Teledyne 6200T User Manual

Operation Manual for

Model 6200T

UV Fluorescence Total Sulfur Analyzer

P/N M6200T

DATE 1/15/14

TELEDYNE ELECTRONIC TECHNOLOGIES

Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91748

Telephone: (626) 934-1500

Fax: (626) 961-2538

Web: www.teledyne-ai.com

Teledyne Analytical Instruments

Teledyne Analytical Instruments

Model 6200T Total Sulfur Analyzer

Copyright © 2013 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any other language or computer language in whole or in part, in any form or by any means, whether it be electronic, mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91748.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from defects of material and of construction, and that our liability shall be limited to replacing or repairing at our factory (without charge, except for transportation), or at customer plant at our option, any material or construction in which defects become apparent within one year from the date of shipment, except in cases where quotations or acknowledgements provide for a shorter period. Components manufactured by others bear the warranty of their manufacturer. This warranty does not cover defects caused by wear, accident, misuse, neglect or repairs other than those performed by Teledyne or an authorized service center. We assume no liability for direct or indirect damages of any kind and the purchaser by the acceptance of the equipment will assume all liability for any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which valuable data can be gathered. The information provided by the instrument may assist the user in eliminating potential hazards caused by his process; however, it is essential that all personnel involved in the use of the instrument or its interface be properly trained in the process being measured, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process conditions. While this instrument may be able to provide early warning of imminent danger, it has no control over process conditions, and it can be misused. In particular, any alarm or control systems installed must be tested and understood, both as to how they operate and as to how they can be defeated. Any safeguards required such as locks, labels, or redundancy, must be provided by the user or specifically requested of Teledyne at the time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser is responsible for the training of personnel, for providing hazard warning methods and instrumentation per the appropriate standards, and for ensuring that hazard warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept responsibility for conditions beyond its knowledge and control. No statement expressed or implied by this document or any information disseminated by the manufacturer or its agents, is to be construed as a warranty of adequate safety control under the user’s process conditions.

Trademarks

All trademarks, registered trademarks, brand names or product names appearing in this document are the property of their respective owners and are used herein for identification purposes only.

ii

6200T Total Sulfur Analyzer |

Configuration |

INFORMATION ABOUT THE SPECIFIC CONFIGURATION OF YOUR MODEL 6200T TOTAL SULFUR ANALYZER

Selected Versions of the Model 6200T

Model 6200T— Standard Version

This Model 6200T Analyzer is a touch screen version designed for analyzing the total sulfur (TS) concentration in a sample gas. The analyzer includes a thermal converter to oxidize sulfur bearing molecules to SO2 which is then analyzed by the analyzer. The converter has an Oxy-Flow Sensor that provides an alarm in the event of a low flow in the combustion air inlet to the converter.

The analyzer is designed for positive pressure applications and is not equipped with an internal pump. The instrument is fitted with standard span and zero valves for switching between sample and calibration gas. Alarm relays are optional and if included, that option will be checked below.

Model 6200T — with Pump

This version is equipped with an internal pump and is designed for positive pressure applications.

Power Requirements

This Model 6200T is configured to operate from the following AC Power source:

100-120 VAC 60 Hz |

220-240 VAC 60 Hz |

100V 60 Hz |

100-120 VAC 50 Hz |

220-240 VAC 50 Hz |

100V 50 Hz |

Analog Output Signals

Analog output signals are available at A1 and A2 on the rear panel. This instrument is configured with the following analog outputs:

A1: 4-20 mA |

|

A2: 0-5 V |

A2: 4-20 mA |

Range Mode

The analyzer can be designed with a single or dual analysis ranges with auto-ranging or dual independent ranges. This analyzer is configured with the following range mode:

Single Range: |

|

|

Dual Range/Auto-ranging |

Dual Range/Independent |

|

Low |

Low |

|

Range: |

|

Range: |

High |

High |

|

Range: |

|

Range: |

Teledyne Analytical Instruments |

iii |

Configuration |

Model 6200T Total Sulfur Analyzer |

Selected Options for the Model 6200T

Calibrator Option:

This option includes a Model 702 Calibrator for precise blending of calibration gases.

Mounting Options

19” rack mounting with 26” sliders with ears 19” rack mounting with ears only

Rear Panel Gas Fittings

1/4” SS Standard 6 mm SS Optional

Valve Options

The standard unit includes internal span and zero valves. Additional valve options are as follows:

Internal Zero/Span Valves with Oven (IZS Option) Internal Zero/Span Valves with Oven and Permeation Tube.

Note: The permeation tube option installed depends on the sample gas (H2S or SO2) and the effusion rate.

Alarm Relays

The standard instrument is equipped with two configurable concentration alarms and one fixed system failure alarm.

Profibus Mounting Option

RS232 to Profibus Circuit Board: Special RS232 to Profibus PCB card for Profibus communication using the existing RS232 port.

Background Gas:

Notes:

Teledyne Analytical Instruments |

iv |

6200T Total Sulfur Analyzer |

About This Manual |

ABOUT THIS MANUAL

This manual describes operation, specifications, and maintenance for the Model 6200T.

In addition this manual contains important SAFETY messages for this instrument. It is strongly recommended that you read that operation manual in its entirety before operating the instrument.

.

Teledyne Analytical Instruments |

v |

About This Manual |

Model 6200T Total Sulfur Analyzer |

This page intentionally left blank.

Teledyne Analytical Instruments |

vi |

6200T Total Sulfur Analyzer |

Safety Messages |

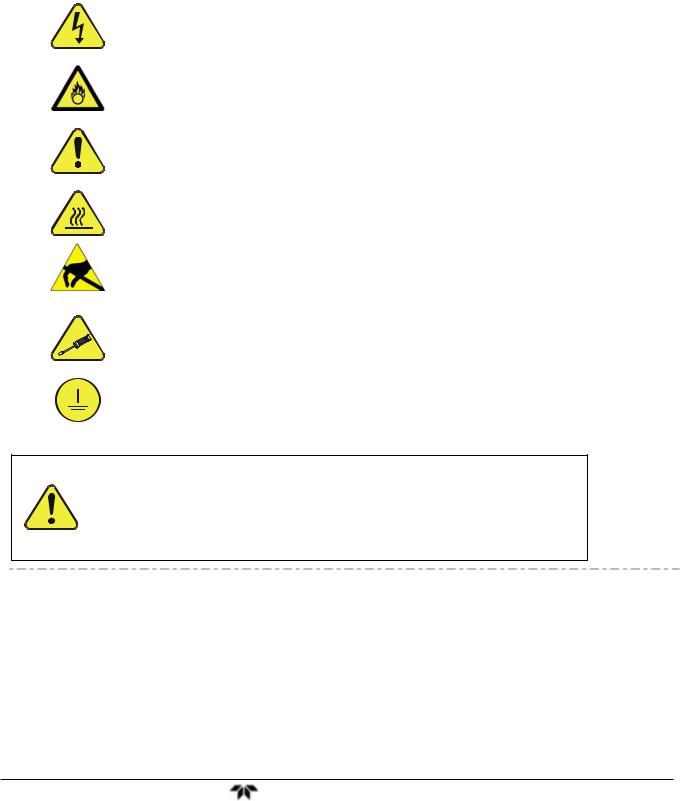

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of avoiding personal injury or instrument damage. Please read these messages carefully. Each safety message is associated with a safety

alert symbol, and are placed throughout this manual; the safety symbols are also located inside the instrument. It is imperative that you pay close attention to these messages, the descriptions of which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message for specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without protection or proper tools could result in damage to the part(s) and/or the instrument.

Technician Symbol: All operations marked with this symbol are to be performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central safety grounding point for the instrument.

CAUTION

This instrument should only be used for the purpose and in the manner described in this manual. If you use this instrument in a manner other than that for which it was intended, unpredictable behavior could ensue with possible hazardous consequences.

NEVER use any gas analyzer to sample combustible gas(es)!

Note: Technical Assistance regarding the use and maintenance of the 6200T or any other Teledyne product can be obtained by contacting Teledyne Customer Service Department:

Phone: 888-789-8168

Email: ask_tai@teledyne.com

or by accessing various service options on our website at http://www.teledyne-ai.com/

Teledyne Analytical Instruments |

vii |

Safety Messages |

Model 6200T Total Sulfur Analyzer |

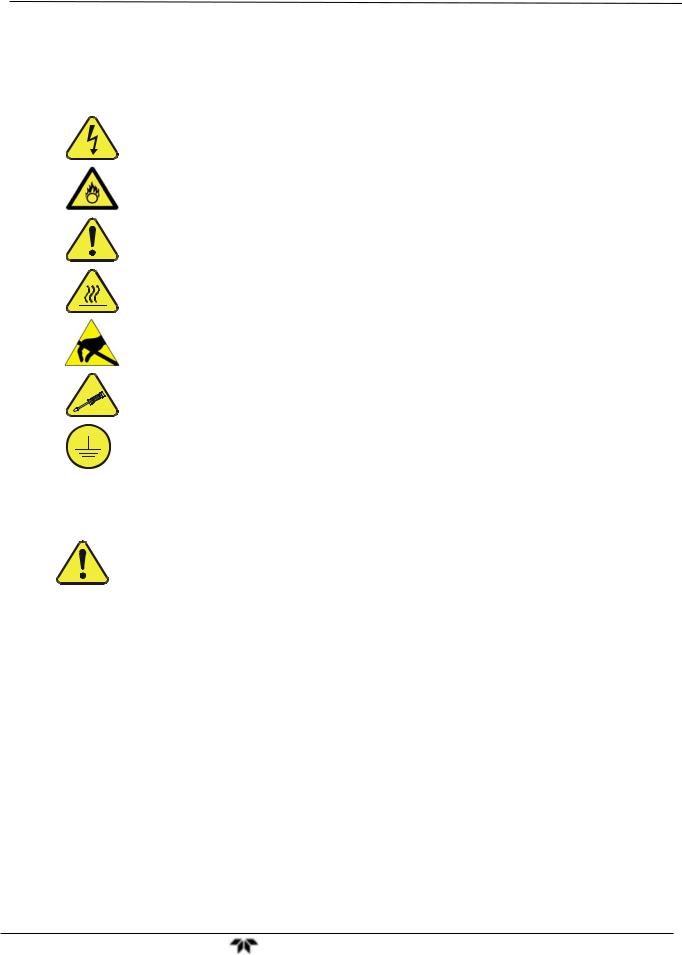

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans le but d’éviter des blessures corporelles ou d’endommager les instruments. Veuillez lire attentivement ces consignes. Chaque consigne de sécurité est représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se retrouvent dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans protection ou sans les outils appropriés pourrait entraîner des dommages aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce symbole doivent être effectuées uniquement par du personnel de maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le point central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière décrite dans ce manuel. Si vous utilisez cet instrument d’une autre manière que celle pour laquelle il a été prévu, l’instrument pourrait se comporter de façon imprévisible et entraîner des conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz combustibles!

Teledyne Analytical Instruments |

viii |

6200T Total Sulfur Analyzer |

Table of Contents |

TABLE OF CONTENTS |

|

Selected Versions of the Model 6200T.............................................................................................................. |

iii |

Model 6200T— Standard Version..................................................................................................................... |

iii |

Model 6200T — with Pump............................................................................................................................... |

iii |

Power Requirements ........................................................................................................................................ |

iii |

Analog Output Signals ...................................................................................................................................... |

iii |

Range Mode...................................................................................................................................................... |

iii |

Selected Options for the Model 6200T.............................................................................................................. |

iv |

Calibrator Option:.............................................................................................................................................. |

iv |

Mounting Options....................................................................................................................................... |

iv |

Rear Panel Gas Fittings................................................................................................................................... |

iv |

Valve Options.................................................................................................................................................... |

iv |

Alarm Relays..................................................................................................................................................... |

iv |

Profibus Mounting Option ................................................................................................................................. |

iv |

Background Gas: .............................................................................................................................................. |

iv |

Notes:................................................................................................................................................................ |

iv |

SAFETY MESSAGES ............................................................................................................. |

VII |

CONSIGNES DE SÉCURITÉ ................................................................................................. |

VIII |

TABLE OF CONTENTS ........................................................................................................... |

IX |

List of Figures..................................................................................................................................................... |

xv |

List of Tables ................................................................................................................................................... |

xviii |

PART I GENERAL INFORMATION ........................................................................................ |

21 |

1. INTRODUCTION, FEATURES AND OPTIONS .................................................................. |

23 |

1.1. 6200T Overview ........................................................................................................................................... |

23 |

1.2. Features ....................................................................................................................................................... |

23 |

1.3. 6200T Documentation................................................................................................................................. |

24 |

1.4. Options......................................................................................................................................................... |

24 |

1.5. Configurations............................................................................................................................................. |

27 |

1.6. The M501TS – Total Reduced Sulfur Converter....................................................................................... |

31 |

2. SPECIFICATIONS, APPROVALS & COMPLIANCE.......................................................... |

35 |

2.1. Specifications and Approvals.................................................................................................................... |

35 |

2.2. EPA Equivalency Designation ................................................................................................................... |

37 |

2.3. CE Mark Compliance .................................................................................................................................. |

38 |

2.3.1. Emissions Compliance........................................................................................................................... |

38 |

2.3.2. Safety Compliance................................................................................................................................. |

38 |

3. GETTING STARTED........................................................................................................... |

39 |

3.1. Unpacking the 6200T Analyzer .................................................................................................................. |

39 |

3.1.1. Ventilation Clearance............................................................................................................................. |

40 |

3.2. Instrument Layout....................................................................................................................................... |

40 |

3.2.1. Front Panel ............................................................................................................................................ |

40 |

3.2.2. Rear Panel ............................................................................................................................................. |

44 |

3.2.3. Internal Chassis Layout ......................................................................................................................... |

46 |

3.3. Connections and Setup.............................................................................................................................. |

48 |

3.3.1. Electrical Connections ........................................................................................................................... |

48 |

3.3.2. Pneumatic Connections ......................................................................................................................... |

62 |

3.4. Startup, Functional Checks, and Initial Calibration................................................................................. |

74 |

3.4.1. Startup.................................................................................................................................................... |

74 |

3.4.2. Warning Messages ................................................................................................................................ |

77 |

3.4.3. Functional Checks ................................................................................................................................. |

79 |

3.4.4. Initial Calibration .................................................................................................................................... |

81 |

PART II OPERATING INSTRUCTIONS.................................................................................. |

87 |

4. OVERVIEW OF OPERATING MODES ............................................................................... |

89 |

4.1. Sample Mode ............................................................................................................................................... |

90 |

4.1.1. Test Functions ....................................................................................................................................... |

90 |

Teledyne Analytical Instruments |

ix |

Table of Contents |

Model 6200T Total Sulfur Analyzer |

|

4.1.2. Warning Messages ................................................................................................................................ |

|

93 |

4.2. Calibration Mode ......................................................................................................................................... |

|

95 |

4.3. Setup Mode.................................................................................................................................................. |

|

95 |

4.3.1. Password Security ................................................................................................................................. |

|

95 |

4.3.2. Primary Setup Menu .............................................................................................................................. |

|

96 |

4.3.3. Secondary Setup Menu (SETUP>MORE)............................................................................................. |

|

96 |

5. SETUP MENU ..................................................................................................................... |

|

97 |

5.1. SETUP – CFG: Configuration Information................................................................................................ |

|

97 |

5.2. SETUP – ACAL: Automatic Calibration Option........................................................................................ |

|

97 |

5.3. SETUP – DAS: Internal Data Acquisition System.................................................................................... |

|

97 |

5.4. SETUP – RNGE: Analog Output Reporting Range Configuration.......................................................... |

97 |

|

5.4.1. Available Analog Output Signals ........................................................................................................... |

|

98 |

5.4.2. Physical Range versus Analog Output Reporting Ranges .................................................................... |

98 |

|

5.4.3. Reporting Range Modes: Single, Dual, Auto Ranges ......................................................................... |

|

100 |

5.4.4. Range Units ......................................................................................................................................... |

|

103 |

5.4.5. Dilution Ratio (Option).......................................................................................................................... |

|

105 |

5.5. SETUP – PASS: Password Protection .................................................................................................... |

|

106 |

5.6. SETUP – CLK: Setting the Internal Time-of-Day Clock ......................................................................... |

|

109 |

5.7. SETUP – COMM: Communications Ports............................................................................................... |

|

111 |

5.7.1. ID (Instrument Identification)................................................................................................................ |

|

111 |

5.7.2. INET (Ethernet).................................................................................................................................... |

|

112 |

5.7.3. COM1 and COM2 (Mode, Baud Rate and Test Port).......................................................................... |

|

112 |

5.8. SETUP – VARS: Variables Setup and Definition.................................................................................... |

|

113 |

5.9. SETUP – DIAG: Diagnostics Functions .................................................................................................. |

|

115 |

5.9.1. Signal I/O ............................................................................................................................................. |

|

117 |

5.9.2. Analog Output Step Test...................................................................................................................... |

|

118 |

5.9.3. Analog I/O Configuration...................................................................................................................... |

|

119 |

5.9.4. Optic Test............................................................................................................................................. |

|

132 |

5.9.5. Electrical Test ...................................................................................................................................... |

|

133 |

5.9.6. Lamp Calibration.................................................................................................................................. |

|

134 |

5.9.7. Pressure Calibration ............................................................................................................................ |

|

135 |

5.9.8. Flow Calibration ................................................................................................................................... |

|

136 |

5.9.9. Test Channel Output............................................................................................................................ |

|

137 |

6. COMMUNICATIONS SETUP AND OPERATION ............................................................. |

|

139 |

6.1. Data Terminal / Communication Equipment (DTE DCE) ....................................................................... |

|

139 |

6.2. Communication Modes, Baud Rate and Port testing ............................................................................ |

|

139 |

6.2.1. Communication Modes ........................................................................................................................ |

|

140 |

6.2.2. COMM Port Baud Rate ........................................................................................................................ |

|

142 |

6.2.3. COMM Port Testing ............................................................................................................................. |

|

143 |

6.3. RS-232 ........................................................................................................................................................ |

|

143 |

6.4. RS-485 (Option) ......................................................................................................................................... |

|

144 |

6.5. Ethernet...................................................................................................................................................... |

|

144 |

6.5.1. Configuring Ethernet Communication Manually (Static IP Address) ................................................... |

144 |

|

6.5.2. Configuring Ethernet Communication Using Dynamic Host Configuration Protocol (DHCP) ............. |

147 |

|

6.5.3. USB Port .............................................................................................................................................. |

|

148 |

6.6. Communications Protocols ..................................................................................................................... |

|

149 |

6.6.1. MODBUS ............................................................................................................................................. |

|

149 |

6.6.2. HESSEN .............................................................................................................................................. |

|

151 |

7. DATA ACQUISITION SYSTEM (DAS) AND AICOM ........................................................ |

|

157 |

7.1. DAS Structure............................................................................................................................................ |

|

158 |

7.1.1. DAS Channels ..................................................................................................................................... |

|

158 |

7.1.2. DAS Parameters .................................................................................................................................. |

|

159 |

7.1.3. DAS Triggering Events ........................................................................................................................ |

|

159 |

7.2. Default DAS Channels .............................................................................................................................. |

|

160 |

7.2.1. Viewing DAS Data and Settings .......................................................................................................... |

|

162 |

7.2.2. Editing DAS Data Channels................................................................................................................. |

|

163 |

7.2.3. Trigger Events...................................................................................................................................... |

|

165 |

7.2.4. Editing DAS Parameters...................................................................................................................... |

|

166 |

Teledyne Analytical Instruments |

x |

6200T Total Sulfur Analyzer |

Table of Contents |

7.2.5. Sample Period and Report Period ....................................................................................................... |

167 |

7.2.6. Number of Records.............................................................................................................................. |

169 |

7.2.7. RS-232 Report Function ...................................................................................................................... |

171 |

7.2.8. Compact Report................................................................................................................................... |

171 |

7.2.9. Starting Date ........................................................................................................................................ |

171 |

7.2.10. Disabling/Enabling Data Channels .................................................................................................... |

171 |

7.2.11. HOLDOFF Feature ............................................................................................................................ |

173 |

7.3. AICOM Remote Control Program ............................................................................................................ |

173 |

7.4. Remote DAS Configuration via AICOM................................................................................................... |

175 |

8. REMOTE OPERATION OF THE ANALYZER................................................................... |

177 |

8.1. Remote Operation Using the External Digital I/O .................................................................................. |

177 |

8.1.1. Status Outputs ..................................................................................................................................... |

177 |

8.1.2. Control Inputs....................................................................................................................................... |

178 |

8.2. Remote Operation Using the External Serial I/O ................................................................................... |

179 |

8.2.1. Terminal Operating Modes .................................................................................................................. |

179 |

8.2.2. Help Commands in Terminal Mode ..................................................................................................... |

180 |

8.2.3. Command Syntax ................................................................................................................................ |

180 |

8.2.4. Data Types........................................................................................................................................... |

181 |

8.2.5. Status Reporting .................................................................................................................................. |

181 |

8.3. Remote Access by Modem....................................................................................................................... |

182 |

8.4. COM Port Password Security .................................................................................................................. |

184 |

8.5. Additional Communications Documentation......................................................................................... |

185 |

9. CALIBRATION PROCEDURES........................................................................................ |

187 |

9.1. Calibration Preparations .......................................................................................................................... |

187 |

9.1.1. Required Equipment, Supplies, and Expendables .............................................................................. |

187 |

9.1.2. Data Recording Devices ...................................................................................................................... |

189 |

9.2. Manual Calibration .................................................................................................................................... |

189 |

9.3. Manual Calibration Checks ...................................................................................................................... |

193 |

9.4. Manual Calibration with Zero/Span Valves............................................................................................. |

194 |

9.5. Manual Calibration with IZS Option ........................................................................................................ |

197 |

9.6. Manual Calibration Checks with IZS or Zero/Span Valves ................................................................... |

197 |

9.7. Manual Calibration in DUAL or AUTO Reporting Range Modes .......................................................... |

200 |

9.7.1. Calibration With Remote Contact Closures ......................................................................................... |

200 |

9.8. Automatic Calibration (AutoCal) ............................................................................................................. |

201 |

9.9. Calibration Quality .................................................................................................................................... |

204 |

9.10. Calibration of Optional Sensors ............................................................................................................ |

205 |

9.10.1. O2 Sensor Calibration ........................................................................................................................ |

205 |

9.10.2. CO2 Sensor Calibration...................................................................................................................... |

209 |

10. EPA PROTOCOL CALIBRATION .................................................................................. |

213 |

10.1. Calibration Requirements ...................................................................................................................... |

213 |

10.1.1. Calibration of Equipment.................................................................................................................... |

213 |

10.1.2. Data Recording Device ...................................................................................................................... |

214 |

10.1.3. Recommended Standards for Establishing Traceability.................................................................... |

215 |

10.1.4. EPA Calibration Using Permeation Tubes......................................................................................... |

215 |

10.1.5. Calibration Frequency........................................................................................................................ |

215 |

10.1.6. Record Keeping ................................................................................................................................. |

215 |

10.1.7. Summary of Quality Assurance Checks ............................................................................................ |

216 |

10.2. Level 1 Calibrations versus Level 2 Checks ........................................................................................ |

216 |

10.3. ZERO and SPAN Checks........................................................................................................................ |

218 |

10.3.1. Zero/Span Check Procedures ........................................................................................................... |

218 |

10.4. Precision Calibration Procedures and Checks.................................................................................... |

218 |

10.4.1. Precision Calibration .......................................................................................................................... |

219 |

10.4.2. Precision Check ................................................................................................................................. |

219 |

10.5. Dynamic Multipoint Span Calibration ................................................................................................... |

219 |

10.6. Special Calibration Requirements for Dual Range or Auto Range.................................................... |

220 |

10.7. References............................................................................................................................................... |

220 |

PART III MAINTENANCE AND SERVICE ........................................................................... |

223 |

Teledyne Analytical Instruments |

xi |

Table of Contents |

Model 6200T Total Sulfur Analyzer |

11. INSTRUMENT MAINTENANCE...................................................................................... |

225 |

11.1. Maintenance Schedule ........................................................................................................................... |

226 |

11.2. Predictive Diagnostics............................................................................................................................ |

227 |

11.3. Maintenance Procedures........................................................................................................................ |

228 |

11.3.1. Changing the Sample Particulate Filter ............................................................................................. |

228 |

11.3.2. Changing the IZS Permeation Tube .................................................................................................. |

229 |

11.3.3. Changing theTS and Zero Air Scrubber Materials............................................................................. |

229 |

11.3.4. Changing the Critical Flow Orifice ..................................................................................................... |

230 |

11.3.5. Checking for Light Leaks ................................................................................................................... |

231 |

11.3.6. Detailed Pressure Leak Check .......................................................................................................... |

232 |

11.3.7. Performing a Sample Flow Check ..................................................................................................... |

233 |

11.3.8. Hydrocarbon Scrubber (Kicker) ......................................................................................................... |

233 |

12. TROUBLESHOOTING & SERVICE ................................................................................ |

237 |

12.1. General Troubleshooting ....................................................................................................................... |

237 |

12.1.1. Fault Diagnostics with Warning Messages........................................................................................ |

239 |

12.1.2. Fault Diagnosis with Test Functions .................................................................................................. |

242 |

12.1.3. Using the Diagnostic Signal I/O Functions ........................................................................................ |

243 |

12.2. Status LEDs ............................................................................................................................................. |

245 |

12.2.1. Motherboard Status Indicator (Watchdog)......................................................................................... |

245 |

12.2.2. CPU Status Indicators........................................................................................................................ |

245 |

12.2.3. Relay Board Status LEDs .................................................................................................................. |

246 |

12.3. Gas Flow Problems................................................................................................................................. |

246 |

12.3.1. Zero or Low Sample Flow.................................................................................................................. |

246 |

12.3.2. High Flow ........................................................................................................................................... |

247 |

12.4. Calibration Problems.............................................................................................................................. |

247 |

12.4.1. Negative Concentrations.................................................................................................................... |

247 |

12.4.2. No Response ..................................................................................................................................... |

247 |

12.4.3. Unstable Zero and Span .................................................................................................................... |

248 |

12.4.4. Inability to Span - No SPAN Button ................................................................................................... |

248 |

12.4.5. Inability to Zero - No ZERO Button .................................................................................................... |

249 |

12.4.6. Non-Linear Response ........................................................................................................................ |

249 |

12.4.7. Discrepancy Between Analog Output and Display ............................................................................ |

249 |

12.5. Other Performance Problems ................................................................................................................ |

250 |

12.5.1. Excessive noise ................................................................................................................................. |

250 |

12.5.2. Slow Response .................................................................................................................................. |

250 |

12.5.3. The Analyzer Doesn’t Appear on the LAN or Internet ....................................................................... |

250 |

12.6. Subsystem Checkout.............................................................................................................................. |

250 |

12.6.1. AC Power Configuration .................................................................................................................... |

251 |

12.6.2. DC Power Supply............................................................................................................................... |

252 |

12.6.3. I2C Bus ............................................................................................................................................... |

252 |

12.6.4. Touch-screen Interface ...................................................................................................................... |

253 |

12.6.5. LCD Display Module .......................................................................................................................... |

253 |

12.6.6. Relay Board ....................................................................................................................................... |

253 |

12.6.7. Motherboard....................................................................................................................................... |

254 |

12.6.8. CPU.................................................................................................................................................... |

255 |

12.6.9. RS-232 Communication..................................................................................................................... |

256 |

12.6.10. Shutter System ................................................................................................................................ |

257 |

12.6.11. PMT Sensor ..................................................................................................................................... |

257 |

12.6.12. PMT Preamplifier Board................................................................................................................... |

257 |

12.6.13. PMT Temperature Control PCA....................................................................................................... |

257 |

12.6.14. High Voltage Power Supply ............................................................................................................. |

258 |

12.6.15. Pneumatic Sensor Assembly........................................................................................................... |

259 |

12.6.16. Sample Pressure ............................................................................................................................. |

259 |

12.6.17. IZS Option........................................................................................................................................ |

259 |

12.6.18. Box Temperature ............................................................................................................................. |

260 |

12.6.19. PMT Temperature............................................................................................................................ |

260 |

12.7. Service Procedures................................................................................................................................. |

261 |

12.7.1. Disk-on-Module Replacement ........................................................................................................... |

261 |

Teledyne Analytical Instruments |

xii |

6200T Total Sulfur Analyzer |

Table of Contents |

12.7.2. Sensor Module Repair & Cleaning .................................................................................................... |

262 |

12.8. M501TS Converter Maintenance............................................................................................................ |

277 |

12.8.1. Changing the Quartz Tube................................................................................................................. |

277 |

12.8.2. Checking the Converter Efficiency..................................................................................................... |

277 |

12.8.3. Sample Diluter Maintenance.............................................................................................................. |

279 |

12.8.4. Thermocouple Replacement.............................................................................................................. |

279 |

12.9. Frequently Asked Questions (FAQs) .................................................................................................... |

283 |

12.10. Technical Assistance............................................................................................................................ |

284 |

13. PRINCIPLES OF OPERATION ....................................................................................... |

285 |

13.1. Sulfur Dioxide (SO2) Sensor Principles of operation .......................................................................... |

285 |

13.1.1. SO2 Ultraviolet Fluorescence Measurement Principle....................................................................... |

285 |

13.1.2. The UV Light Path.............................................................................................................................. |

288 |

13.1.3. UV Source Lamp................................................................................................................................ |

289 |

13.1.4. The Reference Detector..................................................................................................................... |

289 |

13.1.5. The PMT ............................................................................................................................................ |

289 |

13.1.6. UV Lamp Shutter & PMT Offset......................................................................................................... |

290 |

13.1.7. Optical Filters ..................................................................................................................................... |

290 |

13.1.8. Optical Lenses ................................................................................................................................... |

293 |

13.1.9. Measurement Interferences............................................................................................................... |

294 |

13.2. Oxygen (O2) Sensor Principles of Operation ....................................................................................... |

295 |

13.2.1. Paramagnetic Measurement of O2..................................................................................................... |

295 |

13.2.2. O2 Sensor Operation within the 6200T Analyzer ............................................................................... |

296 |

13.3. Carbon Dioxide (CO2) Sensor Principles of Operation ....................................................................... |

297 |

13.3.1. NDIR Measurement of CO2 ............................................................................................................... |

297 |

13.3.2. CO2 Operation within the 6200T Analyzer......................................................................................... |

298 |

13.3.3. Electronic Operation of the CO2 Sensor ............................................................................................ |

298 |

13.4. Pneumatic Operation.............................................................................................................................. |

299 |

13.4.1. Sample Gas Flow............................................................................................................................... |

299 |

13.4.2. Flow Rate Control .............................................................................................................................. |

300 |

13.4.3. Hydrocarbon Scrubber (Kicker) ......................................................................................................... |

301 |

13.4.4. Pneumatic Sensors............................................................................................................................ |

302 |

13.5. Electronic Operation............................................................................................................................... |

303 |

13.5.1. CPU.................................................................................................................................................... |

305 |

13.5.2. Sensor Module................................................................................................................................... |

306 |

13.5.3. Photo Multiplier Tube (PMT).............................................................................................................. |

308 |

13.5.4. PMT Cooling System ......................................................................................................................... |

310 |

13.5.5. PMT Preamplifier ............................................................................................................................... |

311 |

13.5.6. Pneumatic Sensor Board................................................................................................................... |

313 |

13.5.7. Relay Board ....................................................................................................................................... |

313 |

13.5.8. Motherboard....................................................................................................................................... |

315 |

13.5.9. Analog Outputs .................................................................................................................................. |

316 |

13.5.10. External Digital I/O ........................................................................................................................... |

317 |

13.5.11. I2C Data Bus .................................................................................................................................... |

317 |

13.5.12. Power up Circuit............................................................................................................................... |

317 |

13.5.13. Power Supply/ Circuit Breaker......................................................................................................... |

317 |

13.6. Front Panel/Display Interface ................................................................................................................ |

319 |

13.6.1. LVDS Transmitter Board.................................................................................................................... |

319 |

13.6.2. Front Panel Interface PCA................................................................................................................. |

319 |

13.7. Software Operation ................................................................................................................................. |

320 |

13.7.1. Adaptive Filter .................................................................................................................................... |

320 |

13.7.2. Calibration - Slope and Offset............................................................................................................ |

321 |

13.7.3. Temperature and Pressure Compensation (TPC) Feature ............................................................... |

321 |

13.7.4. Internal Data Acquisition System (DAS) ............................................................................................ |

322 |

14. A PRIMER ON ELECTRO-STATIC DISCHARGE .......................................................... |

325 |

14.1. How Static Charges are Created ........................................................................................................... |

325 |

14.2. How Electro-Static Charges Cause Damage........................................................................................ |

326 |

14.3. Common Myths About ESD Damage .................................................................................................... |

327 |

14.4. Basic Principles of Static Control ......................................................................................................... |

328 |

Teledyne Analytical Instruments |

xiii |

Table of Contents |

Model 6200T Total Sulfur Analyzer |

|

14.4.1. General Rules .................................................................................................................................... |

|

328 |

14.5. Basic Anti-ESD Procedures for Analyzer Repair and Maintenance .................................................. |

329 |

|

14.5.1. Working at the Instrument Rack ........................................................................................................ |

|

329 |

14.5.2. Working at an Anti-ESD Work Bench ................................................................................................ |

|

330 |

14.5.3. Transferring Components Between Rack and Bench ....................................................................... |

|

330 |

14.5.4. Opening Shipments from Teledyne Analytical Instruments’s Customer Service ................................ |

331 |

|

14.5.5. Packing Components for Return to Teledyne Analytical Instruments’s Customer Service............... |

331 |

|

15. GLOSSARY..................................................................................................................... |

|

333 |

16. SPARE PARTS ............................................................................................................... |

|

337 |

16.1. Spare Parts and Expendables Lists ...................................................................................................... |

|

337 |

17. INSTRUMENT TEST & CALIBRATION RECORD ......................................................... |

|

341 |

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION

APPENDIX B - SPARE PARTS, 6200T

APPENDIX C - REPAIR QUESTIONNAIRE, 6200T

APPENDIX D - ELECTRONIC SCHEMATICS, 6200T

Teledyne Analytical Instruments |

xiv |

6200T Total Sulfur Analyzer |

Table of Contents |

||

LIST OF FIGURES |

|

|

|

Figure 1-1: |

6200T Basic Configuration........................................................................................................... |

|

28 |

Figure 1-2: |

6200T with IZS/Permeation Tube Option .................................................................................... |

|

29 |

Figure 1-3: |

6200T with M702 Calibrator Option ............................................................................................. |

|

30 |

Figure 1-4: |

M501TS Converter Layout........................................................................................................... |

|

32 |

Figure 3-1: |

Front Panel Layout....................................................................................................................... |

|

41 |

Figure 3-2: |

Display Screen and Touch Control .............................................................................................. |

|

41 |

Figure 3-3: |

Display/Touch Control Screen Mapped to Menu Charts ............................................................ |

|

43 |

Figure 3-4: |

Rear Panel Layout—Converter and Analyzer.............................................................................. |

|

44 |

Figure 3-5A: |

Internal Layout, Basic (no Valve or Second Gas Options) .......................................................... |

|

46 |

Figure 3-6: |

Analog In Connector .................................................................................................................... |

|

49 |

Figure 3-7: |

Analog Output Connector ............................................................................................................ |

|

50 |

Figure 3-8: |

Current Loop Option Installed on the Motherboard ..................................................................... |

|

52 |

Figure 3-9: |

Status Output Connector ............................................................................................................. |

|

53 |

Figure 3-10: |

Control Input Connector............................................................................................................... |

|

55 |

Figure 3-11: |

Concentration Alarm Relay.......................................................................................................... |

|

56 |

Figure 3-12: |

Rear Panel Connector Pin-Outs for RS-232 Mode...................................................................... |

|

58 |

Figure 3-13: |

CPU Connector Pin-Outs for RS-232 Mode ................................................................................ |

|

59 |

Figure 3-14: |

JP2 Pins 21-22 on RS-232-Multidrop PCA.................................................................................. |

|

60 |

Figure 3-15: |

RS-232-Multidrop PCA Host/Analyzer Interconnect Diagram ..................................................... |

|

61 |

Figure 3-16: |

Pneumatic Connections–Basic Configuration–Using Bottled Span Gas..................................... |

|

65 |

Figure 3-17: |

Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator |

.............................66 |

|

Figure 3-18: |

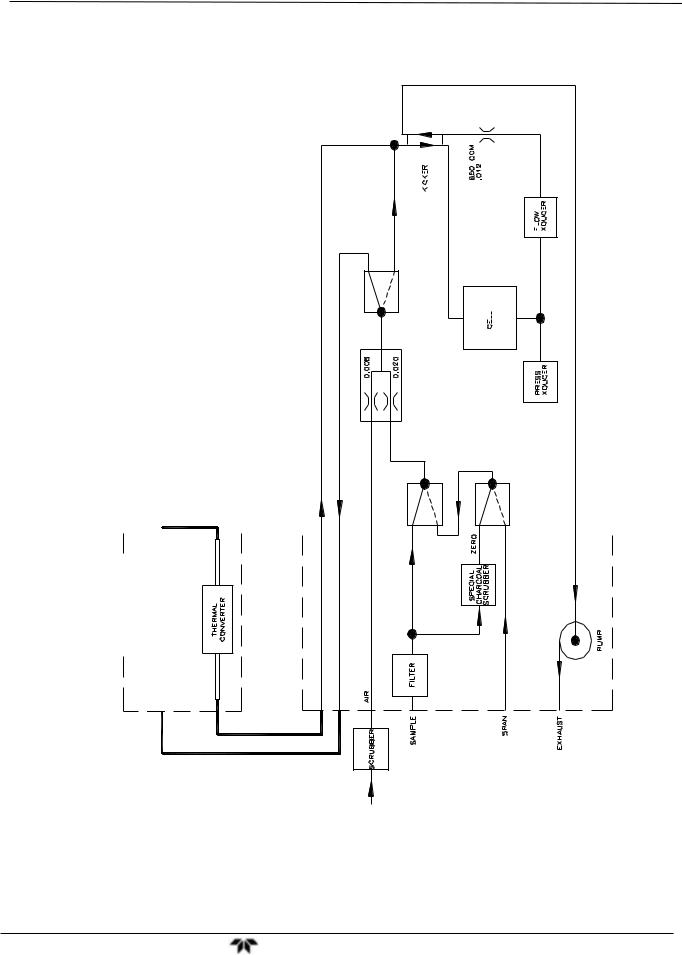

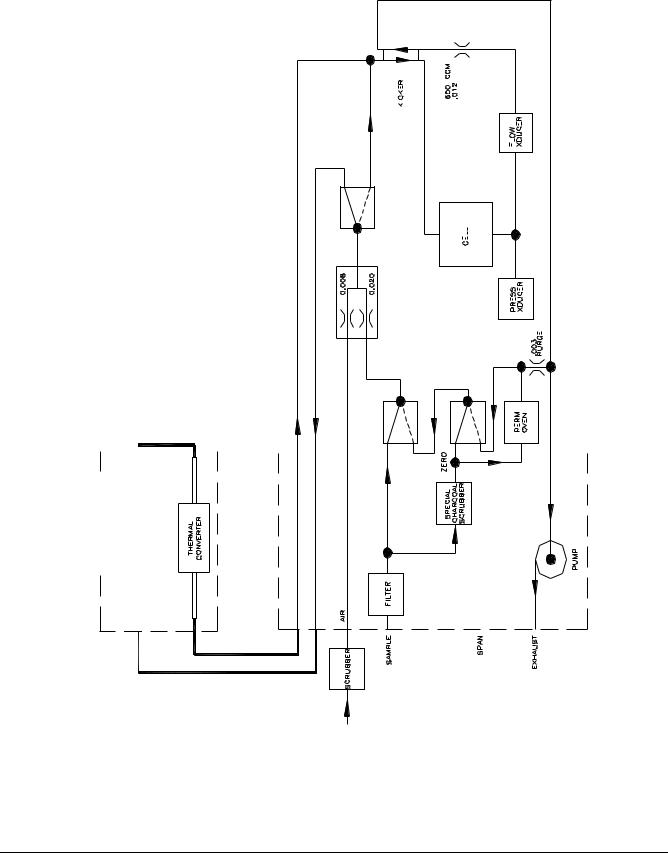

6200T Gas Flow, Basic Configuration ......................................................................................... |

|

67 |

Figure 3-19: |

Pneumatic Layout with Zero/Span Valves Option ....................................................................... |

|

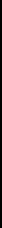

68 |

Figure 3-20: |

Pneumatic Layout with IZS Options............................................................................................. |

|

69 |

Figure 3-21: |

Pneumatic Layout with O2 Sensor ............................................................................................... |

|

71 |

Figure 3-22: |

Pneumatic Layout with CO2 Sensor............................................................................................. |

|

72 |

Figure 3-23: |

Warning Messages ...................................................................................................................... |

|

77 |

Figure 3-24: |

Functional Check ......................................................................................................................... |

|

80 |

Figure 3-25: |

Reporting Range Verification....................................................................................................... |

|

82 |

Figure 3-26: |

Dilution Ratio Setup ..................................................................................................................... |

|

83 |

Figure 3-27: |

SO2 Span Gas Setting ................................................................................................................. |

|

84 |

Figure 3-28: |

Zero/Span Calibration Procedure ................................................................................................ |

|

85 |

Figure 4-1: |

Front Panel Display...................................................................................................................... |

|

89 |

Figure 4-2: |

Viewing 6200T TEST Functions .................................................................................................. |

|

92 |

Figure 4-3: |

Viewing and Clearing 6200T WARNING Messages.................................................................... |

|

94 |

Figure 5-1: |

SETUP – Configuration Information ............................................................................................ |

|

97 |

Figure 5-2: |

SETUP – Analog Output Connector ............................................................................................ |

|

98 |

Figure 5-3: |

SETUP RNGE – Reporting Range Mode .................................................................................. |

|

100 |

Figure 5-4: |

SETUP RNGE – Single Range Mode........................................................................................ |

|

101 |

Figure 5-5: |

SETUP RNGE – Dual Range Mode .......................................................................................... |

|

102 |

Figure 5-6: |

SETUP RNGE – Auto Range Mode .......................................................................................... |

|

103 |

Figure 5-7: |

SETUP RNGE – Concentration Units Selection........................................................................ |

|

104 |

Figure 5-8: |

SETUP RNGE – Dilution Ratio .................................................................................................. |

|

105 |

Figure 5-9: |

SETUP – Enable Password Security......................................................................................... |

|

107 |

Figure 5-10: |

SETUP – Enter Calibration Mode Using Password................................................................... |

|

108 |

Figure 5-11: |

SETUP – Clock .......................................................................................................................... |

|

109 |

Figure 5-12: |

SETUP – Clock Speed Variable ................................................................................................ |

|

110 |

Figure 5-13: |

SETUP – COMM Menu.............................................................................................................. |

|

111 |

Figure 5-14: |

COMM – Machine ID ................................................................................................................ |

|

112 |

Figure 5-15: |

SETUP – VARS Menu ............................................................................................................... |

|

114 |

Figure 5-16: |

DIAG Menu ................................................................................................................................ |

|

116 |

Figure 5-17: |

DIAG – Signal I/O Menu ............................................................................................................ |

|

117 |

Figure 5-18: |

DIAG – Analog Output Menu ..................................................................................................... |

|

118 |

Figure 5-19: |

DIAG – Analog I/O Configuration Menu..................................................................................... |

|

121 |

Figure 5-20: |

DIAG – Analog Output Calibration Mode................................................................................... |

|

122 |

Figure 5-21: |

DIAG – Analog Output Calibration Mode – Single Analog Channel.......................................... |

|

123 |

Teledyne Analytical Instruments |

xv |

Table of Contents |

Model 6200T Total Sulfur Analyzer |

||

Figure 5-22: |

DIAG – Analog Output – Auto Cal or Manual Cal Selection for Channels ................................ |

124 |

|

Figure 5-23: |

Setup for Calibrating Analog Outputs ........................................................................................ |

|

125 |

Figure 5-24: |

Analog Output – Voltage Adjustment......................................................................................... |

|

126 |

Figure 5-25: |

Analog Output – Offset Adjustment ........................................................................................... |

|

127 |

Figure 5-26: |

Setup for Calibrating Current Outputs ....................................................................................... |

|

128 |

Figure 5-27: |

Analog Output – Zero and Span Value Adjustment for Current Outputs................................... |

129 |

|

Figure 5-28: |

DIAG – Analog Output – AIN Calibration................................................................................... |

|

130 |

Figure 5-29. |

DIAG – Analog Inputs (Option) Configuration Menu ................................................................. |

131 |

|

Figure 5-30: |

DIAG – Optic Test...................................................................................................................... |

|

132 |

Figure 5-31: |

DIAG – Electrical Test................................................................................................................ |

|

133 |

Figure 5-32: |

DIAG – Lamp Calibration........................................................................................................... |

|

134 |

Figure 5-33: |

DIAG – Pressure Calibration ..................................................................................................... |

|

135 |

Figure 5-34: |

DIAG – Flow Calibration ............................................................................................................ |

|

136 |

Figure 5-35: |

DIAG – Test Channel Output..................................................................................................... |

|

137 |

Figure 6-1: |

COMM – Communication Modes Setup .................................................................................... |

|

141 |

Figure 6-2: |

COMM – COMM Port Baud Rate .............................................................................................. |

|

142 |

Figure 6-3: |

COMM – COM1 Test Port.......................................................................................................... |

|

143 |

Figure 6-4: |

COMM – LAN / Internet Manual Configuration.......................................................................... |

|

146 |

Figure 6-5: |

COMM – LAN / Internet Automatic Configuration...................................................................... |

|

147 |

Figure 6-6: |

COMM – Change Hostname .................................................................................................... |

|

148 |

Figure 6-7: |

COMM – Activating Hessen Protocol ........................................................................................ |

|

152 |

Figure 6-8: |

COMM – Select Hessen Protocol Type ..................................................................................... |

|

153 |

Figure 6-9: |

COMM – Select Hessen Protocol Response Mode................................................................... |

|

154 |

Figure 6-10: |

COMM – Status Flag Bit Assignment ........................................................................................ |

|

156 |

Figure 7-1: |

Default DAS Channels Setup .................................................................................................... |

|

161 |

Figure 7-2: |

DAS – Data Acquisition Menu ................................................................................................... |

|

162 |

Figure 7-3: |

DAS – Editing DAS Data Channels ........................................................................................... |

|

163 |

Figure 7-4: |

DAS – Editing Data Channel Name........................................................................................... |

|

164 |

Figure 7-5: |

DAS – Trigger Events ................................................................................................................ |

|

165 |

Figure 7-6: |

DAS – Editing DAS Parameters ................................................................................................ |

|

166 |

Figure 7-7: |

DAS – Configuring Parameters for a Specific Data Parameter ................................................. |

167 |

|

Figure 7-8: |

DAS – Define the Report Period................................................................................................ |

|

169 |

Figure 7-9: |

DAS – Edit Number of Records ................................................................................................. |

|

170 |

Figure 7-10: |

DAS – RS-232 Report Function................................................................................................. |

|

171 |

Figure 7-11: |

DAS – Disabling / Enabling Data Channels............................................................................... |

|

172 |

Figure 7-12: |

DAS – Holdoff Feature............................................................................................................... |

|

173 |

Figure 7-13: |

AICOM Remote Control Program Interface ............................................................................... |

|

174 |

Figure 7-14: |

Sample AICOM User Interface for Configuring the DAS ........................................................... |

175 |

|

Figure 7-15: |

DAS Configuration Through a Terminal Emulation Program..................................................... |

176 |

|

Figure 8-1: |

Status Output Connector ........................................................................................................... |

|

177 |

Figure 8-2: |

Control Inputs with Local 5 V Power Supply.............................................................................. |

|

179 |

Figure 8-3: |

Control Inputs with External 5 V Power Supply ......................................................................... |

|

179 |

Figure 8-4: |

COMM – Remote Access by Modem ........................................................................................ |

|

183 |

Figure 8-5: |

COMM – Initialize the Modem ................................................................................................... |

|

184 |

Figure 9-1: |

Setup for Manual Calibration without Z/S valve or IZS Option (Step 1) .................................... |

190 |

|

Figure 9-2: |

Setup for Manual Calibration without Z/S valve or IZS Option (Step 2) .................................... |

191 |

|

Figure 9-3: |

Setup for Manual Calibration without Z/S valve or IZS Option (Step 3) .................................... |

192 |

|

Figure 9-4: |

Setup for Manual Calibration Checks ........................................................................................ |

|

193 |

Figure 9-5: |

Setup for Manual Calibration with Z/S Valve Option Installed (Step 1) ..................................... |

194 |

|

Figure 9-6: |