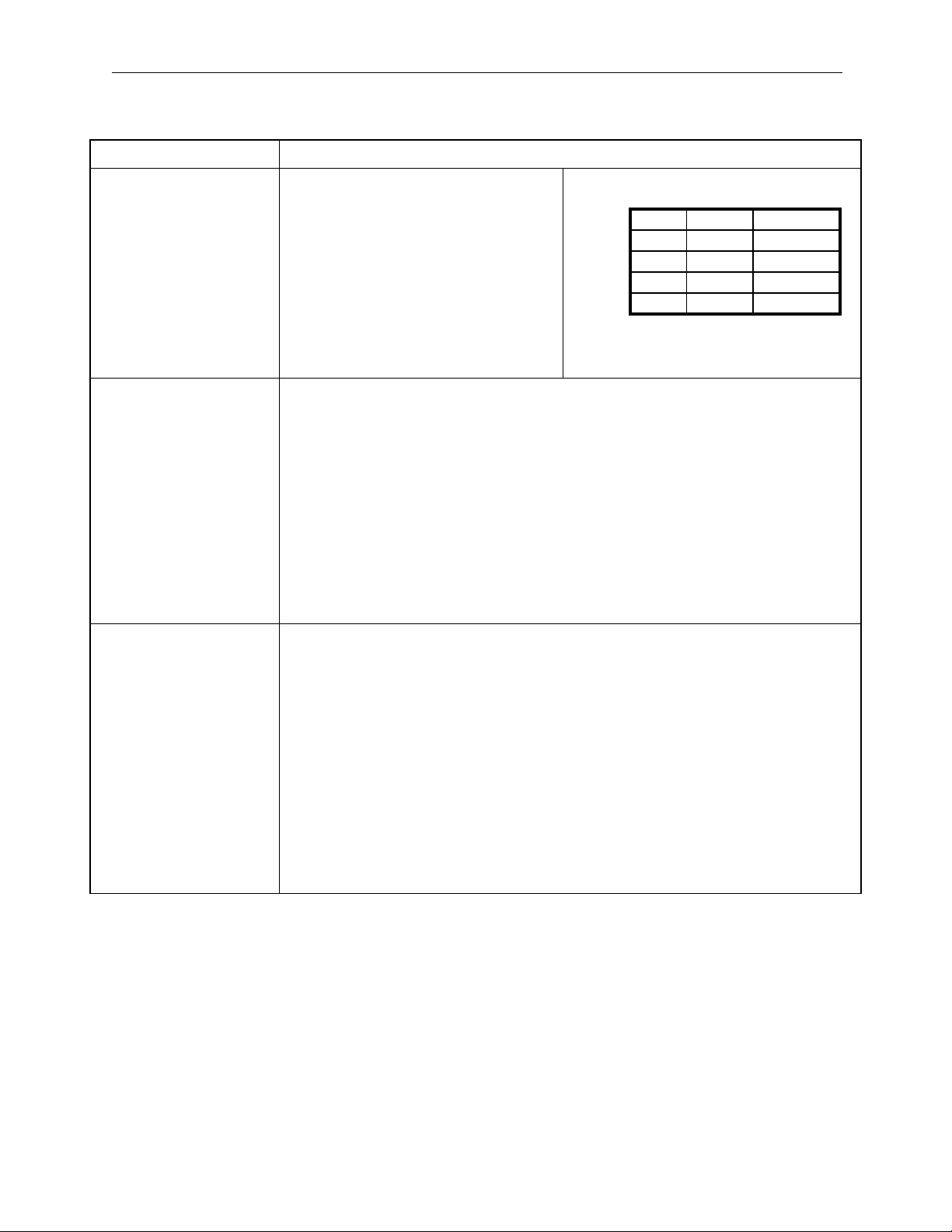

A single controller

The MP940 is composed of the following modules.

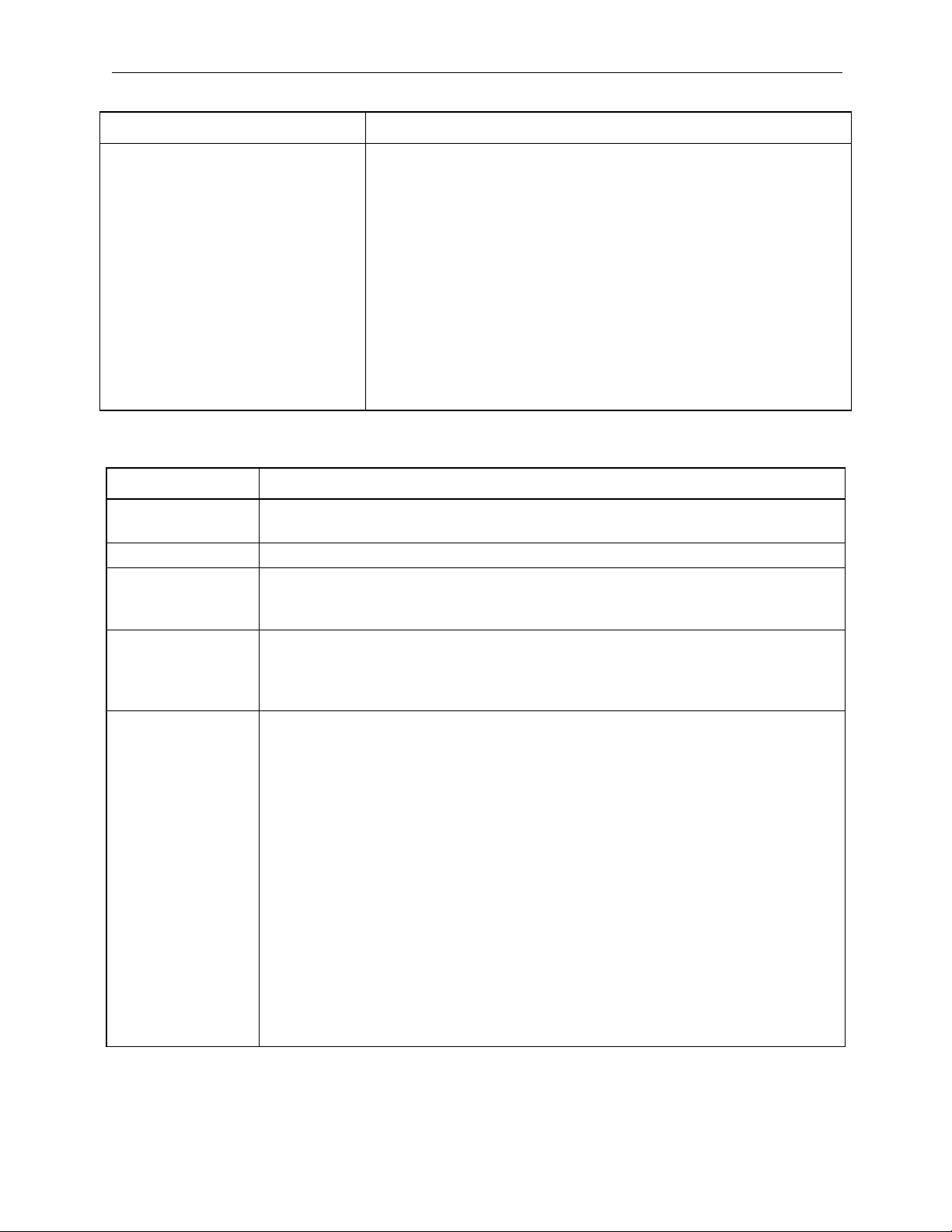

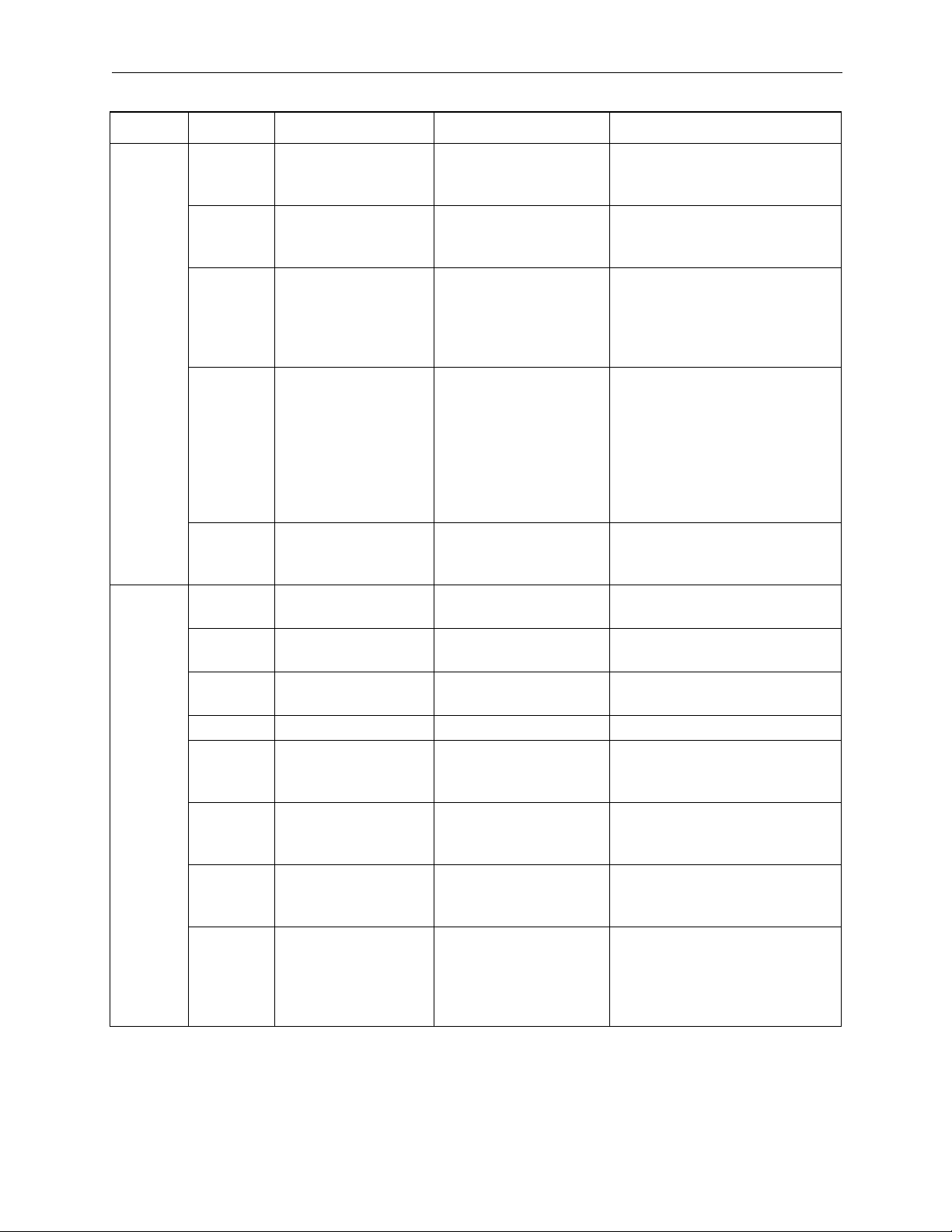

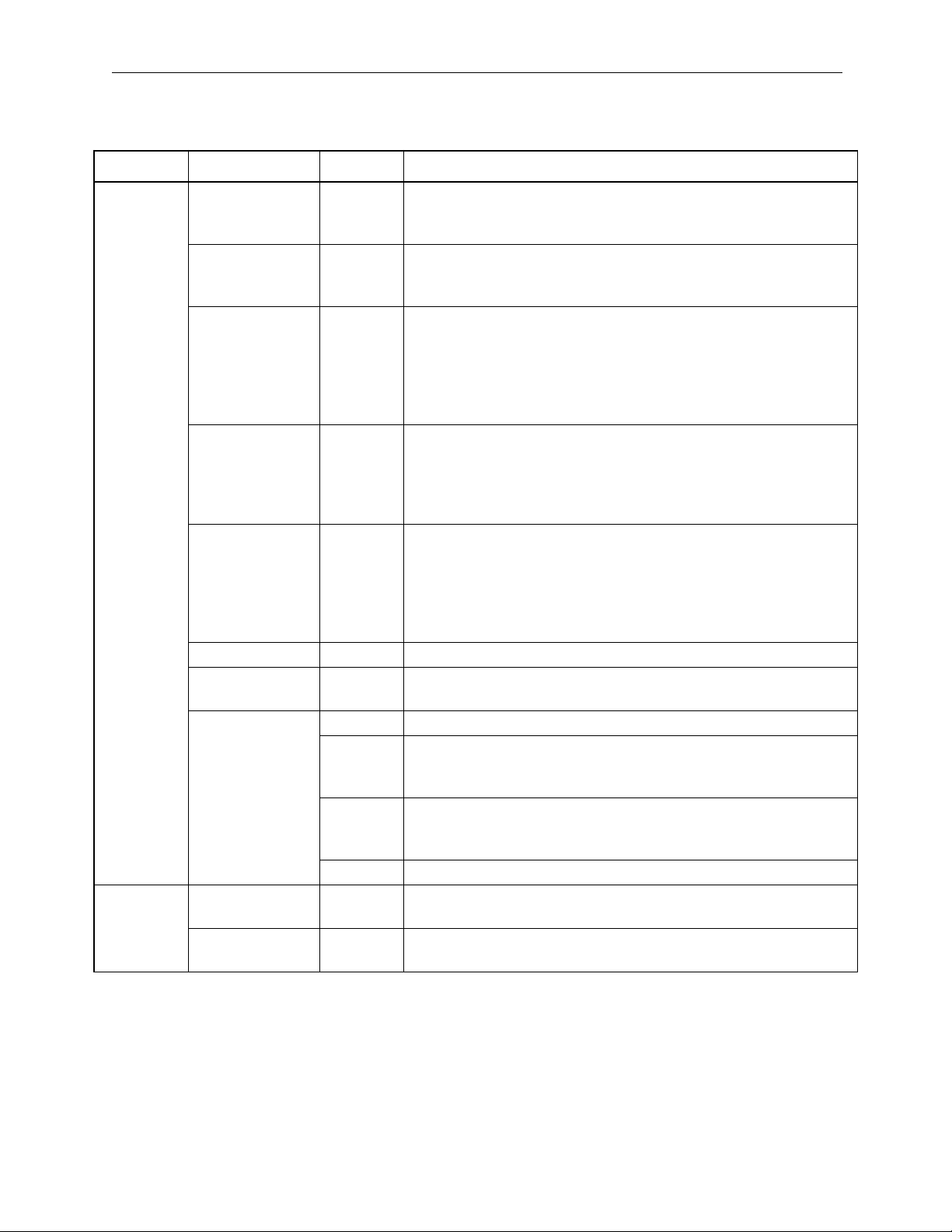

Function Module Content

MP940 CPU

SERIAL Serial communication RS-232C, RS-422/485

LIO Control I/O, DI 8points, DO 8points, AO 1CH

SVA Motion function

CNTR Counter function

MLINK or DeviceNet Mechatrolink I/F function or DeviceNet I/F function

M

PG

AI

SGDH MP940

Current Control

Counter

Speed Control

A/D

DPRAM or Global Memory

Programming Device

Figure 1.2: MP940 Functions

SVA

RS-232C

.

SERIAL

RS-422/485

MP940

CPU

MLINK

or

DeviceNet

MLINK

Device 1

DeviceNet

Local

I/O

or

DI

DO

AO

AI

CNTR

MLINK

Device 2

1-2

Page 8

MotionSuite™ MP940 Machine Controller Reference Manual Outline of the MP940

Synchronized controller and servo amplifier

High-speed/high-prescision control is possible because the controller and

SGDH servo amplifier are bus connected. There is no lag in startup or

monitor time, and execution is accomplished in perfect synchronization.

The control period settings can be set to the following periods:

500 µs, 1 ms, 2 ms 4 ms

Reduced wiring/Smaller size

The combination controller/servo amplifier result in wiring reduction and

space savings.

Variety of motion control modes, including:

• Positioning, linear interpolation motion program commands

• High-speed processing position/synchronous phase/speed control/torque

control

• Excellent for electronic shaft and electronic gear applications

The four control modes (speed, synchronous phase, torque, and position) are

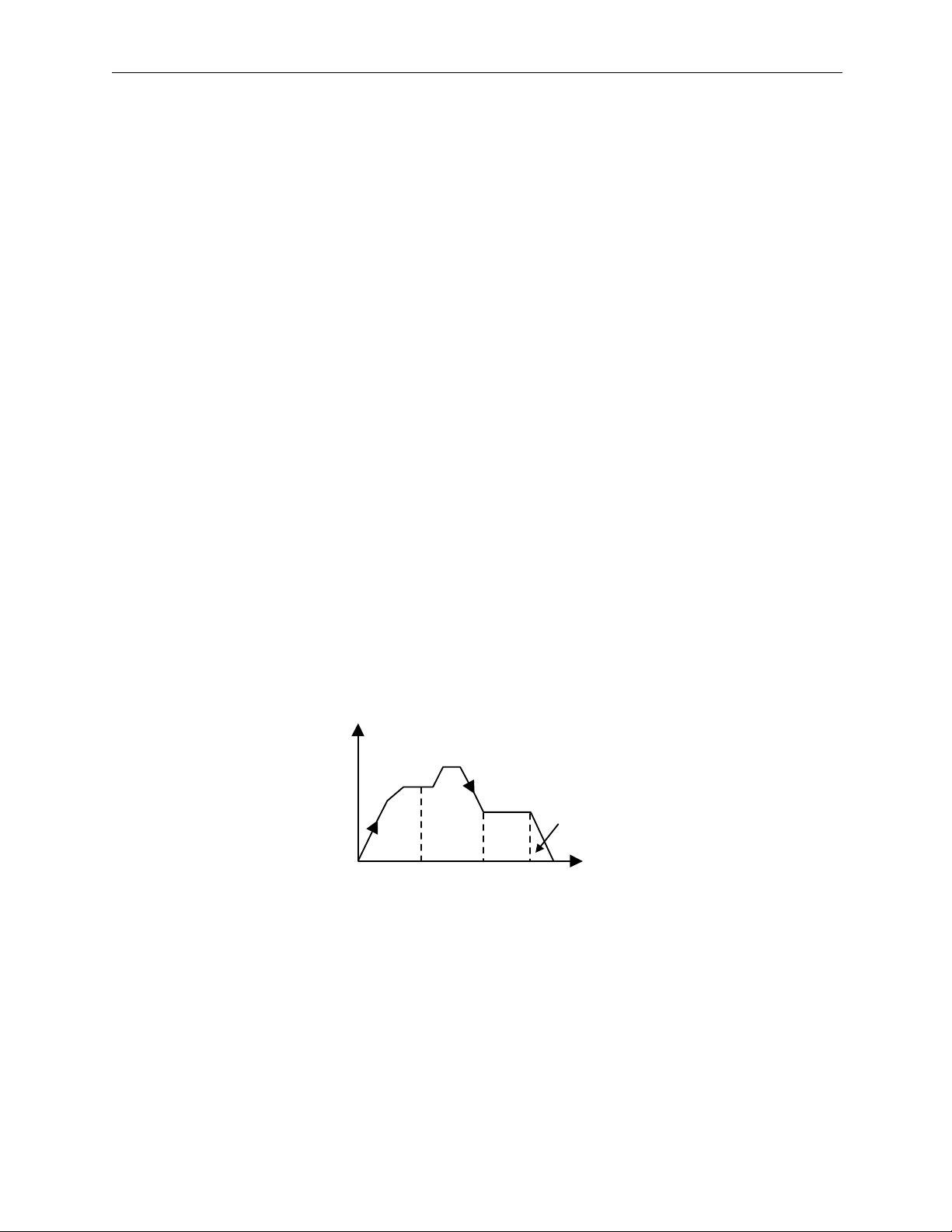

illustrated below..

V

Synchronous

Speed

Phase

Torque

Position

T

Figure 1.3 Four Control Modes

1-3

Page 9

Outline of the MP940 MotionSuite™ MP940 Machine Controller Reference Manual

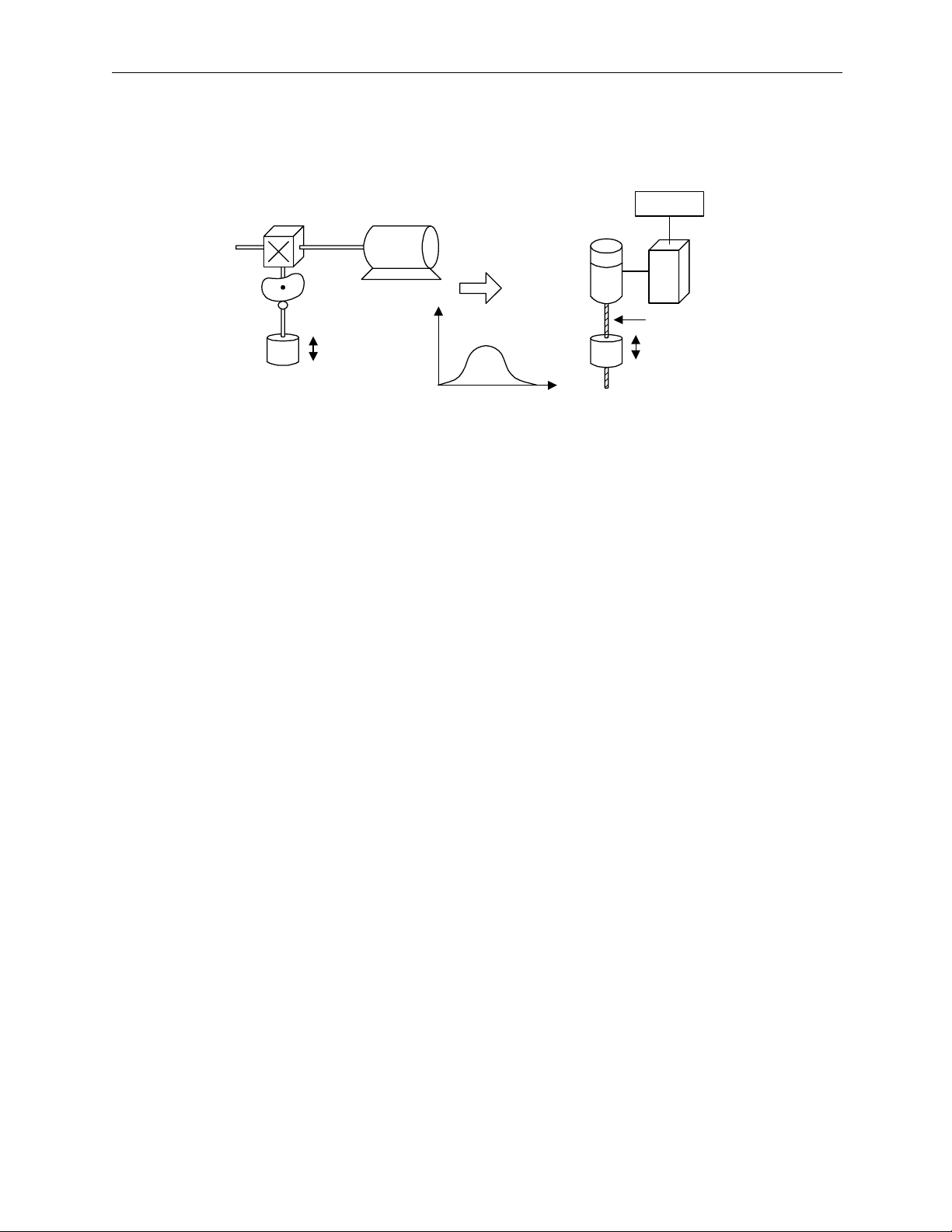

The following figure provides an example of a synchronous phase control

application.

MP920

Servo

Motor

X

Į

Servo

Amp.

Ball Screw

Figure 1.4: Electronic Camming

High-precision synchronous control

User parameter change is executed at high speed for monitor and servo

amplifier data. High-precision synchronous control is possible through the

READ/WRITE function of this data in both ladder and motion programs.

• Mode switching during operation

Switching between position control, torque control, speed control, and

synchronous phase control is possible during operation.

1-4

Page 10

MotionSuite™ MP940 Machine Controller Reference Manual Outline of the MP940

• Run commands

P/PI switching, external torque limit, and speed limit during torque control can be commanded from the MP940 during operation.

• READ/WRITE function of servo amplifier user parameters

User parameters such as Servo Amplifier Position Loop Gain, Speed

Loop Gain, Speed Loop Integral Time Constant, etc. may be modified

during operation.

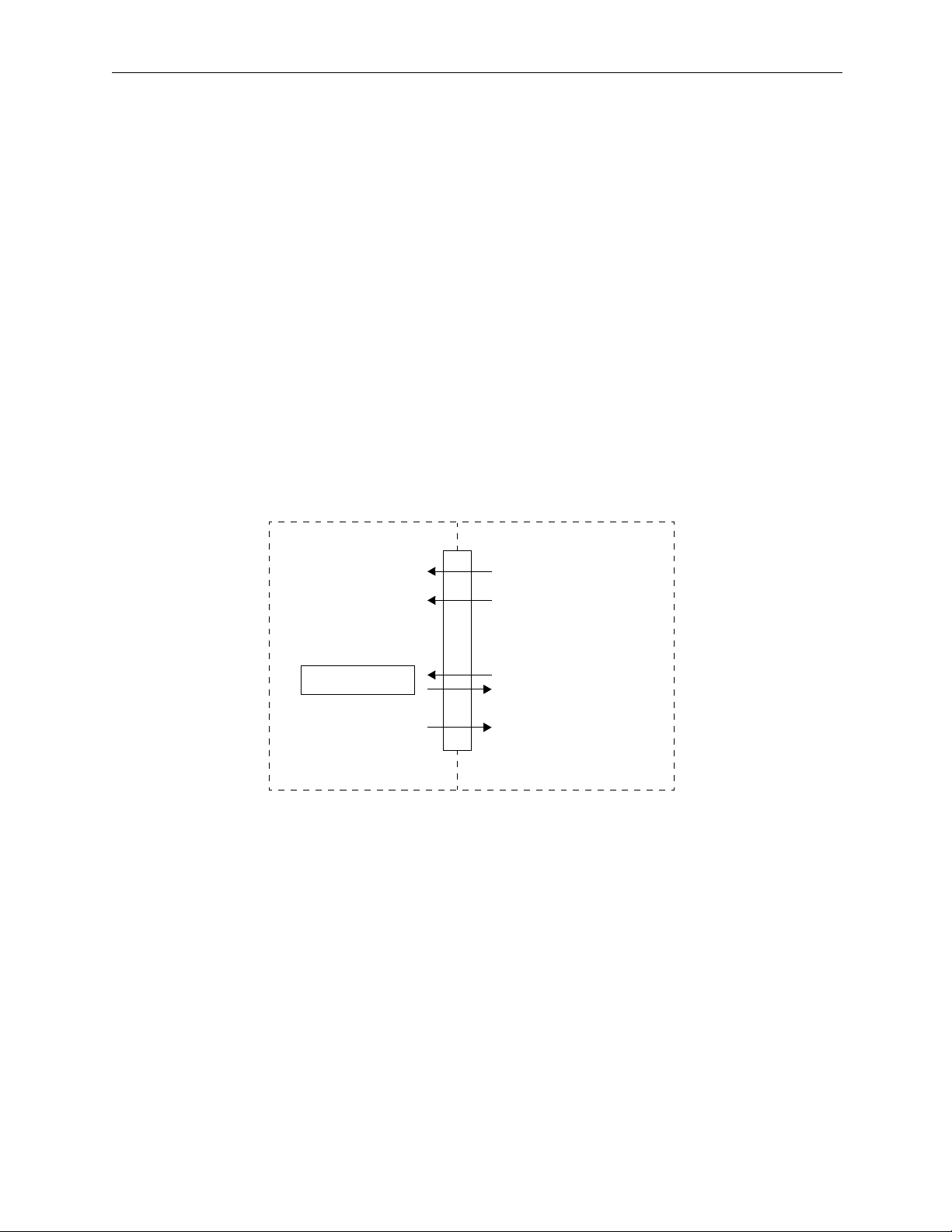

• Position data monitor

The various position data, reference speed, speed monitor, and external

encoder data can be referenced at high speed within the program, as

depicted below.

SGDH MP940

Global Memory or DPRAM

Speed Torq ue

Speed reference

Torque reference

Tor q ue li m it

Speed P/PI

Switching

User parameter

Various monitor data

• Position

• Speed

• Torque

Figure 1.5: Position data monitor

Mode switching command

Various run commands

User parameter

READ/WRITE

Monitor data reference

1-5

Page 11

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Chapter 2: Specifications

This chapter describes the general specifications and functions of the MP940.

Specifications and Functions

This section describes the general specifications and functions of the MP940.

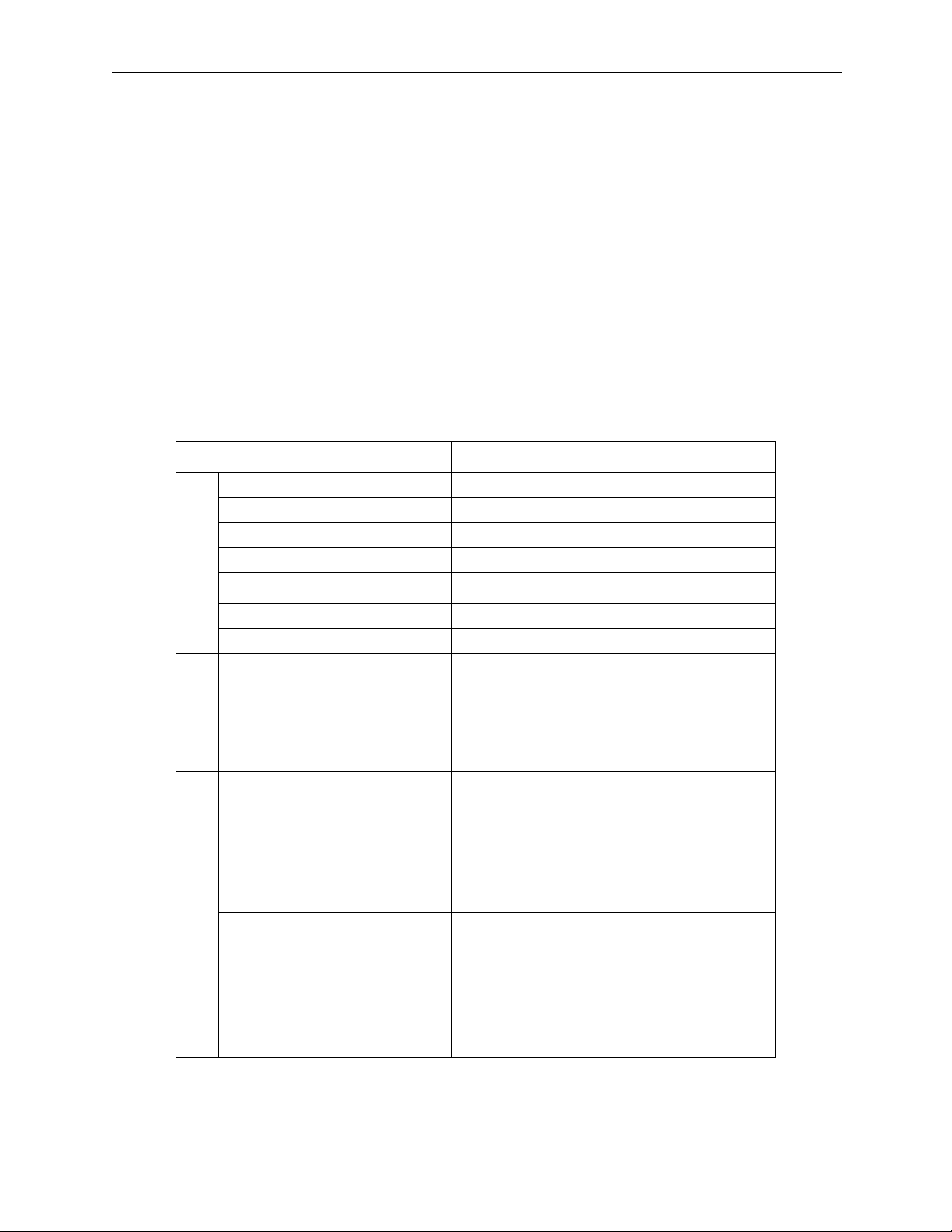

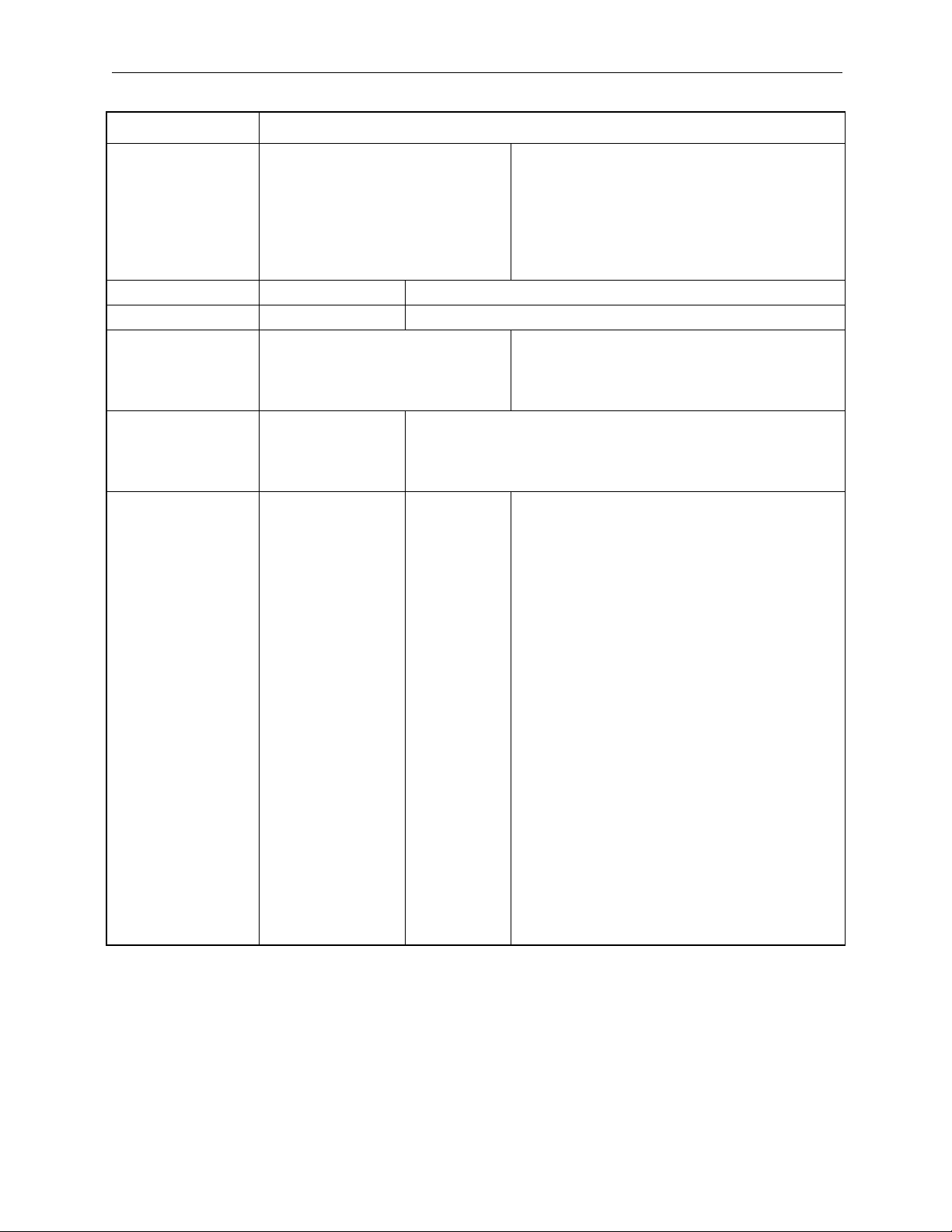

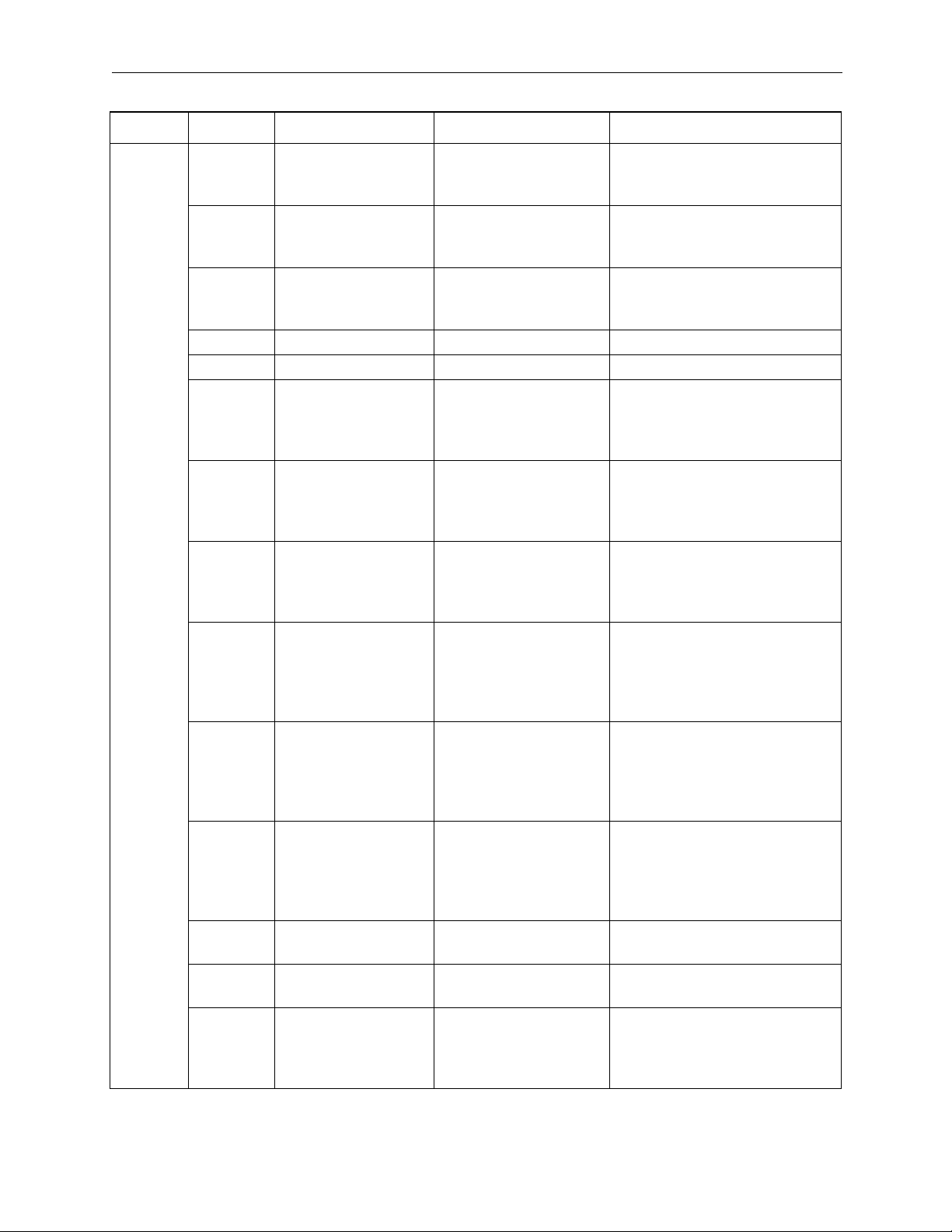

General Specifications

Item Specification

Ambient Usage Temperature 0 ~ +55ºC

Storage Temperature -20 ~ +85º

Ambient Usage Humidity 30 ~ 95% RH (no condensation)

Ambient Storage Temperature 5 ~ 95% RH (no condensation)

Pollution Level JIS B3501 standard pollution level 1

Corrosion Resistance No flammable or corrosive gas

Physical Environment

Usage Altitude less than 2000M above sea level

Noise Resistance JIS B3502 standard

Normal Mode 1500Vp-p

Common Mode 1500Vp-p

Pulse Width 100ns/ 1

Characteristics

Electrical Drive

Vibration Resistance JIS B3502 standard

Characteristics

Mechanical Drive

Shock Resistance JIS B3502 standard

Grounding

Cooling Method

Ground

Conditions

Boot-up time 1ns

(according to noise simulator)

Vibration Amplitude/Acceleration :

10

≤ f<57Hz Half-wave Amplitude 0.075mm

≤ f ≤150Hz set acceleration 9.8m/s

57

Scan in each of the X, Y, Z directions (1

octave/ min.)

× Number of scans 10

Peak Acceleration 147m/s

Twice in each direction ( X, Y, and Z)

Class 3 Grounding

Natural Cooling

2

2

work time 11ms

2-1

Page 12

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

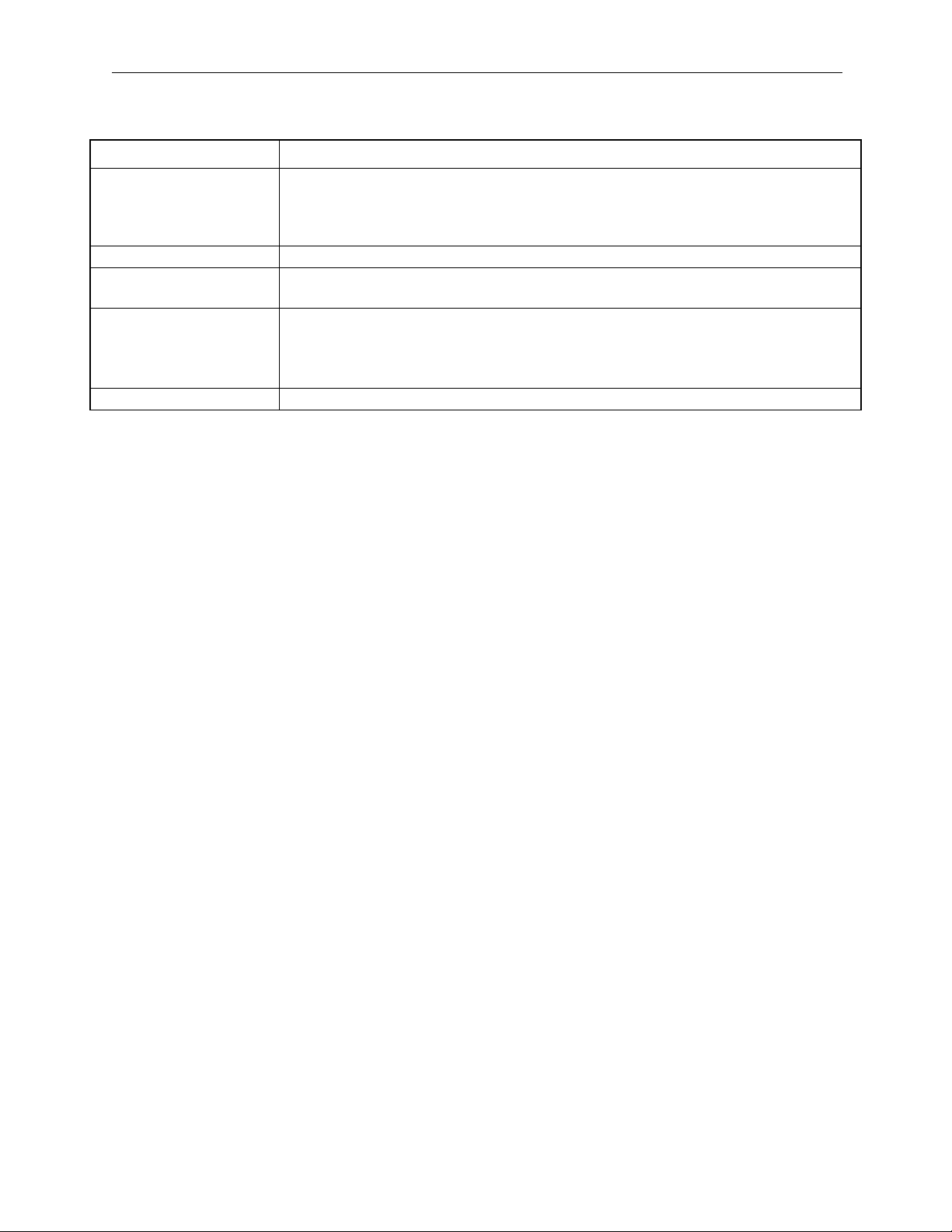

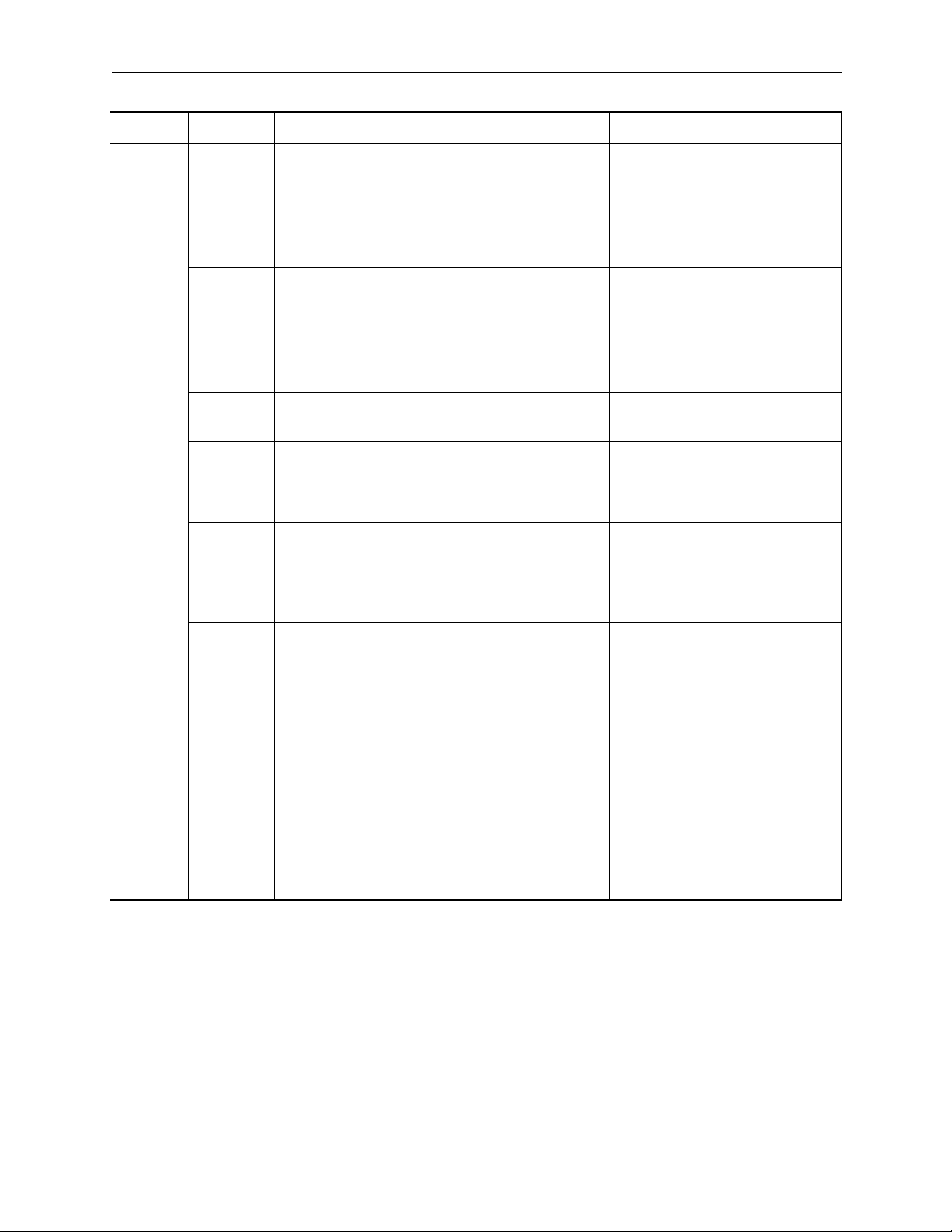

Hardware Specifications

Hardware Specifications

Item Specification

Name MP940 (Mechatrolink) MP940D (DeviceNet)

Model JEPMC-MC400 JEPMC-MC410

Memory FLASH 2MB

SRAM 2MB (battery backup)

Communication Port 1 RS-232C Port (Port1)

Baud Rate Setting 9.6k/19.2kbps

MDR-14 (dedicated pin assignment)

Protocol

• Memobus

• No Protocol

• Melsec Communication

1 RS-422/485 Port (Port2)

Baud Rate Setting 9.6k/19.2kbps

MDR-14 (dedicated pin assignment)

Protocol

• Memobus

•

No Protocol

• Melsec Communication

Network Baud rate: 4Mbps

Cycle: 1ms, 2ms, 4ms

Maximum # of Slaves: 6 @ 1ms, 14 @

2ms, 29 @4ms

Display LEDs Status Display LEDs

READY (Green)

RUN (Green)

ALM (Red)

BATALM (Red)

PRT1 (Green)

PRT2 (Green)

Mechatrolink Operation Display LEDs

RX (Green)

TX (Green)

Setting Switches DIP switches for mode setting

RUN/STOP

INITIAL

TEST

FLASH

PP_INIT

MREG_CPY

Baud rate: 125Kbps, 250 Kbps, 500Kbps

Mode: Slave

Node: 63 maximum

DeviceNet operation display LEDs

M9 (Red/Green)

N9 (Red/Green)

2-2

Page 13

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Hardware Specifications (Continued)

Item Specification

DeviceNet Setting Switch — DR0.DR1: Baud rate

DR0 DR1

OFF OFF 125Kbps

OFF ON 250Kbps

ON OFF 500Kbps

ON ON Do not use

X1: Slave/Master

X2: Reserved

Input Signals Number of Inputs: 8/Common

Input Type: Combined sink/source

Input Type: Type 1 (JIS-B3501)

Insulation Type: Photocoupler Insulation

Base Voltage: 17.4VDC ~ 28.8VDC

35VDC (at peak)

Rated Current: 5.3mA

Input Impedance: approximately 4.4kΩ

Operating Voltage: ON Voltage 15VDC or higher

OFF Voltage 5VDC or less

OFF Current: 0.9mA or less

Response Time: OFF

ON

Output Signals Number of Outputs: 8/Common

Output Type: Sinking Output

Output Type: Transistor Output

Insulation Type: Photocoupler Insulation

Load Voltage: 19.2 ~ 28.8V

35VDC (at peak)

Load Current: 0.1A/Circuit 0.8A/Common

ON Voltage: 1.0V or less

External Source Voltage: 24V

15mA

Output Protection:1 common fuse

Fuse Rating:1.5A (Fusing Time: 5s or less at 3A)

Response Time: OFF

ON

ON 0.5ms or less

OFF 1.5ms or less

DC

±20%

DC

ON 0.25ms or less

OFF 1ms or less

2-3

Page 14

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Hardware Specifications (Continued)

Item Specification

Pulse Input Pulse Input Circuit: 5V Deviation 1MHz input maximum

Pulse Input Circuit: A/B phase input (1×, 2×, 4× multiples can be selected)

AB Format, Sign Format, Add/Subtract Format

Pulse Counter Latch: (the external signal can be switched between 5V/12V/24V)

Analog Input SGDH Servo Amplifier

Analog Output Resolution:16-bit

Output Range: 0 ~ 10V

Power Input Input Signal: 24VDC ±20% (19.2VDC ~ 28.8VDC)

Input Current: 0.4A

Fuse Rating: 1.5A

Safety Criteria: UL, CSA standard

External Dimensions W44mm H142mm D128mm

2-4

Page 15

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

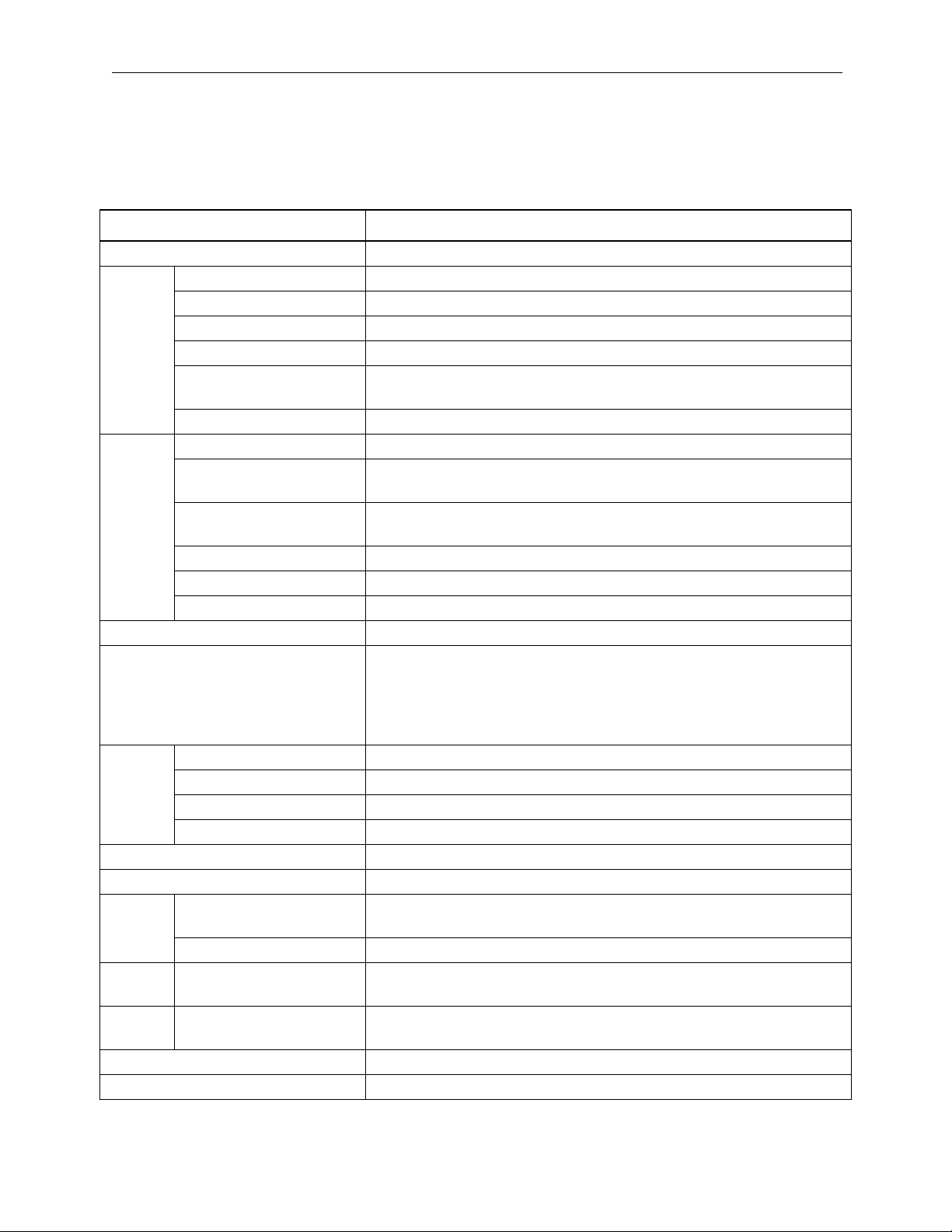

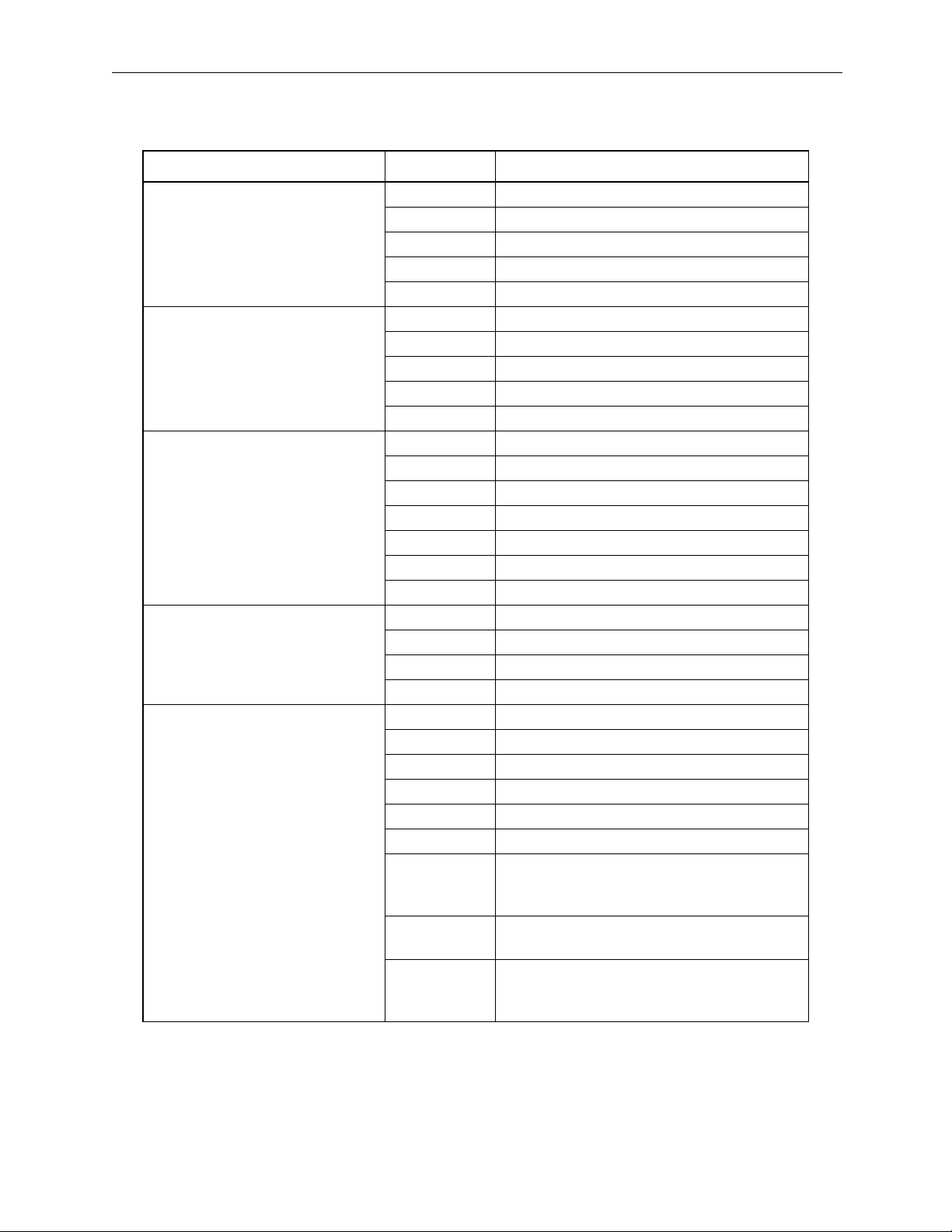

Function List

MP940 Motion Control Function Specificationss

Item Specification

Number of Control Axes 1

PTP Control Linear, Rotary, Unlimited

Interpolation Linear

Speed Reference Output Yes

Torque Reference Output Yes

Position Control Positioning, External Positioning, Zero-point Return, Interpolation,

Interpolation with position detection function, set feed speed, stepping

Phase Control Yes

Contour Specifications

Command Unit mm, inch, degree, pulse

Minimum Command Set-

ting Unit

Maximum Command

Value

Speed Reference Unit mm / min., inch / min., deg / min., pulse / min.

Position Control

Acceleration Type Linear, Asymmetric, S-curve

Override Function 0.01 ~ 327.67%

Coordinates Linear Coordinates

Zero-point Return 8 Types

Language Dedicated motion language ladder

Number of Tasks A maximum of 8 parallel programs can be simultaneously executed.

Number of Programs 32 maximum

Properties

Program Capacity 80kb

Applied Servo Amplifier Analog Type: SGDH-**AE

Encoder Incremental/Absolute

Speed

Control

Speed Reference -327.68 ~ +327.67 %/Rated Speed

Acceleration Type Linear, asymmetric, S-curve (motion average)

Torque

Control

Phase

Control

Torque Reference -327.68 ~ +327.67 %/Rated Torque

Speed Reference Unit -327.68 ~ +327.67 %/Rated Speed

Speed Correction -327.68 ~ +327.67 %/Rated Speed

Position Correction -2147483648 ~ +2147483647 pulses

1, 0.1, 0.01, 0.001, 0.0001, 0.00001

-2147483648~+2147483647 (with 32-bit sign)

1. DEC1+C phase 5. DEC1+ZERO

2. DEC2+C phase 6. DEC2+ZERO

3. DEC1+LMT 7. DEC1+LMT+ZERO

4. C-phase 8. ZERO

With torque limit function

With speed limit function

2-5

Page 16

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Item Specification

Command Language Axis Motion Commands 5

MOV, MVS, ZRN, SKP, EXM

Basic Control Commands 5

ABS, INC, POS, MVM, PLD

Speed, Accel/decel commands 8

ACC, DCC, SCC, VEL, IAC, IDC, IFP, FMX

Upper-level Control Commands 4

PFN, INP, SNG, UFC

Control Commands 10

MSEE, TIM, IOW, END, RET, EOX, IF, ELSE, IEND, WHILE WEND,

SFORK, JOINTO, SJOINT

Operations/Sequence Control Commands 32

=, +, -, *, /, MOD, |, ^, &, !, (), S{}, R{}, SIN, COS, TAN, ASN, ACS,

ATN, SQRT, BIN, BCD, ==, <>, >, <, >=, <=, SFR, SFL, BLK, CLR

PLC Function Specifications

Item Specification

Program Capacity For every 2k steps (varies according to the size of the motion program. 40k steps

maximum)<H>

Control Format Sequence: Scan Format

Program Language CP Code

Ladder Diagram: Relay Circuit

Text-type language: Numerical operations, logical operations, etc.

Scan Servo Control Scan Time Setting: 0.5 / 1.0 / 2.0 / 4.0 ms

High-speed Scan Time Setting: 0.5 ~ 32.0ms (0.01ms units) S scan integer multiples

Low-speed Scan Time Setting: 2.0 ~ 200.0ms (0.01ms units) S scan integer multi-

ples

User Diagrams

Functions, Motion

Programs

Start Drawing (DWG.A):Maximum of 4 drawings, with up to 3 layers per drawing

System Scan Drawing (DWG.S): Maximum of 16 drawings, with up to 3 layers per

drawing

High-speed Scan

Drawing (DWG.H)

:Maximum of 16 drawings, with up to 3 layers

per drawing

Low-speed Scan

Drawing (DWG.L)

Interrupt Drawing (DWG.I)

Number of steps

User Functions

Motion Programs

Drawing, Motion Program Modification History

Drawing, Motion Program Secure Holding Function

2-6

:Maximum of 32 drawings, with up to 3 layers

per drawing

:Maximum of 8 drawings, with up to 3 layers per

drawing

:Maximum 500 steps/drawing

:Maximum 32 functions

:Maximum 32

Page 17

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

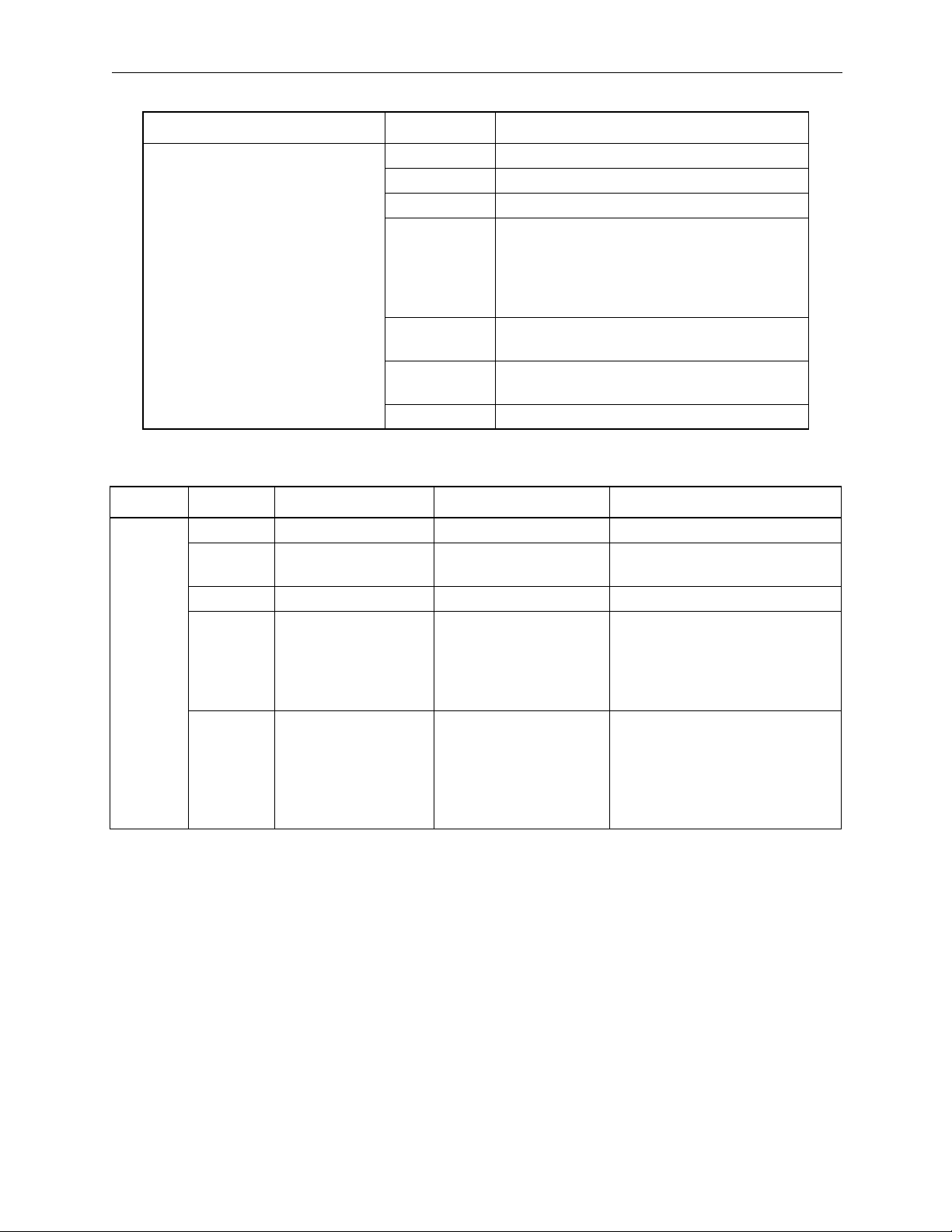

Item Specification

Data Memory Global Data (M) Register

System (S) Register

DWG Local (D) Register

DWG Setting (#) Register

Input (I) Register

Output (I) Register

Constant (C) Register

Trace Memory Data Trace :4k words (4k words × 1 group)

Memory Backup Program Memory :CMOS Battery Backup

Data Type Bit (Relay)

Integer

Double-length Integers

Real Numbers

Register Attribute Register Number

Designation

Symbol Designa-

tion

Command Lan-

guage

Program Control

Commands

During Direct I/O

Commands

Relay Circuit Com-

mands

Logical Operation

Commands

Numerical Opera-

tion Commands

Numerical Conver-

sion Commands

Numerical Compar-

ison Commands

Data Operation

Commands

Basic Function

Commands

Display Data Oper-

ation Commands

DDC Commands

System Functions

: Direct Register Number Designation

: A maximum of 8 alphanumeric characters. (

200 symbols/DWG maximum) Autonumbering and autosymbols available

:14

: 2

:14 (including

set, reset

coils)

: 3

:16

: 9

: 7

:14

:10

:11

:13

:9

: 32 kwords

: 1 kwords

: Maximum 16 words/DWG

: Maximum 16 words/DWG

: 2 kwords (including internal input register)

: 2 kwords (including internal output register)

: 32 kwords

: ON/OFF

: -32768 ~ +32767

: -2147483648 ~ 2147483648

: ±(1.175E-38 ~ 3.402E+38)

Command Language

2-7

Page 18

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Motion Command List

Command Language Types Commands Function

Axis Motion Commands MOV Positioning

MVS Linear Interpolation

ZRN Zero-point return

SKP Skip command

EXM External Positioning

Basic Control Commands ABS Absolute mode

INC Incremental mode

POS Current Variation

MVM Machine Coordinate Designation

PLD Program Current Position Update

Speed/Acceleration Commands ACC Acceleration Time Change

SCC S-curve Parameter Change

VEL Feed Speed Change

IAC Interpolation Acceleration Time Change

IDC Interpolation Deceleration Time Change

IFP Interpolation Feed Speed Ratio Setting

FMX Interpolation Feed High-speed Setting

Upper-level Control Commands PFN In-position Check

INP 2nd in-position check

SNG Ignore Single Block

UFC User Function Call-out

Control Commands MSEE Sub-program Call-out

TIM Timed Wait

IOW I/O Variable Wait

END Program Close

RET Sub-program Close

EOX 1 scan WAIT command

IF

ELSE

IEND

WHITE

WEND

SFORK

JOINTO

SJOINT

Branching Commands

Repetition Commands

Selection Execution Commands

2-8

Page 19

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Command Language Types Commands Function

Sequence Commands = Replacement

+, -, ×, /, MOD Numerical Operations

|, ^, &, ! Logical Operations

SIN, COS,

TAN, ASN,

ACS, ATN,

SQRT, BIN,

BCD

==, <>, >, <,

>=, <=

SFR, SFL,

BLK, CLR

(), S{}, R{} Other

Function Commands

Numerical Comparison Commands

Data Operation

Motion Command List

Type Command Name Command Format Function/Meaning

MOV Positioning MOV [axis1]—; * Executes fast feed positioning.

MVS Linear Interpolation MVS [axis1]—F; Executes linear interpolation at

interpolation feed speed F.

ZRN Zero-point return ZRN [axis1] ; Returns to zero-point.

SKP Skip Command SKP [axis1]SSF; When turned on during linear

interpolation execution, the

machine skips the remaining

motion and proceeds onto the

next block.

EXM External Positioning EXM [axis1] D; Upon input of an external posi-

Axis Motion Commands

tioning signal during positioning

execution, the machine pro-

ceeds to the next block after

positioning only in increments of

the motion designated in “D”.

2-9

Page 20

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Command Name Command Format Function/Meaning

ABS Absolute mode ABS; The following coordinate

expressions are handles as

absolute values.

INC Incremental mode INC: The following coordinate

expressions are handles as

incremental values.

POS Current Variation POS [axis1]; Changes the current value to a

desired coordinate.Subsequent

motion commands execute

motion on the basis if the new

coordinates.

MVM Machine Coordinate

Command

Basic Control Commands

PLD Program Current

Position Update

ACC Acceleration Time

Change

DCC Deceleration Time

Change

SCC S-curve Parameter

Change

VEL Feed Speed Change VEL [axis1] ; Sets feed speed.

IAC Interpolation

Acceleration Time

Change

IDC Interpolation

Deceleration Time

Change

IFP Interpolation Feed

Speed Ratio Setting

Speed/Accel/Decel Commands

FMX Interpolation Feed

High-speed Setting

MVM MOV [axis1];

or

MVM MVS [axis1];

PLD [axis1] ; Updates the current position of

ACC [axis1]; Sets the acceleration time for

DCC [axis1]; Sets the deceleration time for

SCC [axis1]; Sets parameters during motion

IAC T; Sets acceleration time for linear

IDC T; Sets deceleration time for linear

IFP P; Executes speed designation

FMX T; Sets the maximum speed during

These commands are issued

when motion is desired based

on the machine coordinate.The

coordinates automatically set at

zero-point return completion are

called the machine coordinates.These coordinates are not

affected by POS commands.

a program shifted by manual

feed, etc.

linear acceleration

linear acceleration

average accel/decel.

accel/decel during interpolation

motion.

accel/decel during interpolation

motion.

during interpolation feed in % of

maximum speed.

interpolation feed.

This is the time taken in interpolation acceleration to go from

zero to this speed.

2-10

Page 21

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Type Command Name Command Format Function/Meaning

/ Division MW = MW / MW;

MW = MW / 123456;

MW = 123456 / MW;

MOD Modulus MW = MW / MW;

MW = MOD;

| OR (Logical OR) MB = MB | MB;

MB = MB | 1;

MW = MW | MW;

MW = MW | H00FF;

^XOR

(Exclusive Logical

OR)

& AND (Logical AND) MB = MB & MB;

! NOT (Inversion) MB = !MB;

() Parentheses MW = MW— &

S{} Designated bit ON S{MB} = MB & MB; The designated bit goes ON if

Sequence Commands

R{} Designated bit OFF R{MB} = MB & MB; The designated bit goes OFF if

SIN Sine SIN(MW)

COS Cosine COS(MW)

TAN Tangent TAN(MF)

ASN Arc Sine ASN(MF)

MW = MW ^ MW;

MW = MW ^ H00FF;

MB = MB & 1;

MW = MW & MW;

MW = MW & H00FF;

MB = !1;

MW = !MW;

MW = !H00FF;

(MW— | MW—);

;SIN(90);

;COS(90);

;TAN(45.0);

;ASN(90.0);

Executes integer/real number

division.Operates as real numbers when integers and real

numbers are intermixed.

MOD is stored as a modulus

into a designated register when

designated in the next block of

the modulus.

Creates a logical OR in bits or

integers.

Creates an exclusive logical OR

in integers.

Creates a logical AND in bits or

integers.

Creates an inverse value in bits.

Logical operations within parentheses have priority.

the logical operation result is

“Valid”.The designated bit goes

OFF when the result of a logical

operation is “Invalid”.

the logical operation result is

“Valid”.The designated bit goes

ON when the result of a logical

operation is “Invalid”.

Obtains the sine in integers/real

numbers (deg), and returns a

real number value.

Obtains the cosine in integers/

real numbers (deg), and returns

a real number value.

Obtains the tangent in real numbers (deg), and returns a real

number value.

Obtains the arc sine in real numbers, and returns a real number

value.

2-11

Page 22

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Command Name Command Format Function/Meaning

ACS Arc Cosine ACS(MF)

;ACSi_90.0);

ATN Arc Tangent ATN(MW)

;ATNi_45j_;

SQT Square Root SQT(MW)

;SQT(100);

BIN BCD¨_BIN BIN (MW); Converts BCD data to BIN data.

BCD BIN¨_BCD BCD (MW); Converts BIN data to BCD data.

== Coincidence IF MW == MW;

WHILE MW == MW ;

<> Non-coincidence IF MW <> MW;

WHILE MW <> MW;

> Larger than IF MW > MW;

WHILE MW > MW;

< Smaller than IF MW < MW;

WHILE MW < MW;

Sequence Commands

>= Equal to or greater

than

<= Equal to or less than IF MW <= MW;

SFR Right Shift SFR MB N W; Shifts the word variables to the

SFL Left Shift SFL MB N W; Shifts the word variables to the

BLK Block Transfer BLK MW MW W; Treats a designated bit (word)

IF MW >= MW;

WHILE MW >= MW;

WHILE MW <= MW;

Obtains the arc cosine in real

numbers, and returns a real

number value.

Obtains the arc tangent in integers/real numbers, and returns

a real number value (deg).

Obtains the square root in integers/real numbers (deg), and

returns a real number value.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

and right sides coincide.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

and right sides do not coincide.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

side is larger than the right side.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

side is smaller than the right

side.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

side equal to or greater than the

right side.

Used in the IF or WHILE condition formula.The formula is

assumed to be “Valid” if the left

side equal to or less than the

right side.

right by an exponent.

left by an exponent.

variable as opened, and executes transfer by block (parameter designation) unit.

2-12

Page 23

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Type Command Name Command Format Function/Meaning

CLR Clear CLR MB W; The parameter designator num-

ber goes OFF (0) for a variable

group in which the designated

bit (word) variables are

assumed to be started.

MSEE Sub-program Call-out MSEE MPS ; Executes MPS sub-program.

TIM Timed Wait TIM T; Waits for the time designated in

“T”, and proceeds to the next

block.

IOW I/O Variable Wait IOW MB == ∗∗∗; Stops motion control program

execution until the conditional

formula is satisfied.

END Program Close END; Closes the motion program.

RET Sub-program Close RET; Closes the sub-program.

EOX 1 scan WAIT com-

mand

EOX; This command is for cutting into

a continuing sequence com-

mand during operation, and

forcing a single scan wait.

(Process 1) is performed if the

conditional formula is satisfied,

and (process 2) if it is not.

Control Commands

IF

ELSE

IEND

Branching Commands

IF (conditional formula);

(process 1)

ELSE;

(process 2)

IEND;

WHILE

WEND

SFORK

JOINTO

SJOINT

Repetition Commands

Selection Execution

Commands

WHILE (conditional

formula);

•••

WEND;

SFORK conditional formula 1? label 1,

conditional formula 2?

label 2, •••;

label 1: Process 1

JOINTO label

xlabel 2: Process 2

JOINTO label

xlabel •

•label x: SJOINT;

Repeats execution of

WHILE~WEND processing the

conditional formula is satisfied

and continues operating.

(Process 1) is performed if the

conditional formula 1 is satis-

fied, and (process 2) if condi-

tional formula 2 is satisfied.

The “—” symbol in MOV [axis1]— •••; signifies where the numerical data for [axis1] is recorded.

2-13

Page 24

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

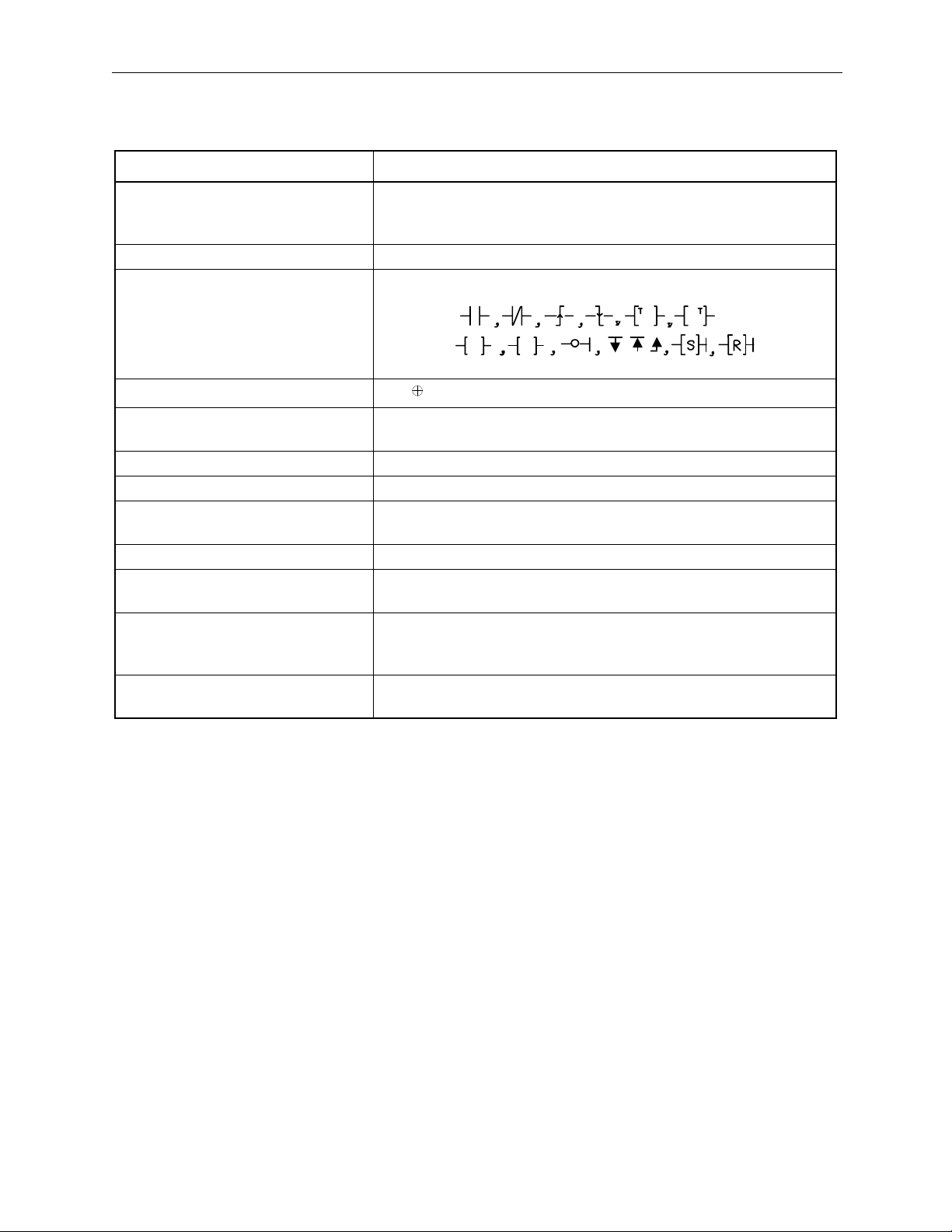

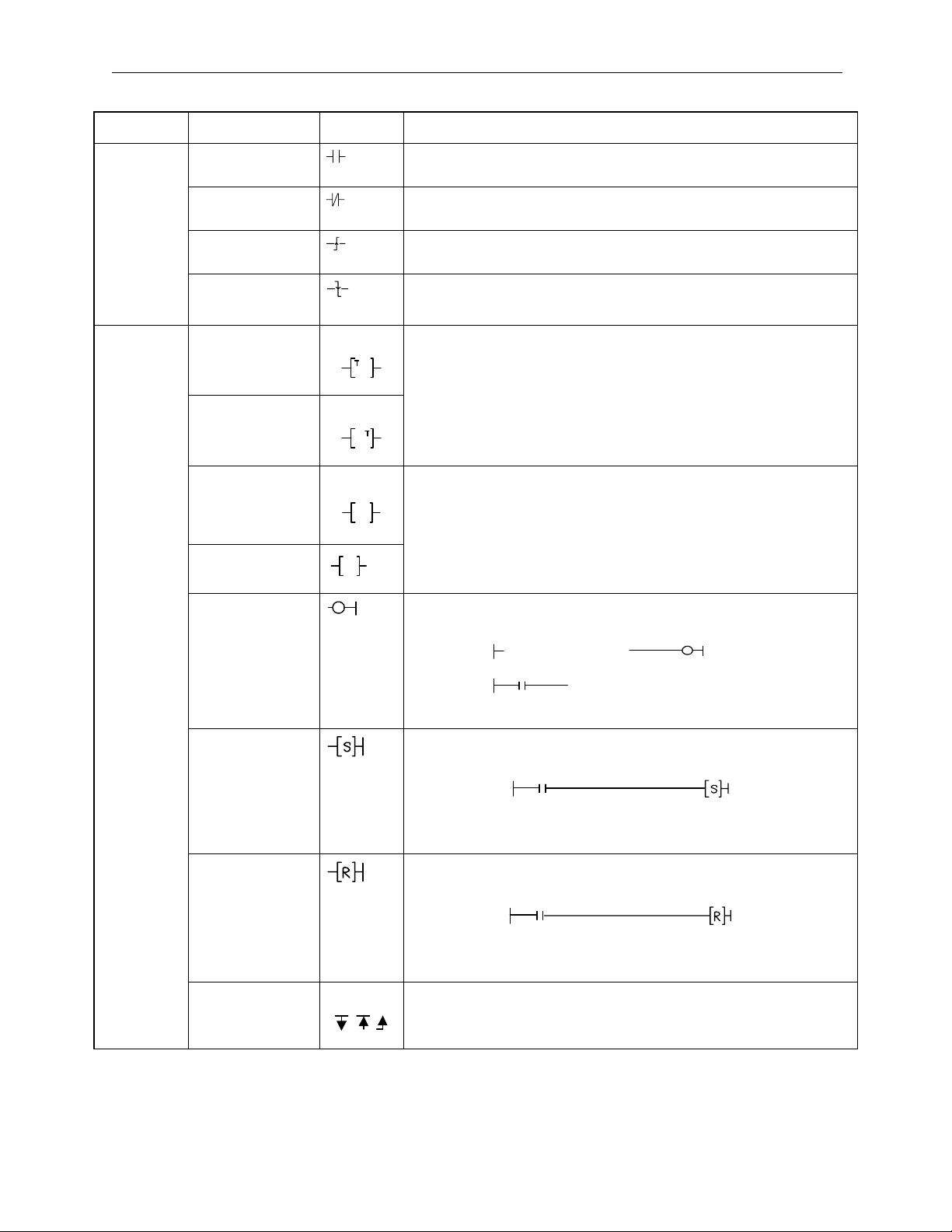

Ladder Command List

Command Language Types Symbol

Program Control Command SEE, FOR FEND, WHILE ON/OFF WEND

, IFON/IFOFF ELSE IEND, DEND

FSTART, FIN, FOUT, XCALL, comment

Direct I/O Commands INS, OUTS

Relay Circuit Commands

Ts

Ts

TsTs

Ts

Ts

TsTs

Logical Operation Commands

∧, ∨,

Numerical Operation Commands +, -, ++, --, ×, ÷, INC, DEC, MOD, REM,

TMADD, TMSUB, SPEND

Numerical Conversion Commands INV, COM, ABS, BIN, BCD, PARITY, ASCII, ASCBIN, BINASC,

Numerical Comparison Commands <,

≤, ≠, ≥, >, RCHK

Data Operation Commands ROTL, ROTR, MOVB, MOVW, XCHG, SETW, BETD, BPRESS,

BSRCH, SORT, SHFTL, SHFTR, COPYW, BSWAP

Basic Function Commands SQRT, SIN, COS, TAN, ASIN, ACOS, ATAN, EXP, LN, LOG

DDC Commands DZA, DZB, LIMIT, PI, PD, PID, LAG, LLAG,

FGN, IFGN, LAU, SLAU, PWM

Display Data Operation Commands TBLBR, TBLBW, TBLSRL, TBLSRC, TBLCL

TBLMV, QTBLR, QTBLRI, QTBLW, QTBLWI

QTBLCL

System Functions COUNTER, FINFOUT, TRACE, DTRC-RD, MSG-SND, MSG-

RCV

2-14

Page 25

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Ladder Command List

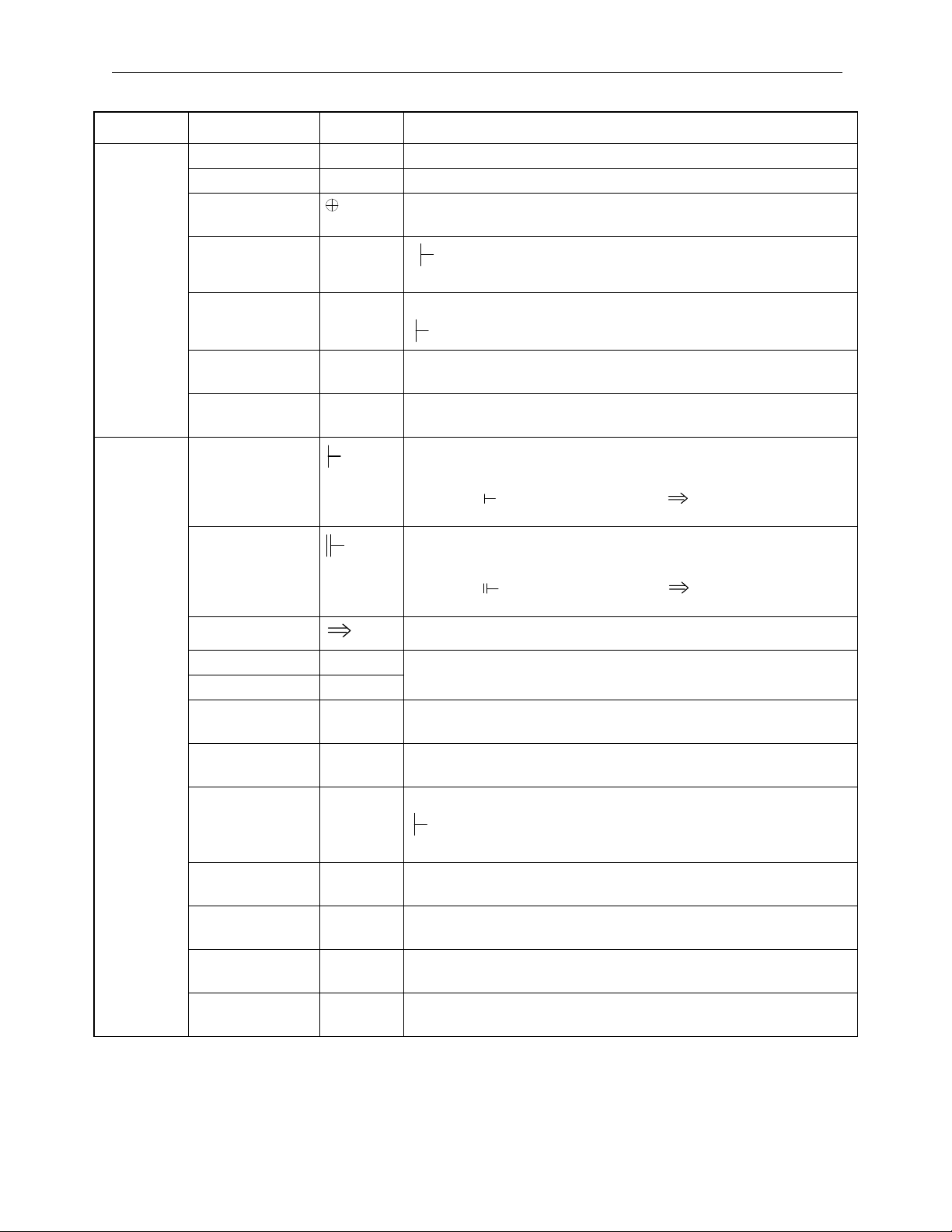

Type Name Symbol Content

Program Control Commands

Direct I/O

Commands

Sub-program

Reference

SEE After “SEE”, designate the sub-program, or sub-sub-program

number to be referenced.

SEE H01

Motion Drawing

Reference

MSEE After “MSEE”, designate the motion program number or status

work address to be referenced.

MSEE MPM001 DA00000

FOR expression FOR

:

:

FEND

Repeat Execution Expression 1

FOR V = a to b by c

V : Either integer register I or J may be designated as desired.

a, b, c :Any desired integer value can be designated (b>a>0,

c>0)

FEND:END of FOR command

WHILE

expression

WHILE

:

Repeat Execution Expression 2

WEND:END of WHILE-ON/OFF command

ON/OFF

:

WEND

IF expression IFON/

IFOFF

Execution expression with conditions

IEND:END of IFON/IFOFF command

:

ELSE

:

IEND

Drawing END DEND END of drawing (DWG)

Comments

“nnnnnnn” Characters surrounded by quotation marks (“ “) are treated as

comments.

Function I/F

FSTART Function Reference Command

FIN Function Input Command

Saves input data from a designated input register to the function

input register.

FOUT Function Output Command

Saves output data from a designated output register to the func-

tion output register.

XCALL Extended Program Reference Command

Input Commands INS INS MA00100 ————————|

Executes data input and storage by interrupt prohibit.

Output Commands

OUTS

OUTS MA00100 ————————|

Executes data setting and output by interrupt prohibit.

2-15

Page 26

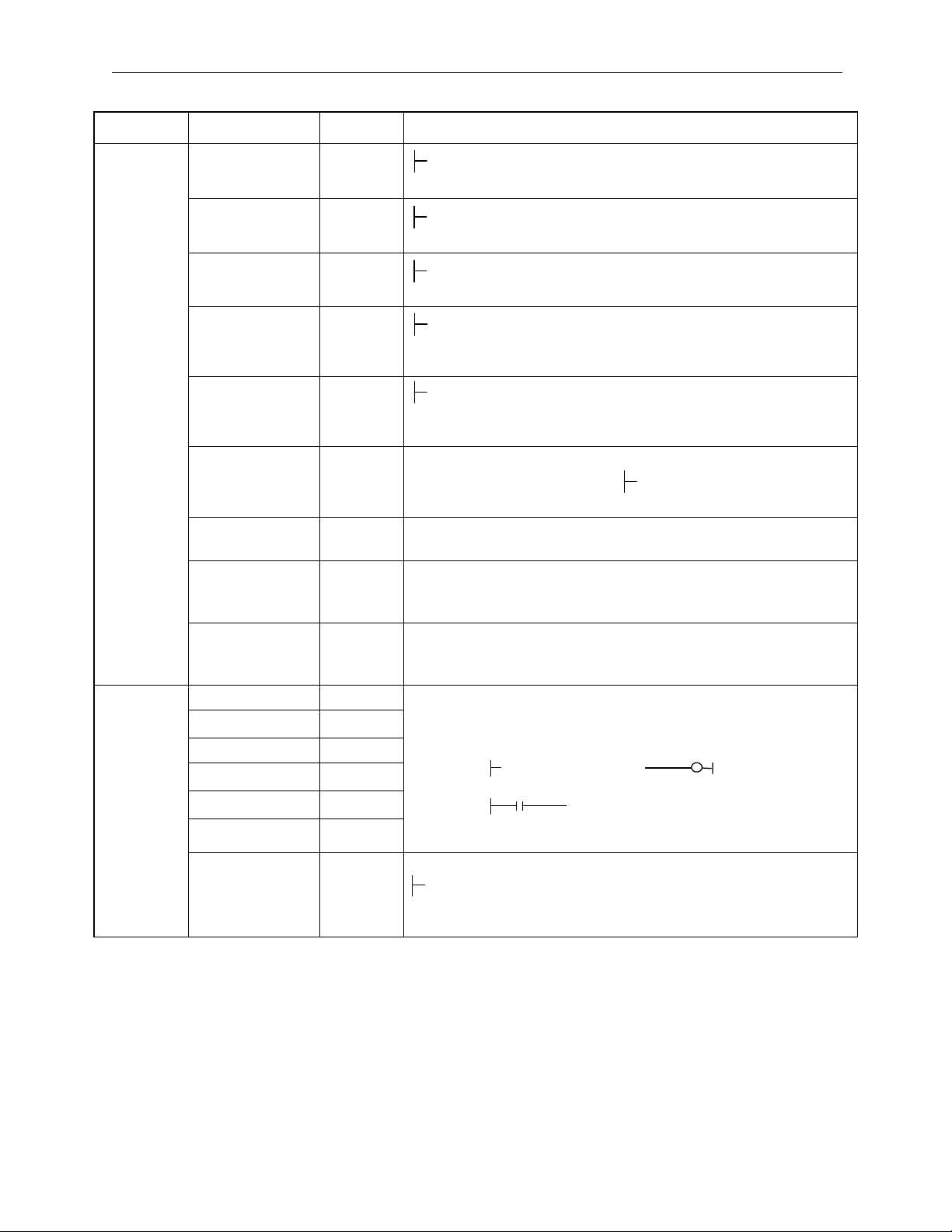

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Name Symbol Content

A Contact No limit on series circuits

All register bit types can be designated as relay numbers.

B Contact No limit on series circuits

All register bit types can be designated as relay numbers.

Rising Edge

Pulse

Falling Edge

Pulse

No limit on series circuits

All register bit types can be designated as relay numbers.

No limit on series circuits

All register bit types can be designated as relay numbers.

Relay Circuit Commands

ON Delay Timer

(10ms)

Setting count register

Setting = all registers, parameters (setting unit: 10ms)

Count register = registers M,D

OFF Delay Timer

(10ms)

ON Delay Timer

(1s)

OFF Delay Timer

(1s)

Coil

Setting Coil

Relay Circuit Commands

Reset Coil

Setting count register

Ts

Ts

Setting = all registers, parameters (setting unit: 1s)

Count register = registers M,D

MB000000

MW0200 = 0001

MB000000

IFON

MB000010MB000000

MB000010 is ON when MB000000 is ON. Subsequently, ON is

obtained even if MB000000 goes OFF.

MB000010MB000020

Branching/

Joining

MB000020 is ON when MB000010 is OFF. Subsequently, OFF

is obtained even if MB000020 goes OFF.

All of the above relay commands can be connected to branching/

joining symbols.

2-16

Page 27

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Type Name Symbol Content

Logical AND ∧ All registers and parameters can be designated in integer form.

Logical OR ∨ All registers and parameters can be designated in integer form.

Exclusive

All registers and parameters can be designated in integer form.

Logical OR

Addition +

Normal numerical addition (with operation error generation)

MW00280 +00100 ⇒ MW00220

Subtraction - Normal numerical subtraction (with operation error generation)

MW00280 -00100 ⇒ MW00220

Logical Operation Commands

Extended

Addition

Extended

Subtraction

Integer

++ Adds closed values (no operation error generation)

0¨→ 32767¨→ -32768¨→ 0

-- Subtracts closed values (no operation error generation)

0~-32767, -32768~0

Integer Operation Start

Replacement

Numerical Operation Commands

MW00220

Real Number

MW00280 + 00100

Real Number Operation Start

Replacement

MW00280 + 00100

MW00220

Storage Stores operation results to a designated register.

Multiplication × Used with × and ÷ in combination for integers and double-length

Division ÷

integers.

Increment INC Adds 1 to a designated register.

INC MW00100

Decrement DEC Subtracts 1 from a designated register.

DEC MW00100

Integer Remain-

MOD Obtains the remainder from the results of division.

der

MW00100 × 01000 ÷ 00121

MOD ⇒ MW00101

Real Number

Remainder

REM Obtains the remainder from the results of division.

MF00200 REM 1.5 ⇒ MF00202

Time Addition TMADD Addition of Hr/Min/Sec

TMADD MW00000, MW00100

Time Subtraction TMSUB Subtraction of Hr/Min/Sec

TMSUB MW00000, MW00100

Time Spent SPEND Requests the elapsed time for two time measures.

SPEND MW00000, MW00100

2-17

Page 28

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Name Symbol Content

Numerical Conversion Commands

Sign Inversion INV

MW00100 INV

Operation result = -99 when MW00100=99

Complement of 1 COM

MW00100 CON

Operation result = 0000H when MW00100= FFFFH

Absolute Conversion

Binary Conversion

BCD Conversion BCD

ABS

BIN

MW00100 ABS

Operation result = 99 when MW00100= -99

MW00100 BIN

Operation result = 1234 (decimal) when MW00100 = 1234H (hexadecimal)

MW00100 BCD

Operation result = 1234H (hexadecimal) when MW00100 = 1234

(decimal)

Parity Conversion

PARITY Calculates the number binary expression bits ON.

The operation result = 8 when MW00100 PARITYMW00100

= F0F0H

ASCII Conversion 1

ASCII Conversion 2

ASCII Converts a designated character string into ASCII, and replaces

it into the register ASCII MW00200 “ABCDEFG”

BINASC Converts 16-bit binary data into four hexadecimal digits in ASCII

code.

BINASC MW00100

ASCII Conversion 3

ASCBIN Converts numbers displayed as four hexadecimal digits in ASCII

code into 16-bit binary data.

ASCBIN MW00100

<<

Leaves the results of the comparison command ON or OFF in the B register.

≤≤

==

≠≠

≥≥

>>

MB000010

MW00000 < 10000

MB000010

IFON

Range Check

RCHK Checks whether the A register value is within range.

MW00100 RCHK -1000, 1000

Numerical Comparison Commands

2-18

Page 29

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Type Name Symbol Content

Right Bit Rotation ROTR Bit-addr Count Width

ROTR MB00100A ¨_ N=1 W=20

Bit Transfer MOVB Source Destination. Width

MOVB MB00100A ¨_ MB00200A W=20

Word Transfer MOVW Source Distribution. Width

MOVW MB00100 ¨_ MB00200 W=20

Replacement

Transfer

XCHG Source1 Source2 Width

XCHG MB00100 ¨_ MB00200 W=20

Data Initialization SETW Destination. Data Width

SETW MW00200 D=00000 W=20

Byte

_

Word Display

Word

_

Byte Compression

BEXTD Displays byte data stored into the word register area as words.

BEXTD MW00100 to MW00200 B=10

BPRESS Concatenates lower-level bytes of word data stored into the word

register area as words.

BPRESS MW00100 to MW00200 B=10

Data Scan BSRCH Searches within a designated register range for register positions

coinciding to the data.

BSRC MW00000 W=20 D=100 R=MW00100

Data Operation Command

Sort SORT Sorts the register within a designated register range.

SORT MW00000 W=100

Left Shift SHFTL Shifts a designated bit queue to the left.

SHFTL MB00100A N=1 W=20

Bit Right Shift SHFTR Shifts a designated bit queue to the right.

SHFTR MB00100A N=1 W=2

Word Copy COPYW Copies a designated register range.

COPYW MW00100 ¨_ MW00200 W=20

Byte Swap BSWAP Swaps the upper and lower-level bytes of designated word vari-

ables.

BSWAP MW00100

2-19

Page 30

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Name Symbol Content

Square Root SQRT The square roots of negative values are the square roots of the

absolute value multiplied by -1.

MF00100 SQRT

Sine SIN Input = degrees

MF00100 SIN

Cosine COS Input = degrees

MF00100 COS

Tangent TAN Input = degrees

MF00100 TAN

Arc Sine ASIN

MF00100 ASIN

Arc Cosine ACOS

MF00100 ACOS

Basic Function Commands

Arc Tangent ATAN

MF00100 EXP

MF00100

MF00100

MF00100MF00100

e

Exponent EXP

MF00100 LN

loge(FM00100)

Naturalized

Logarithm

LN

MF00100 LOG

log10(FM00100)

Common

Logarithm

LOG

2-20

Page 31

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Type Name Symbol Content

Dead Zone A DZA

Dead Zone B DZB

Upper Limit LIMIT

PI Control PI

PD Control PD

PID Control PID

First-order Lag LAG

Phase Lead/Lag LLAG

Function

DDC Commands

Generator

Inverse Function

FGN

IFGN MW00100 IFGN MA00200

MW00100 DZA 00100

MW00100 DZB 00100

MW00100 LIMIT -00100 00100

MW00100 PI MA00200

MW00100 PD MA00200

MW00100 PID MA00200

MW00100 LAG MA00200

MW00100 LLAG MA00200

MW00100 FGN MA00200

Generator

Linear

LAU MW00100 LAU MA00200

Accelerator 1

Linear

SLAU MW00100 SLAU MA00200

Accelerator 2

Pulse Width

PWM MW00100 PWM MA00200

Modulation

2-21

Page 32

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Type Name Symbol Content

Block Write TBLBR TBLBR TBL1, MA00000, MA00100

Block Read TBLBW TBLBW TBL1, MA00000, MA00100

Row Search (Ver-

TBLSRL TBLSRL TBL1, MA00000, MA00100

tical)

Column Search

TBLSRC TBLSRC TBL1, MA00000, MA00100

(Horizontal)

Block Clear TBLCL TBLCL TBL1, MA00000

Block Move TBLMV TBLMV TBL1, TBL2, MA00000

Queue Table

QTBLR QTBLR TBL1, MA00000, MA00100

Read

(invariable

pointer)

Queue Table

QTBLRI QTBLRI TBL1, MA00000, MA00100

Read

(pointer stepping

QTBLW QTBLW TBL1, MA00000, MA00100

Display Data Operation Commands

Queue Table

Write

(invariable

pointer)

Queue Table

QTBLWI QTBLWI TBL1, MA00000, MA00100

Write

(pointer stepping

Queue Pointer

QTBLCL QTBLCL TBL1

Clear

First-in

FINFOUT First-in/First-out

First-out

Trace Function TRACE Data Trace Execution Control

Data Trace Read DTRC-RD Data read from data trace memory into the user memory.

Message

MSG-SND Send message from controller.

Send

System Functions

Message

MSG-RCV Receive message from controller.

Receive

2-22

Page 33

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Servo Amplifier Specifications

External Appearence and Nameplate

Servo amplifier model

サーボパック形式

YASKAWA

SERVOPACK

SGDH-

SGDH-

SGDH-SGDH-

MODE/SET

DATA/

POWER

CHARGE

L1

L1

L1L1

CCCC

NNNN

L2

L2

L2L2

3333

L3

L3

L3L3

1111

2222

CCCC

NNNN

1111

L1C

L1C

L1CL1C

L2C

L2C

L2CL2C

B1

B1

B1B1

B2

B2

B2B2

B3

B3

B3B3

CCCC

UUUU

NNNN

2222

VVVV

WWWW

Serial Number

製造番号

Usage Power

適用電源

18.6

18.6

18.618.6

SGDH-30AE

SGDH-30AE

SGDH-30AESGDH-30AE

適用モータ容量

24.8

24.8

24.824.8

3.0(4.0)

3.0(4.0)

3.0(4.0)3.0(4.0)

Applicable

Motor

Capacity

Σ-II Series

SGDH Servo Amplifier

2-23

Page 34

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Interpretation of Model

SGDH

ΣII Series

Σ-Ⅱシリーズ

SGDH Servo Amp

SGDH

形サーボパック

最大適用サーボモータ容量

(下表を参照)

Voltage

電圧

A:200V

B:100V

D:400V

* for 100V usage

∗

Designation

指定形態

Option and compatability function integrated

E

Option Specs

オプション仕様

Name: Base-mount type

無し:ベースマウント形

R

R: Rack mount type (compatible with 5kW or lower only)

P

P: Rack mount type (compatible with 6kW, 7kW only)

Applicable Motor Capacity

∗

100V

用は,

for 0.2kW or lower motors only

サーボモータの

:オプションユニット対応機能内蔵形

:ラックマウント形(

:ダクト通風形(

(see following table)

SGMAH,SGMPH

0.2kW

以下のみ。

5kW

6kW,7.5kW

以下のみ対応可能)

-

形

のみ対応可能)

10 A E

- □

2-24

Page 35

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Main

Power

200V

singlephase

Maximum applicable

motor capacity symbol

A3 0.03 08 0.75

A5 0.05 10 1.0

01 0.10 15 1.5

02 0.20 20 2.0

04 0.40 30 3.0

05 0.50 — —

Only SGMAH and SGMPH servo motors of 0.2kW or less can be used with

100V.

Servo Motor and Amplifier Combination

Combinations of servo motors and amplifiers, as well as MCCB and phase

capacity with regard to power source capacity are shown below.

Servo

Capacity

(kW)

0.03 A3AD SGMAH–

0.05 A5AD SGMAH–

0.10 01AD SGMAH–

0.20 02AD SGMAH–

0.40 04AD SGMAH–

Amplifier

Mode 1

SGDH-

Applicable

Motor

Model

A3A

A5A

01A

SGMPH–

01A

02A

SGMPH–

02A

04A

SGMPH–

04A

Capacity (kW)

Power

Capacity

per Servo

Amplifier

(kVA)*

0.20 4 LF-205A Single-phase

0.25

0.40

0.75

1.2 8 LF-210A Single-phase

Maximum applicable

motor capacity

Current

Capacity of

Wiring

Breaker or

Fuse

)*†

(A

rms

Recommended Noise

Model Specification

Capacity (kW)

Filter†

current

200V

-class 5A

current

200V class

10A

Open/Close

Type

HI–15E5

(30A)

Compatible

device

2-25

Page 36

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Main

Power

200V

Threephase

Servo

Capacity

(kW)

0.50 05AD SGMGH–

0.75 08AD SGMAH–

1.0 10AD SGMGH–

1.5 15AD SGMPH–

2.0 20AD SGMGH–

3.0 30AD SGMGH–

5.0 50ADA SGMDH–

Amplifier

Mode 1

SGDH-

Applicable

Motor

Model

05A _A

SGMGH–

03A _B

08A

SGMPH–

08A

SGMGH–

06A _B

09A _A

SGMGH–

09A _B

SGMSH–

10A

15A

SGMGH–

13A _A

SGMGH–

12A _B

SGMSH–

15A

20A _A

SGMGH–

20A _B

SGMSH–

20A

30A _A

SGMGH–

30A _B

SGMSH–

30A

32A

SGMDH–

40A

SGMSH–

40A

SGMGH–

44A _A

Power

Capacity

per Servo

Amplifier

(kVA)*

1.4 4 LF-310 Three-phase

1.9 7 LF-315 Three-phase

2.3

3.2 10

4.3 13 LF-320 Three-phase

5.9 17 LF-330 Three-phase

7.5 28 LF-340 Three-phase

Current

Capacity of

Wiring

Breaker or

Fuse

)*†

(A

rms

Recommended Noise

Filter†

Model Specification

current

200V-class

10A

current

200V-class

15A

current

200V-class

20A

current

200V-class

30A

current

200V-class

40A

Open/Close

Type

HI–15E5

(30A)

Compatible

device

HI–18E

(35A)

Compatible

device

2-26

Page 37

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Main

Power

200V

Three-

phase

100V

Singlephase

Servo

Capacity

(kW)

5.0 50ADA SGMDH–

6.0 60ADA SGMGH–

7.5 75ADA SGMGH–

0.03 A3BD SGMAH–

0.05 A5BD SGMAH–

0.10 01BD SGMAH–

0.20 02BD SGMAH–

Amplifier

Mode 1

SGDH-

Applicable

Motor

Model

44A _B

SGMSH–

50A

55A _A

SGMGH–

60A _B

75A _A

SGMSH–

15A

A3B

A5B

01B

SGMPH–

01B

02B

SGMPH–

02B

Power

Capacity

per Servo

Amplifier

(kVA)*

7.5 28 LF-340 Three-phase

12.5 32 LF-350 50A

15.5 41 LF-360 60A

0.15 4 LF-205F Single-phase

0.25

0.40

0.60 6 LF-210 Single-phase

Current

Capacity of

Wiring

Breaker or

Fuse

)*†

(A

rms

Recommended Noise

Filter†

Model Specification

current

200V-class

40A

current

200V-class

5A

current

200V-class

10A

Open/Close

Type

HI–18E

(35A)

Compatible

device

HI–25E

(50A)

Compatible

device

Hi-30E

HI–15E5

(30A)

Compatible

device

All values are given at rated load.When selecting the actual fuse, determine the capacity after performing the

proper derating.

Breaker Characteristics (25ºC):200“_ 2s or more, 700“_ 0.01s or more

High-speed fuses cannot be used.Because the servo amplifiers power supplies are of a capacitor input-type,

high-speed fuses may fuse upon power input.

SGDH servo amplifiers are equipped with a ground fault protection circuit.To create a safer system, connect a

ground fault protection-dedicated leak current breaker in combination with a combined overload/short

protection leak current breaker or a wiring breaker.

2-27

Page 38

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Servo Motors

Example of External Appearence and Nameplate

kW requirement

定格出力

Model type

モータ形式

∑-Ⅱシリーズサーボモータ

Serial Number

製造番号

rpm rating

定格回転速度

製造年月

Interpretation of Model

Standard Servo Motors

SGMPH - 01 A A A 2 S

Sigma-II

Series Servo

Motor Name

SGMAH

SGMPH

SGMGH

SGMSH

SGMDH

Servo Motor Capacity

(See table 1.1)

Voltage

A : 200V

B : 100V

∗

* 100V is for SGMAH and SGMPH

servo motors or 0.2kW or less.

Serial Encoder Specification

Brake, Oil Seal Specifications

1: No brake or oil seal

S: With oil seal

B: With DC90V brake

C: With DC24V brake

D: S + B

E: S + C

Shaft Specifications

(See Table 1.3)

Design Hierarchy

A : SGMAH

SGMPH

SGMGH(1500 r/min)

SGMSH

SGMDH

B: SGMGH(1000 r/min)

2-28

Page 39

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Servo Motor Capacities (kW)

SGMAH SGMPH SGMGH SGMSH SGMDH

Code

3000

rpm

A3 0.03 — — — — — 15 — 1.5 — — 1.5 —

A5 0.05 — — — — — 20 — — 1.8 2.0 2.0 —

01 0.1 0.1 — — — — 22 — — — — — 2.2

02 0.2 0.2 — — — — 30 — — 2.9 3.0 3.0 —

03———0.3——32—————3.2

04 0.4 0.4 — — — — 40 — — — — 4.0 4.0

05 — — 0.45 — — — 44 — — 4.4 4.4 — —

06 — — — 0.6 — — 0 — — — — 5.0 —

08 0.75 0.75 — — — — 55 — — 5.5 — — —

09 — — 0.85 0.9 — — 60 — — — 6.0 — —

10————1.0—75——7.5———

12———1.2—————————

13——1.3——————————

3000

rpm

1500

rpm

1000

rpm

3000

rpm

2000

rpm

Serial Encoder (•:Standard

SGMAH SGMPH SGMGH SGMSH SGMDH

Code

3000

rpm

♦:Optional)

3000

rpm

1500

rpm

1000

rpm

3000

rpm

2000

rpm

Sign Specification SGMAH SGMPH SGMGH SGMSH SGMDH

1 16-bit absolute • •

2 17-bit absolute • • •

A 13-bit incremental • •

B 16-bit incremental ♦♦

C 17-bit incremental • • •

Shaft End Specification (•:Standard

Sign Specification SGMAH SGMPH SGMGH SGMSH SGMDH

2 Straight, no key

3 Taper: 1/10, w/ Parallel key ♦♦♦

4 Straight, w/ key ♦♦

5 Taper: 1/10, w/ half-moon key ♦♦

6 Straight, w/ key and tap ♦♦ ♦ ♦♦

8 Straight, w/ tap ♦♦

•• • ••

♦:Optional)

2-29

Page 40

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Servo Motors with Gearbox

SGMPH - 01 A A A G 1 2 B

Σ-Ⅱシリーズ

ΣII Series

サーボモータ

Servo Motor Series Name

シリーズ名

SGMAH

SGMPH

SGMGH

SGMSH

サーボモータ容量(表1.4参照)

Servo motor capacity

電圧

Voltage

A : 200V

B : 100V

*

* SGMAH, SGMPH are

サーボモータの

for 100V use

シリアルエンコーダ仕様(表

For 0.2kW or lower servo motors

Serial encoder specs

設計順位

A : SGMAH

SGMPH

SGMGH(1500 r/min)

SGMSH

B : SGMGH(1000 r/min)

E : SGMPH(

∗

100V

用は,

SGMAH,SGMPH

防水仕様

0.2kW

IP67)

以下のみ。

1.5

参照)

形

Brake/Oil seal spec

ブレーキ仕様

1: No brake/oil seal

:ブレーキなし

1

B: w/DC 90V brake

B:DC90V

C: w/DC 24V brake

Shaft spec

軸端仕様(表1.8参照)

(differs by gear motor type)

Gear ratio

減速比(表

(differs by gear motor type)

減速機の種類(表

Gear box time

ブレーキ付き

C:DC24V

ブレーキ付き

(減速機の種類により

異なります)

1.7

(減速機の種類により

異なります)

参照)

1.6

参照)

2-30

Page 41

MotionSuite™ MP940 Machine Controller Reference Manual Specifications and Functions

Servo Motor Capacities (kW)

SGMAH SGMPH SGMGH SGMSH

Code

3000

rpm

A3 0.03 — — — — 15 — 1.5 — — 1.5

A5 0.05 — — — — 20 — — 1.8 2.0 2.0

01 0.1 0.1 — — — 22 — — — — —

02 0.2 0.2 — — — 30 — — 2.9 3.0 3.0

03—— —0.3—32—————

04 0.4 0.4 — — — 40 — — — — 4.0

05 — — 0.45 — — 44 — — 4.4 4.4 —

06 — — — 0.6 — 0 — — — — 5.0

08 0.75 0.75 — — — 55 — — 5.5 — —

09 — — 0.85 0.9 — 60 — — — 6.0 —

10 — — — — 1.0 75 — — 7.5 — —

12—— —1.2———————

13 — — 1.3 — — — — — — — —

3000

rpm

1500

rpm

1000

rpm

3000

rpm

SGMAH SGMPH SGMGH SGMSH

Code

3000

rpm

3000

rpm

1500

rpm

1000

rpm

3000

rpm

The number of encoder pulses for the SGM_H servo motor is shown below:

Serial Encoder (•:Standard ♦:Optional)

Sign

Specification SGMAH SGMPH SGMGH SGMSH

1 16-bit absolute

2 17-bit absolute

A 13-bit incremental

B 16-bit incremental ♦♦ 16384

C 17-bit incremental

••

••

••

••

Number of

Encoder

Pulses

16384

32768

2048

32768

The number of bits displaying the resolution of the applied encoder is not the

same as the number of pulses of the encoder signal output (phases A, B)

from the servo amplifier. In the MP940, the number of encoder pulses is

quadrated (×4).

2-31

Page 42

Specifications and Functions MotionSuite™ MP940 Machine Controller Reference Manual

Types with Gearboxes (•:Standard)

Sign Specification SGMAH SGMPH SGMGH SGMSH

G HDS High-precision Planetary Gearbox • •

J General-purpose Gearbox • •

S With mount •

T Flange type •

L IMT High-precision Planetary Gearbox • •

Gearbox (differs according to gearbox type)

Sign Specification SGMAH SGMPH SGMGH SGMSH

A1/6 ——S, T∗ —

B 1/11 or 1/11.13 G — S, T —

C 1/21 G, J G, J S, T —

1 1/5 G, J G, J L L

21/9 G — L L

3 1/10 or 1/10.3 J J — —

51/20 ——L∗ L

7 1/29 or 1/33 G, J G, J L, S, T∗ L∗

81/45 ——L∗ L∗

(Some parts lack compatible devices.)

Shaft End Specifications (differ according to gearbox type)

Sign Specification SGMAH SGMPH SGMGH SGMSH

0 Straight, no key G, J G, J — —

2 Straight, no key G, J G, J — —

4 Straight, w/ key G, J G, J L L

6 Straight, w/ key and tap G, J G, J S, T —

8 Straight, w/ tap G, J G, J — —

2-32

Page 43

MotionSuite™ MP940 Machine Controller Reference Manual Operation Mode

Chapter 3: Basic System Operation

An explanation of the basic system operation of the MP940 is given in this chapter.

Operation Mode

This section describes both of the MP940 operation modes: the run mode and the stop

mode.

Operation Mode Run Mode

• RDY, RUN LEDs ON

• User program, I/O operation functions

Stop Mode

• RUN LED OFF

• User programs stopped

Figure 3.1: MP940 Operation Mode Classifications

Run Mode

When power is fed into the MP940, the READY (RDY) and RUN (RUN)

LEDs light up (the ALARM (ALM) LED is off), and the unit is in the run

mode. This means that there are no errors or failures in the MP940, and that

user programs and I/O operations can be executed. The run mode also

continues when an I/O conversion error, user operation error, or when a user

program is stopped; however, the ALARM (ALM) LED lights. See Chapter

10 "Troubleshooting" for error contents and countermeasures.

Stop Mode

During the stop mode, user program execution is halted, and all outputs are

reset (the digital output = 0).This state is displayed by the RUN LED being

OFF. Drawing programs (DWG.H or DWG.L) are not executed in this state.

3-1

Page 44

Start, Stop Sequence MotionSuite™ MP940 Machine Controller Reference Manual

The stop mode results in the following four situations:

1. When the program memory is not initialized.

2. When a major fault such as watchdog time-out occurs.

3. When a STOP operation is executed from the MotionWorks

TM

.

4. When power is fed with the RUN/STOP switch set to OFF (STOP).

Note: 1 ~ 2 are user program errors or MP940 errors or fail-

ures. (See Chapter 10 Troubleshooting for error contents and countermeasures.)

In 3, the run mode can be entered by executing the

RUN operation.

In 4, the run mode can be entered by turning the RUN/

STOP switch to ON (RUN).

Start, Stop Sequence

This section describes the starting and stopping sequences of the MP940, the attendant

dip switch setting method, as well as the types of self-diagnosis and display light

(LED) patterns.

3-2

Page 45

MotionSuite™ MP940 Machine Controller Reference Manual Start, Stop Sequence

DIP Switch Setting Method

The DIP switches on the CPU are used for start/stop sequence operation

control. The CPU module has six switches as shown in the figure below. The

function of each switch is shown in the following table.

654321

RUN

INIT

TEST

Default

Setting

OFF

NO

ONOFF

FLASH

P.P

COPY

Number Name Setting Operation at Setting

6 RUN ON User Program Run ON

OFF User Program Stop

5 INITIAL ON When SW4 is ON: Clear Memory OFF

OFF When SW4 is ON: Terminal mode

4 TEST ON Terminal Mode/Initialization Mode OFF

OFF Online

3 FLASH ON Program copy from FLASH to RAM OFF

OFF No program copy from FLASH to RAM

2P.P

Default

ON Default Port 1 only OFF

OFF Serial port setting

1 COPY ON M Register Copy when SW3 is ON

Turn the power ON when only SW1 is ON.

SGDH servo parameter in the controller is

transferred to SGDH .

→ to replace

SGDH.

OFF No M Register Copy when SW3 is ON.

M Register has a battery backup.

Although “NO” is displayed on the arrow at the lower right side of the DIP

switches, flipping the switches to the right turns them ON, and left turns them

OFF.

3-3

Page 46

Start, Stop Sequence MotionSuite™ MP940 Machine Controller Reference Manual

Memory Initialization

The memory as initialized, and the user programs and configuration data are

deleted upon setting the DIP switches in the following order, and cycling the

power OFF/ON.

12 3 4 5

Turn MP940

power OFF

Turn DIP

switches INITIAL

and TEST ON.

RUN

56

INITIAL

TEST

FLASH

P.P

1234

COPY

←←←←

NO

Check that the

RDY and RUN

LEDs blink when

power is fed

(approximately

3 seconds).

Return the RUN

DIP switch to the

ON setting

RUN

56

INITIAL

TEST

FLASH

P.P

1234

COPY

←←←←

NO

Turn the power

ON again

Note: The memory is cleared if the battery is removed with the module

power OFF.

Start Sequence

The MP940 makes various determinations at start-up, and upon recognizing

an error, flashes the ERR LED, showing the content of the error by the

number of flashes. MotionWorksTM cannot be operated while the LEDs are

flashing. The following table shows a partial list of the MP940 display LEDs.

3-4

Page 47

MotionSuite™ MP940 Machine Controller Reference Manual Start, Stop Sequence

LED

Type

RDY RUN ALM

Normal User program stopped

User program executing normally

Error Hardware reset state (when display continues)

Initializing (when display continues)

Major fault

2 flashes: RAM error

Warning ? ? ? Battery alarm

Operation error (I/O error)

No LED display. Reports to system (S)

register.

Other Memory initialization by DIP switch setting

RDY and RUN flash simultaneously

– Offline testing mode

BAT

ALM

3 flashes: ROM error

4 flashes: Peripheral LSI error

Hardware status (momentary stop, START/

STOP, testing mode, etc.)

complete.

Display Content

:OFF, :ON, :Flash, ?:Undefined

3-5

Page 48

Start, Stop Sequence MotionSuite™ MP940 Machine Controller Reference Manual

MP940 Start Sequence and Basic Operation

Power ON

Test M ode

Switch

Program

Memory

Check

Program

Data

Self-diagnosis

at Start

Run Switch

Determination

Watchdog

Timer Start

Dwg A

Execution

Memory

Clear

= Test Mode

Normal Mode

Not Damaged

Damaged

S Switch Synchronization

Offline Selfdiagnosis

Interrupt Sigma

Dwg 1 Execution

Finished in 1 turn

Dwg S

Scan Processing

Dwg H

Scan Processing

Dwg L

Scan Processing

Online Self-diagnosis

Executed in

descrete time

units

3-6

Page 49

MotionSuite™ MP940 Machine Controller Reference Manual Start, Stop Sequence

The starting sequence and basic operation of the MP940 are as follows:

1. Self-diagnosis at start-up

The following menu is displayed in self-diagnosis at start-up.

• Memory (RAM) Read/Write Determination

• System Program (ROM ) Diagnosis

• Main Processor (CPU) Function Diagnosis

• Numerical Operation Processor (FCPU) Function Diagnosis

The RDY LED flashes the designated number of times when there is an

error in the diagnostic results.

2. Online Self-diagnosis

The following menu is displayed in online self-diagnosis

• System Program (ROM ) Diagnosis

• Main Processor (CPU) Function Diagnosis

• Numerical Operation Processor (FCPU) Function Diagnosis

The RDY LED flashes the designated number of times when there is an

error in the diagnostic results.

3. Start New Run

Sets the run format to New Run in the CP717 system definition screen.

A new run starts. Unlike the start of a continuous run, self-diagnostic

processing occurs prior to DWG.A execution.

4. Operation Stop

The MP940 stops operation in the following situations:

• When power is interrupted

• When power loss occurs

• When a fatal error is generated

• When a STOP operation is executed from MotionWorksTM.

Note: Restart is not possible in the first and second items

above without restarting the power.

Restart is possible in the third item above by turning

off the power.The cause of the error can be deduced by

checking the LED display.

Restart is possible in the fourth item above by executing the RUN operation in CP717.

3-7

Page 50

Scan Processing MotionSuite™ MP940 Machine Controller Reference Manual

Scan Processing

Outline of Scan Processing

There are three types of MP940 scan processing: S (system) scans, H (Highspeed) scans, and L (Low-speed) scans. Scan processing segments all S scan

periods into descrete time elements and then executes the S scan as a base

period.

When setting the proportion of assignments into the background within the S

scan period, ensure the "Background Processing Time" for PP processing.

Scan Types

Type Content

S Scan

(System Scan)

H Scan

(High-speed Scan)

L Scan

(Low-speed Scan)

Select a base period for scan processing: 0.5, 1.0, 2.0, 4.0ms.

S, H and L scan processing segments all S scan periods into discrete time

elements and then executes the S scan as a base period.

Set the S scan period in integer multiples.

The scan is broken into discrete time elements and executed within the S

scan period.

Set the S scan period in integer multiples.

The scan is broken into discrete time elements and executed within the S

scan period.

3-8

Page 51

MotionSuite™ MP940 Machine Controller Reference Manual Scan Processing

Service Scan of each Function

Except for SVA, a scan can be selected to execute I/O processing for each

function.

Function

Serviceable

Scans

Notes

CNTR S/H/L Simultaneous processing with S, H, or L

LIO (DI/DO/AI/AO) S/H/L Simultaneous processing with S, H, L

Mechatrolink

H/L Simultaneous processing with either H or L.

(distributed I/O, etc.)

SVA S/H Scan Fixation (unselectable)

Synchronous selection of phase control mode

and position control mode is possible in the

setup parameter settings.

Synchronous Selection of Phase Control

Mode (OBC0016)

0:H Scan (default)/1: S Scan

Synchronous Selection of Position Control

Mode(OBC0017)

0:H Scan/1: S Scan (default)

Content of S Scan

The processing content, as well as procedure, within the S scan is as follows:

S-scan synchronization (set to 0.5, 1.0, 2.0, 4.0ms)

Sスキャン周期(0.5,1.0,2.0,4.0msのいずれか設定)

c

L

n

I

t

O

r

HS SS SA HA LA BG

必須

necessary

(スキャン内で完結)

(completed within the scan)

時限タイマ

limit timer

R

I

O

(1スキャン内で終了しない

(executed in the following

場合次のSスキャンで実行さ

S-scan if not completed

れる)

in 1 scan)

C

O

M

時限付き

time limit

R

I

O

-

余り

loss

background

バックグ

processing

ランド

処理時間

time

3-9

Page 52

Scan Processing MotionSuite™ MP940 Machine Controller Reference Manual

Items Completed within the S Scan

c

L

n

I

t

O

r

HS SS SA

S-scan applications (Dwg. S)

Sスキャンのアプリケーション(DWG.S)

S-scan system processing (no SVA

Sスキャンのシステム処理(SVAの制御ループなど)

control loop)

Hスキャンのシステム処理(SVAの加減速処理など)

4 scan system processing (no SVA accel/

(Hスキャン周期に1回動作します)

decel processing) - operates 1 scan in

ローカルI/O処理(DI/DO/AI/AO)

H scan period

(S/H/Lスキャンのいずれかに同期して処理します。)

マスタエンコーダのカウンタ入力処理(CNTR)

Local I/O processing (DVDO/AI/AO)

(S/H/Lスキャンのいずれかに同期して処理します。

(synchronizes and processes for S/H/L

処理する回のSスキャン割り込みの先頭で処理します。)

scans)

Master encoder counter input processing

(synchronizing processes for S/H/L scans

processed by the head of processing

S-scan interrupt)

Time-shared Items

R

I

HA

O

Background

BG

R

C

I

O

M

LA

O

L-scan application (Dwg. L)

Lスキャンのアプリケーション(DWG.L)

H-scan application (Dwg. H)

Hスキャンのアプリケーション(DWG.H)

Distributed I/O (Mechatrolink) processing

分散I/O(MECHATROLINK)処理

(H/Lスキャンのいずれかに同期して処理します。

(synchronizes & processes the H/L scans)

シリアル通信

Serial communication

Background processing (PP processing)

バックグランドタスク(P.P処理)

3-10

Page 53

MotionSuite™ MP940 Machine Controller Reference Manual Scan Processing

Notes on Scan Processing

1. Complete item processing within the S scan in approximately half the

time of the S scan period setting.

2. Set an assignment ratio in the background processing.

Scan Operation

Each scan process is executed as shown below:

S

スキャン周期

S-scan synchronization

DWG,S

Sスキャン処理

S-scan processing

DWG,H

Hスキャン処理

H-scan processing

DWG,L

Lスキャン処理

L-scan processing

Executed in

タイムスライス

descrete

で実行

time units

Scan Time Setting Method

Opening the Scan Time Setting Window

From the MotionWorks

the Definition Folder.

TM

File Manager, click the Scan Time Setting tab in

3-11

Page 54

Scan Processing MotionSuite™ MP940 Machine Controller Reference Manual

The ScanTime Setting window is displayed.

System Scan Time Setting

The MP940 has three scan time levels (System/High-speed/Low-speed),

which determine the flow of the program execution format. Among these,

the system scan time must be set first. The high-speed/low-speed scans are

then set based upon the system scan.

3-12

Page 55

MotionSuite™ MP940 Machine Controller Reference Manual Scan Processing

The following relationship exists in the setting criteria for the various scan

times. For details, see the MotionSuite™ MP940 Machine Controller

Hardware Manual.

Scan Time Level Setting Criteria

System Scan Select from 0.5, 1, 2, and 4ms.

High-speed scan 0.5 ~ 32ms (system scan integer multiple)

Low-speed Scan 2.0 ~ 100ms (system scan integer multiple)

Opening the Setup Window

Select Setup (S), > Base Control Synchronization (B).

Setting Item Content

Set Time Sets the system scan time. The value of the previous step is the current

setting value.

Maximum Time Sets the maximum system scan time. The previous value is the

maximum time measured by the system to this point.

Current Time Displays the current value of the system scan time.

Steps Displays the number of steps of the system scan time.

Background Time Shows the percentage of the total system which is consumed by the

background.

Watch Dog Set Sets the watchdog time which provides system scan time limits.

Restart the power if the base control synchronization has been changed.

The base control synchronization continues to be applied at its current value

and does not return to defaults even if the memory is cleared. Restart power