WAGNER PAINTMATE PLUS User Manual

The Painting People™

The Painting People™

PAINTMATE® PLUS

OWNER’S MANUAL • Read this manual for complete instructions

MANUEL DE L’UTILISATEUR • Ce manuel contient les instructions directives

MANUAL DEL PROPIETARIO • Lea este manual para obtener instrucciones completas

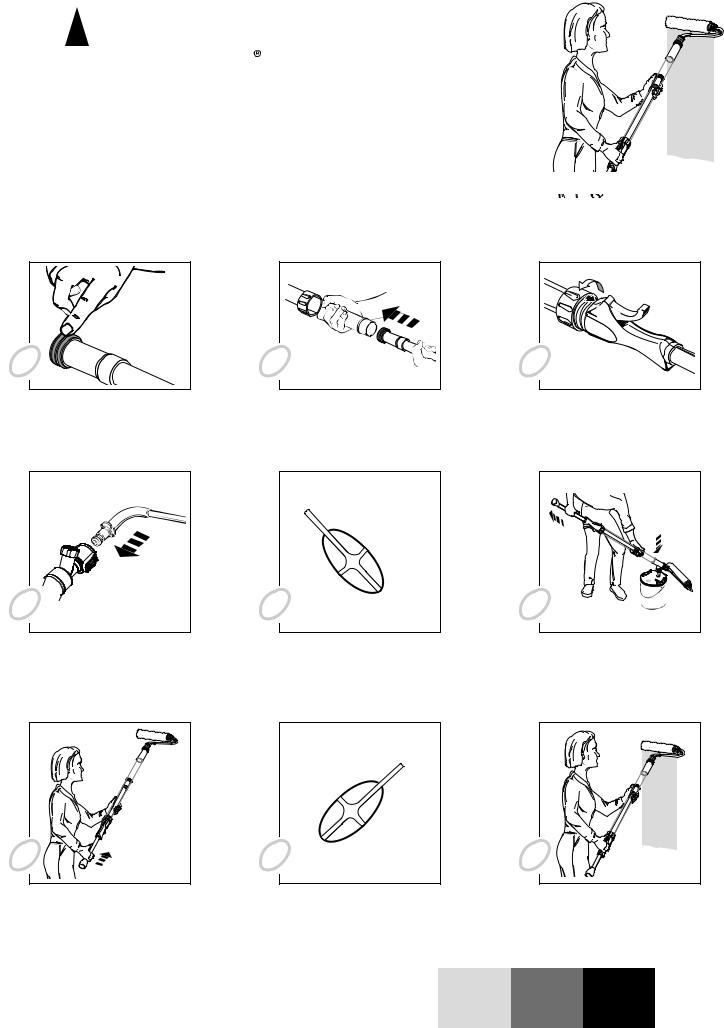

PLUNGER TUBE ASSEMBLY INSTRUCTIONS • INSTRUCTIONS D’ASSEMBLAGE POUR LE PISTON • INSTRUCCIONES DE ENSAMBLAJE PARA EL ÉMBOLO

1

Lubricate plunger O-rings

Lubrifier les joints toriques de la piston Lubrique los anillos en O del émbolo

2 |

Insert the plunger into the main tube Introduire le piston dans le tube principal Introduzca el émbolo en el tubo principal

3 |

Tighten the locking collar securely Serrer le collier solidement Apriete bien el collar inmovilizador

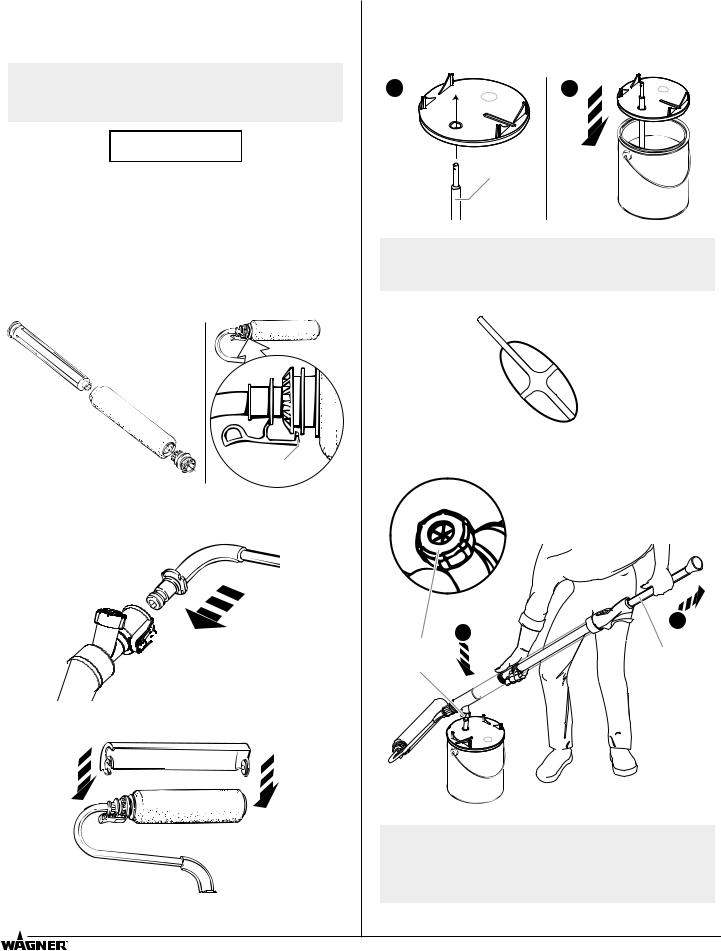

SETUP/USE • MONTAGE/UTILISATION • DISPOSICIÓN/USO :

1 |

Assemble the PaintMate™ Plus Assembler le PaintMateMC Plus Arme el PaintMate™ Plus

4

Push plunger until paint appears in roller cover

Pousser le piston jusqu’à ce que le produit commence à suinter du manchon

Empuje el émbolo hasta que aparezca pintura en el rodillo

1201 • Form No. 0284710A

FILL APPLY

APPLY

2

Set the switch to FILL

Mettre le commutateur à la position FILL Coloque el interruptor en FILL

FILL APPLY

APPLY

5

Set the switch to APPLY

Mettre le commutateur à la position APPLY Coloque el interruptor en APPLY

3

Attach cover, press fill valve onto fill tube, and pull plunger

Installer le couvercle, appuyer la soupape sure le tube de remplissage et tirer le piston

Coloque el rodillo, acople la válvula de llenado al tubo de llenado y jale el émbolo

6

Squeeze Power Trigger® and apply paint

Serrer la détente Power TriggerMD et appliquer le produit

Presione el gatillo Power Trigger® y pinte

Español Français English

BEFORE YOU BEGIN

It is a good idea to have drop cloths protecting your floors and anything else in the room that you do not want accidentally splattered with paint.

NOTE: Make sure the type of paint you use can be cleaned with either mineral spirits (for oilbased paints) or a warm water and soap solution (for latex paints).

CAUTION

CAUTION

Some oil-based paints require a stronger cleaning solution than mineral spirits and should not be used with the PaintMate® Plus. Using a cleaning solution stronger than mineral spirits may cause damage to the PaintMate® Plus. Check with your paint supplier to be sure the oil-based paint you have can be cleaned with mineral spirits.

ASSEMBLING THE PAINTMATE® PLUS

1.Assemble core, roller cover and cap. Then attach assembly to the arm, making sure the roller assembly snaps into the locking tab.

Core

Roller cover

Locking tab

Cap

2.Press the quick-release tabs on the unit and attach the arm to the handle.

Quick-release

Quick-release

tabs

3. If painting a ceiling, attach the spatter shield.

FILLING THE PAINTMATE® PLUS

1.Slide the small end of the fill tube through the hole in the can lid.

2.Attach the can lid securely to the paint can.

1 |

2 |

Fill tube

NOTE: Applying a thin coat of petroleum jelly to the end of the fill tube will help the PaintMate® Plus slide easily off the fill tube.

3. Turn the switch on the main handle to FILL.

FILL APPLY

APPLY

4.Press down and firmly hold the fill valve of the main tube onto the fill tube.

5.Pull the plunger to draw the paint into the main tube.

5 4

5 4

Fill |

Plunger |

|

valve |

||

|

NOTE: If the plunger does not move easily, twist it slightly to free it from sticking.

NOTE: Make sure to press down firmly on the main tube to make sure the PaintMate® Plus fills properly.

The Painting People™ |

English |

2 |

© 2001 Wagner Spray Tech. All rights reserved. |

|

|

|

|

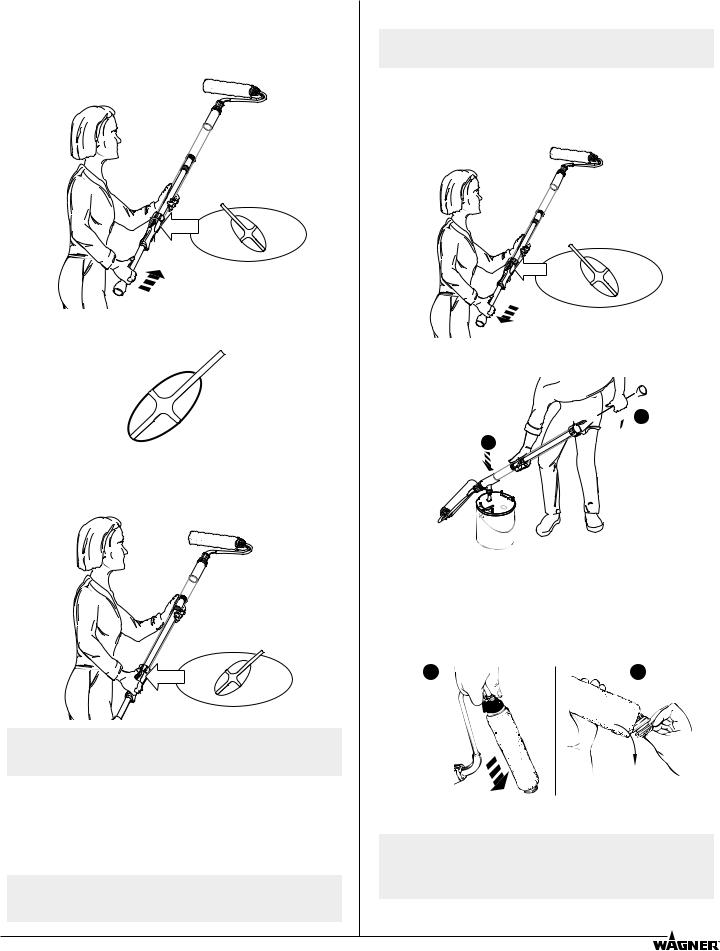

PRIMING THE ROLLER

QUICK PRIMING METHOD

1.Leave switch on FILL and push plunger tube forward until you see paint coming through the roller cover.

FILL APPLY

APPLY

2.Once paint appears, flip switch to APPLY and begin rolling. Squeeze Power Trigger® for additional paint as needed.

FILL APPLY

APPLY

OPTIONAL PRIMING METHOD

1.Move switch to APPLY, then squeeze the trigger on the main tube. It will take several squeezes of the trigger to fully saturate the roller cover.

FILL APPLY

APPLY

NOTE: When using either method, do not oversaturate the roller. An oversaturated roller will slide, drip, and spatter excessively.

APPLYING PAINT

Because priming the roller may use a lot of the paint in the main tube, you may need to refill the main tube after priming. Once paint appears through the roller cover, begin rolling. Keep paint flowing to the roller by squeezing the trigger as necessary.

Refill as necessary to complete project.

NOTE: When painting, make sure your floors and furnishings are sufficiently protected against drips or spatters.

GENERAL CLEANUP

NOTE: These steps can be followed when using oilbased and latex paints.

RETURNING EXCESS PAINT TO PAINT CAN

1.Turn the switch on the main tube handle to FILL.

2.Pull plunger back to draw remaining paint from roller arm into tube.

FILL APPLY

APPLY

3.Press fill valve of main tube onto fill tube.

4.Push plunger forward to return excess paint to can.

4

4

3

CLEANING THE ROLLER ASSEMBLY

1.Remove spatter shield. Press locking tab and remove roller cover assembly from arm.

2.Insert thumb to first knuckle, PRY and PULL the cap from the roller cover. Once the cap is removed, PUSH the roller cover out the other end.

1 |

2 |

Locking

tab

3.Place spatter shield, roller cover, cap and core in a bucket with the appropriate cleaning solution.

NOTE: Make sure your floors and furnishings are protected from dripping paint when removing or disassembling the roller assembly.

© 2001 Wagner Spray Tech. All rights reserved. |

3 |

English |

The Painting People™ |

|

|

|

|

CLEANUP FOR LATEX PAINTS

NOTE: These steps should be followed for cleanup of latex paints ONLY.

1.Remove fill tube from lid and install it into the fill valve housing. Submerge the fill tube into warm, soapy water and pull the plunger in and out a minimum of 5 times.

2.Remove the fill tube, then submerge the fill valve and the roller arm and pull the plunger in and out a minimum of 5 times.

3.Submerge the connecting area and the fill valve under warm, soapy water and pull the plunger in and out a minimum of 5 times.

4. Rinse remaining parts under a faucet and drain all excess fluid.

CLEANUP FOR OIL-BASED PAINTS

NOTE: These steps should be followed for cleanup of oil-based paints ONLY.

1. Remove fill tube from lid and install it into the fill valve housing. Submerge fill tube into a gallon can of mineral spirits and pull plunger in and out a minimum of 5 times.

2. Remove fill tube, then submerge roller arm into the same one

gallon bucket of mineral spirits, making sure that ALL of the holes in the roller arm are

submerged. Pull plunger in and out a minimum of 5 times.

3. Submerge the connecting area and valve housing under the solvent and pull the plunger in and out five a minimum of 5 times.

5. Drain all excess fluid and clean remaining parts by hand.

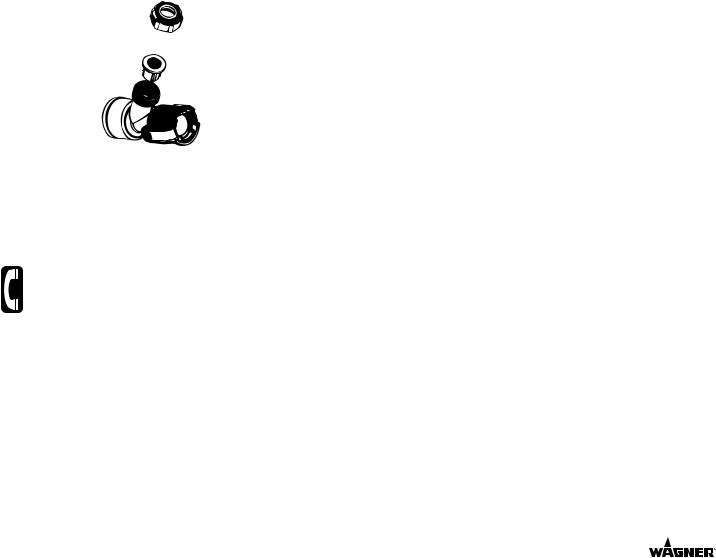

EXTENDED STORAGE

NOTE: When storing your PaintMate® Plus, make sure the fill valve is pointing downward, and never store your unit with the fill tube inserted into the fill valve.

1.Turn the locking collar next to the trigger counterclockwise until the main tube easily slides off the plunger.

Locking collar

2.Thoroughly pack a generous amount of petroleum jelly around and in between the O-rings on the plunger.

3. Reassemble the main tube and plunger.

NOTE: When putting the plunger back into the main tube, make sure the O-rings do not twist or cut.

4.Apply a thin layer of petroleum jelly to the valve housing on the main tube.

5.CLEAN and LUBRICATE the areas on the arm indicated below. Use a thin layer of petroleum jelly to lubricate the indicated areas.

Bearing areas

Seal

Seal

O-Ring

O-Ring

6. Assemble the roller arm, core, and cover.

The Painting People™ |

English |

4 |

© 2001 Wagner Spray Tech. All rights reserved. |

|

|

|

|

TROUBLESHOOTING

PROBLEM |

CAUSE |

SOLUTION |

|

There is paint leakage on the |

The seal on the arm is backwards |

Turn the seal around |

|

roller arm assembly |

The seal and cap were not properly cleaned |

Clean and properly lubricate |

|

|

|||

|

The O-ring and the connecting area were not |

Clean and properly lubricate |

|

|

cleaned properly |

|

|

|

Paint residue on connecting areas |

Clean connecting areas |

|

|

The O-rings are damaged or missing |

Replace the O-rings* |

|

|

The roller cover is worn or damaged |

Replace the roller cover* |

|

|

The core or cap is worn or damaged |

Replace the core or cap* |

|

|

The bearing areas are worn |

Call Customer Service |

|

|

|

|

|

Plunger is difficult to pull/push |

O-rings are not lubricated |

Lubricate the O-rings on the plunger |

|

|

|

|

|

The fill tube will not fill with paint |

Paint residue on fill valve components |

A) |

Insert fill tube firmly into fill valve and |

or paint leaks from fill valve |

|

|

twist fill tube several times to break up |

|

|

|

paint residue |

|

|

B) |

If the problem persists, refer to the |

|

|

|

steps below to clean the fill valve |

|

|

|

components |

|

|

|

|

Locking cap

Locking cap

Retaining disk

Retaining disk  Duckbill valve

Duckbill valve

Valve housing

Valve housing

Connecting

Connecting

area

area

1.Unscrew the locking cap on the valve housing by turning it counterclockwise.

2.Remove the retaining disk and the duckbill from the valve housing.

3.Clean these parts thoroughly using the appropriate cleaning solution.

4.Replace the duckbill valve and retainer disk.

5.Screw the locking cap on the valve housing by turning it clockwise.

* Replacement parts available by calling customer service

Have you tried the recommendations above and are still having problems? In the United States, to speak to a customer service representative, call our Customer Service at 1-763-519-3555 Monday through Friday between 8:00 AM and 4:30 PM Central time. An automated Self-Help option is also available at 1-800-328-8251, seven days a week, twenty-four hours a day.

PRODUCT REGISTRATION CARD

Send in your product registration card or register online at www.wagnerspraytech.com. Proper registration will serve as proof of purchase in the event your original receipt becomes misplaced or lost. Returning this card will expedite the processing of your warranty. Be sure you write your unit’s date code on the card before sending it. The date code is located on the Power Trigger® of your unit (for example, T087A). The additional information will also help us to develop new products that best meet your needs and desires. If you have any questions or concerns regarding your registration card, please call our registration card center at 1-303-394- 9077.

|

|

English |

|

|

© 2001 Wagner Spray Tech. All rights reserved. |

5 |

The Painting People™ |

||

|

|

|

|

|

Loading...

Loading...