Teledyne HASTINGS 200 User Manual

TELEDYNE HASTINGS

INSTRUCTION MANUAL INSTRUMENTS

HASTINGS 200 SERIES

FAST RESPONSE

MASS FLOWMETERS

126B - PAGE 1

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual.The revision level letter increases alphabetically as the manual undergoes subsequent updates.Addenda, which are released between revisions, contain important change information that the user should incorporate immediately into the manual.Addenda are numbered sequentially. When a new revision is created, all addenda associated with the previous revision of the manual are incorporated into the new revision of the manual. Each new revision includes a revised copy of this print history page.

Revision B (Document Number 126-082000) ............................................................ |

August 2000 |

Revision C (Document Number 126-082005) ............................................................ |

August 2005 |

Visit www.teledyne-hi.com for WEEE disposal guidance.

Hastings Instruments reserves the right to change or modify the design of its equipment without any obligation to provide notification of change or intent to change.

126B - PAGE 2

TABLE OF CONTENTS

SECTION 1.0 |

GENERAL INFORMATION.............................................................................................. |

5 |

|

1.1 |

Features ............................................................................................................... |

5 |

|

1.2 |

Specifications ...................................................................................................... |

5 |

|

1.3 |

Accessories .......................................................................................................... |

6 |

|

1.3.1 Power Supplies ................................................................................................. |

6 |

||

1.3.2 Alarms .............................................................................................................. |

6 |

||

1.3.3 Totalizer............................................................................................................ |

6 |

||

1.3.4 4-20 mA Current Converter ............................................................................ |

6 |

||

SECTION 2.0 INSTALLATION AND OPERATION ................................................................................. |

7 |

||

2.1 |

Receiving Inspection ........................................................................................... |

7 |

|

2.2 |

Power Requirements ........................................................................................... |

7 |

|

2.3 |

Output Voltage .................................................................................................... |

7 |

|

2.4 |

Mechanical Connections .................................................................................... |

7 |

|

2.5 |

Electrical Connections ........................................................................................ |

8 |

|

2.6 |

Operation ............................................................................................................ |

8 |

|

2.6.1 |

Power Supply Operation .................................................................................. |

8 |

|

2.6.2 Ambient Temperature....................................................................................... |

8 |

||

2.6.3 Zero Check ...................................................................................................... |

8 |

||

2.7 |

Range Changing .................................................................................................. |

8 |

|

SECTION 3.0 THEORY OF OPERATION ............................................................................................. |

9 |

||

3.1 |

Overall Functional Description ........................................................................... |

9 |

|

3.2 |

Sensor ................................................................................................................. |

9 |

|

3.3 |

Electronics .......................................................................................................... |

10 |

|

3.4 |

Shunt .................................................................................................................. |

10 |

|

SECTION 4.0 |

MAINTENANCE ........................................................................................................... |

13 |

|

4.1 |

Introduction ........................................................................................................ |

13 |

|

4.2 |

Authorized Maintenance ..................................................................................... |

13 |

|

4.3 |

Adjustments......................................................................................................... |

13 |

|

4.3.1 |

Calibration Procedure ...................................................................................... |

13 |

|

4.3.2 ResponseTime Adjustments ............................................................................ |

13 |

||

4.3.3 Miscellaneous Adjustments .............................................................................. |

13 |

||

4.4 |

End Cap Removal ............................................................................................... |

14 |

|

4.5 |

Range Changes ................................................................................................... |

14 |

|

126B - PAGE 3

4.6 |

Printed Circuit Board Replacement .................................................................... |

15 |

4.7 |

Sensor Replacement............................................................................................ |

15 |

4.8 |

Troubleshooting .................................................................................................. |

15 |

SECTION 5.0 REPLACEMENT PARTS ................................................................................................. |

17 |

|

SECTION 6.0 WARRANTY AND REPAIR .............................................................................................. |

19 |

|

SECTION 7.0 DIAGRAMS AND DRAWINGS ........................................................................................ |

21 |

|

AssemblyDiagram,PC810FastReponse............................................................................. |

22 |

|

Schematic, PC-810 Fast Response ..................... ............................................................ |

23 |

|

HFM-200 Outline Drawng................................................................................................ |

24 |

|

HFM-201 Outline Drawing ....................................................................................... |

25 |

|

HFM-200B Outline Drawing .................................................................................... |

26 |

|

Laminar Flow Element Outline Drawing .................................................................. |

27 |

|

126B - PAGE 4

1.0 GENERAL INFORMATION

Hastings Mass Flowmeters are designed to accurately measure mass flow without corrections or compensations for gas pressure and temperature. Due to a linear electrical output signal, the flowmeters are ideal for use with totalizers and recorders. Hastings Mass Flowmeters do not require any periodic maintenance under normal operating conditions with clean gases. No damage will occur from the use of moderate overpressures or overflows.

The standard flowmeter calibration is for air. Special calibrations for most other gases such as oxygen, nitrogen, hydrogen, and carbon monoxide are available on special order, or by use of a gas multiplier. These instruments are calibrated with air at the factory, then the output is adjusted using gas correction factors.

1.1 Features

Hastings Fast Response HFM Flowmeters have response times of less than two seconds to 98% of a 0-100% step change with less than 2% overshoot.

Fast Response HFM Flowmeters are available with a 15-pin “D” connector and are pin for pin compatible with most other manufacturers’ thermal mass flowmeters with 20-pin connectors.

HFM Models incorporate a removable/replaceable sensor which virtually eliminates long down time due to clogging, the most common cause of failure in the industry.

Each flowmeter has a shunt which can be quickly and easily adjusted in the field to different ranges, however, recalibration is normally required.

A 100 micron filter is located upstream of the shunt and sensor to eliminate most of the larger impurities in the system which tend to plug thermal mass flowmeters.

The Model HFM Flowmeter comes in 15 standard ranges from 0-10 SCCM to 0-500 SLPM. Special ranges are available upon request.

Model HFM Flowmeters are constructed of 300 series stainless steel.Viton is standard for O-rings & seals. Neoprene and Kalrez are available upon request, for use with corrosive gases.

1.2 Specifications

• ResponseTime .......................................................... |

(to 98% of 0-100% step change)Less than 2 seconds |

• Accuracy & Linearity ................................................................................................................. |

±1% (F.S.) |

• Repeatability .......................................................................................................................... |

±0.2% (F.S.) |

• Std. Pressure Rating ...................................................................................................................... |

500 psig |

• High Pressure Option ....................................................................... |

1000 psig (proof tested to 1500 psig) |

• Pressure Coefficient ........................................................................................... |

(0-500 psig N2) 0.01%/psi |

• Leak Integrity ................................................................................................................................ |

10-9 sccs |

•Temperature Coefficient of Span ........................................................................................... |

<0.1% per oC |

• Power ........................................................................................................................ |

±15VDC @ ±50mA |

• Flow Signal ................................................................................................. |

0-5.00VDC (inherently linear) |

• Wetted Material ............................................................................ |

316 SS,Viton Seals, Gold/ Nickle Braze |

• Connector ................................................................................................................... |

15 pin D connector |

• FittingsHFM-229, ............................................................................................................ 1/4" Swagelok TM HFM-230, 1/2" Swagelok TM

•Weight (approx)HFM-229, ............................................................................................................. 1.8 lbs. HFM-230, 3.3 lbs.

126B - PAGE 5

1.3Accessories

1.3.1Power Supplies

Hastings’ Power Supplies are designed as combination power supplies and digital readout monitors. They can simultaneously power a combination of different Hastings Flow Instruments.The front panel (9.47"H X 3.47"W) allows mounting of two units in a standard 19" rack. A terminal strip on the rear panel provides the user with continuous analog outputs from all channels.All power supplies have a 3-1/ 2 LCD display.

Models 200 and 400 Power Supplies can accommodate up to two or four Hastings Flow Instruments, respectively, and the Model 40 is for use with flowmeters only, powering up to 4 simultaneously.The Model 40 also features user-adjustable gas conversion factors for direct reading when changing gases. For more information, request Product Bulletin No. 544.

1.3.2 Alarms

The Model AL-1 Flow Alarm is available as an attachment suitable for use with any 0-5.00VDC input signal. Calibrated digital dial precision pots determine the low and high set points as a percent of full scale.This permits use with any range flowmeter or other instrument having a 0-5.00VDC linear output signal. Control action is within 0.2% of scale.The AL-1 is available in the panel mount J package.

1.3.3 Totalizer

The HastingsTR-1 FlowTotalizer integrates the 0-5.00VDC signal generated by the flowmeter to give a total flow reading. Count rates from 0-999 counts per minute are selectable by internal setting.The TR-1 is available in the panel mount J package.

1.3.4 4-20 mA Current Converter

The Hastings Model CC-420 Series Current Converter is an option available with Hastings Mass Flowmeters.The CC-420 produces a 4-20 mA signal from the 0-5.00VDC output of the flowmeter. The CC-420 is available in the panel mount J package.

126B - PAGE 6

2.0 INSTALLATION AND OPERATION

This section is designed to assist in getting a new flowmeter into operation as quickly and easily as possible. Please read the following thoroughly before attempting to install the instrument.

2.1 Receiving Inspection:

Carefully unpack the Hastings Flowmeter and any accessories that arrive with it. Inspect it for any obvious signs of damage due to shipment. Immediately advise the carrier who delivered the shipment if any damage is suspected.

Compare each component shipped against the packing list. Ensure that all parts are present (i.e. flowmeter, power supply, cables, etc.). Optional equipment or accessories will be listed separately on the packing list (see Section 1.4 - Accessories).There may also be one or more OPToptions on the packing list.These normally refer to special ranges or special gas calibrations.They may also refer to special helium leak tests or high pressure tests, or special modifications such as high

temperature or special O-ring materials. In most cases these are not separate parts, but rather special options or modifications built into the flowmeter or power supply.

2.2 Power Requirements:

All HFM Model Flowmeters require ±15VDC @ ±50 mA max .The 15VDC can vary between 14.25 VDC and 15.75VDC.The supply voltage should be regulated with no more than 50 mV ripple. Surge suppressers are recommended to prevent power line spikes from feeding through to the instruments.

These power requirements are satisfied by the Hastings Power Supply described in Section 1.4 - Accessories.

2.3 Output Voltage:

The output of the flowmeter is a 0-5.00VDC signal proportional to the flow rate.The output is sent to the display and is available at terminals at the rear of the Hastings Power Supply. If a Hastings supply is not being used, the output is available on pin 6 of the D connector. It is recommended that the load resistance be no less than 2k Ohms.

2.4 Mechanical Connections:

The transducer may be oriented in any position, as long as the direction of gas flow through the transducer follows the arrow marked on the bottom of the label.The preferred orientation is with the inlet and outlet fittings in a horizontal plane with the connector pointing up.

The smallest passageway encountered on the Hastings HFM Flowmeter is .012" ID, therefore steps should be taken to ensure proper filtering that

prevents blockage of these passageways.

There are two 8-32 threaded holes 1/4" deep in the bottom of the transducer that can be used to secure it to a mounting bracket, if desired.

The standard inlet and outlet fittings for the

HFM-229 Flowmeter are 1/4" Swagelok. For the

HFM-230, the fittings are 1/2"

Swagelok. OptionalVCR andVCO fittings are available from the factory.Viton O-rings are standard with all fittings; Kalrez and

Neoprene O-rings are optional and can be Fig.2.1 ordered from the factory.

126B - PAGE 7

The standard inlet and outlet fittings for the HFM-229B Flowmeter are NPT thread in the size of the pipe listed on the drawing on page 22, for sizes up to 3" laminar. On the 4", 6", and 8" laminars, flange fittings are standard. Smooth tubulation is optional on all sizes.

It is suggested that all connections be checked for leaks after installation.This can be done by pressurizing the transducer (do not exceed 500 psig unless the transducer is specifically rated for higher pressures) and applying a diluted soap solution to the flow connections.

2.5 Electrical Connections:

If a power supply was purchased from Hastings Instruments, installation will consist of connecting the cable, purchased separately from the power supply, from the rear of the supply to the top of the flowmeter. If a Hastings supply was not purchased, follow the instructions below to connect up the flowmeter.

The power supply used must be capable of supplying ±15VDC at ±50mA . These voltages must be referenced to a common ground.

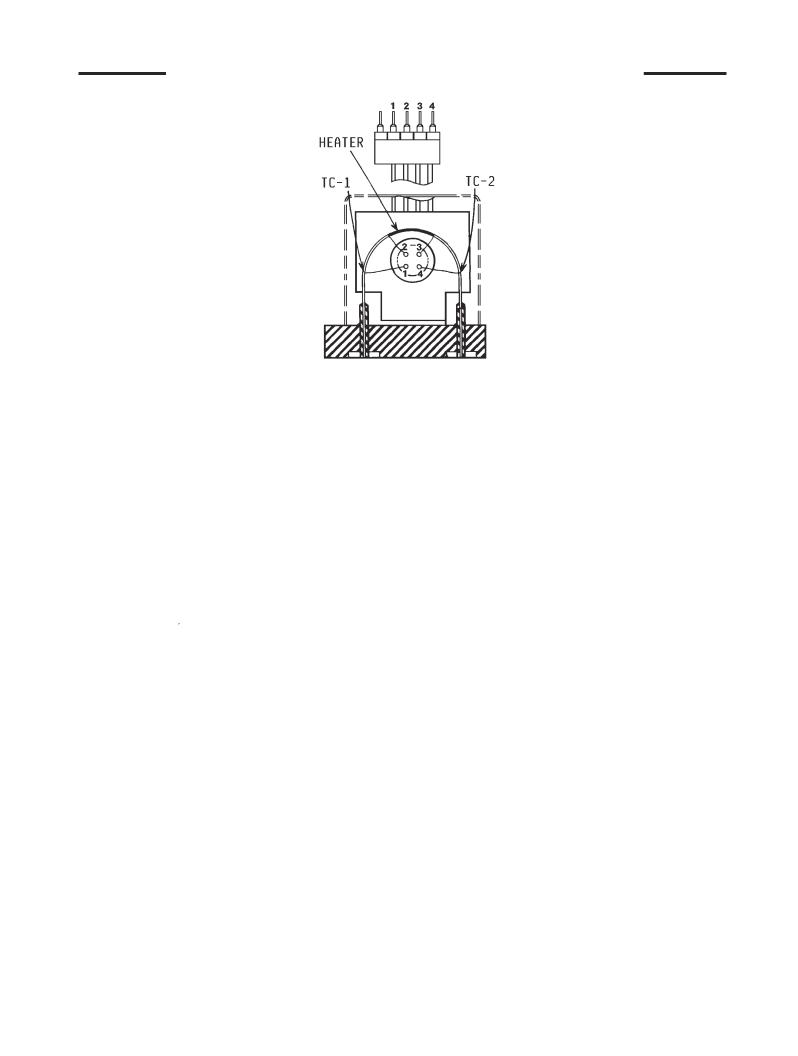

Refer to Fig. 2.1. Connect -15VDC to pin 9 and +15VDC to pin 11. Pin 5 is common and must be connected to the common connection at the power supply. Pin 7 is the case ground and it should be connected to the cable shield if available, and to AC ground of the power supply. Pin 6 is the output signal from the flowmeter.This output will be 0-5VDC, 5VDC being 100% of rated or full flow.

2.6Operation:

2.6.1Power Supply Operation

Do not connect transducers while the power supply is energized.The display may read either percent of full scale or actual flow rate, depending on the power supply purchased. To read flow rate, turn display switch to desired channel.

2.6.2 Ambient Temperature

In order to maintain the accuracy of the flowmeter with changes in ambient temperature, it is necessary to keep the temperature of the transducer between 0oC and 50oC. Since some of the temperature shift results in a slight zero offset, better results are obtained if the flowmeter is re-zeroed at the operating temperature.The flowmeter calibration may change by a factor up to 0.1%/oC. Hastings Mass Flowmeters are for GAS flow, so DO NOT let the temperature and/or pressure of the gas

reach a point that would cause the gas to change to a liquid state, or erroneous indications will result.

2.6.3 Zero Check

Turn the power supply “ON”. Allow the flowmeter 10 minutes to warm up. Stop all flow through the transducer and check electrical zero.

CAUTION: Do not assume that all metering valves will completely shut off flow. Even a slight leakage through a valve will cause an indication on the meter which will falsely appear to be a zero shift.

If necessary, adjust the “ZERO” potentiometer, located on the lower inlet side of the transducer, until the meter indicates zero.This zero should be checked periodically during normal operation.

2.7 Range Changing:

The range of the flowmeter can be changed in the field if recalibration facilities are available.The instructions to change the flow range can be found in Section 4.5. In order to change the range of a Model HFM-230 Flowmeter, a new laminar flow element must be purchased from the factory.

126B - PAGE 8

3.0 THEORY

This of parts

3.

The

rate shunt

shunt

Fig.3.1

to result

3.

The

point from

from

Fig.3.2 |

Fig.3.3 |

Loading...

Loading...