Page 1

INSTRUCTION MANUAL

IM103

5" and Larger

Submersible Pump

INSTALLATION AND OPERATION INSTRUCTIONS

Page 2

TABLE OF CONTENTS

SUBJECT PAGE

Safety Instructions .................................................................................................................................................................... 3

1.0 Preparing for Installation .................................................................................................................................................... 4

2.0 Mechanical Installation.......................................................................................................................................................4

3.0 Electrical Instructions ........................................................................................................................................................ 5

4.0 Operate Pump .................................................................................................................................................................... 7

5.0 Literature and IOM ............................................................................................................................................................ 7

6.0 Accessories .........................................................................................................................................................................7

Single Phase Wiring ..................................................................................................................................................................8

Three Phase Wiring ..................................................................................................................................................................9

Technical Data ........................................................................................................................................................................10

Three Phase, 4" Motor - Electrical Data ..................................................................................................................................12

Generation II - 3-Wire, Single Phase, 4" Motors - Electrical Data ............................................................................................12

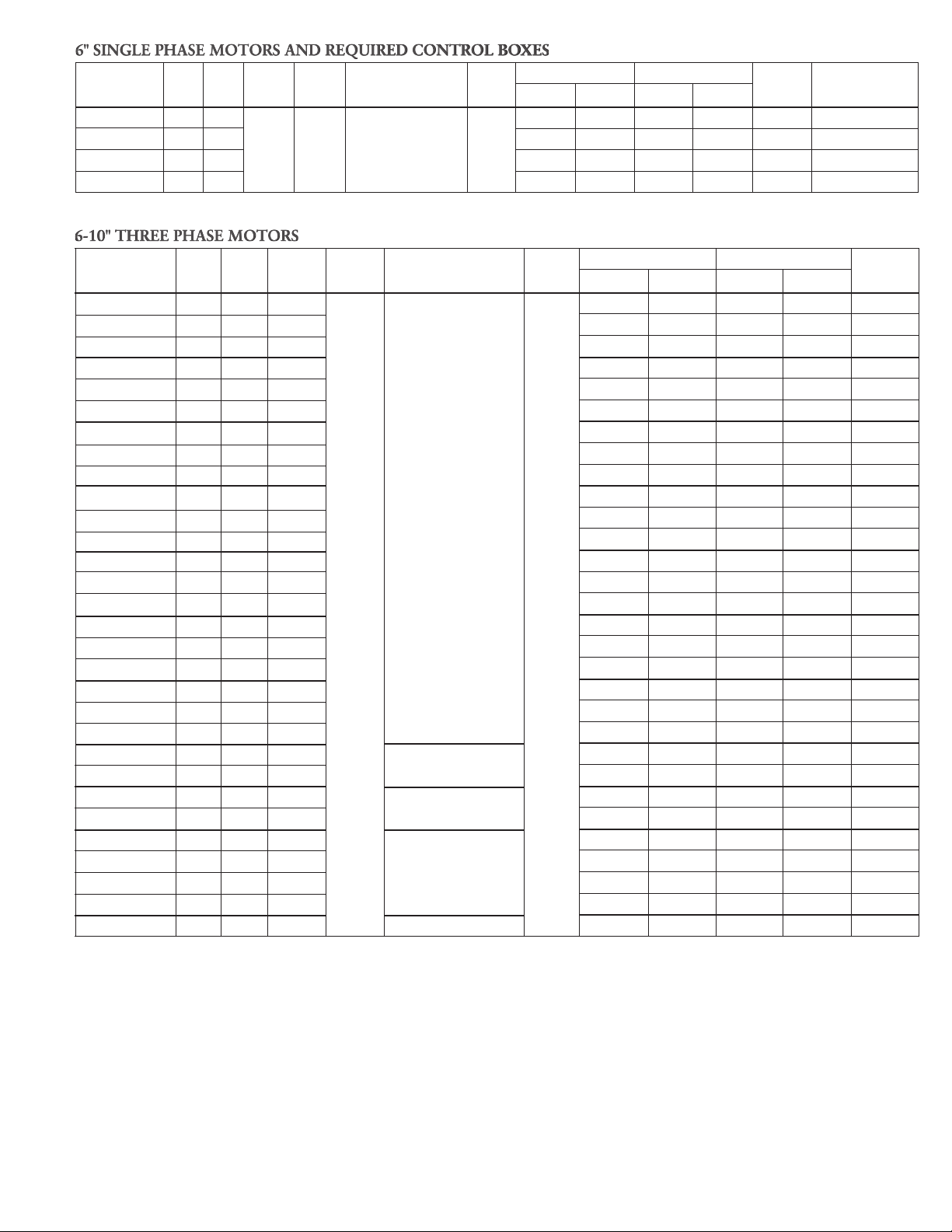

6" Single Phase Motors and Required Control Boxes ..............................................................................................................13

6-10" Three Phase Motors ...................................................................................................................................................... 13

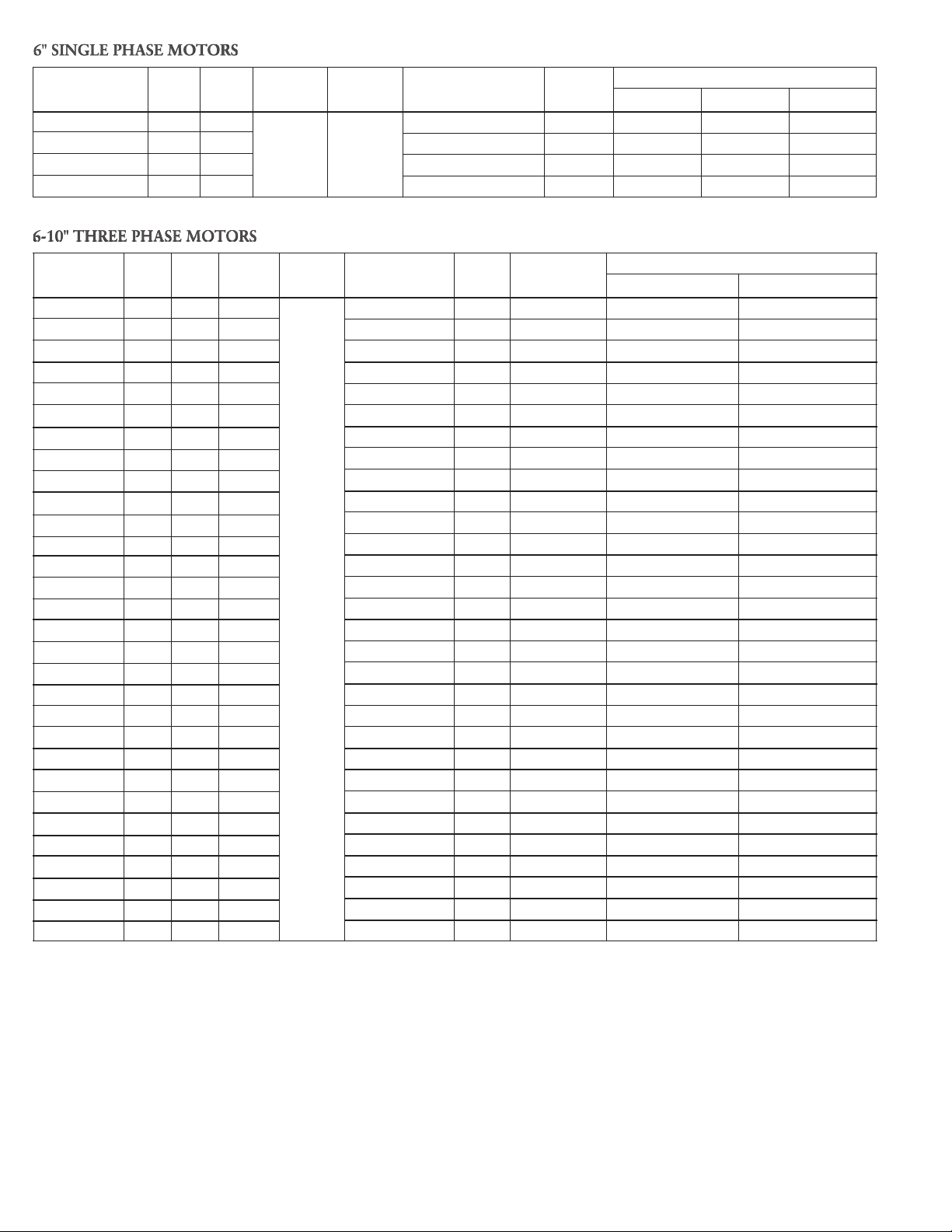

6" Single Phase Motors ........................................................................................................................................................... 14

6-10" Three Phase Motors ...................................................................................................................................................... 14

Three Phase Power Unbalance ................................................................................................................................................15

Troubleshooting .....................................................................................................................................................................16

Limited Warranty ...................................................................................................................................................................17

Owner’s Information

Owner’s Information

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor Serial Number:

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

Dole® is a Registered Trademark of Eaton Corporation.

Cla-Val™ is a Trademark of Griswold Ind.

2

Page 3

WARNING

WARNING

WARNING

SAFETY INSTRUCTIONS

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

CAUTION

DANGER

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR PROPERTY DAMAGE, READ AND FOLLOW ALL

SAFETY INSTRUCTIONS IN MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE INSTALLATION AND OPERATION OF THIS UNIT AND MUST BE

KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL. When you see this symbol on the pump or in the manual, look for one of

the following signal words and be alert to the potential for personal injury or property damage.

DANGER

WARNING

CAUTION

Warns of hazards that WILL cause serious personal injury, death or major property damage.

Warns of hazards that CAN cause serious personal injury, death or major property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS WHICH ARE VERY IMPORTANT AND MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND WARNINGS PRIOR TO PERFORMING ANY WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

Important notice: Read safety instructions before proceeding with any wiring

All electrical work must be performed by a qualified technician. Always follow the National Electrical Code

(NEC), or the Canadian Electrical Code, as well as all local, state and provincial codes. Code questions should be

directed to your local electrical inspector. Failure to follow electrical codes and OSHA safety standards may result in personal

injury or equipment damage. Failure to follow manufacturer’s installation instructions may result in electrical shock, fire hazard,

personal injury or death, damaged equipment, provide unsatisfactory performance, and may void manufacturer’s warranty.

Standard units are designed to pump potable water from wells and storage tanks. They are not designed for use

in swimming pools, open bodies of water, hazardous liquids, or where flammable gases exist. Well must be vented

per local codes.

Only pumps specifically Listed for Class 1, Division 1 are allowable in hazardous liquids and where flammable gases may exist.

See specific pump catalog bulletins or pump nameplate for all agency Listings.

Disconnect and lockout electrical power before installing or servicing any electrical equipment. Many pumps are

equipped with automatic thermal overload protection which may allow an overheated pump to restart

unexpectedly.

Do not lift, carry or hang pump by the electrical cables. Damage to the Electrical Cables can cause shock,

burns or death.

Use only stranded copper wire to pump/motor and ground. The ground wire must be at least as large as the power

supply wires. Wires should be color coded for ease of maintenance and troubleshooting.

Install wire and ground according to the National Electrical Code (NEC), or the Canadian Electrical Code, as well

as all local, state and provincial codes.

Install an all leg disconnect switch where required by code.

The electrical supply voltage and phase must match all equipment requirements. Incorrect voltage or phase can

cause fire, motor and control damage, and voids the warranty.

All three phase (3Ø) controls for submersible pumps must provide Class 10, quick-trip, overload

protection.

All splices must be waterproof. If using splice kits follow manufacturer’s instructions.

Select the correct type and NEMA grade junction box for the application and location. The junction box must

insure dry, safe wiring connections.

Failure to permanently ground the pump, motor and controls before connecting to power can cause shock, burns

or death.

Insure proper motor cooling, see Table 3, minimum flow rates chart in Technical Section.

This pump has been evaluated for use with Water Only.

Never over pressurize a storage tank to a pressure higher than the tank's maximum pressure rating. This will

damage the tank, voids the warranty and may create a serious hazard.

3

Page 4

1.0 PREPARING FOR INSTALLATION

1.0 PREPARING FOR INSTALLATION

The well should be developed (cleaned) and disinfected

before the pump is installed.

Write the pump model number, pump serial number and

motor serial number in the space provided in this Installation

and Operation Manual (IOM). Leave the completed IOM

attached to the tank or control box in a dry area or give it to

the owner. Attach your business card.

Verify that motor voltage, control voltage, coil voltage

(3 phase starters) and power supply voltage match. Electrical

installation must be performed by qualified personnel.

Inspect all components for shipping damage and insure that

you have all the components that are required: Pump Water

End, Motor, 1Ø Motor Control Box or 3Ø Starter with

Overloads, Pressure Tank, Pressure Switch, Copper Wire,

Pressure Relief Valve (if required), Torque Arrestor (if

required), Pipe and Fittings.

2.0 MECHANICAL ASSEMBLY – Pump and Piping

2.0 MECHANICAL ASSEMBLY – Pump and Piping

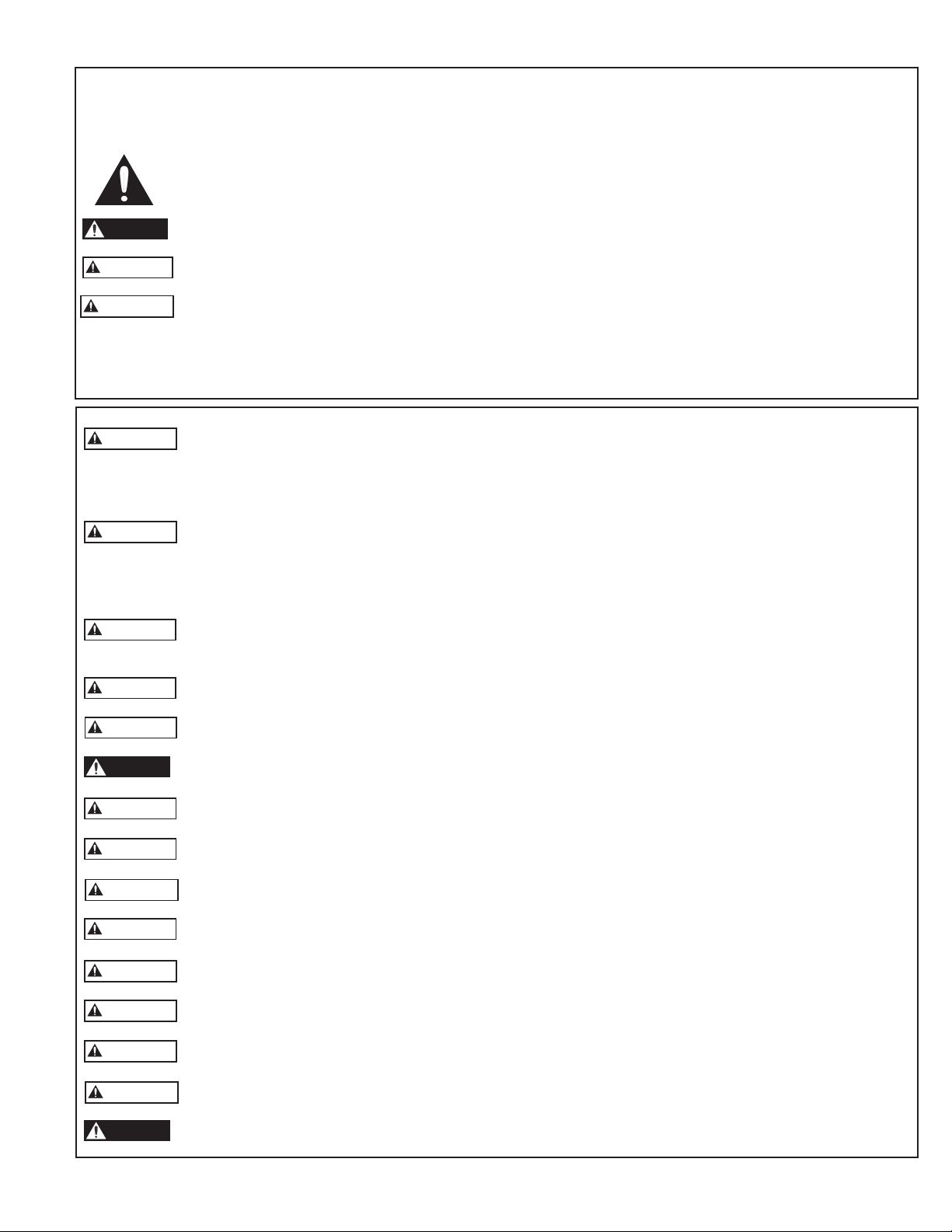

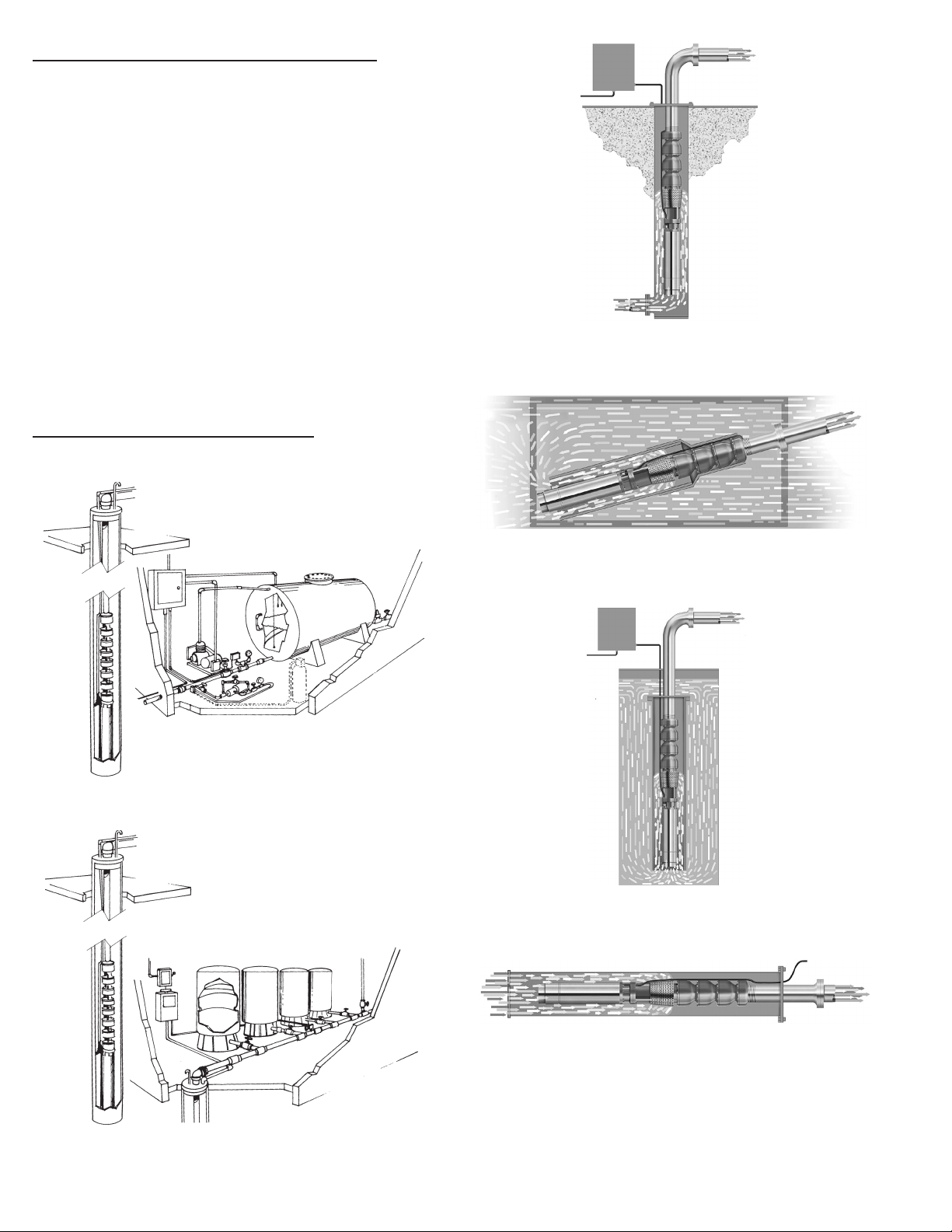

2.1 Typical Systems

Pump in “Can”

Figure 3

Figure 1

Pump with Flow Sleeve in Tank

Figure 4

Pump with Flow Sleeve in Large Diameter Well

Figure 5

Horizontal Pump in “Can”

Figure 6

Figure 2

4

Page 5

2.2 Assemble Pump End to Motor

Under no circumstance should the pump be run dry. Doing

so may damage internal parts. We suggest you check the

rotation on a three phase motor before assembling it to the

water end (pump). All 4" and 6" single phase motors should

rotate counterclockwise when viewed from the shaft end.

Rotation on three phase motors should match pump specifications. Due to the high-starting torque the motor should

be secured in such a way as not to damage the motor but to

hold the motor from spinning.

Lower the pump into the well. Set the pump at least 10' off

the bottom but above the screens. Protect the wires from

chafing on the well casing. Install a pitless adapter or similar

device at the wellhead. Consult the fitting manufacturer or

pitless supplier for specific installation instructions.

Using waterproof electrical tape, or wire ties, fasten the

wires to the drop pipe at 10' intervals. Make sure that the

tape does not loosen as it will block the pump suction if it

falls down the well.

Remove the cable guard from the pump (water end). Install

the motor shaft sand slinger if included with the water end in

the motor mounting hardware package. Attach the water end

to the motor. Align the wires in the cable guard and reinstall

it to the water end.

2.3 Install Check Valve(s)

Discharge heads are threaded with NPT pipe threads. All

models, without built-in check valves, require a spring

loaded check valve within 25' (7.5m) of the pump discharge

and below the drawdown level of the water supply. Motor

manufacturers recommend additional check valves every 200'

to 250' (70m) in the vertical discharge line. Check valves are

used to hold pressure in the system and to prevent backspin,

water hammer and upthrust.

Backspin is allowing water to flow back through the pump to

drain the system. It causes the impellers and motor rotor to

rotate in a reverse direction. This can cause premature thrust

bearing wear and if the motor starts during backspin the

shaft can be twisted or broken.

Water Hammer occurs when the lowest check valve is more

than 30' above the standing water level or the lower check

valve leaks and the check valve above holds. This creates a

partial vacuum (void) in the discharge piping. On the next

start, water moving at a very high velocity fills the void and

strikes the closed check valve and the stationary water in the

pipe above it, causing a hydraulic shock. This shock (water

hammer) can split pipes, break joints, and damage the pump

and motor. Water hammer is an easily detected noise. When

discovered the pump should be immediately shut down and

the installer contacted to resolve the problem.

2.5 Pressure Relief Valve

Pressure relief valves are mandatory (required) on any system

that is capable of producing over 100 psi or 230' TDH. In

an area where a water leak or blow-off may damage property

connect a drain line to the pressure relief valve. Run it to a

suitable drain or an area where the water will not damage

property.

2.6 Pressure Tank and Pressure Switch

(when used)

The pressure switch should be located at the tank cross tee

on a single tank and as close to the center as possible on

multiple tank installations. Multiple tank installations should

have a manifold pipe 1½ to 2 times the size of the supply

pipe from the pump. This is to reduce the friction head loss

or pressure differential in the manifold. Excessive losses

could cause switch chatter. There should be no filters, or

high loss fittings between the switch and the tank(s). Wide

open gate valves are allowed between the tank and switch.

2.7 Adjusting Tank Pre-Charge (when used)

Insure that the tank is empty of water. Use a high quality

pressure gauge to check the tank pre-charge pressure. The

pressure should be 2 psi below the pump cut-in (turn on)

pressure. As an example, a 30-50 psi system would use a

tank pre-charge of 28 psi.

Select an area where the temperature is above 34° F in which

to install the tank, pressure switch, and pressure relief valve.

The tank should be located in an area where a leak will not

damage property.

3.0 ELECTRICAL INSTRUCTIONS

3.0 ELECTRICAL INSTRUCTIONS

Upthrust is an upward movement of the impellers and motor

shaft. It is caused by starting the pump at zero head due to

no check valve or a leaking check valve; or very low system

head due to a high static water level. Repeated upthrust can

cause premature failure of either or both the pump and the

motor. See 4.2

2.4 Installing Pump in Well

If you are using a torque arrestor, install it per the manufacturer’s installation instructions. On top feeding wells or large

diameter wells where water velocity will not cool the motor properly install a flow sleeve over the pump. See Table 3

– Required Cooling Flow.

Connect the discharge pipe to the pump discharge head.

Submersible pumps are capable of very high discharge pressures, consult with your pipe supplier to determine the best

pipe material and schedule for each installation.

3.1 General

Note: Do not power the unit or run the pump until all

electrical and plumbing connections are completed and the

pump is filled with water.

Always follow the National Electric Code (N.E.C.) in the

U.S., or the Canadian Electrical Code in Canada, as well as

all state, provincial, or local codes.

All electrical work must be performed by qualified

personnel. Some local laws require installation by only

“licensed installers”.

We suggest using only copper wire. Size wire from the charts

found in our ITT MAID, Motor Application & Installation

Manual, or an N.E.C.( National Electric Code) manual. If

discrepancies exist the N.E.C. in the U.S., and in Canada the

Canadian Electrical Code prevails.

5

Page 6

3.2 Splice Drop Cable to Motor Leads

When the drop cable must be spliced or connected to the

motor leads it is necessary that the splice be watertight. The

splice can be done with heat shrink kits, compression fittings,

or waterproof tape. Match motor leads and drop cable by

color codes or identify drop cable wires to insure a proper

connection at the control box.

A. Heat Shrink Splice Instructions

To use a typical heat shrink kit: strip ½" from the motor

wires and drop cable wires, it is best to stagger the splices.

Place the heat shrink tubes on the wires. Place the crimps

on the wires and crimp the ends. Slide the heat shrink

tubes over the crimps and heat from the center outward.

The sealant and adhesive will ooze out the ends when the

tube shrinks. The tube, crimps, sealant, and adhesive

create a very strong, watertight seal. Overheating may

burn the heat shrink tubes.

B. Taped Splice Instructions

1) Strip individual conductor of insulation only as far as

necessary to provide room for a stake type connector.

Tubular connectors of the staked type are preferred. If

connector O.D. is not as large as cable insulation,

build-up with rubber electrical tape.

2) Tape individual joints with rubber electrical tape, using

two layers; the first extending two inches beyond each

end of the conductor insulation end, the second layer two

inches beyond the ends of the first layer. Wrap tightly,

eliminating air spaces as much as possible.

3) Tape over the rubber electrical tape with #33 Scotch

electrical tape, or equivalent, using two layers as in step

“B” and making each layer overlap the end of the

preceding layer by at least two inches.

C. Compression Splice Kits

Consult instructions supplied with compression splice kits

or consult your local supplier.

3.3 Mounting the Motor Control Box

Single phase 3-wire control boxes are suitable for vertical

mounting in indoor or outdoor locations. They will operate

at temperatures between 14ºF ( -10º C) and 122º F (50º C).

Select a shaded, dry place to mount the box. Insure that there

is enough clearance for the cover to be removed.

3.6 Make Connection to Single Phase (1Ø)

Control Box or Three Phase (3Ø) Starter

DANGER

Do not power the unit or run the pump until all electrical

and plumbing connections are completed. Exception – to

verify 3 phase motor rotation, it is acceptable to power the

motor before it is attached to the water end to verify correct rotation. After checking rotation lock-out disconnect or

circuit breaker in OFF position!

Verify that the disconnect or breaker is OFF before making any connections to the power supply. Always follow the

National Electric Code (N.E.C.) in the U.S., or the Canadian

Electrical Code in Canada, as well as all state, provincial, or

local codes.

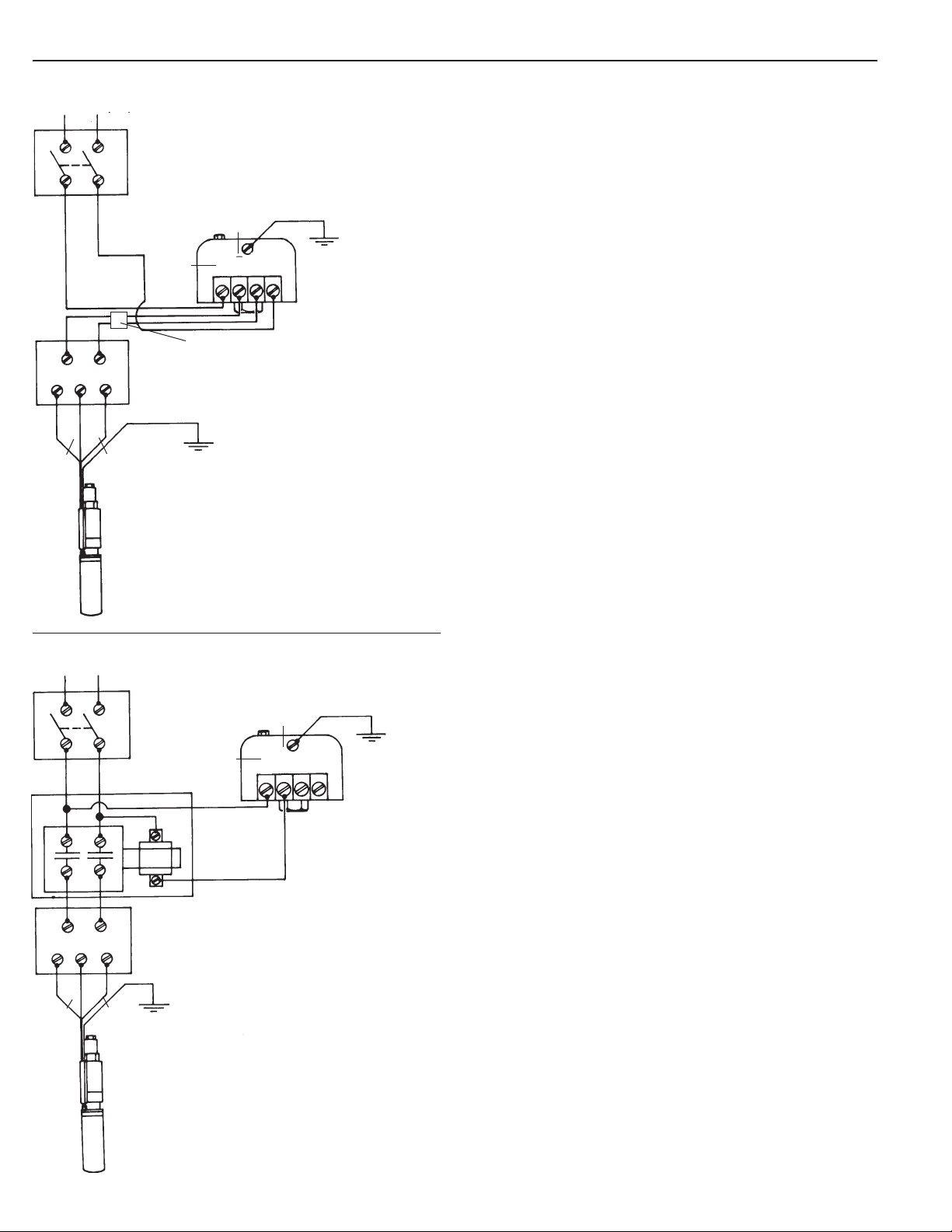

A. Single Phase (1Ø) Three-Wire Control Box Wiring

CAUTION

Connect the color coded motor leads to the motor

control box terminals –

Y (yellow), R (red), and B (black); and the Green or bare

wire to the green ground screw.

Connect wires between the Load terminals on the pressure switch and control box terminals L1 and L2. Run a

ground wire between the switch ground and the control

box ground. See Fig. 7 or 8

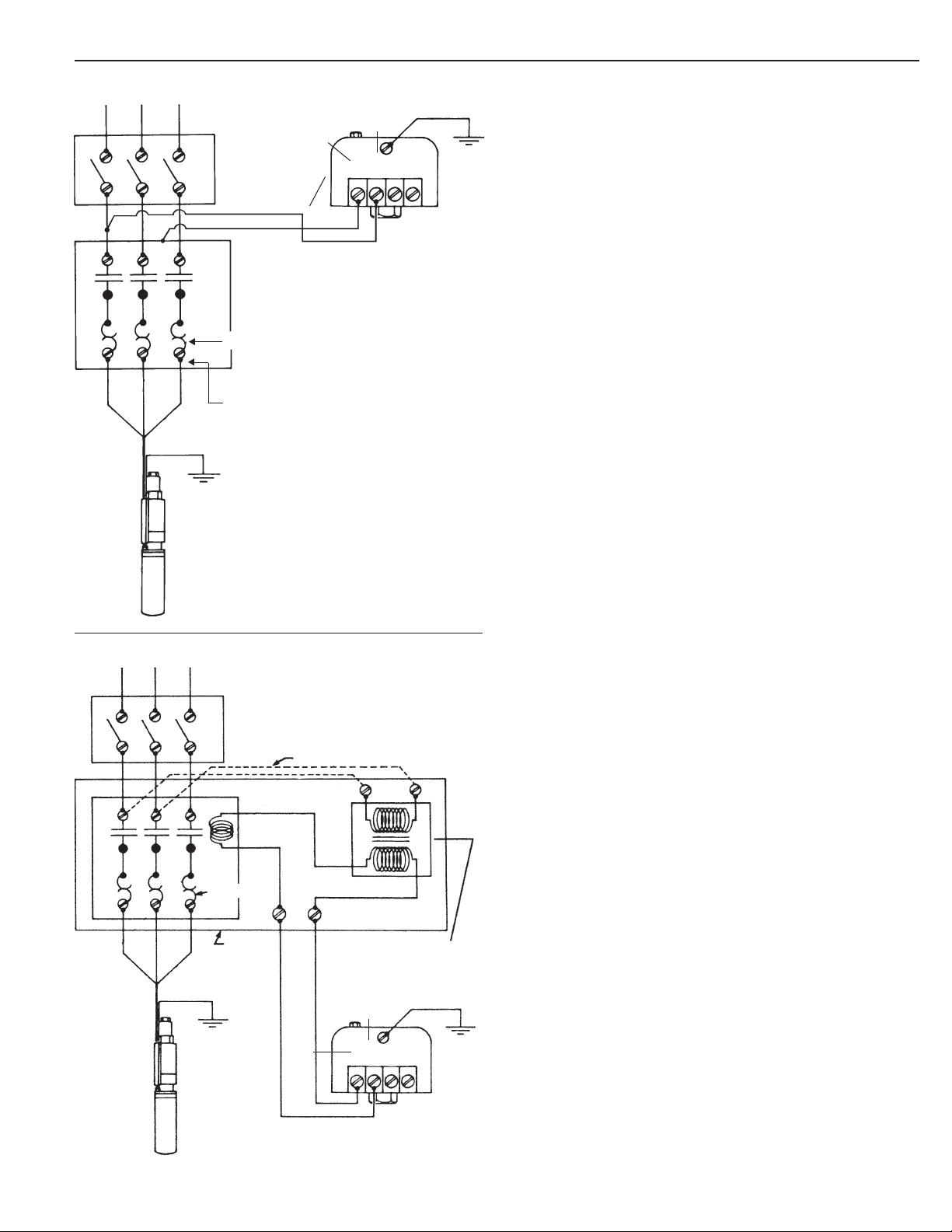

B. Three Phase (3Ø) Starter Wiring

CAUTION

Connect the motor leads to T1, T2, and T3 on the 3

phase starter. Connect the ground wire to the ground

screw in the starter box. Follow starter manufacturers

instructions for connecting pressure switch (where used)

to starter. See Fig. 9 or 10

3.7 Make Power Supply Connection

CAUTION

Provide a separate fused or circuit breaker protected branch

circuit for the pump. Install a main disconnect switch in full

view and easily accessible from the pressure switch and tank

location.

3.4 Verify Voltage

Insure that motor nameplate voltage and power supply

voltage are the same. Three-phase starter coils are very

voltage sensitive, always verify actual supply voltage with

a voltmeter. High or low voltage will damage motors and

controls and is not covered under warranty.

3.5 Turn Supply Power Off

Use a disconnect switch where required by code. Turn the

circuit breaker OFF and lock-out the disconnect switch in

the OFF position to prevent accidentally starting the pump

before you are ready.

6

Single phase:

With pressure switch – make the connection from the pressure switch Line terminals to the disconnect switch (where

used) and then to the circuit breaker panel.

Without pressure switch – make the connection from the

control box L1 and L2 terminals to the disconnect switch

(where used) and then to the circuit breaker panel.

Three phase - make the connections between L1, L2, L3, and

ground on the starter to the disconnect switch and then to

the circuit breaker panel.

Page 7

Three phase submersible motors require Class 10 Quick-Trip

overload protection. Use Furnas Class 14 NEMA starters

with ESP100 adjustable Class 10 overloads. You can also

use Furnas Class 16 starters with ambient compensated “K”

heaters (overloads) which you install in the starter. “K” heaters must be purchased separately. Consult the ITT MAID or

F.E. AIM manual for other acceptable overload protection

devices.

Note: when replacing a line shaft turbine or other above

ground pump with a submersible you must change the Class

20 overloads in the starter to Class 10 quick-trip’s for proper

motor overload protection. Use of Class 20 overloads voids

the submersible motor warranty.

Three phase installations must be checked for motor rotation

and phase unbalance. To reverse motor rotation switch (reverse) any two power leads. See the instructions for checking three phase unbalance in the Technical Section of this

manual. Failure to check and correct three phase unbalance

can cause premature motor failure and nuisance overload

tripping.

4.0 OPERATE PUMP

4.0 OPERATE PUMP

Check amps and insure they are within nameplate amp range

from motor data sheet or motor nameplate. Amps should be

between Rated Input and Service Factor Amps. High amps

may be caused by low or high voltage. Enter the amp readings in this manual along with the pump and motor model

numbers and serial numbers. On all three phase systems a

three phase unbalance test must be performed to insure a

balanced power supply. Leave a copy of the 3Ø unbalance

worksheet with this IOM at the job site for future reference.

On pressure tank/switch systems only – close the valve when

the water clears and allow the pressure to build. If properly

adjusted the switch should turn the pump off at the preset

pressure. Open a few outlets and allow the pump to run

through a few cycles. Check switch operation and verify that

pressure settings are correct. Check all fittings for leaks.

On manual systems, turn the pump off.

5.0 PAPERWORK AND IOM

5.0 PAPERWORK AND IOM

Please give this IOM and your business card to the owner.

A sticker with your name and phone number on the tank or

control box is a great sales tool for future business!

4.1 Throttling Discharge on Start-Up

If the pump will be started or operated with an “open”

discharge you must throttle the discharge before start-up.

Install a ball, globe, or Cla-valve® in the discharge line. Open

the valve to approximately 1⁄3 open on system start-up. This

will prevent upthrust damage to the pump and motor

bearings. You can open the valve when you get a good steady

stream of water. Do not exceed the maximum operating

range in gpm shown on the pump curve. If you do not know

the maximum gpm for the pump, call the distributor who

sold you the pump. Starting or running a pump with little or

no head is a major cause of premature failure.

4.2 Throttling a High Static Level Well to

Prevent Upthrust

A high static water level well may allow a pump to operate

off the right side of the curve or outside the “Recommended

Range” shown on the pump curve. We recommend using a

“Dole®” flow restrictor or throttling the discharge with a ball

valve to prevent upthrust damage to the pump and motor.

The maximum flow must be within the pumps recommended

operating range. If you use a ball valve, set it and remove the

handle, tape the handle to the pipe. Tag the valve with a note

saying, “Do not open this valve or pump may be damaged”.

You can set the valve by installing a pressure gauge between

the well and the valve and throttling the flow/head to a value

within the recommended range. You can also throttle by determining the actual flow rate, see “Determining Flow Rates”

in your catalog Technical Section.

Congratulations on completing a professional installation of

a submersible pump.

6.0 ACCESSORIES

6.0 ACCESSORIES

Pressure Tanks

Tanks should be sized to allow pumps over two (2) hp to run

at least 2 minutes. If the pump averages 80 GPM it requires

tanks to provide a 160 gallon “drawdown”. See your Water

Products catalog for pressure tank data.

Low Water Protection

A low yield well should have low water protection added

to the system. Contact your distributor for information on

SymCom low water protection devices.

Electrical Panels

Customer Service will quote custom pump control panels.

Please send written panel specifications to your authorized

distributor. They will forward it to the Customer Service

Group that supports their product line. Written specifications

should include pump HP, Voltage, Phase, desired NEMA enclosure type, sequence of operation, special options needed,

and a brief statement describing any special logic for alarms,

timers, or duplexing features. The name and number of a

contact person to answer questions is also appreciated and

will speed your quote.

4.3 Start the Pump

Partially open a valve (boiler drain or faucet) in the system

and turn the breaker to the ON position. Allow the pump

to run until the water is clear. On three phase systems verify

rotation, correct rotation will yield the highest flow and

pressure.

7

Page 8

Single Phase Wiring — Cableado monofásico — Montage monophasé

Single Phase Wiring — Cableado monofásico — Montage monophasé

Incoming Supply from Fuse Box or Circuit Breaker (1)

1. Suministro de entrada de la caja de fusibles o del cortacircuitos

L1 L2

R Y Blk

Red

(8)

(9) (10)

L1 L2

Disconnect

Switch (2)

(4)

L1 L2

Black

Yellow

(3)

Three Wire

Control Box

Three Wire – Direct Connected to Pressure Switch

Trifilar – conectado directamente al interruptor

Line

Load

Load

Line

NOTE: SymCom PumpSaver (6)

(7)

por caída de presión

Moteur à trois fils – relié au prossostat

Figure (Figura) 7

Incoming Supply from Fuse Box or Circuit Breaker

Pressure

Switch

(5)

(1)

2. Interruptor de desconexión

3. Línea

4. Carga

5. Interruptor por caída de presión

6. NOTA: PumpSaver

7. Caja de control trifilar

8. Rojo

9. Amarillo

10. Negro

11. Contactador magnético

1. Courant d’entrée provenant de la boîte à fusibles ou du disjoncteur

2. Sectionneur

3. Ligne

4. Charge

5. Pressostat

6. Protection PumpSaver

7. Boîte de commande à trois fils

8. Rouge

9. Jaune

L1 L2

R Y Blk

Red

(8)

(9)

T1 T2

L1 L2

Black

Yellow

(10)

Disconnect

Switch (2)

(3)

Magnetic Contactor (11)

Three Wire

Control Box (7)

Three Wire – Connected through Magnetic Contactor

Trifilar – conectado a través del contactador magnético

Moteur à trois fils – relié par

contacteur magnétique

Line

(4)

Load

Load

Line

Pressure

Switch (5)

10. Noir

11. Contacteur magnétique

Figure (Figura) 8

8

Page 9

Three Phase Wiring — Cableado trifásico — Montage triphasé

Three Phase Wiring — Cableado trifásico — Montage triphasé

Incoming Supply from Fuse Box or Circuit Breaker (1)

1. Suministro de entrada de la caja de fusibles o del cortacircuitos

L1 L2 L3

3

T1 T2 T3

Incoming Supply from Fuse Box or Circuit Breaker (1)

(4)

(3)

Disconnect

Switch (2)

Pressure Switch

Heaters (6)

Ambient Compensated

Magnetic Starter with

Quick-Trip Heaters

Three Phase Starter and Pressure Switch

Tres conexiones de fase

Pressostat et démarreur triphasé

(7)

Line

Load

(5)

Load

Line

Figure (Figura) 9

2. Interruptor de desconexión

3. Línea

4. Carga

5. Interruptor por caída de presión

6. Calentadores

7. Arrancador magnético con compensación ambiental con calentadores de disparo rápido

8. Interruptor por caída de presión u otros interruptores pilotos

9. Tierra

10. Puesta a tierra opcional del motor

11. Conexión de campo

12. Transformador de control (Las derivaciones deben coincidir con la

tensión de suministro)

1. Courant d‘entrée provenant de la boîte à fusibles ou du disjoncteur

2. Sectionneur

3. Ligne

4. Charge

5. Pressostat

6. Dispositifs de protection contre la surcharge (DPS)

L1 L2

T1 T2 T3

Disconnect

Switch (2)

Field Connected (11)

L1 L2

L3

2 3

Ambient

Compensated

Magnetic Starter

with Quick-Trip

Heaters (7)

Optional Motor

Grounding (10)

Three Phase Starter with Control Voltage Transformer

Arrancador trifásico con transformador de tensión de control

Démarreur triphasé avec transformateur de tension de commande

(9) GND

(3)

Control Transformer

(Shunts must be

matched to the Supply Voltage) (12)

(4)

Line

Load

Load

Line

Pressure

Switch

or other

Pilot

Switches (8)

Figure (Figura) 10

7. Démarreur magnétique compensé (température ambiante) avec

DPS à déclenchement rapide

8. Pressostat ou autre contacteur de commande

9. Terre

10. Mise à la terre optionnelle pour le moteur

11. Connexion sur place

12. Transformateur de commande (les circuits dérivés [

convenir à la tension d’alimentation)

shunts

] doivent

9

Page 10

Technical Data

CAUTION

Technical Data

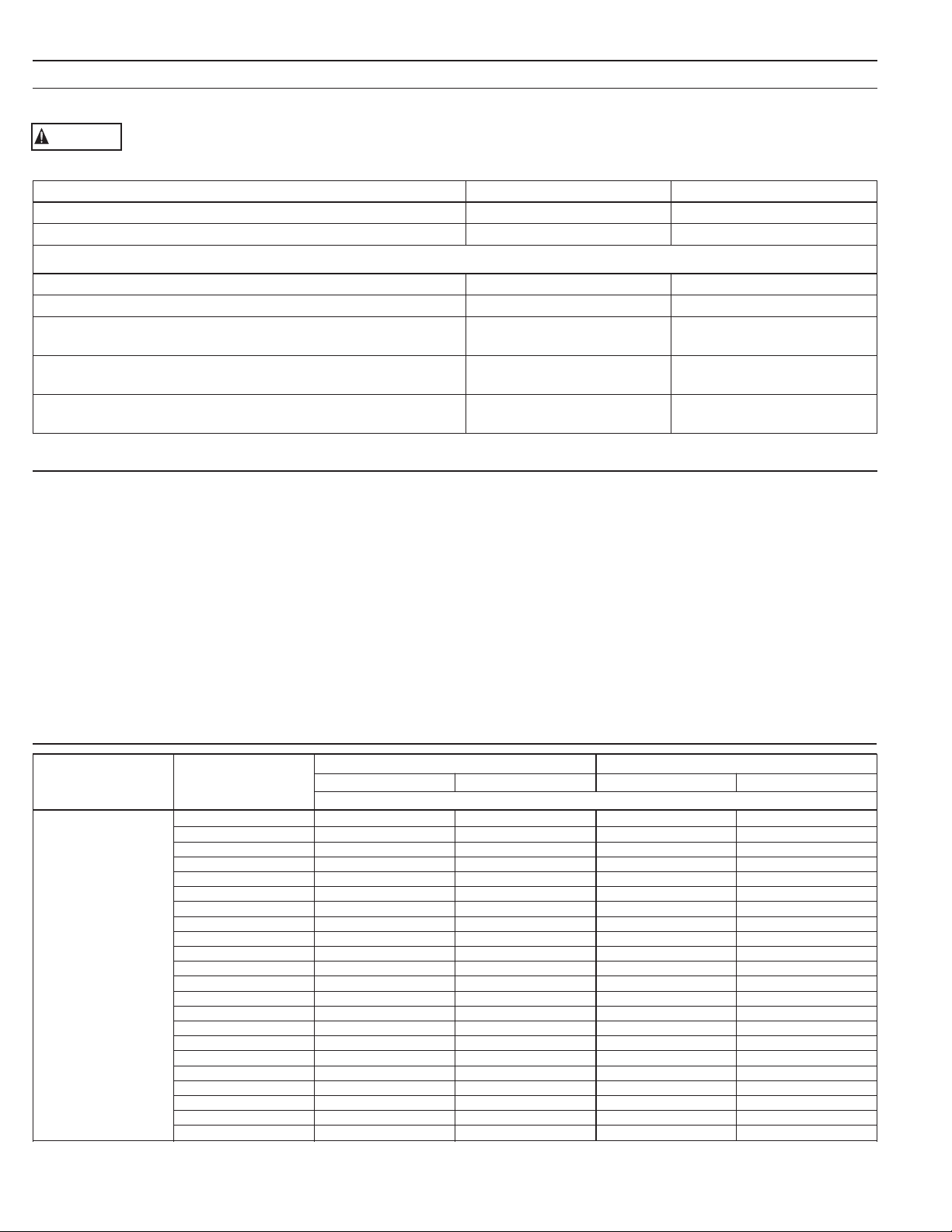

MOTOR INSULATION RESISTANCE READINGS

Normal Ohm/Megohm readings, ALL motors, between all leads and ground

To perform insulation resistance test, open breaker and disconnect all leads from QD control box or

pressure switch. Connect one ohmmeter lead to any motor lead and one to metal drop pipe or

a good ground. R x 100K Scale

Condition of Motor and Leads OHM Value Megohm Value

New motor, without power cable 20,000,000 (or more) 20.0

Used motor, which can be reinstalled in well 10,000,000 (or more) 10.0

Motor in well – Readings are power cable plus motor

New motor 2,000,000 (or more) 2.0

Motor in reasonably good condition 500,000 to 2,000,000 0.5 – 2.0

Motor which may be damaged or have damaged power cable

Do not pull motor for these reasons

Motor definitely damaged or with damaged power cable

Pull motor and repair

Failed motor or power cable

Pull motor and repair

Generator Sizing

Generator Sizing

Note: Always consult the generator

manufacturer when questions arise.

These sizing charts are recommendations based on motor

service factor loading for typical continuous duty generators. If

you need to call the generator manufacturer, be prepared to tell

them the motor KVA code, the service factor amperage, locked

rotor amperage, phase, hertz, motor type, etc.

You must know which type generator you have before using the

charts as the required generator size varies by type. Internally

regulated generators are also called self-excited. Externally

regulated generators are the most common. In addition to the

Kw/KVA rating, the generator frequency (Hertz, typically

Less than 10,000 0 – 0.01

60 HZ in USA) is very important when operating pumping

equipment because frequency variations affect pump output in

direct relation to the pump Affinity Laws. Operating under 60

hertz will reduce flow and head while operating over 60 hertz

will increase flow, head, HP and amp draw and could overload

the motor.

The generator should always be started before the pump/

motor is started and always stop the pump/motor before

shutting down the generator. Operating generators at higher

elevations or using natural gas as fuel can affect performance,

consult the generator manufacturer for their recommendations

in these instances.

20,000 to 500,000 0.02 – 0.5

10,000 to 20,000 0.01 – 0.02

Generator Recommendations

Generator Recommendations

Externally Regulated Internally Regulated

Motor HP KW KVA KW KVA

Minimum Generator Rating

.5 2 2.5 1.5 1.9

.75 3 3.8 2 2.5

1 4 5 2.5 3.2

1.5 5 6.3 3 3.8

2 7.5 9.4 4 5

3 10 12.5 5 6.3

5 15 18.8 7.5 9.4

7.5 20 25 10 12.5

40 100 125 50 62.5

50 150 188 60 75

60 175 220 75 94

75 250 313 100 125

100 300 375 150 188

125 375 469 175 219

150 450 563 200 250

175 525 656 250 313

200 600 750 275 344

10 30 37.5 15 18.8

3-Wire

15 40 50 20 25

1Ø

20 60 75 25 31

and

25 75 94 30 37.5

3Ø

30 100 125 40 50

Motors

10

Page 11

Technical Data (Continued)

Technical Data

Transformer Capacity Required for Submersible

Motors – Single or Three Phase

Distribution transformers must be adequately sized to satisfy

the KVA requirements of the submersible motor. When

transformers are too small to supply the load, there is a

reduction in voltage to the motor.

Table 1 references the motor horsepower rating, single

phase and three phase, total effective KVA required, and the

smallest transformer required for open or closed three phase

systems. Open systems require larger transformers since only

two transformers are used.

Other loads would add directly to the KVA sizing requirements of the transformer bank.

Table 1 – Transformer Capacity

Smallest KVA Rating –

Each Transformers

Motor HP Open WYE Closed

Total Effective or DELTA WYE or DELTA

KVA Required 2 Transformers 3 Transformers

1½ 3 2 1

2 4 2 1.5

3 5 3 2

5 7.5 5 3

7½ 10 7.5 5

10 15 10 5

15 20 15 7.5

20 25 15 10

25 30 20 10

30 40 25 15

40 50 30 20

50 60 35 20

60 75 40 25

75 90 50 30

100 120 65 40

125 150 85 50

150 175 100 60

175 200 115 70

200 230 130 75

NOTE: Transformers shown are standard nominal KVA ratings. If power company experience

and practice allows transformer loading higher than nominal rating under the specific operating conditions and maintains correct voltage and balance, such higher loading values may be

used for transformer(s) to meet total effective KVA required.

Mounting Position

Motors are suitable for operation in mounting positions

from vertical shaft up to horizontal. If 4 inch motors through

2 HP are started more than 10 times per day, it is recommended the shaft be tilted up at 15° from horizontal to

minimize coast-down wear of the upthrust washer.

Frequency of Starts

The average number of starts per day over a period of

months or years influences the life of a submersible pumping

system. Excessive cycling affects the life of control components such as pressure switches, starters, relays and capacitors, plus splines and bearings. Rapid cycling can also cause

motor overheating and winding failures.

The pump size, tank size and other controls should be selected to keep the starts per day as low as practical for longest

life, based upon the maximum number of starts per 24 hour

day, as shown in Table 2.

Motors over 2 HP should be allowed to run a minimum of

2 minutes to dissipate heat build up from starting current.

Table 2 – Number of Starts

Maximum Starts per 24 hour day

Motor Rating

½ HP through 5 HP 100 300

7½ HP through 30 HP 50 100

40 HP and over — 100

Single Phase Three Phase

Motor Cooling, Temperature and Time Ratings

All 4 inch CentriPro motors may be operated continuously

in water up to 86º F. Optimum service life will be attained

by maintaining a minimum flow rate past the motor of .25

feet per second. Use a Flow Sleeve if velocity is below the

.25'/sec, if the well is top feeding or when the pump is used

in a large body of water or large tank.

Six (6) inch canned design motors from 5 – 40 HP will

operate in water up to 95º F (35º C), without any de-rating

of horsepower, with a minimum flow rate of .5 ft./sec. past

the motor. 6" – 50 HP and all 8" – 10" motors can operate in

77º F (25º C) water with .5'/sec velocity past the motor.

Table 3 – Minimum Flow Rates For Proper Motor Cooling

Diameter

4 1.2 – –

5 7 – –

6 13 7 –

7 20 23 –

8 30 41 9

10 50 85 53

12 80 139 107

14 110 198 170

16 150 276 313

Multiply gpm by .2271 for m3/Hr.

Multiply gpm by 3.785 for l/min.

3.75" Diameter CP = 5.5" Dia. CP = 7.52" Dia.

Well or

4" CP or FE Motor 6" CP Motor 8" CP Motor

Sleeve

(inches)

.25'/sec .5'/sec. .5'/sec.

GPM Required

11

Page 12

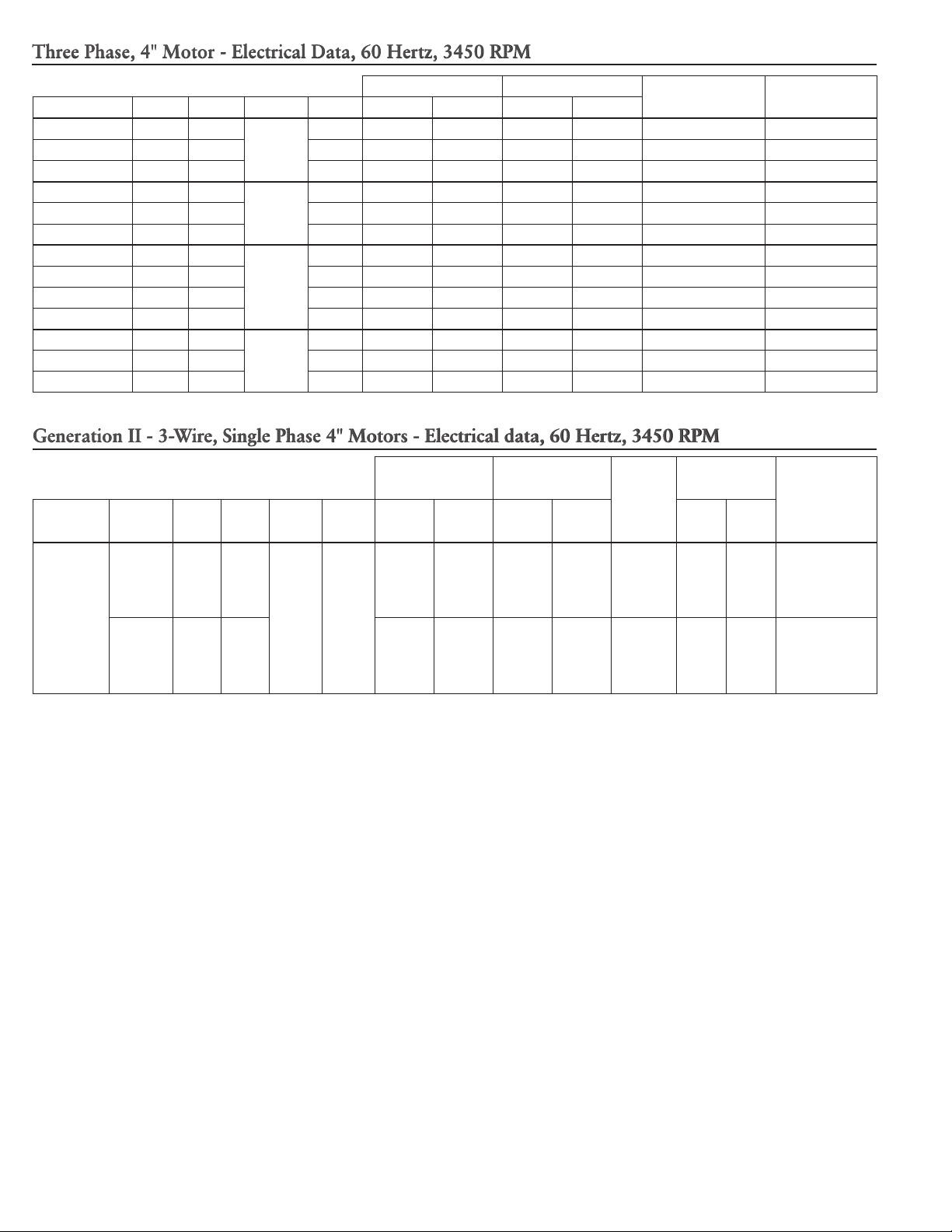

Three Phase, 4" Motor - Electrical Data, 60 Hertz, 3450 RPM

Full Load Service Factor

CentriPro # HP kW Volts SF Amps Watts Amps Watts

M30430 3 2.2

M50430 5 3.7 1.15 18.3 4850 20.2 5515 113 0.4-0.8

200

1.15 10.9 2890 12.0 3290 71 0.9-1.3

Locked Rotor

Amps

Line - Line

Resistance

M75430 7.5 5.5 1.15 27.0 7600 30.0 8800 165 0.5-0.6

M30432 3 2.2

M50432 5 3.7 1.15 15.7 4925 17.5 5650 93 .85-1.25

230

1.15 9.2 2880 10.1 3280 58.9 1.3-1.7

M75432 7.5 5.5 1.15 24 7480 26.4 8570 140 .55-.85

M30434 3 2.2

M50434 5 3.7 1.15 7.6 4810 8.5 5530 48 3.58-4.00

M75434 7.5 5.5 1.15 12.2 7400 13.5 8560 87 1.9-2.3

460

1.15 4.8 2920 5.3 3320 30 5.9-6.5

M100434 10 7.5 1.15 15.6 9600 17.2 11000 110 1.8-2.2

M30437 3 2.2

M50437 5 3.7 1.15 7.0 5080 7.6 5750 55 3.6-4.2

575

1.15 3.7 2850 4.1 3240 21.1 9.4-9.7

M75437 7.5 5.5 1.15 9.1 7260 10.0 8310 55 3.6-4.2

Generation II - 3-Wire, Single Phase 4" Motors - Electrical data, 60 Hertz, 3450 RPM

Full Load Service Factor

Type

3-Wire

with CSCR

(CR) or

Magnetic

Contactor

(MC)

Control

Box

¹ A CSCR control box with a CR suffix can be replaced by a Magnetic Contactor model ending in MC.

Order

No.

M30412 3 2.2

M50412 5 3.7

HP kW Volts SF Amps Watts Amps Watts

230 1.15

Y – 14.3

B – 12.0

R – 5.7

Y – 24.0

B – 19.1

R – 10.2

3170

5300

Y – 16.5

B – 13.9

R – 5.6

Y – 27.0

B – 22.0

R – 10.0

Locked

Rotor

Amps

3620 76

6030 101

Winding

Resistance

Main

(B-Y)

1.1 -

1.4

.62 -

.76

Start

(R-Y)

2.0 -

2.5

1.36 -

1.66

Required

Control Box

CB30412CR or

CB30412MC

CB50412CR or

CB50412MC

1

12

Page 13

6" SINGLE PHASE MOTORS AND REQUIRED CONTROL BOXES

Order No.

6M051 5 3.7 24 4987 27.5 5735 124 CB05MC (3R)

6M071 7.5 5.5

6M101 10 7.5 50 10135 58 11830 202 CB10MC (3R)

6M151 15 11 72 15180 85 18050 275 CB15MC (3R)

➀ NEMA 3R control boxes will be replacing the current models.

Motor

HP kW Volts Phase

230 1 6” x 6” 1.15

Motor Dia.

vs Flange Dia.

Rated Input Service Factor

S.F.

Amps Watts Amps Watts

36 7675 41 8950 167 CB07MC (3R)

L.R. Control Box

Amps Order No.

6-10" THREE PHASE MOTORS

Motor

Order No.

6M058 5 3.7 200 17.5 4910 19.5 5610 124

6M052 5 3.7 230 15.0 4857 17.0 5520 110

6M054 5 3.7 460 7.5 4857 8.5 5520 55

6M078 7.5 5.5 200 25.4 7180 28.5 8230 158

6M072 7.5 5.5 230 22.0 7127 26.0 8140 144

6M074 7.5 5.5 460 11.0 7127 13.0 8140 72

6M108 10 7.5 200 33.3 9360 37.2 10700 236

6M102 10 7.5 230 29.0 9407 33.0 10730 208

6M104 10 7.5 460 14.5 9407 16.5 10730 104

6M158 15 11 200 47.4 13700 53.5 15710 347

6M152 15 11 230 3 6" x 6" 1.15 42.0 13700 46.0 15800 320

6M154 15 11 460 21.0 13700 23.0 15800 160

6M208 20 15 200 61.2 18040 69.5 20820 431

6M202 20 15 230 54.0 17930 60.0 20650 392

6M204 20 15 460 27.0 17930 30.0 20650 196

6M258 25 18.5 200 77.3 22740 87.5 26190 578

6M252 25 18.5 230 68.0 22470 76.0 25800 530

6M254 25 18.5 460 34.0 22470 37.0 25800 265

6M308 30 22 200 91.8 27000 104.0 31120 674

6M302 30 22 230 82.0 27130 94.0 31160 610

6M304 30 22 460 41.0 27130 47.0 31160 305

6M404 40 30 460

66M504 50 37 460 70.0 45210 79.0 52380 465

86M504 50 37 460

86M604 60 45 460 80.0 52850 90.0 60900 510

8M754 75 55 460 3 1.15 96.0 65900 109.0 76100 650

8M1004 100 75 460

8M1254 125 90 460 160.0 110800 180.0 126000 980

8M1504 150 110 460 195.0 130700 220.0 152000 1060

10M2004 200 150 460 10 "x 10" 235.0 171100 270.0 198600 1260

5-30 HP, 3 Phase 230 and 460 Motors have adjustable voltage feature, change voltage plugs to convert from 230V to 460V

operation. Spare Change Plug Order No's are: PLUG-230V or PLUG-460V.

HP kW Volts Phase

Motor Dia.

vs Flange Dia.

6" x 6"

8" x 6"

8" x 8"

Amps Watts Amps Watts

53.0 35530 60.0 41100 340

65.0 44360 73.0 51000 435

127.0 87600 145.0 101300 795

Rated Input Service Factor

S.F.

L.R.

Amps

➀

13

Page 14

6" SINGLE PHASE MOTORS

Motor

Order No.

6M051 5 3.7 74.8 G 2.172 0.512 2.627

6M071 7.5 5.5

6M101 10 7.5 73.6 E 1.052 0.316 1.310

6M151 15 11 73.7 D 0.678 0.230 0.850

HP kW Volts Phase

230 1

Efficiency %

F.L.

72.9 F 1.401 0.400 1.774

Resistance - Ohms

KVA

Code

R - Y B - Y R - B

6-10" THREE PHASE MOTORS

Order No.

6M058 5 3.7 200 75.9 K 0.618 50 25

6M052 5 3.7 230 76.8 K 0.806 45 20

6M054 5 3.7 460 76.8 K 3.050 25 10

6M078 7.5 5.5 200 77.9 J 0.504 80 40

6M072 7.5 5.5 230 78.5 J 0.651 70 30

6M074 7.5 5.5 460 78.5 J 2.430 35 15

6M108 10 7.5 200 79.7 K 0.315 100 50

6M102 10 7.5 230 79.3 K 0.448 90 40

6M104 10 7.5 460 79.3 K 1.619 45 20

6M158 15 11 200 81.7 K 0.213 175 70

6M152 15 11 230 81.7 K 0.312 150 60

6M154 15 11 460 81.7 K 1.074 70 30

6M208 20 15 200 82.7 J 0.189 200 90

6M202 20 15 230 83.2 J 0.258 175 70

6M204 20 15 460

6M258 25 18.5 200 82.0 K 0.146 250 110

6M252 25 18.5 230 83.0 K 0.210 225 90

6M254 25 18.5 460 83.0 K 0.666 110 45

6M308 30 22 200 82.9 J 0.119 300 125

6M302 30 22 230 82.5 K 0.166 250 100

6M304 30 22 460 82.5 K 0.554 125 50

6M404 40 30 460 84.0 H 0.446 175 70

66M504 50 37 460 82.5 J 0.388 225 90

86M504 50 37 460 84.1 H 0.331 200 90

86M604 60 45 460 84.7 H 0.278 250 110

8M754 75 55 460 84.9 H 0.218 300 125

8M1004 100 75 460 85.2 H 0.164 400 175

8M1254 125 90 460 84.2 G 0.132 500 225

8M1504 150 110 460 85.6 G 0.115 600 250

10M2004 200 150 460 87.2 F 0.0929 800 350

Motor

HP kW Volts Phase

F.L. KVA Line - Line

Efficiency % Code Resistance

83.2 J 0.861 90 35

3

Time Delay Fuse

Standard Dual Element

14

Page 15

THREE PHASE POWER UNBALANCE

THREE PHASE POWER UNBALANCE

A full three phase supply consisting of three individual

transformers or one three phase transformer is recommended. “Open” delta or wye connections using only two

transformers can be used, but are more likely to cause poor

performance, overload tripping or early motor failure due to

current unbalance.

Check the current in each of the three motor leads and

calculate the current unbalance as explained below.

If the current unbalance is 2% or less, leave the leads as

connected.

If the current unbalance is more than 2%, current readings

should be checked on each leg using each of the three possible hook-ups. Roll the motor leads across the starter in the

same direction to prevent motor reversal.

Hookup 1 Hookup 2 Hookup 3

Starter Terminals L1 L2 L3 L1 L2 L3 L1 L2 L3

Motor Leads R B Y Y R B B Y R

T3 T1 T2 T2 T3 T1 T1 T2 T3

To calculate percent of current unbalance:

A. Add the three line amp values together.

B. Divide the sum by three, yielding average current.

C. Pick the amp value which is furthest from the average

current (either high or low).

D. Determine the difference between this amp value

(furthest from average) and the average.

E. Divide the difference by the average.

Multiply the result by 100 to determine percent of

unbalance.

Current unbalance should not exceed 5% at service factor

load or 10% at rated input load. If the unbalance cannot be

corrected by rolling leads, the source of the unbalance must

be located and corrected. If, on the three possible hookups,

the leg farthest from the average stays on the same power

lead, most of the unbalance is coming from the power

source.

Contact your local power company to resolve the imbalance.

Example: T3-R = 51 amps T2-Y = 50 amps T1-B = 50 amps

T1-B = 46 amps T3-R = 48 amps T2-Y = 49 amps

T2-Y = 53 amps T1-B = 52 amps T3-R = 51 amps

Total = 150 amps Total = 150 amps Total = 150 amps

÷ 3 = 50 amps ÷ 3 = 50 amps ÷ 3 = 50 amps

— 46 = 4 amps — 48 = 2 amps — 49 = 1 amps

4 ÷ 50 = .08 or 8% 2 ÷ 50 = .04 or 4% 1 ÷ 50 = .02 or 2%

15

Page 16

TROUBLESHOOTING

TROUBLESHOOTING

WARNING

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE ATTEMPTING ANY SERVICE. FAILURE

TO DO SO CAN CAUSE SHOCK, BURNS OR DEATH.

Hazardous voltage

can shock, burn or

cause death.

Symptom Probable Cause Recommended Action

PUMP MOTOR

NOT RUNNING

1. Motor thermal protector tripped

a. Incorrect control box

b. Incorrect or faulty electrical connections

1. Allow motor to cool, thermal protector will

automatically reset

a – e. Have a qualified electrician inspect and

repair, as required

c. Faulty thermal protector

d. Low voltage

e. Ambient temperature of control box/starter

too high

f. Pump bound by foreign matter

g. Inadequate submergence

f. Pull pump, clean, adjust set depth as required

g. Confirm adequate unit submergence in

pumpage

2. Open circuit breaker or blown fuse

2. Have a qualified electrician inspect and repair,

as required

LITTLE OR

NO LIQUID

DELIVERED

BY PUMP

3. Power source inadequate for load

4. Power cable insulation damage

5. Faulty power cable splice

1. Faulty or incorrectly installed check valve

2. Pump air bound

3. Lift too high for pump

4. Pump bound by foreign matter

5. Pump not fully submerged

6. Well contains excessive amounts of air or gases

3. Check supply or generator capacity

4 – 5. Have a qualified electrician inspect and

repair, as required

1. Inspect check valve, repair as required

2. Successively start and stop pump until flow is

delivered

3. Review unit performance, check with dealer

4. Pull pump, clean, adjust set depth as required

5. Check well recovery, lower pump if possible

6. If successive starts and stops does not remedy,

well contains excessive air or gases

7. Excessive pump wear

8. Incorrect motor rotation – three phase only.

7. Pull pump and repair as required

8. Reverse any two motor electrical leads

16

Page 17

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water system products manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in purchases,

consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability company,

association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM103 Revision Number 3 July 2012

17

Page 18

MANUAL DE INSTRUCCIÓN

IM103

Bombas sumergibles de

5 pulgadas y mayores

INSTRUCCIONES DE INSTALACIÓN Y FUNCIONAMIENTO

18

Page 19

ÍNDICE

TEMA PÁGINA

Instrucciones de Seguridad .....................................................................................................................................................20

1.0 Cómo prepararse para la instalación ................................................................................................................................. 21

2.0 Instalación mecánica ......................................................................................................................................................... 21

3.0 Instrucciones eléctricas ....................................................................................................................................................22

4.0 Operación de la bomba ....................................................................................................................................................24

5.0 Literatura y manual de instrucciones ................................................................................................................................24

6.0 Accesorios ........................................................................................................................................................................24

Cableado monofásico ...............................................................................................................................................................8

Cableado trifásico .....................................................................................................................................................................9

Datos técnicos ........................................................................................................................................................................25

Trifásico, 4" motores - datos eléctricos ....................................................................................................................................27

Generación II - 3-Alambre, monofásico, 4" motores - datos eléctricos.....................................................................................27

6" motores la monofásico y rectángulos de control requeridos ................................................................................................ 28

6-10” motores trifásicos .........................................................................................................................................................28

6" motores la monofásico .......................................................................................................................................................29

6-10” motores trifásicos .........................................................................................................................................................29

Desbalance de potencia trifásica .............................................................................................................................................30

Identificación y resolución de problemas ................................................................................................................................31

Garantía limitada ....................................................................................................................................................................32

Información del propietario

Información del propietario

Número de modelo de la bomba:

Número de serie de la bomba:

Número de modelo del motor:

Número de serie del motor:

Agente:

No. telefónico del agente:

Fecha de compra:

Fecha de instalación:

Dole® es una registrada de Eaton Corporation.

Cla-Val™ es una marca comercial de Griswold Ind.

19

Page 20

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES O AÚN FATALES Y SERIOS DAÑOS MATERIALES, LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ESTE MANUAL HA SIDO CREADO COMO UNA GUÍA PARA LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y

SE DEBE CONSERVAR JUNTO A LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE SEGURIDAD. Cuando vea este símbolo en la bomba o en el manual,

busque una de las siguientes palabras de señal y esté alerta a la probabilidad de lesiones personales o daños

materiales.

PELIGRO

AVISO: INDICA INSTRUCCIONES ESPECIALES QUE SON MUY IMPORTANTES Y QUE SE DEBEN SEGUIR DE

RETROCESO DE DRENAJE; ESTOS SISTEMAS DEBEN UTILIZAR OTROS MEDIOS FRANKLIN ELECTRIC

O EN UN MANUAL DEL CÓDIGO N.E.C. (CÓDIGO ELÉCTRICO NACIONAL DE LOS ESTADOS UNIDOS).

EXAMINE BIEN TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN

ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE SEGURIDAD.

Aviso importante: Lea las instrucciones de seguridad antes de proseguir con el cableado.

del código deben ser dirigidas al inspector eléctrico local. Si se hace caso omiso a los códigos eléctricos y normas de seguridad de

OSHA, se pueden producir lesiones personales o daños al equipo. Si se hace caso omiso a las instrucciones de instalación del fabricante, se puede producir electrochoque, peligro de incendio, lesiones personales o aún la muerte, daños al equipo, rendimiento insatisfactorio y podría anularse la garantía del fabricante.

pozo debe contar con ventilación de acuerdo con los códigos locales.

En lugares con líquidos inflamables o donde pudiesen pudiese haber gases inflamables sólo deben usarse bombas específicamente

clasificadas para áreas de Clase 1, División 1. Consulte los boletines de catálogos de bombas específicas o la placa de identificación de

la bomba con respecto a las listas de agencias.

bomba demasiado caliente rearranque inesperadamente.

carse con colores para facilitar el mantenimiento y la identificación y resolución de problemas.

PELIGRO

Advierte los peligros que CAUSARÁN graves lesiones personales, la muerte o daños materiales mayores.

Advierte los peligros que PUEDEN causar graves lesiones personales, la muerte o daños materiales mayores.

Advierte los peligros que PUEDEN causar lesiones personales o daños materiales.

Todo el trabajo eléctrico debe ser realizado por un técnico calificado. Siempre siga el Código Eléctrico Nacional (NEC)

o el Código Eléctrico Canadiense, además de todos los códigos locales, estatales y provinciales. Las preguntas acerca

Las unidades estándar fueron diseñadas para bombear agua potable de pozos y tanques de almacenaje. No fueron

di-señadas para su uso en piscinas, cuerpos abiertos de agua, líquidos peligrosos o donde existan gases inflamables. El

Desconecte y bloquee la corriente eléctrica antes de instalar o dar servicio a cualquier equipo eléctrico. Muchas

bombas están equi-padas con protección automática contra la sobrecarga térmica, la cual podría permitir que una

No levante ni transporte ni cuelgue la bomba de los cables eléctricos. El daño a los cables eléctricos puede producir

electrochoque, quemaduras o aún la muerte.

Use únicamente alambre trenzado de cobre para la bomba/motor y la conexión a tierra. El alambre de conexión a

tierra debe ser al menos del mismo tamaño que los alambres de la fuente de alimentación. Los alambres deben codifi-

Instale los cables y la conexión a tierra de acuerdo con el Código Eléctrico Nacional de EE.UU. (NEC) o el Código

Eléctrico Canadiense, además de los códigos locales, estatales y provinciales.

Instale un desconectador de todos los circuitos donde el código lo requiera.

PELIGRO

20

La tensión y fase de la fuente de alimentación deben corresponder con todos los requerimientos del equipo. La tensión

o fase incorrecta puede producir incendio, daño al motor o a los controles y anula la garantía.

Todos los controles trifásicos (3Ø) para bombas sumergibles deben incluir protección contra sobrecarga de Clase 10,

de disparo rápido.

Todos los empalmes deben ser impermeables. Si utiliza juegos de empalme, siga las instrucciones del fabricante.

Seleccione una caja de conexiones NEMA del tipo correcto para la aplicación y ubicación. La caja de conexiones debe

garantizar conexiones de cableado seguras y secas.

La falla de conectar a tierra permanentemente la bomba, el motor y los controles, antes de conectar la corriente

eléctrica, puede causar electrochoque, quemaduras o la muerte.

Asegure un enfriamiento adecuado del motor, ver Tabla 3, cuadro de Velocidades Mínimas de Flujo en la Sección

Técnica.

Esta bomba se evaluó para uso con Agua Únicamente.

Nunca sobrepresurice un tanque de almacenaje a una presión superior a la presión máxima permitida para el

tanque. El hacerlo dañará el tanque, anula la garantía y puede crear un peligro grave.

Page 21

1.0 CÓMO PREPARARSE PARA LA INSTALACIÓN

1.0 CÓMO PREPARARSE PARA LA INSTALACIÓN

El pozo debe estar desarrollado (limpio) y desinfectado antes

de instalar la bomba.

Escriba el número de modelo y el número de serie de la

bomba y el número de serie del motor en los espacios proporcionados en este Manual de Instrucciones (IOM). Deje el

Manual de Instrucciones completado adjunto al tanque o a

la caja de control en un área seca o entréguelo al propietario.

Adjunte su tarjeta.

Verifique que la tensión del motor, la tensión de control, la

tensión de la bobina (arrancadores trifásicos) y la tensión

de la fuente de alimentación correspondan. La instalación

eléctrica debe ser realizada por personal calificado.

Inspeccione todos los componentes para verificar que no

hayan sido dañados durante el envío y para asegurar que

tenga todos los componentes requeridos: extremo de agua

de la bomba, motor, caja de control del motor monofásico

o arrancador trifásico con sobrecargas, tanque de presión,

interruptor por caída de presión, alambre de cobre, válvula

de alivio de presión (si se requiere), mecanismo antitorsión

(si se requiere), tubería y accesorios.

2.0 CONJUNTO MECÁNICO – bomba y tuberías

2.0 CONJUNTO MECÁNICO – bomba y tuberías

2.1 Sistemas típicos

Bomba en “lata”

Figura 3

Bomba con camisa de flujo en el tanque

Figura 4

Figura 1

Figura 2

Bomba con camisa de flujo en un pozo de diámetro grande

Figura 5

Bomba horizontal en “lata”

Figura 6

21

Page 22

2.2 Conexión del extremo de la bomba al motor

Quite el protector de cable de la bomba (extremo del agua).

Instale el deflector de arena del eje del motor si se incluye con

el extremo del agua en el paquete de accesorios de montaje

del motor. Conecte el extremo del agua al motor. Alinee los

alambres en el protector de cable y reinstálelo en el extremo

del agua.

La bomba no debe hacerse funcionar seca bajo ninguna

circunstancia. Under no circumstances should the pump be

run dry, doing so may damage internal parts. Sugerimos que

verifique la rotación en un motor trifásico antes de conectarlo

al extremo del agua (bomba). Todos los motores monofásicos

de 4 pulgadas y 6 pulgadas deben rotar en sentido contrahorario cuando se observan desde el extremo del eje. La rotación

en los motores trifásicos debe corresponder con las especificaciones de la bomba. Debido a la alta torsión de arranque, el

motor debe sujetarse de manera que no gire, pero sin dañarse.

2.3 Instalación de la(s) válvula(s) de retención

Las cabezas de descarga están roscadas con roscas de tubo

NPT. Todos los modelos necesitan una válvula de retención a

resorte a menos de 25 pies (7.5 m) de la descarga de la bomba

y debajo del nivel de descenso del suministro de agua. Los

fabricantes de motores recomiendan válvulas de retención adicionales cada 200 a 250 pies (70 m) en la tubería de descarga

vertical. Las válvulas de retención se utilizan para retener la

presión en el sistema e impedir el contragiro, el ariete hidráulico y el empuje hacia arriba.

Contragiro es permitir que el flujo se devuelva por la bomba

para drenar el sistema. Hace que los impulsores y el rotor del

motor giren en dirección inversa. Esto puede producir un desgaste prematuro del cojinete de empuje y si el motor arranca

durante el contragiro, el eje puede torcerse o romperse.

Se produce ariete hidráulico cuando la válvula de retención

más baja está más de 30 pies por encima del nivel del agua

en reposo o si la válvula de retención inferior tiene una fuga

y la válvula de retención de arriba la aguanta. Esto crea un

vacío parcial (espacio) en la tubería de descarga. Durante el

arranque siguiente, el agua moviéndose a una velocidad muy

alta llena el espacio y golpea la válvula de retención cerrada y

el agua estacionaria en el tubo sobre la misma, produciendo

un choque hidráulico. Este choque (ariete hidráulico) puede

partir los tubos, romper las juntas y dañar la bomba y el motor. El ariete hidráulico es un ruido que se detecta fácilmente.

Cuando se descubra, la bomba debe apagarse de inmediato y

debe contactarse al instalador para que solucione el problema.

Empuje hacia arriba es un movimiento ascendente de los

impulsores y eje del motor. Se produce al arrancar la bomba

con cero carga debido a que no hay válvula de retención o a

una fuga en dicha válvula; o a una carga muy baja del sistema

debido a un alto nivel de agua estática. El empuje hacia arriba

recurrente puede producir una falla prematura de la bomba o

el motor o ambos. Consulte 4.2

2.4 Instalación de la bomba en el pozo

Si está utilizando un mecanismo antitorsión, instálelo de acuerdo con las instrucciones de instalación del fabricante. En los

pozos de alimentación superior o pozos de diámetro grande

donde la velocidad del agua no enfría correctamente el motor,

instale una camisa de flujo sobre la bomba. Consulte la Tabla 3

– flujo de enfriamiento requerido.

Conecte la tubería de descarga a la cabeza de descarga de

la bomba. Las bombas sumergibles son capaces de producir

presiones de descarga muy altas, consulte con su proveedor de

tuberías para determinar cuál es el mejor material y especificación para cada instalación.

22

Baje la bomba al interior del pozo. Coloque la bomba al

menos a 10 pies del fondo, pero sobre las rejillas. Proteja los

alambres para que no rocen contra el revestimiento del pozo.

Instale un adaptador sin depresión o un dispositivo similar en

el cabezal del pozo. Consulte con el fabricante del accesorio o

con el proveedor del adaptador con respecto a instrucciones

específicas de instalación.

Utilice cinta aislante impermeable o amarras para alambres

para sujetar los alambres al tubo de bajada a intervalos de 10

pies. Asegúrese de que la cinta no se suelte ya que bloqueará la

succión de la bomba si cae dentro del pozo.

2.5 Válvula de alivio de presión

Se requieren válvulas de alivio de presión en cualquier sistema

que sea capaz de producir más de 100 lbs./pulg. cuadrada

o 230 pies de carga dinámica total. En un área donde una

purga o fuga de agua podría dañar la propiedad, conecte una

línea de drenaje a la válvula de alivio de presión. Tiéndala a

un drenaje adecuado o a un área donde el agua no dañará la

propiedad.

2.6 Tanque de presión e interruptor por caída de

presión (si se usa)

El interruptor por caída de presión debe situarse en la doble

T del tanque en instalaciones de un solo tanque y lo más cerca

posible del centro en instalaciones de varios tanques. Las instalaciones de varios tanques deben tener un tubo de distribución

cuyo tamaño sea 1½ a 2 veces el tamaño del tubo de suministro de la bomba. Esto es para reducir la pérdida de carga por

fricción o el diferencial de presión en el múltiple. Las pérdidas

excesivas pueden producir chasquido del interruptor. No debe

haber filtros o accesorios de pérdida alta entre el interruptor

y el (los) tanque(s). Se permite instalar válvulas de compuerta

completamente abiertas entre el tanque y el interruptor.

2.7 Cómo ajustar la precarga del tanque (si se usa)

Asegure que no haya nada de agua en el tanque. Utilice un

indicador de presión de alta calidad para medir la presión de

precarga del tanque. La presión debe ser 2 lbs./pulg. cuadrada

menos que la presión de conexión (activación) de la bomba.

Como ejemplo, un sistema de 30-50 lbs./pulg. cuadrada utilizaría una precarga del tanque de 28 lbs./pulg. cuadrada.

Seleccione un área que siempre esté a más de 34ºF en la cual

instalar el tanque, el interruptor por caída de presión y la válvula de alivio de presión. El tanque debe estar situado en un

área donde una fuga no produzca daños materiales.

3.0 INSTRUCCIONES ELÉCTRICAS

3.0 INSTRUCCIONES ELÉCTRICAS

3.1 Generalidades

Nota: No energice la unidad ni haga funcionar la bomba hasta

que se hayan completado todas las conexiones eléctricas y de

plomería y la bomba esté llena con agua.

Siempre siga las instrucciones del Código Eléctrico (N.E.C.) de

los Estados Unidos o del Código Eléctrico Canadiense, además

de todos los códigos estatales, provinciales o locales.

Todo el trabajo eléctrico debe ser realizado por personal calificado. Algunas leyes locales requieren que la instalación sea

realizada por “instaladores licenciados” únicamente.

Sugerimos usar únicamente cable de cobre. Utilice el tamaño

de cable que figura en nuestro Manual de Aplicación e Instalación de ITT MAID, o en un manual de Código Eléctrico

Nacional (N.E.C. – National Electric Code). En caso de

discrepancias, prevalecen el N.E.C. en EE.UU., y en Canadá,

el Código Eléctrico Canadiense (Canadian Electrical Code).

Page 23

3.2 Empalme del cable de bajada a los conductores

del motor

Cuando deba empalmarse o conectarse el cable de bajada

a los conductores del motor, es necesario que el empalme

sea imper-meable. El empalme puede realizarse con juegos

de contracción por calor, accesorios de compresión o cinta

impermeable. Haga corresponder los conductores del motor

con el cable de bajada de acuerdo con los códigos de colores

o identifique los alambres del cable de bajada para asegurar la

conexión apropiada en la caja de control.

A. Instrucciones de empalme con un juego de contracción

por calor

Para utilizar un juego típico de contracción por calor: pele

½ pulgada de los alambres del motor y de los alambres del

cable de bajada; es mejor escalonar los empalmes. Coloque los tubos de contracción por calor sobre los alambres.

Coloque los plegadores sobre los alambres y pliegue los

extremos. Deslice los tubos de contracción por calor sobre

los plegadores y caliéntelos desde el centro hacia afuera.

El sellador y el adhesivo saldrán por los extremos cuando

el tubo se contrae. El tubo, los plegadores, el sellador y el

adhesivo crearán un sello impermeable muy resistente. El

calentamiento excesivo puede quemar los tubos de

contracción por calor.

B. Instrucciones de empalme con cinta

1) Pele el aislamiento del conductor individual sólo lo

necesario para dejar espacio para un conector tipo estaca.

Se prefieren los conectores tubulares tipo estaca. Si el D.E.

del conector no es tan grande como el aislamiento del

cable, auméntelo con cinta aislante de caucho.

2) Encinte las juntas individuales con cinta aislante de

caucho, empleando dos capas; la primera extendiéndose

dos pulgadas más allá de cada extremo de aislamiento del

conductor, la segunda capa extendiéndose dos pulgadas

más allá de la primera capa. Envuelva en forma apretada,

eliminando los espacios de aire lo más posible.

3) Aplique cinta aislante Scotch #33 o equivalente sobre

la cinta aislante de caucho, empleando dos capas como en

el paso “B” y haciendo que cada capa se superponga al

menos dos pulgadas al extremo de la capa anterior.

C. Juegos de empalme por compresión

Consulte las instrucciones suministradas con los juegos de

empalme por compresión o consulte con su proveedor

local.

3.3 Cómo montar la caja de control del motor

Las cajas de control monofásicas trifilares cumplen con los

requerimientos de U.L. para las cubiertas tipo 3R. Son

adecuadas para montaje vertical en lugares interiores o exteriores. Funcionarán a temperaturas entre 14°F (-10°C) y 122°

(50°C). Seleccione un lugar sombreado y seco para montar la

caja. Asegure que haya suficiente espacio para quitar la tapa.

3.4 Verificación de la tensión

Asegure que la tensión del motor y la tensión de la fuente

de alimentación sean iguales. Las bobinas de arrancadores

trifásicos son muy sensibles a la tensión; sugerimos que

siempre verifique la tensión de suministro actual con un

voltímetro. La alta o baja tensión dañará los motores y

controles y eso no está cubierto por la garantía.

3.5 Apague la fuente de alimentación

Utilice un interruptor de desconexión cuando el código así

lo requiera. Apague el cortacircuitos y trabe el interruptor de

desconexión en la posición apagada para impedir el arranque

accidental de la bomba antes que usted esté listo.

3.6 Conexión a una caja de control monofásica

(1ø) o a un arrancador trifásico (3ø)

PELIGRO

No energice la unidad ni haga funcionar la bomba hasta que

haya completado todas las conexiones eléctricas y de tuberías.

Excepción – para verificar la rotación del motor trifásico, es

aceptable energizar el motor antes de conectarlo al extremo del

agua para comprobar la rotación correcta. ¡Después de verificar la rotación, trabe el desconector o el cortacircuitos en la

posición APAGADA!

Verifique que el desconector o cortacircuitos esté APAGADO

antes de hacer cualquier conexión a la fuente de alimentación.

Siempre siga las instrucciones del Código Eléctrico (N.E.C.) de

los Estados Unidos o del Código Eléctrico Canadiense, además

de todos los códigos estatales, provinciales o locales.

A. Cableado de la caja de control trifilar monofásica (1ø)

PRECAUCIÓN

Conecte los conductores del motor codificados con colores a

los terminales de la caja de control del motor - Y (amarillo),

R (rojo) y B (negro) y el alambre verde o desnudo al tornillo

verde de puesta a tierra.

Conecte los alambres entre los terminales de carga en el interruptor por caída de presión y los terminales L1 y L2 de la

caja de control. Conecte un alambre de puesta a tierra entre

la tierra del interruptor y la tierra de la caja de control.

Consulte la Figura 7 u 8

B. Cableado del arrancador trifásico (3ø)

PRECAUCIÓN

Conecte los conductores del motor a T1, T2 y T3 en el

arrancador trifásico. Conecte el alambre de puesta a tierra al

tornillo de puesta a tierra en la caja del arrancador. Siga las

instrucciones del fabricante del arrancador para conectar el

interruptor por caída de presión (cuando se use) al arrancador. Consulte la Figura 9 ó 10

3.7 Conexión de la fuente de alimentación

PRECAUCIÓN

Suministre un circuito derivado separado con fusible o protegido con un cortacircuitos para la bomba. Instale un interruptor

de desconexión principal a plena vista y fácilmente accesible

desde la ubicación del tanque e interruptor de presión.

Monofásica:

Con interruptor por caída de presión – haga la conexión desde

los terminales de línea de dicho interruptor al interruptor de

desconexión (cuando se use) y luego al panel de cortacircuitos.

Sin interruptor por caída de presión – haga la conexión desde

los terminales L1 y L2 de la caja de control al interruptor de

desconexión (cuando se use) y luego al panel de cortacircuitos.

Instalaciones trifásicas – haga las conexiones entre L1, L2, L3 y

tierra en el arrancador al interruptor de desconexión y luego al

panel de cortacircuitos.

23

Page 24

Los motores sumergibles trifásicos requieren protección de

sobrecarga Quick-Trip de la Clase 10. Use arrancadores NEMA

Clase 14 de Furnas con sobrecargas de la Clase 10 ajustables

ESP100. También se puede utilizar arrancadores de la Clase 16

de Furnas con calentadores “K” (sobrecargas) que se instalan

en el arrancador. Los calentadores “K” deben comprarse por

separado. Consulte el manual ITT MAID o F.E. AIM para otros

dispositivos de protección de carga aceptables.

Nota: Cuando reemplace una turbina de eje de línea u otro tipo

de bomba sobre el suelo con un tipo sumergible, debe cambiar

las sobrecargas Clase 20 en el arrancador a Clase 10 de disparo rápido para obtener una protección adecuada contra las

sobrecargas del motor. El uso de sobrecargas Clase 20 anula la

garantía de la bomba sumergible.

Deben verificarse las instalaciones trifásicas con respecto a la

rotación del motor y al desbalance de fase. Para invertir la rotación del motor, cambie (invierta) dos conductores de alimentación cualquiera. Consulte las instrucciones para identificar el

desbalance trifásico en la Sección Técnica de este manual. Si no

se revisa y corrige el desbalance trifásico, se puede producir una

falla prematura del motor o un disparo falso por sobrecarga.

4.0 FUNCIONAMIENTO DE LA BOMBA

4.0 FUNCIONAMIENTO DE LA BOMBA

4.1 Estrangulación de la descarga durante la