Whirlpool WDT750SAHZ Installation Manual

INSTALLATION INSTRUCTIONS UNDERCOUNTER DISHWASHER STAINLESS STEEL TUB

LAVAVAJILLAS EMPOTRADA CON TINA

DE ACERO INOXIDABLE

INSTRUCTIONS D’INSTALLATION LAVE-VAISSELLE ENCASTRÉ AVEC CUVE EN ACIER INOXYDABLE

Table of Contents........................................................ |

2 |

Indice......................................................................... |

27 |

Table des matières.................................................... |

52 |

W10806906D

TABLE OF CONTENTS |

|

DISHWASHER SAFETY.................................................... |

3 |

INSTALLATION REQUIREMENTS................................... |

4 |

Tools and Parts.......................................................................... |

4 |

Location Requirements............................................................. |

6 |

Product and Cabinet Opening Dimensions............................... |

7 |

Drain Requirements................................................................... |

8 |

Water Supply Requirements...................................................... |

8 |

Electrical Requirements............................................................. |

8 |

INSTALLATION INSTRUCTIONS..................................... |

9 |

Prepare Cabinet Opening – New Utilities.................................. |

9 |

Install Optional Moisture Barrier................................................ |

9 |

Electrical Connection.............................................................. |

10 |

Prepare Dishwasher................................................................ |

11 |

Remove Access Panel............................................................. |

11 |

Connect Water Line to Fill Valve.............................................. |

12 |

Connect Fill Hose to Fill Valve................................................. |

13 |

Drain Hose Connection .......................................................... |

13 |

Power Cord Connection.......................................................... |

14 |

Install Door Handle.................................................................. |

16 |

Place Diswasher in Cabinet..................................................... |

16 |

Custom Panel Installation........................................................ |

17 |

Choose Anchor Attachment Method....................................... |

17 |

Final Installation Check........................................................... |

18 |

Secure Dishwasher in Cabinet Opening.................................. |

19 |

Direct Wire Connection........................................................... |

20 |

Connect Water Line to House Shutoff Valve........................... |

22 |

Connect Drain Hose ............................................................... |

22 |

Complete Installation............................................................... |

24 |

Install Access Panel................................................................ |

25 |

Check Operation..................................................................... |

26 |

If Dishwasher Does Not Operate............................................. |

26 |

Additional Tips......................................................................... |

26 |

2

DISHWASHER SAFETY

Your safety and the safety of others are very important.

many important safety messages in this manual and on your appliance. Always read and obey all safety

safety alert symbol.

alerts you to potential hazards that can kill or hurt you and others.

messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

mean:

DANGER

DANGER  WARNING

WARNING

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

WARNING

WARNING

Tip Over Hazard

Do not use dishwasher until completely installed. Do not push down on open door.

Doing so can result in serious injury or cuts.

You Need to:

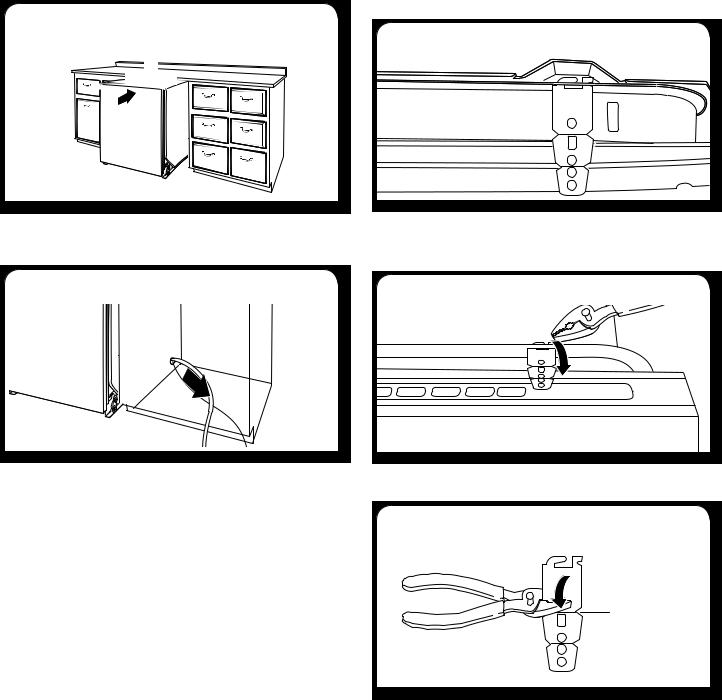

■■ Slowly open dishwasher door while someone grasps the rear of the dishwasher. Remove shipping materials and drain hose. Close dishwasher door until latched.

NOTE: Each dishwasher is tested at the factory and may contain some residual water in the tub as a result of the test.

■■ Observe all governing codes and ordinances.

■■ Install this dishwasher as specified in these instructions.

■■ Installation should be performed by a qualified service technician.

■■ The dishwasher must be installed to meet all electrical and plumbing national and local codes and ordinances.

Care shall be exercised when the appliance is installed or removed, to reduce the likelihood of damage to the power cord.

WARNING: To reduce the risk of electric shock, fire, or injury to persons, the installer must ensure that the dishwasher is completely enclosed at the time of installation.

3

INSTALLATION REQUIREMENTS

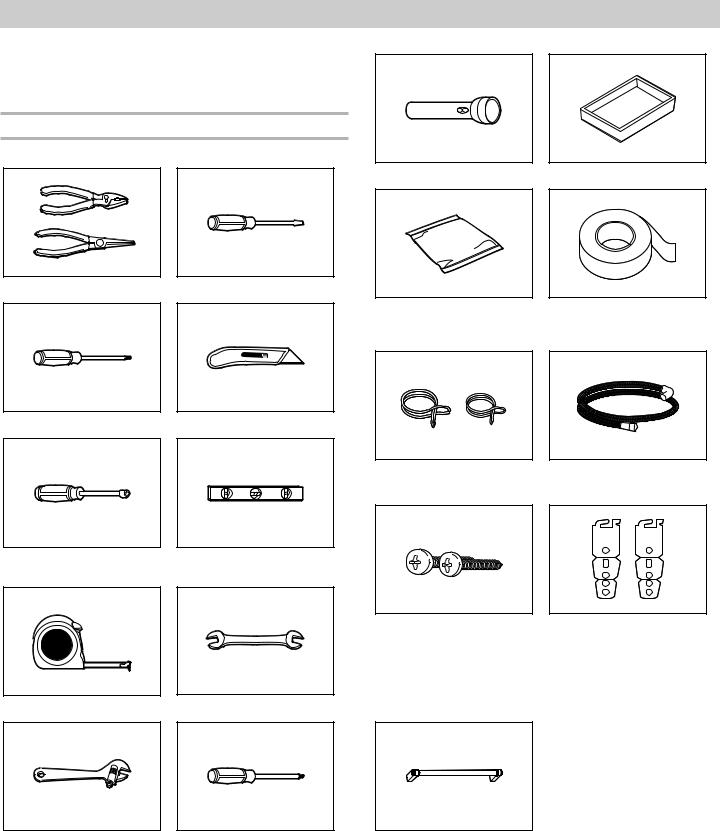

TOOLS AND PARTS

Other Useful Items You May Need:

Gather the recommended tools and parts before starting installation. Read and follow the instructions provided with any tools listed here.

All Installations

Tools Needed:

Flashlight

Shallow pan

Pliers |

Flat-blade screwdriver |

Bath towel |

Masking or duct tape |

Parts Supplied:

Phillips screwdriver |

Utility knife |

Drain hose clamps (2) |

Drain hose |

(1 large/red and 1 small/green) |

|

5/16" and 1/4" nut drivers or hex sockets

Measuring tape or ruler

10" adjustable wrench that opens to 11/8" (29 mm)

Small level

5/8" open-end wrench

Torx®† T20® and, if installing custom front panels, Torx® T15® screwdrivers

#10 x 1/2" Phillips-head |

Undercounter mounting |

screws (2) |

brackets (2) |

Make sure all these parts are included in the literature package. If parts are not included, call us at our toll-free number or visit our website listed in the User Guide.

Door handle (on some models)

†®TORX, T15, and T20 are registred trademarks of Acument Intellectual Properties, LLC.

4

Other Parts Needed (not provided):

3/8" Compression x 3/4" Hose Fitting with rubber seal and 90° elbow (required to properly connect household water line to the dishwasher) (Whirlpool Part Number W10685193)

Household Wiring (Metallic) Strain Relief to fit 7/8" (22 mm)

hole (required to properly

secure household wiring to

the dishwasher terminal box)

(Whirlpool Part

Number 4396672)

NOTE: Use only UL Listed/ CSA Approved part.

Twist-On Wire Connectors

NOTES:

■■ Confirm proper size for connecting your gauge of household wiring to the 16-gauge wiring in the dishwasher.

■■ Use only UL Listed/CSA Approved parts.

Call us at our toll-free number, visit our website listed in the User Guide for part numbers above, or see local electrical/plumbing supply retailer for equivalent.

Optional Accessory Parts Available:

Moisture Barrier Tape

NOTE: Moisture barrier tape is an optional, added level of protection if installing a dishwasher under a wooden countertop. (Whirlpool Part Number 4396277)

Side Panel Kit

For enclosing the side of the dishwasher when installing it at the end of your cabinetry (Whirlpool Part Number varies with color.)

Call us at our toll-free number or visit our website listed in the User Guide for part numbers above.

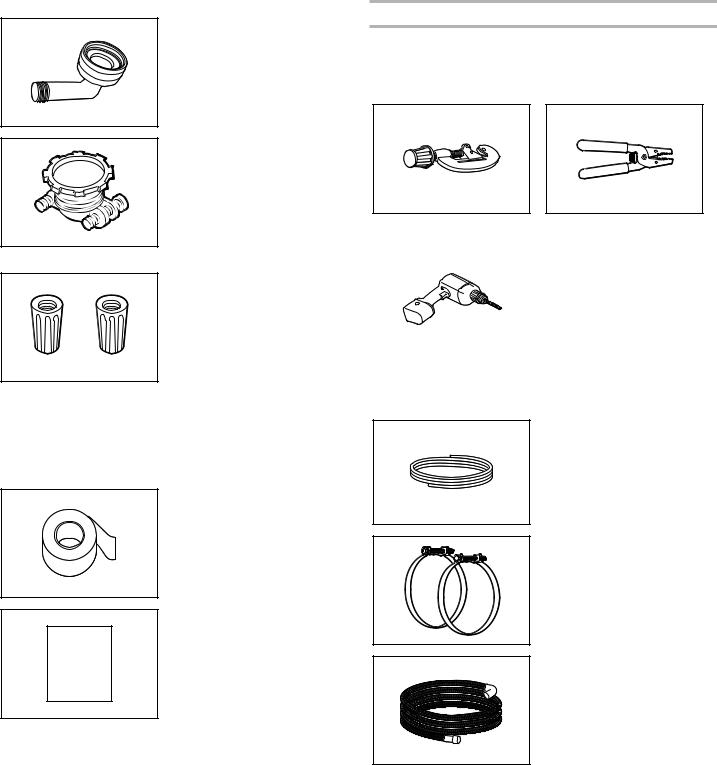

First-Time Installations

Check local codes. Check existing electrical supply. See the “Electrical Requirements” section. It is recommended that electrical connections be made by a licensed electrical installer.

Additional Tools Needed:

Small tubing cutter |

Wire stripper |

|

|

|

|

Cordless drill with 1/2", 3/4", and 11/2" hole saw bits

Additional Parts Needed (not provided):

Copper Tubing (3/8" O.D. suggested) or Flexible Braided Water Supply Line Kit (Whirlpool Part Number W10278635RP). Kit includes braided hose and 3/8"

compression x 3/4" hose fitting.

Screw-Type Clamps 11/2"-2" (38-50 mm) (3 maximum)

Optional-Longer Drain Hose

Maximum length 12 ft (3.7 m) (Whirlpool Part Number 3385556)

NOTE: Must meet AHAM/IAPMO test standards, fit 1" (25 mm) drain connection, and be resistant to heat and detergent

Call us at our toll-free number, visit our website listed in the User Guide for part numbers above, or see local plumbing supply retailer for equivalent.

NOTE: If using a flexible braided hose, replace inlet hose after 5 years to reduce the risk of hose failure. Record hose installation or replacement dates on the hose for future reference.

5

For Direct Wire |

|

|

For Power Cord |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cabinet Grommet |

Power Cord Kit |

|

For 11/2" (38 mm) hole in |

Kit typically includes |

|

cabinet. (Whirlpool |

power cord, metallic strain |

|

Part Number 302797) |

relief, grommet, and twist-on |

|

NOTE: Required for metal |

wire connectors. (Whirlpool |

|

Part Number 4317824) |

||

cabinets |

||

|

Call us at our toll-free number, visit our website listed in the User Guide for part numbers above, or see local electrical supply retailer for equivalent.

LOCATION REQUIREMENTS

Dishwasher must be fully enclosed (top, sides, back, and floor) upon installation. A side panel kit is available from your dealer for installing your dishwasher at the end of your cabinetry.

An optional moisture barrier accessory is also available for installing underneath a wooden countertop. See the “Tools and Parts” section at the front of the guide for part details and orders.

Check location where dishwasher will be installed. The location must provide:

■■ Convenient access for loading and unloading dishes. Corner locations require a 2" (51 mm) minimum clearance between the side of the dishwasher door and the wall or cabinet.

■■ Easy access to water, electricity, and drain: ■■ Grounded electrical supply is required.

■■ This dishwasher has a water heating feature and also requires a connection to a hot water supply line.

■■ Make sure pipes, wires and drain hose are within the shaded area shown in the “Product and Cabinet Opening Dimensions” section.

■■ Do not run drain lines, water lines, or electrical wiring where they can interfere with or contact dishwasher motor or legs.

■■ Shelter dishwasher and water lines leading to dishwasher against freezing. Damage from freezing is not covered by the warranty.

NOTE: If dishwasher will be left unused for a period of time or in a location where it may be subject to freezing, have it winterized by authorized service personnel.

■■ If installed in new construction, flush the water supply line of debris before connecting it to the fill valve. If it is not flushed, debris from the water supply could plug the fill valve screen.

■■ A square opening for proper operation and appearance ■■ The cabinet front to be perpendicular to floor

■■ A level floor

Helpful Hint: If floor at front of opening is not level with floor at rear of opening, shims may be used to level dishwasher.

NOTE: To avoid shifting during dishwasher operation, shims must be securely attached to the floor.

■■ The location where the dishwasher will be installed must provide clearance between motor and flooring. Motor should not touch the floor.

■■ Do not install dishwasher over carpeted flooring.

6

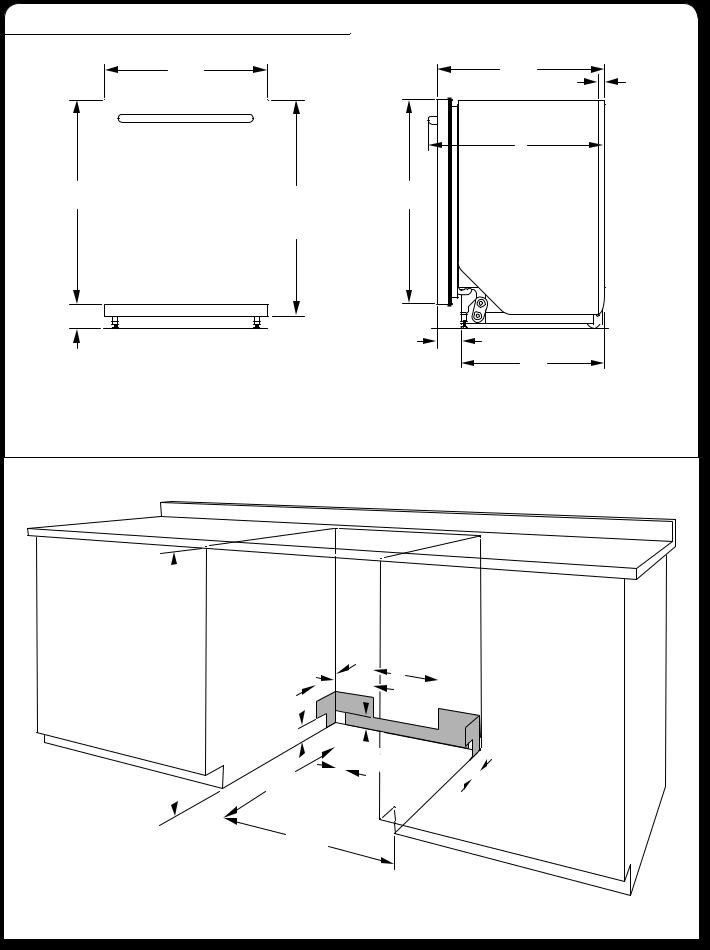

Product and Cabinet Opening Dimensions |

|

|

|

|

237/8" |

241/2" |

|

|

(606 mm) |

(622 mm) |

3/4" |

|

|

B |

(19 mm) |

|

|

|

A |

|

|

C |

|

30" |

331/2" |

30" |

|

(762 mm) |

(851 mm) |

(762 mm) |

|

|

min. with |

|

|

|

wheels |

|

|

|

removed |

|

|

|

|

33/4" |

|

31/2" - 41/2" |

|

(94 mm) |

|

(88 mm - 106 mm) |

|

21" |

|

|

|

(533 mm) |

|

For 4" (100 mm) toe kick, height of cabinet opening is 341/2" (863 mm). |

A. Insulation may be compressed (not used on all models). |

||

|

|

B. For panel-ready models, dishwasher depth is 24" (610 mm), |

|

|

|

not including the 3/4" (19 mm) custom door panel. |

|

|

|

C. Door handles may protrude forward of the face of the |

|

|

|

dishwasher, varies by model. |

|

|

|

Check that all surfaces have no protrusions |

|

|

|

that would prohibit dishwasher installation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: Shaded areas |

|

|

|

|

|

|

|

|

|

|

|

|

of cabinet walls |

|

|

|

|

|

|

|

|

|

|

|

|

show where utility |

|

|

|

|

|

|

|

|

|

101/2" |

|

|

connections may |

|

|

|

|

|

|

|

|

|

|

|

be installed. |

|

34" |

|

|

|

|

|

|

|

(267 mm) |

|

|||

(864 mm) |

4" |

|

|

|

|

|

|

63/4" |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

D |

|

|

|

|

|

|

|

|

|

|||

|

|

(102 mm) |

|

|

|

|

|

(172 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

3" |

|

|

|

|

|

|

|

|

|

61/4" |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

(76 mm) |

|

|

|

|

|

|

|

|

(159 mm) |

|

|

|

|

|

|

|

21 |

/4" |

|

|

|

|

|

|

|

24" |

|

|

|

(64 mm) |

|

|

||||

|

|

(620 mm) |

13/4" |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

(44 mm) |

2" |

|

|

|||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

(51 mm) |

|

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

D.Measured from the lowest point on the underside of the countertop. May be reduced to 331/2"

(851 mm) by removing the wheels and perforated area of insulation (blanket) on dishwasher.

E.Minimum, measured from narrowest point of opening

24" (620 mm) E

7

DRAIN REQUIREMENTS

■■ A new drain hose is supplied with your dishwasher.

If drain hose is not long enough, use a new drain hose with a maximum length of 12 ft (3.7 m) that meets all current AHAM/ IAPMO test standards, is resistant to heat and detergent, and fits the 1" (25 mm) drain connector of the dishwasher. See the “Tools and Parts” section at the front of the guide for part details and orders.

NOTE: Do not connect multiple drain hoses together.

■■ Make sure to connect drain hose to waste tee or disposer inlet above drain trap in house plumbing and 20" (508 mm) minimum above the floor. It is recommended that the drain hose either be looped up and securely fastened to the underside of the counter or be connected to an air gap.

■■ Make sure to use an air gap if the drain hose is connected to house plumbing lower than 20" (508 mm) above subfloor or floor.

Use of air gap

Air gap |

■■ If required, the air gap should be installed in accordance with the air gap installation instructions. When you are connecting the air gap, a rubber hose (not provided) will be needed to connect to the waste tee or disposer inlet.

■■ Use 1/2" minimum I.D. drain line fittings.

WATER SUPPLY REQUIREMENTS

■■ This dishwasher has a water heating feature and also requires a connection to a hot water supply line.

■■ A hot water line with 20 to 120 psi (138 to 862 kPa) water pressure can be verified by a licensed plumber.

■■ 120°F (49°C) water at dishwasher

■■ 3/8" O.D. copper tubing with compression fitting or flexible braided water supply line. See the “Tools and Parts” section at the front of the guide for part details and orders.

NOTE: 1/2" minimum plastic tubing is not recommended.

■■ A 90° elbow with 3/4" hose connection with rubber washer. See the “Tools and Parts” section at the front of the guide for part details and orders.

■■ Do not solder within 6" (152 mm) of the water inlet valve.

■■ If installed in new construction, make sure the house water supply lines have been flushed prior to connecting the dishwasher to remove any debris that may exist in the supply line.

NOTE: If replacing an existing dishwasher, it is recommended to install a new water line (see the “Tools and Parts” section at the front of the guide for part details) and drain hose (supplied) with the new dishwasher.

ELECTRICAL REQUIREMENTS

Be sure that the electrical connection and wire size are adequate and in conformance with the National Electrical Code, ANSI/NFPA 70 - latest edition, and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association 1 Batterymarch Park

Quincy, MA 02169-7471

You Must Have:

■■ 120-volt, 60 Hz, AC-only, 15or 20-amp, fused electrical supply

■■ Copper wire only

■■ A maximum of 2 field wiring supply conductors (12 AWG largest size) plus 1 grounding conductor are permitted in the terminal box.

We Recommend:

■■ A time-delay fuse or circuit breaker ■■ A separate circuit

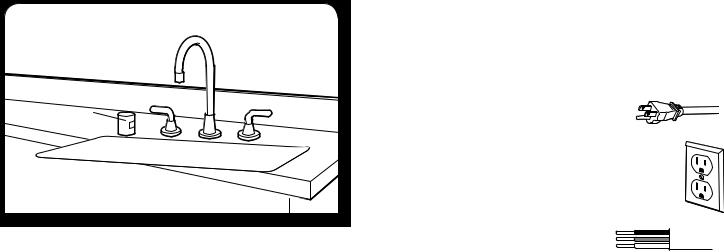

If Connecting Dishwasher with a Power Cord:

■■ Use UL Listed power cord kit marked for use with dishwasher. See the “Tools and Parts” section at the front of the guide for

part details and orders.

■■ Plug into a grounded 3 prong outlet. Outlet must meet all local codes and ordinances.

If Connecting Dishwasher with Direct Wiring:

■■ Use flexible, armored, or nonmetallic

sheathed copper wire with grounding wire that meets the wiring requirements

for your home and local codes and ordinances.

■■ Use a UL Listed/CSA Approved metallic strain relief. See the “Tools and Parts” section at the front of the guide for part details and orders.

8

INSTALLATION INSTRUCTIONS

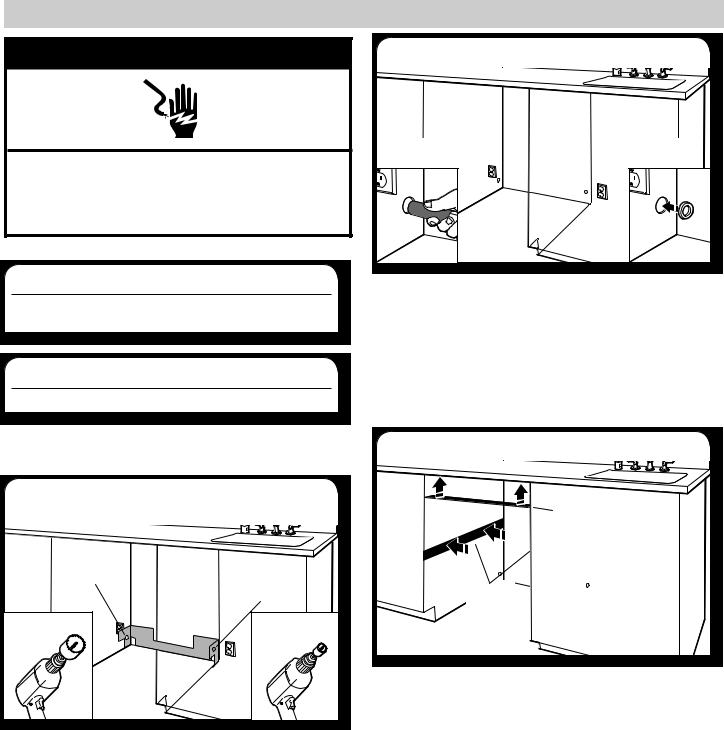

WARNING

WARNING

Electrical Shock Hazard

Disconnect electrical power at the fuse box or circuit breaker box before installing dishwasher.

Failure to do so can result in death or electrical shock.

1. Disconnect power

Disconnect electrical power at the fuse box or circuit breaker box before installing dishwasher.

2. Shut off water supply

Shut off the water supply to the dishwasher.

PREPARE CABINET OPENING –

NEW UTILITIES

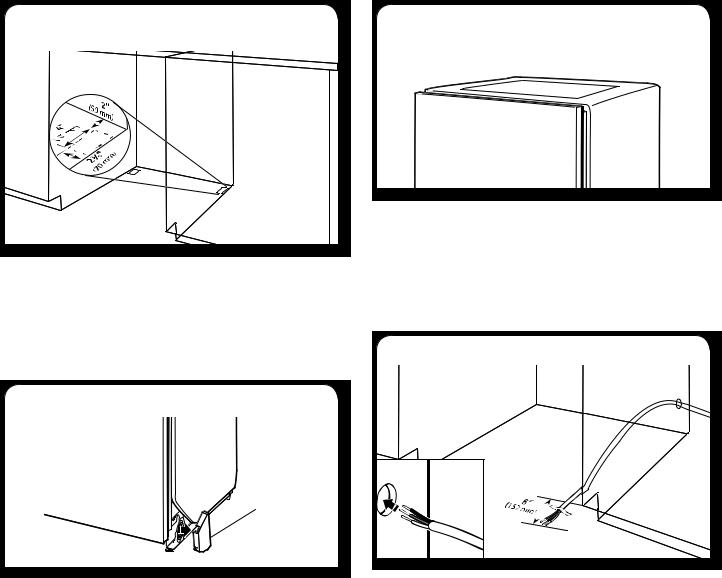

3. Drill hole locations - new construction

|

Optional |

|

|

location |

Preferred |

|

|

|

|

|

location |

11/2" |

|

1/2" |

(38 mm) |

|

(12.7 mm) |

NOTE: Refer to the “Product and Cabinet Opening Dimensions” section for the correct hole placement and dimensions of the shaded area.

Drill a 11/2" (38 mm) drain hose hole in the side or rear of cabinet, depending on location of drain hose routing and drain hose connection location.

Drill a 1/2" (12.7 mm) water supply hose hole in the side or rear of cabinet, depending on location of water supply routing and connection location

Drill a 11/2" (38 mm) electrical conduit hole in the right-hand side or rear of cabinet.

4. |

Sand holes smooth |

|

|

Wood |

Metal |

cabinet |

cabinet |

|

Wood cabinet: Sand the hole until smooth.

Metal cabinet: Cover edges of hole with grommet included with power cord kit. See the “Tools and Parts” section at the front of the guide for part details.

Helpful Tip: Wiring the dishwasher will be easier if you route the cable into the cabinet opening from the right-hand side.

INSTALL OPTIONAL MOISTURE BARRIER –

RECOMMENDED FOR WOOD COUNTERTOPS

Moisture barrier/wood shims

Moisture |

barrier |

Install |

wood |

shims |

See the “Tools and Parts” section at the front of the guide for part details and orders. Make sure the area under the cabinet is clean and dry for installation of the moisture barrier. Remove the backing of the moisture barrier, and apply to underside of the countertop along the front edge of the counter.

NOTE: Install wood shims if side anchoring and the gap between the sides of the cabinet and sides of the dishwasher are greater than 1/2" (12.7 mm) on each side or are greater than the length of the side anchor screws.

9

5. Built-up floors –

add shims as needed

Built-up floors: If the kitchen floor is higher than the cabinet opening’s floor - for example, the kitchen floor tile does not extend into the cabinet opening - add shims, as needed, in the area shown to bring the dishwasher up to 34" (864 mm) below the countertop.

NOTE: Shims must be securely attached to floor to avoid movement when the dishwasher is in use.

6. |

Remove foam block |

|

Foam block |

Remove and discard the foam blocks (if blocks are present; not all models have them) located above the front legs on each side of the dishwasher. The blocks cover the rope/link pulleys on the dishwasher.

If installing into a |

331/2" (851 mm) opening |

Cut insulation blanket along perforation for cabinet opening height of 331/2" (851 mm). For other cabinet opening heights, do not cut the insulation blanket.

ELECTRICAL CONNECTION

–For Direct Wire, begin with Step 7

–For Power Cord, wait until Step 22

7. |

Direct wire – route cable |

If installing with direct wire, route the cable as shown.

Route cable from power supply through cabinet hole. (Cable must extend to the right front side of cabinet opening.) Tape cable to the floor in area shown. This will prohibit cable from moving when dishwasher is moved into cabinet opening.

NOTE: If removing a previous dishwasher with a power cord, you will need to transfer the power cord to the new dishwasher.

10

PREPARE DISHWASHER

WARNING

WARNING

Tip Over Hazard

Do not use dishwasher until completely installed. Do not push down on open door.

Doing so can result in serious injury or cuts.

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install dishwasher.

Failure to do so can result in back or other injury.

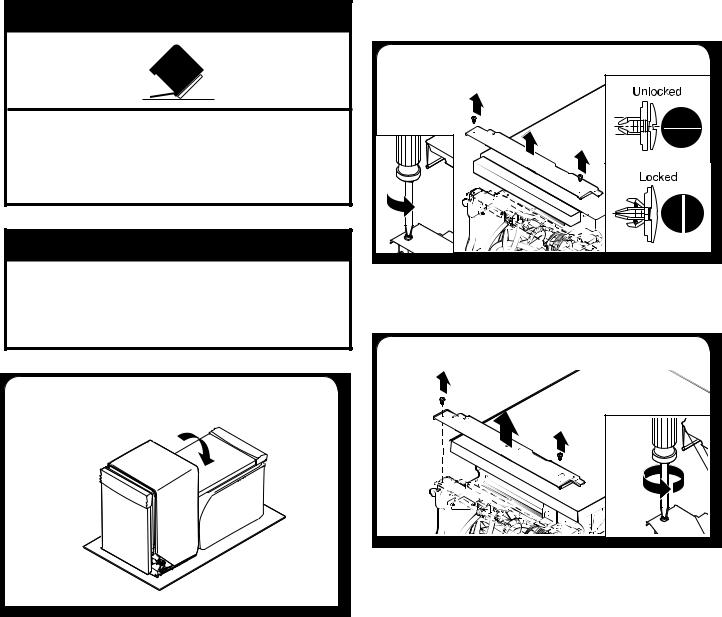

8. Put dishwasher on its back

REMOVE ACCESS PANEL

–For Plastic Access Panels, go to Step 9

–For Metal Access Panels, go to Step 10

9. |

Plastic panel |

|

1/4 |

|

turn |

Using a flat-blade screwdriver, turn the plastic fasteners 1/4 turn counterclockwise to unlock them. Remove panel. Do not remove tech sheet from access panel. Go to Step 11.

10. Metal panel

Helpful Tip: Place cardboard under dishwasher until installed in cabinet opening to avoid damaging floor covering.

Using 2 or more people, grasp sides of dishwasher door frame, and place the dishwasher on its back.

Do not use the door panel as a worktable without first covering it with a towel to avoid scratching the door panel.

NOTE: On some models, once the dishwasher is on its back, pull on the door handle to remove it from the access panel.

Using a 1/4" nut driver or Phillips screwdriver, remove 2 screws attaching access panel to dishwasher. Do not remove tech sheet from access panel.

11

11. Measure cabinet opening

Measure height of cabinet opening from underside of countertop to floor where dishwasher will be installed. Be sure to measure the lowest point on the underside of the countertop and the highest point on the floor.

Dishwasher Height Adjustment Chart

Cabinet opening |

Front legs |

Wheel |

Insulation |

height |

height |

position |

blanket |

|

|

|

|

331/2" (851 mm) |

3/8" (9.8 mm) |

Removed |

Cut |

34" (864 mm) |

9/16" (14 mm) |

1 |

No Cut |

341/4" (871 mm) |

13/16" (21 mm) |

2 |

No Cut |

341/2" (876 mm) |

11/16" (27 mm) |

3 |

No Cut |

Front legs – A

Adjust both front leveling legs to the same height. Put the rear wheels in the correct position according to the “Dishwasher Height Adjustment Chart.”

NOTE: If the minimum cabinet opening height is less than 34" (864 mm), the rear wheels can be removed for additional clearance.

This will allow the dishwasher to fit into a 331/2" (851 mm) high cabinet opening, but the dishwasher will be more difficult to move. Measurements are approximate.

12. Adjust wheels and legs

Refer to the “Dishwasher Height Adjustment Chart” for wheel position and for height of front legs needed for your cabinet opening height.

13. Remove plastic rail cover (only on certain models)

Plastic |

rail cover |

Remove and discard the plastic rail cover on each side of the dishwasher frame. To remove the plastic rail cover, push upward and back to unsnap it from the dishwasher frame.

CONNECT WATER LINE TO FILL VALVE

–For Copper line, begin with Step 14

–For Flexible line, begin with Step 16

14.Copper water line

If using copper tubing, measure overall length of copper tubing required to reach the water supply, cut to length, and attach with compression fittings.

12

15. Slide nut and ferrule onto tubing (copper tubing only)

Nut |

Ferrule |

Copper tubing only: Put the tubing into the 90° elbow fitting as far as it will go. (The copper tubing bends and kinks easily.) Slide the nut and ferrule forward and start the nut onto the elbow threads.

NOTE: To avoid vibration during operation, route the water supply line so that it does not touch the dishwasher base, frame, or motor. Go to Step 17.

16. Flexible line

Flexible braided line: Confirm the flexible braided line is long enough. See the “Tools and Parts” section at the front of the guide for part details and orders.

17. Add 90° elbow fitting to the water supply line

Get 3/8" compression x 3/4" hose fitting with 90° elbow. See the “Tools and Parts” section at the front of the guide for part details and orders. Connect the 3/8" compression fitting of the 90° elbow fitting to the water supply line. Attach such that the 3/4" connection is facing upward as shown above.

CONNECT FILL HOSE TO FILL VALVE

18. Tighten 90° elbow fitting to valve

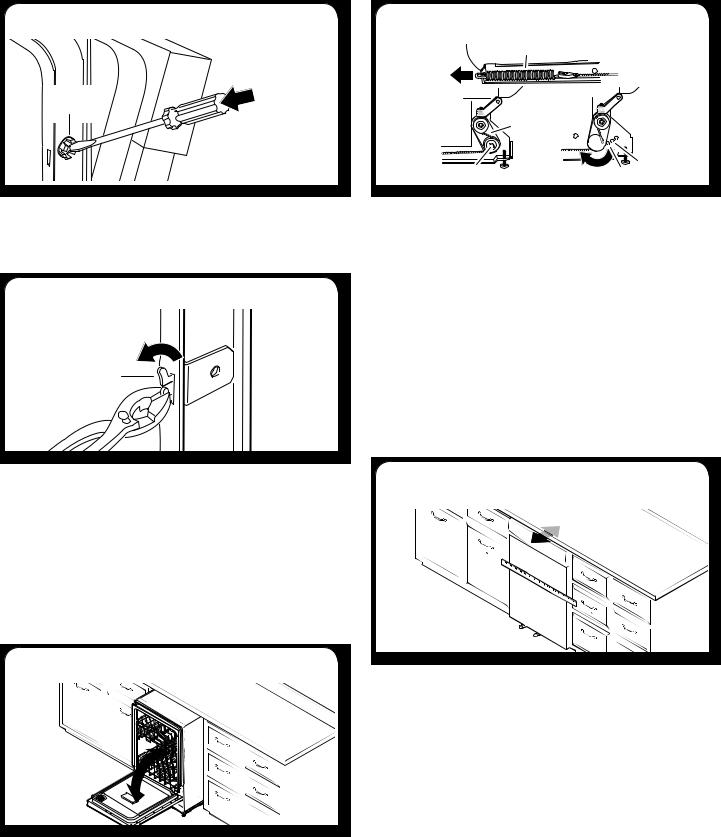

Be sure rubber washer is properly seated in fitting. Slide the 3/4" fitting of the 90° elbow up to the valve and hand tighten to avoid cross-threading. Hand tighten until the coupling is tight. Using pliers, check the tightness of the coupling. An additional 1/4 to 1/2 turn may be required to seal the rubber gasket. Route fill hose out the rear left side of unit.

NOTE: Do not over-tighten. Damage to the coupling can result.

DRAIN HOSE CONNECTION

19. Connect drain hose

Small clamp |

|

|

Rubber drain hose |

Drain hose |

|

connector |

||

|

||

|

Drain hose stop |

Stop

Stop

Place towel under drain hose to catch any water in drain hose. Place the small (green) drain hose clamp onto the small end of the drain hose. Push the new drain hose into the rubber drain hose connector up to the drain hose stop.

20. Slide clamp onto connector

Drain hose

Small clamp |

|

Rubber drain hose |

|

connector |

Drain hose stop |

|

|

Stop Stop |

|

Using pliers, squeeze open the small drain hose clamp and slide it onto the connector between stops.

13

21. Hose clamp final position |

24. Install strain relief |

Drain hose |

Drain hose stop |

Small clamp |

Rubber drain hose |

connector |

Stop Stop |

NOTE: Route drain hose out the rear of the dishwasher.

POWER CORD CONNECTION

NOTE: If removing a previous dishwasher with a power cord, you will need to transfer the power cord to the new dishwasher.

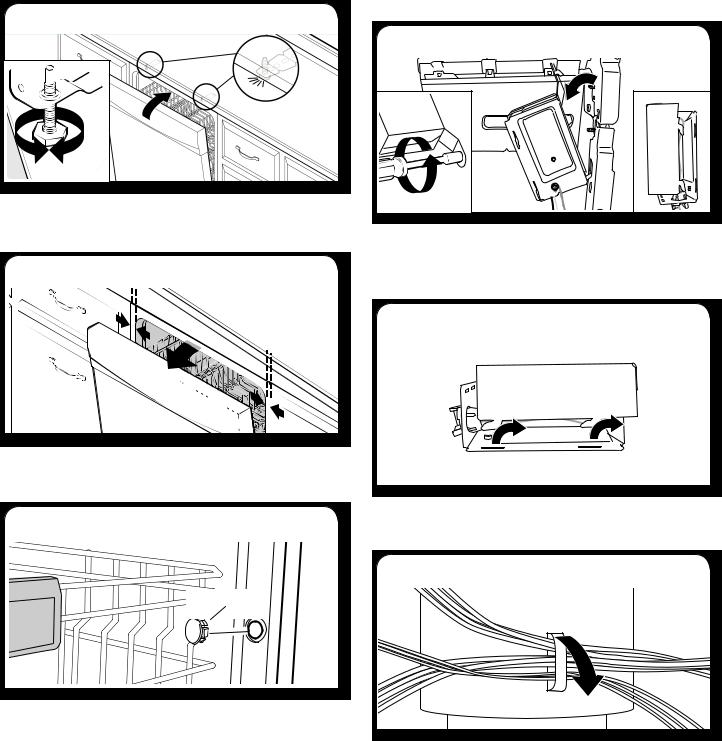

Install a UL Listed/CSA Approved metallic strain relief. Make sure screw heads are facing up when tightening conduit nut. Strain relief is provided with the power cord kit. See the “Tools and Parts” section at the front of the guide for part details and orders.

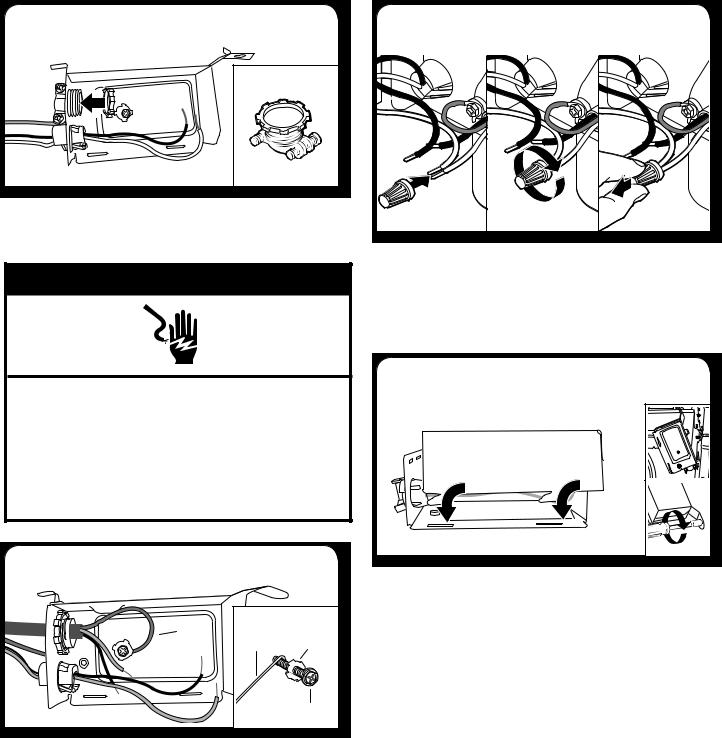

22. Remove terminal box |

25. Power cord – route cord |

|

into terminal box |

Use a 1/4" nut driver or 1/4" hex head socket wrench to remove the screw that holds the terminal box to the cross brace. Then, tilt the terminal box, free the tab, and lift the terminal box away from the crossbar.

23. Remove cover

Remove the cover by sliding it up and lifting its hooks out of the slot. Retain cover for later use.

Route cord so that it does not touch dishwasher motor or lower part of dishwasher tub. Pull cord through strain relief in terminal box.

NOTE: A maximum of 2 power cord supply conductors (12 AWG largest size) plus 1 grounding conductor are permitted in the terminal box.

14

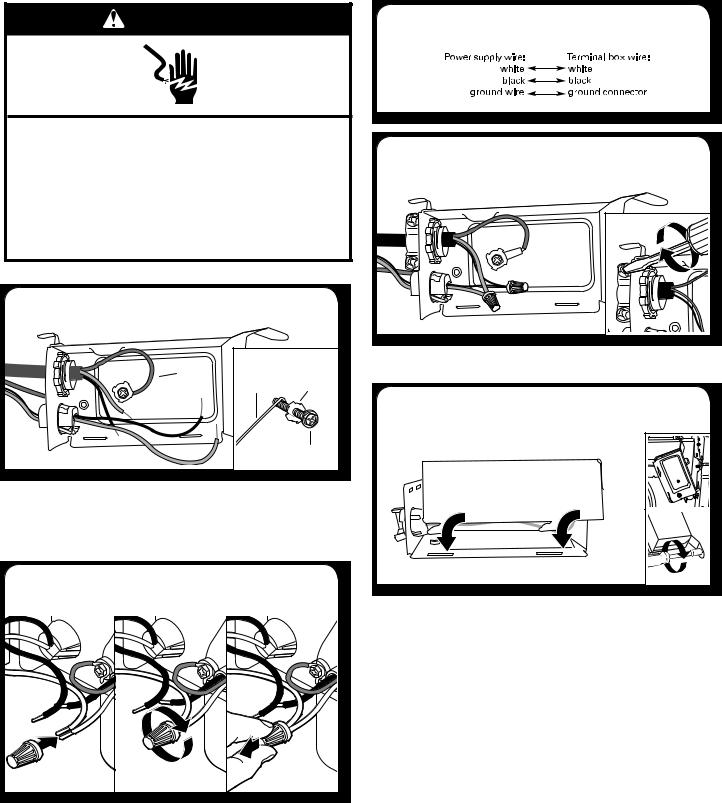

ARNING

Electrical Shock Hazard Electrically ground dishwasher.

Connect ground wire to green ground connector in terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

26. Power cord – connect ground wire

Ground |

|

|

wire |

Ground |

Washer |

|

wire |

|

|

|

Ground |

|

|

screw |

Remove the ground connector screw on the raised floor inside the box and place it through the ring terminal of the green ground wire of power cord. Reattach and tighten the ground connector screw to the raised floor of the box.

27. Power cord – connect remaining wires

Select UL Listed/CSA Approved twist-on wire connectors of the proper size. See the “Tools and Parts” section at the front of the guide for part details. Connect wires, black-to-black and white-to-white, using the twist-on wire connectors.

NOTE: Do not pre-twist stranded wire. Twist on wire connector. Gently tug on wires to be sure both are secured.

Wiring configuration

28. Power cord – secure cord on strain relief

Tighten strain relief screws to secure cord.

29. Power cord – reinstall terminal box cover and wires

Place wires inside terminal box. Replace the cover by inserting the hooks of the terminal cover into the slots in the floor of the terminal box and sliding the cover tight against the back wall where wires come in. Make sure wires are tucked inside the box and not pinched by the cover.

Put the terminal box back on the crossbar with the tab in place. Use a 1/4" nut driver and the screw removed in Step 22 to secure the terminal box to the crossbar.

Once the terminal box has been remounted on the dishwasher, tuck any excess length or slack over nearby components or clip them back into the nearby clips to help keep them off

the floor.

NOTE: Route power cord out the rear of the dishwasher. Do not plug cord into an outlet until instructed to do so.

15

INSTALL DOOR HANDLE

(ON SOME MODELS)

30. Install door handle

Mounting stud |

Handle |

Setscrew |

(in bottom |

of handle) |

Hex key |

IMPORTANT: Do not scratch the front panel during this procedure. If door panel has a protective film, peel film back past the point of the handle studs before installing handle. Handle is easiest to install while unit is on its back.

Remove the door handle and hex key from the packaging. Setscrews are already installed in the handle. Place handle on mounting studs with the setscrews facing down. Push the door handle tightly against the door. Insert the short end of the hex key into the setscrews. Tighten the setscrews

1/4 turn past snug.

Retain hex key with Installation Instructions.

PLACE DISHWASHER IN CABINET

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install dishwasher.

Failure to do so can result in back or other injury.

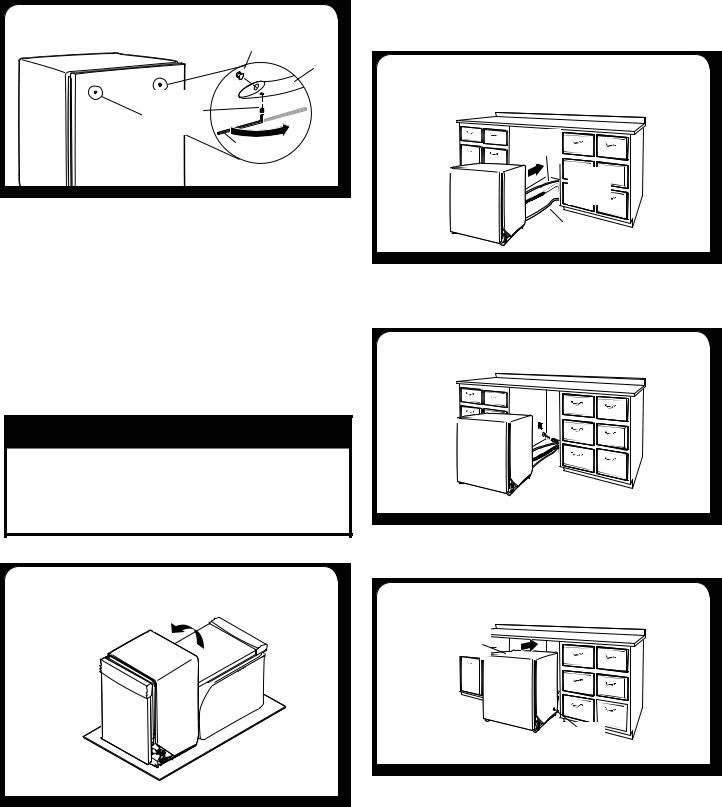

31. Stand dishwasher upright

Using 2 or more people, stand the dishwasher up. NOTE: Do not install kick plate until instructed to do so.

IMPORTANT: If wheels were removed, cover the floor when moving the dishwasher. Slowly move dishwasher completely into cabinet opening. Do not kink or pinch water line, drain hose, power cord, or direct wire between dishwasher and cabinet. Remove cardboard from under dishwasher.

It is all right if dishwasher fits tightly into cabinet opening. Do not remove insulation blanket – the blanket reduces the sound level.

NOTE: Route water supply, drain hose, and power cord out the rear of the dishwasher.

32. Move dishwasher close to cabinet opening

Water

line

Drain

hose

hose

Cable

Route the utilities through the holes in the cabinet, and pull the slack out at the same time as the dishwasher is pushed into the cabinet.

33. Route power cord

If using a power cord, make sure to route end through hole in cutout before sliding dishwasher into cabinet opening.

34. Secure insulation blanket

Insulation

blanket

Secure blanket

blanket

NOTE: Make sure insulation blanket is secured at both left and right rear corners before pushing into cabinet opening to keep the blanket from bunching up in a tight fitting cabinet.

16

35. Move dishwasher all but 6" (152 mm) into cabinet opening

6" (152 mm)

NOTE: Leave unit about 6" (152 mm) out from cabinet in order to install anchor brackets and adjust door tension if needed.

36. Pull slack from utilities

NOTE: Pull slack out of utilities at the same time the dishwasher is pushed into the cabinet opening to avoid any kinks.

CUSTOM PANEL INSTALLATION

(CUSTOM PANEL MODELS ONLY)

For custom panel installation, refer to the Custom Panel Installation Instruction Sheet (Part Number W10750117A). Complete custom panel installation before proceeding to the “Choose Anchor Attachment Method” section.

CHOOSE ANCHOR ATTACHMENT METHOD

IMPORTANT: The dishwasher must be secured to the cabinet as one of the final steps. Prepare the dishwasher for this by attaching the 2 brackets found in the parts bag to the dishwasher.

–For countertops that are wood, laminate or another similar surface, use Countertop Attachment: go to Step 37.

–For countertops that are marble, granite, or another hard surface, use Side Attachment: go to Step 38.

NOTE: If the gap between the top of the door and the underside of the counter top is tight (less than 1/4" [6,35 mm]), we suggest using Side Attachment to keep from scratching the User Interface or console with the anchor screws.

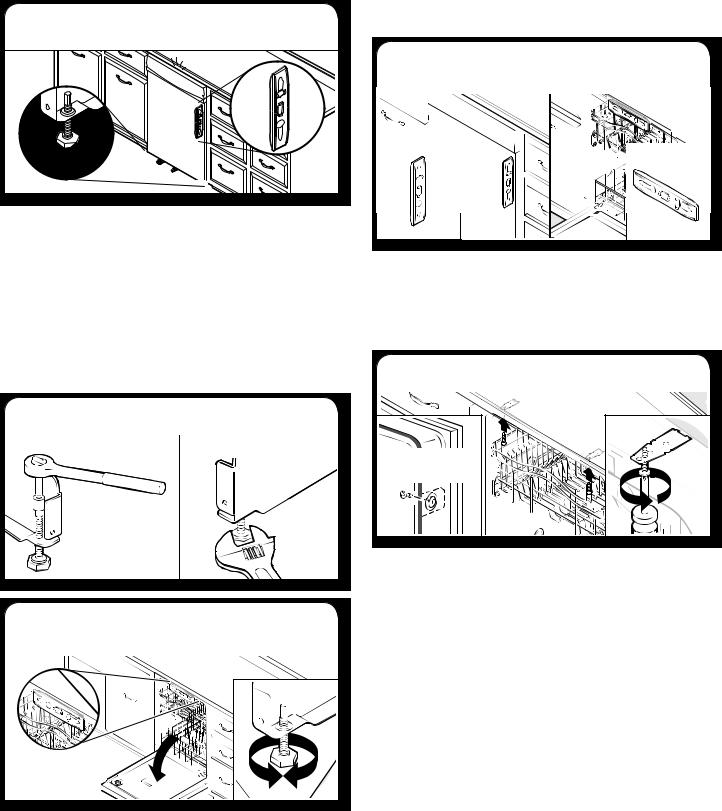

Countertop Attachment:

37. Insert bracket

Tabs must point to the right.

Remove the brackets from the package, and insert into the open slots on the leftand right-hand top of the dishwasher collar as shown. Go to Step 41.

Bend tab

Using pliers, bend/twist tab to lock the brackets in place.

Side Attachment:

38. Break end of bracket

Score line

Break off the end of the bracket along the scored line using pliers.

17

39. Remove plastic buttons

Plastic

button

Push the plastic buttons out of the side of the tub.

NOTE: Save the buttons to cover the holes after dishwasher is installed.

40. Install bracket

Bend

tabs

Push bracket into slot on the side of dishwasher, and bend tab in toward the side of the dishwasher so that it keeps the bracket in place. Repeat this step for the other side of the dishwasher.

NOTE: Install wood shims to the inside of the cabinets if the gap between the sides of the cabinet and the sides of the dishwasher are greater than 1/2" (13 mm) on each side.

NOTE: Do not attach the dishwasher. This will be done later.

FINAL INSTALLATION CHECK

41. Open and close door

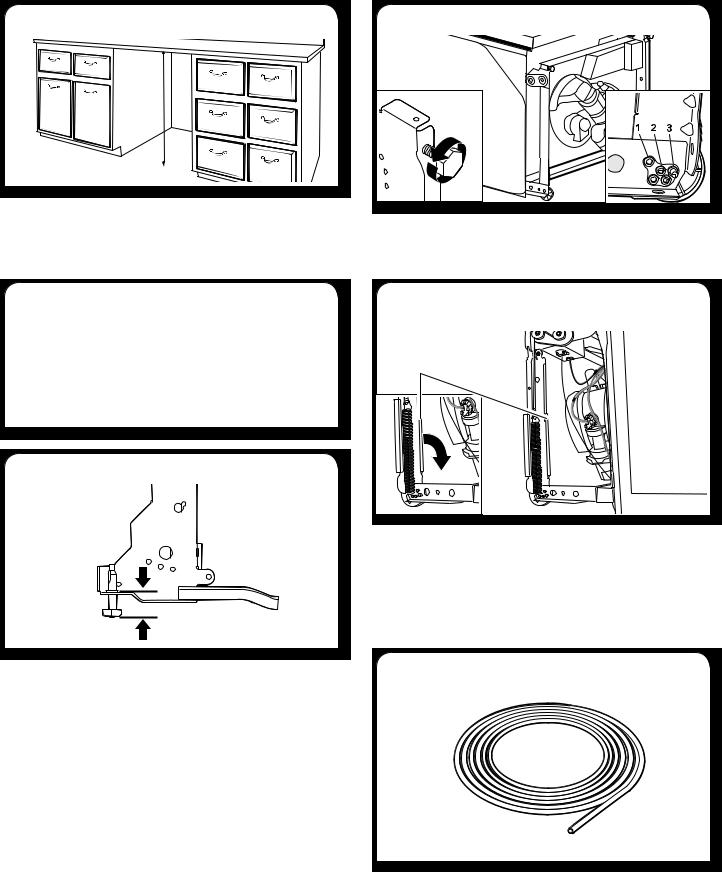

42. Door spring tension adjustment

Spring

Plastic rope end

Tensioner

3

3

Screw |

1 2 |

If door closes too quickly or falls, open and adjust spring tension.

To adjust the door spring tension, remove the white plastic rope end attached to the door hinge. Using a 5/16" nut driver or hex socket, remove the screw from the tensioner. The screw can be put into one of 3 holes (1, 2, 3) in the front leg of the dishwasher.

If the door closes by itself: Move the tensioner to a lowernumbered hole and replace the screw. Reattach the white plastic rope end to the door hinge.

If the door opens by itself: Move the tensioner to a higher numbered hole and replace the screw. Reattach the white plastic rope end to the door hinge.

NOTE: Tensioners on both sides of dishwasher should be secured at same holes.

43. Align front of dishwasher with front of cabinet doors

Align front of dishwasher door panel with front of cabinet doors. You may need to adjust alignment to be even with your cabinets.

18

44. Check for plumb and adjust legs if needed

SECURE DISHWASHER

IN CABINET OPENING

46. Double-check dishwasher alignment in cabinet opening

Check that leveling legs are firmly against the floor. Close and latch the door and place level against the front panel. Check that dishwasher is centered from front to back in the opening. If needed, adjust leveling leg until dishwasher is plumb. Repeat for other side of dishwasher.

Helpful Tip: Push up on front of dishwasher to raise dishwasher off the ground to adjust front legs. With some installations, it may be easier to adjust the front leg using a 3/16" hex head socket or adjustable wrench. If the gap between the top of the door and the underside of the counter top is tight (less than

1/4" [6 mm]), we suggest side anchoring to keep from scratching the User Interface or console.

Level legs

Preferred method |

Optional method |

45. Check level side to side and adjust legs if needed

Place level against top front opening of tub. Check that dishwasher is level from side to side. If dishwasher is not level, adjust front legs up or down until dishwasher is level.

Check that dishwasher is still level front to back and side-to-side in the cabinet opening.

Open dishwasher door and place towel over pump assembly and spray arm of dishwasher. This will keep screws from falling into pump area when you are securing dishwasher to cabinet.

47. Secure dishwasher

Screw to side |

cabinet |

Open dishwasher door to prepare for securing the dishwasher to the countertop or side cabinet.

NOTES:

■■ The dishwasher must be secured to keep it from shifting when the door is opened or closed.

■■ Do not drop screws into bottom of dishwasher.

■■ Locate brackets installed in the “Choose Anchor Attachment Method” section, either on top or on the sides of the dishwasher.

■■ If countertop anchoring: Secure dishwasher to the countertop with two #10 x 1/2" Phillips-head screws (included).

■■ If side anchoring: Drill pilot holes in cabinet to avoid splitting the wood. Secure dishwasher to cabinet with two #10 x1/2" Phillips-head screws (included). Remove upper rack for easier access. See the Use and Care Guide for instructions how to remove the upper rack if needed.

19

48. Check door clearance

IMPORTANT: Check that top of door does not contact screws, brackets, or countertop. If it does, adjust leveling legs or use the side attachment option.

49. Check inner spacing

Open door and check that space between dishwasher cabinet opening and tub is equal on both sides. If spacing is not equal, loosen bracket screws and shift tub. Tighten bracket screws.

50. Reinstall plastic buttons

Plastic button |

If side attachment method was used, reinstall the gray plastic buttons removed in Step 39 to hide the screw holes.

DIRECT WIRE CONNECTION

51. Remove terminal box

Use a 1/4" nut driver or 1/4" hex head socket wrench to remove the screw that holds the terminal box to the cross brace. Then, tilt the terminal box, free the tab, and lift the terminal box away from the crossbar.

52. Remove cover

Remove the cover by sliding it up and lifting its hooks out of the slots. Retain cover for later use.

53. Unclip green, white, and black wires

There should be adequate length in the wires to pull the terminal box out from under the dishwasher. Lift the wires off of the nearby clips or components to extend the length of wire harness for easier access.

20

54. Install strain relief |

56. Direct wire – connect |

|

remaining wires |

Install a UL Listed/CSA Approved metallic strain relief. See the “Tools and Parts” section at the front of the guide for part details and orders.

WARNING

WARNING

Electrical Shock Hazard Electrically ground dishwasher.

Connect ground wire to green ground connector in terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

55. Direct wire – connect ground wire

Ground |

|

|

wire |

Ground |

Washer |

|

wire |

|

|

|

Ground |

|

|

screw |

Form bare ground wire into a U-shaped hook. Wrap ground wire hook clockwise around the ground connector screw on the raised floor inside the box and under the dishwasher. Securely tighten ground connector.

Select UL Listed/CSA Approved twist-on wire connectors of the proper size. See the “Tools and Parts” section at the front of the guide for part details. Connect wires, black-to-black and white-to-white, using the twist-on wire connectors.

NOTE: Do not pre-twist stranded wire. Twist on wire connector. Gently tug on wires to be sure both are secured.

57. Direct wire – reinstall terminal box cover and wires

Place wires inside terminal box. Replace the cover by inserting the hooks of the terminal cover into the slots in the floor of the terminal box and sliding the cover tight against the back wall where wires come in. Make sure wires are tucked inside the box and not pinched by the cover.

Put the terminal box back on the crossbar with the tab in place. Use a 1/4" nut driver and the screw removed in Step 51 to secure the terminal box to the crossbar.

Once the terminal box has been remounted on the dishwasher, tuck any excess length or slack over nearby components or clip them back into the nearby clips to help keep them off the floor.

21

CONNECT WATER LINE TO HOUSE SHUT-OFF VALVE

NOTE: If using a flexible braided hose, replace inlet hose after 5 years to reduce the risk of hose failure. Record hose installation or replacement dates on the hose for future reference.

58. Attach water supply line

Attach the water supply line (copper tubing or flexible braided line) to the hot water line using a connection configuration that is in compliance with local codes and ordinances. The water supply to the dishwasher should have a manual shut-off valve located under the sink.

CONNECT DRAIN HOSE

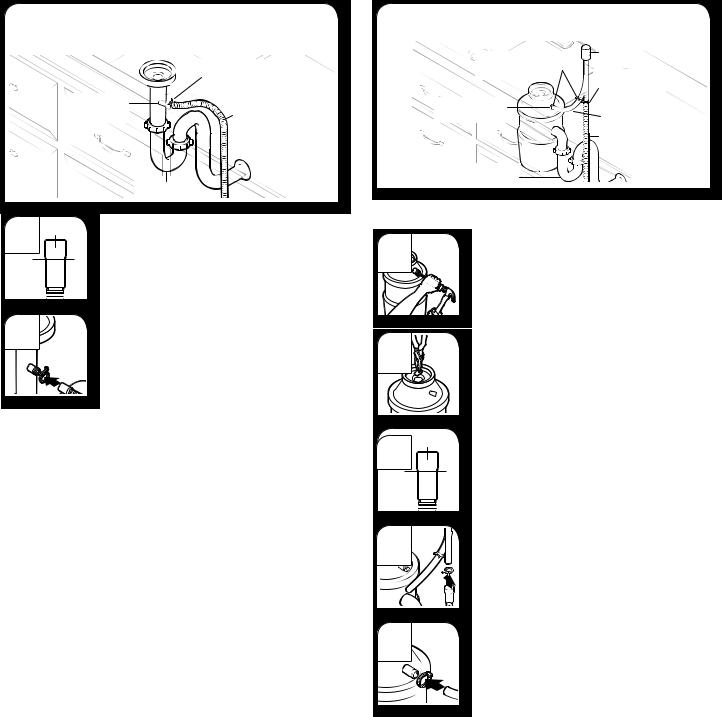

59. Connect drain hose

Connect drain hose to waste tee or waste disposer using one of the following options:

■■ Option A: Waste disposer – no air gap

■■ Option B: No waste disposer – no air gap ■■ Option C: Waste disposer – with air gap

■■ Option D: No waste disposer – with air gap

IMPORTANT: The drain hose connection of the disposer or a waste tee must be made before the drain trap and at least 20" (508 mm) above the floor where the dishwasher will be installed.

Helpful Tip: To reduce vibration of the hose, keep the hose away from the floor.

Option A: Waste disposer – no air gap

Disposer inlet |

Large drain |

|

hose clamp |

||

|

||

|

Drain hose |

|

|

Drain trap |

Helpful Tip: Remove disposer knockout plug.

1 |

1. Using a hammer and screwdriver, knock |

|

plug into disposer. |

||

|

2 |

2. Use needle-nose pliers to remove plug. |

|

|

||

3 |

3. Attach drain hose to disposer inlet with |

|

large drain hose clamp (provided). Use |

||

|

||

|

pliers to squeeze clamp open and move |

|

|

into position. |

22

Option B: No waste disposer – no air gap

|

Large drain |

|

hose clamp |

Waste tee |

Drain hose |

|

|

|

Drain trap |

1 |

1. Fit rubber end of drain hose |

to waste tee and cut if needed. |

|

|

NOTE: Do not cut ribbed section. |

Rubber |

|

end |

|

2 |

2. Attach rubber end of drain hose to |

waste tee with a large drain hose clamp |

(provided). Use pliers to squeeze clamp open and move into position. If the drain hose was cut, use a 11/2" to 2" (38 to

50 mm) screw-type clamp (not provided).

Option C: Waste disposer – with air gap

Screw-type clamps |

Air gap |

|

|

|

Large drain |

|

hose clamp |

Disposer inlet |

Rubber hose |

|

connector |

|

Drain hose |

Drain trap |

|

Helpful Tip: Remove disposer knockout plug.

1 |

1. Using a hammer and screwdriver, knock |

plug into disposer. |

2 |

3 |

Rubber |

end |

4 |

5 |

2.Use needle-nose pliers to remove plug.

3.Connect rubber end of drain hose to air gap and cut if needed.

NOTE: Do not cut ribbed section.

4.Attach drain hose to air gap with large drain hose clamp (provided). Use pliers to squeeze clamp open and move into position. If the drain hose was cut, use a 11/2" to 2" (38 to 50 mm) screw-type clamp (not provided).

5.Use a rubber hose (not provided) with screw-type clamps (not provided) to connect from air gap to disposer inlet.

23

Loading...

Loading...