Toshiba HFC R407C Installation Instructions

1402241301R01

Modular Multi System

Outdoor

Installation Instructions

Air Conditioner – Multi Split Type System

Instructions d’Installation Extérieure

Climatiseur – Système de Type Multi Split

Außengerät

Installationsanleitung

Klimaanlage – Geteilte Multi-Bauweise

Exterior

Instrucciones de Instalación

Aire acondicionado – Sistema de Tipo Multi Split

Istruzioni per l’installazione dell’unità esterna

Condizionatore d’aria – Tipo Multi Split

Buiten

Installatievoorschriften

Airconditioning – Multi-delig Type Systeem

HFCR407C

GB

F

D

E

I

NL

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

GB

Passer à la page 65 pour lire le manuel d’installation en

F français.

D Die deutsche Montageanleitung finden Sie auf Seite 127.

EPor favor, vaya a la página 189 para seguir las instrucciones del manual de instalacíon en lengua española.

I Il manuale d’installazione italiano è a pagina 251.

NL Zie bladzijde 313 voor de Nederlandse Installatichandleiding.

3

|

Introduction |

|

|

Contents |

|

|

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.5 |

|

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.6 |

|

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

GB |

Metric/Imperial pipe conversion . . . . . . . . . . . . . . . . . . . . . |

7 |

4

Introduction

Precautions

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of the works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage immediately.

These units comply with EC Directive:

73/23/EEC (Low Voltage Directive) and 89/336/EEC (Electro Magnetic Compatibility).

Accordingly, they are designated for use in commercial and industrial environments.

Avoid installation in the following locations:

Where the water drainage may cause a nuisance or a hazard when frozen.

Where there is a danger of flammable gas leakage.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas). Special maintenance is required to maintain product design life.

Where the airflow from the outdoor unit may cause annoyance.

Where the operating noise of the outdoor unit may cause annoyance.

Where the foundation is not strong enough to fully withstand the weight of the outdoor unit.

Where strong winds may blow against the air inlet of the outdoor unit.

Precautions for R407C Systems

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure that the refrigerant system is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has been used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to use a gauge manifold set equipped with a liquid sight glass fitted in the centre (entry) port.

GB

5

Introduction

Operating Conditions

Outdoor Temperature |

–5 ~ 43°C |

Cooling |

|

|

|

||

–15 ~ 21°C |

Heating |

||

|

|||

|

|

|

|

Room Temperature |

18 ~ 32°C |

Cooling |

|

15 ~ 29°C |

Heating |

||

|

|||

Room Humidity |

<80% |

Cooling |

|

|

|

|

GB

1. Allocation standard of Model name

OUTDOOR

MM–A0280HT

Modular Multi

INDOOR

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A – Outdoor |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

0280 |

– 28.0kW (10HP) |

|

C – Cooling |

|

|

|

||

|

|

|

|

|

|

|

|

T – Inverter |

||||||

|

|

|

|

|

|

0224 |

– 22.4kW (8HP) |

|

|

|||||

|

|

|

|

|

|

|

H – Heating |

|

||||||

|

|

|

|

|

|

|

|

X – Fixed Speed |

||||||

|

|

|

|

|

|

0160 |

– 16.0kW (6HP) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MM–TU056

Modular Multi

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

– Built-In Duct Type |

|

|

|

|

|

028 – 2.8kW (1HP) |

|||||

|

C (CR) – Ceiling Type (IR Remote) |

|

||||

|

|

042 – 4.2kW (1.5HP) |

||||

|

K (KR) – High Wall Type (IR Remote) |

|

||||

|

|

056 – 5.6kW (2HP) |

||||

|

N |

– Carcase Type |

|

|||

|

|

080 – 8.0kW (3HP) |

||||

|

S (SR) |

– Low Wall Type (IR Remote) |

|

|||

|

|

112 – 11.2kW (4HP) |

||||

|

SB |

– Built-In Slim Duct Type |

|

|||

|

|

140 – 14.0kW (5HP) |

||||

|

TU |

– 2 Way Cassette Type |

|

|||

|

|

|

|

|||

|

|

|

||||

|

U |

– 4 Way Cassette Type |

|

|

|

|

|

|

|

|

|

|

|

2. Range of combined units

No. of combined units |

: 1 to 5 units |

Capacity range |

: Equivalent to 14HP (0384kW type) to 46HP (1288kW) |

3.Restriction for combination units

(1)The Inverter Unit should have the maximum capacity among all units in that combination.

(2)The 6HP fixed-speed unit is available only with the combination of 14HP and 22HP. (It cannot be used for any other combination.)

4.Rated conditions

Cooling |

: Indoor air temperature 27°C DB/19°C WB |

|

Outdoor air temperature 35°C DB/25°C WB |

Heating |

: Indoor air temperature 21°C DB/15.5°C WB |

|

Outdoor air temperature 7°C DB/6° C WB |

5. Mode Priority

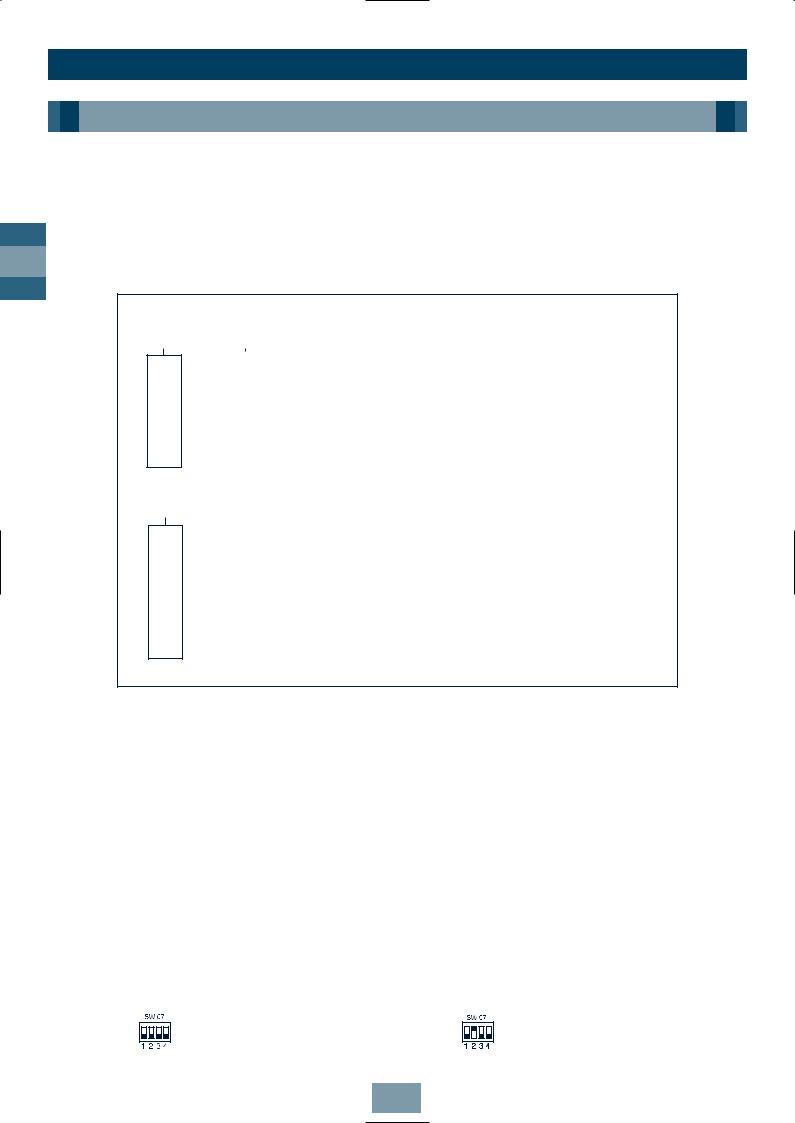

This Outdoor Unit is set to operate with the Heating mode taking precidence. This precidence can be switched between Heat and Cool mode using the DIP switch 07 on the Outdoor Unit Interface PCB (MCC-1343-01) as follows:

ON OFF

Heat Priority (factory set)

ON OFF

Cool Priority

6

Introduction

Components

1. Outdoor Unit

|

Inverter unit |

|

Fixed-speed unit |

|

Appearance |

|||

Corresponding HP |

|

|

|

|

|

|

|

|

8HP |

10HP |

6HP |

|

8HP |

|

10HP |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||

Model name |

MM-A0224HT |

MM-A0280HT |

MM-A0160HX |

MM-A0224HX |

MM-A0280HX |

|

||

|

|

|

|

|

|

|

|

|

Cooling capacity (kW) |

22.4 |

28.0 |

16.0 |

|

22.4 |

|

28.0 |

|

|

|

|

|

|

|

|

|

|

Heating capacity (kW) |

25.0 |

31.5 |

18.0 |

|

25.0 |

|

31.5 |

|

|

|

|

|

|

|

|

|

|

GB

2. Outdoor Units (Combination of Outdoor Units)

Corresponding HP |

8HP |

10HP |

14HP |

16HP |

18HP |

20HP |

22HP |

24HP |

26HP |

28HP |

30HP |

32HP |

34HP |

36HP |

38HP |

40HP |

42HP |

44HP |

46HP |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Combined Model MM-A~HT |

0224 |

0280 |

0384 |

0440 |

0504 |

0560 |

0608 |

0672 |

0728 |

0784 |

0840 |

0896 |

0952 |

1008 |

1064 |

1120 |

1176 |

1232 |

1288 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Cooling capacity (kW) |

22.4 |

28.0 |

38.4 |

44.8 |

50.4 |

56.0 |

60.8 |

67.2 |

72.8 |

78.4 |

84.0 |

89.6 |

95.2 |

100.8 |

106.4 |

112.0 |

117.6 |

123.2 |

128.8 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inverter unit |

8HP |

10HP |

8HP |

8HP |

10HP |

10HP |

8HP |

8HP |

10HP |

10HP |

10HP |

8HP |

10HP |

10HP |

10HP |

10HP |

10HP |

10HP |

10HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Combined |

|

— |

— |

6HP |

8HP |

8HP |

10HP |

8HP |

8HP |

8HP |

10HP |

10HP |

8HP |

8HP |

10HP |

10HP |

10HP |

8HP |

10HP |

10HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

— |

— |

— |

— |

— |

— |

6HP |

8HP |

8HP |

8HP |

10HP |

8HP |

8HP |

8HP |

10HP |

10HP |

8HP |

8HP |

10HP |

||

outdoor |

Fixed- |

||||||||||||||||||||

units |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

speed unit |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

8HP |

8HP |

8HP |

8HP |

10HP |

8HP |

8HP |

8HP |

||

|

|||||||||||||||||||||

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

8HP |

8HP |

8HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. of connectable |

13 |

16 |

16 |

18 |

18 |

20 |

22 |

24 |

26 |

28 |

30 |

32 |

34 |

36 |

38 |

40 |

40 |

40 |

40 |

||

indoor units |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Min. HP Connection |

4 |

5 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Max. HP Connection |

10.8 |

13.5 |

18.9 |

21.6 |

24.3 |

27 |

29.7 |

32.4 |

35.1 |

37.8 |

40.5 |

43.2 |

45.9 |

48.6 |

51.3 |

54 |

56.7 |

59.4 |

62.1 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metric/Imperial pipe conversion

Diameter (mm) |

6.4 |

9.5 |

12.7 |

15.9 |

19.0 |

22.0 |

28.6 |

34.9 |

41.3 |

54.1 |

|

|

|

|

|

|

|

|

|

|

|

Nominal Diameter (inch) |

1/4 |

3/8 |

1/2 |

5/8 |

3/4 |

7/8 |

1 1/8 |

1 3/8 |

1 5/8 |

2 1/8 |

|

|

|

|

|

|

|

|

|

|

|

Note: 1.0MPaG = 10.2kgf/cm2G

7

Introduction

Components

3. Indoor Unit

GB

Type |

Appearance |

Model name |

Capacity code/ |

Cooling Capacity |

Heating Capacity |

|

|

|

HP |

(kW) |

(kW) |

4 Way Cassette |

|

MM-U056 |

2 |

5.6 |

6.4 |

|

MM-U080 |

3 |

8.0 |

9.6 |

|

Type ‘U’ |

|

||||

|

MM-U112 |

4 |

11.2 |

12.8 |

|

|

|

||||

|

|

MM-U140 |

5 |

14.0 |

15.8 |

|

|

|

|

|

|

2 Way Cassette |

|

MM-TU028 |

1 |

2.8 |

3.2 |

Type ‘TU’ |

|

MM-TU042 |

1.5 |

4.2 |

4.8 |

|

|

MM-TU056 |

2 |

5.6 |

6.4 |

|

|

|

|

|

|

Built-In Slim |

|

|

|

|

|

Duct Type ‘SB’ |

|

MM-SB028 |

1 |

2.8 |

3.2 |

|

|

|

|

|

|

Built-In Duct, |

|

MM-B056 |

2 |

5.6 |

6.4 |

|

MM-B080 |

3 |

8.0 |

9.6 |

|

Type ‘B’ |

|

||||

|

MM-B112 |

4 |

11.2 |

12.8 |

|

|

|

||||

|

|

MM-B140 |

5 |

14.0 |

15.8 |

|

|

|

|

|

|

|

|

MM-C/CR042 |

1.5 |

4.2 |

4.8 |

Ceiling |

|

MM-C/CR056 |

2 |

5.6 |

6.4 |

Type ‘C’ |

|

MM-C/CR080 |

3 |

8.0 |

9.6 |

|

|

MM-C/CR112 |

4 |

11.2 |

12.8 |

|

|

MM-C/CR140 |

5 |

14.0 |

15.8 |

|

|

|

|

|

|

High Wall |

|

MM-K/KR042 |

1.5 |

4.2 |

4.8 |

|

MM-K/KR056 |

2 |

5.6 |

6.4 |

|

Type ‘K’ |

|

||||

|

MM-K/KR080 |

3 |

8.0 |

9.6 |

|

|

|

||||

|

|

|

|

|

|

Carcase |

|

MM-N028 |

1 |

2.8 |

3.2 |

|

MM-N042 |

1.5 |

4.2 |

4.8 |

|

Type ‘N’ |

|

||||

|

MM-N056 |

2 |

5.6 |

6.4 |

|

|

|

||||

|

|

MM-N080 |

3 |

8.0 |

9.6 |

|

|

|

|

|

|

Low Wall |

|

MM-S/SR056 |

2 |

5.6 |

6.4 |

Type ‘S’ |

|

||||

|

MM-S/SR080 |

3 |

8.0 |

9.6 |

|

|

|

||||

|

|

|

|

|

|

8

Installation

Contents

Outdoor Unit

Transportation of the Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . |

.10 |

|

|

Installation of Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

|

Dimensional Drawings Outdoor Unit |

12 |

|

|

|

|||

Dimensional Drawings Two Units Connected |

13 |

|

|

GB |

|||

Dimensional Drawings Three Units Connected |

14 |

||

|

|||

|

|||

Dimensional Drawings Four Units Connected . . . . . . . . . . . . . . . . . . . . |

15 |

|

|

|

|||

Dimensional Drawings Five Units Connected . . . . . . . . . . . . . . . . . . . . |

16 |

|

|

Multiple Installation on the Rooftop . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

Piping

Free Branching System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Connecting Refrigerant Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 Permissible Length/Height Separation of Refrigerant Piping . . . . . . . .21 Selection of Refrigerant Piping and Charge Requirement . . . . . . . . . .22 Branch Headers/Branch Joints (Accessories) . . . . . . . . . . . . . . . . . . . . .24 Branch Header/T-shape Branch Joint . . . . . . . . . . . . . . . . . . . . . . . . . .25 Connecting the Branching Kit/Y-shape Branching Joint . . . . . . . . . . . .26 Heat Insulating the Branching Pipes/Branching Header . . . . . . . . . . .27 T-shape Branching Joint – to Connect Outdoor Units . . . . . . . . . . . . . .29 Installation of Gas/Liquid Branching Pipes . . . . . . . . . . . . . . . . . . . . . .30 Airtight Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Leak Position Check/Air Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 Calculating the Additional Refrigerant Required . . . . . . . . . . . . . . . . .33 Additional Charge Amounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Wiring

General/Wiring System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connecting Power Source Cable/Control Cable . . . . . . . . . . . . . . . . . .36

Control Wiring Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9

Installation

Outdoor Unit

Transportation of the Outdoor Unit

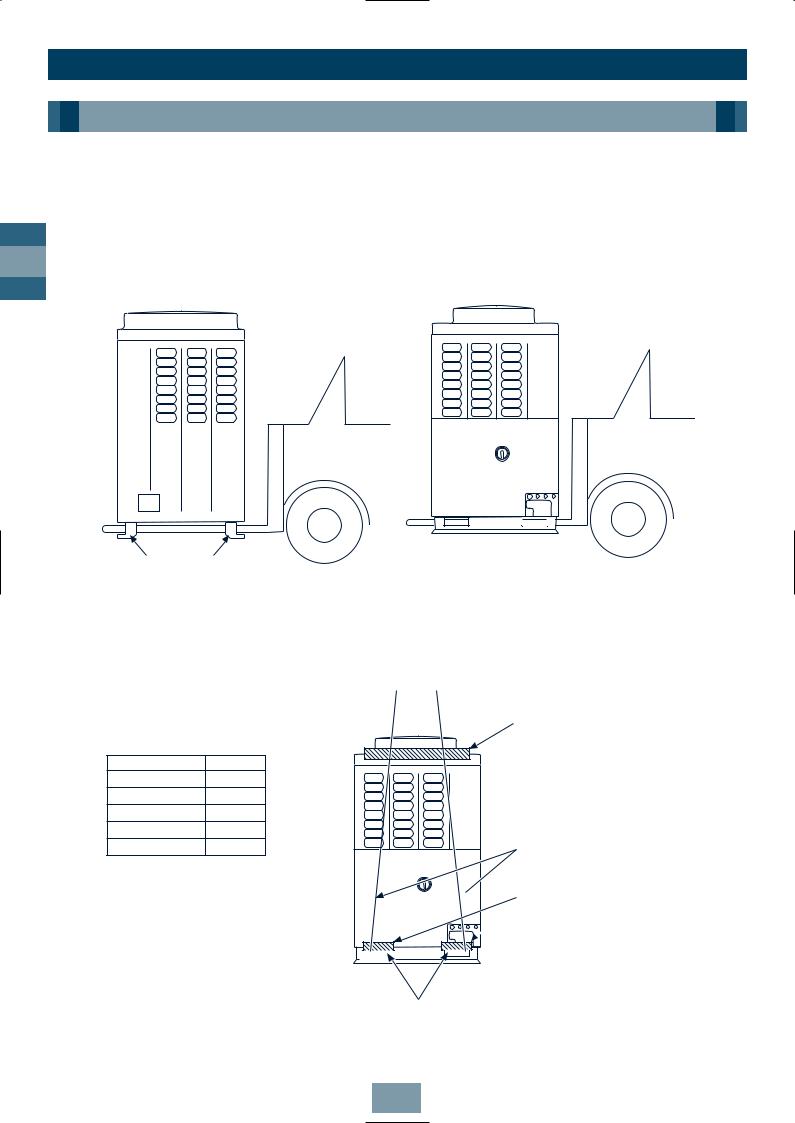

Fork Lift

•Front Access – insert the forks into the slots on the fixing legs.

•Side Access – see diagram.

GB

Front Access |

Side Access |

Fork lift

Fixing Leg

Crane

•Check the suitability of the lifting rope (see table).

•Secure lifting rope through transportation slot.

•Protect the unit where rope contact could scratch or deform it.

Fork lift/ Hand Truck

Model Weight

MM-A0280HT 284.0kg

MM-A0224HT 282.0kg

MM-A0280HX 280.0kg

MM-A0224HX 278.0kg

MM-A0160HX 204.0kg

Protection

Rope

Protection

Protection

Transportation Slots

10

Installation

Outdoor Unit

Installation of Outdoor Unit

1.Align the outdoor units at intervals of 20mm or more.

Fix the outdoor units with M12 anchor bolts. (4 positions per unit.)

Anchor bolt with 20mm length is suitable.

20mm

≥ 20mm |

≥ 20mm |

GB

M12 anchor bolt,

4 positions per unit

• Anchor bolt pitch is as shown in the following figure.

700mm ≥ 310mm 700mm ≥ 310mm 700mm

755mm

15 x 20mm slot

•However, the equivalent pipe length between the nearest outdoor unit and farthest outdoor unit of the refrigerating cycle system should not exceed 20m.

2.When routing the refrigerant piping through the base, the fixing height of the base (two-divided foundations) must be 500m or more.

≥ 500mm

Refrigerant Piping

Refrigerant Piping

3. Correct foundation mounts for supporting the Outdoor unit:

Note: The leading outdoor unit to be connected to the main refrigerant piping for the indoor units must be an inverter unit.

11

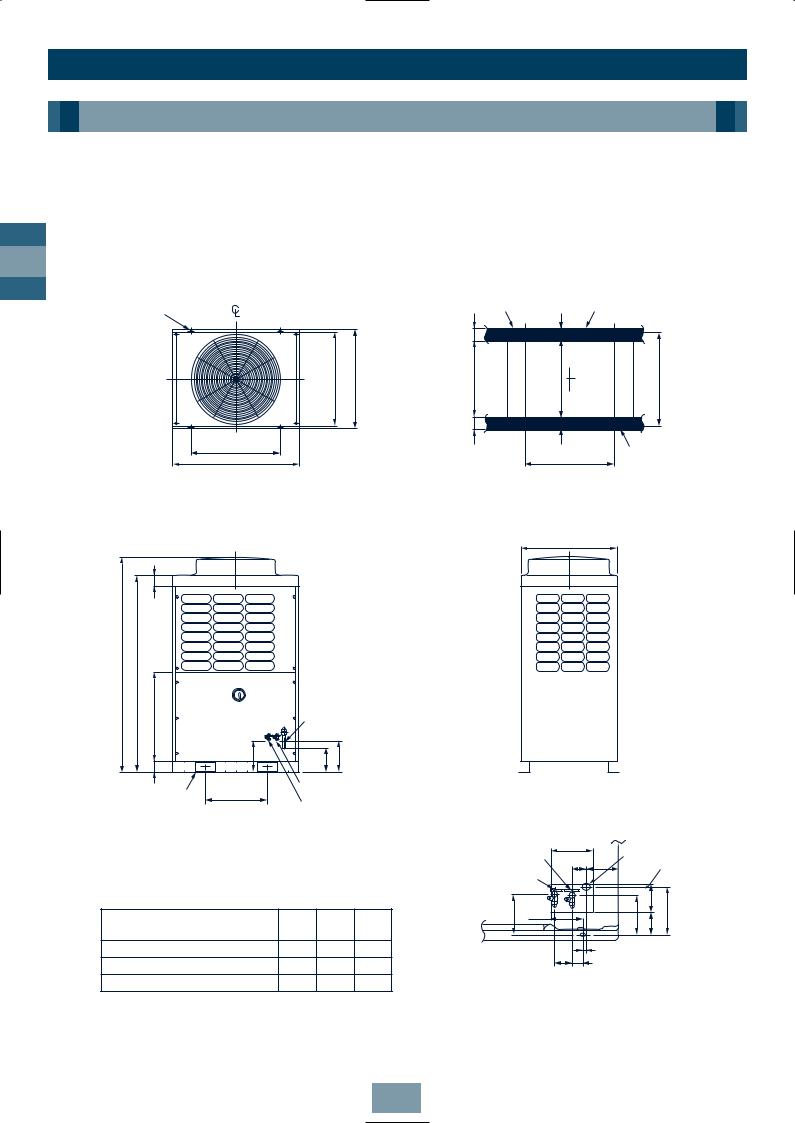

Installation

Outdoor Unit

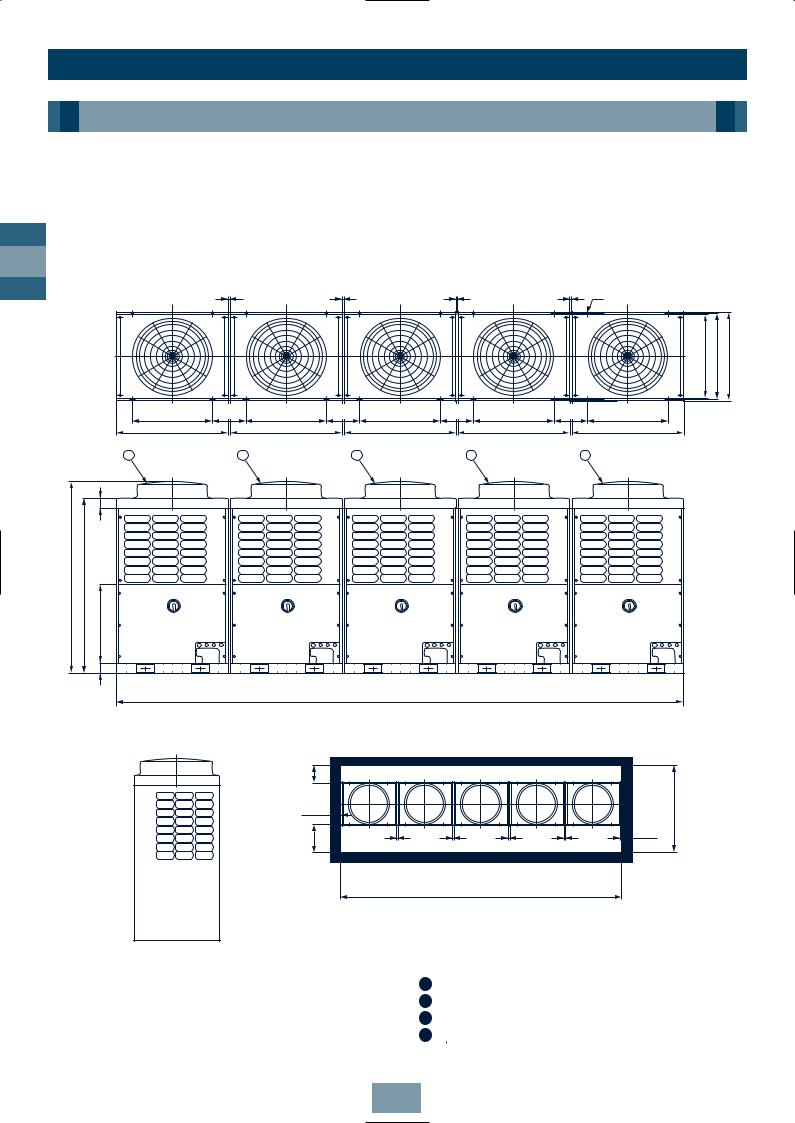

Dimensional Drawings

Outdoor Unit

GB

Model Name:

MM-A0280HT, MM-A0224HT, MM-A0280HX, MM-A0224HX, MM-A0160HX

|

|

|

|

Grounding part |

|

|

|

|

4-15 x 20 (Slot) |

|

|

|

of bottom plate |

|

|

Base |

|

|

|

|

|

80 |

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

100 610 100 |

|

|

|

|

Fixing bolt pitch |

755 |

790 |

(including fixed leg) |

630 |

|

755 |

Fixing bolt pitch |

|

Fixing bolt pitch |

|

|

|

|

80 |

|

|

|

700 |

|

|

|

|

|

|

Base |

|

990 |

|

|

|

|

|

700 |

|

|

|

|

|

|

|

|

|

Fixing bolt pitch

Base bolt position

750

90

1700 |

1560 |

700 |

|

Refrigerant pipe connecting port |

|

|

(Gas side) braze connection (ØA) |

||

88 |

245 |

190 |

235 |

2-60 x 150 Slot |

|

Refrigerant pipe connecting port |

|

|

|

|

|

|

|||

500 |

(Liquid side) flare connection (ØB) |

|

|

|

|

|

|

||||

(for transport) |

(Slot pitch) |

Balance pipe connecting |

|

|

|

|

Refrigerant pipe |

||||

|

|

|

|

|

|||||||

|

|

port flare connection (ØC) |

Refrigerant pipe |

(knock out) |

|||||||

|

|

connecting port |

|||||||||

|

|

|

|

|

|||||||

Note: All dimensions in (mm) |

|

|

|

connecting port |

173 |

|

(Gas side) |

||||

|

|

|

(Liquid side) |

|

|

||||||

|

|

|

|

60 |

115 |

|

|

(knock out) |

|||

|

|

|

|

|

Balance pipe |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connecting port |

|

|

|

64 125 |

|

|

Model |

|

ØA |

ØB |

ØC |

145 |

130 |

|

|

140 |

170 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

mm |

mm |

mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

MM-A0280HT, MM-A0280HX |

28.6 |

12.7 |

9.52 |

|

|

|

20 |

|

|

|

|

|

|

65 35 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

MM-A0224HT, MM-A0224HX 22.2 12.7 9.52

MM-A0160HX |

22.2 9.52 9.52 |

Details of piping |

|

connections |

|||

|

|

12

Installation

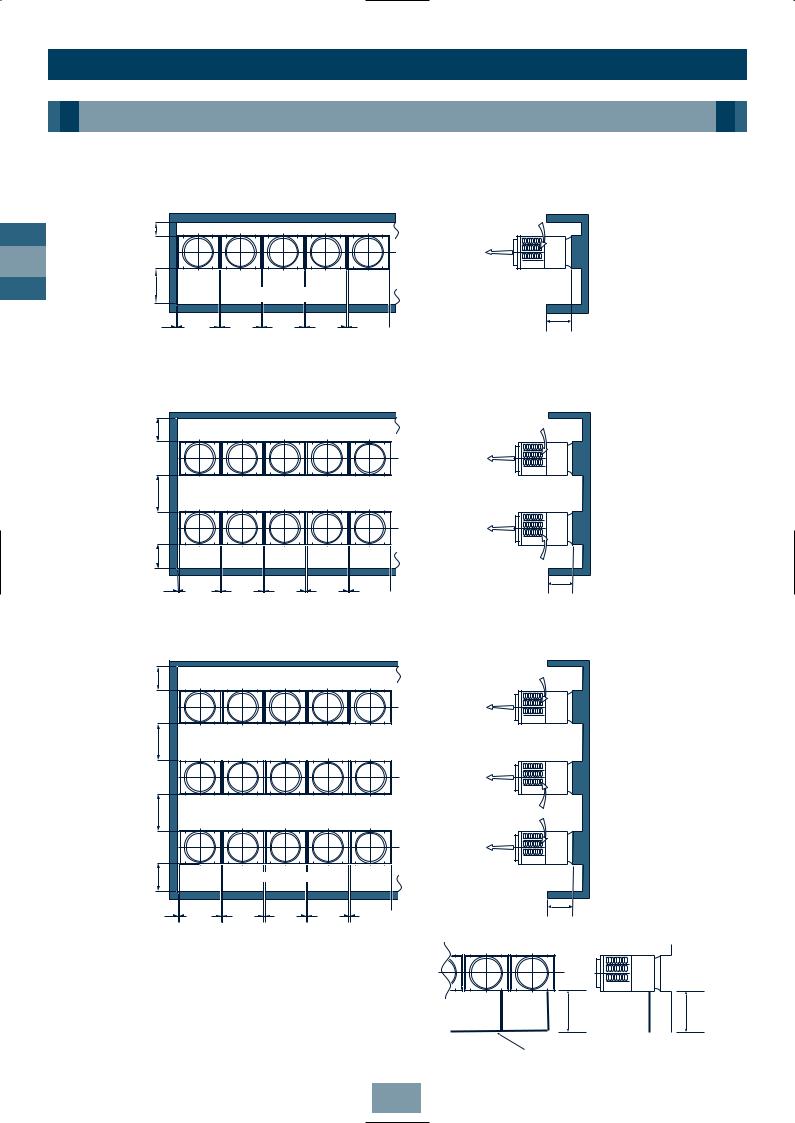

Outdoor Unit

Dimensional Drawings

Two Units Connected

Model Name:

MM-A0384HT, MM-A0440HT, MM-A0504HT, MM-A0560HT

|

≥ 20 |

|

|

|

|

8-15 x 20 (Slot) |

|

|

|

|

750 |

755 Fixing bolt pitch |

790 |

(including fixed leg) |

700 |

700 |

|

|

|

Fixing bolt pitch |

Fixing bolt pitch |

|

|

|

990 |

990 |

|

|

|

1 |

2 |

|

|

|

GB

90

1700 |

1560 |

88 700

|

|

2000 |

|

300 |

(Rear side) |

|

|

≥ |

|

|

1550≥ |

≥ |

10 |

|

|

|

|

||

≥ 500 |

|

≥ 10 |

|

|

≥ 20 |

|

|

|

side) |

≥ 2020 |

|

|

(Front |

|

|

|

No. |

Name |

1 |

Outdoor Unit (Inverter type) |

2 |

Outdoor Unit (Fixed-speed type) |

Note: All dimensions in (mm)

13

Installation

Outdoor Unit

Dimensional Drawings

Three Units Connected

GB

Model Name:

MM-A0608HT, MM-A0672HT, MM-A0728HT, MM-A0784HT, MM-A0840HT

|

≥ 20 |

|

≥ 20 |

12-15 x 20 (Slot) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

750 |

755 Fixing bolt pitch |

790 |

(including fixed leg) |

700 |

310 |

700 |

310 |

700 |

|

|

|

Fixing bolt pitch |

Fixing bolt pitch |

Fixing bolt pitch |

|

|

|

||

990 |

|

990 |

|

990 |

|

|

|

1 |

|

2 |

|

3 |

|

|

|

90

1700 |

1560 |

|

700 |

|

88 |

300 |

(Rear side) |

|

≥ |

|

1550≥ |

≥ 10 |

|

|

|

|

|

≥ 500 |

|

≥ 10 |

≥ 20 |

≥ 20 |

side) |

≥ 3030 |

|

|

||||

(Front |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

Name |

|||

Note: All dimensions in (mm) |

|

|

|

1 |

|

Outdoor Unit (Inverter type) |

|

|

|

|

2 |

|

Outdoor Unit (Fixed-speed type 1) |

|

|

|

|

|

|

|

|

||

|

|

|

|

3 |

|

Outdoor Unit (Fixed-speed type 2) |

|

|

|

|

|

|

|

|

|

14

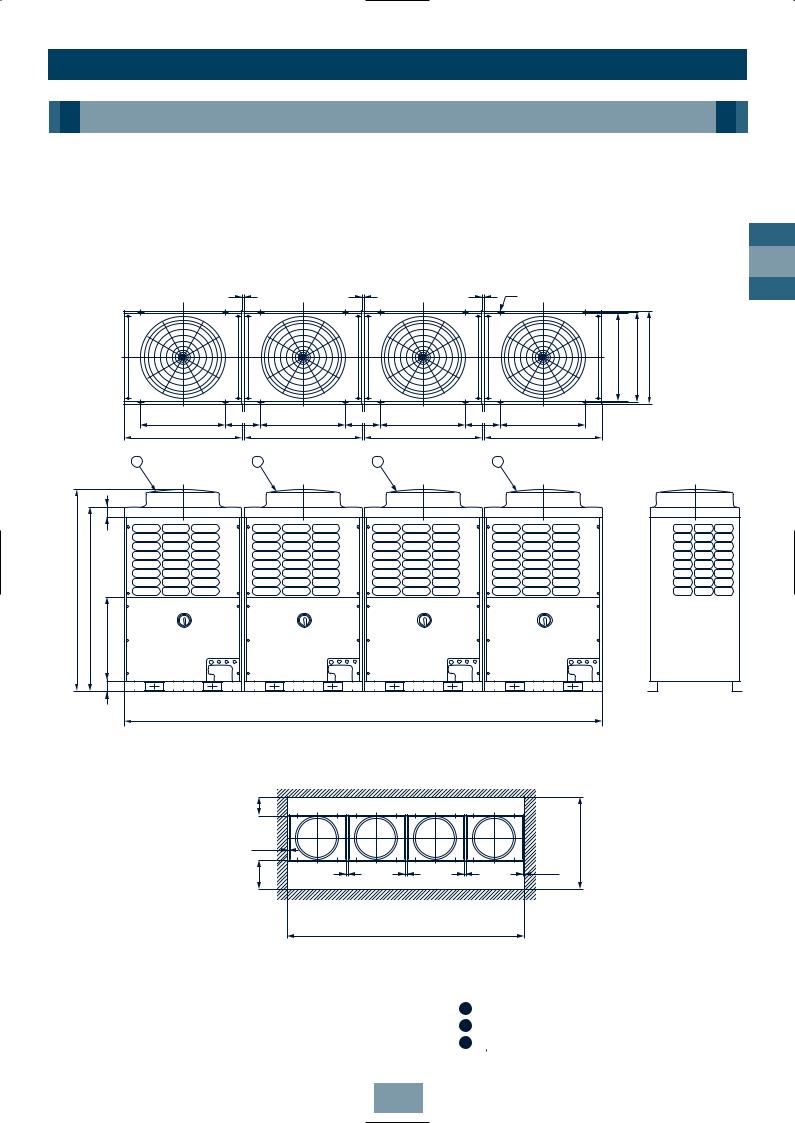

Installation

Outdoor Unit

Dimensional Drawings

Four Units Connected

Model Name:

MM-A0896HT, MM-A0952HT, MM-A1008HT, MM-A1064HT, MM-A1120HT

|

|

|

≥ 20 |

|

≥ 20 |

|

≥ 20 |

16 - 15 x 20 (Slot) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

750 |

755 Fixing bolt pitch |

790 |

(including fixed leg) |

|

|

700 |

310 |

700 |

310 |

700 |

310 |

700 |

|

|

|

|

|

Fixing bolt pitch |

Fixing bolt pitch |

Fixing bolt pitch |

Fixing bolt pitch |

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

990 |

|

990 |

|

990 |

|

990 |

|

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

90 |

|

|

|

|

|

|

|

|

|

|

1700 |

1560 |

|

|

|

|

|

|

|

|

|

|

|

700 |

|

|

|

|

|

|

|

|

|

|

|

88 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4020 |

|

|

|

|

|

|

|

|

|

300 |

(Rear side) |

|

|

|

|

|

|

|

|

|

|

≥ |

|

|

|

|

|

|

|

|

≥ 10 |

|

|

1550≥ |

|

|

|

|

≥ 500 |

|

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

|

side) |

|

|

|

(Front |

|

≥ 4040 |

|

|

|

|

|

No. |

Name |

|||

|

|

1 |

|

Outdoor Unit (Inverter type) |

|

Note: All dimensions in (mm) |

|

2 |

|

Outdoor Unit (Fixed-speed type 1) |

|

|

|

|

Outdoor Unit (Fixed-speed type 2) |

|

|

|

|

3 |

|

|

|

|

|

|

|

||

|

|

4 |

|

Outdoor Unit (Fixed-speed type 3) |

|

|

|

|

|

|

|

GB

15

Installation

Outdoor Unit

Dimensional Drawings

Five Units Connected

|

Model Name: |

|

|

|

|

|

|

|

|

|

|

|

GB |

MM-A1176HT, MM-A1232HT, MM-A1288HT |

|

|

|

|

|

|

|

||||

|

|

≥ 20 |

|

≥ 20 |

|

≥ 20 |

|

≥ 20 |

20 - 15 x 20 (Slot) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

755 Fixing bolt pitch |

790 |

(including fixed leg) |

|

700 |

310 |

700 |

310 |

700 |

310 |

700 |

310 |

700 |

|

|

|

|

Fixing bolt pitch |

|

Fixing bolt pitch |

|

Fixing bolt pitch |

|

Fixing bolt pitch |

|

Fixing bolt pitch |

|

|

|

|

990 |

|

990 |

|

990 |

|

990 |

|

990 |

|

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

|

|

|

90 |

|

|

|

|

|

|

|

|

|

|

|

1700 |

1560 |

|

|

|

|

|

|

|

|

|

|

|

|

700 |

|

|

|

|

|

|

|

|

|

|

|

|

88 |

|

|

|

|

|

|

|

|

|

|

|

|

5030 |

|

|

|

300 |

(Rear side) |

|

|

|

≥ |

|

|

|

|

≥ 10 |

|

|

1550 |

|

|

|

|

|

|

500 |

|

|

|

≥ 10 |

|

|

|

≥ |

|

≥ |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

side) |

|

(Front |

≥ 5050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

Name |

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

1 |

|

Outdoor Unit (Inverter type) |

|

|

|

|

|

|

|

2 |

|

Outdoor Unit (Fixed-speed type 1) |

|

Note: All dimensions in (mm) |

|

3 |

|

Outdoor Unit (Fixed-speed type 2) |

|

||||

|

4 |

|

Outdoor Unit (Fixed-speed type 3) |

|

|||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

5 |

|

Outdoor Unit (Fixed-speed type 4) |

|

|

|

|

|

|

|

|

|

|

|

16

Installation

Outdoor Unit

Multiple Installation on the Rooftop

When the Outer Wall is Higher than the Outdoor Unit

If a hole can be made in the wall:

≥ 300 |

|

|

|

|

|

≥ 600 |

|

(Front side) |

|

|

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

|

|

|

|

|

|

HD |

1. Set an aperture ratio so that suction air volume |

|

||||

Vs from the hole becomes 1.5m/s or less. |

H |

||||

|

|

|

|

|

|

2. Height of discharge duct: HD = H - h. |

|

h |

|||

If a hole cannot be made:

≥ 300 |

|

|

|

|

≥ 600 |

|

(Front side) |

|

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

GB

Discharge duct

Vs |

1000 ≥ |

Hole in wall

1.Set a base with 500 to 1,000mm height.

2.Height of discharge duct: HD = H - h.

Note: All dimensions in (mm)

Discharge duct

H

h

Base

500 – 1000

17

GB

Installation

Outdoor Unit

When the Outer Wall is Lower than the Outdoor Unit

1-line installation |

|

|

|

|

|

≥ 300 |

|

|

|

|

|

≥ 500 |

|

(Front side) |

|

|

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

≤ 800 |

|

|

|

|

|

|

2-parallel lines installation

|

≥ 300 |

|

|

600 |

1000) |

(Front side) |

|

≥ |

≥ |

||

|

|||

|

*( |

|

|

≥ 300 |

|

|

|

|

|

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

≤ 800 |

|

|

|

|

|

|

|

3-parallel lines installation |

|

|

|

|||

|

≥ 300 |

|

|

|

|

|

≥ 600 |

≥ 1000) |

|

(Front side) |

|

|

|

|

*( |

|

|

|

|

|

|

≥ 600 |

|

|

|

|

|

|

500≥ |

|

(Front side) |

|

|

|

|

|

|

|

|

||

|

≥ 10 |

≥ 20 |

≥ 20 |

≥ 20 |

≥ 20 |

≤ 800 |

|

|

|||||

*When refrigerant piping is routed from the front |

|

|

of the unit, distance between Outdoor Unit and |

|

|

Connecting piping must be 500mm or more. |

≥ 500 |

≥ 500 |

Note: All dimensions in (mm) |

Connecting Piping |

Piping |

|

18

Installation

Piping

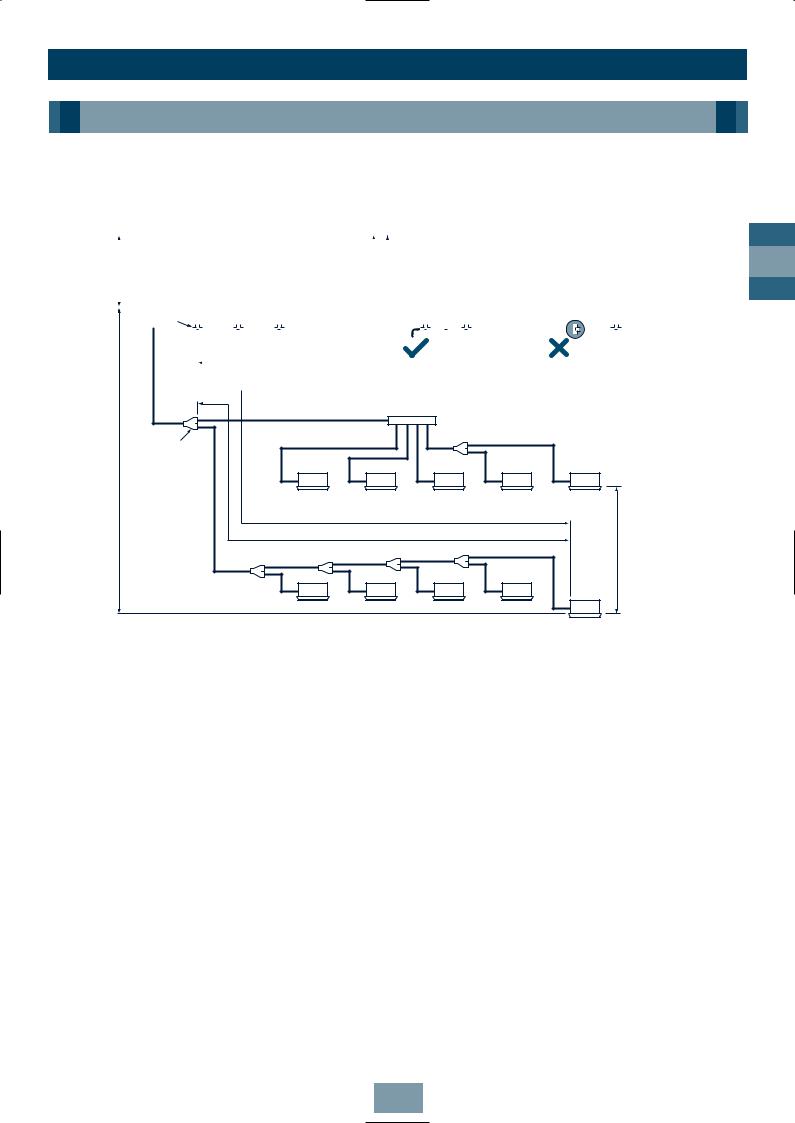

Free Branching System

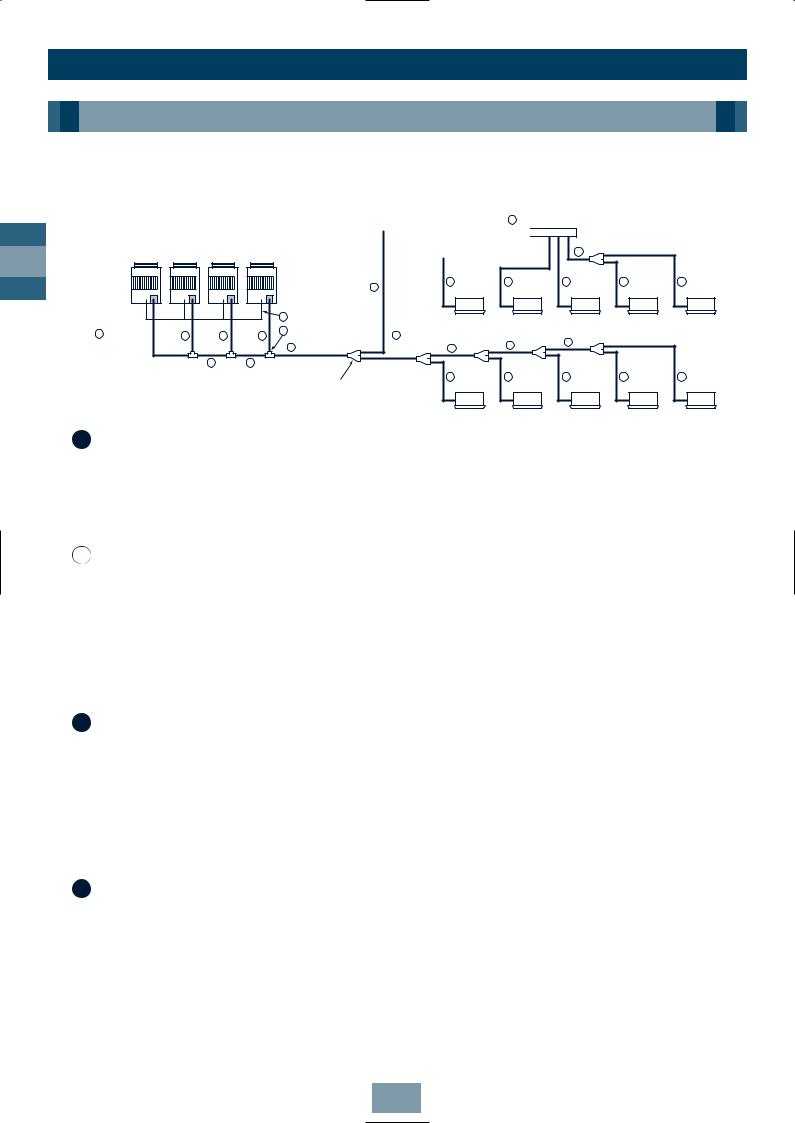

The following five branching systems are available to increase the flexibility of refrigerant piping design.

1

system

2Header branching system

3Header branching system after line branching

4Line branching system after header branching

5Header branching system after header branching

GB

Outdoor units

Indoor

units

Remote

Remote

controller

controller

Outdoor units

Branching header

Indoor

units

Remote controller

Remote controller

Outdoor units

Branching joint

Branching header

Indoor

units

Remote

Remote  controller

controller

Outdoor units

Outdoor units

Branching header

Branching joint

Indoor units

Remote

Remote

controller

controller

19

Installation

Piping

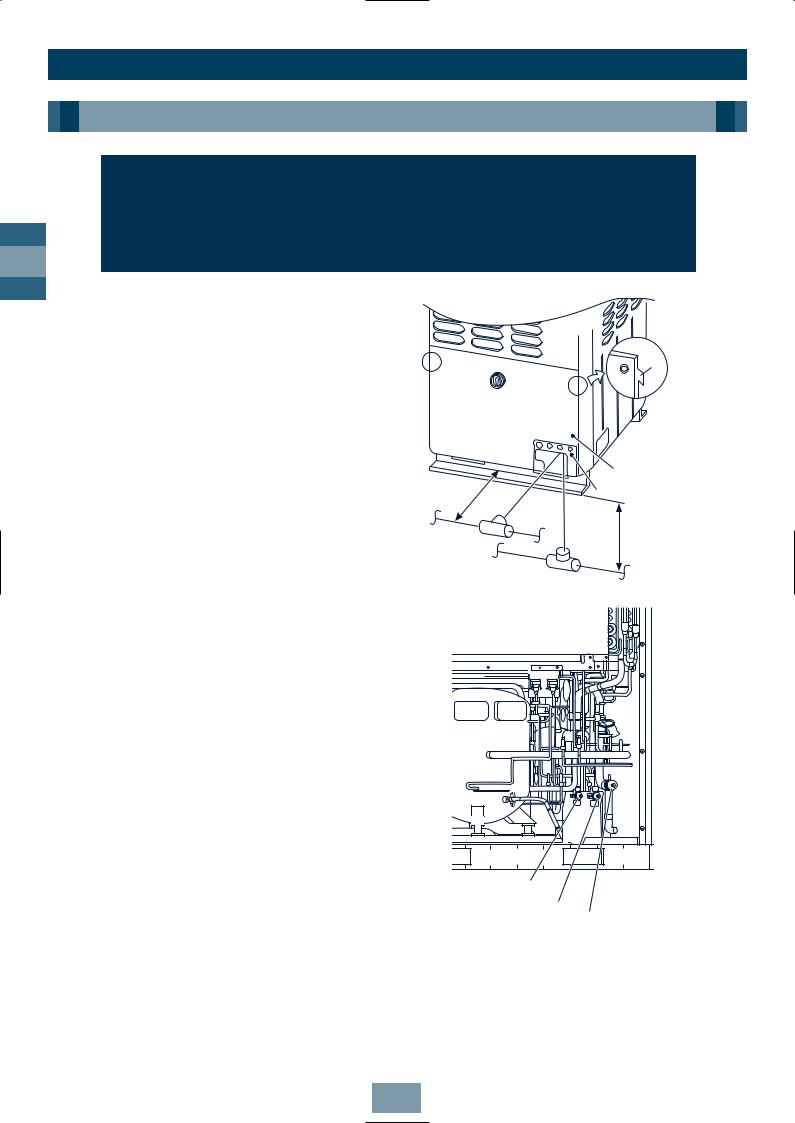

WARNING!

During installation – if the refrigerant gas leaks, ventilate the room. After installation – check for gas leakages.

If refrigerant gas comes into contact with fire – noxious gas may result!

GB

Connecting Refrigerant Pipes

1.To access the refrigerant piping connections and electrical wiring terminals, remove the 7xM5 securing bolts in the front panel. To remove the panel, lift it up and away from its hanging tabs – See diagram.

2.The refrigerant pipes can be routed forwards, downwards or sideways.

3.If the pipes are routed forwards, make sure they exit through the Piping/Wiring Panel – (remove knock out section) and allow at least 500mm between the Outdoor Unit and the main pipe connecting it to the Indoor Unit. This is for servicing access. (Replacing the compressor, for example, requires a space of at least 500mm.)

4.If the pipes are routed downwards, remove the knockout section in the baseplate of the Outdoor Unit. This will enable access. They can then be connected to the left or right, or the rear side. (Leading pipe of the balancing should be within 4m.)

Notes:

1.When brazing, use nitrogen. This prevents internal oxidisation of the pipes.

2.Always use clean new pipe, and ensure it is not contaminated by water or dust.

3.Always use a double spanner on the flare nut – and tighten to the specified torque: (see table).

Note: All dimensions in (mm)

Tab

Front panel

Piping/Wiring Panel

≥ |

500 |

4m |

|

||

|

|

|

Pipes routed |

Within |

|

|

||

forward |

|

|

|

|

Pipes routed downwards |

Valve at balance side (oil)

Valve at liquid side

Valve at gas side

Connecting pipe |

Tightening |

Re-tightening |

|

outer dia. (mm) |

torque (Nm) |

torque (Nm) |

|

|

|

|

|

Ø6.4 |

11.8 (1.2kgf m) |

13.7 |

(1.4kgf m) |

Ø9.5 |

24.5 (2.5kgf m) |

29.4 |

(3.0kgf m) |

Ø12.7 |

49.0 (5.0kgf m) |

53.9 |

(5.5kgf m) |

Ø15.9 |

78.4 (8.0kgf m) |

98.0 (10.0kgf m) |

|

Ø19.0 |

98.0 (10.0kgf m) |

117.7 |

(12.0kgf m) |

20

Installation

Piping

Permissible Length/Height Separation of Refrigerant Piping

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fixed-speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit n |

|

|

|

|

|

|

<Ex. 1> |

|

|

|

|

|

<Ex. 2> |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(d) |

|

|

|

|

|

|

|

|

|

|

Fixed- |

|

Fixed- |

|

|

|

|

|

Fixed- |

Fixed- |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fixed- |

|

Fixed- |

|

|

|

|

|

|

|

|

|

|

Inverter |

Inverter |

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

Inverter |

|

speed |

|

speed |

|

|

|

|

|

|

|

|

|

|

speed |

|

speed |

speed |

speed |

||||||||||||||||||||||||||||||||||||

Height |

|

|

|

|

|

|

Unit |

|

|

Unit 1 |

|

Unit 2 |

Connecting |

|

|

|

|

|

|

Unit |

|

|

Unit 1 |

|

Unit 2 |

|

Unit |

|

Unit |

1 |

Unit |

2 |

|||||||||||||||||||||||||||||

difference |

|

Outdoor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

between |

|

Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

piping of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Outdoor |

|

|

|

|

|

|

(a) |

|

|

|

(b) |

|

|

|

(c) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

Units |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

T-shape branching |

La |

|

|

|

|

Lb |

|

|

|

|

Lc |

Ld |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

H3≤ 4m |

|

LA |

LB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

joint |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

Main connecting piping between Outdoor Units |

|

|

|

|

|

|

|

|

|

|

Valve for |

|

|

|

|

|

|

|

Valve for |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Length corresponded to farthest piping |

|

|

|

|

|

|

|

|

|

|

|

|

|

additional Units |

|

|

|

|

|

|

|

additional Units |

||||||||||||||||||||||||||||

|

|

Main |

between Outdoor Units LO≤ 20m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Note: In <Ex.2>, a large amount of refrigerant and oil may |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

|

|

piping |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

return to the Inverter Unit. Therefore, set the |

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T-shape joint so that oil does not enter directly. |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

L1 |

Branching piping |

L2 |

Branching header |

|

|

|

|

|

|

|

|

|

|

1st branching |

Connecting piping of Indoor Unit |

L7 |

|

|

||

|

|

|

|

|

|

|

section |

a |

|

b |

c |

d |

e |

|

|

|||||

Height |

L3 |

|

Indoor Unit |

|

|

|

Length corresponded to farthest piping L≤ 125m |

|

|

||||

difference |

|

Height difference |

||||

|

|

|

|

|

||

between |

Length corresponded to farthest piping after 1st branching L≤ 50m |

between Indoor |

||||

Outdoor |

|

|

|

|

|

Units |

Units |

L4 |

|

L5 |

L6 |

|

H2≤ 30m |

H1≤ 50m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

f |

g |

|

h |

i |

j |

|

Y-joint |

|

|

|

|

|

|

|

|

|

Indoor Unit |

|

|

GB

System Restrictions |

|

|

|

|

|

|

|

|

|

Notes: Combination of Outdoor Units: Inverter Unit + |

|

|

|

|

|

||||

Max. No. of combined outdoor units |

5 units |

||||||||

|

Fixed-speed Unit (0 to 4 units). |

|

|

|

|

|

|

|

|

|

|

Max. capacity of combined outdoor units |

128.8kW/46HP |

||||||

|

Combination of Fixed-speed Units without |

||||||||

|

|

|

|

|

|

|

|||

|

Max. No. of connected indoor units |

40 units |

|||||||

|

Inverter Unit is not permissible. |

|

|||||||

|

|

|

|

|

|

|

|

||

|

|

Max. capacity of combined |

H2≤ 15 |

135% |

|||||

|

The Inverter Unit is the master Outdoor Unit |

||||||||

|

|

|

|

|

|

|

|||

|

indoor units |

|

H2>15 |

105% |

|||||

|

and is directly connected to the indoor |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

distribution pipe. |

|

|

|

|

|

|

|

|

|

Install the Outdoor Units in order of capacity. |

|

|

|

|

|

|

||

|

(Inverter Unit≥ |

Fixed-speed Unit 1> Fixed-speed Unit 2>Fixed-speed Unit n). |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Allowable value |

|

Piping section |

|

|

|

|

|

|

|

|

|

|

|

|||

|

Total extension of pipe (Liquid pipe, real length) |

250m |

|

LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4+ |

|

||||

|

|

L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j |

|

||||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

|

Farthest piping length L (*) |

Real length |

100m |

|

LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j |

|

|||

Piping |

Equivalent length |

125m |

|

|

|||||

|

|

|

|

|

|

|

|||

length |

Equivalent length of farthest piping from 1st branching Li (*) |

50m |

|

|

L3 + L4 + L5 + L6 + j |

|

|

||

|

|

|

|

|

|

|

|

||

|

Equivalent length of farthest piping between outdoor units LO (*) |

20m |

|

LA + LB + Ld, LA + Lb, LA + LB + Lc |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Max. equivalent length of outdoor unit connecting piping |

10m |

|

|

Ld, La, Lb, Lc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height between indoor |

Upper outdoor unit |

50m |

|

|

—— |

|

|

|

Height |

and outdoor units H1 |

Lower outdoor unit |

30m |

|

|

—— |

|

|

|

|

|

|

|

|

|

|

|

|

|

difference |

Height between indoor units H2 |

30m |

|

|

—— |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height between outdoor units H3 |

4m |

|

|

—— |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*(d) is Outdoor Unit farthest from branching and (j) is Indoor Unit farthest from 1st branching.

21

Installation

Piping

Selection of Refrigerant Piping and Charge Requirement

GB

Branching piping |

6 Header Branching Pipe |

FixedFixedFixed- |

|

|

|

|

||

|

|

|

|

|||

speed |

speed |

speed |

Inverter |

Indoor Unit connecting pipe |

|

|

Unit n |

Unit 2 |

Unit 1 |

Unit |

|

|

|

|

|

|

|

|

Outdoor Unit |

4 |

|

|

5 |

5 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

Balance pipe |

|

|

|

|

|

|

1 |

Outdoor |

1 |

1 |

1 |

6 |

T-shape branching joint |

6 |

Y-shape branching |

|

|||

|

|

Main piping |

|

4 |

||||||||

|

Unit |

|

|

|

|

3 |

|

|

joint |

4 |

||

|

connecting |

|

2 |

2 |

|

|

|

|

|

|

|

|

|

piping |

|

|

|

|

|

|

|

|

|

||

|

|

Main connecting |

|

|

|

|

|

|

5 |

5 |

||

|

|

|

|

|

1st branching |

|

Indoor Unit |

|||||

|

|

|

piping between |

|

|

|

|

|

||||

|

|

|

|

|

|

connecting |

|

|

||||

|

|

|

Outdoor Units |

|

|

section |

|

|

|

|||

|

|

|

|

|

|

piping |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

4

5 |

5 |

5 |

Indoor Unit

4

5 |

5 |

5 |

Indoor Unit

1

kW |

HP |

Model name |

Gas side |

Liquid side |

16.0 |

6 |

MM-A0160HX |

Ø22.2 |

Ø9.5 |

22.4 |

8 |

MM-A0224HT, MM-A0224HX |

Ø22.2 |

Ø12.7 |

28.0 |

10 |

MM-A0280HT, MM-A0280HX |

Ø28.6 |

Ø12.7 |

2 Connecting Pipe Size Between Outdoor Units

Total capacity code of outdoor |

Gas side |

Liquid side |

Balance pipe |

units |

|

|

|

Below 16 |

Ø28.6 |

Ø15.9 |

Ø9.5 |

|

|

|

|

16 to Below 20 |

Ø34.9 |

Ø15.9 |

Ø9.5 |

|

|

|

|

20 to Below 26 |

Ø41.3 |

Ø19.0 |

Ø9.5 |

|

|

|

|

26 to Below 32 |

Ø41.3 |

Ø22.2 |

Ø9.5 |

|

|

|

|

32 or more |

Ø54.1 |

Ø22.2 |

Ø9.5 |

3 Size of Main Pipe

Total capacity code of all outdoor units |

Gas side |

Liquid side |

Below 10 |

Ø22.2 |

Ø12.7 |

10 to Below 14 |

Ø28.6 |

Ø12.7 |

14 to Below 20 |

Ø34.9 |

Ø15.9 |

20 to Below 26 |

Ø41.3 |

Ø19.0 |

26 to Below 32 |

Ø41.3 |

Ø22.2 |

32 or more |

Ø54.1 |

Ø22.2 |

4 Size Between Branching Sections

Total capacity code of indoor units |

Gas side |

Liquid side |

|

downstream (*1) |

|

|

|

Below 4.0 |

|

Ø15.9 |

Ø9.5 |

4.0 to Below |

6.4 |

Ø19.0 |

Ø9.5 |

6.4 to Below 13.2 |

Ø22.2 |

Ø12.7 |

|

13.2 to Below |

19.2 |

Ø34.9 |

Ø15.9 |

19.2 to Below |

25.2 |

Ø41.3 |

Ø19.0 |

25.2 to Below |

31.2 |

Ø41.3 |

Ø19.0 |

|

|

|

|

31.2 or more |

Ø54.1 |

Ø22.2 |

|

|

|

|

|

Note: All dimensions in (mm)

22

Installation

Piping

5

Unit |

Gas side (*4) |

Liquid side |

|

|

|

028 type to 056 type |

Ø12.7 |

Ø 6.4 |

|

|

|

080 type |

Ø15.9 |

Ø 9.5 |

112 type to 140 type |

Ø19.0 |

Ø 9.5 |

i.e. MM-SB028 = Gas Ø12.7, Liquid Ø6.4

6 Branching joints/headers

|

|

Model name |

|

Usage |

|

|

|

Appearance |

|

|

RBM-Y018 |

Indoor unit capacity code (*1): Total below 6.4 |

|

|

|||

Y-shape |

RBM-Y037 |

Indoor unit capacity code (*1): Total 6.4 or more and below 13.2 |

(*2) |

|

||||

branching joint |

RBM-Y071 |

Indoor unit capacity code (*1): Total 13.2 or more and below 25.2 |

(*2) |

|

||||

|

|

RBM-Y129 |

Indoor unit capacity code (*1): Total 25.2 or more |

(*2) |

|

|||

4-branching header (*3) |

RBM-H4037 |

Indoor unit capacity code (*1): Total below 13.2 |

Max. 4 |

|

||||

RBM-H4071 |

Indoor unit capacity code (*1): Total 13.2 or more and below 25.2 |

branches |

|

|||||

|

|

|

||||||

8-branching header (*3) |

RBM-H8037 |

Indoor unit capacity code (*1): Total below 13.2 |

Max. 8 |

|

||||

|

|

RBM-H8071 |

Indoor unit capacity code (*1): Total 13.2 or more and below 25.2 |

branches |

|

|||

|

|

|

1 set of 3 types of T-shape joint pipes as described below: |

|

|

|||

|

|

|

The required quantity is arranged and they are combined at the site. |

|||||

T-shape branching joint |

|

|

|

|

|

|

|

|

|

|

Connecting pipe |

Corresponding dia. (mm) |

|

Qty |

|

||

(For connection of |

RBM-T129 |

|

|

|

||||

|

|

|

|

|

|

|||

|

Balancing pipe |

Ø9.52 |

|

1 |

|

|||

outdoor unit) |

|

|

|

|

||||

|

|

Piping at liquid side |

Ø12.7 to Ø22.2 |

|

1 |

|

||

|

|

|

|

|

|

|||

|

|

|

|

Piping at gas side |

Ø22.2 to Ø54.1 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GB

7 Additional Refrigerant Amount

Liquid pipe size |

Additional refrigerant amount for liquid pipe 1m (kg) |

Ø6.4 |

0.030 |

Ø9.5 |

0.065 |

Ø12.7 |

0.115 |

Ø15.9 |

0.190 |

Ø19.0 |

0.290 |

Ø22.2 |

0.420 |

|

|

(*1) Code is determined according to the capacity code of the Indoor Units connected. For details, refer to the Introduction section in this manual.

(*2) If the total capacity code value of Indoor Units exceeds that of Outdoor Units, apply the capacity code of Outdoor Units.

(*3) When using a branch header, Indoor Units with a maximum of 6.0 capacity code in total can be connected to each branch.

(*4) If the length of the gas pipe exceeds 30m from the 1st branching to an Indoor Unit, increase the Gas pipe section by 1 size, i.e. MM-U140 = Gas Ø22.2, Liquid Ø9.5.

Note: All dimensions in (mm)

23

Installation

Piping

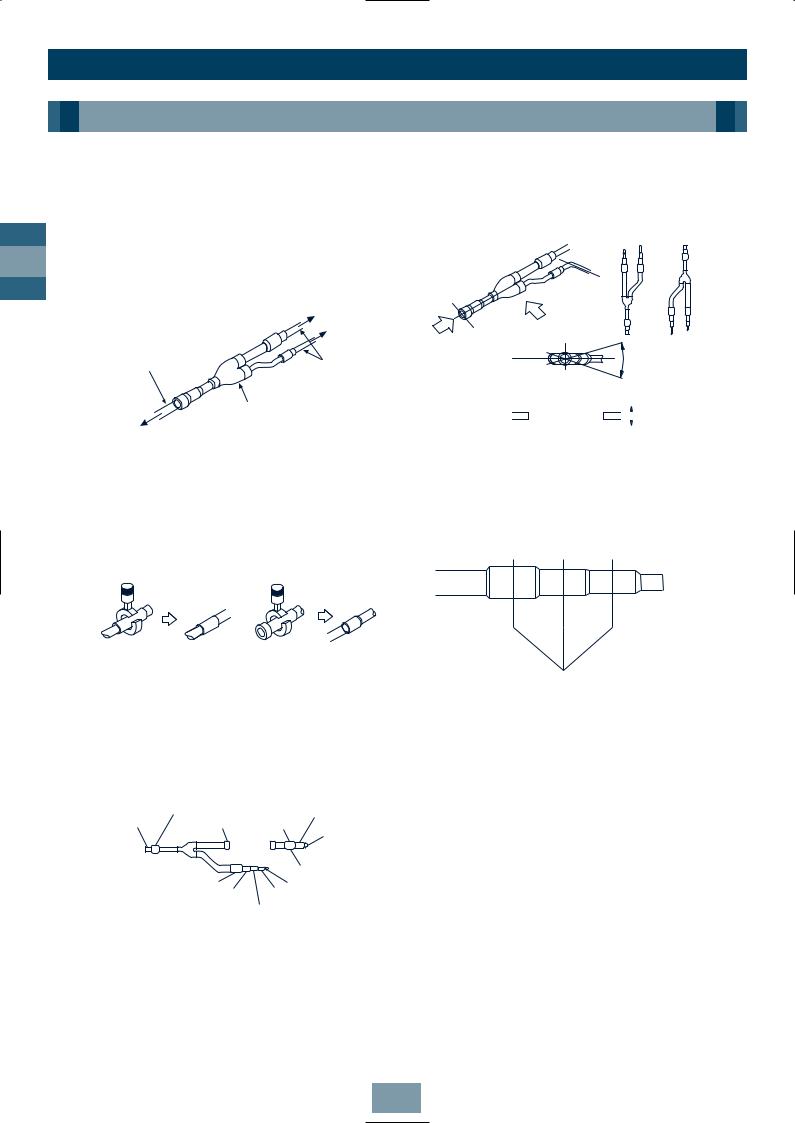

Branch Headers/Branch Joints (Accessories)

GB

Y-shape Branch Joint

|

RBM-Y018 |

|

[Gas side] |

|

|

|

528 |

|

|

Ø15.9 |

|

|

Ø19.0 |

|

Ø15.9 |

|

Ø19.0 |

Ø19.0 |

|

Ø15.9 |

Ø22.2 |

Heat insulator |

|

|

|

|

Ø15.9 |

|

Ø12.7 |

|

Ø9.5 |

|

Ø12.7 |

|

|

Ø9.5 |

|

Ø6.4 |

|

|

80 |

|

Heat insulator |

Ø6.4 |

|

Ø12.7 |

Ø9.5 |

|

420 |

|

[Liquid side]

Ø12.7

Ø9.5

100

Ø9.5

Ø12.7

RBM-Y037

[Gas side]

571

|

Ø22.2 |

Ø19.0 |

|

|

Ø15.9 |

|

|

|

Ø28.6 |

|

|

|

|

|

|

Ø22.2 |

|

44 |

120 |

Ø28.6 |

|

||

|

|

||

Ø31.8 |

|

|

|

Heat insulator |

|

Ø9.5 |

|

|

Ø22.2 |

Ø12.7 |

|

|

Ø15.9 |

|

|

|

Ø19.0 |

|

|

|

|

|

|

Ø15.9 |

Ø12.7 |

|

|

Ø12.7 |

Ø9.5 |

|

|

Ø9.5 |

Ø6.4 |

|

|

|

|

|

|

|

80 |

|

|

Heat insulator |

Ø6.4 |

|

|

Ø12.7 |

Ø9.5 |

|

|

420 |

|

|

|

[Liquid side]

RBM-Y071 |

RBM-Y129 |

[Gas side]

638

444

|

|

Ø41.3 |

|

|

|

A |

122.5 |

Ø34.9 |

|

|

|

|

|

|

|

Ø41.3 |

|

|

|

|

Heat insulator |

|

Ø12.7 |

|

Ø34.9 |

|

Ø15.9 |

|

|

Ø22.2 |

Ø19.0 |

|

423 |

Ø15.9 |

|

|

Ø19.0 |

|

|

Ø19.0 |

Ø12.7 |

|

|

|

|

||

Ø15.9 |

|

Ø9.5 |

|

|

|

85 |

|

|

Heat insulator |

Ø6.4 |

|

|

Ø9.5 |

|

|

|

|

|

|

|

Ø15.9 |

Ø12.7 |

|

[Gas side]

|

160 |

126 |

253.5 |

|

||

Ø41.3 |

|

Ø54.1 |

Ø54.1 (outer dia.) |

|

||

|

|

|

||||

Ø54.1 |

Ø54.1 |

212 |

Ø41.3 |

Ø34.9 |

Ø22.2 |

|

Ø41.3 |

Ø34.9 |

|||||

|

(outer dia.) |

|

||||

|

|

|

(outer dia.) |

|

||

|

Ø54.1 |

|

|

|

||

|

|

|

|

|

||

|

|

Ø41.3 |

160 |

|

237 |

|

|

|

Ø41.3 (outer dia.) |

Ø41.3 |

Ø22.2 |

|

|

|

|

|

Ø34.9 |

Ø19.0 |

||

|

Ø22.2 |

Ø22.2 |

|

Ø19.0 |

Ø15.9 |

|

|

|

|

|

Ø12.7 |

||

Ø19.0 |

|

523 |

|

Ø15.9 |

||

|

|

|

||||

|

|

|

|

Ø12.7 |

|

|

|

|

|

|

85 |

|

|

|

Heat insulator |

|

Ø6.4 |

|

||

|

|

518 |

|

Ø9.5 |

|

|

|

|

Ø19.0 |

Ø15.9 |

Ø12.7 |

|

|

[Liquid side]

Ø34.9 Ø22.2

Ø19.0

194

[Liquid side]

Note:

This additional connecting pipe is used if the gas pipe size is Ø41.3 or less. When brazing, the minimum insertion margin is 15mm.

Note: All dimensions in (mm)

24

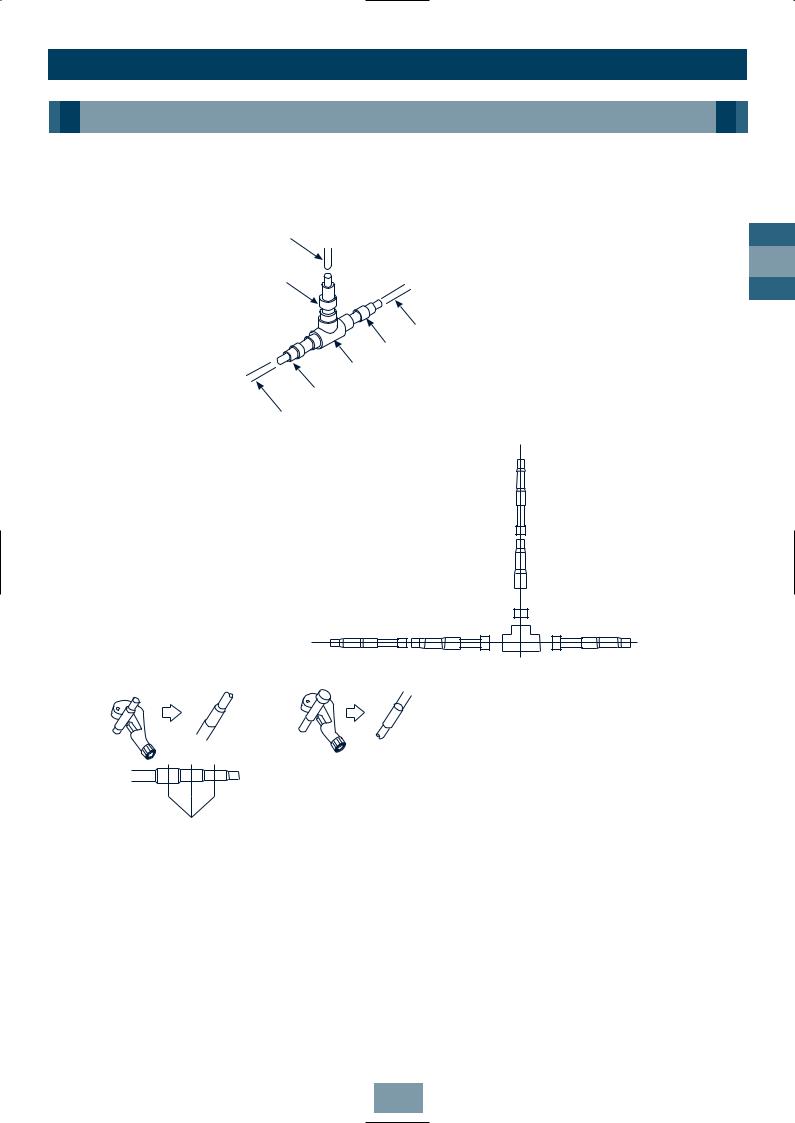

Installation

Piping

Branch Header

Note: Pipe dia. shown indicates dia. of pipe to be connected.

|

|

RBM-H4037 |

|

|

|

|

|

RBM-H8037 |

|

|||||

[Gas side] |

|

|

|

|

|

[Gas side] |

|

|

|

|

|

|

|

|

|

|

515 |

|

|

|

|

|

|

|

795 |

|

|

|

|

|

Ø9.5 |

80 |

80 |

80 |

|

|

Ø9.5 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

|

Ø12.7 |

|

|

|

|

|

Ø12.7 |

|

|

|

|

|

|

|

|

Ø15.9 |

|

|

|

204 |

|

Ø15.9 |

|

|

|

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

Ø15.9 |

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ø2.22 |

|

|

|

|

|

|

|

|

|

Ø22.2 |

|

Heat insulator |

|

|

|

|

|

|

|

|

|

|||

Ø28.6 |

|

|

Ø28.6 |

|

|

|

Heat insulator |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

522 |

|

|

|

|

|

|

|

842 |

|

|

|

|

|

|

Heat insulator |

75 |

|

|

|

|

Heat insulator |

|

|||||

Ø9.5 |

|

|

|

|

109 |

Ø9.5 |

|

|

|

|

|

|

|

|

Ø12.7 |

|

|

|

|

Ø12.7 |

|

|

|

|

|

|

|

|

|

Ø15.9 |

Ø9.5 |

|

|

|

|

Ø15.9 |

Ø9.5 |

|

|

|

|

|

|

|

Ø19.0 |

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Ø6.4 |

80 |

80 |

80 |

|

|

Ø6.4 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

[Liquid side] |

|

|

|

|

|

[Liquid side] |

|

|

|

|

|

|

|

|

|

|

RBM-H4071 |

|

|

|

|

|

|

RBM-H8071 |

|

|

||||

[Gas side] |

|

|

|

|

|

|

[Gas side] |

|

|

|

|

|

|

|

|

|

|

|

449 |

|

|

|

|

|

|

|

|

769 |

|

|

|

|

Ø9.5 |

80 |

80 |

80 |

|

|

|

Ø9.5 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

|

Ø12.7 |

|

|

|

|

|

|

Ø12.7 |

|

|

|

|

|

|

|

|

Ø15.9 |

|

|

|

|

209 |

|

Ø15.9 |

|

|

|

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

Ø34.9 |

|

|

|

|

|

|

Ø34.9 |

|

|

|

|

|

|

|

|

Ø41.3 |

|

|

Heat insulator |

|

|

Ø41.3 |

|

|

|

|

Heat insulator |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

522 |

|

|

|

|

|

|

|

842 |

|

|

|

||

|

|

|

Heat insulator |

75 |

|

|

|

|

|

Heat insulator |

|

||||

Ø9.5 |

|

|

|

|

|

109 |

Ø9.5 |

|

|

|

|

|

|

|

|

Ø12.7 |

|

|

|

|

|

Ø12.7 |

|

|

|

|

|

|

|

|

|

Ø15.9 |

Ø9.5 |

|

|

|

|

|

Ø15.9 |

Ø9.5 |

|

|

|

|

|

|

|

Ø19.0 |

Ø6.4 |

|

|

|

|

|

Ø19.0 |

|

|

|

|

|

|

|

|

|

80 |

80 |

80 |

|

|

|

Ø6.4 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

|

[Liquid side] |

|

|

|

|

|

|

[Liquid side] |

|

|

|

|

|

|

|

|

T-shape Branch Joint |

|

|

|

RBM-T129 |

|

|

|

|

|

|