Page 1

Sump Pumps

INSTRUCTION MANUAL

IM105

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Page 2

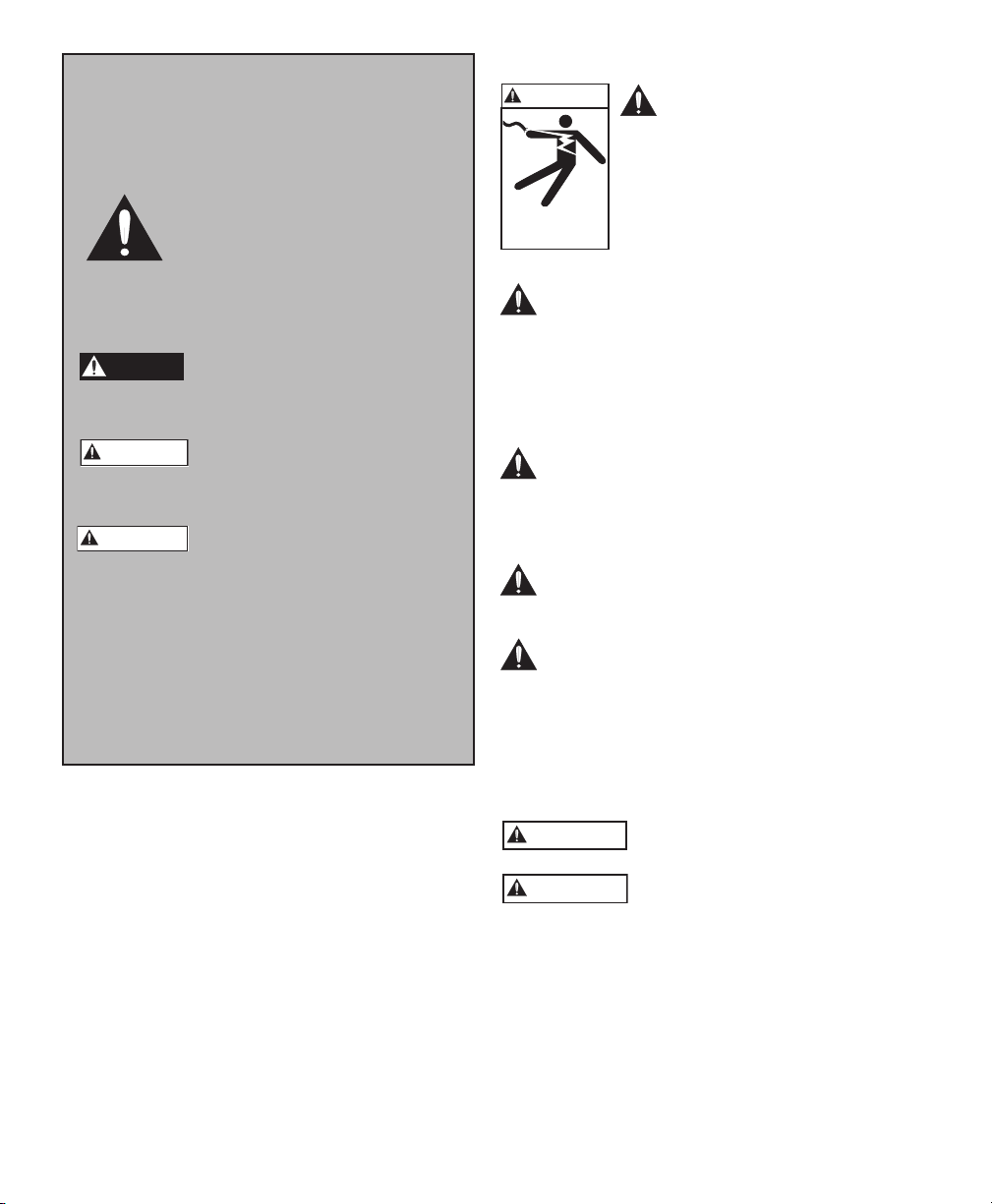

DANGER

TO AVOID SERIOUS OR FATAL

WARNING

CAUTION

WARNING

Hazardous voltage

can shock, burn or

cause death.

PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS

IN MANUAL AND ON PUMP.

This is a SAFETY ALERT

SYMBOL. When you see this

symbol on the pump or in the

manual, look for one of the

following signal words and

be alert to the potential for

personal injury or property

damage.

Warns of hazards that WILL

cause serious personal injury,

death or major property

damage.

Warns of hazards that CAN

cause serious personal injury,

death or major property

damage.

Warns of hazards that CAN

cause personal injury or

property damage.

NOTICE: Indicates special instructions which

are very important and must be followed.

THIS MANUAL MUST BE KEPT WITH

THE PUMP.

MAINTAIN ALL SAFETY LABELS.

IMPORTANT PRE-INSTALLATION INFORMATION

All electrical work must be

performed by a qualified

technician. Always follow

the National Electrical Code

(NEC), or the Canadian

Electrical Code, as well as

all local, state and provincial

codes.

The pump must be connected to a dedicated electrical circuit protected by a properly sized circuit breaker or fuses. Install

a disconnect where required by code.

Code questions should be directed to your

electrical inspector. See Chart 1 for specific

information.

Disconnect electrical power before installing or servicing the pump. The motor’s

automatic thermal overload protection

may allow an overheated pump to restart

unexpectedly.

Pump is not designed for use in swimming

pools, open bodies of water, hazardous

liquids, or where flammable gases exist.

Pumps and floats equipped with a 3-prong

grounded plug must be connected to a

3-wire receptacle. Do not attach to extensions or connectors without a 3-prong

grounded plug. NOTE: Removing the plug

from the power cord is not allowable per

NEC code. Removing the plug will void

the agency listing.

CAUTION

WARNING

This pump has been evaluated

for use with water only.

Risk of electric shock – this

pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric

shock, be certain that it is connected only

to a properly grounded, grounding-type

receptacle.

2

Page 3

1. GENERAL INFORMATION

1. GENERAL INFORMATION

1.1. Sump pumps are designed to operate inter-

mittently and usually seasonally. It is recommended that you test the pump before your

rainy season begins to insure that the pump

and switch are operating properly.

1.2. We suggest installing a high water alarm

system and a battery back-up pump system

for finished basements or areas where flooding will cause property damage. A back-up

generator is another option you can discuss

with your pump installer. Most power outages occur during rain storms, just when

you need your sump pump the most! Pump

manufacturer's warranties cover only the

pump. Labor and incidental damage such as

flooding is not covered.

2. PRE-INSTALLATION CHECKS

2. PRE-INSTALLATION CHECKS

2.1. Open all cartons and inspect for shipping

damage. Report any damage to your supplier

immediately.

2.2. Verify that all equipment is the correct volt-

age. Warranty does not cover damage caused

by connecting pumps and controls to incorrect voltage.

2.3. Is your basin sized correctly and the proper

type for the location?

Diameter - It must be wide enough to allow

the pump and switch to physically fit and

provide room for the switch to operate

freely. The vertical switch models typically

require less diameter than the wide-angle

float models. See "min. basin diameter" in

Chart 1.

CAUTION

Depth - It must be deeper

than the minimum depth at

which the switch turns the pump On. As an

example, if the pump turns on at 15" you

want to use a basin deeper than 15”.

See "On level" in Chart 1.

WARNING

Style - There are several

sump basin styles available.

The location of the sump determines if you

require a cover and what type you require.

It is important to keep debris from entering

the sump and clogging the pump. An open

sump in a traffic area such as a basement is

dangerous. If children or pets will be playing

in the area a bolt-on or child-proof cover is

recommended.

3. PIPING

3. PIPING

3.1. Discharge pipe should be the same size

as the pump discharge to insure optimum

performance. Using undersized pipe may

dramatically reduce the flow and therefore

waste energy. Your pump supplier can suggest the correct pipe for your installation.

3.2. Install a threaded pipe adapter, matched

to the pipe type you are using, into the

threaded pump discharge. One end will have

a male thread and the other end will have

a barbed connector, compression fitting or

solvent weld connector. Use Teflon® tape on

all threaded joints. If using solvent welded

pipe and fittings it is best to dry fit them first

and after verifying the fit, solvent weld. A

union installed just above the sump or basin

cover will facilitate future maintenance and

replacement. See Chart 1 for discharge sizes.

3.3. Install a line check valve within 2 feet of

the pump. Install per valve manufacturer’s

instructions.

IMPORTANT - Drill a 1⁄8" (3.2mm) relief hole

in the discharge line approximately 2” (51

mm) above the pump discharge connection

but below the check valve and within the

sump. This “relief” hole allows trapped air

to escape from the pump and prevents airlocking the pump. Failure to drill this hole

is a major cause of sump pumps failing to

pump after long periods of inactivity such as

seasonal use. Model ST is self-venting - no

hole is required.

4. INSTALLATION IN SUMP

4. INSTALLATION IN SUMP

4.1. The pump can be placed directly on the

bottom of a poly or fiberglass sump basin

or a concrete sump bottom. If the bottom is

packed gravel the stones must be larger than

½” (13mm) in diameter and the pump

should be placed on bricks for support.

4.2. After connecting the discharge pipe to the

pump it can be lowered into the sump (basin). Always lower the pump by the handle

and the pipe, never by the power cord. Place

the pump against the basin wall so the switch

is to the center. See "Installation Data".

3

Page 4

4.3. Check to insure all piping connections are

tight. The pipes should be supported by

fastening to floor joists or wall. This will

prevent the pump from moving in the sump.

If it moves the switch could get stuck and

either keep the pump running or not let it

turn on.

4.4. The power to the outlet should be Off at

this point. The dedicated outlet should supply power only to the pump.

4.5. Our sump pumps have either a single power

cord for pumps with built-in switches or

two power cords for pumps with piggyback

switches:

Built-In/Single Cord - plug the single power

cord into a dedicated power outlet.

Piggyback/Two Power Cords - insert the piggyback switch male plug into a dedicated

power outlet. You then plug the standard

male pump plug into the back, female side,

of the piggyback switch plug.

4.6. Fasten the power cords to the discharge

pipes using tie wraps or electrical tape. Coil

and store any excess power cord outside the

sump.

5. OPERATION

5. OPERATION

5.1. Turn the power On at the breaker panel

and/or the disconnect switch.

5.2. Fill the basin with water and observe where

the pump turns On and Off. It should go On

well before the water overflows the top of

the sump. The pump should go Off before

the water goes below the pump suction. The

On-Off cycle on models with wide-angle

float switches is adjustable. Adjustment is

made by changing the tether length between

the switch body and the switch tether (pivot)

point. The tether length cannot be less than

3” – 3.5”. Tethers less than 3” may not allow

the float to drop down enough to turn off.

See "Installation Data".

5.3. Install a cover on the sump

WARNING

basin if there is a danger

of debris, children, or pets falling into the

basin. See Basin “Style” in Section 2.3.

6. SEASONAL SERVICE / MAINTENANCE

6. SEASONAL SERVICE / MAINTENANCE

6.1. If your sump pump only operates seasonally

and then sits idle for months it is recom-

4

mended that you test the pump before your

rainy season begins. Fill the sump with water

and check for debris and proper switch

operation. Remove any debris which could

clog the suction strainer or jam the switch.

Insure that the switch operates freely and

does not hit the sump wall or hang-up on

piping or power cords.

7. OPTIONS

7. OPTIONS

7.1. Your pump supplier has a full line of basins,

covers, high water alarms, and battery backup pump systems available to complete your

system. We also sell simplex and duplex

pump control panels. A duplex system is

recommended when the inflow is constant

and the pumps run almost continuously. The

duplex system provides a back-up pump in

the event the primary pump fails.

8. TROUBLE SHOOTING CHART

8. TROUBLE SHOOTING CHART

Extreme caution should be exercised when servicing electrical devices. Fatal injuries could result from electrical shock. Always disconnect the

electrical power from the device being serviced

unless it is necessary for the work being done.

MOTOR NOT RUNNING

(See causes 1, 2, 3, 4, 6, 8)

LITTLE OR NO LIQUID DELIVERED

(See causes 5, 6, 7, 8, 10)

PUMP WILL NOT TURN OFF

(See causes 7, 8, 9, 10, 13)

PUMP CYCLES CONSTANTLY

(See causes 9, 11, 12, 13)

PROBABLE CAUSES:

1. Tripped thermal protector.

2. Open Circuit breaker of blown fuse.

3. Rotating parts binding.

4. Defective motor.

5. Air locked.

6. Low voltage.

7. System head too high.

8. Pump clogged.

9. Level control defective or switch not

properly positioned.

10. Improper check valve direction.

11. Check valve leaking.

12. Incorrect size basin or wet-well.

13. Inflow excessive for size of pump.

Page 5

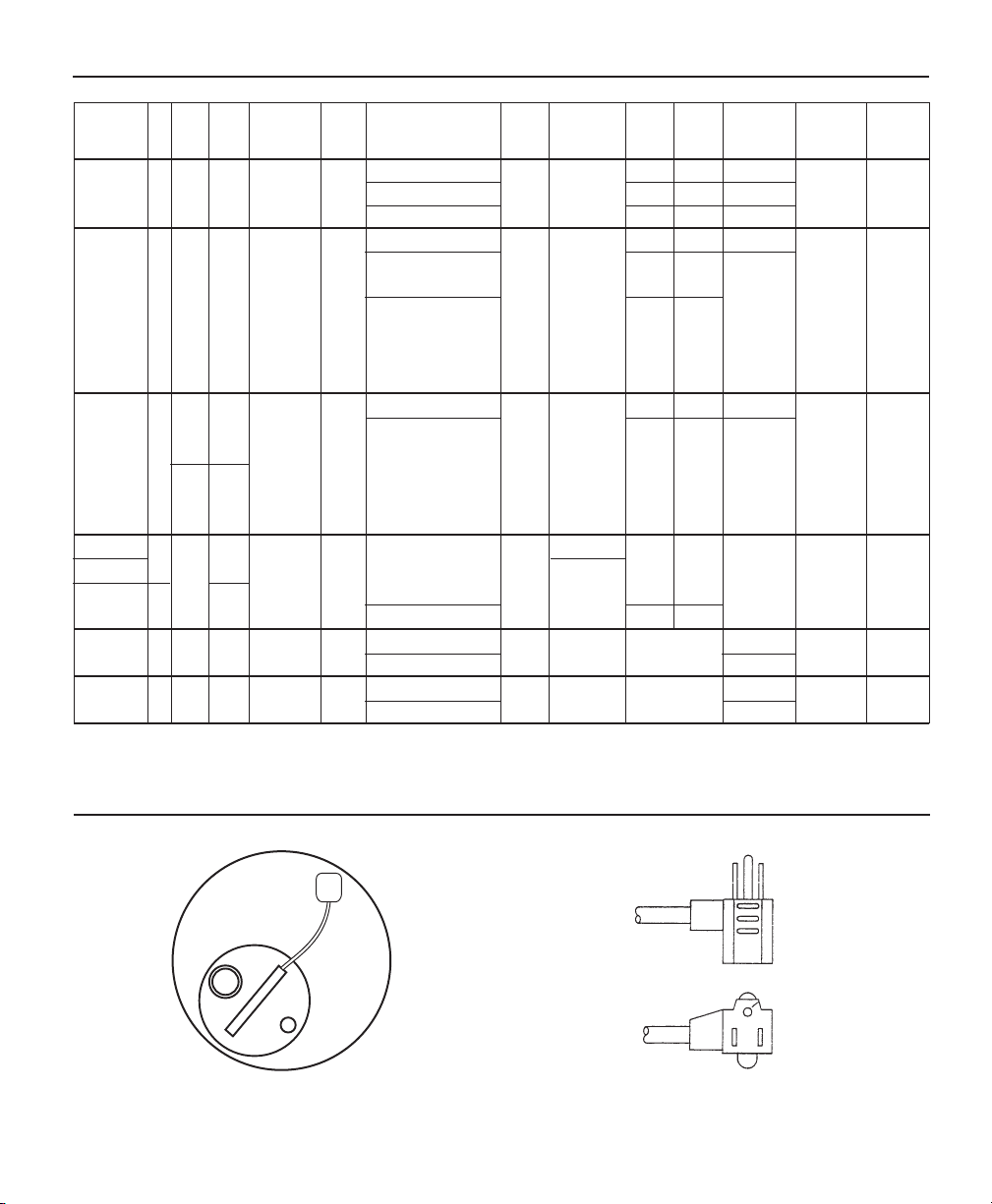

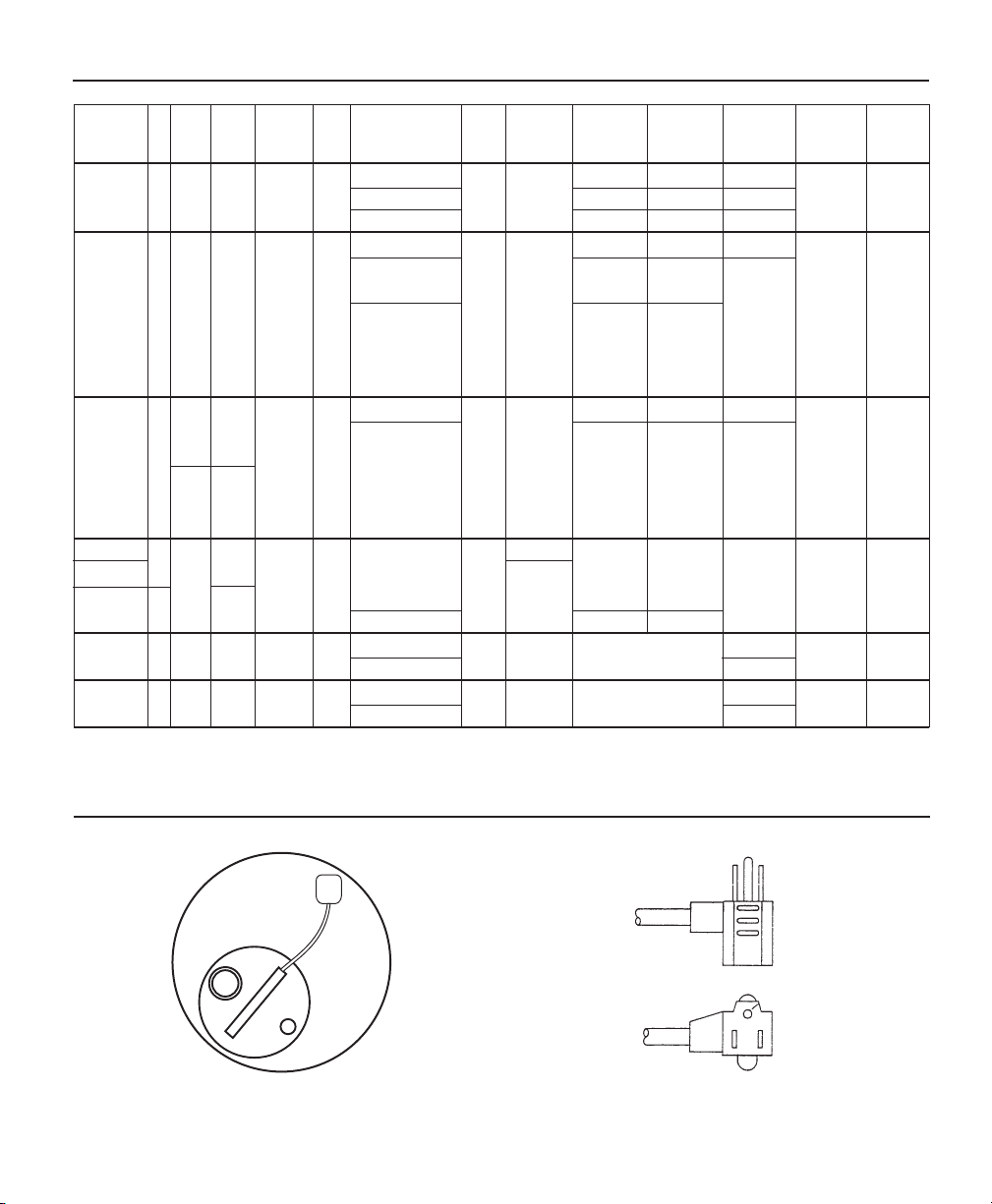

MODEL INFORMATION (CHART 1)

MODEL INFORMATION (CHART 1)

Minimum

Series No. HP Volts Amps Circuit Phase

Breaker Level Level Diameter Size lbs/kg

Float Cord Discharge

Switch Style Length Connection

Min. Min. Minimum Maximum Shipping

On Off Basin Solids Weight

Vertical Switch 8" 3.5" 11"

ST31 1⁄3 115 12.0 20 1 Wide Angle Switch 10' 1½" 14" 7" 18" ½" 29 / 13.2

No Switch Manual Manual 11"

No Switch Manual Manual 9"

LSP03 1⁄

3

115 2.9 10 1

Wide Angle Switch

Vertical Switch

10' /

1½" 3⁄8" 11 / 5

20'

11" 5"

8.5" 2"

12"

No Switch Manual Manual 9"

115 7.1

LSP07 ¾

Wide Angle Switch 12.5" 6.5" 12"

10 1

20' 1½"

3

⁄8" 15 / 6.8

230 3.5

SP024

SP025

SP035 1⁄

No Switch Manual Manual

STS21 ¼ 115 2.5 10 1

No Switch 9"

STS31

No Switch 9"

* This is a D.C. motor. It starts every 1 minute looking for a load. If there is water in the basin it will pump down to 5⁄8" and shut-off. There is no HP rating.

¼ 2.4

3

1

⁄

3

1¼"

115

3.0

10 1

1½"

115 4.5 10 1

Vertical Switch

Vertical Switch

Vertical Switch

6" 3" 9"

10'

20' 1¼" Adjustable

20' 1¼" Adjustable

11"

11"

3

⁄

"

8 / 3.6

8

3

⁄16" 10 / 4.5

3

⁄16" 10 / 4.5

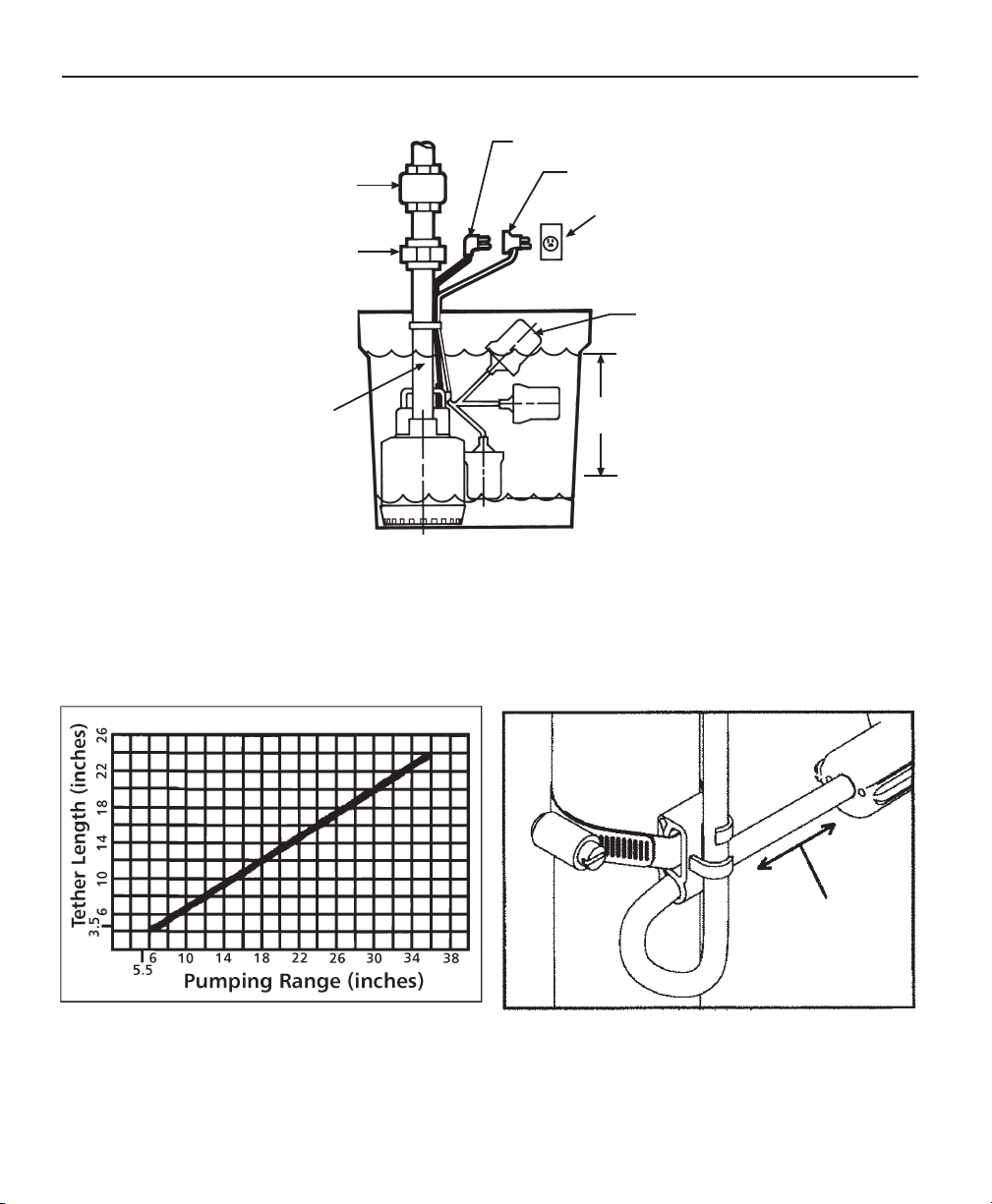

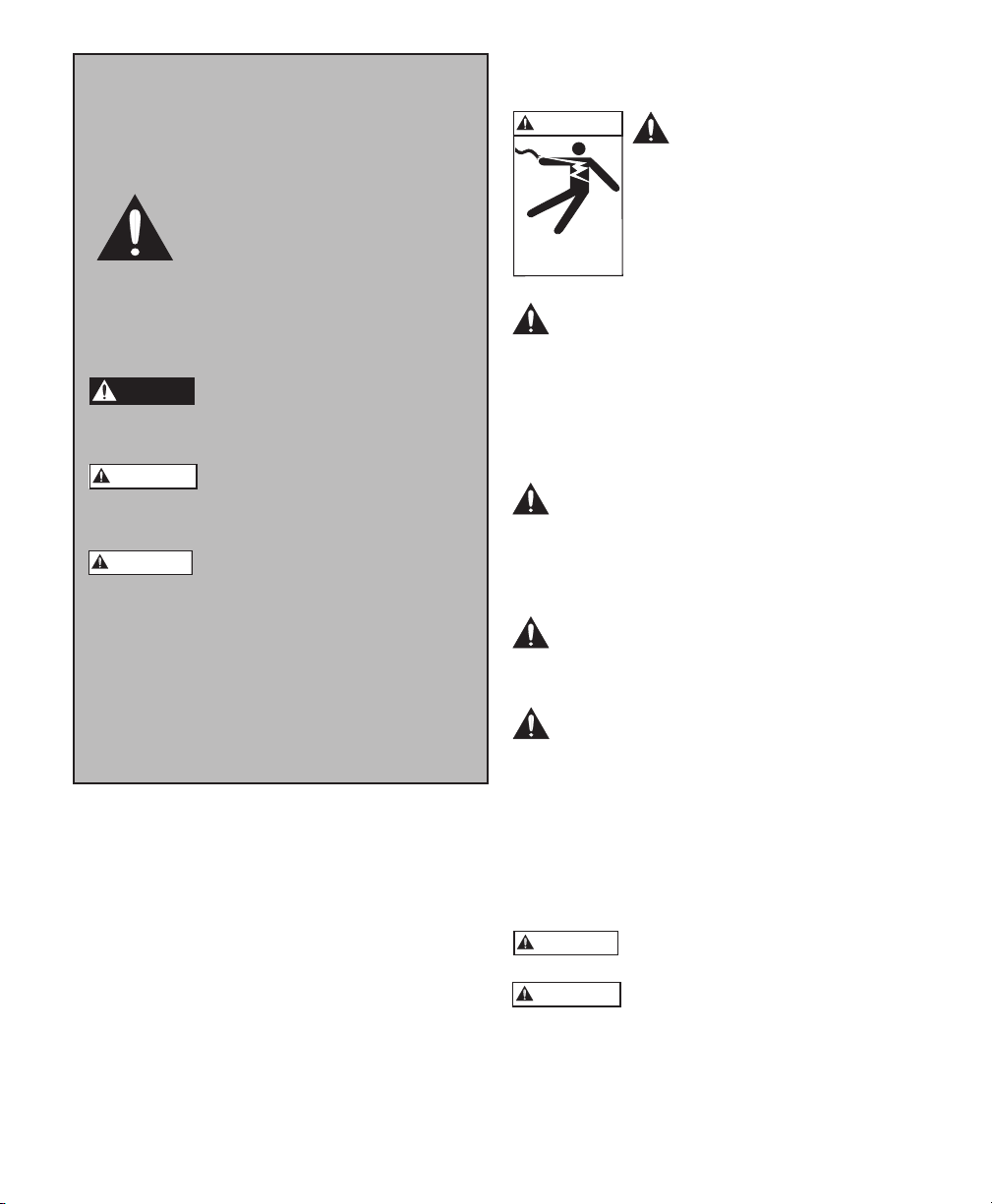

INSTALLATION DATA

INSTALLATION DATA

Suggested Pump Positioning in Sump

Figure 1

Piggyback Plug

Figure 2

5

Page 6

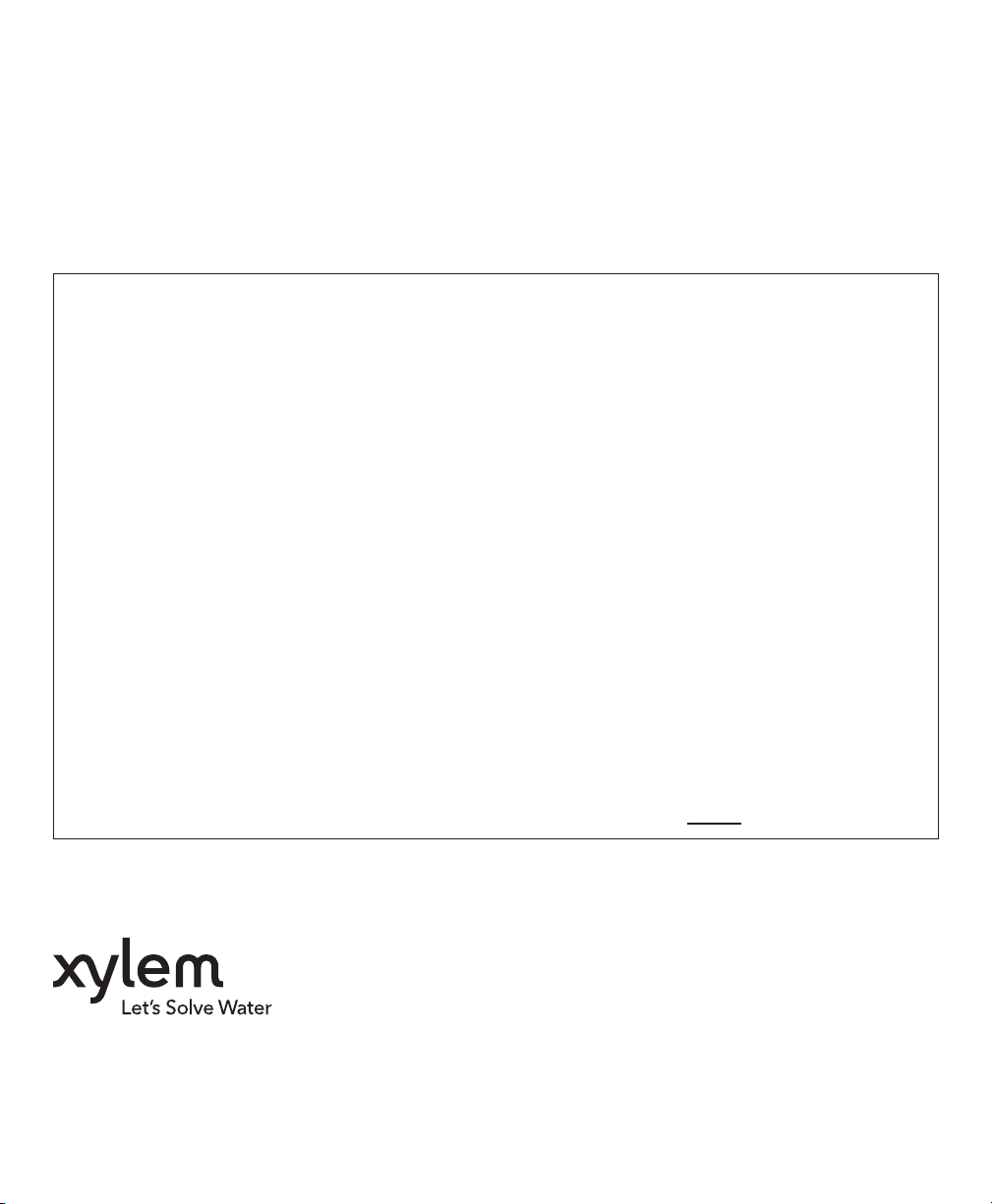

INSTALLATION DATA

INSTALLATION DATA

CHECK

VALVE

UNION

PUMP ELECTRICAL PLUG

PIGGYBACK

SWITCH PLUG

GROUNDED

WALL OUTLET

FLOAT

SWITCH

1/8''

"RELIEF"

HOLE

Typical Pump Installation in Sump

Figure 3

PUMPING

RANGE

Tether length

Tether Length vs. Pumping Range Curve

Figure 4

6

Wide Angle Float Mounting Strap

Figure 5

Page 7

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the

warranty period. The warranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18)

months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from

whom the pump was purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any

warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between

Goulds Water Technology and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the

business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an indi-

vidual, partnership, corporation, limited liability company, association or other legal entity which may engage in any type

of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

Teflon is a registered trademark of Dupont.

© 2011 Xylem Inc. IM105 Revision Number 5 December 2011

7

Page 8

MANUAL DE INSTRUCCIÓN

IM105

Bombas para sumideros

MANUAL DE INSTALACIÓN Y OPERACIÓN

8

Page 9

PELIGRO

ADVERTENCIA

Un voltaje peligroso puede

producir golpes el ctricos,

quemaduras o la muerte.

ADVERTENCIA

ADVERTENCIA

PARA EVITAR LESIONES PERSONALES GRAVES

O AÚN FATALES O SERIOS DAÑOS MATERIALES, LEA Y SIGA TODAS LAS INSTRUCCIONES

DE SEGURIDAD EN EL MANUAL Y EN LA

BOMBA.

Éste es un SÍMBOLO DE

ALERTA DE SEGURIDAD.

Cuando vea este símbolo en la

bomba o en el manual, busque

una de las siguientes palabras

de señal y esté alerta a la probabilidad de lesiones personales o

daños materiales.

Advierte los peligros que

CAUSARÁN graves lesiones

personales, la muerte o daños

materiales mayores.

Advierte los peligros que PU-

EDEN causar graves lesiones

personales, la muerte o daños

materiales mayores.

PRECAUCIÓN

AVISO: Indica instrucciones especiales que son

muy importantes y que se deben seguir.

ESTE MANUAL DEBE MANTENERSE CON

LA BOMBA.

MANTENGA TODAS LAS ETIQUETAS DE

SEGURIDAD.

Advierte los peligros que PUEDEN causar lesiones person-

ales o daños materiales.

INFORMACIÓN IMPORTANTE DE

PREINSTALACIÓN

Todo el trabajo eléctrico debe

ser realizado por un técnico

calificado. Siempre siga el

Código Eléctrico de EE.UU.

(NEC) o el Código Eléctrico

Canadiense, además de todos

los códigos locales, estatales y

provinciales.

La bomba debe conectarse a un circuito

eléctrico dedicado protegido con un cortacircuitos o fusible del tamaño apropiado.

Instale un desconectador cuando el código

así lo requiera. Las preguntas acerca del

código deben ser dirigidas al inspector

eléctrico. Ver la Tabla 1 para obtener infor-

mación específica.

Desconecte la corriente eléctrica antes

de instalar o dar servicio a la bomba. La

protección automática contra la sobrecarga

térmica del motor podría permitir que una

bomba recalentada arranque inesperadamente.

La bomba no está diseñada para usarse en

albercas, masas abiertas de agua, líquidos

peligrosos o donde existan gases inflamables.

Las bombas y flotadores equipados con un

enchufe de 3 clavijas conectado a tierra

deben enchufarse a un receptáculo trifilar.

No conecte a extensiones o conectores sin

un enchufe de 3 clavijas conectado a tierra.

NOTA: La eliminación del enchufe del

cable eléctrico no es permisible por código

del NEC. La eliminación del enchufe anulará el listado de la agencia.

PRECAUCIÓN

Esta bomba ha sido evaluada solo

para uso con agua.

Riesgo de descarga eléctrica –

esta bomba está provista con un

conductor de conexión a tierra y enchufe

accesorio del tipo para conexión a tierra.

Para reducir el riesgo de descarga eléctrica,

asegúrese de que sea conectado únicamente

a un receptáculo del tipo para conexión a

tierra, correctamente conectado a tierra.

9

Page 10

1. INFORMACIÓN GENERAL

ADVERTENCIA

1. INFORMACIÓN GENERAL

1.1. Las bombas para sumidero están diseñadas

para funcionar intermitentemente y habitualmente por temporadas. Se recomienda que

pruebe la bomba antes del comienzo de la

estación lluviosa para asegurar que la bomba

y el interruptor estén funcionando correctamente.

1.2. Sugerimos instalar un sistema de alarma por

alto nivel de agua y un sistema de bomba

de reserva a batería para sótanos habitables

o áreas donde la inundación podría causar

daños materiales. Un generador de reserva es

otra opción que puede consultar con el instalador de la bomba. La mayoría de los cortes

eléctricos ocurren durante temporales de

lluvia, justo cuando necesita más su bomba

para sumidero. Las garantías del fabricante

de la bomba sólo cubren la bomba. La mano

de obra y los daños y perjuicios imprevistos,

tales como inundaciones, no están cubiertos.

2. VERIFICACIONES PRELIMINARES

2. VERIFICACIONES PRELIMINARES

A LA INSTALACIÓN

A LA INSTALACIÓN

2.1. Abra todas las cajas e inspeccione el equipo

para determinar si se ocasionaron daños

durante el envío. Notifique cualquier daño a

su proveedor de inmediato.

2.2. Verifique que todo el equipo sea de la ten-

sión correcta. La garantía no cubre daños

causados por conectar bombas y controles a

la tensión incorrecta.

2.3. ¿Es el estanque del sumidero del tamaño y

tipo correctos para la ubicación?

Diámetro – debe ser suficientemente ancho

para permitir introducir la bomba y el interruptor y además dejar espacio para operar

libremente el interruptor. Los modelos de

interruptor vertical típicamente requieren

menos diámetro que los modelos anchos de

flotador angular. Consulte el “diámetro mín.

del estanque” en la Tabla 1.

PRECAUCIÓN

Profundidad – Debe ser más

profundo que la profundidad

mínima a la cual el interruptor enciende la

bomba. Por ejemplo, si la bomba se enciende

a 15 pulgadas, el estanque debe ser de más

de 15 pulg. de profundidad. Consulte el

“Nivel de encendido” en la Tabla 1.

10

Estilo - Hay varios estilos

de estanque de sumidero

disponibles. La ubicación del sumidero

determina si se requiere una cubierta y de

qué tipo. Es importante impedir la entrada

de residuos al sumidero ya que podrían

obstruir la bomba. Un sumidero abierto en

un área de mucho tráfico como un sótano es

peligroso. Si el área es frecuentada por niños

o animales domésticos, se recomienda una

cubierta empernada o a prueba de niños.

3. TUBERÍAS

3. TUBERÍAS

3.1. La tubería de descarga debe ser del mismo

tamaño que la descarga de la bomba para

asegurar un rendimiento óptimo. Si se utiliza

una tubería de tamaño insuficiente, podría

reducirse marcadamente el flujo y, por lo

tanto, derrocharse energía. El proveedor de

la bomba puede sugerir la tubería correcta

para su instalación.

3.2. Instale un adaptador roscado, que cor-

responda con el tipo de tubería que está

utilizando, en la descarga roscada de la

bomba. Un extremo tendrá una rosca macho

y el otro extremo tendrá un conector tipo

arpón, un accesorio tipo compresión o un

conector tipo soldadura con solvente. Utilice

cinta de Teflon® en todas las uniones roscadas. Si está utilizando accesorios y tubería

soldados con solvente, es mejor ajustarlos

al seco primero y verificar el ajuste antes de

soldar. Una unión instalada justo arriba de la

cubierta del sumidero o estanque facilitará el

mantenimiento y reemplazo futuros. Con-

sulte la Tabla 1 con respecto a los tamaños

de descarga.

3.3. Instale una válvula de retención de línea

a menos de 2 pies de la bomba. Instale de

acuerdo con las instrucciones del fabricante

de la válvula.

IMPORTANTE – Perfore un orificio de alivio de

1

⁄8 pulg. (3.2 mm) en la línea de descarga a

aproximadamente 2 pulg. (51 mm) sobre la

conexión de descarga de la bomba, pero debajo de la válvula de retención y dentro del

sumidero. Este orificio de “alivio” permite

que el aire atrapado escape de la bomba e

impide que la bomba se bloquee con aire. La

no perforación de este orificio es una de las

Page 11

causas principales por las cuales las bombas

ADVERTENCIA

de sumidero no bombean después de largos

períodos de inactividad, tal como el uso por

temporada. El ST del modelo es uno mismoexpresio’n - no se requiere ningún agujero.

4. INSTALACIÓN EN EL SUMIDERO

4. INSTALACIÓN EN EL SUMIDERO

4.1. La bomba puede colocarse directamente en

el fondo de un estanque de sumidero de polietileno o fibra de vidrio, o en el fondo de

un sumidero de concreto. Si el fondo es de

grava compactada, la grava debe ser de más

de ½ pulg. (13 mm) de diámetro y la bomba

debe colocarse sobre un soporte de ladrillos.

4.2. Después de conectar la tubería de descarga

a la bomba, ésta puede ser bajada al interior

del sumidero (estanque). Siempre sujete la

bomba de la manija y la tubería al bajarla, y

nunca del cable de alimentación. Coloque

la bomba contra la pared del estanque, de

manera que el interruptor esté en el centro.

Consulte los “Datos de instalación”.

4.3. Inspeccione para asegurar que todas las

conexiones de tubería estén apretadas. Las

tuberías deben apoyarse afianzándolas a las

vigas del piso o a la pared. Esto impedirá

que la bomba se mueva en el sumidero. Si se

mueve, podría atascarse el interruptor y ya

sea mantener a la bomba funcionando o no

dejar que se encienda.

4.4. Por ahora, la corriente a la salida debe estar

apagada. La salida dedicada debe suministrar

electricidad a la bomba únicamente.

4.5. Nuestras bombas para sumidero tienen

ya sea un solo cable de alimentación para

bombas con interruptores incorporados o

dos cables de alimentación con interruptores

en tándem.

Interruptores incorporados / un solo cable

– enchufe el cable de alimentación único a

una salida de corriente dedicada.

Interruptores en tándem / cables de alimentación – introduzca el enchufe macho de

los interruptores en tándem en una salida

de corriente dedicada. Luego conecte el

enchufe macho estándar de la bomba a la

parte trasera, lado hembra, del enchufe de

los interruptores en tándem.

4.6. Afiance los cables de alimentación a las

tuberías de descarga con amarras o cinta

aislante. Enrolle y guarde el exceso de cable

de alimentación fuera del sumidero.

5. OPERACIÓN

5. OPERACIÓN

5.1. Encienda la corriente en el panel de cort-

acircuitos y/o interruptor desconexión.

5.2. Llene el estanque con agua y observe dónde

la bomba se enciende y se apaga. Debe

encenderse mucho antes que el agua rebase

el sumidero. La bomba debe apagarse antes

de que el nivel de agua llegue por debajo de

la succión de la bomba. El ciclo de encendido – apagado en los modelos con flotador

de ángulo ancho es ajustable. El ajuste se

realiza cambiando el largo de la traba entre

el cuerpo del interruptor y el punto de traba

(pivote) del interruptor. El largo de la traba

no puede ser de menos de 3 a 3.5 pulg.

Las trabas de menos de 3 pulg. podrían no

permitir que el flotador baje lo suficiente

para apagar la bomba. Consulte los “Datos

de instalación”.

5.3. Instale una cubierta sobre el

estanque del sumidero si pudiesen caer residuos o si fuese peligroso para

los niños o animales domésticos. Consulte el

“Estilo” del estanque en la Sección 2.3.

6. SERVICIO DE TEMPORADA /

6. SERVICIO DE TEMPORADA /

MANTENIMIENTO

MANTENIMIENTO

6.1. Si la bomba para sumidero sólo funciona

por temporada y luego permanece inactiva

durante varios meses, se recomienda que

pruebe la bomba antes del comienzo de la

estación lluviosa. Llene el sumidero con

agua, verifique que no haya residuos y que el

interruptor esté funcionando correctamente.

Quite cualquier residuo que pudiese obstruir

el colador de succión o atascar el interruptor. Asegure que el interruptor funcione

libremente y que no choque contra la pared

del sumidero que se atasque en la tubería o

en los cables de alimentación.

11

Page 12

7. OPCIONES 8. TABLA DE IDENTIFICACIÓN Y

7. OPCIONES

7.1. El proveedor de la bomba tiene una línea

completa de estanques, cubiertas, alarmas

por alto nivel de agua y sistemas de bombas

de reserva a batería disponibles. También

vendemos paneles de control de bombas

simples y dobles. Se recomienda un sistema

doble cuando el flujo de entrada es constante

y las bombas funcionan casi continuamente.

El sistema doble proporciona una bomba de

reserva en caso de falla de la bomba principal.

8. TABLA DE IDENTIFICACIÓN Y

RESOLUCIÓN DE PROBLEMAS

RESOLUCIÓN DE PROBLEMAS

Hay que ser extremadamente cauteloso cuando

se dé servicio a dispositivos eléctricos. El electrochoque puede producir lesiones fatales. Siempre

desconecte el suministro eléctrico del dispositivo

que está recibiendo servicio, a menos que sea

necesario para el trabajo que se está realizando.

EL MOTOR NO ESTÁ FUNCIONANDO

(Ver las causas 1, 2, 3, 4, 6, 8)

SE ENTREGA POCO O NADA DE LÍQUIDO

(Ver las causas 5, 6, 7, 8, 10)

LA BOMBA NO SE APAGA

(Ver las causas 7, 8, 9, 10, 13)

LA BOMBA CICLA CONSTANTEMENTE

(Ver las causas 9, 11, 12, 13)

CAUSAS PROBABLES:

1. Protector térmico disparado.

2. Cortacircuitos abierto o fusible quemado.

3. Roce de las partes giratorias.

4. Motor defectuoso.

5. Bloqueo con aire.

6. Baja tensión.

7. Carga del sistema demasiado alta.

8. Bomba obstruida.

9. Control de nivel defectuoso o interruptor

situado incorrectamente.

10. Dirección incorrecta de la válvula de

retención.

11. Fuga de la válvula de retención.

12. Tamaño incorrecto del estanque o del pozo

del sumidero.

13. Flujo de entrada excesivo para el tamaño de

la bomba.

12

Page 13

INFORMACIÓN DEL MODELO (TABLA 1)

INFORMACIÓN DEL MODELO (TABLA 1)

Corta- Estilo de Largo Conexión Nivel Nivel Diám. Tamaño Peso de

N°. de

orden

HP

Volt- Am-

ios perios

circuitos Fase interruptor del de mín. de mín. de mín. del máx. de envío

mín. del flotador cable descarga encendido apagado estanque sólidos Lbs/kg

Interr. vertical 8" 3.5" 11"

ST31 1⁄3 115 12.0 20 1

Interr. de ángulo ancho

10' 1½" 14" 7" 18" ½" 29 / 13.2

Sin interr. Manual Manual 11"

Sin interr. Manual Manual 9"

Interr. de

LSP03 1⁄

3

115 2.9 10 1

ángulo ancho

Interr. vertical

10' /

1½" 3⁄8" 11 / 5

20'

11" 5"

8.5" 2"

12"

Sin interr. Manual Manual 9"

115 7.1

LSP07 ¾

230 3.5

SP024

SP025

SP035 1⁄

Sin interr. Manual Manual

STS21 ¼ 115 2.5 10 1

Sin interr. 9"

STS31

Sin interr. 9"

¼

115

3

1

⁄

115 4.5 10 1

3

1¼"

2.4

1½"

3.0

10 1

Interr. vertical

10 1

Interr. vertical

Interr. vertical

Interr. de

ángulo ancho

20' 1½"

12.5" 6.5" 12"

6" 3"

10'

20' 1¼" Ajustable

20' 1¼" Ajustable

11"

11"

9"

3

⁄8" 15 / 6.8

3

⁄

"

8

3

⁄16" 10 / 4.5

3

⁄16" 10 / 4.5

8 / 3.6

* Éste es un motor de CC. Arranca cada minuto buscando una carga. Si hay agua en el estanque, bombeará hasta reducir el nivel a 5/8 y se

apagará. No hay clasificación de potencia.

DATOS DE INSTALACIÓN

DATOS DE INSTALACIÓN

Posicionamiento sugerido

de la bomba en el sumidero

Figura 1

Enchufe en tándem

Figura 2

13

Page 14

DATOS DE INSTALACIÓN

DATOS DE INSTALACIÓN

VÁLVULA DE

RETENCIÓN

UNIÓN

ORIFICIO DE

“ALIVIO”

DE 1/8

PULG.

ENCHUFE ELÉCTRICO DE LA BOMBA

ENCHUFE DE INTERR.

EN TÁNDEM

RECEPTÁCULO

DE PARED

CONECTADO A

TIERRA

INTERRUPTOR

DE FLOTADOR

RANGO DE

BOMBEO

Instalación típica de la

bomba en el sumidero

Figura 3

Largo de la traba (pulgadas)

Rango de bombeo

Curva del largo de la traba

vs. rango de bombeo

Figura 4

14

Largo de

la traba

Correa de montaje del

flotador de ángulo ancho

Figura 5

Page 15

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de

garantía sin cargo para el comerciante. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El

distribuidor está autorizado a liquidar todos los reclamos por garantía a través del Departamento de Servicios a Clientes de

Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Goulds

Water Technology y el comerciante para la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta

o alquiler-venta (leasing) de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante.

El término “cliente” puede significar un individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

Teflon es una marca registrada de Dupont.

© 2011 Xylem Inc. IM105 Révision Nombre 5 Deciembre 2011

15

Page 16

MANUEL D'UTILISATION

Pompes de puisard

IM105

MANUEL D’INSTALLATION ET D’UTILISATION

16

Page 17

DANGER

AVERTISSEMENT

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

lectrique, des br lures

ou la mort.

ATTENTION

AVERTISSEMENT

ATTENTION

AFIN DE PRÉVENIR LES BLESSURES GRAVES

OU MORTELLES ET LES DOMMAGES MATÉRIELS IMPORTANTS, LIRE ET SUIVRE TOUTES

LES CONSIGNES DE SÉCURITÉ FIGURANT

DANS LE MANUEL ET SUR LA POMPE.

Le symbole ci-contre est un

SYMBOLE DE SÉCURITÉ

employé pour signaler sur la

pompe et dans le manuel les

mots-indicateurs dont on trouvera

la description ci-dessous. Sa

présence sert à attirer l’attention

afin d’éviter les blessures et les

dommages matériels.

Prévient des risques qui VONT

causer des blessures graves, la

mort ou des dommages matériels

importants.

Prévient des risques qui

PEUVENT causer des blessures

graves, la mort ou des dommages

matériels importants.

Prévient des risques qui

PEUVENT causer des blessures

ou des dommages matériels.

AVIS : Sert à énoncer les directives spéciales de

grande importance que l’on doit suivre.

LE PRÉSENT MANUEL DOIT ÊTRE

CONSERVÉ PRÈS DE LA POMPE.

N’ENLEVER AUCUNE ÉTIQUETTE DE

SÉCURITÉ.

INFORMATIONS IMPORTANTES À LIRE AVANT

L’INSTALLATION

L’installation électrique doit

être entièrement effectuée

par un technicien qualifié. Il

faut toujours suivre les prescriptions du code provincial

ou national de l’électricité.

On doit brancher la pompe à un circuit

électrique indépendant protégé par un

disjoncteur ou des fusibles de calibre approprié. Poser un sectionneur si le code de

l’électricité l’exige. Adresser toute question

relative au code à un inspecteur en électricité. Voir les informations sur les modèles

dans la table 1.

Couper l’alimentation électrique de la

pompe avant de procéder à l’installation ou

à l’entretien de celle-ci. Le protecteur thermique du moteur arrête automatiquement

celui-ci en cas de surchauffe et le redémarre

de façon imprévue quand il a refroidi.

La pompe n’est pas conçue pour les piscines, l’eau libre, les liquides dangereux

ni les endroits pouvant contenir des gaz

inflammables.

Les contacteurs à flotteur et les pompes

munis d’une fiche à trois broches (avec mise

à la terre) doivent être branchés sur une

prise à trois fils. Ne pas les brancher à une

rallonge électrique ni à une prise sans une

fiche à trois broches (avec mise à la terre).

NOTA : selon le NEC (code de l'électricité

des É.-U.), enlever la fiche du fil d'alimentation est inadmissible et annulera l'inscription dans la liste UL.

L'utilisation de la pompe a été

évaluée pour l'eau seulement.

Risque de choc électrique — la

pompe est munie d'un cordon à

conducteur et à fiche de mise à la terre.

Afin de réduire les risques de choc électrique, s'assurer que la pompe est branchée

à une prise trifilaire appropriée correctement mise à la terre.

17

Page 18

1. INFORMATIONS GÉNÉRALES

AVERTISSEMENT

ATTENTION

1. INFORMATIONS GÉNÉRALES

1.1. Les pompes de puisard sont conçues pour un

usage intermittent, généralement saisonnier.

Il est recommandé d’essayer la pompe avant

la fonte des neiges et le début des pluies

printanières pour s’assurer de son bon fonctionnement et de celui du contacteur.

1.2. La pose d’un avertisseur de haut niveau

d’eau et d’un système de pompage de réserve

à batterie est suggérée dans tout endroit ou

sous-sol aménagé où une inondation causerait des dommages matériels. Discuter de

l’utilisation d’une génératrice de secours

avec l’installateur de la pompe. La plupart

des pannes de courant ont lieu pendant les

pluies torrentielles, quand on a le plus besoin

de la pompe ! Les garanties des fabricants

de pompes ne couvrent que les pompes, pas

les frais de main-d’œuvre ni les dommages

accessoires dus aux inondations.

2. VÉRIFICATIONS AVANT INSTALLATION

2. VÉRIFICATIONS AVANT INSTALLATION

2.1. Ouvrir tous les cartons et vérifier si le maté-

riel est endommagé. Signaler immédiatement

tout dommage au fournisseur.

2.2. Vérifier si la tension d’alimentation est

appropriée pour tout le matériel. La garantie

ne couvre pas les pompes ni les commandes

endommagées par une mauvaise tension

d’alimentation.

2.3. Vérifier si la cuve est de la dimension et du

type appropriés :

Diamètre de cuve — il doit être suffisant

pour permettre la pose de la pompe et le

libre mouvement de son contacteur. Les

contacteurs verticaux requièrent moins

d’espace que les contacteurs à grand déplacement angulaire. Voir le diamètre de cuve

minimal dans la table 1.

Profondeur de cuve — elle

doit être supérieure au niveau

de démarrage minimal de la pompe. Par

exemple, si ce niveau est de 15 po, employer

une cuve d’une profondeur de plus de 15 po.

Voir le niveau de démarrage minimal dans la

table 1.

Type de cuve — il existe divers

types de cuves. Selon l’empla-

ce-ment du puisard, un couvercle peut être

18

nécessaire pour empêcher débris et objets

de tomber dans le puisard et d’engorger la

pompe. Un puisard ouvert situé dans un

sous-sol ou autre endroit passants représente

un danger pour les enfants et les animaux de

compagnie. La pose d’un couvercle boulonné ou à l’épreuve des enfants est alors

recommandée.

3. TUYAUTERIE

3. TUYAUTERIE

3.1. Le tuyau et l’orifice de refoulement de la

pompe devraient avoir le même calibre pour

permettre des performances optimales. Un

tuyau de calibre moindre pourrait réduire

le débit de la pompe de beaucoup et causer

ainsi une perte d’énergie. Le fournisseur de

pompes peut suggérer le calibre de tuyau

convenant à l’installation.

3.2. Visser à l’orifice de refoulement de la pompe

un raccord-adaptateur de tuyau convenant

au type de tuyau employé. Le raccord est

du type à barbillons, à compression ou à

coller au solvant à une extrémité et à filetage

extérieur à l’autre extrémité. Utiliser du

ruban de TéflonMD sur chaque joint fileté. Si

l’on utilise un tuyau et un raccord à coller au

solvant, il vaut mieux en vérifier l’ajustement

avant de les coller. Un raccord union posé

juste au-dessus du puisard ou du couvercle

de la cuve facilitera l’entretien et l’enlèvement de la pompe. Voir le diamètre de

raccord de refoulement dans la table 1.

3.3. Poser un clapet de non-retour sur le tuyau

de refoulement, à moins de 2 pi de la

pompe, suivant les directives du fabricant du

clapet.

IMPORTANT : afin de prévenir l’accumulation

de poches d’air dans la pompe, percer un

trou-purgeur d’air de 3,2 mm (1⁄8 po) de

diamètre dans le tuyau de refoulement à

environ 51 mm (2 po) au-dessus du raccord

de refoulement de la pompe, en amont du

clapet de non-retour, mais à l’intérieur du

puisard. L’absence du trou-purgeur d’air est

la principale cause de l’accumulation d’air

dans la pompe et, ainsi, du débit de pompage trop faible après les longues périodes

d’arrêt saisonnières. Modèle ST est art de

l’auto-portrait-venting - aucun trou n’est

exigé.

Page 19

4. INSTALLATION DANS LE PUISARD

AVERTISSEMENT

4. INSTALLATION DANS LE PUISARD

4.1. On peut placer la pompe directement au

fond d’une cuve en polyéthylène ou en fibre

de verre ou d’un puisard en béton. Si le

fond est en gravier compacté, la grosseur du

gravier doit dépasser 13 mm (½ po), et l’on

doit utiliser des briques comme assise pour

la pompe.

4.2. Une fois le tuyau de refoulement raccordé

à la pompe, on peut poser celle-ci dans

le puisard (ou la cuve) en la saisissant par

la poignée et le tuyau, mais jamais par le

cordon d’alimentation. La placer contre la

paroi du puisard, le contacteur orienté vers

le centre du puisard. Voir les « Données sur

l’installation ».

4.3. Vérifier si tous les joints sont étanches. La

tuyauterie devrait être fixée aux solives de

plancher et aux murs avec des attaches pour

immobiliser la pompe dans le puisard. Si

la pompe bougeait, le contacteur pourrait

rester coincé et empêcher la pompe d’arrêter

ou de démarrer.

4.4. L’alimentation de la prise de courant réser-

vée devrait être coupée à cette étape-ci. La

prise devrait alimenter seulement la pompe.

4.5. Les pompes à contacteur intégré sont mu-

nies d’un seul cordon d’alimentation, et les

pompes à contacteur à fiche-prise, de deux

cordons.

Pompe à contacteur intégré, à cordon simple

— brancher la fiche sur la prise de courant

réservée.

Pompe à contacteur à fiche-prise, à cordon

double — brancher la fiche-prise du contac-

teur sur la prise de courant réservée, puis la

fiche de la pompe sur la fiche-prise.

4.6. Après avoir enroulé et accroché la longueur

excédentaire du (ou des) cordon d’alimentation hors du puisard, fixer le (ou les) cordon

d’alimentation au tuyau de refoulement avec

des attaches autobloquantes (tie wraps) ou

du ruban isolant.

5. UTILISATION

5. UTILISATION

5.1. Rétablir le courant au panneau de disjonc-

teurs ou au sectionneur, ou aux deux si c’est

le cas.

5.2. Remplir le puisard (ou la cuve) d’eau et

noter le niveau de l’eau quand la pompe

démarrage et arrête. La pompe devrait

démarrer bien avant que le puisard déborde

et s’arrêter avant que le niveau de l’eau

atteigne l’orifice d’aspiration. On peut régler

les cycles de marche et d’arrêt des pompes à

contacteur à flotteur en changeant la longueur du câble du contacteur. Celle-ci ne

doit pas être inférieure à 3 po (ou 3,5 po),

car le flotteur pourrait ne pas baisser suffisamment pour arrêter la pompe. Voir les

« Données sur l’installation ».

5.3. Poser un couvercle sur le

puisard ou la cuve si les enfants, les animaux de compagnie et les débris

risquent d’y tomber. Voir « Type de cuve »,

à 2.3.

6. ENTRETIEN SAISONNIER

6. ENTRETIEN SAISONNIER

6.1. Si la pompe n’a qu’un usage saisonnier

et ne sert donc pas des mois durant, il est

recommandé de l’essayer avant la fonte des

neiges et le début des pluies printanières :

remplir le puisard, en enlever les débris, qui

pourraient engorger la crépine d’aspiration

ou bloquer le contacteur, puis vérifier le

bon fonctionnement de ce dernier. S’assurer

que celui-ci peut bouger librement, qu’il ne

touche pas à la paroi du puisard et qu’il ne

peut rester accroché à la tuyauterie ni au(x)

cordon(s) d’alimentation.

7. PRODUITS EN OPTION

7. PRODUITS EN OPTION

7.1. Le fournisseur de pompes offre une gamme

complète de produits : cuves, couvercles,

avertisseurs de haut niveau d’eau et systèmes

de pompage de réserve à batterie. Goulds

vend en outre des tableaux de commande

pour système à pompe simple ou double. Un

système à pompe double est recommandé

quand le débit entrant est constant et que la

pompe fonctionne presque sans arrêt, car la

pompe de réserve se mettrait en marche si la

pompe principale tombait en panne.

19

Page 20

8. DIAGNOSTIC DES ANOMALIES

8. DIAGNOSTIC DES ANOMALIES

On doit prendre des précautions extrêmes quand

on effectue l’entretien d’un appareil électrique.

Les chocs électriques peuvent être mortels. On

doit toujours débrancher l’appareil avant de procéder à son entretien, sauf si la tâche en question

requiert l’utilisation de courant.

ANOMALIE

NON-FONCTIONNEMENT DU MOTEUR

(V. causes probables 1, 2, 3, 4, 6 et 8)

DÉBIT DE REFOULEMENT FAIBLE OU NUL

(V. causes probables 5, 6, 7, 8 et 10)

FONCTIONNEMENT SANS ARRÊT DE LA

POMPE

(V. causes probables 7, 8, 9, 10 et 13)

RÉPÉTITION SANS ARRÊT DU CYCLE DE

FONCTIONNEMENT

(V. causes probables 9, 11, 12 et 13)

CAUSES PROBABLES

1. Protecteur thermique déclenché

2. Disjoncteur ouvert ou fusible sauté

3. Pièces mobiles grippées

4. Moteur défectueux

5. Poche d’air dans la pompe

6. Basse tension électrique

7. Hauteur de charge trop élevée du système

8. Pompe obstruée

9. Régulateur de niveau défectueux ou con-

tacteur à flotteur mal placé

10. Clapet de non-retour posé à l’envers

11. Fuite du clapet de non-retour

12. Puisard, cuve ou fosse humide de dimensions

inappropriées

13. Débit entrant supérieur au débit de

refoulement

20

Page 21

TABLE 1 — INFORMATIONS SUR LES MODÈLES

TABLE 1 — INFORMATIONS SUR LES MODÈLES

Calibre (A) Type de contact. Long. du Diam. de Niv. de Niv. Diam. Grosseur Poids à

No de

hp V A min. du Ø à flotteur cordon raccord de démarr. d’arrêt de cuve max. des l’expéd.

catal.

disjonct. (pi) refoul. (po) min. (po) min. (po) min. (po) solides (po) (lb/kg)

Vertical 8 3,5 11

ST31 1⁄3 115 12,0 20 1 À déplacem. angul. 10 1½ 14 7 18 ½ 29/13,2

Aucun contacteur Manuel Manuel 11

Aucun contacteur Manuel Manuel 9

LSP03 1⁄

3

115 2,9 10 1

À déplacem.

angul.

Vertical

10 ou

1½ 3⁄8 11/5

20

11 5

8,5 2

12

Aucun contacteur Manuel Manuel 9

115 7,1

LSP07 ¾

230 3,5

SP024

SP025

SP035 1⁄

Aucun contacteur Manuel Manuel

STS21 ¼ 115 2,5 10 1

Aucun contacteur 9"

STS31

Aucun contacteur 9"

* Cette pompe, alimentée en courant continu, démarre à toutes les minutes à la recherche d’une charge. S’il y a de l’eau dans la cuve, elle la pompera jusqu’à ce

que le niveau atteigne 5⁄8 po du fond, puis elle s’arrêtera. La puissance (hp) nominale n’est pas indiquée.

¼

1

⁄

2,4

115

3,0

3

115 4,5 10 1

3

10 1

À déplacem.

12,5 6,5 12

angul.

20 1½

3

⁄8 15/6,8

1¼

10 1

1½

Vertical 10 6 3

Vertical

Vertical

20' 1¼" Réglable

20' 1¼" Réglable

11"

11"

9

3

⁄

8

3

⁄16"

3

⁄16"

8/3,6

10 / 4,5

10 / 4,5

DONNÉES SUR L’INSTALLATION

DONNÉES SUR L’INSTALLATION

Position suggérée de la

pompe dans le puisard

Figure 1

Fiche-prise

Figure 2

21

Page 22

DONNÉES SUR L’INSTALLATION

DONNÉES SUR L’INSTALLATION

CLAPET DE

NON-RETOUR

RACCORD

UNION

TROU-PURGEUR D’AIR

DE

1/8 po

FICHE DE LA POMPE

FICHE-PRISE DU

CONTACTEUR

PRISE MURALE

MISE À LA TERRE

CONTACTEUR

À FLOTTEUR

PLAGE DE

POMPAGE

Installation type

Figure 3

Longueur du câble (po)

3,5

5,5

Plage de pompage (po)

Courbe plage de pompage-

longueur du câble

22

Figure 4

Longueur

du câble

Fixation du contacteur à grand

déplacement angulaire

Figure 5

Page 23

NOTES/NOTAS

NOTES/NOTAS

23

Page 24

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant

la première : douze (12) mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur

Goulds Water Technology agréé chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le

distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water Technology.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité

juridique servant d’intermédiaire entre Goulds Water Technology et le détaillant pour les achats, les consignations ou les

contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité

juridique dont les activités commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une

personne, une société de personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre

entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (866) 325-4210

Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

Téflon est une marque déposée de Dupont.

© 2011, Xylem Inc. IM105 Révision numéro 5 Décembre 2011

Loading...

Loading...