Toshiba HVK-6M40A, VK-6P32A, HVK-6P40A, VK-8M40A, VK-8P40A Installation Operation & Maintenance

...

lvlav.

31, 2012 9:lSAlVl

TOSHIBA

No

1530

P,

2

Document; GF0776{'I-B

INSTRUGTION$

IilSTALLATION

.

OPEFATION

.

MAINTENANCE

Type

VK

&

HVK

Series

Vacuum

Circuit

Breakers 5-15kV

APPLICABLE TYPE FORMS

(1200A) (20004)

(30004)

VK.6M32A VK.6P32A

I.IVK.6M32A

HVK-6P32A

VK.6M4OA VK.BP4OA

HVK-6M4OA HVK'6P4OA

VK"8M4OA

VK-8P4OA VK-8O40

HVK-8M4OA HVK-8P4OA

,VK.1OM25A2

VK-1OF25A2

HVK-lOM25A2

HVK-I0P26A2

VK-10M40A VK-10P40A VK-10040

HVK-1OM4OA HVK.IOP4OA

vK-6M50

vK-6P50 VK-6050

vK-10M50 VK-10P50 VK-10()50

NOTES:

t) The

designation of

H

before

vK

(i€.

HVKI

dsnot€s that the circuit braaker unit

was assembled

in the USA using domestic

and

foreigri

components.

All

'

relErgnces to modal numbere in thie manual will

be by the numbets following

the VK- and

HVK-.

2l Thi! manuel waB writtan

lor tha Toshiba typ€ form circuit

brsakers listed on

thi$

page

used in coniunction

with Toshiba

cells.

For

circuit

brsek6rs

utilized in

the convereion

of

othsr

equipment, a supplemental

i struction manu8l Should

be obEain6d

from lhe conversion manufacturer.

lssued 2/95.

Supemedee GF077401-A Deted 12194.

N4av.

31 2012

9: l5AlVl

t0, )tu

r,

1

INTRODUCTION

Page i

READ THIS MANUAL carefully

for imponant information about

safety, handling,

installation,

operation,

maintenrnce, and

parts

replacements for

spring-operation-type.

VK

and

HVK

series

vacuum

circuit breake6.

This manual

and all accompanying

drawhg$ should

b6 consid€r€d a

pgrmanent paft

of the equlpmgnt.

They should

be

readily

available

for /eview

and

reference

at all timos.

DIMENSIONS

shown in th€ manual are

metric and/or their 1,.S. equivalgnt.

INOUIRIES

should be addressed to;

Field

$ervice

Department

Toshiba lnternational Corporation

13.l31

West Littls York Road

Houston, Texas 77041

USA

Telephone:

1713't

466"0277

(800)

231-1412

(800)

527-12O4

(Cenada)

Fax:

|'7131

466"8773

ll[ffiFiliilC-l

uaa only Torhtba-authodzad

rBptacamont

padr.

nWiF-MiEl

tiris

equipment

is

de3igned and buitt

in

accordance

with

opptioable

sttetl

etandqrds

in 6l{sct on ttle date of manutactu.c. Unautho.hed

modElcadonr wlll

vold wattalty

and cEn ra:uh ln rwera lnJury, daath and

propsrty

dnmag6, Do not

mak6 nny moditicadons to

thi8

ecpipmefi without

tho

written

tpproval of

Toshiba.

6

TOSHIBA INTEFNATIONAL

CORPORATION,

1 995

t!1ay.31.2012

9:15Att1

No.

1510

P,

4

TABLE OF CONTENTS

Page ii

SAFETY

RECEIVING,STORAGEANDHANDLING

,........,,4

Receiving and Unpacking

.........4

Acc€pl6nca lnspection

,...4

Lifting for Handling and Moving

" "

'

5

Stotage,

..'.". t,

lnspection During Stolage

........-

6

GENERALDESCRIPTION

.,..,...7

gafety

Deviceg

........' I

lnterlock Lever , ,

........9

Sell Coupling Type Secondary

(Csntrol

Circuit)

Disconngcts

, .

'

. . 10

INSTALLATION

.,...,

11

Service Conditions

....

..'...... 11

Bating..

...... 11

Lifting tor lnstellation

',.'

13

Using the

Portable Lifter

...'.'.'. 13

Moving the Circuit Breaker in the Cell

.-.....15

PRE-ENERGIZATION

CHECK

..,, 18

General ,

.. ... .

18

Elactrical Checks .

...... t8

oPERATtoN

..,,"..,

19

Manual Operation.....

.'..'.". 19

Electrical Op€ration

.

'

... 20

Controf Ckcult

Oparation

..,.

'., , '

ZO

Closing Sequence.....

..'.20

Charging Sequence

'.......20

Tripping

(Oponing)

Saquanca

....."' 20

Mechanism Operation

....25

Closing .

,.......

25

Charging

.......' 25

Tripping ,

.......

25

Trip Frae

.""...25

MAINTENANCE

...,,, 26

Maintenance Progtam

.... 26

Maintgnanca R€cord

,

.,"

26

Servioing

Equipment

..... ?7

lnspaction

and Maintenance

Type3..

'..'.'.2e

lnspgction and

Mainlenanc€

lnterv8ls

'.

', ',.

30

Wipe Measutement

...

......

'..

36

Vacuum

Chack

,

..-...'

37

Troubleshoothg Guidelines

.,"".41

Replacement of

Parts .

... 44

Auxiliary Switch,

"'.'....45

Closing Coil

and Trip Coil

,

..

....

' ' '

47

Control Citcuit

Board .

..'..4S

Control Circuit Board Fuse

'."'

. . .. .

51

Feplacement

Pans List

...

53

CoNVERS|ONS

.

^....

54

WARBANTYandLIMITATIONOFLIABILITY

..'..'' 57

tvlav

31

2012 9:

l5Al!1

[1o

1530

P5

SAFETY

Page

1

IITJIPO

RTAI{T MESSAG

ES

R€ad

thls manual and follow

lt3 Instruotlons.

Signal

words

such as DANGER'

WAFNING

enrf CAUTION

will bB lollowsd

by imponam

safety information

that

must be catafullv

reviewed.

lndjcates a

situation which

will tesult

in

death,

serious iniury,

and

s€vsrB

propeny

damage

if

you

do

not follow

instructions'

|[mmiilG"l

M66n3 that

you

might be seriouslv

iniured

or

killod

if

you

do

not lollow

r-:'-J

instructions, S€vste

property

demage

tflight

also

occur.

A CAlmOil

: Mean3

that

you

might be

injured if

vou

do

not follow

instructions.

Equipment

damage

might elso occur.

NOTE:

Gives

you

nelpful

informallon'

SAFETY

CODE$

Comply

with all applicable

state and

local codes' Unless $upsrssdad

by etate and

local

codei, adhere

to all appliceble

ANSI, OSHA, IEEE,

NEMA and

National

Eteclrical

Cods

{NFPA

70) and'Maintenance

ProcEdures

in NFPA 708

standarde.

This includes sl6ndards

penalnlng

to

the manufaetu.e,

a88embly, installation,

grounding,

maintananca, conversion,

lating and ope€tion

of:

1

)

Metehclad switchgear

2) Power swltchge8r

3) MetaFclad

snd stEtion

typg cubiclE switchgsar

4) AC hiqh voltagB

circuit braakers

llav.

3I 2012

0,

15AM

No. 1530

P6

Page 2

SAFETY

READ ALL SAFETY SIGNS

Safety

slgns are

placed

on ths circuit

breaker

for

your

safety

and imtruction.

BeEd and follow tha

instructions in this

manual

and on tho safety

signs locatod

on rhe equipment.

Keep

the sefsty

sign viaible

and in

good

shape,

Never removg, damag6, or covat

any

safety sign.

ElDltagr|rtnfilrlclElrltr

ictllim.

eemre

orlanrrr

lta

E[Et

H^TNHEH'IE

r ArN.irfit'

m,tla

tFGaHtE

. tt clal tFq-llll

i-HirdE

. DEEdtgqt

trLrd

arqrc(ilt* Hlf,ln*f

a

irll

trdrlecEtd

hrb

. ffi lrrildr,iq

ntt

!.ltffilr

*flm

rrrlt

r[ ffiEF]a

!!

cltlrdhLilriFtLE

. btuhht!5ttrttll

dy-tCrttlUEl*'E

trf

rrE t&r'ClUfiFa

'd.aEr,

.

orF

tFtt cF#tbr

tdfr

FEAD tt€tnrJdflol{

t&lluAl BEFoRE ATTElptlE

THE

FoUOlltttt

pfiQOEltJfiES

uAr{rAl oFEE

s PmcEDt'Ae

To $lA*E

stf,Negl n

.g chlrliE f5t*

toqrl cevst

crd hE

(t1.

ii!

;htd. bro Soqbr

OF..fte.

BtEa

-l}

t& tlF fd

Dcttt

unfl a cH b tLtlll

erd sEtla

rr&or R.le ofiAndD

g.lqr).

Rd€ ldt{e

Fdt r'

ilttHr

l5t rtd

R€tbat 8o.ld

Csnr'

1rO.La!!FSREAIGRT

Fllhdlrat,(!

G eJfllll

Ctqi Es'b.lre

\irf, Tllql

R€rd

ctoeED

(is0

{td OlSCt{AffiED

0rn'}

7o OPB{ BRE

xE t h.lr

A. TflrP

gJftSL

Ch * hdr..li*dor

lr

Thrl h

@sl

(Glifit

rd ol8C+lrhOED

$nr.!

lfiftE

fhe Folci'rn C||t

R€sa

h Ef,+trsr Olttqg.

o.dgidl

*

rlE cLodta

gt

tTct{

lllfi 1'lr€ drEi

Er*. clllg4r'

aj-r!+*n Oa

The

cr.CElcc BUTllll

Yflt llro wTEH.rffi

lE\rEB Br*rr

D.i.doi Cl Tlta

dr6

E

gufltil

!\{l

lltelilP Jtlofi

D'F t'c5'

NsnLLAfn chElaol/^l.j

ITFEATOB t{$i FFd

OtSfi

RaED

(!lt{t}

Atld OpBl

GlE€o)

8.aort

lttc

gr*.

Cfi tf mH

lllo cjr Fentle<t

lErnn Tll. Ocl

(ffi).

N4av.

3I 2012

9: l5AlV

No

1530

P,

1

gAFETY

Page

3

OUALIFIED

OPERATORS

OilLY

only

quslified

persons

are to

lnstall, op€rate

or service

this €qulpmefi

accordjng

to all

applicabls

codes and established

safgty

practic6s.

A

quallfle

d

person

must:

1

)

Getelully

tead th6 entlte

iGtruction

tnanual.

2) Be $killed

in the

installation, construction

or opgration

of the Equipment

and awa/e Ol

the hazards involved.

3l

Be lrainad

and suthorized to $sf€ly

energizB,

de-enetgize,

clear,

ground,

lockout

8nd

tag circuits

ln accordEnce

wilh estSbli$hed

sefsty

practice.

4) Be trained ahd

Suthorized

to

parform

the service,

maiftenancs or

rspair of this

aquipment.

5)

Be

trained

in the

proper

care

and use of

protectiva

equipment

such as

rubber

glove$,

hsrd hat, safety

glassos,

face shield'

flash clothing, etc.

in

accordance

with

astabllshBd

practlces.

6)

Bp

tr9ln6d

in rendering

first aid.

Nlav

31. 2012 9:15AN4

No.

1530

P.

I

Page 4

RECEIVING, HANDLING

AND $TORAGE

RECEIVIIIo AND UIUPACKING

The

clrcuh breqker

unite

are aubjected to

fEctory

production

testlng

prlor

to

being

packed

and shipped.

ACCSPTAilCE IiI$PECNON

Confirm that

the

circuil breake, unit

is

oompleta,

conect as :pecified and undamaged

trom shipment 6nd

handling.

Upon

recelpt

of the

equipmBnt, do the

following:

1) Make

an

lmm€diat€ ircpeclion

for damag€

which miotx

have

occurred

durlng

Ehipment

(Fig.

1

).

lf

damage

is

discove.ed,

it

should

be notad with th€ carrier

prior

to

accepting

the

shipment

if

p+asibla.

2)

Carelully

unpack tha aquipmant sufficiently

to cheok

for missing

pens

or concealed

damage-

3l Keep the equipmefi

upright

(Flg.

2).

A

CAltflOil

r ltl.vat

hy th6

esripmam on lia

elde or upslde dwn. Tlf$

may

cause

equhmrm

drmrge to occur.

4) File

a

claim with the

csrrier

for

$ny

damaggd

or missing itsms €nd immediately

notily the

neaiest Toshlbe lnternational

Corporation representative.

IZffil

oo nor i6ral or en€rllze

eqrlpmEnt trat

has

bcan *rflagsd.

Drmegod

iquipmilt can fdl drdng operadon, tctultidg

in fire snd

exploEion.

5) lf the cucuit

braikor

haa

baen

utilized

for

rhe conveFion of olher equipmert, see the

CONVERSIONS

S6etion ot this manual.

Cofifirm th€t

yo{lr

conver8ion

msnufecturer

is in compliance with

thi$ section.

Flg. t lnspedl for Damaga

Fi!. Z Thb Circuit Brdsk8r Bhould

Uprighr

kept

llav.31

2012

9:16AM

No

1530

P9

RECEIVING,

HANDLING

AND STORAGE

Page 5

LIFTINd

FOR HANDLING

AND MOVING

When

handllng

and

movlng

the

circuit braskdr,

rhe suspension

technlques shown

ln this

saction

may b6 used. When installing

or

removing

th6 circuit braaker

from the csll

above

floor

level, refer

to the

"Lifting For

I nstaltation"

instructions

id the

I N$TALLATIO

N

Sgction

of thie mpnual,

ffmnlGl Do nor atbmpr instattation

of

the clrouit bteaker

above

floot leyel u3ing the

lifting

m€thod8 d€scdbed

ln thls section.

Alway$ u$e

e Tolhibe

Portsbla Llfter

for

lnstalladon,

Care and

csution

should ba

usad when

handling

the circuit

breaker units

to avoid

damage to tha aquipment

and

personal

injury.

Always

keep the circuit bf€aker

in e

genBrally

upright

position.

ACAUflON

!

when

littlng,

the oircuit

breekar

vvlll tllt rllghtly backwards.

Stand clear

of

the bteake.

whon

lifting or

you

may be

inlured,

Always use

lifting

equipmant

suilable for

handling ths weight of the

unit.

The

capability

of the

llfting equipment to

handle the size and

weight

of the ciicuit

br6aker should

be

confirmed

prior

to lifting,

A

CAlmON

I

Attempting

to

menually lift

the

circull bruakar

csn caure ledous injury

or

equiprro

t damtge.

Alwey: u:a

eultoHe llftlng

equJpmerTt,

FlE.

3

Lifting

the Cirouit

Hooks.

Breaker

with Lifting

Fig. 4 Circuit

Br6ehsr Tihing Beckward

whils

Lifting.

WHEN

LIFTING:

6M32A

6P32A

6M4OA

6P4OA

8M4OA

8P4OA

10M25A2

10P25A2

10M40A

10P40A

Lift ihe

circuit breaker as

shown

ih Fig. 3 end

Fig. 4.

li1av

31 2012 9:

l6AlVl

Itlo,

1 13 0

P

t0

WHEN LIFTING:

6M50

6P50

6050

8040

Lift the circuil

breaker

as shown in

Fig. 5.

The

circuit

braak€r

ha,B a eet of

lifting

plates

as accessories.

Ufting

pletes

must be

removed before

atterfiptlng

to lnstall into c6ll.

WHEN LIFTING FOR

INSTALLATION:

The VK & HVK Gircuit Breaker

Types listed ln

thi$

manual

us€ the

procedure

described

in the

INSTALLATION

section-

STORAGE

lf the

circuit breaker

is

to be

stored

lor any

length of

timB

prior

to installation,

the

following

precautiotar

should

be taken:

The original

packing

should be

restor€d, lf

possibl6.

Do

not

subject

th€

€quipmBnt

to moisturB

or aun

rays. srote in oool,

cl6an, and dry

locetlon.

Place a dust cover over

the circuit

br€ak6r

packaging

to

prot€ct

against dift

and

moisture.

$tote

in an upright

Position.

INSPECTION

OURING STORAGE

Rouine

scheduled

inspection ls nec6s34ry

if

storage

iE lor En extended

period.

The

dlit

should b€ checked

for condensation,

moi$ure,

cottogion,

and vermin,

ftior to instEllation,

the circuit breaker

should

be crrefully

6xamined

lor ovidence of

phy$ical

damage. cotto$ion,

or othsr

doteaioration.

Hof6r

to thc PRE-ENERGIZATION

ssctlon of

this

menual.

The MAINTENANCE

sEction of this

manual

describes

vatious typ$

of

impsc.tiong

recommsndsd

for this

circuit breaksr

durlng

the

operstlon

P€riod.

REGEIVING,

HANDLING

AND

STOHAGE

t

1

10040

10M50

10P50

roo50

NOTE:

Fig. 5

Lifting Circuit

Plat68,

with Lifting

1)

2t

3)

4)

Fig, e

Circuir

Breekef

S$.ag€

lvlav.

31 2012

9: 16AM

No

1530

P.

tl

GENERAL

DESCRIPTION

Page 7

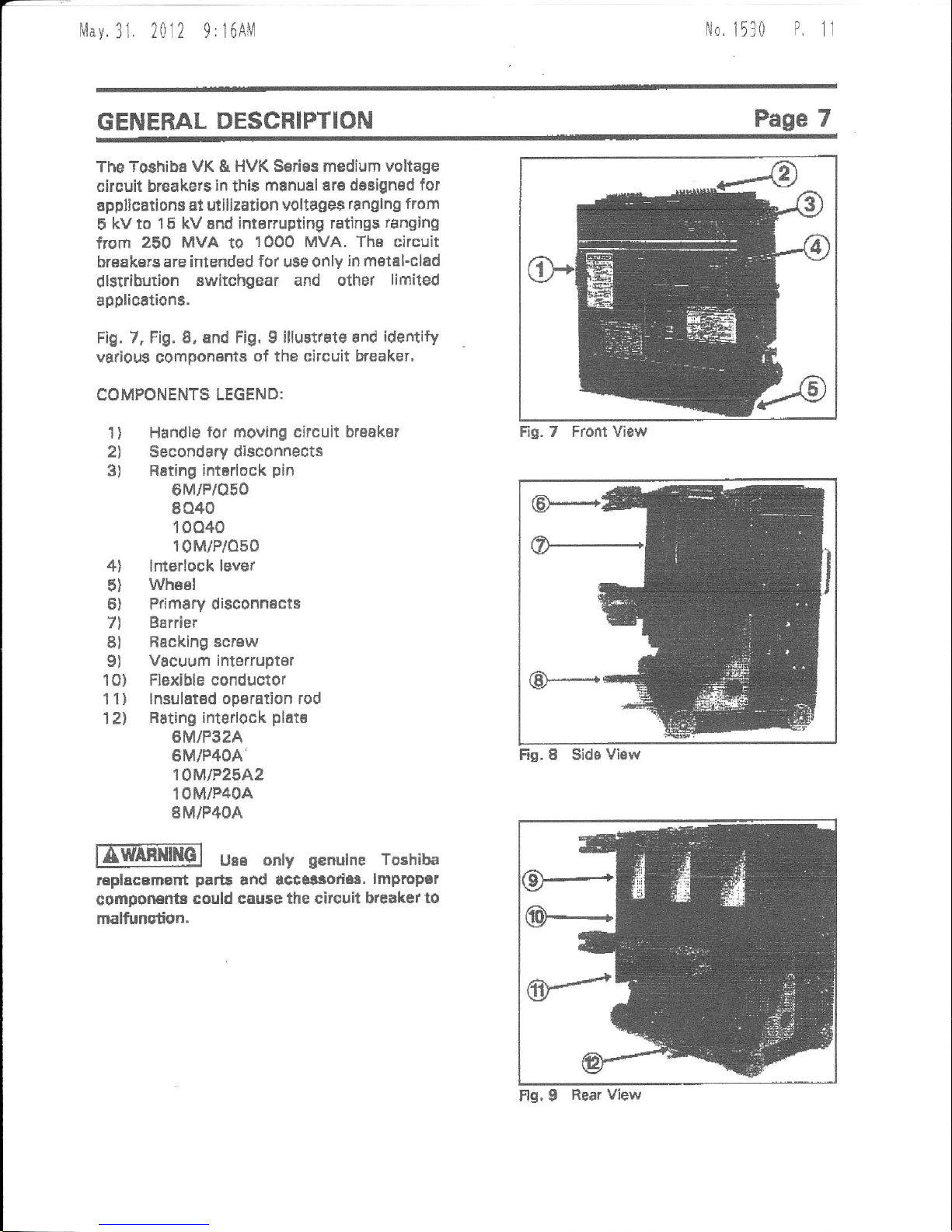

The Toshiba

VK

&

HVK Serias medium voltage

circuit breakers

in

thi6

manuel are dasigned

for

applica offi at utilization

voltages

ranglno from

5

kv to 15 kV and intorrupting ratings

ranging

from

250 MvA

to

1000 MVA. The circuit

breakarg are inlended

for

use only

in metal-clad

dlstriburion

switchgear and other

lifitited

applicttions.

Fig. 7, Fig. 8, and Fig,

g

illust.ate and

identify

various component8

of the circuit b'eaker,

COMPONENTS

LEGEND:

1

)

Handle

lor moving circuit breakar

2l Secondary disconnects

3) Rsting

intBrlock

pin

0M/P/oF0

8040

10040

10M/P/o50

4l lnterlock lever

5)

Whssl

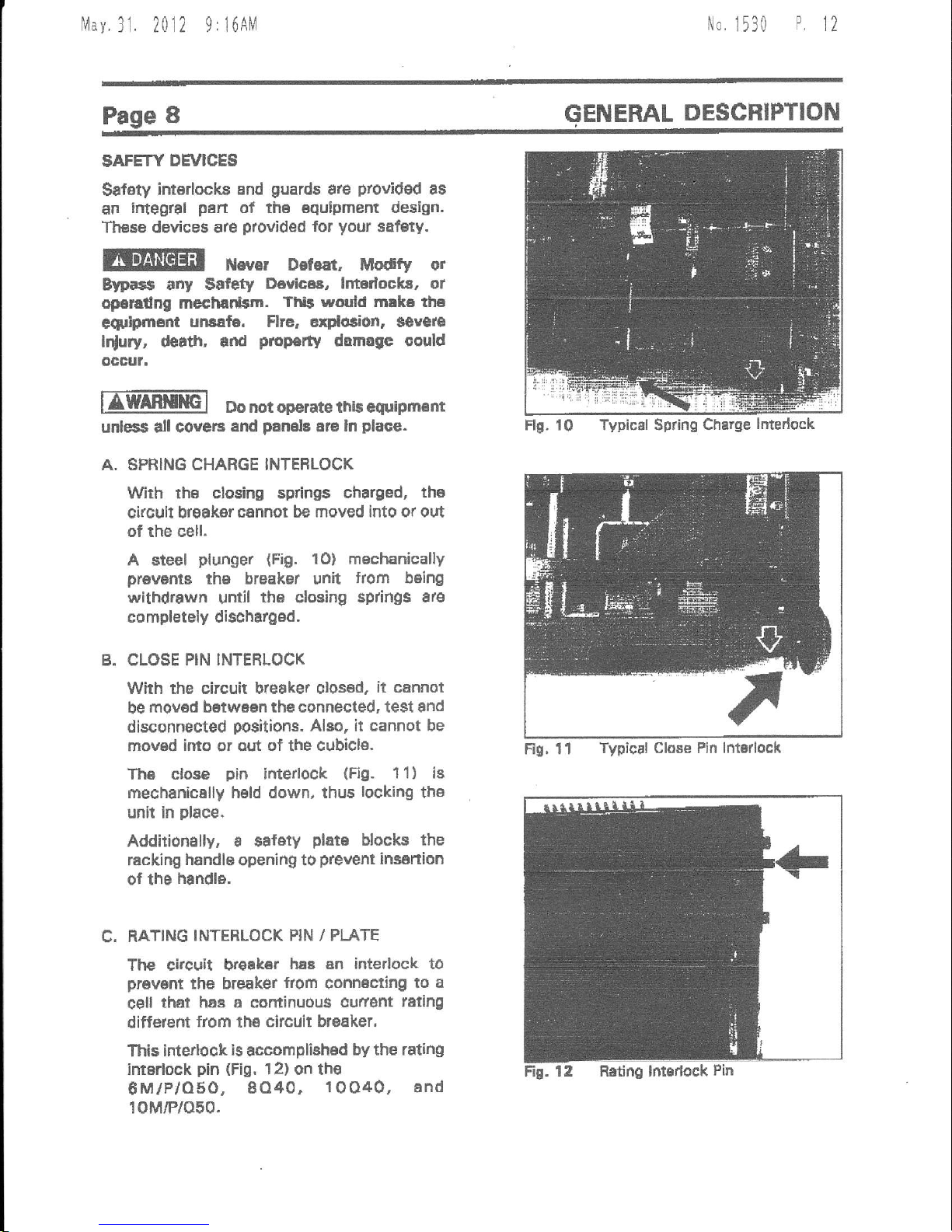

6) Primary disconnscts

7l

Barrier

Bl

Rscking scrsw

9)

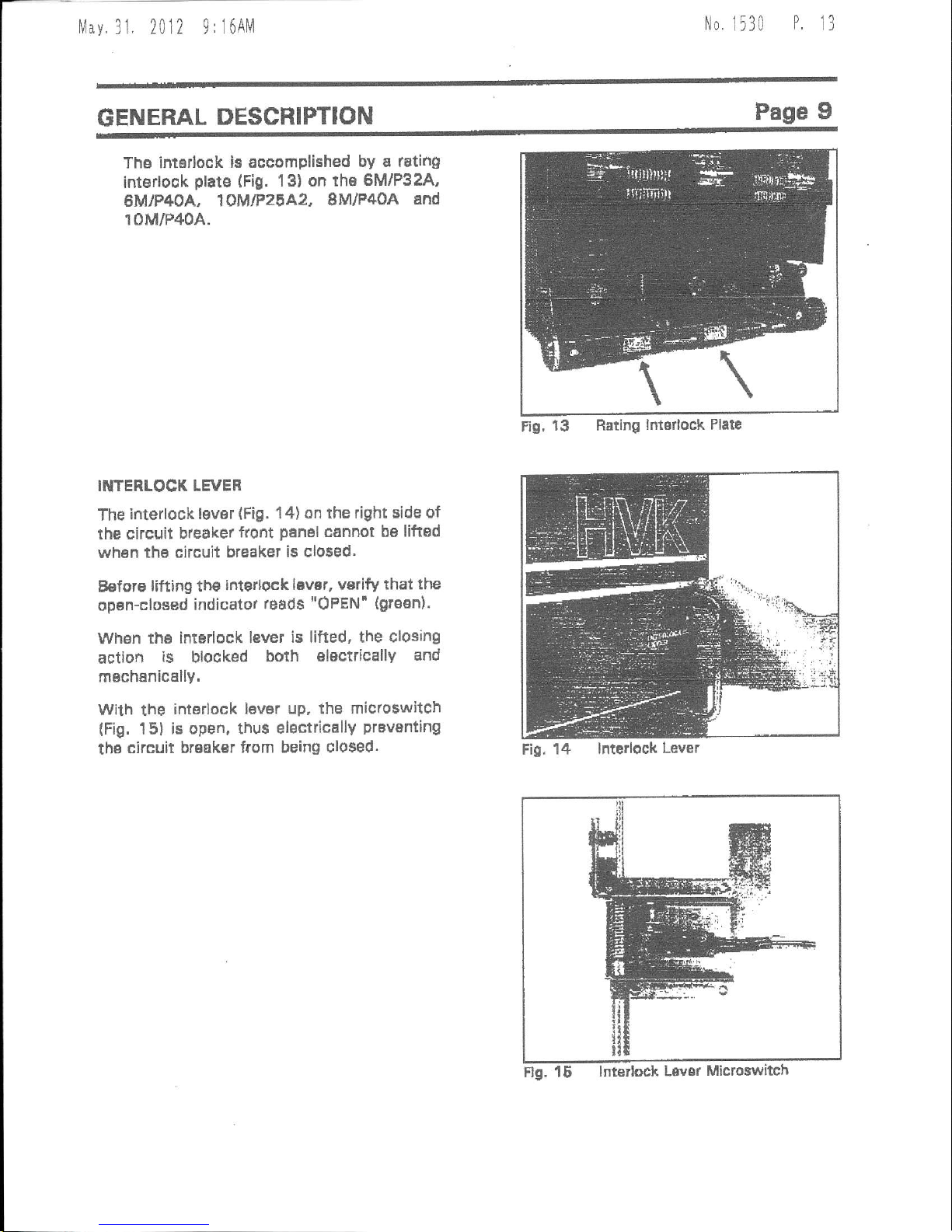

Vacuum interrupter

1O)

Flexible conductor

11) lnsulatsd

opsration rod

1Zl

Bating interlock

plat€

6M/P32A

6M/P4OA'

10M|P25A2

10M/P40A

8M/P4OA

UBE only

g€nulne

Toshiba

replacBm€nt

parE

and accatsod68.

lmproP€r

componEl'tr

could cauee the citcuit breaker

to

malfunction.

Fis. 8 Sids

View

Fio.

7 Front Viaw

Fls, I

Rear View

Mav.31

2012 9rl6AM

No,

1530

P.

12

SAFETY

DEI/ICES

Sat61y

inr€rlockg and

guards

sre

provid€d

as

an

iftegr8l

pen

ol th€ €quipment deslgn.

These devices are

provided

for

your

BafBty.

Never Defeat, Modfy or

Bypa*

any Satety

El6vlc53,

lmerloeks. or

operadng mechanfim.

Ttrt world

make

the

enripment

unsati. Flre. erploCon,

gevere

Ir{ury,

death, and

propafi

damage could

occul,

nml

Do not o'€rate th* equipm€nt

unle$s all soverE

and

panelr

sr€ ln

place-

A. SPRING CHARGE INTEFLOCK

With the clesing springs

charged,

tha

circuft break€r

cannot be moved into or out

of the cell.

A steel

plunger

{Fig.

10} mechanically

prawms

th€

breakel unit

from being

withdrawn

until

thB

closing

sp ngs 8re

completely dischargod.

B. CLOSE

PIN INTERLOCK

With the circuit bteaker olosed,

it cannot

be

mov6d betwaen the connected, test and

disconnected

positiorc.

Alao, it cannot be

mov6d

into

or aut of the

cubicl6.

Th6 close

pin

ifiterlock

(Fig.

1 1

)

is

mechanically held down, thus

locking

the

unit in

place.

Addition€lly, a salety

plats

blocks the

racking handle opening to

prevent

insartion

0f

the

handle.

C. RATING

INTERLOCK PIN / PI-ATE

The citcuit H€ak€r

hsB sn interlock to

prevsnt

the breaker

fiom

conn6cting

to a

c€ll

that hae a cominuous

cufierrt

reling

difterent

from

the

circuit br6aker,

This intertock

is

accomplished

by the rating

intarlock

pin

(Fig,

l2) on the

8M/P/O50,

8O40.

1OO40, and

10M/P/O50.

ENERAL

DESCFIPTION

Rs, 11

Typical Close Pin lntorlock

Flg. 10 TypicNl Spring

Charge

lntedock

Mav.31,

2012

9:i6AM

No,

1530

P

t3

GENERAL

DESCRIPTION

Page

9

Ths intddock

ie accomplished

by a rating

interlook

plats

(Fig.

1 3) on the

6MlP32A,

eMlP4OA,

19MtP2gA2,

8M/P40A

and

10M/P40A.

INTENLOCK LEVER

The

interlock

lever

(Fig.

'14)

on the right side

of

the circuit

bleaker

front

panal

cannot be liftad

wh6n

thB circuit breaket

is clo$ed.

Belore

lifting th€

interlock lBvsr, vsrify

that the

opan-closed

indicator

reads

"OPEN'

(grosn).

when

tho interlock lever

is lifted, the

closing

action

is

blocked

boih

electrically

and

rnsch6nically.

wilh

the

interlock

lever up. the micloswitch

(Fig,

151 is

open, thus electricallY

prevsnting

the

circuit brsak€r from

being closed.

Fig,

13 Rating

lntorlock Plate

Fig,

14 lnterlock

Lever

f/av

31. 2012 9:17Ah1

No,

1530

P.

14

Page

1O

GENERAL

DESCRIPTION

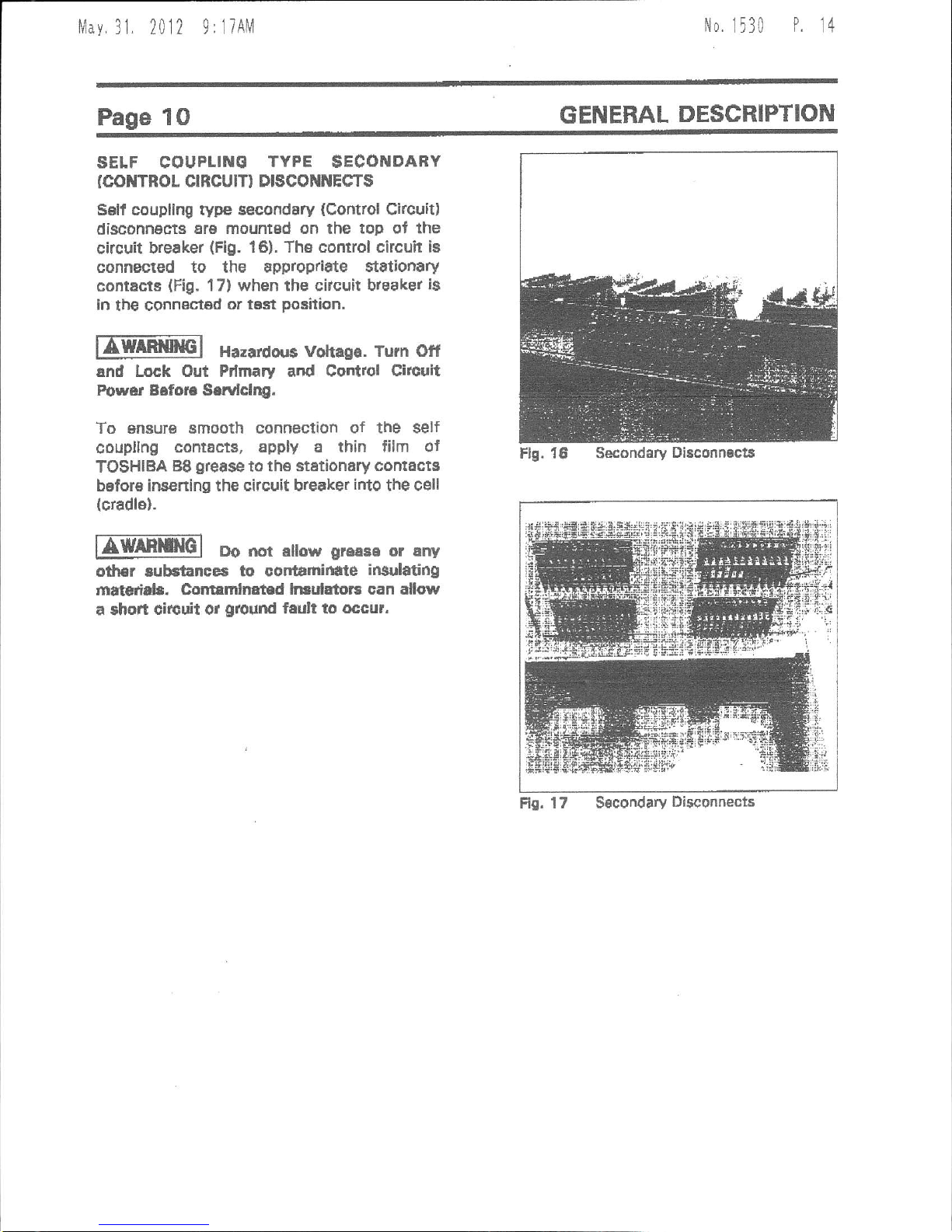

SELF COUPLINE

TYPE

$ECONDAEY

(col{TRor

crRcurr) DrscoililEcT$

Sslt coupllng

rype

secondary

(Control

Cl.cult)

disconnects

Er6 mountsd on the top of the

circuit breaker

(Fig.

16).

The comrol circuh ia

connected to the approp/idte $t8tionary

contacts

{Fig.

17} when the citcuit breake.

is

ln

tbe

connestsd

or t6st

position.

fA-l

Hazardorr6 votraga,

Turn otf

and Lock Out Pdmary and Control Circuit

Power B6for€ Sarvlclqg.

To snsur€ smooth connection

of the self

coupllng

contact8, apply a thin film ol

TOSHIBA

B8

grease

to

th€ stationary

cornacts

before insening the

circuit breaker

irto

the cell

(cradle).

nWAf,rcl

Do mt alow

greese

or any

od|3r aubstanccs to cortamid

te

insulating

mNtcriab. Colrtrmlnat

d ln ulatots can allow

a shon

circuit or

ground

fadt to occur.

Fr0.

17

Secondary

Disconnecis

Flg. 16 Secondary

Di8conn€ct8

lvlay.

31, 2012

9:lTAlVl

No

1530

P.

1t

INSTALLATION

Page

11

SERVICE

CONDITTOilS

EWAEtlilG-l

Do nqt ini1pll

rhis

aquipm.m

in areas

where unurual

serviae condition$

erist.

Using thiE €quipm€nt

ln othsr than uaual

aervlce

condffod$ can

relult in squipm€nt

fallura,

Toshibs

VK

&

HVK

$eri€s

Circuit Brsak€rt ara

intended

for

use

in u6ual servioe

conditions as

dellndd

by ANSI. The

temperatule of the air

(arfibient

air temp6raturs)

surrounding

the

Ewitchgear

should be

between the

limits of

-3OoC

l.22oF)

snd +4OoC

(104oF),

The

altitude of the equipffient

instsllation should

nor exceed

3300 ft

{100o

m},

IUOTE;

Temperature,

ehitutle ot othar

conditions outside

of the usual

limitt

may raquire derating

or other special

equiPment.

Contact ToEhiba

lntsrnational CorPoration

for

additional lntormstion.

RATIIVG

Prior

to

ln$tallation:

The

maximum fault curredt

capaoily

ol tho

powsr

sy3t6m

at thB

point

of

installstion

should be

verified. This

valug must not exceed

ths symmetrical

interruptino eapability

ot the

circult

bteaker.

Fig. 18 illuetrEtes

a typical

circuit breaket

nameplatg

and

ratings.

Do not exceed

the

tati

ga

$pecified

on

fi6 circult

braak€r nameplate

ot

aystem acces5orie5.

undefrated

equipment

can

fail

durlng oparallon caudng

flre, erploaion,

sgvgrg

inju

. d6rth,

ind

proP.dy

damagc,

To calculat€ .th€

required Symmetrical

lnterrupti

g

Capability.

usatheformula

in Note

4 and 5

of Table 1, All system

accss9origs

Buch as surge supprasaors,

lightning arlestols,

etc, should

be checked

to

varify thsir ratingi

capacity.

Flg. 18 Typical

Ciacuit Br3aker

Nsmsplac

1,,1av.31.

2012 9:17AM

N0.

1530

P

16

Idofiificdidr

RddVdlr

::;..itH6l

it:iji6flil;&l

i"i;6,1.{iri:

|-., i..i i:lc

.3frNt

ltl.i irE8li.i

"t:i

'.

Er!

r!t5! r

+.r'ri ,

r}'

H

f,..!H

V*{t

0t

!.Yl

tldt

3tln

{xv t

r4ahg

tffi)

r#*

r,iri{

Dty, V

!E

6a.d

Htr-

E

{rYl

t2f

Y*rt

nrrF

t

cat'

ht

\'hrg

tsr

lhr

rl

€oll

{At

ESA

Atrr

*sln

ht}rg

la

lls.

rvt

lrat

t4)'

F4ruy

VB

lvl

AIE2A

6Fil2A

4.16

!t.16

2SO

150

1,76

4.78

't.24

1,21

l9

to

60

m

1200

zxxt

29

za

I

3 2

E.a6

s,gt

3lt

3A

a0 6E

5A

al,tloA {rf

6goa

of

4.lE

!t.t6

s60

950

\7d

d76

t-d

I

O

te

IE

60

@

l roo

zu)

,t1

3

2

2

4.78

1.',1c

4t

4l

41

+1

SB

6E

Etfio

6F60

6(rc

4,16

4.16

ILI

E

Ito

360

361)

47',

+76

4.ta

l-lr

t.t3

t0

19

19

60

60

c0

t tod

20@

3000

tll

4t

4t

I

I

s

,

z

2

lto

a.o

40

43

att

49

49

a0

4S

7t

7t

7e

Ar,lbA

I'IIOA

80,to

tlf

7,4

7.2

300

6('0

500

d.:5

a.r3

a,z5

l.r5

LB

t.lE

36

3t

IE

95

tt

SE

I400

20s

gooo

33

t3

3

a

s

2

2

2

4.6

6,6

6,8

41

4i

a1

41

d6

66

6A

I6MfiA'

tot:lt l 13.4

500

5m

t6

l5

t

-30

tJo

36

t!

gE

s

I uao

zn

16

IE

3

s 7

I t.5

l t,3

,3

23

tt

t3

a7

t7

toM{an

't{tFttoa

roq40

tll'

1C.E

I

s.a

l3.a

750

7A

7

IE

ll

IE

t.ao

1.30

t

-so

a8

36

3t

6

t5

t6

1200

:000

3000

2A

28

2E

3

3

2 11.5

36

t6

86

3g

36

36

5S

EA

6E

roP4oA fil

lmto fl r

l!-6

13.8

1066

100(l

t3

IE

t.0

t-0

3C

36

t5

s

2o0o

3000

B7

37

a 2

1E

15

37

g7

l7

6A

F9

lotFo

totto

iooEo

19.t

13,t

t3,8

t 000

looo

1000

16

t5

l5

!

-lo

l,$

1.30

36

3!

36

s

E6

1206

2l'qt

30m

s7

g7

3

I

3

2

2

i t,5

I 1,5

116

49

.t6

4E

4{

*0

46

't7

77

17

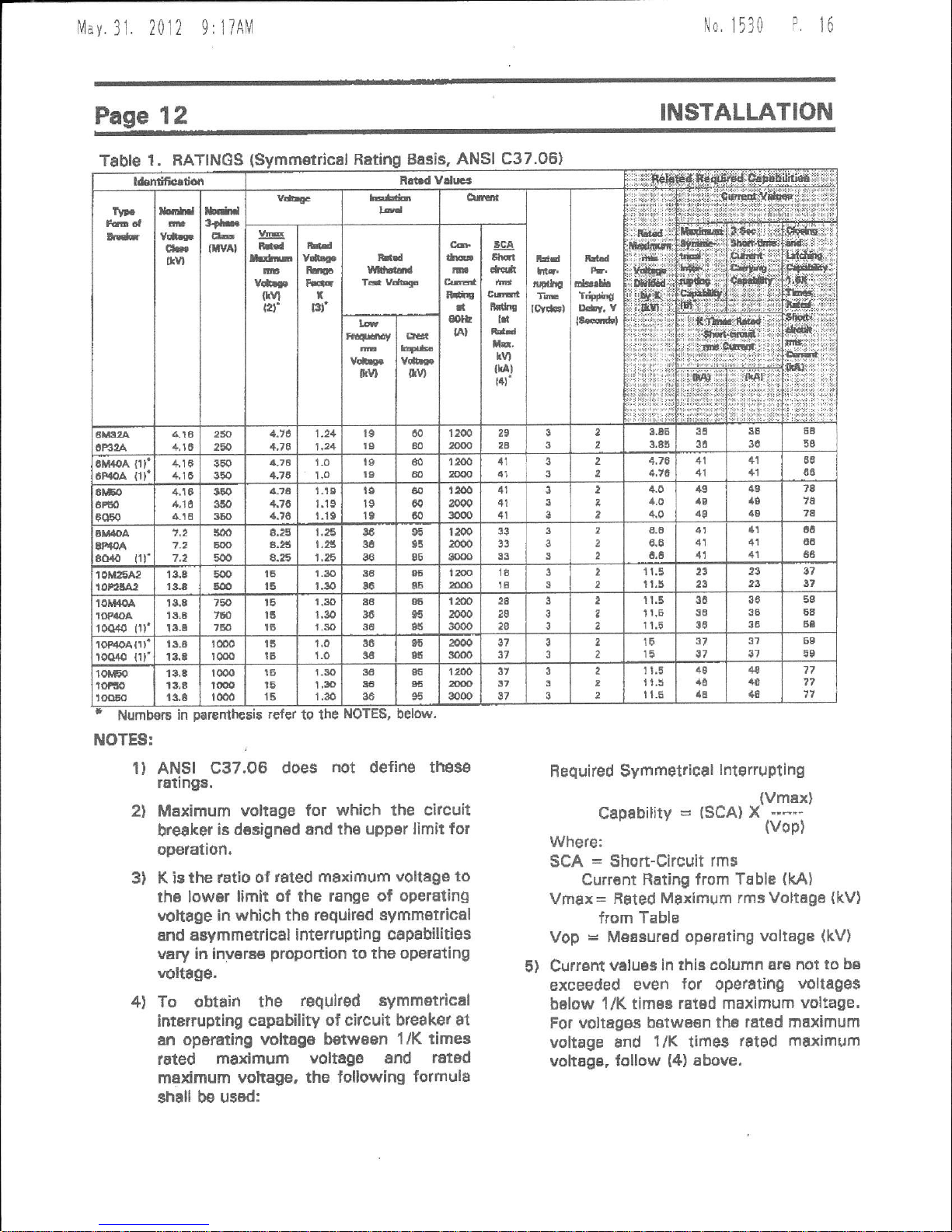

Table

1 . RATINGS

Numbol6

ITIOTES:

Basis,

ANSI C37.06)

r€fer

to the

r)

2l

3)

ANSI C37.OB

does

not

define

thes€

r6tings.

MEximum voltage

for which lhe circuit

breaker

i6 d€signed and th6

upper limit for

operation.

K ic

the

latio

of

rSted maximum

vollage to

th6 lowar limit

of the range ot

opetating

vohage

in which tha roguir€d

symm€trical

and asymmefiical

interrupting cap8bilitiss

vary in inv€rs€

proportion

to the oper€ting

voltSge.

To obtain the

requked symmetrical

interrupting capability

of citcuit breaker

at

an

operEting voltsga betwsBn

1/K times

Irted

m€ximum

voltage

snd

ratad

maximum vohage,

the tollowing formulS

shall be

usBd:

Required Symmetrical

lfierruptlng

(vmex)

Capability=(SCA)X*-*

(vop)

where:

SCA = Short-Circuit

rms

Currant

Rating from

Table

(kAl

Vmax=

Faled

Maximum rms Voltega

{kV}

from Table

Vop

=

Measured

operating

voltage

(kV)

5) Crlrrsnt

veluas in thb column

are not to

be

excEeded even

{or

operatihg

voltages

below

1/K tim6s

rated maximum voltage'

For voltages bstwBsn

the ratad maximum

voltage

8nd

l/K

times

rated maximum

voltage, lollow

{4)

above,

4)

Nlav

31. 2012 9:liAM

No.

1530

P

17

INSTALLATION

Page 13

LIFTING FOF INSTALLATIOil

lJnlika the

lifting

procedures

recommended

in

the

FECEIVING,

STORAGE AND HANDLING

section,

Lifting

for lnstallation

pulposas

raquires a different technique,

A Portablg

liftdr ss shown ln Fig. 19 should ba

used

for lhe insettion ot

removal

of a clrcuit

br€ak6r to th6 switchgear

compartment above

floor level,

Ths

ponable

lifter may also

be used to

trtnsport

ths circuit brsakar to 6nd

from th€

switchgear.

EWffiMt{6]

Do not

attempt to

irstar

ot

remova

a circult

breaker abova floor level

from

a

compartmefit by uting th6

lifting 6y68 or

plater,

Ure a To5hlba

portable

lifter,

lIffiEl

Dbcharge sprtngs

compt€rcly

ffilre

irHtallution.

A CAtmOil

: Alwaya lnsurs the

portibl€

llfter ls operated

on a

fififi

and

l€vel

Surface.

USIilO

THE PORTABLE LIFTER

1)

$et

wheel

stops to

the

lock€d

position.

2) Place the circult,brsaksr

on lhs liltBr buckat

and

lock in

place

with

the

inte,look

pin

(Fig.

2o).

EEm[im]

Do nor traffipon

the circuit

breraker

without

th€ intsrlock

pln

lockad

ln

place,

Flg. 19

Po*able Lifter in use

ng.2O

Portable Lifter lntsrlock Pin

in Placg

klay

31. 2012

9:18AM

No.

1530

P

18

Page 14

INSTALLATION

lIffil

Do nar rrrEport the vac.um

Clrcuh

Ercaker in dle dc{iNted

pocition

whila

udru

por$lc

llfter,

3l Unlock

the

wheel

stops and

move the lifter

into

position

in front of

the

oell.

4l Before moving the citouit hreaket on or off

th6 liftor bucket, make sure that:

al The buckst tab is lowered over the sell

stud to

lnsure

the

lifter does not movs

(Fig,

21).

b)

Ths wheel stops Ere again locked.

nmmG]

The

porrdue

riftGr must b6

s€cu]€ly flx6d to ths clrcult breaket cell befu|e

traGfcrdng the cirllir't

k..ler lo or from lha

cell.

5) Ramove

the circuit bteaker

ifiterlock

pin.

6) Follow the

procedure

"MOVING

THE

CIRCUIT

EREAKER

lN

THE

GELL" for

insertion

into

the equlpment

cell.

MOUNTING

PADS

Some installations

utilize

elevated equipment

mounting

pads.

This ryp€ of irEtallation

will

increa$e

ths

ovorell heigtrt of thB Bquipment,

Pads should not increa$e the equlpmsnt

height

more

than 6 inches, or tho

ponable

lifter ftay

not work.

Addltlonally,

mounting

pads

should

ext€dd

no moru than 6

inches lorward of the

switchgBar.

Lifar Buckat Tab

over

Cell Stud

Eq,

2l

|!lav

3l.

20l2 9

r

lBAM

No,

1530

P

19

INSTALLATION

Page

15

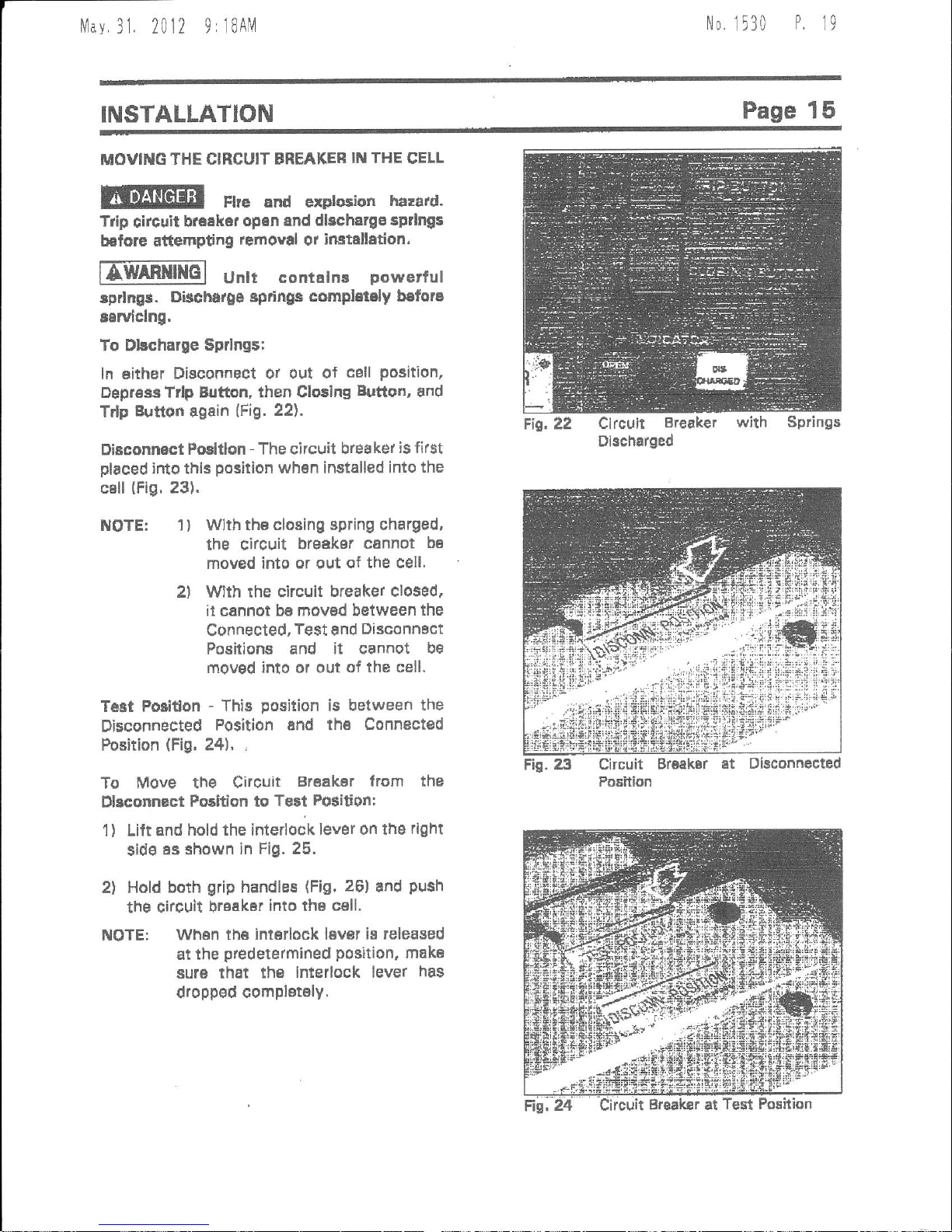

MOVING

THE CIRCUIT

BREAKER

IN THE

CELL

lilE@

Ftre and exptoiion

harard.

Trip

clrcuit

ba€ekar

opan and dlecharoa

sptlng$

b€lore

attempting

lemoyil

or

instellation.

ITMRNINGI

unh

conratns

powerrut

sprlngr.

Discturge ep,ingc

completely befora

rswlclng,

To Dkcharse

$prlngs;

ln either

Disconnect ot out

of

cell

position,

Dep.ess

Trlp Bjtton, then Clo3ing

Button,

and

Trlp

Eutton

again

(Fig.

22).

Disconnact

posltlon

-

The circuit

breaker

is first

placed

into

thlr

posilion

whsn installed

into the

cBll

(Fig.

231.

Fic. 22

Clrcult

Breaket

with

Dlscharged

Springs

NOTE:

2t

1)

T6Bt Poiiffon

Disconnected

Position

(Fig,

Wlth th€ closing spring charged,

the circuit

brgdker

cannot

bB

moved into or out

of the cell'

With rhe circuit

breaker closed.

it cannot

be moved between

the

Connected,

Test

snd

Disconnact

Positions and

it cannot

be

moved into ol oui

of the cell,

-

This

position

is between

the

Position and th6 Connected

24t,

,

Dbconnected

1)

To

Move the

circuir

Br€akEr trom

the

Dbconnact

Fosltlon to

Te3t

Position:

Lift and

hold the inlerlook lever

on ths

rlght

sid€

as shown in

Fig. 25.

Hold

both

grip

handles

Fig,

26]

and

push

the circuil

breaker

into the cell.

2l

Whsn

th6 interlock laver

is released

at the

predetermined

position,

mak€

sUrS that the

interlock lever

has

dropped

compl€t€ly.

Loading...

Loading...