Page 1

mäìë

T

R

Prog.

S

kV

mA

P1

loqelmelp=ud

=ap=L=`ÉéÜ

loqelmelp=ud=R=ap=L=`ÉéÜ

loqelmelp=ud=P=ap

pЙкобЕЙ=j~ем~д

bеЦдблЬ

ORTHOPHOS XG

Easypad

ORTHOPHOS XG 5 / 3 / 3 PPE DS

Multipad

sЙклбзе=NPKM

Plus

DS

Page 2

About the Service Manual:

• This Service Manual is valid for the following unit versions:

Plus

– ORTHOPHOS XG

– ORTHOPHOS XG 5 DS / Ceph

– ORTHOPHOS XG 3 DS*

i

NOTE

These two system versions differ regarding the equipment offered by their user interfaces and their

possible configuration levels (see page 1-5).

i

NOTE

Board DX41 is no longer installed in units with hardware version BA or higher (as of November 2006).

In addition, you also require:

• Spare parts list: Order No. 59 38 423

– ORTHOPHOS XG

ORTHOPHOS XG 3 DS

DS / Ceph

Plus

DS / Ceph, ORTHOPHOS XG 5 DS / Ceph,

• Wiring diagrams: Order No. 59 38 332

Plus

– ORTHOPHOS XG

ORTHOPHOS XG 3 DS

• Installation Instructions

– ORTHOPHOS XG

– ORTHOPHOS XG 5 DS / Ceph: Order No. 60 04 902

– ORTHOPHOS XG 3 DS: Order No. 60 51 416

• Tools

– Screwdriver, medium sized

– Torx offset screwdrivers TX10, TX20, TX25

– Open-end wrench, 13 mm A/F

– Socket wrench, 13 mm A/F

– Side cutters

– Spirit level

• Auxiliary devices

– Digital multimeter, Accuracy Class 1

– Soldering tool for repairing cables

– Cable ties

– Teflon tape

– Loctite

DS / Ceph, ORTHOPHOS XG 5 DS / Ceph,

Plus

DS / Ceph: Order No. 59 87 651

Page 3

General information/Software update 1

Messages

Troubleshooting

Adjustment

2

3

4

Service routines

Repair

Maintenance

5

6

7

Page 4

Page 5

Contents

1 General information ..................................................................... 1-5

1.1 Safety .................................................................................. 1-5

1.2 XG

1.3 Programs and functions of the

1.4 Programs and functions of the XG

1.5 Operation notes ................................................................. 1-11

1.6 Demo mode – Operation without radiation release ........... 1-13

1.7 Demo mode – Repacking and transport ........................... 1-15

1.8 List of software versions .................................................... 1-16

1.9 Software update ................................................................ 1-22

1.10 Selecting More details ....................................................... 1-32

1.11 The most important modules and components ................. 1-34

1.12 Cabling overview ............................................................... 1-38

1.13 Illustrations of boards ........................................................ 1-42

1.14 Removing the covers ........................................................ 1-50

Plus

and XG 5 / 3 / 3 PPE system classes ...................... 1-6

XG 5 / 3 / 3 PPE system class ............................................ 1-8

Plus

system class ........... 1-9

2 Messages .................................................................................... 2-3

2.1 Help messages ................................................................... 2-4

2.2 System messages ............................................................... 2-6

2.3 Status displays .................................................................... 2-6

2.4 Error messages ................................................................... 2-6

2.5 List of error messages ......................................................... 2-9

2.6 List of available service routines ....................................... 2-62

3 Troubleshooting .......................................................................... 3-3

3.1 Error logging memory .......................................................... 3-4

3.2 Check the CAN bus ............................................................. 3-6

3.3 Checking the boards ......................................................... 3-12

3.4 Checking the motors ......................................................... 3-14

3.5 Checking the light barriers ................................................ 3-15

3.6 Device leakage current too high ........................................ 3-16

3.7 Checking the cables .......................................................... 3-17

3.8 Error analysis of X-RAY control signal path:

up to unit hardware revision AG

(with board DX41) ............................................................. 3-18

3.9 Error analysis of X-RAY control signal path:

unit HW version BA or higher

(without board DX41) ........................................................ 3-22

3.10 Check data paths/Generate test images ........................... 3-25

59 38 399 D3352

D3352.076.01.13.02 07.2008

V

Page 6

Contents

4 Adjustment ................................................................................... 4-3

4.1 Important information concerning adjustment ...................... 4-3

4.2 Diaphragm/system adjustment menu .................................. 4-5

4.3 Adjusting the panoramic X-ray unit ...................................... 4-9

4.4 Adjusting the cephalometer

4.5 TSA sensor adjustment

4.6 Resetting the adjustment

(XG

(XG

(XG

Plus

/ XG 5, if ceph is installed) ..................................... 4-56

Plus

full version only) .................................................. 4-107

Plus

/ 5 / 3 / 3 PPE) ..................................................... 4-115

5 Service routines ........................................................................... 5-9

5.1 Selecting the Service menu ............................................... 5-10

5.2 Selecting a service routine ................................................. 5-15

5.3 Service routines with SIDEXIS .......................................... 5-18

5.4 Service routine S001 ......................................................... 5-21

5.5 Service routine S002 ......................................................... 5-23

5.6 Service routine S005 ......................................................... 5-28

5.7 Service routine S007 ......................................................... 5-40

5.8 Service routine S008 ......................................................... 5-48

5.9 Service routine S009 ......................................................... 5-56

5.10 Service routine S012 ......................................................... 5-59

5.11 Service routine S014 ......................................................... 5-67

5.12 Service routine S015 ......................................................... 5-74

5.13 Service routine S017 ......................................................... 5-77

5.14 Service routine S018 ....................................................... 5-109

Plus

5.15 Service routine S020 (XG

5.16 Service routine S021 (not for XG 3 / 3 PPE) ................... 5-121

5.17 Service routine S032 ....................................................... 5-126

5.18 Service routine S033 (not for XG 3 / 3 PPE) ................... 5-130

5.19 Service routine S034 ....................................................... 5-134

5.20 Service routine S037 ....................................................... 5-151

only) .................................. 5-118

VI D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 7

Contents

6 Repair .......................................................................................... 6-5

6.1 Replacing the height adjustment motor (M1_4)/spindle ...... 6-6

6.2 Replacing the ring motor (M1_3) ....................................... 6-14

6.3 Replacing the PAN actuators (M1_1/2) ............................. 6-17

6.4 Replacing the headrest ..................................................... 6-19

6.5 Replacing the Easypad (XG

or the Multipad (XG 5 / 3 / 3 PPE) ..................................... 6-21

6.6 Replacing the control panel ............................................... 6-24

6.7 Replacing/adjusting the FH light localizer (PAN) .............. 6-26

6.8 Replacing/adjusting the MS light localizer

laser module (PAN) ........................................................... 6-28

6.9 Replacing/adjusting the FH light localizer (Ceph) ............. 6-30

6.10 Removing the light localizers from the ring

(for the XG

Plus

and XG 5, if present) ................................. 6-32

6.11 Replacing the support piece (bite block holder) ................ 6-33

6.12 Replacing the motor-driven diaphragm

(for XG

Plus

/ XG 5) ............................................................. 6-34

6.13 Replacing the fixed diaphragm

(only XG 3 / 3 PPE) ........................................................... 6-37

6.14 Replacing the X-ray tube assembly .................................. 6-38

6.15 Replacing the fan (tube assembly) .................................... 6-42

6.16 Replacing the PAN (TSA) sensor holder ........................... 6-43

6.17 Replacing the ceph sensor holder ..................................... 6-47

6.18 Replacing the sensor ........................................................ 6-48

6.19 Replacing the light barriers ............................................... 6-49

6.20 Replacing circuit boards .................................................... 6-59

6.21 Replacing cables ............................................................... 6-91

Plus

)

59 38 399 D3352

D3352.076.01.13.02 07.2008

VII

Page 8

Contents

7 Maintenance ................................................................................ 7-3

7.1 Checking the height adjustment .......................................... 7-4

7.2 Checking the forehead and temple supports ....................... 7-6

7.3 Checking the sensor holder (pan and ceph) ........................ 7-7

7.4 Checking the support piece (bite block holder) .................... 7-9

7.5 Checking the light localizers .............................................. 7-10

7.6 Checking the X-ray images ................................................ 7-12

7.7 Checking the tube data ...................................................... 7-13

7.8 Checking the diaphragm .................................................... 7-17

7.9 Checking the cables for damage ....................................... 7-35

7.10 Checking the idling rollers .................................................. 7-36

7.11 Checking the grounding straps .......................................... 7-37

7.12 Checking the cable shields ................................................ 7-38

7.13 Checking the protective ground wires ................................ 7-39

7.14 Checking the device leakage current ................................. 7-43

VIII D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 9

ORTHOPHOS XG

1General information

Page 10

Tab 1

Contents

1.1 Safety ......................................................................1 – 5

1.2 XG

Plus

and XG 5 / 3 / 3 PPE system classes..........1 – 6

1.2.1 Overview of the ORTHOPHOS XG system

classes and versions ............................................ 1 – 7

1.3 Programs and functions of the

XG 5 / 3 / 3 PPE system class ................................1 – 8

1.3.1 XG 5 system version ............................................ 1 – 8

1.3.2 XG 3 system version ............................................ 1 – 8

1.3.3 XG 3 PPE (pay per exposure) system version..... 1 – 8

1.4 Programs and functions of the XG

1.4.1 Programs and functions of the basic version ....... 1 – 9

1.4.2 Programs and functions of the full version ......... 1 – 10

Plus

system class1 – 9

1.5 Operation notes.....................................................1 – 11

1.6 Demo mode – Operation without radiation release1 – 13

1.6.1 Switching the demo mode ON............................ 1 – 14

1.6.2 Switching the demo mode OFF.......................... 1 – 14

1.7 Demo mode – Repacking and transport ...............1 – 15

1.8 List of software versions........................................1 – 16

1.8.1 ORTHOPHOS XG 3 PPE .................................. 1 – 16

1.8.2 ORTHOPHOS XG 3 .......................................... 1 – 17

1.8.3 ORTHOPHOS XG 5 / Ceph ............................... 1 – 18

1.8.4 ORTHOPHOS XG

Plus

/ Ceph............................. 1 – 20

1.9 Software update ....................................................1 – 22

1.9.1 Important information on the software update.... 1 – 22

1.9.2 Permissible software updates ............................ 1 – 23

1.9.3 Performing a software update ............................ 1 – 24

1.9.4 Software update for ORTHOPHOS XG 5

to V02.30 or higher ............................................. 1 – 29

1.9.5 Software Update for ORTHOPHOS XG

from V02.20 to V02.30 or higher ........................ 1 – 30

1.9.6 Software update for ORTHOPHOS XG

from V02.22 to V02.30 or higher ........................ 1 – 31

Plus

Plus

1.10 Selecting More details...........................................1 – 32

1 – 2 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 11

Tab 1

1.11 The most important modules and components .....1 – 34

1.11.1 Slide ................................................................... 1 – 35

1.11.2 Stand .................................................................. 1 – 36

1.11.3 Cephalometer

(arm mounted on left side or on right side)......... 1 – 37

1.11.4 Remote control ................................................... 1 – 37

1.12 Cabling overview...................................................1 – 38

1.13 Illustrations of boards ............................................1 – 42

1.13.1 Boards in the slide.............................................. 1 – 42

1.13.2 Boards in the stand ............................................ 1 – 46

1.13.3 Boards in the cephalometer

(arm mounted on right side or on left side)......... 1 – 47

1.13.4 Boards in the remote control .............................. 1 – 48

1.14 Removing the covers.............................................1 – 50

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 3

Page 12

Tab 1

1 – 4 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 13

Tab 1 1.1 Safety

1 General information

1.1 Safety

It is essential that you comply with the warning and safety information contained in this Service Manual.

All such information is highlighted by one of three signal words, i.e. CAUTION,

WARNING or DANGER.

CAUTION

Nonobservance may result in minor physical injuries or material damage and

malfunctions.

WARNING

Nonobservance may lead to serious physical injury or death.

DANGER

Immediate danger to life and limb. Threat of serious physical injury or

death.

1.1

1.1

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 5

Page 14

1.2 XG

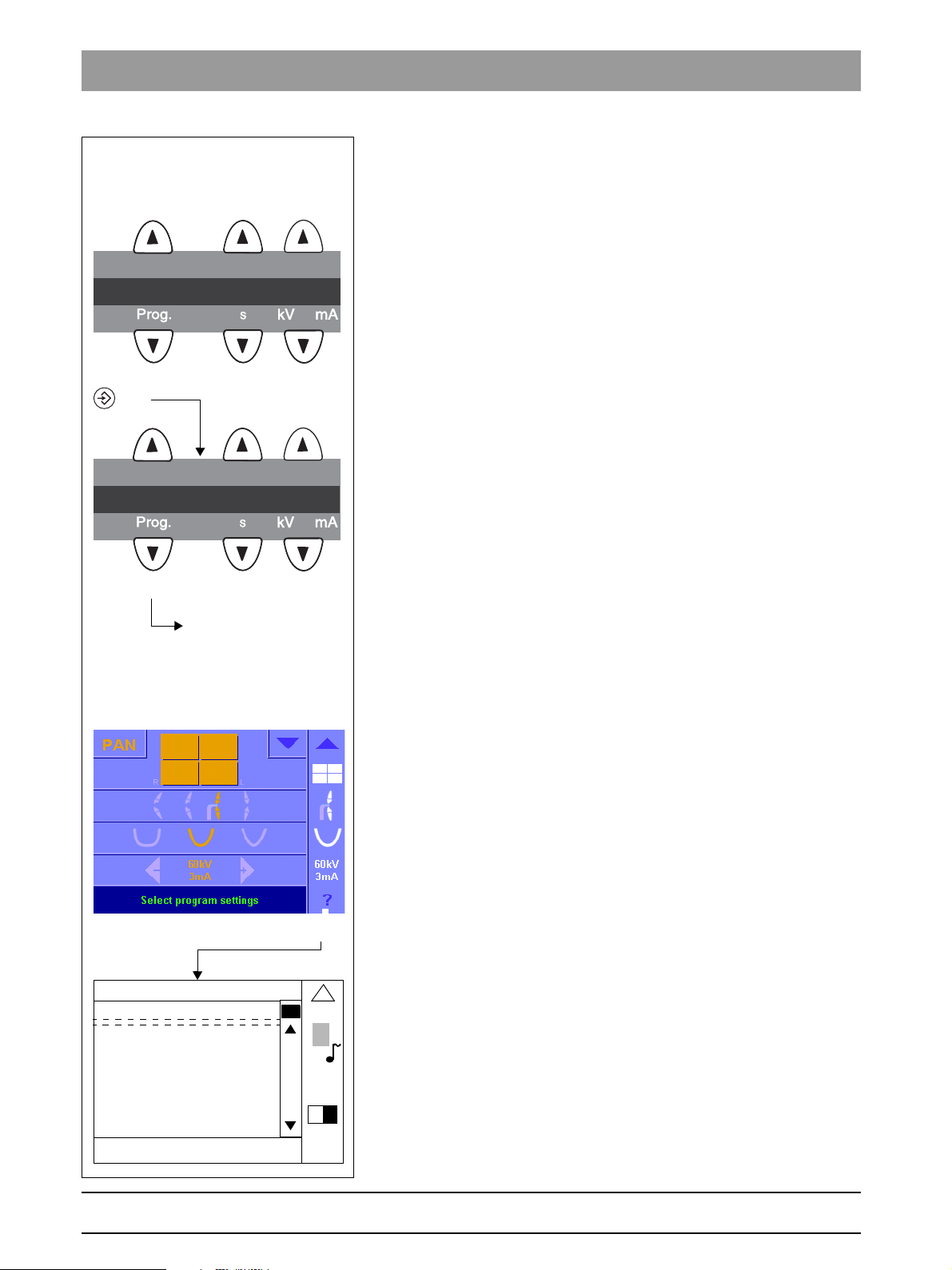

T

R

Prog.

S

kV

mA

Plus

and XG 5 / 3 / 3 PPE system classes Tab 1

Plus

1.2

XG

and XG 5 / 3 / 3 PPE system classes

Comfort class with Easypad (XG

Basic class with Multipad

(XG 5 / 3 / 3 PPE)

Plus

The XG

)

Plus

and XG 5 / 3 / 3 PPE system versions differ with regard to their

user interface. While the ORTHOPHOS XG (XG

with a color touchscreen (Easypad), the (XG 5 / 3 / 3 PPE) basic class is

equipped with a simpler control panel with a single-line display (Multipad).

Due to their different control panels, the operating procedures for these two

system classes also vary.

All ORTHOPHOS XG units are digital systems (DS).

The ORTHOPHOS XG

tion with a cephalometer (ceph). The cephalometer for the XG

sion is also available with the ceph arm mounted either on the left or the right

side. Only the cephalometer version with the arm mounted on the left side is

offered for the XG 5 system version. Operation of the XG 3/3 PPE system version is not possible with a cephalometer.

i

NOTE

The version with the ceph arm mounted on the left side is basically described

and illustrated in this Service Manual. Unless described separately, all dismantling and assembly steps must be performed laterally reversed for the version with the ceph arm mounted on the right side.

Remote control operation is possible in all system versions.

The (XG

however, the basic system class (XG 5 / 3 / 3 PPE) is available only in a basic

version.

The XG

This Service Manual describes both system classes in the highest possible

configuration.

Plus

) system class comes in a basic and a full version (see page 1-9),

Plus

system class optionally includes TSA operation.

Plus

and XG 5 system versions are suitable for opera-

Plus

) features a control panel

Plus

system ver-

For more information on the different installation versions, please refer to the

Installation Instructions.

i

NOTE

The empty digits in the single-line display of the Multipad are marked

with underscores in this Manual. They have been added to enhance clarity

and are not present on the real Multipad.

S005_______1____

n

(

123

1 – 6 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 15

Tab 1 1.2 XG

T

R

Prog.

S

kV

mA

T

R

Prog.

S

kV

mA

T

R

Prog.

S

kV

mA

T

R

Prog.

S

kV

mA

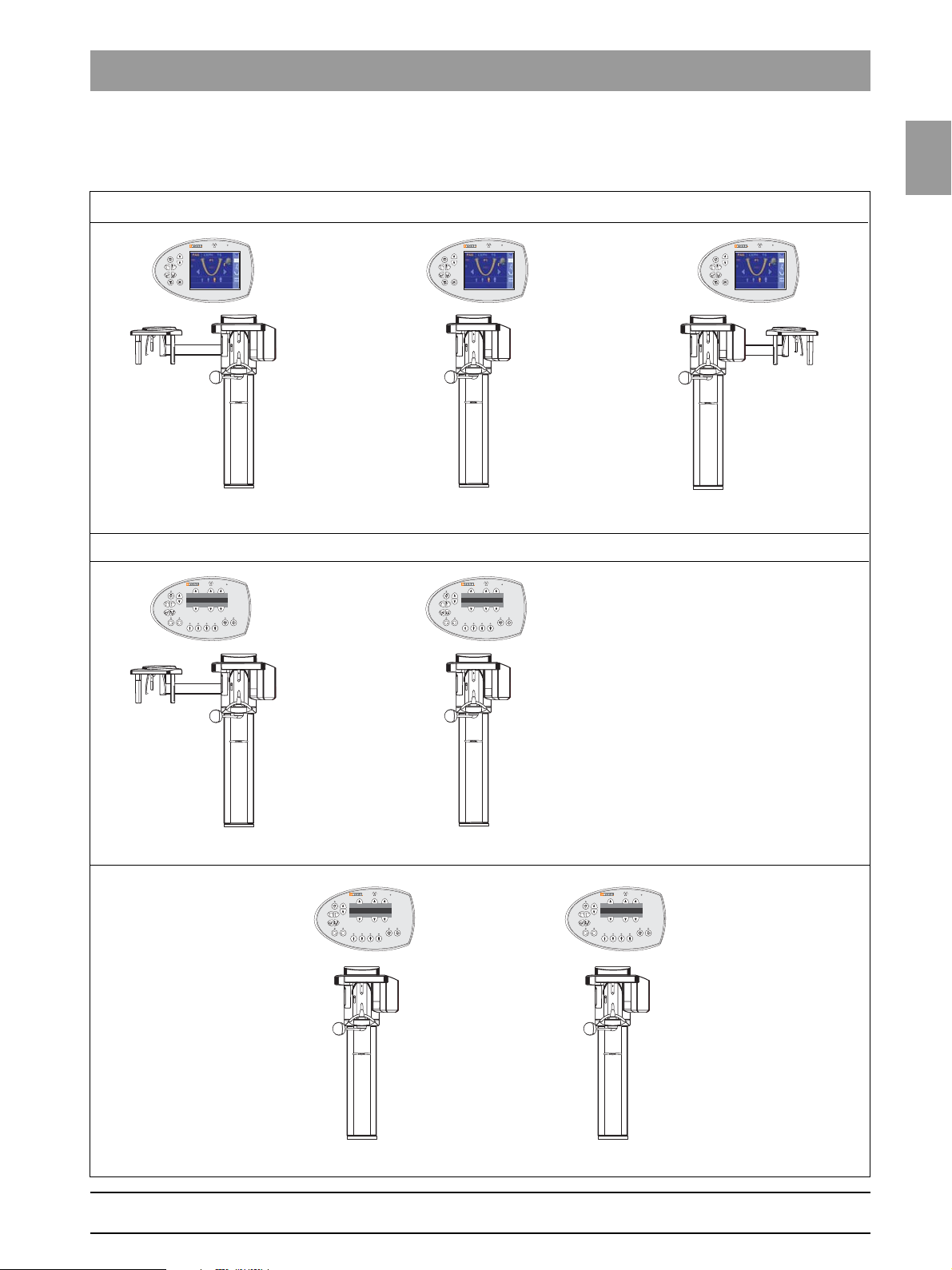

1.2.1 Overview of the ORTHOPHOS XG system

Comfort class (Easypad, basic or full version, TSA option, remote control option)

Plus

and XG 5 / 3 / 3 PPE system classes

classes and versions

1.2

1.2

bеЦдблЬ

ORTHOPHOS XG

Plus

with ceph arm on right sidewith ceph arm on left side

Basic class (Multipad, basic equipment, remote release optional)

ORTHOPHOS XG 5with ceph arm on left side

ORTHOPHOS XG 3

ORTHOPHOS XG 3 PPE

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 7

Page 16

1.3 Programs and functions of the XG 5 / 3 / 3 PPE system class Tab 1

1.3

Programs and functions of the

XG 5 / 3 / 3 PPE system class

1.3.1 XG 5 system version

8 panoramic programs z P 1, P 1C, P 10

z P 1L, P 1R

z TM 1.1/TM 1.2

z S 1

z MS 1

5 Ceph programs z C 1, C 2, C 3, C 3F, C 4

Functions z Half-views of right/left side possible only with P1

(not upper/lower jaw).

z Constant magnification factor of 1.25 possible only with program P 1.

z No Quickshot function.

z No "jaw shape" program presetting.

z No artifact-free display mode.

z No orthodontic image series P 1 - C 3 - C 4 without cooling periods.

z No TSA configuration level.

z No TSA operation possible.

z No welcome screen.

1.3.2 XG 3 system version

5 panoramic programs z P 1, P 1C

z P 1L, P 1R

z TM 1.1/TM 1.2

Functions z Half-views of right/left side possible only with P1

(not upper/lower jaw).

z Constant magnification factor of 1.25 possible only with program P 1.

z No Quickshot function.

z No "jaw shape" program presetting.

z No artifact-free display mode.

z No orthodontic image series P 1 - C 3 - C 4 without cooling periods.

z No TSA configuration level.

z No TSA operation possible.

z No welcome screen.

z

1.3.3 XG 3 PPE (pay per exposure) system version

ORTHOPHOS XG 3 with PPE concept (for USA only).

Functionality and programs identical to those of system version XG 3.

1 – 8 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 17

Tab 1 1.4 Programs and functions of the XG

Plus

system class

1.4 Programs and functions of the XG

class

The XG

z Basic version

z Full version

This Service Manual describes the full version of the system.

1.4.1 Programs and functions of the basic version

10 panoramic programs z P 1, P 1C, P 2, P 10

z P 1L, P 1R

z P 12

z TM 1.1/TM 1.2

z S 1

z MS 1

5 Ceph programs z C 1, C 2, C 3, C 3F, C 4

Functions z Half-views of right/left side possible only with P1

z Preselection of individual quadrants not possible.

z Constant magnification factor of 1.25 possible only with program P 1.

z No Quickshot function.

z No "jaw shape" program presetting.

z No artifact-free display mode.

z No orthodontic image series P 1 - C 3 - C 4 without cooling periods.

z No TSA configuration level (TSA operation retrofittable).

z No welcome screen with patient data from SIDEXIS.

z Ceph: No shadowing in upper head region with programs C3 and C3F.

z Ceph: No shadowing in thyroid region with programs C1 and C2.

Plus

system class is available in two configuration levels:

(not upper/lower jaw).

Plus

system

1.4

1.4

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 9

Page 18

1.4 Programs and functions of the XG

Plus

system class Tab 1

1.4.2 Programs and functions of the full version

The full version offers the following programs and functions in addition to

those featured in the basic version:

Additional Pan programs z Constant magnification factor of 1.25 P 2C, P 10C

z Artifact-free display P 1A, P 2A, P 10A

Additional functions z Selectable right/left partial view and individual quadrants

P 1A, P 2/A/C, P 10/A/C, P12.

z Selectable upper/lower jaw partial view and individual quadrants

P 1/A/C, P 2/A/C, P 10/A/C.

z Temporomandibular joint views TM 2, TM 3, TM 4, TM 5, TM 6

z Sinus views S2, S3, S4.

z Selectable "jaw shape" program setting.

z Quickshot function possible (for Pan and Ceph).

z Orthodontic image series P 1 - C 3 - C 4 without cooling periods possible.

z TSA configuration level

z TSA operation possible (optional)

z Welcome screen with patient data from SIDEXIS

(SIDEXIS V01.50 and higher).

z Ceph: Shadowing in upper head region with programs C3 and C3F.

z Ceph: Shadowing in thyroid region with programs C1 and C2.

1 – 10 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 19

Tab 1 1.5 Operation notes

1.5 Operation notes

Rated line voltage The ORTHOPHOS XG X-ray unit can be operated in the following

rated line voltage ranges:

z 200 V - 240 V

z 50/60 Hz

The permissible line voltage fluctuations are as follows:

z 200 - 230 V: ± 10 %

The internal line impedance must not exceed max. 0.8 Ω.

i

NOTE

Only permanent electrical connection of the system is allowed in Germany.

Remote control The system can be equipped with...

z a 1 - 3 m coiled cable with release button inside the treatment room or ...

z a remote control with or without coiled cable located outside the X-ray

room (see installation instructions).

1.5

1.5

bеЦдблЬ

Warm-up time After it is switched ON, the system requires a warm-up time of approx. 1 min.

Self-adjustment routine At the same time, a mechanical and electronic self-adjustment routine is exe-

cuted. If a button is pressed during the self-adjustment routine, an error message is displayed on the Multipad (XG 5 / 3 / 3 PPE) or Easypad (XG

Cooling period The cooling period between two exposures is maintained by an automatic

exposure blocking function according to the pulse/pause ratio. A countdown

of the waiting time is displayed on the Multipad (XG 5 / 3 / 3 PPE) or

Easypad (XG

Turn-off time The turn-off time must amount to at least 60s.

Demo units If the X-ray unit is to be presented as a demo unit at trade fairs or exhibitions,

it must be ensured that radiation release is blocked (see “Demo mode –

Operation without radiation release” on page 1-13).

Software version The overall system software version is determined by the software statuses of

the EEPROMs on the boards (see “List of software versions” on page 1-16).

Wireless phone interference with

medical electrical equipment

Disposal The X-ray tube assembly contains a tube with potential implosion hazard,

To ensure safe operation of medical electrical equipment, the use of mobile

wireless phones in practice or hospital environments is prohibited.

a small amount of beryllium, a lead lining as well as mineral oil.

Plus

).

Plus

).

Error messages Error messages are displayed on the single-line display of the Multipad

(XG 5 / 3 / 3 PPE) or on the touchscreen of the Easypad (XG

59 38 399 D3352

D3352.076.01.13.02 07.2008

Plus

).

1 – 11

Page 20

1.5 Operation notes Tab 1

Help messages in case exposure

readiness cannot be attained

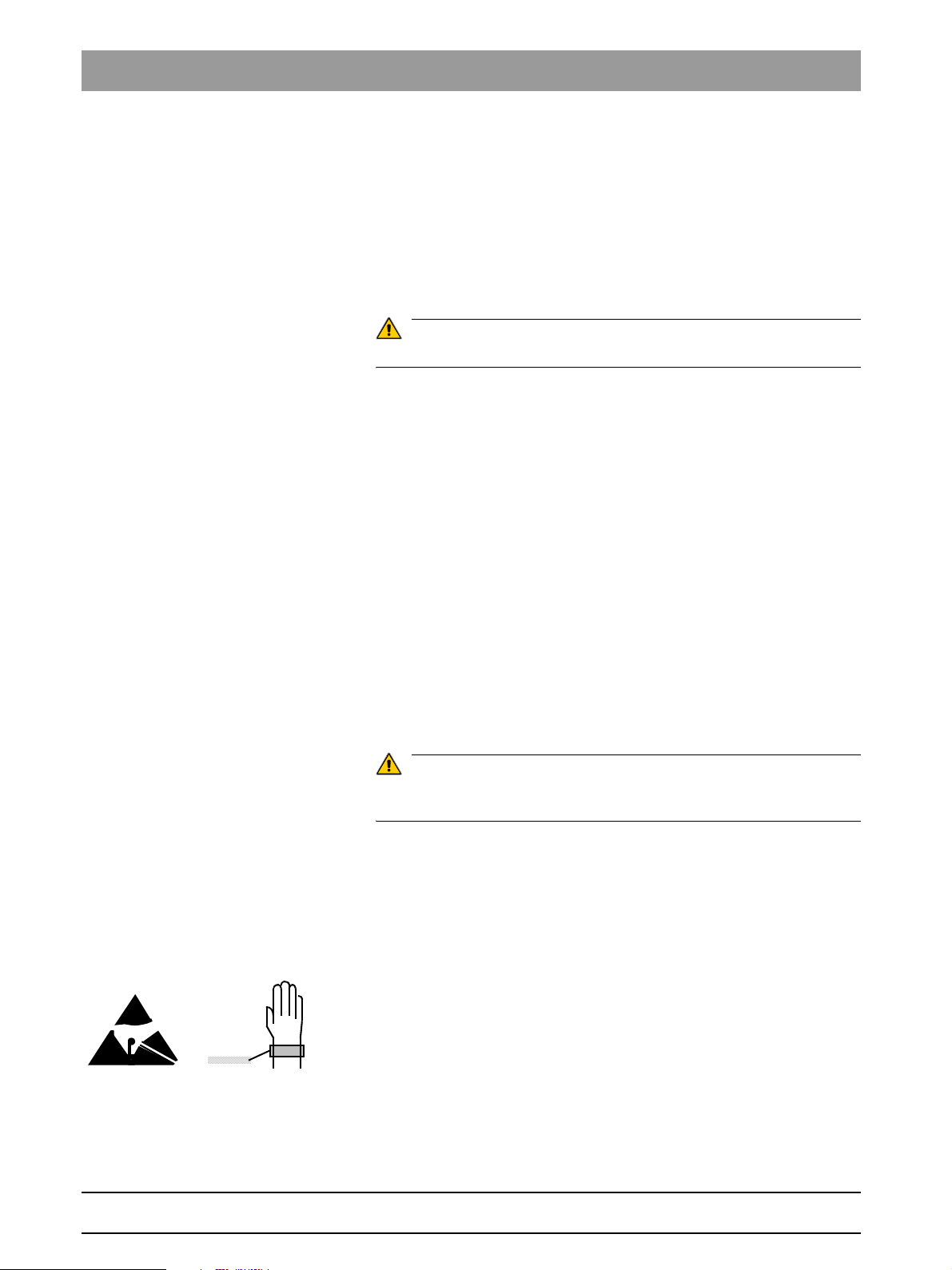

If you have to remove covers from the

unit

Help messages are displayed on the single-line display of the Multipad

(XG 5 / 3 / 3 PPE) or on the touchscreen of the Easypad (XG

Proceed according to section "1.14 Removing the covers".

When removing covers, always remember that direct sunlight or bright room

lighting can cause system malfunctions due to activated light barriers.

Therefore: avoid direct sunlight and bright room lighting above the unit!

When attaching the covers: be sure to screw the sheet metal cover back on.

Plus

).

CAUTION

For reasons of electromagnetic compatibility, be sure to fasten all screws.

Reattach the covers.

Secondary diaphragm Do not manually move or otherwise exert force on the secondary diaphragm

(e.g. when removing it from its packaging).

Measurements Always switch the unit OFF before connecting a measuring instrument.

Select the correct current/voltage type and adjust the measuring range to

match the expected readings.

Perform continuity tests only on units which are switched off.

If several exposures with radiation must be taken to check a measurement,

make sure that the prescribed cool-down intervals are observed. They are

maintained by an automatic exposure blocking function (see operating

instructions).

The pulse/pause ratio is 1: 10, i.e. a 10-second pause is maintained for each

second of radiation emission. The pulse/pause ratio is automatically maintained (automatic exposure blocking).

A pulse/pause ratio of 1:20 is better for the X-ray tube.

WARNING

It is essential that you observe the radiation protection regulations applicable in your country prior to radiation release.

The test rotations triggered by pressing the T key on the Easypad and then

the release button are executed without radiation.

When replacing parts Switch the unit OFF before replacing parts.

The unit must be disconnected from the junction box of the building installation before replacing any parts near the power supply, power switch, board

DX 32 or the X-ray tube assembly!

Please always wear an ESD wrist band to protect sensitive components on

printed circuit boards (ESD).

Always check the system and adjust it as required after replacing a board or

the X-ray tube assembly.

The article numbers for ordering spare parts can be found in the spare parts

list, Order No. 59 38 423. The diagrams contained in the spare parts list provide a useful guide when replacing parts.

1 – 12 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 21

Tab 1 1.6 Demo mode – Operation without radiation release

1.6 Demo mode – Operation without radiation

release

1.6

1.

2.

1.6

bеЦдблЬ

A

B

4.3.

Board DX6

59 38 399 D3352

D3352.076.01.13.02 07.2008

S2

J6

i

NOTE

Starting with system SW version V02.28, the complete possible functionality

of the system class is simulated, regardless of the current configuration.

1 – 13

Page 22

1.6 Demo mode – Operation without radiation release Tab 1

1.6.1 Switching the demo mode ON

5.

Info menu for XG 5 / 3 / 3 PPE

P1______14.1__64_8

n

(

When operated in demo mode, the unit must not release any radiation. For

this reason, you must take the following safety measures:

z Switch the unit OFF.

1. Remove the cover of the tube assembly.

2. Loosen screws A and remove cover plate B.

3. Set dip switch S2 (DX6) to position 2.

4. Pull cable L5 (X-RAY) off of connector J6 (DX6).

Radiation release is now no longer possible.

123

(

SYSTEM SOFTWARE____

n

(

123

Scroll through the list

until the demo mode is

displayed

Info screen for XG

Plus

(

5. Switch the unit ON and check the mode with the

info menu (XG 5 / 3 / 3 PPE) or the info screen (XG

Demo mode: ON means that: The demo mode is switched ON

(Radiation release is not possible)

Demo mode: OFF means: The demo mode is switched OFF

(Radiography, X-ray radiation are possible!)

z Switch the unit OFF again and reattach cover plate B and the tube assem-

bly covers by following the dismantling procedure in reverse order.

Plus

).

1.6.2 Switching the demo mode OFF

z Switch the unit OFF.

1. Remove the cover of the tube assembly.

2. Loosen screws A and remove cover plate B.

3. Set dip switch S2 (DX6) to position 1.

4. Pull cable L5 (X-RAY) off of connector J6 (DX6).

Radiation release is now once again possible.

5. Switch the unit ON and check the mode with the

info menu (XG 5 / 3 / 3 PPE) or the info screen (XG

Demo mode: ON means that: The demo mode is switched ON

(Radiation release is not possible)

Demo mode: OFF means: The demo mode is switched OFF

(Radiography, X-ray radiation are possible!)

z Switch the unit OFF again and reattach cover plate B and the tube assem-

bly covers by following the dismantling procedure in reverse order.

Plus

).

Orthophos XG configuration

Mac adress : 010001200000

IP adress : 192.168.15.19

Subnet mask : 155.155.255.0

Default Gateway : 192.168.15.1

Net API version : 1

Net API revision : 14

Demomode : ON

Tube Exposures : 2217

2/2

)

65

59 38 399 D3352

1 – 14 D3352.076.01.13.02 07.2008

Page 23

Tab 1 1.7 Demo mode – Repacking and transport

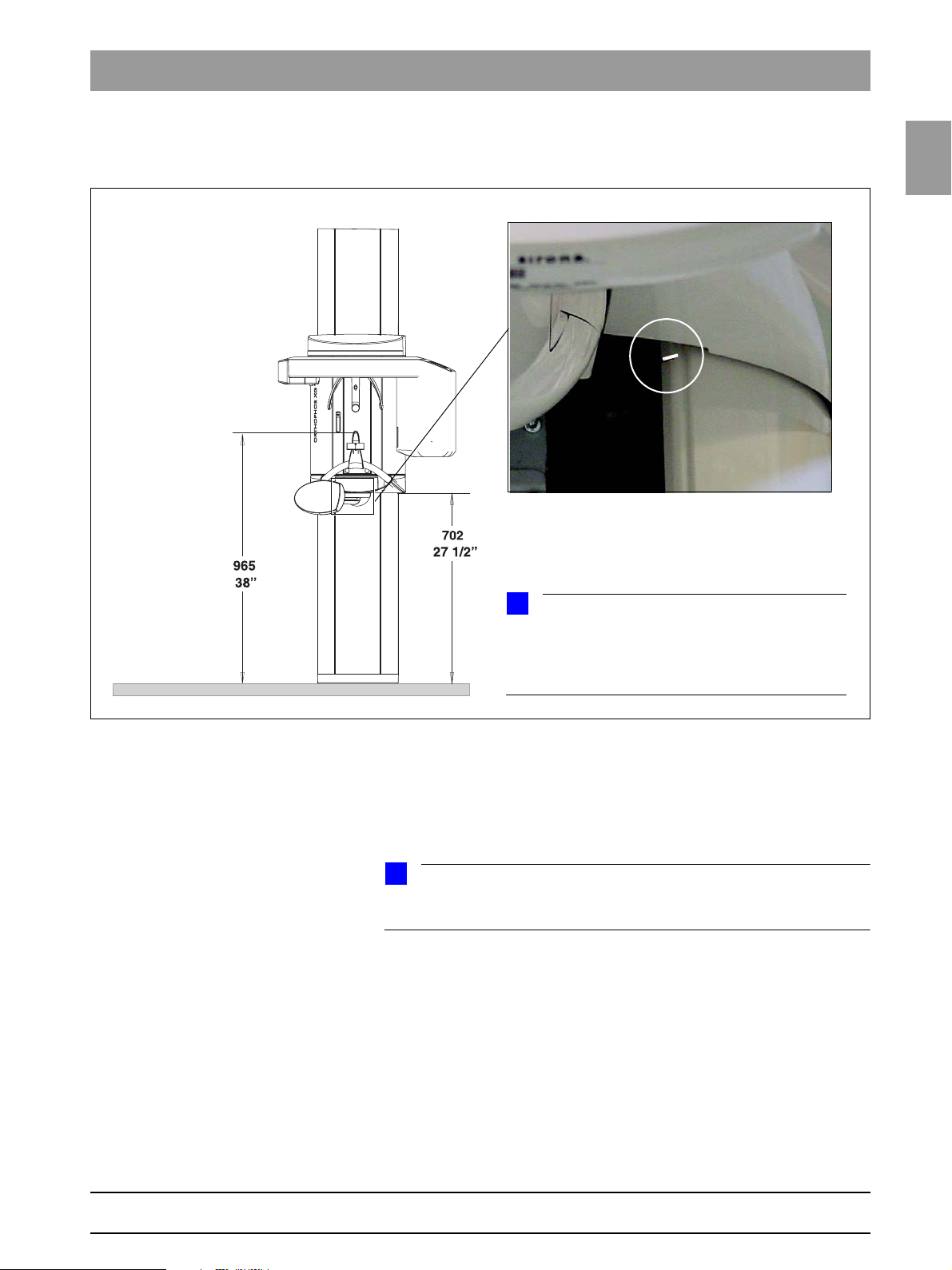

1.7 Demo mode – Repacking and transport

1.7

1.

A

i

NOTE

If the unit is installed with a floor stand, its height increases by 30 mm. The bite block height value displayed on the Multipad (XG 5 / 3 / 3 PPE) or

Easypad (XG

Plus

) remains the same, however!

1.7

bеЦдблЬ

Panoramic X-ray unit z Switch the panoramic X-ray unit ON and move it to its packing height by

pressing the

Easypad (XG

– Bite block height = 965 mm (displayed as height on

Multipad (XG 5 / 3 / 3 PPE) or Easypad (XG

– Bottom edge of slide cover = 702 mm

i

NOTE

The bottom edge of the slide cover must be at the same height as the markings A in the column.

Cephalometer z Start service routine S034, test step 6.

z Move the cephalometer to the packing position

(see page 5-143).

z For information on packing the units and on the packing condition, see the

relevant installation instructions.

59 38 399 D3352

D3352.076.01.13.02 07.2008

UP/DOWN keys on the Multipad (XG 5 / 3 / 3 PPE) or

Plus

).

Plus

)

1 – 15

Page 24

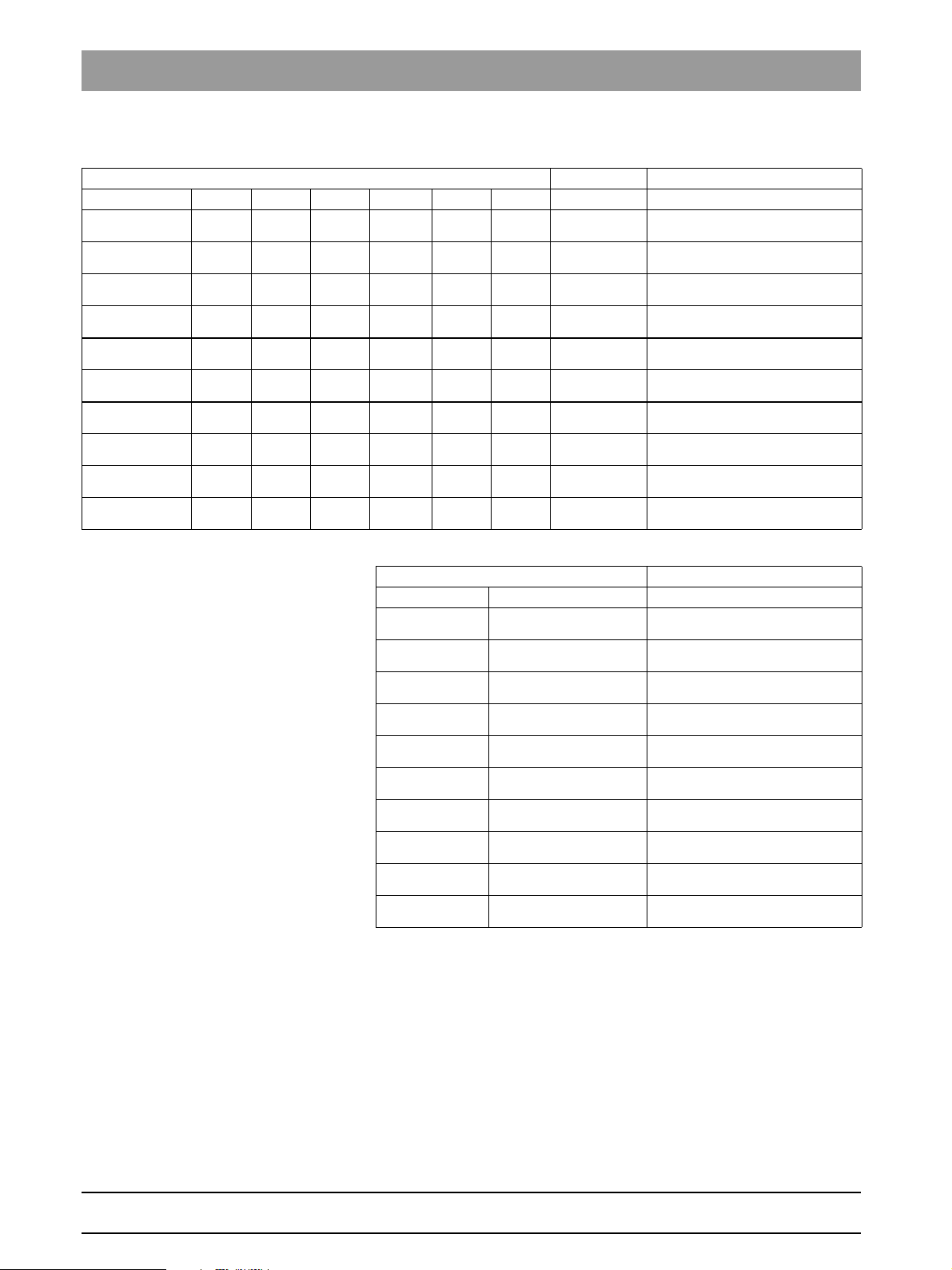

1.8 List of software versions Tab 1

1.8

i

List of software versions

NOTE

Any software combinations other than those listed here are not allowed.

If the software version of any particular module does not match the overall

software version, the overall software version will be marked with an asterisk

on the info screen (e.g. 02.20*).

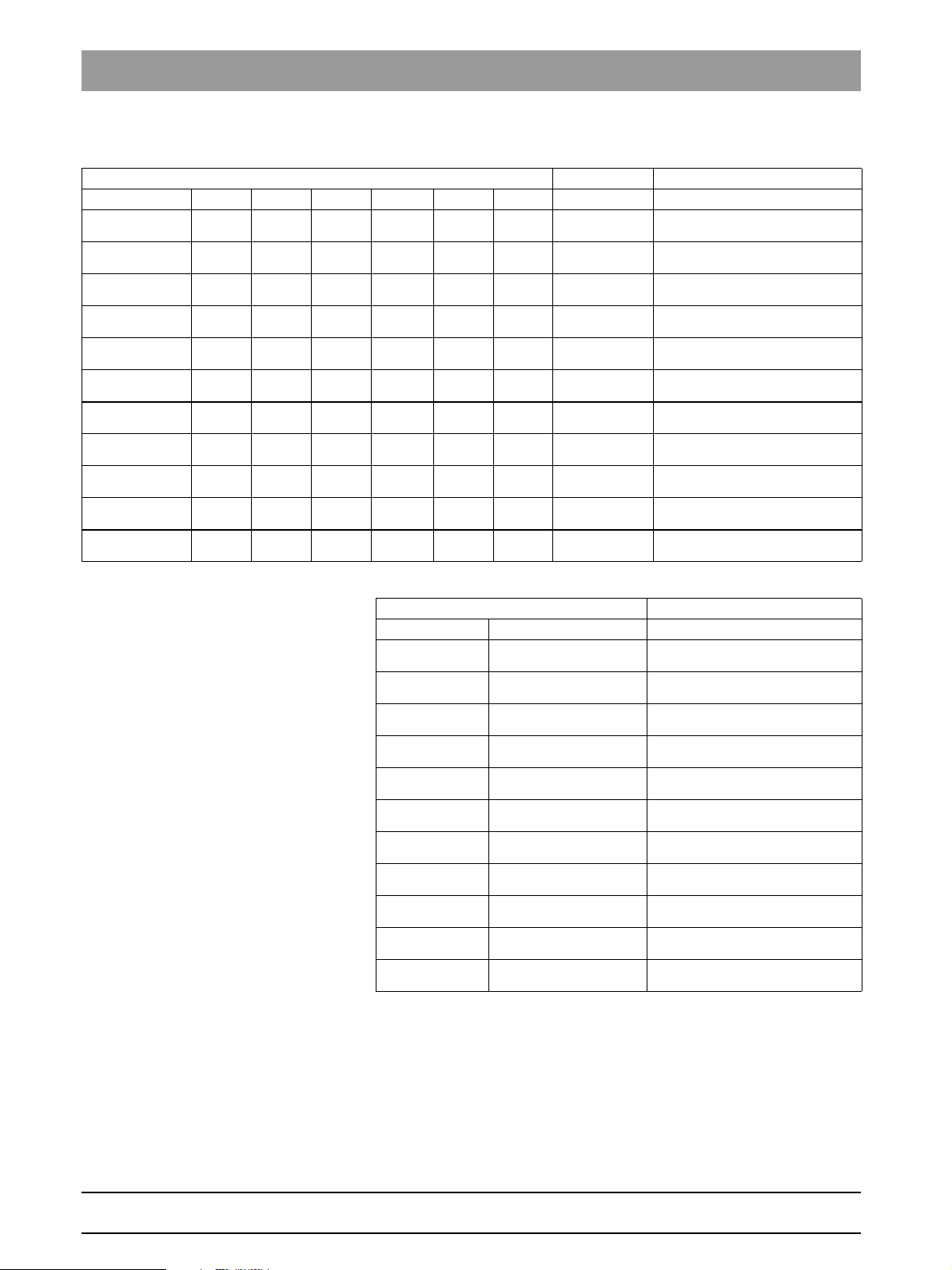

1.8.1 ORTHOPHOS XG 3 PPE

Panoramic unit

Board DX6 DX71 DX11 DX81

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.60 02.33 02.40 02.33

02.60 02.33 02.40.01 02.33

02.60 02.34 02.42 02.33

02.60 02.34 02.42 02.33

02.60 02.34 02.43 02.33

Remarks

compatible with SIDEXIS versions

V01.61 and higher

compatible with SIDEXIS versions

V01.61 and higher

compatible with SIDEXIS versions

V01.61 and higher

compatible with SIDEXIS versions

V01.61 and higher

compatible with SIDEXIS versions

V01.61 and higher

Remote control

Board DX42

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

Sidexis XG

V 01.53

V 01.54

V 01.55

V 01.61

V 02.00

V 2.2

V 2.3

Remarks Database

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

requires ORTHOPHOS XG 3 PPE

Overall Software Version V02.28.2 or higher

02.30

02.30

02.31

02.31

02.31

Remarks

old Database

new Database

1 – 16 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 25

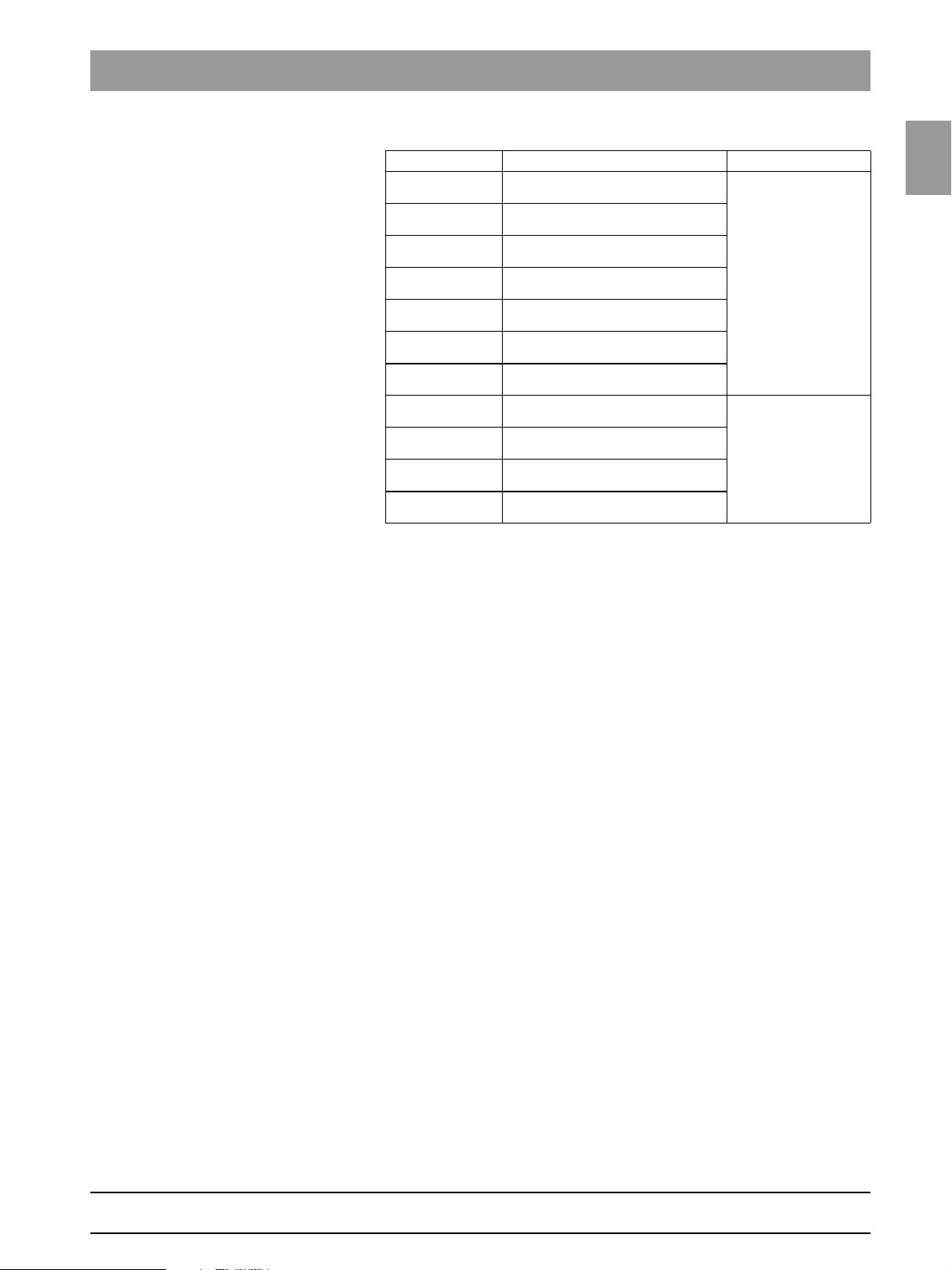

Tab 1 1.8 List of software versions

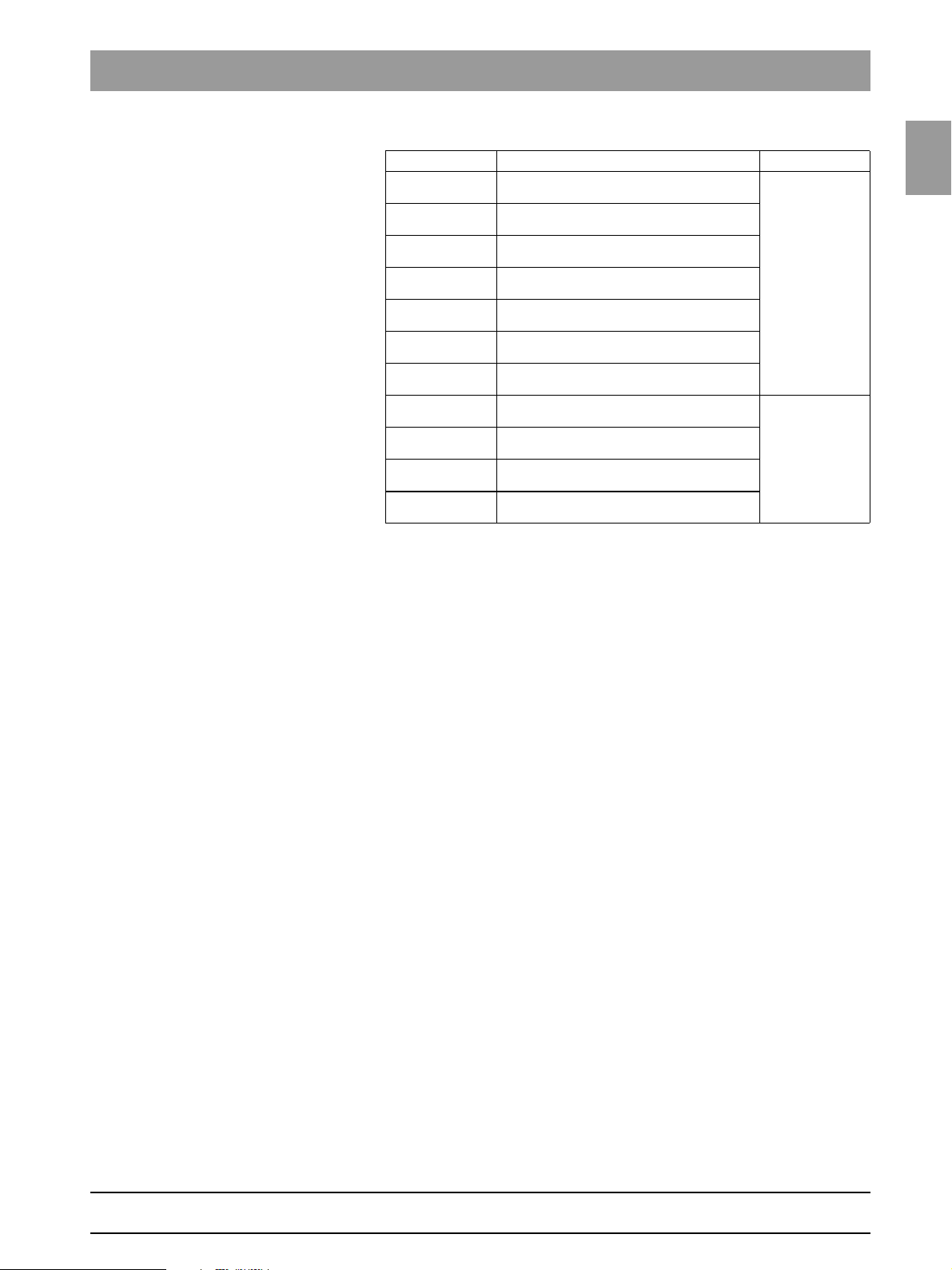

1.8.2 ORTHOPHOS XG 3

Panoramic unit

Board DX6 DX71 DX11 DX41 DX81

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.57 02.29 02.37 02.22 02.30

02.60 02.31 02.39 02.23 02.32

02.60 02.33 02.40 (02.23*) 02.33

02.60 02.33 02.40.01 (02.23*) 02.33

02.60 02.34 02.42 (02.23*) 02.33

02.60 02.34 02.42 (02.23*) 02.33

02.60 02.34 02.43 (02.23*) 02.33

Remarks

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

1.8

1.8

bеЦдблЬ

Remote control

Board DX42

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

Sidexis XG

V 01.51

V 01.53

V 01.54

V 01.55

V 01.61

V 02.00

V 2.2

V 2.3

Remarks Database

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

requires ORTHOPHOS XG 3 Overall Software Version V02.25 or higher

02.27

02.28

02.30

02.30

02.31

02.31

02.31

Remarks

old Database

new Database

59 38 399 D3352

D3352.076.01.13.02 07.2008

* As of hardware version BA (from November 2006) new systems will be delivered without

board DX41 (see also page 1-44).

1 – 17

Page 26

1.8 List of software versions Tab 1

1.8.3 ORTHOPHOS XG 5 / Ceph

Panoramic unit Cephalometer

Board DX6 DX71 DX11 DX41 DX61 DX81 DX91

Overall software

V 02.18.1

Overall software

V 02.20

Overall software

V 02.22

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.45 02.23 02.31 02.19 02.20 02.25 02.32

02.56 02.28 02.33 02.22 02.26 02.29 02.34

02.56 02.28 02.35 02.22 02.30 02.29 02.38

02.57 02.29 02.37 02.22 02.30 02.30 02.40

02.60 02.31 02.39 02.23 02.33 02.32 02.42

02.60 02.33 02.40 (02.23*) 02.33 02.33 02.42

02.60 02.33 02.40.01 (02.23*) 02.34 02.33 02.43

02.60 02.34 02.42 (02.23*) 02.34 02.33 02.43

02.60 02.34 02.42 (02.23*) 02.34 02.33 02.44

02.60 02.34 02.43 (02.23*) 02.35 02.33 02.44

Remote control

Board DX42

Overall software

V 02.18.1

Overall software

V 02.20

Overall software

V 02.22

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.22

02.27

02.27

02.27

02.28

02.30

02.30

02.31

02.31

02.31

Remarks

compatible with SIDEXIS versions

up to and incl. V01.44

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

Remarks

1 – 18 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 27

Tab 1 1.8 List of software versions

Sidexis XG

V 01.33 - V01.44

V 01.45

V 01.50

V 01.51

V 01.53

V 01.54

V 01.55

V 01.61

V 02.00

V 2.2

V 2.3

* As of hardware version BA (from November 2006) new systems will be delivered without

board DX41 (see also page 1-44).

Remarks Database

requires ORTHOPHOS XG 5 Overall

Software Version < V02.20

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

requires ORTHOPHOS XG 5 Overall

Software Version V02.20 or higher

old Database

new Database

1.8

1.8

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 19

Page 28

1.8 List of software versions Tab 1

1.8.4 ORTHOPHOS XG

Panoramic unit Cephalometer

Board DX6 DX7 DX11 DX41 DX61 DX81 DX91

Overall software

V 02.17

Overall software

V 02.19

Overall software

V 02.20

Overall software

V 02.22

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.41 02.25 02.30 02.16 02.17 02.23 02.31

02.52 02.31 02.32 02.20 02.25 02.26 02.34

02.56 02.35 02.33 02.22 02.26 02.29 02.34

02.56 02.38 02.35 02.22 02.30 02.29 02.38

02.57 02.40 02.37 02.22 02.32 02.30 02.40

02.60 02.42 02.39 02.23 02.33 02.32 02.42

02.60 02.44 02.40 (02.23*) 02.33 02.33 02.42

02.60 02.44 02.40.01 (02.23*) 02.34 02.33 02.43

02.60 02.44 02.42 (02.23*) 02.34 02.33 02.43

02.60 02.44 02.42 (02.23*) 02.34 02.33 02.44

02.60 02.44 02.43 (02.23*) 02.35 02.33 02.44

Plus

/ Ceph

Remarks

compatible with SIDEXIS versions

up to and incl. V01.44

compatible with SIDEXIS versions

up to and incl. V01.44

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.45 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

compatible with SIDEXIS versions

V01.53 and higher

Remote control

Board DX42

Overall software

V 02.17

Overall software

V 02.19

Overall software

V 02.20

Overall software

V 02.22

Overall software

V 02.25

Overall software

V 02.27

Overall software

V 02.28

Overall software

V 02.28.2

Overall software

V 02.30

Overall software

V 02.31

Overall software

V 02.32

02.17

02.24

02.27

02.27

02.27

02.28

02.30

02.30

02.31

02.31

02.31

Remarks

1 – 20 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 29

Tab 1 1.8 List of software versions

Sidexis XG

V 01.33 - V01.44

V 01.45

V 01.50

V 01.51

V 01.53

V 01.54

V 01.55

V 01.61

V 02.00

V 2.2

V 2.3

* As of hardware version BA (from November 2006) new systems will be delivered without

board DX41 (see also page 1-44).

Remarks Database

requires ORTHOPHOS XG

ware Version < V02.20

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

requires ORTHOPHOS XG

Overall Software Version V02.20 or higher

Plus

Overall Soft-

Plus

Plus

Plus

Plus

Plus

Plus

Plus

Plus

Plus

Plus

old Database

new Database

1.8

1.8

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 21

Page 30

1.9 Software update Tab 1

1.9

Software update

1.9.1 Important information on the software update

i

NOTE

Read the information provided on the ORTHOPHOS XG Software CD and

on the SIRONA dealer page on the internet very carefully. It always contains the latest information on the software update.

i

NOTE

Before performing a software update, it is essential to read the program-version-specific information in sections 1.9.4 to 1.9.6.

CAUTION

Important for TSA operation:

For downgrading from a software version ≥ V2.20 to one < V2.20 with the TSA

mode activated, the TSA sensor holder must be equipped with the transport

safety device and set to the PAN position!

CAUTION

Important for XG

21007 (without Ceph) or 41001 (with Ceph):

A downgrade to a software version V02.25 must not be performed on these

units in any case. Such a downgrade would result in permanent and

irreparable failure of the user interface!

Plus

units with serial numbers

CAUTION

Important for units with the following serial numbers or higher:

ohne Ceph mit Ceph

XG 3 PPE 104000 –

XG 3 104000 –

XG 5 63500 83500

Plus

XG

A downgrade to a software version < V02.32 cannot be performed on these

units.

23500 43500

1 – 22 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 31

Tab 1 1.9 Software update

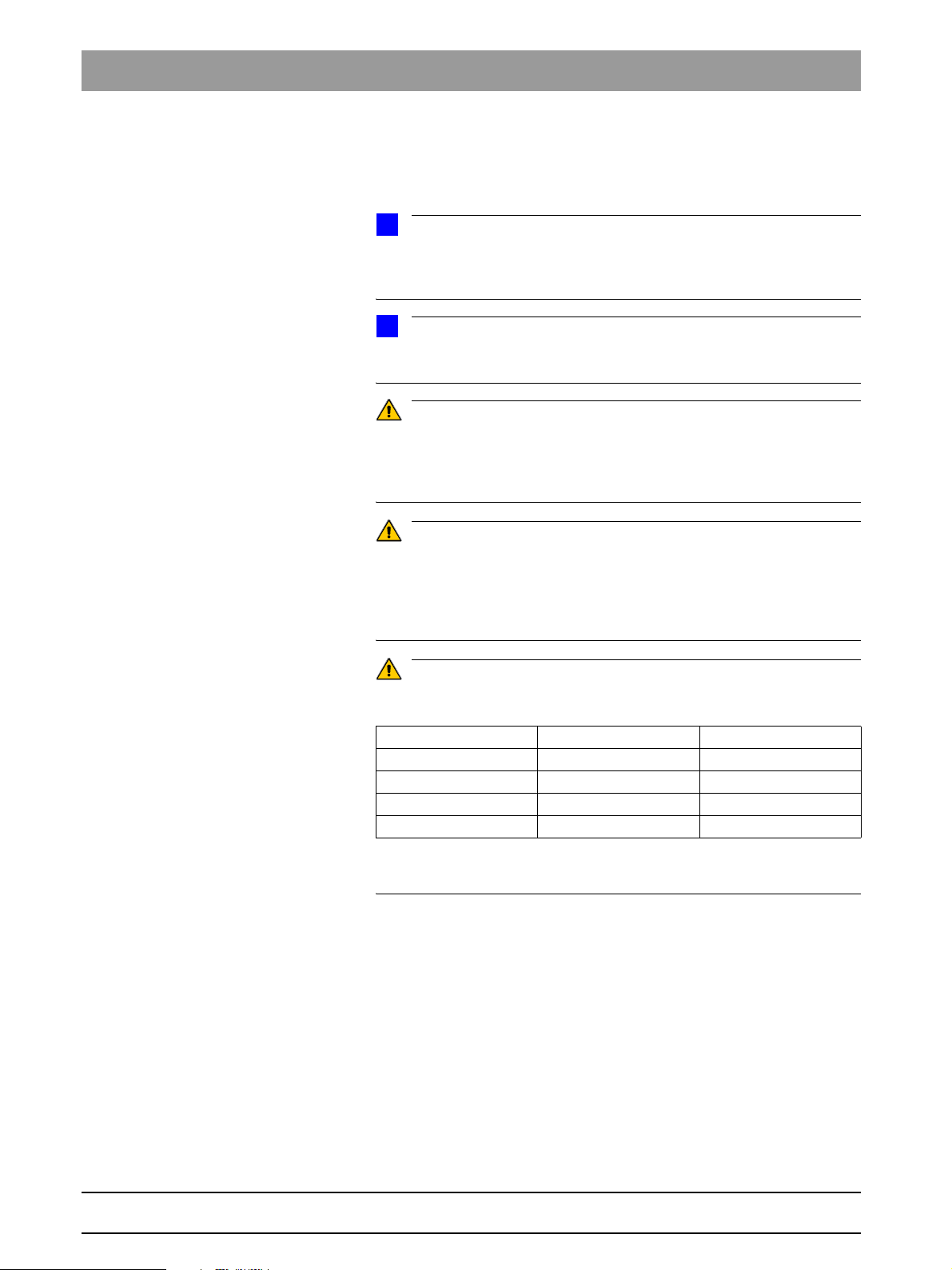

1.9.2 Permissible software updates

Not all software versions are suitable for both system classes. The following

table gives you an overview of the software version permissible for each system class.

1.9

Overall software XG 3 PPE XG 3 XG 5 XG

V 02.17 – – – X

V 02.18.1 – – X –

V 02.19 – – – X

V 02.20 – – X X

V 02.22 – – X X

V 02.25 – X X X

V 02.27 – X X X

V 02.28 X X X X

V 02.28.2 X X X X

V 02.30 X X X X

V 02.31 X X X X

V 02.32 X X X X

CAUTION

If an update is nevertheless performed accidentally, the version must be

downgraded again immediately before acknowledging any error messages or

executing any service routines!

Plus

1.9

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 23

Page 32

1.9 Software update Tab 1

1.9.3 Performing a software update

Opening SIXABCON.exe 1. Open the SIXABCON utility program in the SIDEXIS XG program folder.

Click on SIXABCON.exe (see screen shot) or

use the pull-down menus

X-RAY COMPONENTS.

PROGRAMS ‡ SIDEXIS ‡ CONFIGURATION OF

1.

to open the SOFTWARE UPDATE menu 2. Open the SOFTWARE UPDATE menu.

Click the

The dialog box for entering the service password appears on the screen.

ATTRIBUTES tab and then SOFTWARE UPDATE.

2.

Entering the password 3. Enter the service password.

i

NOTE

As servicepassword, enter the first 4 digits of the current system date in reverse

order (e.g. on 05/24/1995, 5042 must be entered as the service password.

If an incorrect service password or no password at all is then entered, the limited update menu for users will then be started. This includes only the possibility for an automatic update (see page 1-26).

The dialog box for selecting the installation source opens.

1 – 24 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 33

Tab 1 1.9 Software update

Selecting an installation source 4. IMAGE FILE is preset as the installation source for the software update.

5. Select the path and the desired update file and confirm your selection by

clicking

Click on

i

The update file can be found on the ORTHOPHOS XG Software CD. It is delivered with each DX11 replacement board and also included in the country

4. 5.

Selecting the update mode 6. Select the mode for the software update.

set. The contents of the CD can be downloaded from the Dealer domain of the

SIRONA Internet home page (under Product Info

www.sirona.com

You can select two different update modes via the index tabs:

z Automatic

The software of all components is automatically updated to a higher software version.

z Main version

The software can be upgraded or downgraded to the desired version.

This update mode is required e.g. if a replacement component delivered

out of stock has a newer status than the prevailing overall system status.

In this case, a main version update to the overall system status (displayed

on the info screen) must be performed for the corresponding component

with the appropriate update file (*.SUI). The module is then reprogrammed.

OPEN.

NAME UPDATE and OPEN.

NOTE

‡

X-ray Systems):

1.9

1.9

bеЦдблЬ

(For more information on the update mode, see the next page.)

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 25

Page 34

1.9 Software update Tab 1

User domain

Automatic

(Accessible without password.)

Service domain

Automatic

A list of modules, their installed software version and the latest software

version offered by the update function is displayed in the right pane.

Main version

(E.g. if modules have a newer version status than the overall system

following module replacement.)

i

NOTE

Modules which are connected and whose program status agrees

with that of the current main program version are marked by a continuous

green bar.

Modules which are not elements of the current system configuration

(e.g. DX71 with XG

connected, are marked by a broken red bar.

If the actual status of the module could not be polled forthe update, the actual SW version will then be displayed as = V00:00.

If a module has a hardware incompatibility to the program status to be programmed or the software version on the module is newer than the one in the

update file, this will be indicated by a red triangle with an exclamation mark.

If the version of the selected update file is lower than the current software version of the unit, then there will be no display in the right window. The downgrade required in this case is possible only via the MAIN VERSION mode.

Plus

) or, as a removable medium (e.g. sensors) are not

7. Select the update mode and the update or component.

1 – 26 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 35

Tab 1 1.9 Software update

Starting the update 8. Start the update by clicking START UPDATE.

i

NOTE

Before starting the software update, make sure that no unit movements are

active (especially any diaphragm movements)! Otherwise the system may become inoperable in rare cases.

All of the sensors located in the unit (Pan or Ce ph ) must be in ser ted in th e corresponding slots. Exposure readiness must be deselected in SIDEXIS and the

system must not be in the service mode already.

The update is started. A message box informs you when the update process is completed. Confirm the update with

OK.

7.

Checking the log file 9. Check the log file to make sure that the update was completed success-

fully.

SHOW LOGFILE.

Click

1.9

1.9

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

i

NOTE

If messages such as Update of DXxx failed! appear there, please perform

the update again. Repeat this procedure as often as necessary until the

“failed” messages no longer appear.

1 – 27

Page 36

1.9 Software update Tab 1

10. Reboot the system.

CAUTION

It is always necessary to reboot the system after any software

update. (The new DX11 version will run only after the system has been rebooted (see also Section 6.20.1, "Measures following replacement of boards").

i

NOTE

Any errors with the consecutive numbers 01, 03, 04, 06 and/or 07 displayed

immediately following the software update may be ignored. If these messages

appear again after the unit is rebooted, perform troubleshooting according to

Section 2.5.

If anything conspicuous occurs in connection with system handling on completion of the software update, please repeat the software update as the first

measure. Also check whether the system software version is displayed without an asterisk (*) on the info screen.

Checking the program versions 11. Check whether all modules contain the current program version via the

SW Update Manager or service routine S008.2 (see page 5-48).

Program version included.

SW Update Manager

i

NOTE

Modules which are connected and whose program status agrees with

that of the current main program version are marked by a continuous green

bar.

Modules which are not elements of the current system configuration

(e.g. DX71 with XGPlus) or, as a removable medium (e.g. sensors) are not

connected, are marked by a broken red bar.

If the actual status of the module could not be polled forthe update, the actual

SW version will then be displayed as = V00:00.

If a module has a hardware incompatibility to the program status to be programmed or the software version on the module is newer than the one in the

update file, this will be indicated by a red triangle with an exclamation mark.

If the version of the selected update file is lower than the current software version of the unit, then there will be no display in the right window. The downgrade required in this case is possible only via the MAIN VERSION mode.

12. Open the "Extended Details“ via SIXABCON.

This generates an XML file (with the system parameters) which is filed under the network name of the system in the PDATA/P2K_Config folder (see

also section 1.10 on page 1-32).

1 – 28 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 37

Tab 1 1.9 Software update

R

R

1.9.4 Software update for ORTHOPHOS XG 5 to

V02.30 or higher

i

NOTE

If the sensors previously used are to be used in the future as well, plug them

into the slots on the panoramic unit and/or cephalometer before you begin the

update.

1. Switch the unit ON.

2. Execute the software update to Version V02.30 or higher (automatic up-

date) as described on page 1-24.

3. Switch the unit OFF.

Wait for approx. 1 minute. Then switch the unit ON again.

Error message E6 15 04 (undefined activation data) is displayed.

1.9

1.9

bеЦдблЬ

E6 15 04

4. Acknowledge the error message with the R key .

(

5. Perform a ceph adjustment if a cephalometer is installed (see chapter

4.4).

6. Switch the unit OFF.

Wait for approx. 1 minute. Then switch the unit ON again.

z The process is completed.

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 29

Page 38

1.9 Software update Tab 1

E6 15 04

R

(

1.9.5 Software Update for ORTHOPHOS XG

Plus

from V02.20 to V02.30 or higher

i

NOTE

If the sensors previously used are to be used in the future as well, plug them

into the slots on the panoramic unit and/or cephalometer before you begin the

update.

1. Switch the unit ON.

2. Execute the software update to Version V02.25 or higher (automatic up-

date) as described on page 1-24.

3. Switch the unit OFF.

Wait for approx. 1 minute. Then switch the unit ON again.

Error message E6 15 04 (undefined activation data) is displayed.

4. Acknowledge the error message with the R key .

5. Open the Service menu (see page 5-10).

6. Start service routine S008.3 and confirm the unit serial number (see page

5-50).

i

NOTE

The unit serial number is located on the rating plate of the unit.

R

CAUTION

In case of a wrong serial number, cancel the update and contact the SIRONA

Customer Service Center!

7. Start service routine S008.3 and enable the function activation. Exit the

Service menu again.

8. Switch the unit OFF.

Wait for approx. 1 minute. Then switch the unit ON again.

9. Perform the complete system adjustment (see chapter ):

– PAN adjustment

– For TSA units: TSA adjustment

– CEPH adjustment if cephalometer is installed

z The process is completed.

1 – 30 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 39

Tab 1 1.9 Software update

1.9.6 Software update for ORTHOPHOS XG

Plus

from

V02.22 to V02.30 or higher

i

NOTE

If the sensors previously used are to be used in the future as well, plug them

into the slots on the panoramic unit and/or cephalometer before you begin the

update.

1. Switch the unit ON.

2. Execute the software update to Version V02.30 or higher (automatic up-

date) as described on page 1-24.

3. Switch the unit OFF.

Wait for approx. 1 minute. Then switch the unit ON again.

– Perform a ceph adjustment if a cephalometer is installed (see chapter

4.4).

z The process is completed.

1.9

1.9

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 31

Page 40

1.10 Selecting More details Tab 1

1.10

Opening SIXABCON.exe 1. Open the SIXABCON utility program in the SIDEXIS XG program folder.

Selecting More details

Click on SIXABCON.exe (see screen shot) or

use the pull-down menus

X-RAY COMPONENTS.

PROGRAMS ‡ SIDEXIS ‡ CONFIGURATION OF

1.

Opening the

EXTENDED DETAILS menu 2. Open the EXTENDED DETAILS menu.

Click the

The current parameters are read from the unit and stored as an XML file

under the network name of the unit in the PDATA/P2K_Config folder.

This process can take up to 30 seconds.

ATTRIBUTES tab and then EXTENDED DETAILS.

2.

After the parameters are read, an editor displaying the XML file is opened

automatically.

1 – 32 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 41

Tab 1 1.10 Selecting More details

i

NOTE

You can scroll down further in the file using the scroll bar. The "Changed

system parameters", i.e. the system parameters that were modified in relation

to the factory setting, are displayed there. This is especially interesting after a

module change. The parameter settings can thus be easily traced.

1.10

1.10

bеЦдблЬ

--------------------------------------------------------------------------

--------------------- Changed Systemparameter ---------------------

-------------------------------------------------------------------------The following systemparameters have been changed compared to the factory

settings.

After replacing an DX11-PCB, the listed values must be reconfigured.

--- Changed System Configuration Settings --Setting of system version (configured in S17.2)

actual value: 0x0043

Setting of head rest type (configured in S17.10)

actual value: 1

Setting of language index (configured in S17.4)

actual value: 0x0001

Setting of language-set index (configured in S17.5)

actual value: 0x0002

Setting of remote control activation (configured in S17.6)

actual value: active (01)

Setting of DX41 configuration (configured in S17.9)

actual value: mounted (01)

Setting of image format (configured in S17.11)

actual value: enabled (01)

Settings of welcome-screen configuration (configured in S17.14)

actual value: 01=1, 02=1, 03=1, 04=1, 05=0, 06=0, 07=0, 08=0

Settings of CEPH-adjustment (Stored by the adjustment-routines)

actual value: DAlpha = 2810 | DX = 0 | DY = 35160

Settings of CEPH-adjustment QuickShot (Stored by the adjustment-routines)

actual value: DAlpha = 2810 | DX = 0 | DY = 35160

Settings of PAN- and TSA-adjustment (Stored by the adjustment-routines)

actual value: DAlpha = -202 | DX = -191 | DY = -6044 | A1 = 0 | A2 = 0 | C1 =

-77

Setting of ring type (configured in S34.7)

actual value: 100

Setting of kVmA level series (configured in S17.8)

actual value: FIFO_2A

Settings of network configuration

actual value: IP: 192.168.15.176 | Subnet: 255.255.255.0 | Gateway:

192.168.15.1

--- Changed User Preference Settings --Settings of patientensymbols PAN (configured in 'select basic settings')

Settings of patientensymbols CEPH (configured in 'select basic settings')

Setting of anomaly default (configured in 'select starting settings')

Setting of default patientsymbol PAN (configured in 'select starting settings')

Setting of default patientsymbol CEPH (configured in 'select starting settings')

1951C59C.txt

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 33

Page 42

1.11 The most important modules and components Tab 1

Cephalometer,

arm on right side or on left side

(see section 1.11.3)

1.11

The X-ray system comprises the following main modules:

z Slide with rotary unit

z Stand

z Cephalometer, arm on right side or on left side (optional)

z Remote control (optional)

The most important modules and components

Slide

(see section 1.11.1)

Remote control

(see section 1.11.4)

Stand

(see section 1.11.2)

1 – 34 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 43

Tab 1 1.11 The most important modules and components

1.11.1 Slide

LS

MU

LS

M AK1, M AK2

DX81P*, DX85P*

DX7*

Easypad (XG

Plus

DX11

1.11

M1*, M2*

LS*

DX1

DX5*

DX6*

DX61**

)

1.11

bеЦдблЬ

DX71

Multipad (XG 5 / 3 / 3 PPE)

Component Designation Function

Boards DX1 Open-loop/automatic control in general

Motors M1*, M2* Linear movement of headrest

*) not available as individual spare part

(see spare parts list)

**) not for XG 3 / 3 PPE (fixed diaphragm)

DX11 Controller board

DX5* Headrest adapter

DX6* Open-loop/automatic control for tube assembly

Plus

DX7* Touchscreen on the Easypad (XG

DX71 LED display on Multipad (XG 5)

DX61** Diaphragm control

DX81P Digital sensor

DX85P* Digital sensor power supply

M U Rotary movement of rotating element

AK1, AK2 Linear movement of rotating element

)

59 38 399 D3352

D3352.076.01.13.02 07.2008

Light barriers LS Position check

1 – 35

Page 44

1.11 The most important modules and components Tab 1

1.11.2 Stand

M HA

DX32*

DX41**

Component Designation Function

Boards DX32* Power supply board

DX41** Interface board

Motors M HA Linear movement of height adjustment

* As of hardware version BA (from November 2006) new systems will be delivered with

the new version of board DX32 (see Section 1.9).

** As of hardware version BA (from November 2006) new systems will be delivered without

board DX41.

1 – 36 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 45

Tab 1 1.11 The most important modules and components

1.11.3 Cephalometer

(arm mounted on left side or on right side)

1.11

DX91

M S

Component Designation Function

Boards DX91 Cephalometer control

Motors M S Stepping motors:

linear movement of secondary diaphragm

and sensor

Light barriers LS Position check

LS

1.11

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1.11.4 Remote control

DX42

Component Designation Function

Boards DX42 Display board for remote control

1 – 37

Page 46

1.12 Cabling overview Tab 1

DX32 / X2

DX32 / X1

DX1 / J302

1.12

1

Cabling overview

DX1

4

5

DX6

2

Power switch

3

DX6 / X3

3

DX32

4

1

2

DX1 / X100

Line filter

5

DX6 / J6

6

Wago terminal

DX1 / J306 – J302

DX1 / J901

DX1 / X303

DX1 / X104

DX1 / X302

7

8*

108*

9

10

11

DX6 / J2 – J3

DX41

DX41 / X100

DX7 / X102

* Unit HW version BA and higher

** Board DX 41 omitted in unit HW version

DX7 / X103

BA and higher

10

9

DX7/DX71

8/108*

DX1

6

DX6

DX61

11

7

DX41**

DX1 / X102

DX61 / X501

59 38 399 D3352

1 – 38 D3352.076.01.13.02 07.2008

Page 47

Tab 1 1.12 Cabling overview

DX1 / X306

DX1 / X404

DX5 / X1

12

13

16

18

19

DX61 / X101

DX1 / X610

13

19

16

MHA

DX1

DX81

DX5

LS

DX61

18

sensor

12

1.12

1.12

bеЦдблЬ

DX1 / X403

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 39

Page 48

1.12 Cabling overview Tab 1

DX42 / X100

DX61

DX91

DX5

DX61

17

117*

21

22

23

24***

Potentiometer

DX41 / X103

DX81

DX91

Laser module

DX42

212131

17/117*

MU

LS

Sensor

22/24***

35

DX41**

DX1

23

21

/24***

DX61

38

25

DX41

DX1 / X503

25

31

35

38

* Unit HW version BA and higher

** Board DX 41 omitted in unit HW version

BA and higher

Media Konverter

DX81 / X100

Media converter

1 – 40 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 49

Tab 1 1.12 Cabling overview

DX1 / X103

DX1 / X309

36

37

39

40

DX91 / X6

DX91 / X101

DX91

36

37

39

DX1

40

1.12

1.12

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 41

Page 50

1.13 Illustrations of boards Tab 1

1.13

Illustrations of boards

1.13.1 Boards in the slide

Boards DX1 / DX11

To facilitate cable routing to the side, RJ 45 connectors with a 45° incline were introduced in August 2006.

DX1

X103

X102

X1000

X404

X100

X104

X403

X611

X607

X402

J302

J309 only with GALILEOS

J306

J307

X303

X306X302

X309

X307X503

X500

X804

X802

X803

Board DX5

X811

X812

X813

X610

DX11

X5X7

X3

X4

X6 X1 X2

59 38 399 D3352

1 – 42 D3352.076.01.13.02 07.2008

Page 51

Tab 1 1.13 Illustrations of boards

Board DX6 (not available as spare part)

J2

J3

J6

S2

X3

X2X1 X306X305

1.13

1.13

bеЦдблЬ

Board DX61 (not for XG 3 / 3 PPE)

X101

X202

X203

X405

X406

59 38 399 D3352

D3352.076.01.13.02 07.2008

X402 X401

F201

X400 X304

X201

X303 X302

X301

X501

X300 X200

1 – 43

Page 52

1.13 Illustrations of boards Tab 1

Board DX7 (XG

Plus

only, not available as repair part)

i

NOTE

Board DX7 is shown here only for enhanced clarity. The Easypad may be

replaced only as a complete unit!

Board DX7 (XG 5/3/3 PPE only, not available as repair part)

X203

X202

X104

X106

X103 X102

i

NOTE

Board DX71 is shown here only for enhanced clarity. The Multipad may be

replaced only as a complete unit!

59 38 399 D3352

1 – 44 D3352.076.01.13.02 07.2008

Page 53

Tab 1 1.13 Illustrations of boards

Boards DX81P / DX85P (not available as repair parts)

DX81

DX85

1.13

1.13

bеЦдблЬ

59 38 399 D3352

D3352.076.01.13.02 07.2008

i

NOTE

Boards DX81 and DX85 are shown here only for enhanced clarity.

CAUTION

It is not allowed to open the sensor! The sensor may be replaced only as

a complete unit!

1 – 45

Page 54

1.13 Illustrations of boards Tab 1

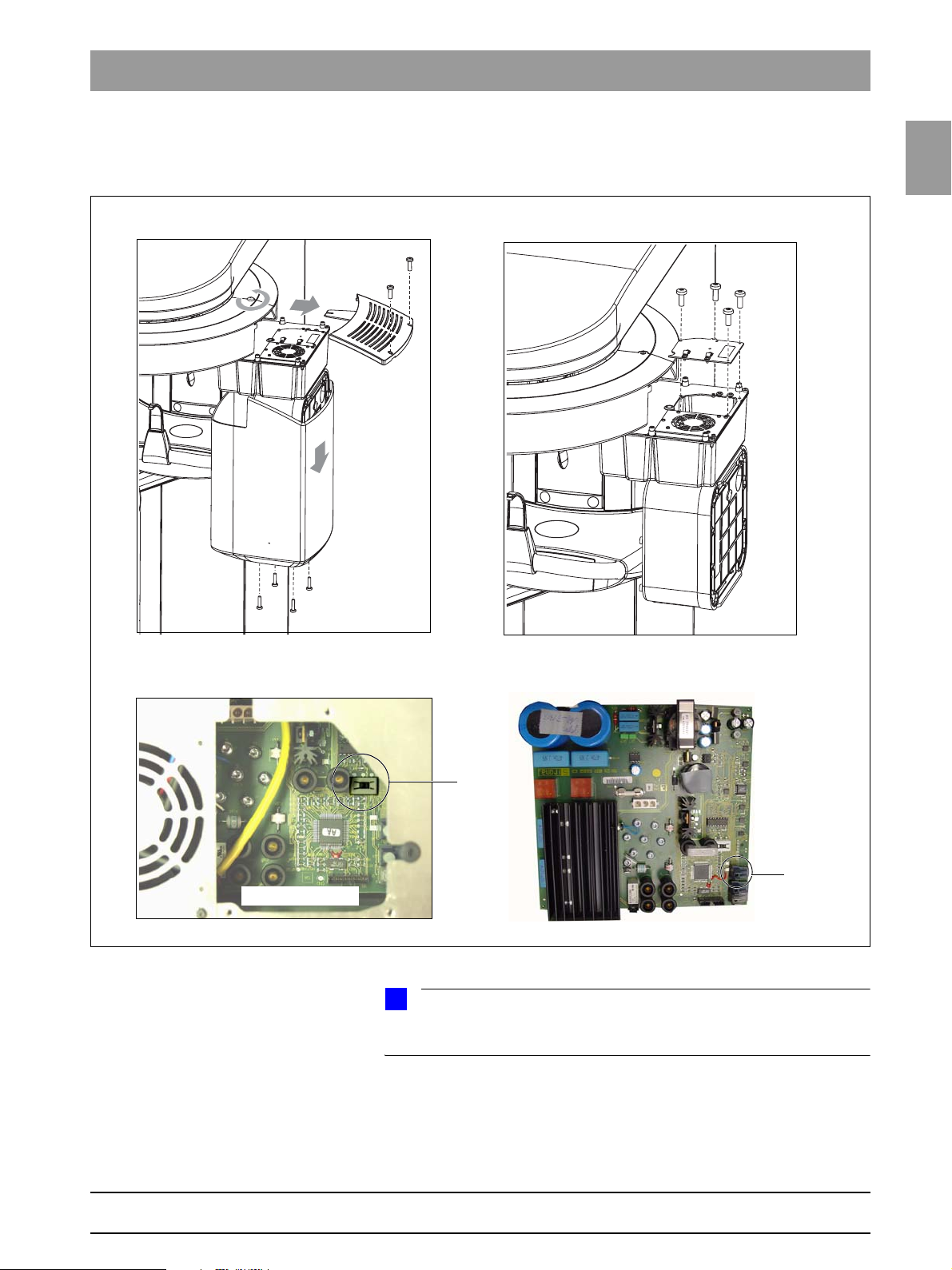

1.13.2 Boards in the stand

Board DX32

up to unit hardware version AG

F100X1

X100

F101 F102 F103

Board DX32

as of unit hardware version BA

(from November 2006)

F101 F102

X2

F100X1

X100

X2

1 – 46 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 55

Tab 1 1.13 Illustrations of boards

Board DX41

omitted as of unit hardware version BA

(from November 2006)

X100

1.13

1.13

bеЦдблЬ

Board DX91

X101

X202

X104X102

1.13.3 Boards in the cephalometer

(arm mounted on right side or on left side)

X306X307X308

X103

X501

X407

59 38 399 D3352

D3352.076.01.13.02 07.2008

X201

X304

X302

1 – 47

Page 56

1.13 Illustrations of boards Tab 1

1.13.4 Boards in the remote control

Board DX42

up to unit hardware version AG

V101

X100

V103

X105

X200

X101

V100

X201

X107

1 – 48 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 57

Tab 1 1.13 Illustrations of boards

Board DX42

as of unit hardware version BA

(from November 2006)

V101

X108 X105 Jumper X109 und X110

X200

V103

X201

X101

1.13

1.13

bеЦдблЬ

V100

X107

59 38 399 D3352

D3352.076.01.13.02 07.2008

1 – 49

Page 58

1.14 Removing the covers Tab 1

11

1.14

Removing the covers

3

9

13

4

10

8

5

6

12

1. Profile cover

2. Intermediate piece

3. Arm cover, top

4. Slide cover, top rear

5. Slide cover, bottom rear

6. Support cover, top

7. Support cover, bottom

8. Tube assembly cover, front

9. Tube assembly cover, rear

10. Slide cover, center rear

11. Sensor holder cover

12. Slide cover, front complete

13. Ring cover

14. Cephalometer cover

7

2

1

14

1 – 50 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 59

ORTHOPHOS XG

2 Messages

Page 60

Tab 2

Contents

2.1 Help messages .......................................................2 – 3

2.2 System messages...................................................2 – 6

2.3 Status displays ........................................................ 2 – 6

2.4 Error messages.......................................................2 – 6

2.4.1 Ex yy zz................................................................ 2 – 7

2.4.2 Ex yy zz................................................................ 2 – 8

2.4.3 Ex yy zz ................................................................ 2 – 8

2.4.4 General handling of error messages .................... 2 – 8

2.5 List of error messages.............................................2 – 9

2.6 List of available service routines ...........................2 – 62

2 – 2 D3352.076.01.13.02 07.2008

59 38 399 D3352

Page 61

Tab 2

2 Messages

The different message texts are displayed...

Plus

z For XG

z For XG5/3/3 PPE: on the Multipad display

z on the display of the remote control

There are 3 groups of message texts:

z Help messages (Hxxx)

– Help messages are caused by operator errors

– The user must take action

z Error messages (Exyyzz)

– Error messages indicate system faults

– The user must take action to eliminate the fault(s)

: on the Easypad touchscreen

bеЦдблЬ

z System messages (Sxxx)

– System messages inform the user about the current operating status of

the system

– The user is not required to take action

59 38 399 D3352

D3352.076.01.13.02 07.2008

2 – 3

Page 62

2.1 Help messages Tab 2

2.1

Help messages are displayed as help codes (Hxxx) on the touchscreen of the

Easypad (XG

remote control display (if available). The codes tell you how to operate the

system if radiation release is not possible due to a previous operator error.

The following list provides you with an overview of all help codes, their meaning and the action required to eliminate the corresponding problems:

Help messages

Plus

), on the display of the Multipad (XG5/3/3 PPE) or on the

Help code Description Actions required

H3 01

H3 10

H3 20

H3 21

H3 22

(for XG

Plus

only)

H3 30

(XG 3 PPE only)

H3 31

The rotating element on the panoramic unit is

not located in its starting position.

The system is performing an action.

The exposure parameters have not been

acknowledged yet.

The X-ray room door contact is not detected.

Quadrant for TSA exposure is not selected.

Indicates number of exposures remaining

(PPE concept).

1. After each switch-on (see S017.22)

2. After each exposure if the number of exposures remaining is below the defined warning

level (see S017.23)

No further exposures available.

z Press the R key:

The panoramic unit moves to the starting

position.

z Wait until the system is ready.

z Press the R key:

The exposure parameters are confirmed.

z Close the door or check door contact.

z Select quadrant via Easypad.

z Request new activation code via Sirona

Customer Service Center (CSC) in due

time.

z Enter new activation code.

(XG 3 PPE only)

H4 01

The sensor on the panoramic unit is not properly

plugged in or is missing.

z Plug sensor into PAN slot.

i

HINWEIS

If this message does not disappear after the

sensor is plugged in, this indicates a system error. Perform error diagnosis according to

Section 3.2.

H4 02

H4 03

H4 04

H4 05

H4 06

The sensor on the cephalometer is not properly

plugged in or is missing.

SIDEXIS is not ready for exposure.

The sensor does not match the selected exposure type

The sensor does not match the selected exposure type

The cephalometer is not located in its starting

position.

z Plug sensor into Ceph slot.

i

HINWEIS

If this message does not disappear after the

sensor is plugged in, this indicates a system error. Perform error diagnosis according to

Section 3.2.

z Make SIDEXIS ready for exposure.

z Plug in the ceph sensor.

z Plug in the TSA sensor.

z Press the R key:

The cephalometer moves to the starting position.

59 38 399 D3352

2 – 4 D3352.076.01.13.02 07.2008

Page 63

Tab 2 2.1 Help messages

Help code Description Actions required

H4 07

H4 10

H4 20

Unit supports default settings for this exposure,

since the settings specified by SIDEXIS cannot

be taken over.

The sensor is being polled.

The image could not be transferred to SIDEXIS.

VORSICHT

Do not switch the system off until the help message has disappeared.

i

HINWEIS