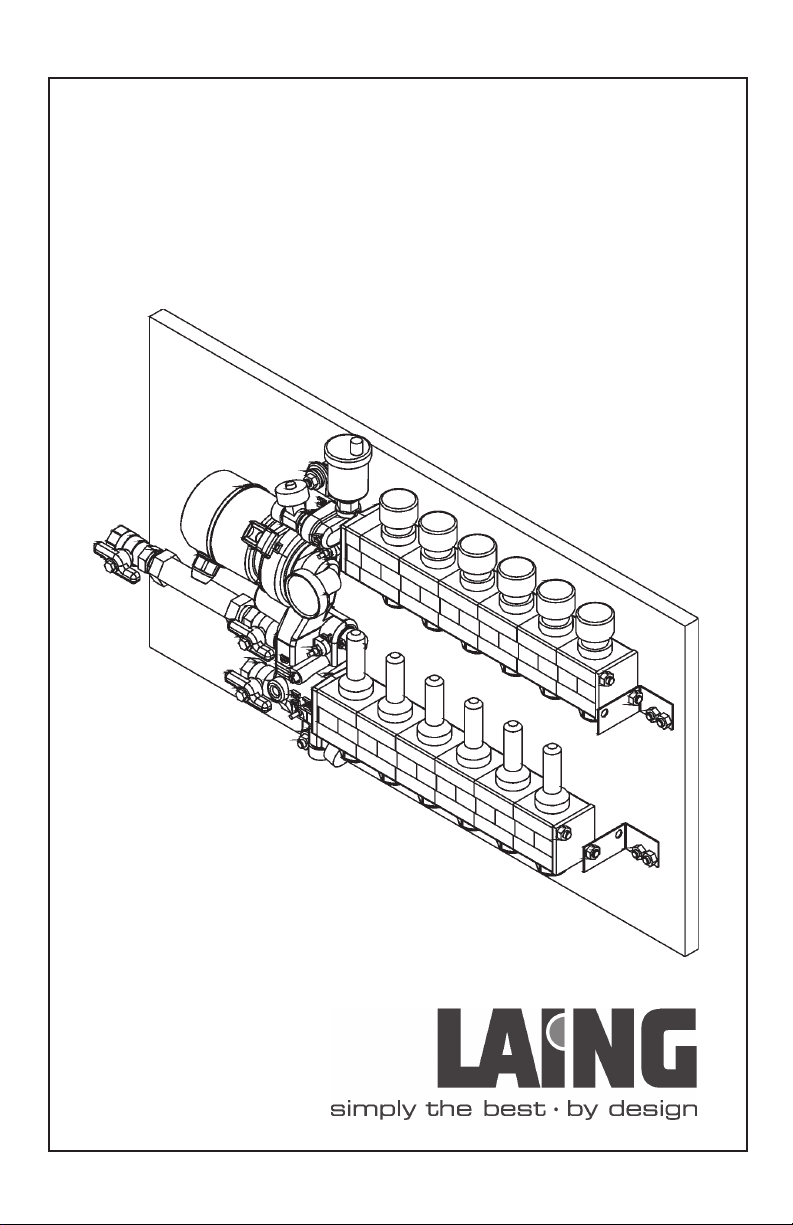

Page 1

Installation and operation manual

for multi zone

mixing module

MOH2

Page 2

Installation and operation manual MOH2

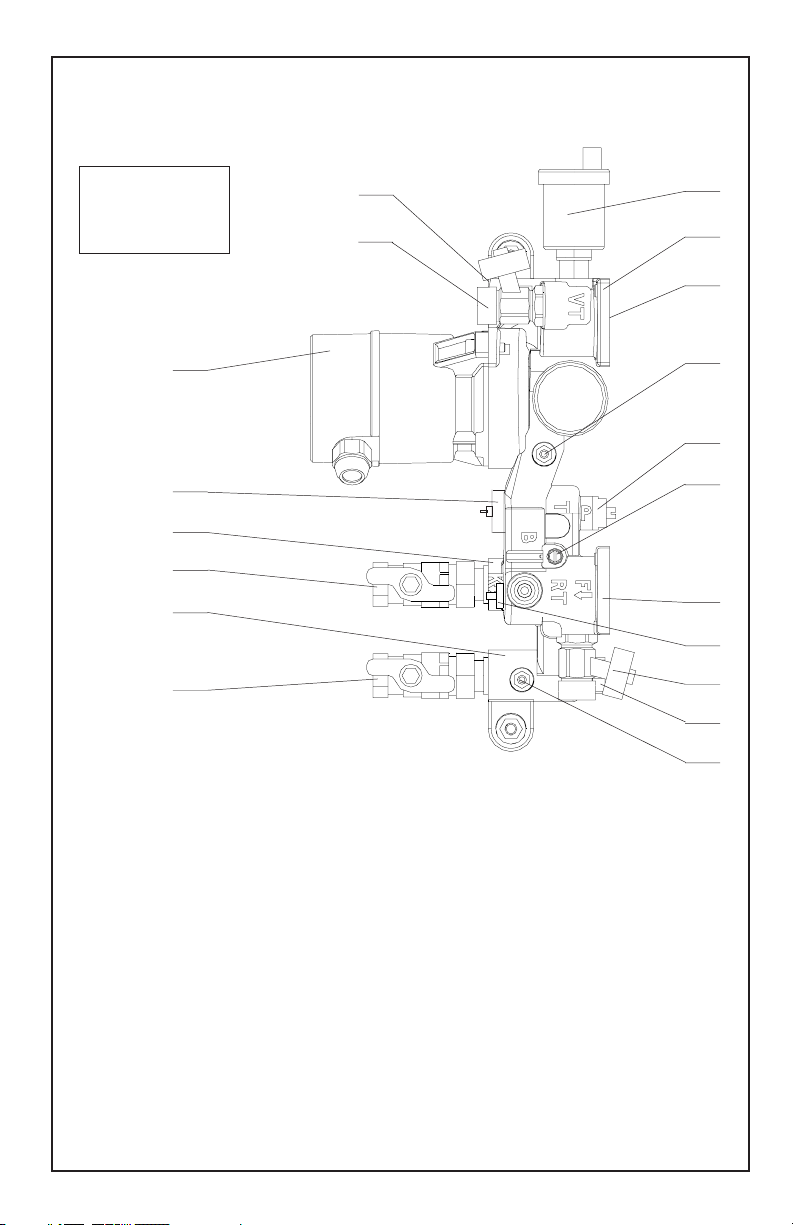

Design MOH2 base module Schematics

Control

11

10

16

12

19

2

7

1

14

5

4

6

9

8

3

15

13

18

17

1 Circulator pump

2 Floor heating loop feed side

3 Floor heating loop return side

4 Control valve

5 Presetting knob for control valve

6 Bypass valve

7 Check valve for filling of floor hea-

ting loops

8 Boiler loop feed side

9 Boiler loop return side

10 Ball valve boiler loop feed side

11 Ball valve boiler loop return side

2

12 Fill valve

13 Drain valve

14 Sensor position for floor heating

loop feed temperature

15 Sensor position for floor heating

loop return temperature

16 Sensor position for safety tempe-

rature

17 Sensor position for boiler feed

temperature

18 Plug for calorimeter dip tube

19 Automatic air purger

www.lainginc.com

Page 3

Installation and operation manual MOH2

Table of contents

Design MOH2 base module .................................................................. 2

Application of the MOH2 mixing module ............................................... 4

Construction .......................................................................................... 4

Function ................................................................................................ 4

Attaching a manifold to the MOH2 to base module ............................... 6

Attaching other kinds of manifolds ........................................................ 7

Changing the number of loops of the segmented plastic manifold ........ 7

Installation of the MOH2 station ............................................................ 8

Hydraulic connection ........................................................................... 10

Connection of calorimeter sensor........................................................ 10

Connection of the controls ...................................................................11

Bypass valve 6 .....................................................................................11

Presetting knob for control valve 5 ...................................................... 13

Filling the system................................................................................. 14

Pressure test ....................................................................................... 14

Start-up ................................................................................................ 15

Technical data ..................................................................................... 16

Dimensions ......................................................................................... 18

Changing out the circulator ................................................................. 19

Troubleshooting................................................................................... 20

www.lainginc.com

3

Page 4

Installation and operation manual MOH2

Application of the MOH2 mixing module

Connection of low temperature heating systems to the boiler loop,

for example

• Floor heating systems

• Wall heating systems

Installation of the MOH2 is possible in the manifold cabinet, because

• It is very compact

• It operates very quietly

• In multifamily dwellings, the feed temperature for the low temperature

loop can be selected individually for each apartment.

Construction

The Laing mixing module MOH2 consist of a bronze cast main body, which

contains [see schematics on page 2]

• Connections for feed and return of the boiler loop

• Connections for feed and return of the low temperature loop

• Circulator

• Control valve

• Presetting knob for control valve

• Air purger as well as fill and drain valves

• Connections for all necessary sensors

• Bypass valve

Function

Floor heating loop

• The circulator 1 circulates the water through the floor heating feed connection and the floor heating loops to the floor heating return connection.

Mixing

• When the mixing valve 4 opens, boiler loop feed water 8 is mixed to the

floor heating loop feed side and the same amount of water is returned

from the floor heating return side 3 to the boiler loop return side 9.

• The mixing valve adjusts the quantity of water coming from the boiler

loop to control the desired floor heating feed temperature.

4

www.lainginc.com

Page 5

Installation and operation manual MOH2

Control

18 16

17

8 10 14 2

5 4 7

1

12

6

15

9 11 3

13

1 Circulator

2 Feed for floor heating circuit

3 Return for floor heating circuit

4 Control valve

5 Presetting knob for control valve

6 Adjustable bypass valve

7 Check valve for filling of floor heating loops

8 Boiler feed connection

9 Boiler return connection

10 Ball valve of boiler feed connection

11 Ball valve of boiler return con-nection

12 Fill valve

13 Drain valve

14 Sensor for floor heating feed temperature

15 Sensor for floor heating return temperature

16 Sensor for safety temperature

17 Sensor for boiler feed temperature

18 Space for calorimeter dip tube

www.lainginc.com

5

Page 6

Installation and operation manual MOH2

Presetting knob for control valve

• The control valve is equipped with a presetting knob 5, with which the

maximum amount of water from the boiler loop can be reduced. The

unit is shipped with the presetting knob completely open.

Bypass for step-down control

• If the bypass valve 6 is opened, a small quantity of boiler feed water will

run constantly through the mixing module. This is necessary for a stepdown control, which derives its outside temperature information from

the boiler feed temperature. The unit is shipped with the bypass valve

opened 1/2 turn.

Fill and drain valves

• If you fill the system from the fill valve 12, the check valve 7 will close.

In this way, the water will flow through the floor heating loops and not

through the mixing module. Excess water drains through the drain valve

13.

Sensor positions integrated in the base module

• Floor heating feed temperature 14

• Floor heating return temperature 15

• Safety temperature 16

• Boiler feed temperature 17

• Dip tube for calorimeter sensor 18

Attaching a manifold to the MOH2 to base module

Attaching a Laing segmented plastic manifold

• Attach the manifolds before mounting the module.

• Attach manifolds directly to the flanges of the MOH2

• Adjusts the length of the threaded rods according to the number of zones

• Screw the threaded rods into the MOH2

• If the manifolds should be offset, use one or two 20 mm spacers on the

feed or return side

• Insert the red segments on the feed side [top], the blue segments on

the return side (bottom) onto the threaded rods. Caution: make sure

that the seal surfaces and seal rings are free of dirt.

• Close manifolds with end plate (caution: plastic cover must face the

water) and tighten the nuts evenly.

6

www.lainginc.com

Page 7

Installation and operation manual MOH2

Attaching other kinds of manifolds

• The flanges contain a 1" female thread to enable connection of other

kinds of manifolds. Attach the manifolds here using a proper pipe thread

sealant

• If the manifolds should be offset, use a spacer or a longer insert.

• We recommend to use a union connection between the manifolds and

the base module. This facilitates disassembly in case of repairs.

Changing the number of loops

of the segmented plastic manifold

• Make sure to adjust the number of loops before installing the module in

a manifold cabinet, since it may be impossible to remove the threaded

rods with the unit mounted in a cabinet.

Reduce number of loops, disassembly

• Remove both nuts at the end plate

• Remove end plate and unneeded manifold segments

• Cut the threaded rods to proper length [55 mm for every segment

removed]. Caution: take care not to damage the thread or the seal

surface of the last segment.

• If the threaded rods cannot be cut in place, remove them and shorten

them elsewhere. Caution: take care not to damage threads.

Increase number of loops, disassembly

• Remove both nuts at the end plate

• Remove the end plate

• Remove both threaded rods

• Install new threaded rods with the appropriate length [additional 55 mm

for every segment]. Caution: take care not to damage the thread.

• Install additional segments

Reassembly of manifold

• Caution: if manifolds have been in operation, it is necessary to clean

carefully the seal rings and the seal surfaces of each segment as well

as the end plates.

• Reinstall the end plates and tighten the nuts equally.

www.lainginc.com

7

Page 8

Installation and operation manual MOH2

Installation of the MOH2 station

Installation options

The MOH2 station can be installed in two different ways. The mounting

hardware required for both ways is included with the station.

• Parallel installation: the floor heating pipes are guided parallel to the

wall. At the place were the pipes leave the floor, they have to be fastened

to ensure that they come straight up into the manifold.

• Angled installation: in this case the MOH2 unit is installed at an angle

of approximately eight degrees, so that the floor heating pipes are guided

to the wall at that angle and enter the floor directly at the wall.

Parallel installation

The picture below shows the parallel installation with the mounting

hardware attached accordingly.

• Use the 0.8‘‘ (20 mm) spacer at the upper mounting eyelet

• Use the 0.87 (22 mm) and the 0.2‘‘ (5 mm) spacer at the lower mounting

eyelet.

• Turn the rubber grommets in such a way that they are parallel to the

wall. [The part of the grommets facing the wall has to have its thickest

part facing downward]

• Fix the manifold by attaching the side of the mounting bracket with the

large hole spacing to the manifold.

Grommet Mounting

bracket

Spacer 20 mm

Spacer 22 mm

Spacer 5 mm

Grommet

8

[large hole spacing]

www.lainginc.com

Page 9

Installation and operation manual MOH2

Angled installation

The picture below shows the angled installation with the mounting

hardware attached accordingly

• Use the 0.8‘‘ (20 mm) and the 0.87‘‘ (22 mm) spacer at the upper

mounting eyelet

• Use the 0.2‘‘ (5 mm) spacer at the lower mounting eyelet

• Turn the rubber grommets in such a way that they are parallel to the

wall.

• Fix the manifold by attaching the side of the mounting bracket with the

small hole spacing to the manifold.

If you purchased the base module without manifold

• Attach the manifold [see previous chapter]

• Install the station directly on the wall or in a sufficiently large cabinet

• Use the two eyelets of the base module for installation

• Use the spacers, the grommets and the washers.

• In addition, attach the manifolds. (For the Laing segmented plastic

manifold, special attachment hardware is available)

Important advice for avoiding noise problems

• Avoid any metal contact between the base module and the wall

• Avoid any metal contact between the manifold and the wall

• Use rubber grommets at all mounting points on both sides to avoid

metal contact between the mounting screws and base module or

manifold [the rubber grommets and washers for the mounting eyelets

of the MOH2 are supplied with the station].

www.lainginc.com

Grommet Mounting

bracket

[large hole spacing]

Spacer 20 mm

Spacer 22 mm

Spacer 5 mm

Grommet

9

Page 10

Installation and operation manual MOH2

If you purchased the station on mounting rails

• Attach the station directly to the wall

• Observe the above advice for avoiding noise problems

• You can use the mounting rails to mark the mounting holes before drilling

If you purchased the station with cabinet

• Remove the front cover of the cabinet

• Install the station in the appropriate niche in the wall and attach it there

• Cover the station with plastic film to keep dirt out

• Use plaster to fill the space between the niche and the cabinet

• Reattach the front cover so that the cover is flush with the plaster surface

Calorimeter

• A parts kit for the attachment of a calorimeter can be ordered as an

option

• Leave enough space in the return of the boiler loop for installation

• There is no need for a sensor fitting on the feed side. The feed side

temperature sensor can be installed directly in the base module

Hydraulic connection

General guideline

• Attach the pipes taking care to avoid too much stress on the module

• To avoid noise, the station must not touch the wall or the mounting

fittings. Use rubber grommets.

• The boiler loop pipes must be insulated inside the wall to avoid noise.

Connection

• First connect the boiler loop return side to the MOH2. If necessary,

install a calorimeter here.

• Next, attach the boiler feed side to the MOH2.

• Attach the low temperature heating loops using compression fittings

starting from the left side. When using plastic tubes, observe the instructions of the system manufacturer.

Connection of calorimeter sensor

• The base module has a 1/2" connection for the dip tube of the calorimeter

next to the boiler feed connection.

• Install the dip tube of the calorimeter here.

10

www.lainginc.com

Page 11

Installation and operation manual MOH2

Connection of the controls

For the connection of controls, the MOH2 base module has 4 positions

for thermal sensors [see sketch on page 2]

• Floor heating feed temperature for control and display [wet sensor]

• Floor heating feed temperature for safety control [dry sensor]

• Floor heating return temperature [wet sensor]

• Boiler feed temperature [wet sensor]

Installation of wet sensors

• The sensors are directly in contact with the water. This results in fast

reaction and accurate temperature sensing.

• Installs the wet sensors before filling the system.

• Insert the sensors and tighten them with the compression fitting.

Installation of dry sensors

• The temperature is read through the wall of the base unit.

• Insert the sensors in the appropriate sensor holes

• Make sure that the sensors are held securely in place. If necessary,

use silicone grease or heat conducting paste to fix them.

• Do not squeeze the sensors under any circumstances.

Electrical connection of thermal drives, sensors and circulator

• If your ordered your station with controls, the electrical installation will

have been completed already.

• If the control has been ordered separately, the sensors and the thermoelectric drive will already be connected to the control. Only the pump

will have to be wired. Observe the installation manual of the control.

• Route all wires to avoid mechanical stress and ensure that they will be

out of the way of anyone operating the station.

Bypass valve 6

Application

• The bypass valve is only needed when the mixing module MOH2 is

operated in conjunction with a step-down control, since the step-down

control derives its outside temperature information from the boiler feed

temperature.

• For all other control methods, this valve remains closed. [Turn clockwise

to full stop]

• The bypass forms of small connection between the boiler feed and return.

www.lainginc.com

11

Page 12

Installation and operation manual MOH2

With the help of this bypass, the boiler feed temperature can be sensed at

the boiler feed connection even when the control valve is closed.

Setting [only in conjunction with a step down control]

• Open the bypass valve sufficiently to allow correct sensing of the boiler

feed temperature even when the control valve is closed. The setting

depends on the length of the boiler feed pipe, the insulation and the

differential pressure of the boiler loop.

• For short boiler feed pipe lengths, is usually sufficient to open the bypass

valve 1/2 turn counter clockwise.

• For long pipe runs between the boiler and the MOH2, the bypass needs

to be opened further. When the control valve is closed, enough water

has to circulate through the bypass so that the correct boiler feed

temperature can be sensed at the boiler feed connection of the MOH2.

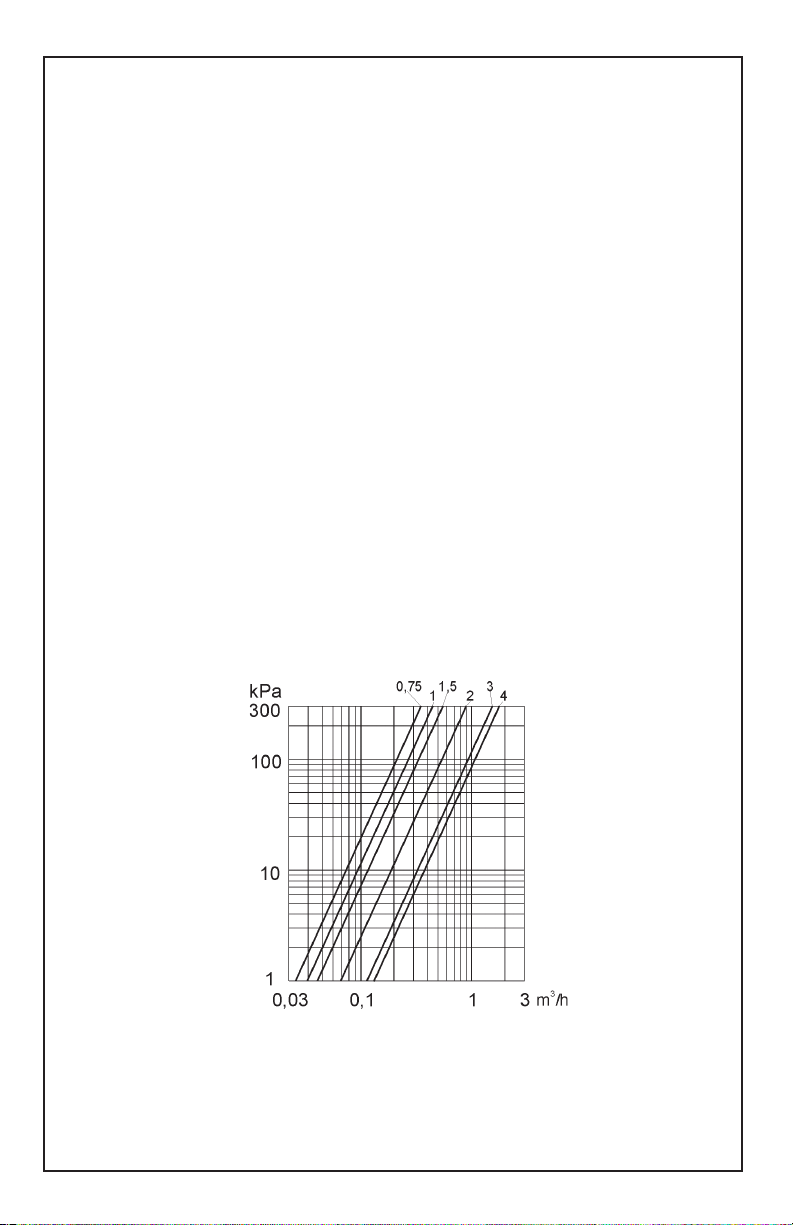

• Use the following diagram to set the valve correctly. It shows the flow

rate through the bypass valve depending on various differential pressures

in the boiler loop.

• To set the valve correctly, close it completely and then turn it counter

clockwise the indicated number of turns

12

Flow rate bypass valve

www.lainginc.com

Page 13

Installation and operation manual MOH2

Presetting knob for control valve 5

Application

• With this knob you can adjust the resistance value of the MOH2 control

valve.

• This controls the maximum amount of water which enters the MOH2

from the boiler loop with the control valve fully open.

• Use this knob to adapt the MOH2 to the heating system and to optimize

the control characteristics.

• It is especially important to adjust the presetting knob correctly if several

MOH2 stations are attached to one boiler loop. This ensures that all

stations will get a sufficient amount of water from the boiler loop.

Setting

• Use the diagram below for setting the presetting knob correctly. It shows

the differential pressure vs. flow rate for the boiler side of the MOH2

including control valve.

• First, determine the amount of boiler water needed during peak heat

demand.

Using this amount of water and the differential pressure available during

peak heat demand, you find the appropriate setting of the knob in the

diagram.

• Close the presetting knob completely [turn right until full stop]. Open

counter clockwise the number of turns shown in the diagram.

www.lainginc.com

Resistance curve presetting knob

13

Page 14

Installation and operation manual MOH2

Filling the system

Preparation

• Close the ball valves 10 and 11 at the boiler feed and return of the

MOH2 mixing module.

• Open the feed valve and return flow adjuster of the left most floor heating

loop directly adjacent to the fill- and drain valves 12 and 13

• Close the feed valves and return flow adjusters of all other floor heating

loops.

Filling of the boiler loop

• Fill the boiler loop as usual. No special precautions are necessary.

Filling of floor heating loops

• Connect the fill hose to the upper fill valve 12.

• Connect the drain hose to the lower drain valve 13.

• In this way, the built in check valve 7 at the floor heating feed side will

close and the water will run through the floor heating loops.

• Flush the first loop until it is completely free of air.

• Close the first loop and open the next loop going from left to right.

Repeat until all loops have been flushed.

After filling

• Open the valves 10 and 11 of the boiler loop

• Open all floor heating loops

Verification of proper filling

• Shut down the heating system or set the boiler temperature to ambient

• Switch on the boiler circulator and the circulator of the mixing module

• Open the control valve. Remove the valve cover to do so if necessary.

• You should hear very few air noises, which should get less over time.

• If the air noises do not decrease but persist or even increase, is

necessary to repeat the air purging as described above.

Pressure test

Preparation

• Open all feed valves of the floor heating loops.

• Close the ball valves 10 and 11 [which connect the module to the boiler

loop]

• Close all return flow adjusters of the floor heating loops.

• Connect the pressure hose to the fill valve 12.

14

www.lainginc.com

Page 15

Installation and operation manual MOH2

Pressure test

• Pressurize the pressure hose

• Now all heating loops including the compression fittings are being

pressure tested.

Start-up

Preconditions:

•The system boiler loop must be filled properly.

• The floor heating system must be filled properly

• A suitable control for the MOH2 module must be in place. Caution:

operation without a suitable control can result in overheating of the floor

heating system.

• The bypass valve must be set in accordance with the control method

selected and the system parameters.

• The presetting knob must be set correctly for the system.

• The heating loops must be open.

• The connection to the boiler loop [ball valves 10 and 11] must be open.

Start-up

• If the preconditions are met, the system can be started up.

• First switch on the control.

• The first heating up of a floor heating system can take a long time since

the floor can absorb a lot of heat. Additionally, in new construction, the

high humidity in the slab can delay the heat up process.

www.lainginc.com

15

Page 16

Installation and operation manual MOH2

Technical data

Maximum system pressure 145 PSI (10 bar )

Circulator see diagram

Floor heating loop

Maximum temperature 140°F (60°C)

Feed connection 1" female thread/flange for segmented

plastic manifold

Return connection...

Boiler loop

Maximum temperature 220°F (105°C)

Feed connection 3/4" female thread in ball valve

Return connection...

Heating performance of MOH2 module

• The heating performance of the MOH2 module is dependent on

- Hydraulic characteristic of the floor heating system

- Differential pressure between boiler feed and return

- Temperature difference between boiler loop and floor heating loop

• Example

- Floor heating feed temperature 50°C [120°F]

- Floor heating return temperature 42°C [108°F]

- Pressure drop in floor heating loops including manifolds 23 kPa [7.5ft]

- The pump curve yields for this differential pressure a flow rate of the

integrated circulator of 1.7 m3/h [7.48 US GPM].

- This means that the MOH2 module can distribute 15.8 kW. in the

floor heating system.

- With an assumed delta T in the boiler loop of 25 K. [45°F], the boiler

loop needs to furnish 0.5 m3/h [2.2 US GPM] at peak heat demand

- Since the boiler return temperature is equal to or larger than the

floor heating return temperature, the minimum boiler feed temperature

at peak heat demand is 67°C [150°F]

- The diagram for the presetting knob which adjusts the boiler side

differential pressure shows that for this flow rate, the differential

pressure in the boiler loop needs to be at least 20 kPa [6.6 ft].

16

www.lainginc.com

Page 17

Installation and operation manual MOH2

Pump curve

The pump curve shows the hydraulic performance available at the

manifold connections

14

12

10

8

6

4

2

Pump head [ft]

0

0 2 4 6 8 10 12 14

Flow rate [US GPM]

www.lainginc.com

17

Page 18

Installation and operation manual MOH2

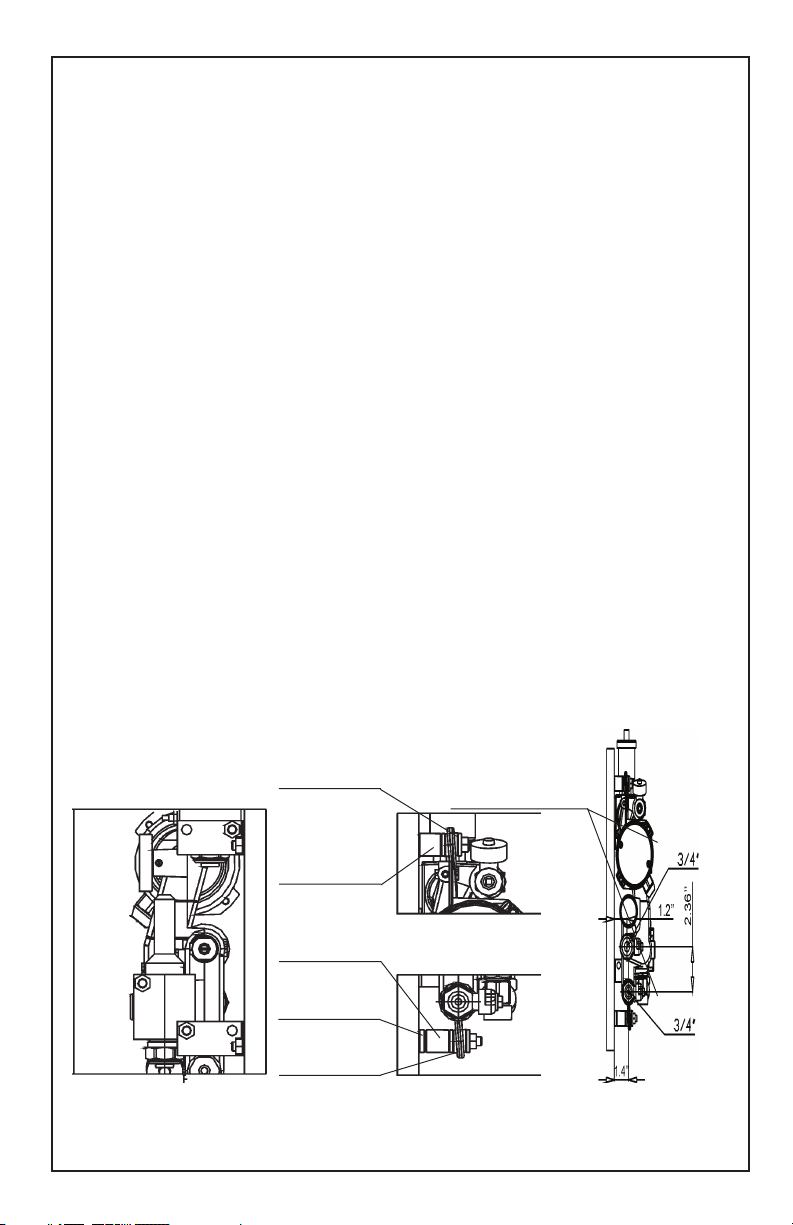

Dimensions

Side view for angled installation Side view for paralell installation

18

www.lainginc.com

Page 19

Installation and operation manual MOH2

Changing out the circulator

Preparation

• Caution: only a properly licensed electrician should disconnect and

reconnect the circulator.

• Remove electrical power even if you only want to clean the circulator

and not remove it.

• Close the ball valves 10 and 11 on the boiler feed and return side

• Connect the drain hose to the lower drain valve 13. In this way, the

check valve 7 will close automatically and the manifold will not drain

completely.

• Make sure that the drain hose can drain below the level of the circulator

pump

Draining of the water

• Open the drain valve 13

• When all water has drained, loosen the upper pump mounting screw to

allow air entry.

• Drain an additional 1/4 liter.

• Now the water should be below the level of the pump

Changing the circulator

• Remove both pump mounting screws.

• Take care when removing the pump since the rotor is only sitting loosely

on the ceramic ball and can fall out. Tilt the wiring end downward slightly

to prevent this.

• After removing the drive unit you can remove the rotor and clean it if

necessary.

• If the rotor have scratches in the lower part, the bearing has run out and

a new drive unit needs to be installed

• Have a properly licensed electrician disconnect the old circulator and

reconnect a new one.

• Before reassembly, carefully clean the seal ring and the housing.

• Reinsert the drive unit and tighten the two pump mounting screws

Restarting the system

• Refill unit by connecting the drain hose to a faucet. The air will bleed

through the automatic air purger.

• Open the valves on the boiler feed and return side

• Re-energize the unit

• The unit should be ready for operation

www.lainginc.com

19

Page 20

Installation and operation manual MOH2

Troubleshooting

• If you use Laing controls, you’ll get error messages for typical errors.

You find the explanation of these error messages in the manual of the

control. In most cases, this will answer your question.

Step-down control doesn’t work:

• The sensors for boiler feed temperature and floor heating feed temperature

have not been connected properly.

Connect sensors according to the appropriate instruction.

• The bypass valve is closed or opened

insufficiently. Open the bypass valve

according to the appropriate instruction.

The feed temperature is oscillating significantly:

• The presetting valve is opened too far,

therefore too much boiler water is entering the floor heating loop. Adjust the

presetting valve according to the appropriate instruction.

• If the heating load is very small, for

example, if only one short loop is open,

an oscillation of the feed temperature is

normal.

The pump is not running: • Possibly the over temperature protec-

tion has tripped and shut off the pump.

• If not, the pump may be clogged by dirt.

Remove the circulator to inspect it.

Heating performance is insufficient:

• The presetting knob is turned in too far

• The bypass valve is opened too far

• The system is just being put into

service, in which case it may take

longer to heat the floor for the first time.

As long as the floor heating return

temperature is still cold, the feed

temperature also cannot increase

independently since most of the feed

water comes from the floor heating

return and only a small portion is boiler

water.

20

www.lainginc.com

Page 21

Installation and operation manual MOH2

www.lainginc.com

21

Page 22

03282006 Subject to change without notice

Phone: (619) 575-7466 · Fax: (619) 575-2739 · E-Mail technicalsupport@lainginc.com

Laing Thermotech, Inc. · 830 Bay Blvd. Suite #101 · Chula Vista, CA 91911

or customerservice@lainginc.com · Internet: www.lainginc.com

Loading...

Loading...