Wagner Project Sprayer User Manual

Owner’s Manual

1-800-328-8251

Wagner Technical Service

1770 Fernbrook Lane, Plymouth, MN 55447

http://www.wagnerspraytech.com

Register your product online at:

Read this manual for complete instructions

Table of Contents

Safety Information ................................................... 2

What’s in the Box ....................................................3

Before you Begin .....................................................4

Selecting the proper spray tip............................. 4

Important preparation tips ..................................4

Setup ......................................................................5-6

Material container setup ..................................... 5

Remote suction set setup ................................... 6

Flow Control Knob / Practice Spraying ................. 7

Material thinning ................................................. 7

Usage ........................................................................ 8

Priming with remote suction set .........................8

Spraying (Overspray) ......................................... 8

Spray Technique...................................................... 9

Cleanup - Latex Materials ................................ 10-11

Cleaning the material container........................ 10

Cleaning the remote suction set ....................... 11

Cleanup - Oil-based Materials .............................. 12

Cleaning the material container........................ 12

Cleaning the remote suction set ....................... 13

Cleaning the Components .................................... 14

Reassembly............................................................ 14

Maintenance ........................................................... 15

Replacement parts ................................................15

Troubleshooting .................................................... 16

Product registration .......................................... 16

Parts List ........................................................... 50-51

Warranty ................................................................. 52

Need Help? Call us rst for answers fast.

Call Wagner Spray Tech toll-free if you have any

comments or problems with this product.

Technical service hours: Monday through Friday, 8:00 am to 7:00 pm Central Time

0109 • Form No. 0525800B

English

Important Safety Information · Read all safety information before operating

Minimum gauge for extension cords

Cord length (feet)Voltage

Ampere

rating

range

2 - 3

120V

25-50

100 150 200 250 300 400 500

18

16 14 14 12 12 10 10

the equipment. SAVE THESE INSTRUCTIONS.

To reduce the risks of re or explosion, electrical shock and the injury to persons, read and understand all instructions included in

this manual. Be familiar with the controls and proper usage of the equipment.

This symbol indicates a hazardous situation, which, if not

not avoided could result in death or serious injury.

HAZARD: INJECTION INJURY

A high pressure stream of paint produced by this equipment

can pierce the skin and underlying tissues, leading to serious

injury and possible amputation.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE

CUT! Injection can lead to amputation. See a physician

immediately.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important to treat

the injury surgically as soon as possible. DO NOT delay treatment to

research toxicity. Toxicity is a concern with some coatings injected

directly into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

PREVENTION:

• NEVER aim the gun at any part of the body.

• Do not aim the gun at, or spray any person or animal.

• NEVER allow any part of the body to come in contact with the uid

stream.

• NEVER put your hand in front of the gun. Wear gloves. Gloves will

not provide protection against an injection injury.

• Keep hands and other body parts away from the discharge. For

example, do not try to stop leaks with any part of the body.

• Always unplug the spray gun before servicing, cleaning tip guard,

changing tips, or leaving unattended.

• Always use the nozzle tip guard. Do not spray without nozzle tip

guard in place.The tip guard provides some protection against

injection injuries but is mainly a warning device. Only use a nozzle

tip specied by Wagner.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite, causing

property damage and/or severe injury.

PREVENTION:

• Exhaust and fresh air introduction must be provided

to keep the air within the spray area free from accumulation of

ammable vapors.

• Avoid all ignition sources such as static electricity

sparks, open ames, pilot lights, hot objects,

cigarettes, and sparks from connecting and

disconnecting power cords or working light switches.

• Fire extinguishing equipment must be present and in

good working order.

• Follow the material and solvent manufacturer’s safety precautions

and warnings.

• Do not spray ammable or combustable materials near an open

ame or sources of ignition such as cigarettes, motors, and electrical

equipment.

• Know the contents of the paints and solvents being sprayed. Read

all Material Safety Data Sheets (MSDS) and container labels

provided with the paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use bleach.

• Do not use halogenated hydrocarbon solvents such as methylene

chloride and 1,1,1 - trichloroethane. They are not compatible with

aluminum and may cause an explosion. If you are unsure of a

material’s compatibility with aluminum, contact your coating supplier.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can be

harmful if inhaled or come in contact with the body. Vapors

can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be

sure it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions for equipment and

spray material before operating any equipment.

• Comply with all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• Keep sprayer out of the reach of children.

• Hearing protection is recommended for extended use.

• Always wear appropriate gloves, eye protection and a respirator or

mask when painting.

• Do not operate or spray near children. Keep children away from

equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective

footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the inuence of

drugs or alcohol.

HAZARD: ELECTRIC SHOCK HAZARD

May cause severe injury.

PREVENTION:

• Keep electrical cord plug and spray gun trigger free

from paint and other liquids. Never hold cord at plug connections to

support cord. Failure to observe may result in an electrical shock.

• Never immerse electrical parts in water or any other liquid. Wipe the

exterior of the sprayer with a damp cloth for cleaning. Always make

sure the sprayer is unplugged before taking it apart for cleaning.

IMPORTANT: Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. For lengths less than 50 feet, use a No.

18 AWG extension cord. For lengths more than 50 feet, use a No. 14 or

No. 16 AWG extension cord. An undersized cord will cause a drop in

line voltage resulting in loss of power and overheating.

Wagner Spray Tech accessory extension cords recommended:

P/N 0090241 20 foot extension cord.

P/N 0090242 35 foot extension cord.

2

English

Important Safety Information · Read all safety information before operating

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

(e)

(f)

(g)

(a)

(6)

(5)

(4)

(3)

(2)(1)

(k)

(i)

(m)

(j)

(l)

(h)

the equipment. SAVE THESE INSTRUCTIONS.

Grounding Instructions

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary,

do not connect the green grounding wire to either at blade

terminal. The wire with insulation having a green outer surface

with or without yellow stripes is the grounding wire and must be

connected to the grounding pin.

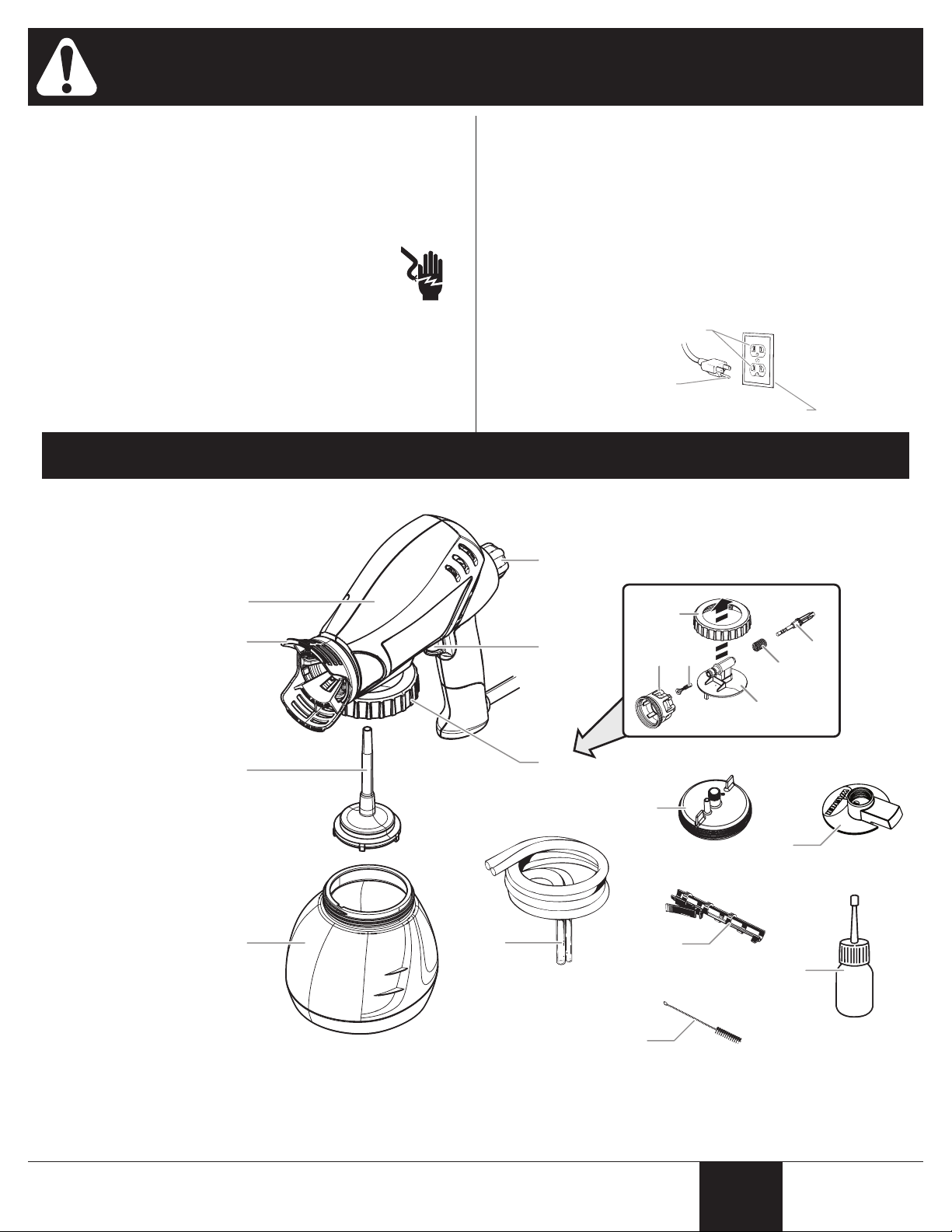

What’s in the Box

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify

the plug provided. If the plug will not t the outlet, have the proper

outlet installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the same

conguration as the plug. No adapter should be used with this

product.

a) Sprayer assembly

b) Spray tip

c) Suction tube with lter

d) Material container

e) Flow control knob

f) Trigger

g) Pump assembly

1) Locking nut

2) Atomizer valve

3) Pump housing ring

4) Pump housing

5) Spring

6) Piston

h) Dual hose tting

i) Quick Flush lid

j) Remote suction hoses

k) Container clip

l) Oil lubricant*

m) Cleaning brush

* Included in some models.

3

English

Before You Begin

(a)

(b)

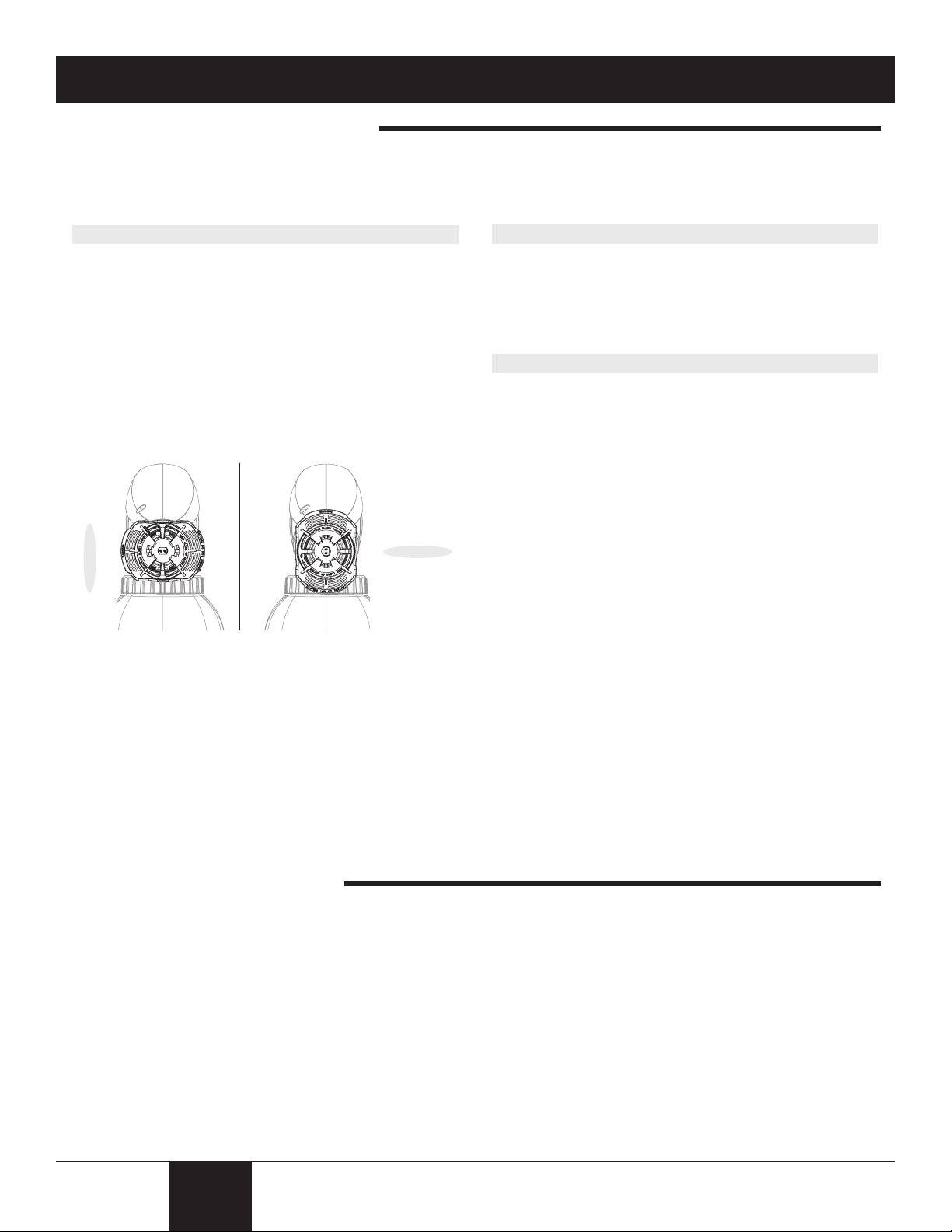

Selecting the Proper Spray Tip:

It is important that you use the proper spray tip based on your type of spraying job and the type of material you plan to spray.

Read below for details.

Optimus™ Spray Tip (included)

An Optimus™ spray tip produces a wide pattern that can be

adjusted horizontally or vertically.

To adjust:

1. Make sure the sprayer is unplugged and that spray tip is

sufciently hand-tightened.

2. Orient the spray tip to achieve your desired spray

pattern.

a. If you plan to spray horizontally (side to side), orient

the spray tip as shown in (a).

b. If you plan to spray vertically (up and down), orient

the spray tip as shown in (b).

Round Tip (sold separately)

A round tip produces a round pattern. Use a round tip if the

surface you are spraying is too small for use with the wide

angle tip.

A round tip is available at your local retailer.

Stain Tip (sold separately)

The stain tip has a specially designed opening for use with thin

materials such as thin stains, sealers and waterproofers, and

can be adjusted to reduce overspray. If you did not receive a

stain tip and will be spraying one of these materials, the tip can

be purchased at your local retailer.

The stain tip pattern is round with a ne spray. To adjust

the spray pattern size and coarseness, turn the tip slightly

counterclockwise to narrow the pattern and make the spray

more coarse. Turn the tip slightly clockwise to widen the

pattern and make the spray more ne.

IMPORTANT: Make sure to tighten all spray tips firmly by hand. If the spray tip is not tightened firmly enough, the

sprayer could leak or the tip could be damaged. Do not use a tool to tighten the spray tip. If the tip is too tight, it may be

damaged.

IMPORTANT: Use only Optimus™-labeled spray tips with this sprayer. Other tips are not compatible with this sprayer.

Important Preparation Tips:

• It is important to mix the material thoroughly before you begin. Do not shake the material to mix it. Always stir the material

gently but thoroughly before use.

• Remove any skin that has formed on the top of the material. Do not mix the skin into the material. The skin can break up

and clog the sprayer. Older paint may need to be strained.

4

English

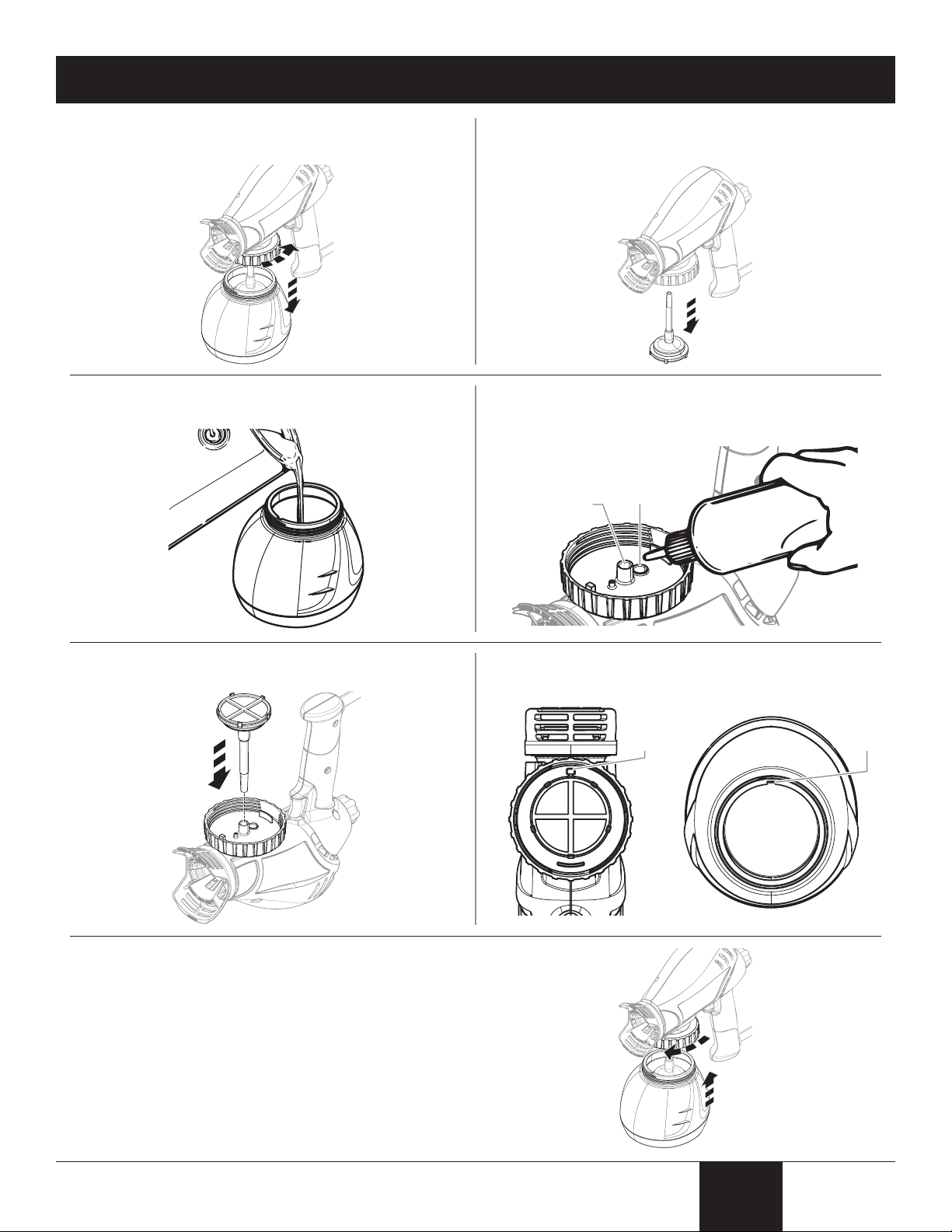

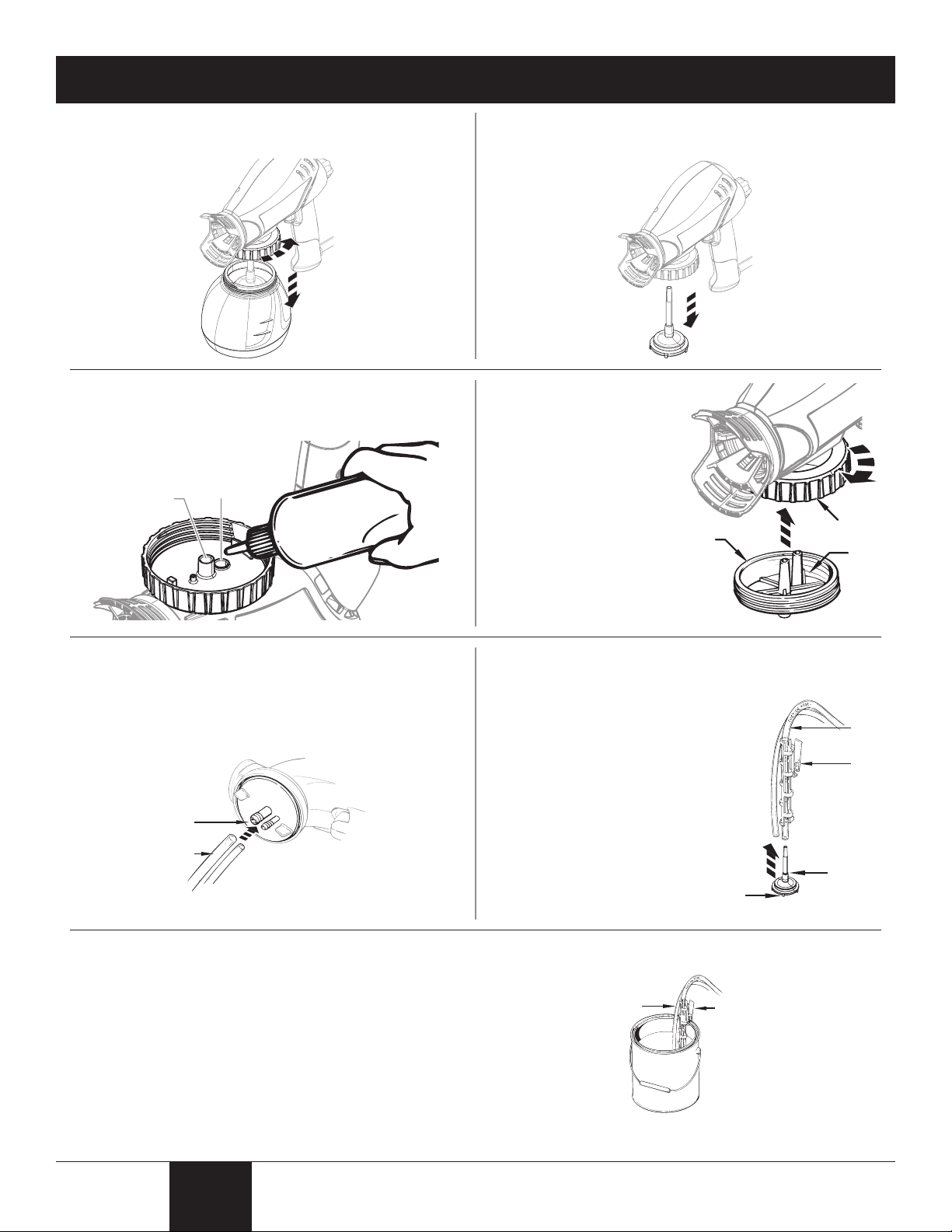

Material Container Setup

(a)

(b)

(c)(d)

1. Remove the material container from the pump housing

by turning the pump housing ring counterclockwise.

3. Fill the container with the material to be used.

2. Remove the suction tube.

4. Place a few drops of household oil down the intake (a)

and return openings (b) in the pump housing.

5. Insert the suction tube into the intake opening.

7. Twist the pump housing ring to thread the container onto

the pump housing. Plug in the unit.

6. Line up the tab (c) on the pump housing with the notch

(d) on the material container.

5

English

Remote Suction Set Setup (optional)

(m)

(l)

(g)

(f)

(d)

(c)

(e)

(a)

(b)

(i)

(h)

(j)

(k)

1. Remove the material container from the pump housing

by turning the pump housing ring counterclockwise.

3. Place a few drops of household oil down the intake (a)

and return (b) openings in the pump housing.

2. Remove the suction tube.

4. Push the dual hose

tting (c) into the intake

and return openings

on the bottom of the

housing. The tting

with the ridge (d) goes

into the return opening.

Twist the pump housing

ring (e) clockwise to

tighten the dual hose

tting into place.

5. Push the remote suction hose onto the intake and return

ports of the dual hose tting. The larger hose (f) goes

onto the intake port (g).

7. Submerge the suction tube assembly into the material

container and attach the container clip (l) to the side

to hold it securely. Make certain the return line (m) is

inside the container.

6. Slide the intake hose [(h), the larger hose] through

the container clip (i). You may need to pull the hoses

slightly apart.

Push the intake hose onto

the suction tube so that it

is ush with the ridge (j).

Make certain that the intake

lter (k) is in place on the

suction tube.

English

6

Loading...

Loading...