Page 1

INSTRUCTION MANUAL

MM-702F

Series 14-B Ball Type

Blow Down Valve

Applications:

For Series 47, 67, and 70 boiler control blow

down valve replacement.

• Before using this product read and understand instructions.

N

TIO

U

A

C

NING

R

A

W

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

WARNING

!

EASY

OPEN

HANDLE!

Series 14-B

• To prevent serious burns, wear heat resistant gloves when opening and closing valves, or

handling hot equipment.

• To prevent serious burns, allow the control and surrounding equipment to cool to 80˚F

(27˚C) and allow pressure to release to 0 psi (0 bar) before servicing.

• When flushing control (blow down), hot water and steam will flow out. To prevent serious

personal injury, connect a drain pipe to the control opening to avoid exposure to steam

discharge.

To prevent flooding,do not puncture float.

•

California Proposition 65 warning! This product contains chemicals known to the

•

•

!

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

&

'

of installation or two (2) years from the date of manufacture.

Page 2

2

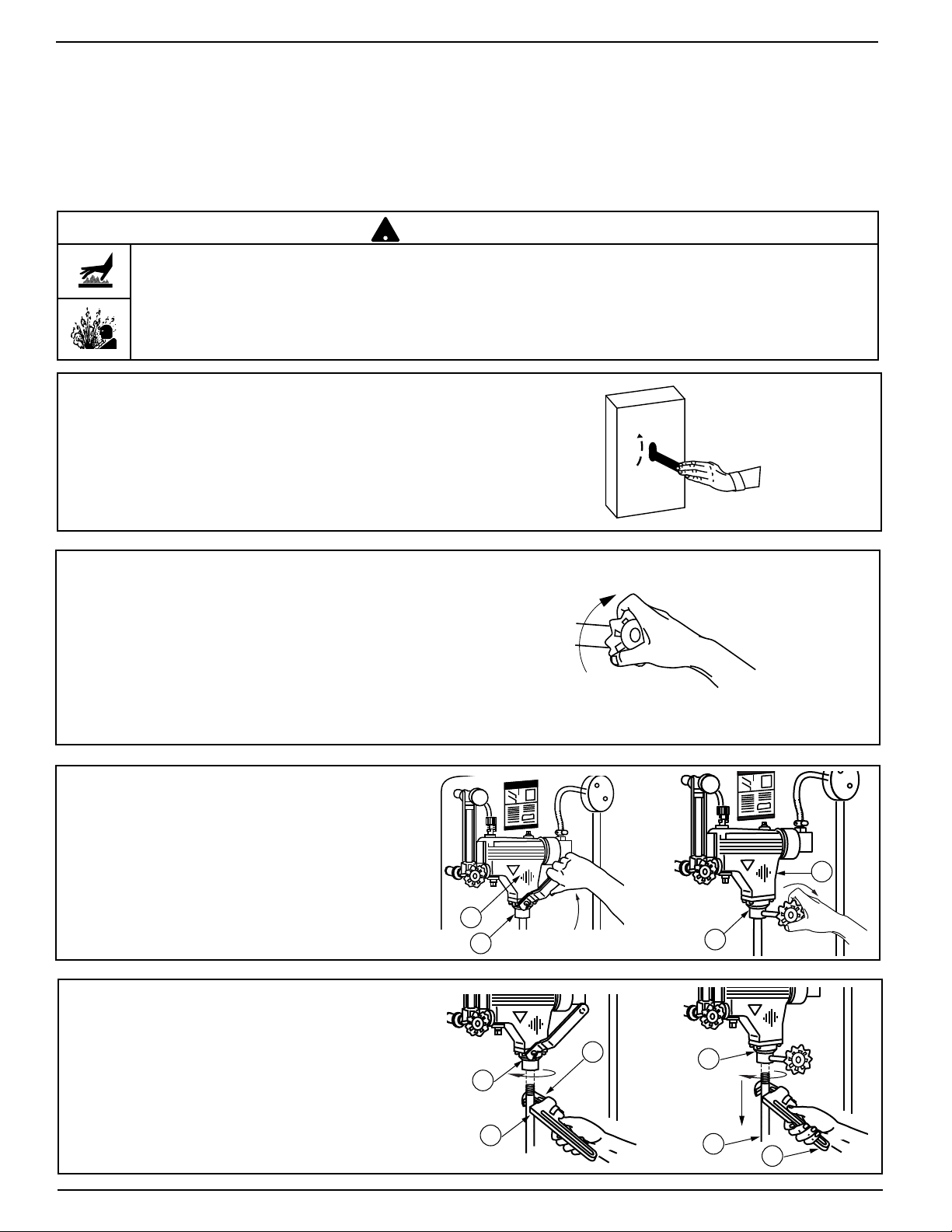

b. Shut off the inlet water supply by closing the make

up water feed valve.

c. Open the blow down valve (D). Drain

the control (A) to a point where no additional water can enter the control. Let

the control (A) and surrounding equipment to cool to 80˚F (27˚C) and allow

pressure to release to 0 psi (0 bar).

A

D

A

D

d. Using a pipe wrench (B), remove the

blow down pipe (C) from the existing

blow down valve (D).

B

D

C

C

D

B

STEP 1 - Preparation

INSTALLATION –

TOOLS NEEDED:

One (1) flathead screwdriver, one (1) scraper, one (1) pipe

wrench, one (1) hammer, and pipe sealing compound.

a. Shut off the boiler and disconnect the power to the

entire boiler system.

OFF

ON

OR

OR

To prevent serious burns, wear heat resistant gloves when opening and closing valves, or handling hot

equipment.

To prevent serious burns, allow the control and surrounding equipment to cool to 80˚F (27˚C) and allow

pressure to release to 0 psi (0 bar) before servicing.

Failure to follow this caution could cause personal injury.

!

CAUTION

Page 3

3

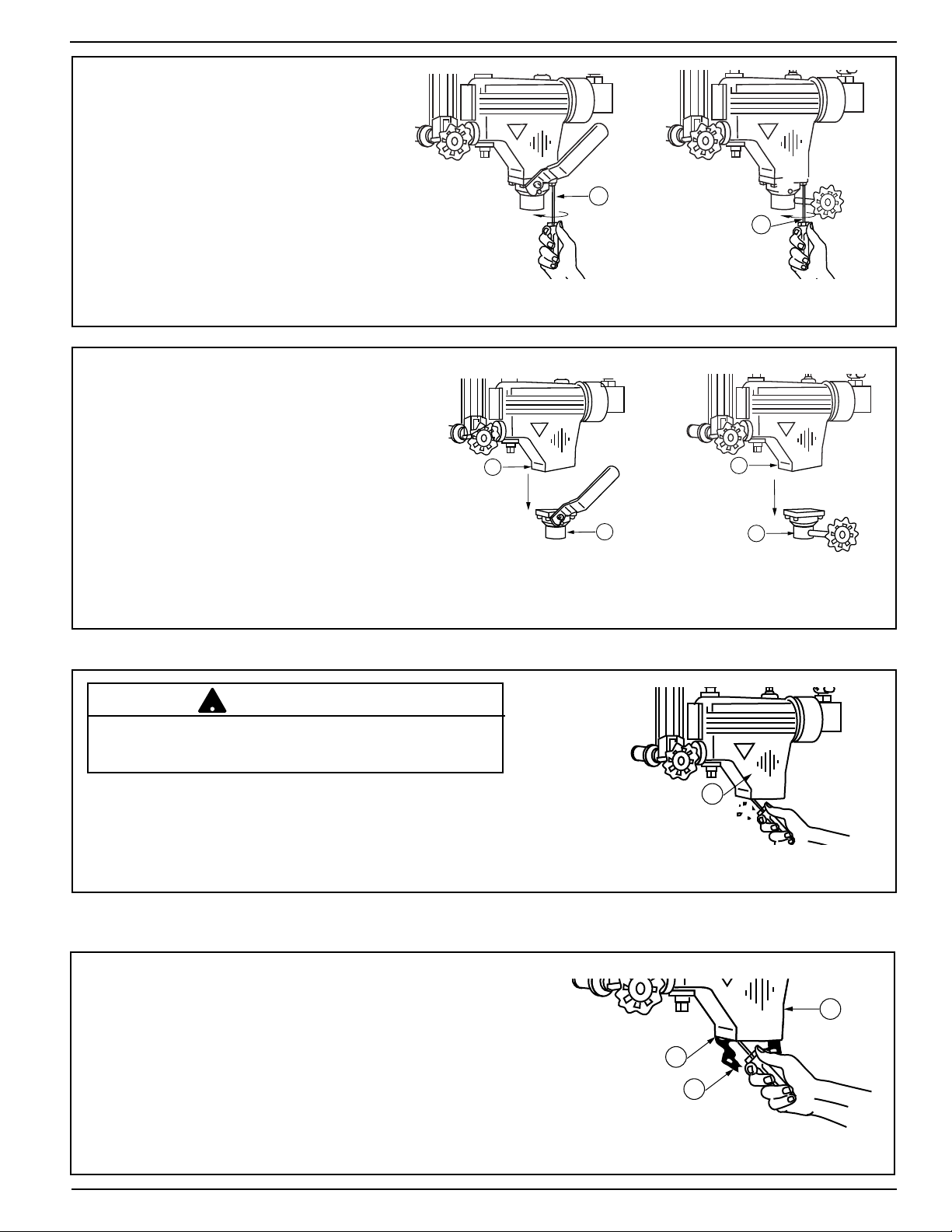

h. Using a scraper, remove the old gasket (F)

from the control (A). The gasket sealing surface (G) must be smooth and clean for

proper installation.

G

F

A

e. Using a flathead screwdriver (E),

loosen the four (4) screws.

E

E

f. Remove the blow down valve (D) from

the control (A). If necessary, use a

hammer to tap it loose.

D

D

A

A

g. Inspect the float chamber (E) for debris.

Carefully remove any debris, mud, or other foreign matter which may obstruct the float's full

range of motion, without puncturing the float.

E

OR

OR

To prevent flooding, do not puncture float.

Failure to follow this caution could cause property damage.

!

CAUTION

NOTE: For spring type blow down

valves, the spring mechanism must

be removed from the control body.

Page 4

4

H

CLOSED

OPEN

G

K

STEP 2 - Installing the New Blow Down Valve

a. Hold the new replacement blow down

valve (H) upright and remove the rubber

band around the valve body.

Be careful not to tip the valve as its

components might fall out. If this

occurs, reassemble as shown (J).

H

Gasket

PTFE Seal

PTFE Seal

Spring

Ball

Housing

J

b. Position the blow down valve (H) onto the control's

mating surface (G). So that it's handle (K) is accessible and is able to swing through its full range of

motion (90˚).

c. Insert the four (4) screws provided through the blow

down valve and gasket (D) into the threaded holes

on the mating surface (G).

G

D

d. Using a flathead screwdriver (L), tighten the screws

to approximately 15 ft•lb (20 N•m).

L

Page 5

5

e. Verify that the blow down valve (H) is unobstructed

by opening and closing the valve over its full range

of motion (90˚).

f. Apply pipe sealing compound to the threaded end of

a 3/4" (20mm) NPT blow down pipe (M) and screw it

into the control (N). Tighten the pipe (M) with a pipe

wrench (P) to approximately 47 ft•lb (64 N•m).

M

P

N

g. Turn the blow down valve handle (K) to its closed

position.

K

CLOSED

h. Hang the enclosed blow down card (Q) as close to

the control as possible, or remove the protective

backing and affix the card on the boiler jacket close

to the control.

Q

H

Page 6

6

IMPORTANT: The burner must not turn on until the water

level has reached its minimum safe operating level as determined by the boiler manufacturer. If the burner turns on

before this point, immediately shut off the boiler and correct

the problem. Other equipment may be involved and the system should be inspected by qualified personnel.

d. Verify that the burner is off and that the system is filling

with water by observing the water level rise in the

gauge glass(R)

R

STEP 3 - Testing

a. Make sure that the blow down valve handle (K) is in

its closed position.

K

CLOSED

b. Open the make-up water feed valve.

c. Turn on the power to the boiler system and turn on

the boiler.

OFF

ON

Page 7

7

To prevent serious personal injury from steam blow down, connect a drain pipe to avoid exposure to steam

discharge.

Failure to follow this caution could cause personal injury or death.

!

WARNING

IMPORTANT: If the control (A) does not blow down

and/or the burner does not shut-off, close the blow

down valve (H), immedialety shut off the boiler, and

correct the problem. Other equipment may be involved

and the system should be inspected by qualified personnel.

e. Allow the system to build to its normal operating pres-

sure and check for leakage around the mating surface

(G), the shaft (S), and the pipe opening (T).

1.

If leakage occurs around the mating surface (G),

retighten the four (4) screws. If leakage continues,

follow "Step 1" to remove the blow down valve (H).

Closely following the installation instructions, replace it.

2.

If leakage occurs around the valve shaft (S),

follow

"Step 1" to remove the blow down valve (H). Closely

following the installation instructions, replace it.

3.

If leakage occurs around the pipe outlet (T),

follow

"Step 1" to remove the blow down valve (H) and

verify that it has been properly assembled as shown

in "Step 2-a". Inspect the blow down valve (H) for

debris which may prevent it from completely closing

or sealing. If leakage continues, follow "Step 1" to

remove it. Closely following the installation instructions, replace the blow down valve (H).

T

GSG

H

f. Open the blow down valve (H) to "blow down" the

control (A). The burner should shut-off.

A

H

g. Close the blow down valve (H) and check for

leakage by following the instructions in "Step 3"

section e.

H

INSTALLATION COMPLETE

Page 8

MAINTENANCE

SCHEDULE:

• Blow down weekly when the boiler is

in operation.

• Disassemble and inspect annually. Replace

the control if it is worn, corroded, or if components no longer operate properly.

• Inspect the float chamber and equalizing

piping annually. Remove all sediment

and debris.

• Replace the blow down valve every 10 years.

More frequent replacement may be required

if it is used in locales where significant water

treatment is required, where more frequent

cleaning is necessary, or in applications with

high make-up water requirements.

PROCEDURE:

CAUTION

!

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to avoid

exposure to steam discharge.

Failure to follow this caution could cause

personal injury.

1. Blow down the low water cut-off when the

water level is at its normal level and the burner

is on. Slowly open the blow down valve until it

is fully open and observe the water level fall in

the gauge glass. Close the valve after verifying

that the burner shuts off. If this does not

happen, immediately shut off the boiler and

correct the problem.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-702F July 2013 Part No. 210286

Loading...

Loading...