Page 1

INSTRUCTION MANUAL

IM107R06

Wastewater Pumps

Dewatering, Efuent and Sewage

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

TABLE OF CONTENTS

SUBJECT PAGE

Safety Instructions .........................................................................................................................................................3

Pre-Installation Checks ..................................................................................................................................................3

Lifting of Pump .............................................................................................................................................................3

Optional Guide Rail or Lift-Out System ........................................................................................................................3

Piping ............................................................................................................................................................................4

Wiring and Grounding ..................................................................................................................................................4

Selecting and Wiring Pump Control Panels and Switches ............................................................................................4-5

Installation ....................................................................................................................................................................5

Operation ...................................................................................................................................................................5-6

Float Switch and Panel Chart .........................................................................................................................................6

Three Phase Power Unbalance .......................................................................................................................................7

Insulation Resistance Readings ......................................................................................................................................7

Engineering Data ...........................................................................................................................................................8

Troubleshooting ............................................................................................................................................................9

Typical Installations .....................................................................................................................................................10

Limited Warranty ........................................................................................................................................................11

Owner’s Information

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.

Date of Purchase: Installation:

Current Readings at Startup:

1Ø 3Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

Page 3

DANGER

WARNING

CAUTION

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

WARNING

CAUTION

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the following signal words and be alert to the

potential for personal injury or property

damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

All electrical work must be performed

by a qualified technician. Always follow

the National Electrical Code (NEC), or the Canadian

Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes and

OSHA safety standards may result in personal injury or

equipment damage. Failure to follow manufacturer’s

installation instructions may result in electrical shock, fire

hazard, personal injury or death, damaged equipment,

provide unsatisfactory performance, and may void manufacturer’s warranty.

Standard units are not designed for use in

swimming pools, open bodies of water,

hazardous liquids, or where flammable gases exist. These

fluids and gases may be present in containment areas.

Tank or wetwell must be vented per local codes.

Only pumps specifically Listed for Class 1, Division 1

are allowable in hazardous liquids and where flammable

gases may exist. See specific pump catalog bulletins or

pump nameplate for all agency Listings.

Disconnect and lockout electrical power

before installing or servicing any electri-

cal equipment. Many pumps are equipped

with automatic thermal overload protection which may

allow an overheated pump to restart unexpectedly.

All three phase (3Ø) control panels for

submersible pumps must provide

Class 10, quick-trip, overload protec-

tion.

PRE-INSTALLATION CHECKS

Open all cartons and inspect for shipping damage. Report

any damage to your supplier or shipping carrier immediately.

Important: Always verify that the pump nameplate Amps,

Voltage, Phase and HP ratings match your control panel

and power supply.

Many of our sewage pumps are oil-filled. If there are any

signs of oil leakage or if the unit has been stored for an

extended period check the oil level in the motor dome

and the seal housing, if so equipped.

Check the motor cover oil level through the pipe plug on

top of the unit. The motor chamber oil should just cover

the motor. Do not overfill, leave room for expansion!

To check the seal housing oil level, where used, lay the

unit on its side with the fill plug at 12 o’clock. Remove

the plug. The oil should be within ½” (13mm) of the top.

If low, refill with an ASTM 150 turbine oil. Replace the

plug.

You can source oil locally at motor repair shops. Typical oil brands are: Shell Turbo 32, Sunoco Sunvis 932,

Texaco Regal R&O 32, Exxon Nuto 32 and Mobil DTE

Light.

Check the strain relief nut on power cable strain assemblies. Power cables should be torqued to 75 in. lbs. for

#16 cables and 80 in. lbs. for all other cable assemblies.

Seal/heat sensor cables, where used, should be torqued to

75 in. lbs.

Warranty does not cover damage caused by connecting

pumps and controls to an incorrect power source (voltage/phase supply).

Record the model numbers and serial numbers from the

pumps and control panel on the front of this instruction

manual for future reference. Give it to the owner or affix

it to the control panel when finished with the installation.

LIFTING OF PUMP

DO NOT LIFT, CARRY OR HANG

PUMP BY THE ELECTRICAL

CABLES. DAMAGE TO THE

ELECTRICAL CABLES CAN CAUSE

SHOCK, BURNS OR DEATH.

Lift the pump with an adequately sized chain or cable attached to the lifting eye bolt. DO NOT damage electrical

and sensor cables while raising and lowering unit.

OPTIONAL GUIDE RAIL

OR LIFT-OUT SYSTEM

In many effluent and sewage basins or lift stations it is

advisable to install the pump on a guide rail system or on

a lift-out adapter to facilitate installation and removal for

inspection and/or service. Most codes do not allow personnel to enter a wetwell without the correct protective equipment and training. Guide rails are designed to allow easy

removal of the pump without the need for entry into the

wetwell or need to disturb piping. The guide rail or liftout adapter should locate the pump opposite the influent

opening preventing stagnate areas where solids can settle.

3

Page 4

WARNING

Hazardous

voltage

WARNING

WARNING

The basin or pit must be capable of supporting the weight

of the pump and guide rail. The pit floor must be flat.

NOTICE: FOLLOW THE INSTRUCTIONS THAT

ARE PROVIDED WITH THE GUIDE RAIL

ASSEMBLY.

PIPING

Discharge piping should be no smaller than the pump

discharge diameter and kept as short as possible, avoiding

unnecessary fittings to minimize friction losses.

Install an adequately sized check valve matched to the

solids handling capability of the pump to prevent fluid

backflow. Backflow can allow the pump to spin backwards and may cause premature seal, bearing, shaft wear.

If the pump is turning backwards when it is called on to

start the increased torque may cause damage to the pump

motor and/or motor shaft.

Install an adequately sized gate valve AFTER the check

valve for pump, plumbing and check valve maintenance.

Important – Before pump installation. Drill a 3⁄16”

(4.8mm) relief hole in the discharge pipe. It should be

located within the wetwell, 2” (51mm) above the pump

discharge but below the check valve. The relief hole allows any air to escape from the casing. Allowing liquid

into the casing will insure that the pump can start when

the liquid level rises. Unless a relief hole is provided, a

bottom intake pump could “air lock” and will not pump

water even though the impeller turns.

All piping must be adequately supported, so as not to

impart any piping strain or loads on the pump.

The pit access cover must be of sufficient size to allow for

inspection, maintenance and crane or hoist service.

WIRING AND GROUNDING

Important notice: Read Safety Instructions before

proceeding with any wiring.

Use only stranded copper wire to pump/motor and

ground. The ground wire must be at least as large

as the power supply wires. Wires should be color

coded for ease of maintenance and troubleshooting.

Install wire and ground according to the National

Electrical Code (NEC), or the Canadian Electrical

Code, as well as all local, state and provincial codes.

Install an all leg disconnect switch where required

by code.

Disconnect and lockout electrical power before

performing any service or installation.

The electrical supply voltage and phase must match

all equipment requirements. Incorrect voltage or

phase can cause fire, motor and control damage,

and voids the warranty.

All splices must be waterproof. If using splice kits

follow manufacturer’s instructions.

Select the correct type and NEMA grade

junction box for the application and location. The junction box must insure dry,

safe wiring connections.

Seal all controls from gases present which

may damage electrical components.

4

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO POWER CAN CAUSE SHOCK,

BURNS OR DEATH.

SELECTING AND WIRING

PUMP CONTROL PANELS AND SWITCHES

FLOAT SWITCH TYPES

There are two basic float switch designs; single-action

and wide-angle. Single-action switches operate over a

range of 15º so they open and close quickly. Wide-angle

floats operate over a 90º swing with the tether length between the float body and the pivot point controlling the

On-Off range. The design determines how many floats

are required with different systems or controls.

Floats may be normally open (NO) for pump down

applications or to empty a tank. Normally closed (NC)

switches are used to pump up or to fill a tank.

A single-action control switch may be used only with a

control panel, never direct connected to a pump.

The wide-angle, pump down switches may be used as

direct connected pump switches or as control switches.

SETTING THE FLOAT SWITCHES

There are no absolute rules for where to set the float

switches, it varies from job to job.

Suggested Rules to Follow:

All floats should be set below the Inlet pipe!

Off Float: Best: set so free hanging the water level is

always above the top of the pump (motor dome). Next

Best: set so the water level is not more than 6" below the

top of the pump.

On Float: set so the volume of water between the On and

Off floats allows pumps of 1½ HP and under to operate

for 1 minute minimum. Two (2) HP and larger pumps

should run a minimum of 2 minutes. Basin technical

brochure states the gallons of storage per inch of basin

height.

Lag/Alarm Float(s): should be staggered above the Off

and On floats. Try to use most of the available storage

provided by the basin, save some space for reserve storage capacity. Exact reserve may be called out by local

codes. See Diagrams and Charts in Float Switch Chart

Section.

PANEL WIRING DIAGRAMS

Our control panels are shipped with instructions and wiring diagrams. Use those instructions in conjunction with

this IOM. Electrical installation should be performed

only by qualified technicians. Any problem or questions

pertaining to another brand control must be referred to

that control supplier or manufacturer.

ALARMS

We recommend the installation of an alarm on all Wastewater pump installations. Many standard control panels

come equipped with alarm circuits. If a control panel is

not used, a stand alone high liquid level alarm is available. The alarm alerts the owner of a high liquid level

in the basin so they can contact the appropriate service

personnel to investigate the situation.

SINGLE PHASE PUMPS

Single phase (1Ø) pumps may be operated using a piggy-

Page 5

back or in conjunction with, or a Simplex or Duplex control

DANGER

Hazardous Machinery

!

WARNING

Hazardous voltage

can shock, burn or

cause death.

panel. See Figures 1, 2 and 5.

Most 1/3 and ½ HP, 115 or 230 volt pumps, and some ¾

and 1 HP pumps, are supplied with plug style power cords.

They may be plugged into piggyback float switches for simple installations. It is allowable to remove the plugs in order

to hardwire or connect to a Simplex or Duplex controller.

Removing the plug neither voids the warranty nor violates

the agency Listings. See Figure 5.

Pumps with bare lead power cords can be hard-wired to a

float switch, wired to a 1Ø contactor, a Simplex controller

or a Duplex controller. Always verify that the float switch

is rated for the maximum run amperage, maximum starting

amperage, and the HP rating on the pump. Single-phase

wastewater pumps contain on-winding overloads, unless

noted on the pump nameplate. See Figures 1 and 2.

THREE PHASE PUMPS:

As a Minimum a 3Ø pump requires a 3 pole circuit breaker/

fused circuit, an across the line magnetic starter rated for the

pump HP, and ambient compensated Quick Trip Class 10

overloads.

SINGLE AND THREE PHASE CONTROL PANELS:

Control panels are available as Simplex (controls 1 pump)

or Duplex (controls 2 pumps). Our standard SES Series

Panels are available with many standard features and can be

built with our most popular options. We also custom build

panels which offer many more design options. Custom

control panels are available in many different configurations. Custom panel quote requests may be forwarded to

Customer Service through any authorized distributor.

Our duplex panels feature a solid-state printed circuit board

design with standard high level alarm circuits. Other standard features are: an auxiliary dry alarm contact for signaling a remote alarm and float switch position indicator lights.

Our 3Ø panels have built-in, adjustable, Class 10 overloads.

The adjustable overloads on all our 3Ø panels mean less labor for the installer and no need to order specific overloads.

Most panels are in stock for immediate delivery without

options.

Heat Sensor and Seal Failure Circuit - Some Pumps are

equipped with a seal failure circuit and a Heat sensor. On

standard product the seal failure circuit, if supplied without

Heat sensor will have an extra lead from the motor with

two conductors. These leads will be Black and White and

should be connected to the seal failure terminals in a panel

supplied with this option. If a seal failure circuit and Heat

sensor are supplied with the pump there will be a separate

lead with four conductors. For these leads the connection

for seal failure will be Black and Green and the Heat sensor

will be Red and White. The model 1GD/12GDS can be ordered with an optional seal failure circuit, but most dual seal

pumps come with the seal failure circuit as a standard.

Models with a 4NS/4DWC/4XD/4XWS have a standard

configuration with seal failure and heat sensor. The leads

are in a separate jacket with 5 leads. Black (tagged P1) and

PLUG-CONNECTED UNITS MUST

BE CONNECTED TO A PROPERLY

GROUNDED, GROUNDING TYPE

RECEPTACLE.

ON NON-PLUG UNITS, DO NOT

REMOVE CORD AND STRAIN RELIEF.

DO NOT CONNECT CONDUIT TO

PUMP.

White (tagged P2) should be connected to thermal protection terminals. The seal fail leads are Red (tagged W1) and

Orange (tagged W2) and should be connected to the seal

fail terminals. The additional lead is Green and should be

connected to Ground. Panels will come equipped with a

wiring diagram designating your connections. Panels must

be ordered with the options for seal failure circuits and heat

sensor circuits, since these panels can also be used on pumps

without the option for these connections they do not come

as standard on most panels.

One additional style of seal failure and heat sensor circuits

is our product sold with models GA(X) / 15GDS(X) /

20GDS(X); 2, 3, 4GV(X); 2, 3, 4MV(X); 2, 3, 4, 6MK(X).

These units come with a single lead for power and controls.

The conductor will come with 7 leads (previous to January

2013). Leads For seal failure and heat sensor will be Orange

and Blue. Since these units use a different style sensor in the

pump as well as a different option in the panel the connections require only two leads. After January 2013 the lead

colors on the pumps were changed to two (2) white leads

for the seal failure and heat sensor.

Be careful to choose the correct options in the panel selection for each style pump. Always follow wiring schematic

of the panel. Failure to wire the seal failure and heat sensor

leads correctly may prevent the pump from running or

cause nuisance tripping.

INSTALLATION

Connect the pump(s) to the guide rail pump adapters or to

the discharge piping. Slide rail bases should be anchored to

the wetwell floor.

Complete all wiring per the control panel wiring diagrams

and NEC, Canadian, state, provincial and/or local codes.

This a good time to check for proper rotation of the motors/impellers.

DO NOT PLACE HANDS IN PUMP

SUCTION WHILE CHECKING

MOTOR ROTATION. TO DO SO WILL

CAUSE SEVERE PERSONAL INJURY.

Always verify correct rotation. Correct

rotation is indicated on the pump casing.

Three phase motors are reversible. It is

allowable to bump or jog the motor for a

few seconds to check impeller rotation. It is

easier to check rotation before installing the pump. Switch

any two power leads to reverse rotation.

Lower the pump(s) into the wetwell.

Check to insure that the floats will operate freely and not

contact the piping.

OPERATION

Once the piping connections are made and checked you can

run the pumps.

Piggyback Switch Operation – Plug the piggyback switch

into a dedicated grounded outlet and then plug the pump

into the switch. Test the pump by filling the wetwell until

the pump goes On. If the pumps run but fail to pump, they

are probably air locked, drill the relief holes per the instructions in the Piping Section.

Check the operating range to insure a minimum one minute

run time and that the pump goes Off in the correct position.

Control Panel Operation – Fill the wetwell with clear water.

5

Page 6

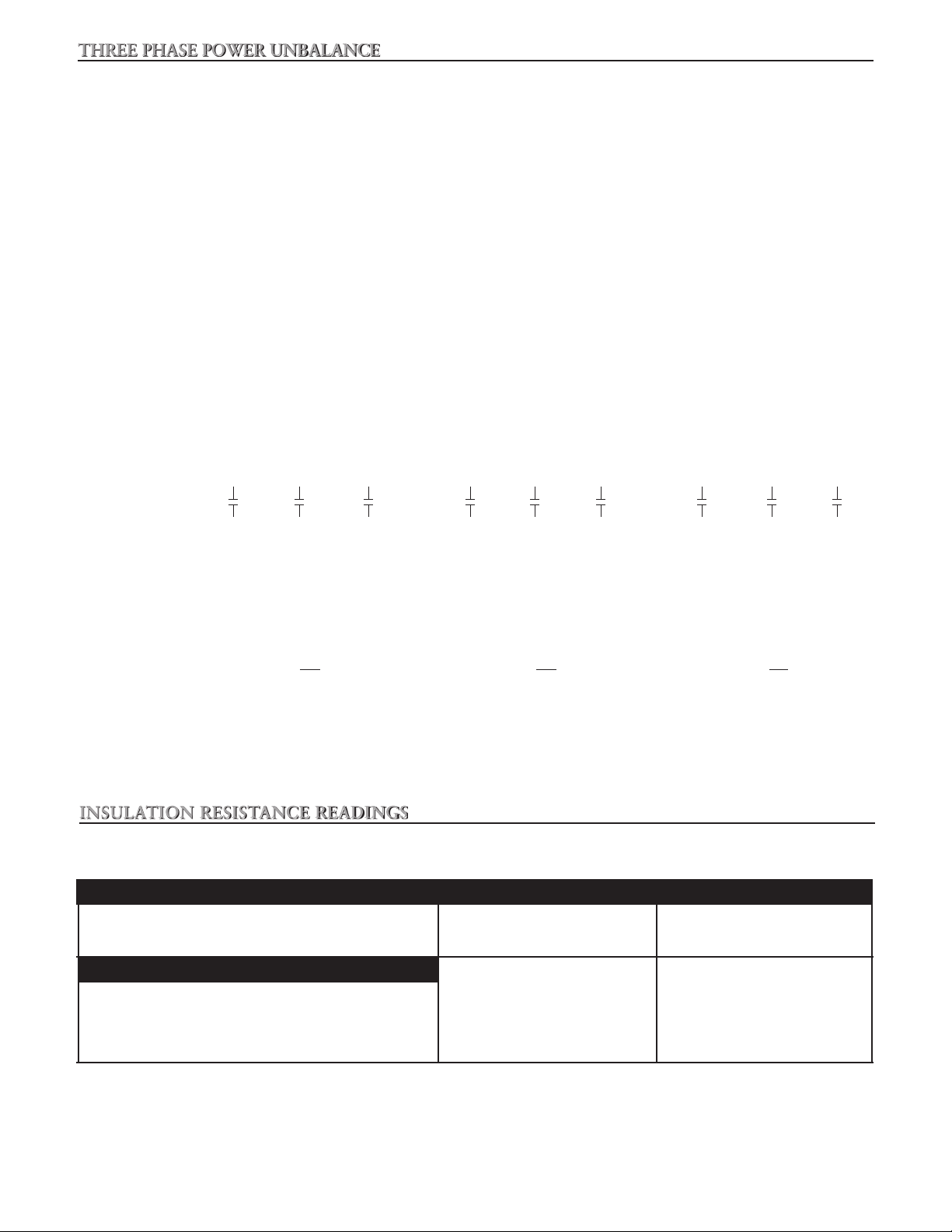

Use the pump H-O-A (Hand-Off-Automatic) switches in

Inlet

Alarm SW3

Pump On SW2

Pump Off SW1

Discharge

Inlet

Alarm SW4

Lag Pump On

SW3

Pump Off

SW1

Discharge

Lead Pump On

SW2

Hand to test the pumps. If they operate well in Hand proceed to test Automatic operation. If the pumps run but fail

to pump, they are probably air locked, drill the relief holes

per the instructions in the Piping Section.

Place Control Panel switch(es) in Automatic position and

thoroughly test the operation of the ON, OFF, and Alarm

floats by filling the wetwell with clear water. Important:

Failure to provide a Neutral from the power supply to a

1Ø, 230 volt Control Panel will not allow the panel control

circuit to operate. The Neutral is necessary to complete the

115 volt control circuit.

Check voltage and amperage and record the data on the

front of this manual for future reference. Compare the amperage readings to the pump nameplate maximum amperage. If higher than nameplate amperage investigate cause.

FLOAT SWITCH AND PANEL CHART

The purpose of this chart is to show the required switch

quantities and the function of each switch in a typical

wastewater system. The quantities required vary depending on the switch type, single-action or wide-angle.

Switch quantities also vary by panel type: simplex with

and without alarms, and duplex with alarms.

Duplex Panels using single-action switches:

Three Float Panel Wiring

SW1 Bottom Pumps Off

SW2 Middle 1st Pump On

SW3 Top 2nd Pump & Alarm On

Operating the pump off the curve, i.e. with too little head

or with high or low voltage will increase amperage. The

motor will operate properly with voltage not more than

10% above or below pump nameplate ratings. Performance

within this range will not necessarily be the same as the published performance at the exact rated nameplate frequency

and voltage. Correct the problem before proceeding. Three

phase unbalance is also a possible cause. See Three Phase

Power Unbalance and follow the instructions.

Reset the Alarm circuit, place pump switch(es) in the Automatic position and Control Switch in ON position. The

system is now ready for automatic operation.

Explain the operation of the pumps, controls and alarms to

the end user. Leave the paperwork with the owner or at the

control panel if in a dry, secure location.

Simplex Panel using wide-angle switches:

Simplex Panel with Alarm

SW1 Bottom Pump On/Off

SW2 Top Alarm On/Off

Simplex Panel with No Alarm

SW1 Pump On/Off

Four Float Panel Wiring ➁

SW1 Bottom Pumps Off

SW2 2nd 1st Pump On

SW3 3rd 2nd Pump On

SW4 Top Alarm On

Duplex Panels using wide-angle switches:

Three Float Panel Wiring

SW1 Bottom 1st Pump On/Both Off

SW2 Top 2nd Pump & Alarm On

Four Float Panel Wiring

SW1 Bottom 1st Pump On/Both Off

SW2 Middle 2nd Pump On

SW3 Top Alarm On

Simplex Panel using single-action switches:

Simplex Panel with Alarm ①

SW1 Bottom Pump Off

SW2 Middle Pump On

SW3 Top Alarm On/Off

Simplex Panel with No Alarm

SW1 Bottom Pump Off

SW2 Top Pump On

Simplex ①

Duplex ➁

6

Page 7

THREE PHASE POWER UNBALANCE

A full three phase supply consisting of three individual

transformers or one three phase transformer is recommended. “Open” delta or wye connections using only

two transformers can be used, but are more likely to

cause poor performance, overload tripping or early motor failure due to current unbalance.

Check the current in each of the three motor leads and

calculate the current unbalance as explained below.

If the current unbalance is 2% or less, leave the leads as

connected.

If the current unbalance is more than 2%, current readings should be checked on each leg using each of the

three possible hook-ups. Roll the motor leads across the

starter in the same direction to prevent motor reversal.

To calculate percent of current unbalance:

A. Add the three line amp values together.

B. Divide the sum by three, yielding average current.

C. Pick the amp value which is furthest from the average

current (either high or low).

D. Determine the difference between this amp value

(furthest from average) and the average.

E. Divide the difference by the average. Multiply the

result by 100 to determine percent of unbalance.

Current unbalance should not exceed 5% at service

factor load or 10% at rated input load. If the unbalance

cannot be corrected by rolling leads, the source of the

unbalance must be located and corrected. If, on the three

possible hookups, the leg farthest from the average stays

on the same power lead, most of the unbalance is coming

from the power source.

Contact your local power company to resolve the imbalance.

Hookup 1 Hookup 2 Hookup 3

Starter Terminals L1 L2 L3 L1 L2 L3 L1 L2 L3

Motor Leads R B W W R B B W R

T3 T1 T2 T2 T3 T1 T1 T2 T3

Example:

T3-R = 51 amps T2-W = 50 amps T1-B = 50 amps

T1-B = 46 amps T3-R = 48 amps T2-W = 49 amps

T2-W = 53 amps T1-B = 52 amps T3-R = 51 amps

Total = 150 amps Total = 150 amps Total = 150 amps

÷ 3 = 50 amps ÷ 3 = 50 amps ÷ 3 = 50 amps

– 46 = 4 amps – 48 = 2 amps – 49 = 1 amps

4 ÷ 50 = .08 or 8% 2 ÷ 50 = .04 or 4% 1 ÷ 50 = .02 or 2%

INSULATION RESISTANCE READINGS

Normal Ohm and Megohm Values between all leads and ground

Condition of Motor and Leads Ohm Value Megohm Value

A new motor (without drop cable). 20,000,000 (or more) 20 (or more)

A used motor which can be reinstalled in well. 10,000,000 (or more) 10 (or more)

Motor in well. Readings are for drop cable plus motor.

New motor. 2,000,000 (or more) 2 (or more)

Motor in good condition. 500,000 - 2,000,000 .5 - 2

Insulation damage, locate and repair. Less than 500,000 Less than .5

Insulation resistance varies very little with rating. Motors of all HP, voltage and phase ratings have similar values of

insulation resistance.

Insulation resistance values above are based on readings taken with a megohmmeter with a 500V DC output.

Readings may vary using a lower voltage ohmmeter, consult factory if readings are in question.

7

Page 8

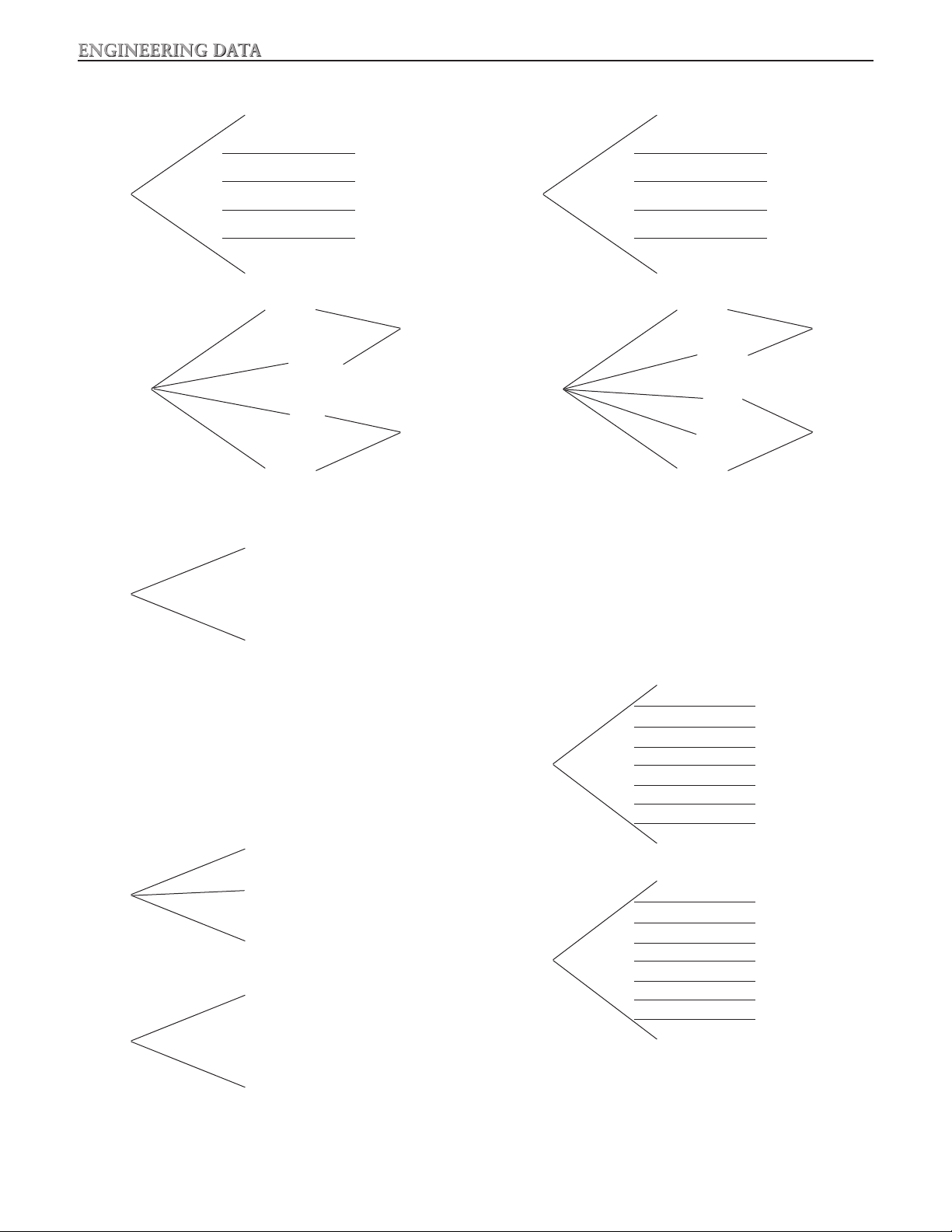

ENGINEERING DATA

6" (15.3 cm)

6" (15.3 cm)

8" (20.3 cm) TURN ON LEVEL

WEIGHT

L1

L2

L3

GRD

S1

Red

Black

White

Green

PUMP

Engineering data for specic models may be found in your catalog and on our website (address is on the cover).

Control panel wiring diagrams are shipped with the control panels. Please use the control panel drawings in

conjunction with this instruction manual to complete the wiring.

PUMP OPERATION

Minimum Submergence

Continuous

Duty

Intermittent

Duty

NOT RECOMMENDED

Pumpmaster and Pumpmaster Plus -

Fully Submerged

6" Below Top of Motor

Hard Wired

Figure 1

Maximum Fluid Temperature

Continuous

Operation

Intermittent

Operation

Single-Action Float Switch

"Typical" Installation

104º F 40º C

140º F 60º C

Figure 4

NOT RECOMMENDED

Double Float - Hard Wired

Figure 2

Determining Pumping Range

Wide-Angle Float Switch

Pump plug

Figure 5

Three Phase Connection Diagram

Standard without seal failure and heat sensor

for powering pump.

Piggyback

switch plug

Pumping

range

8

Figure 3

Figure 6

Page 9

ENGINEERING DATA

Three Phase Standard Product Leads 4NS/4XD/4XS/4DWC

Black Black

Power

Lead

Sensor Lead

with Seal

Fail only

and High

Temp

OR

Sensor

Lead

Seal

Failure

only

Red Red

White White

Green Green

Black Black

Green

Red

White Green

Black

White

Figure 7

Seal

Failure

Heat

Sensor

Power

Sensor

Figure 9

1/2GA(X), 15/20GDS(X)

2, 3, 4GV(X) – 2, 3, 4, 6MK(X) – 2, 3, 4MV(X)

White

Red

Orange

Seal

Heat

Sensor

Sensor

Seal

Failure

Single Phase

Black

White

Green

Black

White

No Heat Sensor available

Previous to

January

2013

After

January

2013

Black

Red

White

Green

Green/Yellow

Orange

Blue

Gray

Red

Black

Green

White

White

Empty lead

Figure 10

Figure 8

9

Page 10

TROUBLESHOOTING

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL

POWER BEFORE ATTEMPTING ANY SERVICE CAN CAUSE

SHOCK, BURNS OR DEATH.

SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION

MOTOR NOT RUNNING Motor thermal protector tripped. Allow motor to cool. Insure minimum pump

submergence. Clear debris from casing and impeller.

NOTE: If circuit breaker

Open circuit breaker or blown fuse. Determine cause, call a qualified electrician.

“OPENS” repeatedly,

DO NOT reset. Call

Pump impeller binding or jammed. Check motor amp draw. If two or more times higher

qualified electrician.

than listed on pump nameplate, impeller is locked,

a) Manual operation Power cable is damaged. motor bearings or shaft is damaged. Clear

Resistance between power leads and ground should

b) Automatic operation No neutral wire read infinity. If any reading is incorrect, call a

connected to control panel. qualified electrician.

Inadequate electrical connection Inspect control panel wiring. Call a qualified

in control panel. electrician.

NOTE: Check the pump

Defective liquid level switch. With switch disconnected, check continuity while

in manual mode first to

activating liquid level switch. Replace switch, as

confirm operation. If pump

required.

operates, the automatic

Insufficient liquid level to Allow liquid level to rise 3" to 4" (76 mm - 101 mm)

control or wiring is at fault.

activate controls. above turn-on level.

If pump does not operate,

Liquid level cords tangled. Untangle cords and insure free operation.

see above.

PUMP WILL NOT Liquid level cords tangled. Untangle cords and insure free operation.

TURN OFF

Pump is air locked. Shut off pump for approximately one minute, then

restart. Repeat until air lock clears. If air locking

persists in a system with a check valve, a 3⁄16" (4.8 mm)

hole may be drilled in the discharge pipe approximately

2" (51 mm) above the discharge connection.

Inadequate electrical connection

in control panel.

debris from casing and impeller, consult with dealer.

Influent flow is matching pump’s Larger pump may be required.

discharge capacity.

LITTLE OR NO LIQUID Check valve installed backwards, Check flow arrow on valve and check valve

DELIVERED BY PUMP plugged or stuck closed. operation.

Excessive system head. Consult with dealer.

Pump inlet plugged. Inspect and clear as required.

Improper voltage or wired Check pump rotation, voltage and wiring.

incorrectly. Consult with qualified electrician.

Pump is air locked. See recommended action, above.

Impeller is worn or damaged. Inspect impeller, replace as required.

Liquid level controls defective Inspect, readjust or replace as required.

or improperly positioned.

PUMP CYCLES Discharge check valve inoperative. Inspect, repair or replace as required.

CONSTANTLY

Liquid level controls defective or Inspect, readjust or replace as required.

improperly positioned.

Influent excessive for this size Consult with dealer.

pump.

Sewage containment area too small. Consult with dealer.

10

Page 11

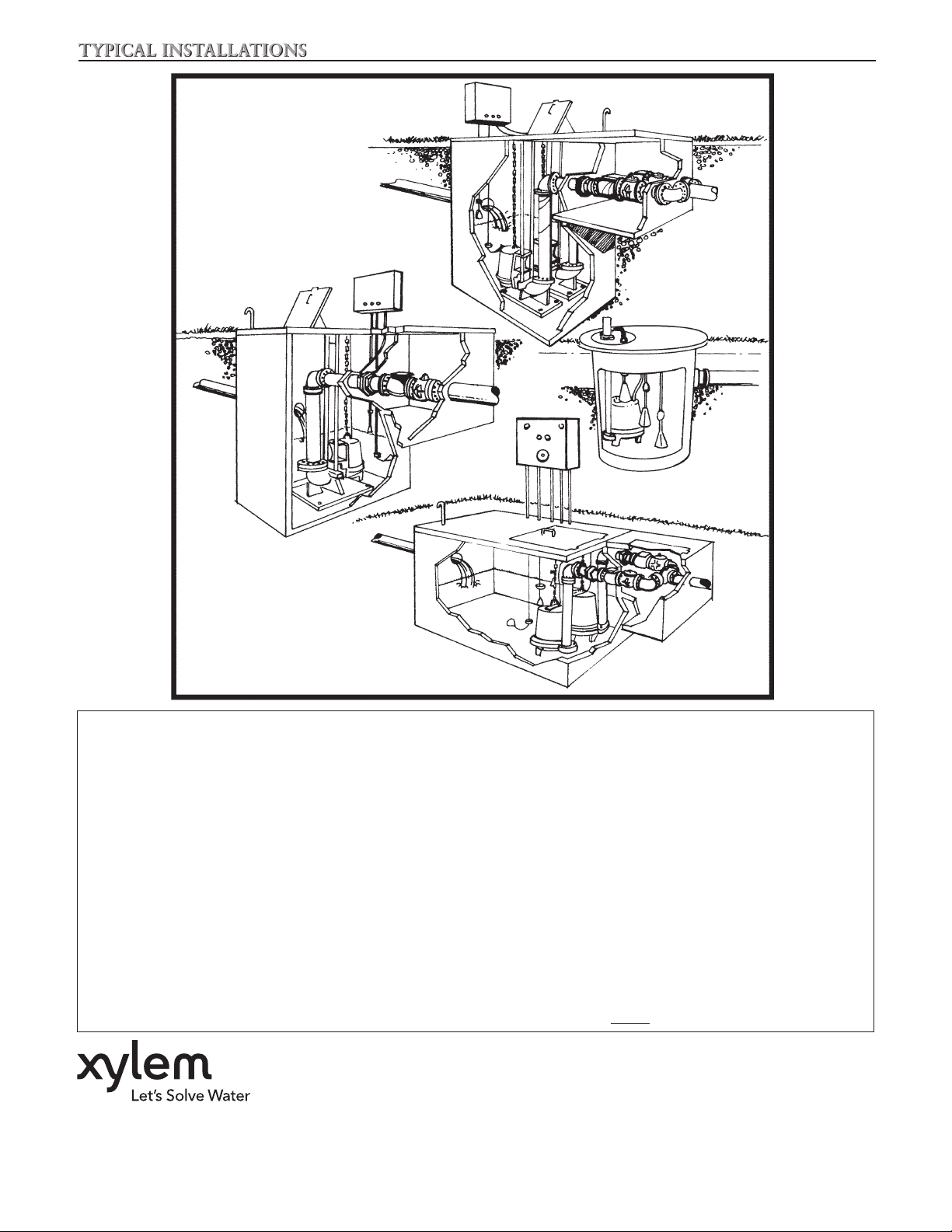

TYPICAL INSTALLATIONS

Typical Efuent, Sewage and

Dewatering Pump Installations

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall

exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer

in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to

customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited

liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM107 Revision Number 6 May 2014

11

Page 12

MANUAL DE INSTRUCCIÓN

IM107R06

Bombas para aguas residuales,

para extracción de agua, para

euente y para alcantarillado

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

12

Page 13

ÍNDICE

TEMA PÁGINA

Instrucciones de seguridad ...........................................................................................................................................14

Verificaciones preliminares a la instalación...................................................................................................................14

Levantamiento de la bomba .........................................................................................................................................14

Riel corredizo o sistema de levantamiento opcional .....................................................................................................15

Tuberías ....................................................................................................................................................................... 15

Cableado y conexión a tierra .......................................................................................................................................15

Selección y cableado de los interruptores y paneles de control de la bomba ............................................................15-16

Instalación ...................................................................................................................................................................17

Operación ...................................................................................................................................................................17

Tabla del panel e interruptores de flotador ...................................................................................................................18

Desbalance de potencia trifásica ..................................................................................................................................19

Lecturas de resistencia de aislamiento ..........................................................................................................................19

Datos de ingeniería ......................................................................................................................................................20

Instalaciones típicas .....................................................................................................................................................21

Identificación y resolución de problemas .....................................................................................................................22

Garantía limitada .........................................................................................................................................................23

Información del propietario

Número de modelo de la bomba:

Número de serie de la bomba:

Número de modelo del control:

Agente:

No. telefónico del agente:

Fecha de compra: Instalación:

Lecturas actuales en el momento de la puesta en marcha:

1Ø 3Ø L1-2 L2-3 L3-1

Amperios: Amperios:

Voltios: Voltios:

13

Page 14

INSTRUCCIONES DE SEGURIDAD

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

PARA EVITAR LESIONES PERSONALES GRAVES

O AÚN FATALES Y SERIOS DAÑOS MATERIALES,

LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ESTE MANUAL HA SIDO CREADO COMO UNA

GUÍA PARA LA INSTALACIÓN Y OPERACIÓN DE

ESTA UNIDAD Y SE DEBE CONSERVAR JUNTO A

LA BOMBA.

EXAMINE BIEN TODAS LAS INSTRUCCIONES

Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

Código Eléctrico de EE.UU. (NEC) o el Código Eléctrico

Canadiense, además de todos los códigos locales, estatales

y provinciales. Las preguntas acerca del código deben ser

dirigidas al inspector eléctrico local. Si se hace caso omiso

a los códigos eléctricos y normas de seguridad de OSHA,

se pueden producir lesiones personales o daños al equipo.

Si se hace caso omiso a las instrucciones de instalación del

fabricante, se puede producir electrochoque, peligro de

incendio, lesiones personales o aún la muerte, daños al

equipo, rendimiento insatisfactorio y podría anularse la

garantía del fabricante.

agua, líquidos peligrosos o donde existan gases inflamables. Estos fluidos y gases podrían estar presentes en áreas

de contención. El tanque o pozo debe ser ventilado de

acuerdo con los códigos locales.

En lugares con líquidos inflamables o donde pudiese

haber gases inflamables sólo deben usarse bombas específicamente clasificadas para áreas de Clase 1, División 1.

Consulte los boletines de catálogos de bombas específicas

o la placa de identificación de la bomba con respecto a las

listas de agencias.

equipo eléctrico. Muchas bombas están equipadas con protección automática contra la sobrecarga térmica, la cual podría

permitir que una bomba demasiado caliente rearranque

inesperadamente.

14

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque una

de las siguientes palabras de señal y esté

alerta a la probabilidad de lesiones personales o daños materiales.

Advierte los peligros que CAUSARÁN

graves lesiones personales, la muerte o

daños materiales mayores.

Advierte los peligros que PUEDEN causar

graves lesiones personales, la muerte o

daños materiales mayores.

Advierte los peligros que PUEDEN causar

lesiones personales o daños materiales.

AVISO: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y QUE

SE DEBEN SEGUIR.

Todo el trabajo eléctrico debe ser realizado

por un técnico calificado. Siempre siga el

Las unidades estándar no están diseñadas

para usarse en albercas, masas abiertas de

Desconecte y bloquee la corriente eléctrica

antes de instalar o dar servicio a cualquier

Todos los paneles de control trifásicos (3Ø)

para bombas sumergibles deben incluir pro-

tección contra sobrecarga de Clase 10, de disparo rápido.

VERIFICACIONES PRELIMINARES

A LA INSTALACIÓN

Abra todas las cajas e inspeccione el equipo para determinar si se ocasionaron daños durante el envío. Notifique

cualquier daño a su proveedor o a la compañía de transporte de inmediato.

Importante: Siempre verifique que las clasificaciones de

corriente, tensión, fase y potencia en la placa de identificación de la bomba correspondan con las del panel de

control y fuente de alimentación.

Muchas de nuestras bombas para alcantarillado están

llenas con aceite. Si hay alguna señal de fuga de aceite

o si la unidad estuvo almacenada durante largo tiempo,

verifique el nivel de aceite en la cúpula del motor y la caja

del sello, en caso de haberla.

Verifique el nivel de aceite de la cubierta del motor a

través del tapón de la tubería en el extremo superior de

la unidad. El aceite en la cámara del motor debe cubrir

apenas el motor. ¡No llene en exceso, deje espacio para

expansión!

Para verificar el nivel de aceite de la caja del sello, en caso

que se use, coloque la unidad de lado con el tapón de

llenado en la posición de las 12:00 horas. Retire el tapón.

El aceite debe estar a menos de ½ pulg. (13 mm) del

borde superior. Si el nivel está bajo, agregue aceite para

turbinas ASTM 150. Reinstale el tapón.

Puede obtener aceite a nivel local en talleres de reparación de motores. Las marcas típicas de aceite son: Shell

Turbo 32, Sunoco Sunvis 932, Texaco Regal R&O 32,

Exxon Nuto 32 y Mobil DTE Light.

Inspeccione la tuerca de alivio de tensión en los conjuntos de protección contra tirones de los cables de alimentación. Torsión de los cables de alimentación: 75 pulg.-lbs.

para cables #16 y 80 pulg.-lbs. para todos los otros tipos

de cable. La torsión de los cables de sensores de sello/

calor, cuando se usen, debe ser de 75 pulg.-lbs.

La garantía no cubre daños causados por conectar bombas y controles a la fuente de energía incorrecta (fuente

de tensión/fase).

Anote los números de modelos y números de serie de las

bombas y del panel de control en la sección delantera

de este manual de instrucciones para referencia futura.

Entregue el manual al propietario o adjúntelo al panel de

control una vez finalizada la instalación.

LEVANTAMIENTO DE LA BOMBA

NO LEVANTE NI TRANSPORTE

NI CUELGUE LA BOMBA DE LOS

CABLES ELÉCTRICOS. EL DAÑO A

LOS CABLES ELÉCTRICOS PUEDE

PRODUCIR ELECTROCHOQUE,

QUEMADURAS O AÚN LA MUERTE.

Levante la bomba con una cadena o cable de tamaño

adecuado conectado al perno de ojo de levantamiento.

NO dañe los cables eléctricos o de los sensores al subir y

bajar la unidad.

Page 15

ADVERTENCIA

Tensión

peligrosa

ADVERTENCIA

ADVERTENCIA

RIEL CORREDIZO O SISTEMA DE

LEVANTAMIENTO OPCIONAL

En muchos estanques de efluente y aguas negras o estaciones de levantamiento se recomienda instalar la bomba

en un sistema de riel corredizo o sobre un adaptador de

levantamiento para facilitar la instalación y retiro para

inspección y/o servicio. La mayoría de los códigos no

permiten que el personal entre al pozo sumidero sin el

equipo de protección y la capacitación correctos. Los

rieles corredizos están diseñados para facilitar el retiro de

la bomba sin necesidad de entrar al pozo o perturbar la

tubería. El riel corredizo o el adaptador de levantamiento

debe situar la bomba opuesta a la abertura para el líquido

de entrada, evitando las áreas estancadas donde pudiesen

asentarse sólidos. El estanque o fosa debe ser capaz de

soportar el peso de la bomba y del riel de deslizamiento. El

piso de la fosa debe ser plano.

AVISO: SIGA LAS INSTRUCCIONES INCLUIDAS

CON EL CONJUNTO DEL RIEL CORREDIZO.

TUBERÍAS

La tubería de descarga no debe ser más pequeña que el

diámetro de descarga de la bomba y debe mantenerse lo

más corta posible, evitando los accesorios innecesarios para

reducir al mínimo las pérdidas por fricción.

Instale una válvula de retención de tamaño adecuado que

corresponda con la capacidad de manejo de sólidos de la

bomba para evitar el contraflujo de fluido. El contraflujo puede hacer que la bomba vuelta en dirección inversa, produciendo un desgaste prematuro del sello, del cojinete, del eje.

Si la bomba gira en sentido inverso al arrancar, el aumento

de torsión puede dañar el motor y/o el eje del motor.

Instale una válvula de compuerta de tamaño adecuado

DESPUÉS de la válvula de retención para facilitar el mantenimiento de la bomba, las tuberías y la válvula de retención.

Importante – antes de instalar la bomba. Perfore un orificio

de alivio de 3⁄16 pulg. (4.8 mm) en la tubería de descarga.

Debe situarse dentro del pozo, a 2 pulg. (51 mm) sobre la

descarga de la bomba, pero debajo de la válvula de retención. El orificio de alivio permite el escape de aire de la

carcasa. Al permitir que entre líquido a la carcasa se asegura

que la bomba pueda arrancar cuando el nivel de líquido

aumente. A menos que se proporcione un orificio de alivio,

una bomba de toma inferior podría “obstruirse con aire” y

no bombear agua, a pesar de que el impulsor gire.

Todas las tuberías deben estar apoyadas correctamente, de

modo que no se apliquen esfuerzos o cargas de las tuberías a

la bomba.

La cubierta de acceso a la fosa debe ser de tamaño suficiente

para permitir realizar el servicio de inspección, mantenimiento y levantamiento con grúa o montacargas.

CABLEADO Y CONEXIÓN A TIERRA

Aviso importante: Lea las instrucciones de seguridad antes

de proseguir con el cableado.

Use únicamente alambre trenzado de cobre para la

bomba/motor y la conexión a tierra. El alambre de

conexión a tierra debe ser al menos del mismo tamaño

que los alambres de la fuente de alimentación. Los

alambres deben codificarse con colores para facilitar

el mantenimiento y la identificación y resolución de

problemas.

Instale los cables y la conexión a tierra de acuerdo con

el Código Eléctrico de EE.UU. (NEC) o el Código

Eléctrico Canadiense, además de los códigos locales,

estatales y provinciales.

Instale un desconectador de todos los circuitos donde

el código lo requiera.

Desconecte y bloquee la corriente eléctrica antes de

instalar o dar servicio.

La tensión y fase de la fuente de alimentación debe

corresponder con todos los requerimientos del equipo.

La tensión o fase incorrecta puede producir incendio,

daño al motor o a los controles y anula la garantía.

Todos los empalmes debe ser impermeables. Si utiliza

juegos de empalme, siga las instrucciones del fabricante.

Seleccione una caja de conexiones NEMA

del tipo correcto para la aplicación y ubicación. La caja de conexiones debe garantizar conexiones de cableado seguras y secas.

Selle todos los controles de los gases presentes que pudiesen dañar los componentes

eléctricos.

LA FALLA DE CONECTAR A TIERRA

PERMANENTEMENTE LA BOMBA,

EL MOTOR Y LOS CONTROLES,

ANTES DE CONECTAR LA CORRIENTE ELÉCTRICA, PUEDE CAUSAR

ELECTROCHOQUE, QUEMADURAS

O LA MUERTE.

SELECCIÓN Y CABLEADO DE LOS

INTERRUPTORES Y PANELES DE

CONTROL DE LA BOMBA

TIPOS DE INTERRUPTORES DE FLOTADOR

Hay dos tipos de diseños de interruptor de flotador: de

acción simple y de ángulo amplio. Los interruptores de

acción simple funcionan en un rango de 15º, de manera

que pueden abrirse y cerrarse con rapidez. Los flotadores

de ángulo amplio funcionan con un giro de 90º con el

largo de la traba entre el cuerpo del flotador y el punto

de pivote controlando al rango de encendido-apagado. El

diseño determina cuántos flotadores se requieren con los

diferentes sistemas o controles.

Los flotadores pueden estar normalmente abiertos (NO)

para aplicaciones de reducción de nivel o para vaciar un

tanque. Los interruptores normalmente cerrados (NC) se

utilizan para aumentar el nivel o para llenar un tanque.

Un interruptor de control de acción simple sólo puede

usarse con un panel de control, pero nunca directamente

conectado a una bomba.

Los interruptores de ángulo ancho de reducción de nivel

pueden usarse como interruptores directamente conectados a la bomba o como interruptores de control.

INSTALACIÓN DE LOS INTERRUPTORES DE

FLOTADOR

No hay reglas absolutas acerca de dónde instalar los

interruptores de flotador, varía de trabajo a trabajo.

Reglas sugeridas a seguir:

¡Todos los flotadores deben instalarse debajo de la tubería

de entrada!

Flotador de apagado: Primera preferencia: instálelo de

manera que cuelga tan libremente el nivel del agua quede

15

Page 16

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

siempre sobre el extremo superior de la bomba (cúpula

del motor). Segunda preferencia: instálelo de manera que

el nivel del agua quede a no más de 6 pulg. por debajo

del extremo superior de la bomba.

Flotador de encendido: instálelo de manera que el volumen de agua entre los flotadores de encendido y apagado

permita bombas de 1½ HP y menores funcionar al menos

1 minuto. Las bombas de dos (2) HP y mayores deben

funcionar al menos 2 minutos. El folleto técnico sobre estanques establece los galones de almacenaje por pulgada

de altura del estanque.

Flotador(es) de retardo/alarma: deben escalonarse sobre

los flotadores de apagado y encendido. Trate de utilizar

la mayoría del almacenaje disponible ofrecido por el

estanque, ahorre espacio para la capacidad de almacenaje

de reserva. La reserva exacta se puede decir en voz alta

por códigos locales. Consulte los diagramas y tablas en la

Sección de Tablas de Interruptores de Flotador.

DIAGRAMAS DE CABLEADO DEL PANEL

Nuestros paneles de control se envían con instrucciones

y diagramas de cableado. Utilice dichas instrucciones

en conjunto con este manual de instrucciones (IOM).

La instalación eléctrica debe ser realizada por técnicos

calificados únicamente. Cualquier problema o preguntas

con respecto al control de otras marcas debe dirigirse a

ese proveedor o al fabricante del control.

ALARMAS

Recomendamos la instalación de una alarma en todas las

bombas para aguas residuales. Muchos paneles de control

estándar vienen equipados con circuitos de alarma. Si

no se usa un panel de control, se ofrece una alarma por

alto nivel de líquido independiente. La alarma alerta

al propietario acerca de una situación de alto nivel de

líquido en el sistema, de manera que pueda comunicarse

con el personal de servicio apropiado para que investigue

la situación.

BOMBAS MONOFÁSICAS

Las bombas monofásicas (1Ø) pueden operarse utilizando

transporte por ferrocarril o conjuntamente con o un

panel de control simple o doble. Ver las Figuras 1,2 y 5.

La mayoría las bombas de 1⁄3 y ½ HP, de 115 ó 230

voltios y algunas bombas de ¾ y de 1 HP están equipadas con cables de alimentación estilo enchufe. Pueden

enchufarse a interruptores de flotador en tándem para

instalaciones sencillas. Se permite quitar los enchufes

para conectar directamente o conectar a un controlador

simple o doble. El retiro del enchufe no anula la garantía

ni viola las aprobaciones de las agencias. Ver la figura 5.

Las bombas con cables de alimentación con conductores

desnudos pueden conectarse directamente a un interruptor de flotador, cablearse a un contactador de 1 fase,

a un controlador simple o doble. Siempre verifique que

16

LAS UNIDADES CON ENCHUFE

DEBEN CONECTARSE A UN TOMACORRIENTES TIPO TIERRA CONECTADO CORRECTAMENTE A

TIERRA.

EN EL CASO DE UNIDADES SIN

ENCHUFE, NO QUITE EL CABLE NI

EL PROTECTOR CONTRA TIRONES.

NO CONECTE EL TUBO-CONDUCTO A LA BOMBA.

el interruptor de flotador esté clasificado para el amperaje de funcionamiento máximo, amperaje de arranque

máximo y la capacidad nominal de potencia de la bomba.

Las bombas monofásicas para aguas residuales contienen

sobrecargas de devanado de encendido, a menos que se

especifique lo contrario en la placa de identificación de la

bomba. Ver las Figuras 1 y 2.

BOMBAS TRIFÁSICAS:

Como mínimo, una bomba trifásica requiere un cortacircuitos/circuito con fusible trifásico, un arrancador magnético en la línea clasificado para la potencia de la bomba y

sobrecargas Clase 10, de disparo rápido y compensación

ambiental.

PANELES DE CONTROL

MONOFÁSICOS Y TRIFÁSICOS:

Los paneles de control pueden ser simples (controlan 1

bomba) o dobles (controlan 2 bombas). Nuestros paneles

Serie SES se ofrecen con muchas características estándar

y pueden construirse con nuestras opciones más populares. También construimos paneles de acuerdo con las especificaciones del cliente, los cuales ofrecen muchas más

opciones. Los paneles de control construidos de acuerdo

con las especificaciones del cliente se ofrecen en muchas

configuraciones diferentes. Las solicitudes de cotizaciones

para paneles a la medida pueden enviarse a Servicio a los

Clientes mediante nuestro distribuidor autorizado.

Nuestros paneles dobles presentan un diseño de tablero

de circuito impreso de estado sólido con circuitos de alarmas de alto nivel estándar. Otras características estándar

son: un contacto de alarma seco auxiliar para señalizar

una alarma remota y luces indicadoras de posición del

interruptor de flotador. Nuestros paneles trifásicos tienen

sobrecargas Clase 10 incorporadas y ajustables. Las

sobrecargas ajustables en todos nuestros paneles trifásicos

significa menos trabajo para el instalador y la eliminación

de la necesidad de ordenar sobrecargas específicas. La

mayoría de los paneles se mantienen en inventario para

entrega inmediata sin opciones.

Sensor térmico y circuito de falla de sellado - Algunas

bombas están equipadas con un circuito de falla de sellado

y un sensor térmico. En el producto estándar, el circuito de

falla de sellado, si se provee sin sensor térmico, tendrá una

derivación adicional del motor con dos conductores. Estas

derivaciones serán blancas y negras y deben conectarse a los

terminales de falla de sellado en un panel provisto con esta

opción. Si se proveen un circuito de falla de sellado y sensor

térmico con la bomba, habrá una derivación separada con

cuatro conductores. Para estas derivaciones, la conexión de

falla de sellado será negra y verde y el sensor térmico será

rojo y blanco. Se puede pedir el modelo 1GD/12GDS con

un circuito de falla de sellado opcional, pero la mayoría de

las bombas con sellado doble vienen estándar con el circuito

de falla de sellado.

Los modelos con 4NS/4DWC/4XD/4XWS tienen una

configuración estándar con falla de sellado y sensor térmico.

Las derivaciones están en una camisa separada con 5 derivaciones. La negra (rotulada P1) y la blanca (rotulada P2)

deben conectarse a las terminales de protección térmica. Las

derivaciones de falla de sello son rojas (rotulada W1) y naranja (rotulada W2) y deben conectarse a los terminales de

falla de sello. La derivación adicional es verde y debe conectarse a la conexión a tierra. Los paneles vienen equipados

con un diagrama de cableado que indica las conexiones. Se

deben pedir los paneles con las opciones de circuitos de falla

de sellado y circuitos de sensor térmico; debido a que estos

Page 17

PELIGRO

Maquinaria peligrosa.

!

paneles también pueden usarse en bombas sin la opción de

estas conexiones, no vienen estándar en la mayoría de los

paneles.

Un estilo adicional de circuitos de falla de sellado y sensor térmicos es nuestro producto vendido con los modelos

GA(X)/15GDS(X)/20GDS(X), 2,3,4GV(X), 2,3,4MV(X),

2,3,4,6MK(X). Estas unidades vienen con una única derivación para energía y controles. El conductor viene con

7 derivaciones (antes de enero de 2013). Las derivaciones

para falla de sellado y sensor térmico serán naranja y azul

(antes de 2013). Debido a que estas unidades usan un sensor

de estilo diferente en las bombas así como una opción diferente en el panel, las conexiones solo requieren dos derivaciones. A partir de enero de 2013, los colores de derivaciones en las bombas cambiaron a dos (2) derivaciones blancas

para la falla de sellado y sensor térmico. El cable más nuevo

para estas unidades ahora tiene 7 derivaciones con (2) derivaciones blancas; estas derivaciones son tanto para la falla

de sellado como el dispositivo de sensor térmico.

Tenga cuidado de elegir las opciones correctas en la selección de panel para cada estilo de bomba. Siempre siga el

diagrama de cableado del panel. Si no se cablean las derivaciones de falla de sellado y sensor térmico correctamente, la

bomba puede no funcionar o causar disyunción molesta.

INSTALACIÓN

Conecte la(s) bomba(s) a los adaptadores de riel

corredizo o a la tubería de descarga. Las bases del riel

corredizo deben anclarse al piso del pozo.

Todas las conexiones deben realizarse de acuerdo con los

diagramas de cableado del panel de control, el código

eléctrico de EE.UU., el código canadiense y los códigos estatales, provinciales y/o locales. Éste es un buen

momento para verificar la rotación apropiada de los

motores/impulsores.

NO COLOQUE LAS MANOS EN LA

SUCCIÓN DE LA BOMBA MIENTRAS VERIFICA LA ROTACIÓN DEL

MOTOR. EL HACERLO PRODUCIRÁ

GRAVES LESIONES PERSONALES.

Siempre verifique la rotación correcta.

La rotación correcta se indica en la carcasa de la bomba. Los motores trifásicos

son reversibles. Se permite arrancar

brevemente o en marcha lenta el motor

durante unos segundos para verificar

la rotación del impulsor. Es más fácil

verificar la rotación antes de instalar la

bomba. Intercambie dos de los conductores de potencia cualquiera para

invertir la rotación.

Baje la(s) bomba(s) al pozo sumidero.

Inspeccione para verificar que los flotadores funcionen

libremente y que no hagan contacto con la tubería.

OPERACIÓN

Una vez que se hayan hecho y verificado las conexiones

de las tuberías, se pueden poner en funcionamiento las

bombas.

Operación de interruptor en tándem – Enchufe el interruptor en tándem a un tomacorrientes dedicado conectado a tierra y luego enchufe la bomba al interruptor.

Pruebe la bomba llenando el pozo hasta que la bomba

se active. Si las bombas funcionan pero no bombean,

probablemente estén obstruidas con aire; perfore los

orificios de alivio de acuerdo con las instrucciones en la

Sección de Tuberías.

Verifique el intervalo de operación para asegurar un

tiempo de funcionamiento mínimo de un minuto y que la

bomba se apague en la posición correcta.

Operación del panel de control – Llene el pozo con agua

limpia.

Utilice los interruptores H-O-A (manual – apagado – automático) de la bomba en la posición manual para probar

las bombas. Si funcionan bien en la posición manual,

pruebe la posición automática. Si las bombas funcionan

pero no bombean, probablemente estén obstruidas con

aire; perfore los orificios de alivio de acuerdo con las

instrucciones en la Sección de Tuberías.

Coloque el (los) interruptor(es) del panel de control en la

posición automática y pruebe minuciosamente el funcionamiento de los flotadores de ENCENDIDO, APAGADO

y alarma llenando el pozo con agua limpia. Importante:

Si no se proporciona un neutro desde la fuente de

alimentación a un panel de control monofásico de 230

voltios, el circuito de control del panel no operará. Es

necesario el neutro para completar el circuito de control

de 115 voltios.

Verifique la tensión y la corriente y anote los datos en la

sección delantera de este manual para referencia futura.

Compare las lecturas de amperaje con el amperaje máximo indicado en la placa de identificación de la bomba. Si

es más alto que el amperaje de la placa de identificación,

investigue la causa. Si la bomba se hace funcionar fuera

de la curva; es decir, con demasiado poca carga o con

tensión alta o baja, aumentará el amperaje. El motor

funcionará correctamente con tensión no más de un 10%

por encima o por debajo de las clasificaciones en la placa

de identificación de la bomba. El rendimiento dentro de

este rango no será necesariamente igual al rendimiento

publicado a la frecuencia y tensión exactas indicadas en

la placa de identificación. Corrija el problema antes de

continuar. También es posible que la causa sea un desbalance trifásico. Consulte la sección de Desbalance de

potencia trifásica y siga las instrucciones.

Reposicione el circuito de alarma, coloque el (los)

interruptor(es) de la bomba en posición automática y

el interruptor de control en la posición de encendido.

Ahora la unidad está lista para la operación automática.

Explique la operación de las bombas, controles y alarmas

al usuario final. Entregue la documentación al propietario

o déjela en un lugar seco y seguro en el panel de control.

17

Page 18

TABLA DEL PANEL E INTERRUPTORES

Entrada

Alarma SW3

Bomba encendida

SW2

Bomba apagada

SW1

Descarga

DE FLOTADOR

El propósito de esta tabla es mostrar las cantidades de

interruptores requeridas y la función de cada interruptor

en un sistema de aguas residuales típicas. Las cantidades

requeridas varían dependiendo del tipo de interruptor:

de acción simple o de ángulo amplio. Las cantidades de

interruptores varían también de acuerdo con el tipo de

panel: simple con y sin alarmas y doble con alarmas.

Paneles dobles utilizando interruptores de acción simple:

Cableado del panel de tres flotadores

SW1 Fondo Bombas apagadas

SW2 Medio Primera bomba del

medio encendida

SW3 Extremo Segunda bomba y alarma

superior encendidas

Cableado del panel de cuatro flotadores ➁

SW1 Fondo Bombas apagadas

SW2 Segundo Primera bomba encendida

SW3 Tercero Segunda bomba encendida

SW4 Extremo Alarma encendida

superior

Paneles dobles utilizando interruptores de ángulo

amplio:

Cableado del panel de tres flotadores

SW1 Fondo Primera bomba encendida/

ambas apagadas

SW2 Extremo Segunda bomba y

superior alarma encendidas

Cableado del panel de cuatro flotadores

SW1 Fondo Primera bomba encendida/

ambas apagadas

SW2 Medio Segunda bomba encendida

SW3 Extremo Alarma encendida

superior

Paneles simples utilizando interruptores de acción simple:

Panel simple con alarma ①

SW1 Fondo Bomba apagada

SW2 Medio Bomba encendida

SW3 Extremo Alarma encendida/apagada

superior

Panel simple sin alarma

SW1 Fondo Bomba apagada

SW2 Extremo Bomba encendida

superior

Paneles simples utilizando interruptores de ángulo

amplio:

Panel simple con alarma

SW1 Fondo Bomba encendida/apagada

SW2 Extremo

superior Alarma encendida/apagada

Panel simple sin alarma

SW1 Bomba encendida/apagada

Simple ➀

Entrada

Alarma SW4

Bomba secundaria

encendida SW3

Bomba principal

encendida SW2

Bomba apagada

SW1

Descarga

Doble ➁

18

Page 19

DESBALANCE DE POTENCIA TRIFÁSICA

Se recomienda un suministro trifásico completo incluyendo tres transformadores individuales o un transformador trifásico. Se pueden usar conexiones en estrella o

en triángulo “abierto” empleando sólo dos transformadores, pero hay más posibilidad de que produzcan un

rendimiento inadecuado, disparo por sobrecarga o falla

prematura del motor debido al desbalance de corriente.

Mida la corriente en cada uno de los tres conductores del

motor y calcule el desbalance de corriente en la forma

que se explica abajo.

Si el desbalance de corriente es del 2% o menos, deje los

conductores tal como están conectados. Si el desbalance

de corriente es de más del 2%, hay que verificar las lecturas de corriente en cada derivación empleando cada una

de las tres conexiones posibles. Enrolle los conductores

del motor en el arrancador en la misma dirección para

evitar una inversión del motor.

Para calcular el porcentaje de desbalance de corriente:

A. Sume los tres valores de corriente de línea.

B. Divida la suma por tres, con lo cual se obtiene la

corriente promedio.

C. Seleccione el valor de corriente más alejado de la

corriente promedio (ya sea alto o bajo).

D. Determine la diferencia entre este valor de corriente

(más alejado del promedio) y el promedio.

E. Divida la diferencia por el promedio. Multiplique el

resultado por 100 para determinar el porcentaje de

desbalance.

El desbalance de corriente no debe exceder el 5% con

la carga del factor de servicio o el 10% con la carga de

entrada nominal. Si el desbalance no puede corregirse

enrollando los conductores, la causa del desbalance debe

determinarse y corregirse. Si, en las tres conexiones

posibles, la derivación más alejada del promedio está en

el mismo conductor de potencia, entonces la mayoría del

desbalance proviene de la fuente de potencia.

Contacte a la compañía de electricidad local para

solucionar el desbalance.

Conexión 1 Conexión 2 Conexión 3

Terminales del L1 L2 L3 L1 L2 L3 L1 L2 L3

arrancador

Conductores R B W W R B B W R

del motor

T3 T1 T2 T2 T3 T1 T1 T2 T3

Ejemplo:

T3-R = 51 amps T2-W = 50 amps T1-B = 50 amps

T1-B = 46 amps T3-R = 48 amps T2-W = 49 amps

T2-W = 53 amps T1-B = 52 amps T3-R = 51 amps

Total = 150 amps Total = 150 amps Total = 150 amps

÷ 3 = 50 amps ÷ 3 = 50 amps ÷ 3 = 50 amps

– 46 = 4 amps – 48 = 2 amps – 49 = 1 amps

4 ÷ 50 = .08 or 8% 2 ÷ 50 = .04 or 4% 1 ÷ 50 = .02 or 2%

LECTURAS DE RESISTENCIA DEL AISLAMIENTO

Valores normales en ohmios y megaohmios entre todos los conductores y tierra

Condición del motor y los conductores Valor en ohmios Valor en Megaohmios

Un motor nuevo (sin cable de bajada). 20,000,000 (o más) 20 (o más)

Un motor usado que puede reinstalarse en el pozo. 10,000,000 (o más) 10 (o más)

Motor en el pozo. Las lecturas son para el cable de bajada más el motor.

Motor nuevo. 2,000,000 (o más) 2 (o más)

El motor está en buenas condiciones. 500,000 - 2,000,000 .5 - 2

Daño de aislamiento, localícelo y repárelo. Menos de 500,000 Menos de 0.5

La resistencia del aislamiento varía muy poco con la clasicación. Los motores de todas las clasicaciones de

potencia, tensión y fase tienen valores similares de resistencia de aislamiento.

Los valores de resistencia de aislamiento anteriores están basados en lecturas obtenidas con un megaohmiómetro con salida de 500 V CC. Las lecturas pueden variar utilizando un ohmiómetro de tensión más baja; consulte con la fábrica si tiene dudas acerca de las lecturas.

19

Page 20

L1

L2

L3

Tierra

S1

Rojo

Negro

Blanco

Verde

BOMBA

DATOS DE INGENIERÍA

6 pulg. (15.3 cm)

6 pulg. (15.3 cm)

PESO

NIVEL DE ENCENDIDO:

8 pulgadas (20.3 cm)

Los datos de ingeniería para modelos especícos pueden encontrarse en su catálogo y en nuestro sitio Web

(dirección en la cubierta).

Los diagramas de cableado del panel de control se envían con los paneles de control. Utilice los dibujos del

panel de control junto con este manual de instrucciones para completar el cableado.

OPERACIÓN DE LA BOMBA

Sumersión mínima

Servicio continuo Sumergida totalmente

Servicio intermitente

extremo superior del motor

Pumpmaster y Pumpmaster Plus -

caja de

conexiones

Flotador doble – de cableado directo

caja de

conexiones

6 pulg. por debajo del

NO RECOMENDADO

Cableado directo

Instalación

fuente

de cableado

de ali-

directo para

men-

aplicaciones

tación

de 120 V o

verde

negro

blanco

Negro

Conector

verde

negro

blanco

Blanco

del cable

conexión a tierra

Figura 1

NO RECOMENDADO

fuente de

aliment-

ación

verde - tierra

blanco - neutro

Negro

negro - activado

Blanco

blanco - neutro

verde - tierra

Rojo

negro - activado

conexión a tierra

bomba

Conector

del cable

230 V.

bomba

interruptor

Temperatura máxima del uido

Operación continua 104º F 40º C

Operación

intermitente

Interruptor de otador de acción simple

Instalación “típica”

Figura 4

Interruptor de otador

de ángulo amplio

Tapón de la

bomba

140º F 60º C

Enchufe de los

interruptores

en tándem

Rango de

bombeo

20

Figura 2

Determinación del rango de bombeo

Largo de la traba (pulgadas)

Rango de bombeo (pulgadas)

Figura 3

Figura 5

Diagrama de conexión trifásica

Estándar sin el sensor del incidente y del calor del

sello para la bomba que acciona.

Figura 6

Page 21

DATOS DE INGENIERÍA

Terminal

de componente

de la

potencia

Terminal

de componente

del sensor

con fall

del sello

solamente

y de alta

temperatura

O

Terminales de componente

estándar trifásicos del producto

Negro Negro

Verde

Rojo

Blanco

4NS/4XD/4XS/4DWC

Negro Negro

Rojo Rojo

Blanco Blanco

Verde Verde

Incidente

del

sello

Sensor

del

calor

Potencia

Sensor

Blanco

Rojo

Anaranjado

Verde

Figura 9

Sello

Sensor

del

calor

Incidente

del sello

del terminal

de com-

ponente

del sensor

solamente

Incidente del

sello del

sensor

Negro

Blanco

Figura 7

Monofásico

Negro

Blanco

Verde

Negro

Blanco

1/2GA(X), 15/20GDS(X)

2, 3, 4GV(X) – 2, 3, 4, 6MK(X) – 2, 3, 4MV(X)

Anterior al

enero

de 2013

Después

de enero

de 2013

Figura 10

Negro

Rojo

Blanco

Verde

Verde/Amarillo

Anaranjado

Azul

Gris

Rojo

Negro

Verde

Blanco

Blanco

Vacie el

terminal de

componente

Ningún sensor del calor disponible

Figura 8

21

Page 22

ADVERTENCIA

Tensión

peligrosa

IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

LA FALLA DE DESCONECTAR Y BLOQUEAR LA CORRIENTE ELÉCTRICA ANTES DE IN-

TENTAR CUALQUIER SERVICIO, PUEDE CAUSAR ELECTROCHOQUE, QUEMADURAS O LA

MUERTE.

SÍNTOMA CAUSA PROBABLE ACCIÓN RECOMENDADA

EL MOTOR NO

ESTÁ FUNCIONANDO

carcasa y el impulsor.

NOTA: Si el cortacircuitos se

Cortacircuitos abierto o fusible quemado. Determine la causa, llame a un electricista calificado.

“ABRE” repetidamente, NO

lo reposicione. Llame a un

Impulsor de la bomba rozando o atascado.

electricista calificado.

veces más alto que el indicado en la placa de

a) Operación manual El cable de alimentación está dañado.

La resistencia entre los conductores de alimentación y

b) Operación automática No hay alambre neutro tierra debe indicar infinito. Si alguna lectura es

conectado al panel de control. incorrecta, llame a un electricista calificado.

Conexiones eléctricas inadecuadas Inspeccione las conexiones del panel de control.

en el panel de control. Llame a un electricista calificado.

NOTA: Inspeccione la

Interruptor de nivel de líquido Con el interruptor desconectado, verifique la

bomba en modo manual

defectuoso para activar los controles. continuidad mientras activa el interruptor de nivel de

primero para confirmar el

líquido. Reemplace el interruptor, según se requiera.

funcionamiento. Si la bomba

Nivel de líquido insuficiente Deje que el nivel de líquido aumente de 3 a 4 pulgadas

funciona, el control au para activar los controles. (76 mm –101 mm) sobre el nivel de activación.

tomático o el cableado está

Cordones de los sensores de nivel Desenrede los cordones y asegure el

defectuoso. Si la bomba no

de líquido enredados. funcionamiento libre.

funciona, vea arriba.

LA BOMBA NO Cordones de los sensores de nivel Desenrede los cordones y asegure el

SE APAGA de líquido enredados. funcionamiento libre.

La bomba está atascada con aire. Apague la bomba durante aproximadamente un minuto

y arránquela nuevamente. Repita hasta que se despeje la

obstrucción de aire. Si la obstrucción de aire persiste en

un sistema con tubo con válvula de retención, puede

perforarse un agujero de 3/16 pulg. (4.8 mm) en el tubo

de descarga aproximadamente a 2 pulgadas (51 mm) de

la conexión de descarga.

El flujo de líquido entrante coincide Podría requerirse una bomba más grande.

con la capacidad de descarga de la bomba.

LA BOMBA ENTREGA La válvula de retención está instalada Verifique la flecha de flujo en la válvula y

POCO O NADA invertida, está obstruida o atascada verifique el funcionamiento de ésta.

DE LÍQUIDO en posición cerrada.

Carga excesiva del sistema. Consulte con el agente.

Entrada a la bomba obstruida. Inspeccione y despeje, según sea requerido.

Tensión incorrecta, o Verifique la rotación, la tensión y las conexiones

conectada incorrectamente. de la bomba. Consulte con un electricista calificado.

La bomba está atascada con aire. Consulte la acción recomendada, arriba.

El impulsor está gastado o dañado. Inspeccione el impulsor, reemplácelo

según sea necesario.