Page 1

SINUMERIK 840C

Software Version 6

User's Guide

09.2001 Edition

OEM Version for Windows

TM

Manufacturer Documentation

Page 2

Page 3

SINUMERIK 840C

Introduction 1

Software Version 6

User's Guide

OEM Version for Windows

Overview and Installation 2

System Structure of 840C 3

Alarms 4

DDE Interface 5

Sample Programs 6

Appendix

Applies to

Control Software Version

SINUMERIK 840C/CE 6

(Standard/Export version)

09.01 Edition

I Code Interface A1

Reference Guide A2

Function Identifiers

for Data Management A3

Abbreviations A4

Page 4

SINUMERIK Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the "Remarks" column.

Status code in the "Remarks" column:

A ...........................New documentation.

B ...........................Unrevised reprint with new Order No.

C ...........................Revised edition with new status.

Edition Order No. Remarks

06.94 6FC5198-3AA70-0BP0 A

11.94 6FC5198-4AA70-0BP0 C

12.95 6FC5198-5AA70-0BP0 C

04.96 6FC5198-5AA70-0BP1 C

07.97 6FC5198-6AA70-0BP0 C

01.99 6FC5198-6AA70-0BP1 C

09.01 6FC5198-6AA70-0BP2 C

This manual is included in the documentation on CD-ROM (DOCONCD)

Edition Order No. Remarks

10.01 6FC5 198-6CA00-0BG2 C

Trademarks

SIMATIC

, SIMATIC HMI, SIMATIC NET, SIROTEC, SINUMERIK and SIMODRIVE are

registered trademarks of Siemens AG. Other brands mentioned in this publication might be trademarks

whose use by a third party for his own purposes could violate the rights of the proprietors.

Further information is available on the Internet under:

http:/www.ad.siemens.de/sinumerik

This publication was produced with Microsoft Word V 7.0

and Designer V 4.0.

The reproduction, transmission or use of this document or its contents

is not permitted without express written authority. Offenders will be

liable for damages. All rights, including rights created by patent grant

or registration of a utility model or design, are reserved.

Siemens AG 2001. All rights reserved

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to the

hardware and software described. Nonetheless, differences might exist

and therefore we cannot guarantee that they are completely identical.

The information contained in this document is, however, reviewed

regularly and any necessary changes will be included in the next

edition. We welcome suggestions for improvement.

Subject to change without prior notice.

Order No. 6FC5198-6AA70-0BP2 Siemens-Aktiengesellschaft

Printed in the Federal Republic of Germany

Page 5

09.01

Preliminary Remarks

Notes for the reader: The SINUMERIK documentation is organized in 4 parts:

• General Documentation

• User Documentation

• Manufacturer Documentation and

• Service Documentation

This manual is intended for OEM customers and manufacturers of

machine tools who use the SINUMERIK 840C OEM Version for

Windows.

The software of the integrated MMC of the SINUMERIK 840C OEM

Version for Windows includes the operating systems:

• MS-DOS 6.22

• MS-Windows for Workgroups 3.11 (WfW 3.11)

• FlexOS

The control can be started up both under Windows for Workgroups

3.11 and FlexOS. If FlexOS is booted, the control is functionally

identical with the SINUMERIK 840C/CE (basic version).

Booting under WfW 3.11 provides the OEM customer or machine

manufacturer with a way of integrating his own technological expertise

into the control under a widely used operating system platform.

Moreover, with MS Windows it is possible to make use of the wide

range of inexpensive software for technical and industrial applications

on the control.

This manual describes the method of operation and parameter options

of the internal software modules of the integrated MMC and provides

the user with the information required to develop and integrate his own

applications into the software system.

This manual is intended to be introductory, so the reader does not

need any special knowledge except for experience of NC technology

and a basic knowledge of how to program the MS Windows operating

system.

For the acquisition or improvement of knowledge of these subjects, we

recommend the training courses provided by SIEMENS. Please

consult your local SIEMENS branch office or national company for

further information.

Page 6

09.01

The Manufacturer Documentation for the 840C control is subdivided

into the following parts:

• Interface

- Part 1: Signals

- Part 2: Connection Conditions

• PLC 135 WB/WB2/WD Planning Guide

• Function Macros

• Planning Guides

- Package 0: Basic Functions

- Package 1: Tool Management

- Package 4/5: Computer Link

- Package 7: Code Carriers

- Package 8: PLC Controlled Data Input/Output

There are also SINUMERIK publications that apply to all SINUMERIK

controls (e.g. Measuring Cycles, CL 800 Cycle Language)

You can obtain more details from your local Siemens branch office or

national company.

When using SINUMERIK Safety Integrated (SI) in connection with

OEM applications for 840 C Windows, please observe the notes

given in the Safety Integrated documentation.

This manual only applies to the control

SINUMERIK 840C, OEM Version for Windows,

Software Version 4, 5 and 6

For more detailed information on the MS DOS and MS Windows

operating systems, please refer to the original documentation of the

Microsoft Corporation

MS-DOS is a registered trademark of the Microsoft Corporation

is a registered trademark of the Microsoft Corporation

MS

Microsoft

is a registered trademark of the Microsoft Corporation

Windows

Visual Basic

Visual C++

ROBOHELP

is a trade name of the Microsoft Corporation

is a trade name of the Microsoft Corporation

is a trade name of the Microsoft Corporation

is a registered trademark of the Blue Sky Software Corporation

Page 7

09.01

Warning notes

The following warning notes with varying degrees of severity are used in the documentation:

Danger

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury or in substantial property damage.

Warning

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury or in substantial property damage.

Caution

Used with the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate injury or

in property damage.

Caution

Used without safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

Notice

Used without the safety alert symbol indicates a potential situation

which, if not avoided, may result in an undesirable result or state.

Page 8

09.01

Page 9

Table of Contents

1 Introduction ..................................................................................................................1-1

2 Overview and Installation............................................................................................ 2-1

2.1 System requirements ..................................................................................................... 2-2

2.2 Installation procedure..................................................................................................... 2-2

2.3 Additional notes on the OEM test environment.............................................................. 2-3

2.4 Directory structure of the OEM test environment...........................................................2-4

3 System Structure of 840C ........................................................................................... 3-1

3.1 Overview ........................................................................................................................ 3-1

3.1.1 Hardware concept .................................................................................................... 3-1

3.1.2 Software structure of the integrated PC ................................................................... 3-2

3.1.3 Basic modules .......................................................................................................... 3-4

3.1.4 NCK / PLC / SIMODRIVE 611-D interface ...............................................................3-6

3.2 Hardware configuration..................................................................................................3-7

3.2.1 Brief description of hardware.................................................................................... 3-7

3.2.2 Integrated PC ........................................................................................................... 3-9

3.2.2.1 Block diagram........................................................................................................... 3-10

3.2.2.2 Processor 80486....................................................................................................... 3-10

3.2.2.3 System memory........................................................................................................ 3-10

3.2.2.4 Mass storage medium .............................................................................................. 3-12

3.2.2.5 Watch Dog................................................................................................................3-12

3.2.2.6 VGA video graphic unit............................................................................................. 3-12

3.2.2.7 Electrical and mechanical data................................................................................. 3-12

3.2.2.8 PCMCIA software support........................................................................................ 3-12

3.2.1.9 I/O address areas..................................................................................................... 3-26

3.2.1.10 Interrupt assignments............................................................................................... 3-27

3.2.3 Hardware interfaces on the MMC CPU ....................................................................3-28

3.2.3.1 Serial interface RS232 (COM1)................................................................................ 3-28

3.2.3.2 Serial interface RS232/TTY (COM2)........................................................................ 3-28

3.2.3.3 Parallel interface (LPT1)........................................................................................... 3-29

3.2.3.4 Keyboard interface.................................................................................................... 3-30

3.2.3.5 RGB interface........................................................................................................... 3-30

3.2.3.6 VGA analog interface (PC-compatible)..................................................................... 3-30

3.2.3.7 Hardware settings on the MMC CPU ....................................................................... 3-31

3.2.3.8 Operator controls and displays................................................................................. 3-31

3.2.3.9 SINUMERIK link bus................................................................................................. 3-31

3.2.3.10 AT96 local bus..........................................................................................................3-32

3.2.3.11 Use of interfaces COM3 and COM4......................................................................... 3-33

3.2.4 The AT box............................................................................................................... 3-34

3.2.4.1 Overview................................................................................................................... 3-34

3.2.4.2 The ISA local bus in the AT rack .............................................................................. 3-35

3.2.4.3 AT bus power supply................................................................................................ 3-36

3.2.4.4 Using PC/AT cards................................................................................................... 3-36

3.3 New features in software version 6................................................................................3-38

3.3.1 Transmission of key code to PLC............................................................................. 3-38

Page 10

3.3.2 Program frame for WINDOWS and DOS applications (SW 6 and higher)................3-39

3.3.2.1 Integrating Windows programs.................................................................................3-39

3.3.2.2 Integrating DOS programs........................................................................................3-40

3.3.3 Storing the alarm messages as a file for DOS applications (SW 6 and higher)........3-42

3.3.4 Mode switchover without displaying Siemens pictures (SW 6 and higher)...............3-43

3.4 Basic modules ................................................................................................................3-44

3.4.1 Application structure and operation ..........................................................................3-44

3.4.1.1 Display applications..................................................................................................3-45

3.4.1.2 Background applications...........................................................................................3-45

3.4.1.3 Operation via softkeys ..............................................................................................3-45

3.4.2 Start-up of the control ...............................................................................................3-46

3.4.2.1 Merging files with the "MIXER" program...................................................................3-46

3.4.2.2 Merging initialization files (*.INI)................................................................................3-47

3.4.2.3 Merging batch files (*.BAT).......................................................................................3-49

3.4.2.4 Merging (CONFIG.SYS) configuration files ..............................................................3-51

3.4.2.5 Merging autostart files (REG_AUTO.CFG)...............................................................3-53

3.4.3 Area switchover ........................................................................................................3-54

3.4.3.1 Configuration options in REGIE.INI ..........................................................................3-54

3.4.3.2 Switching off the control............................................................................................3-59

3.4.3.3 Express shutdown.....................................................................................................3-60

3.4.3.4 Autostart function via REG_AUTO.CFG...................................................................3-62

3.4.3.5 Starting applications via the job list...........................................................................3-65

3.4.4 NCK task...................................................................................................................3-66

3.4.4.1 Output window..........................................................................................................3-66

3.4.4.2 Menus and softkey labeling ......................................................................................3-67

3.4.4.3 Language dependence.............................................................................................3-67

3.4.4.4 Available areas (menus) of the NCK.........................................................................3-68

3.4.4.5 Storing the menus in the NCK area..........................................................................3-68

3.4.4.6 Changing the operating mode...................................................................................3-68

3.4.4.7 PLC inserts ...............................................................................................................3-68

3.4.4.8 Color settings for NCK task and alarm/message line ...............................................3-69

3.4.5 Keyboard driver.........................................................................................................3-73

3.4.5.1 Operator panel keyboard..........................................................................................3-74

3.4.5.2 Full keyboard on KYRU II .........................................................................................3-74

3.4.5.3 MF2 keyboard on SBC..............................................................................................3-74

3.4.5.4 Key codes.................................................................................................................3-75

3.4.5.5 Kyru expansions .......................................................................................................3-77

3.4.5.6 New features in Software version 5.1.......................................................................3-79

3.4.6 Data manager...........................................................................................................3-92

3.4.6.1 Reading files in and out ............................................................................................3-93

3.4.6.2 Editor "WEdit" ...........................................................................................................3-95

3.4.6.3 Expansion options.....................................................................................................3-98

3.4.6.4 Access rights in data management...........................................................................3-100

3.4.6.5 The NCK data selector..............................................................................................3-101

3.4.6.6 Data handling via DB 37...........................................................................................3-102

3.4.7 V24 parameterization................................................................................................3-105

3.4.8 Softkey manager.......................................................................................................3-106

3.4.8.1 Setting/deleting characters in the RECALL field.......................................................3-109

3.4.8.2 NCK font ...................................................................................................................3-110

3.4.8.3 Operating the softkey menu with an external keyboard............................................3-110

3.4.8.4 Operating the softkey menu with the mouse.............................................................3-110

3.4.9 Clock.........................................................................................................................3-111

3.4.10 Watchdog..................................................................................................................3-111

3.4.11 Access protection......................................................................................................3-111

Page 11

3.4.11.1 Password management............................................................................................ 3-112

3.4.11.2 Setting up the password levels................................................................................. 3-114

3.4.12 FDD/MSD service display......................................................................................... 3-115

3.4.13 OEM information....................................................................................................... 3-115

3.4.14 840C language concept............................................................................................ 3-116

3.4.14.1 Change language .....................................................................................................3-116

3.4.14.2 Method of operation.................................................................................................. 3-117

3.4.14.3 Special features of initial start-up.............................................................................. 3-118

3.4.15 840C directory tree................................................................................................... 3-119

3.5 SIN840C.INI...................................................................................................................3-120

4 Alarms...........................................................................................................................4-1

5 DDE Interface................................................................................................................5-1

5.1 Windows DDE................................................................................................................5-1

5.1.1 Establishing a link..................................................................................................... 5-1

5.1.2 Types of link..............................................................................................................5-2

5.1.2.1 Static data................................................................................................................. 5-2

5.1.2.2 Dynamic updating..................................................................................................... 5-3

5.1.2.3 Notification of change...............................................................................................5-4

5.1.3 Terminating links....................................................................................................... 5-6

5.1.4 The DDEML library................................................................................................... 5-6

5.2 DDE server of the SIN 840C OEM version for Windows................................................ 5-7

5.2.1 Activating the server................................................................................................. 5-8

5.2.2 Link initiation with the server..................................................................................... 5-8

5.2.3 Time response.......................................................................................................... 5-9

5.3 Alarm handling via DDE.................................................................................................5-10

5.3.1 Setting alarms........................................................................................................... 5-10

5.3.2 Clear all alarms.........................................................................................................5-11

5.3.3 Reading alarms......................................................................................................... 5-12

5.3.4 Changing the display mode of the alarm/message line............................................ 5-13

5.4 Central status scan......................................................................................................... 5-14

5.5 MMC NCK interface ....................................................................................................... 5-16

5.5.1 Command interface (EXECUTE).............................................................................. 5-16

5.5.1.1 File transfer............................................................................................................... 5-16

5.5.1.2 DELETE_FILE.......................................................................................................... 5-19

5.5.1.3 RENAME_FILE......................................................................................................... 5-19

5.5.2 Read and write accesses.......................................................................................... 5-20

5.5.2.1 Data format............................................................................................................... 5-20

5.5.2.2 Variable names......................................................................................................... 5-20

5.5.2.3 List of the variable names......................................................................................... 5-20

5.5.2.4 Data fields................................................................................................................. 5-25

5.5.2.5 Error messages ........................................................................................................5-25

5.5.3 DDEML access to NC data....................................................................................... 5-29

5.5.3.1 Synchronous reading................................................................................................5-29

5.5.3.2 Asynchronous reading.............................................................................................. 5-30

5.5.3.3 Synchronous writing of NC data...............................................................................5-31

5.5.3.4 Asynchronous writing of NC data ............................................................................. 5-31

5.5.4 Transparent data transmission................................................................................. 5-32

5.5.4.1 How transparent data transmission works................................................................ 5-32

5.5.4.2 Cyclic requests/change requests..............................................................................5-34

Page 12

5.6 MMC PLC interface........................................................................................................5-37

5.6.1 Overview...................................................................................................................5-37

5.6.2 Data exchange on the PLC side...............................................................................5-37

5.6.2.1 Writing to the MMC...................................................................................................5-38

5.6.2.2 Reading from the MMC.............................................................................................5-38

5.6.3 Data exchange on the MMC side..............................................................................5-39

5.6.4 Structure of data packets on the PLC side ...............................................................5-40

5.6.4.1 Structure for receiving...............................................................................................5-40

5.6.4.2 Structure for sending.................................................................................................5-42

5.6.5 MMC-PLC data exchange (examples)......................................................................5-43

5.6.5.1 Reading PLC data (DDE_REQUEST)......................................................................5-43

5.6.5.2 Writing PLC data (DDE_POKE)................................................................................5-44

5.6.5.3 Advise link for PLC data (DDE_ADVISE) .................................................................5-45

5.6.5.4 PLC user program (DDETESST.S5D)......................................................................5-48

5.6.6 Execution of MMC applications by the PLC side......................................................5-51

5.6.6.1 Overview...................................................................................................................5-51

5.6.6.2 Starting an MMC application from the PLC...............................................................5-51

5.6.6.3 Terminating an MMC application from the PLC side ................................................5-52

5.6.6.4 I code description (42EH) .........................................................................................5-52

5.6.6.5 Terminating DOS programs......................................................................................5-55

5.6.6.6 PLC user program (WINOEMST.S5D) .....................................................................5-56

6 Sample Programs.........................................................................................................6-1

6.1 Integration of customer applications...............................................................................6-1

6.1.1 Development systems...............................................................................................6-1

6.1.2 Integration into the OEM test environment ...............................................................6-2

6.1.3 Testing DDE client applications................................................................................6-2

6.1.4 Integration of applications into the control ................................................................6-3

6.2 Sample programs (MS Visual Basic)..............................................................................6-4

6.2.1 Project: Tacho...........................................................................................................6-4

6.2.2 Project: DDETEST....................................................................................................6-7

6.3 Sample programs (MS Windows 3.1 SDK) ....................................................................6-8

6.3.1 Project: VSASERV....................................................................................................6-8

6.3.2 Project: Message......................................................................................................6-9

6.3.3 OEM client ................................................................................................................6-10

6.3.4 OEM client ADVTEST...............................................................................................6-11

6.3.5 Gearbox interpolation................................................................................................6-13

6.4 Network DDE..................................................................................................................6-17

6.4.1 Link initiation for network DDE..................................................................................6-17

6.4.2 Creating a DDE SHARE ...........................................................................................6-17

6.4.3 Network modules......................................................................................................6-19

6.4.4 Summary...................................................................................................................6-19

A1 I Code Interface.............................................................................................................A1-1

A1.1 ADS communication via mailboxes...........................................................................A1-1

A1.2 I code description......................................................................................................A1-2

A1.2.1 Application areas ......................................................................................................A1-2

A1.2.1.1 Single data item and list transfer...............................................................................A1-2

A1.2.1.2 Data transfer extensions...........................................................................................A1-2

A1.2.1.3 Executing functions...................................................................................................A1-2

Page 13

A1.2.1.4 Selective data transfer..............................................................................................A1-3

A1.2.1.5 File transfer............................................................................................................... A1-5

A1.2.1.6 Reserved applications for OEM................................................................................A1-5

A1.2.2 Structure of the I code header.................................................................................. A1-6

A1.2.3 Protocol types...........................................................................................................A1-9

A1.2.3.1 Protocol type 0.......................................................................................................... A1-10

A1.2.3.2 Protocol type 1.......................................................................................................... A1-10

A1.2.3.3 Protocol type 2.......................................................................................................... A1-11

A1.2.3.4 Protocol type 3.......................................................................................................... A1-11

A1.2.3.5 Protocol type 4.......................................................................................................... A1-13

A1.2.3.6 Protocol type 5.......................................................................................................... A1-14

A1.3 Tabular overview of the I code command in SINUMERIK 840C OEM

Version for Windows.................................................................................................A1-15

A2 Reference Guide........................................................................................................... A2-1

A2.1 I code command description.....................................................................................A2-1

A2.1.1 Single data item and list transfer: 1xxH....................................................................A2-1

A2.1.1.1 Read value(s): 01xxH............................................................................................... A2-1

A2.1.1.2 Write value(s): 01xxH...............................................................................................A2-3

A2.1.1.3 Read/write GI buffer: 0117H..................................................................................... A2-6

A2.1.2 Data transfer extensions: 2xxH.................................................................................A2-10

A2.1.2.1 Read service values of axes: 020EH........................................................................ A2-10

A2.1.2.2 Read service values of spindles: 020FH ..................................................................A2-12

A2.1.2.3 Read/write PLC data via PLC DAD: 0210H.............................................................. A2-14

A2.1.2.4 Read/write PLC data blocks: 0211H......................................................................... A2-16

A2.1.2.5 Read PLC error ID: 0212H....................................................................................... A2-19

A2.1.2.6 Read control mode: 0213H....................................................................................... A2-20

A2.1.2.7 Read/write program pointers: 0216H........................................................................ A2-21

A2.1.3 Command execution: 4xxH.......................................................................................A2-23

A2.1.3.1 Abort current I code request: 0400H ........................................................................ A2-23

A2.1.3.2 Initiate drift compensation: 0419H............................................................................ A2-24

A2.1.3.3 Initiate file transfer: 0421H........................................................................................ A2-25

A2.1.3.4 Initiating job list processing / workpiece transfer with Windows applications............ A2-31

A2.1.3.5 Select workpiece name / machining program: 0422H.............................................. A2-32

A2.1.3.6 Start / stop an MMC application from the PLC side: 042EH..................................... A2-34

A2.1.3.7 Express shutdown: 042FH........................................................................................A2-37

A2.1.4 Selective data transfer: 5xxH.................................................................................... A2-38

A2.1.4.1 Transfer data block description to the NCK: 0500H .................................................A2-38

A2.1.4.2 Delete DBB from NCK: 0501H ................................................................................. A2-40

A2.1.4.3 DBB data transfer 0502H ......................................................................................... A2-41

A2.1.4.4 Read DBB directory of NCK: 0503H......................................................................... A2-43

A2.1.4.5 Issue cyclic request/change request: 0504H............................................................ A2-44

A2.1.4.6 Delete cyclic request/change request: 0505H.......................................................... A2-46

A2.1.5 Process file: 6xxH.....................................................................................................A2-47

A2.1.5.1 Open file: 0601 H...................................................................................................... A2-47

A2.1.5.2 Close file: 0602H......................................................................................................A2-50

A2.1.5.3 Read file: 0603H.......................................................................................................A2-51

A2.1.5.4 File transfer NCK

A2.1.5.5 Write file: 0604H....................................................................................................... A2-54

A2.1.5.6 File transfer MMC

A2.1.5.7 Delete file: 0605H..................................................................................................... A2-57

A2.1.5.8 Rename file: 0606H..................................................................................................A2-59

A2.1.5.9 Display directory: 0607H...........................................................................................A2-60

A2.1.5.10 Read/write file attribute: 0608H................................................................................A2-62

A2.2 PLC function macros FX73/FX74............................................................................. A2-64

→ MMC (MMC: Services/NC/Save Start).................................... A2-53

→ NCK (MMC: Services/NC/Load Start) .................................... A2-56

Page 14

A2.2.1 Function macro FX73, OEM-SEND..........................................................................A2-64

A2.2.1.1 Additional information ...............................................................................................A2-65

A2.2.1.2 Block call (FX73: OEM-SEND) .................................................................................A2-65

A2.2.1.3 Signal description......................................................................................................A2-66

A2.2.1.4 FX73 behavior on restart..........................................................................................A2-66

A2.2.2 Function macro FX74, OEM-EMPF..........................................................................A2-67

A2.2.2.1 Additional information ...............................................................................................A2-68

A2.2.2.2 Block call (FX 74: OEM-EMPF) ................................................................................A2-68

A2.2.2.3 Signal description......................................................................................................A2-69

A2.2.2.4 FX74 behavior on restart..........................................................................................A2-69

A2.2.3 OEM information bit..................................................................................................A2-70

A2.2.4 Acknowledgements...................................................................................................A2-70

A2.2.4.1 Error lists for FX73/FX74..........................................................................................A2-71

A2.2.5 Transmission times...................................................................................................A2-73

A3 Function Identifiers for Data Management ................................................................A3-1

A3.1 Function group: delete..............................................................................................A3-2

A3.2 Function group: edit..................................................................................................A3-3

A3.3 Function group: copy/duplicate.................................................................................A3-4

A3.4 Function group: create..............................................................................................A3-8

A4 Abbreviations................................................................................................................A4-1

Page 15

1 Introduction

09.01

1 Introduction

More and more often machine tool manufacturers are faced with the task not only of developing

standardized machine tools but also special solutions for manufacturing technology. In particular,

higher and higher demands are being placed on the functionality of a CNC control. The demands are

often machine-specific and cannot be fully covered by standard products.

On the other hand, there is a desire to use the freedom afforded by the control to give it its own

appearance and/or include technological know-how. Previous man-machine interfaces (MMC) were

mostly based on control-specific software systems and demanded special knowledge of the solution in

question. A further disadvantage of such systems is their "closed" character which often means that

function expansions can only be included with great effort.

Today, there is a demand for "open-ended" control systems. This applies not only to the user interfaces

and the operating system but also to the entire computer hardware. To meet this demand, SIEMENS

has developed the SINUMERIK 840C OEM Version for Windows, an AT compatible MMC that is based

on the "open" operating systems MS-DOS 6.22 and MS Windows for Workgroups 3.11.

The MMC variation permits the use of numerous commercially available hardware modules in

conjunction with the AT box and therefore the integration of existing hardware solutions directly into the

control. The applications of such solutions include:

• Remote diagnostics

• Measuring data acquisition for quality assurance and process control

• MDA/PDA systems (machine and production data acquisition)

• DNC systems (program management and transmission)

Moreover, it is possible to benefit directly from the advantages of the broad range of industrial and

commercial software available. This means that the same programming workstation software with the

same user-friendliness can be used both on an external PC during work preparation and directly on the

control.

For customer developments, Windows for Workgroups 3.11 provides a reliable and stable platform and

a minimization of compatibility problems in the future. Moreover, this operating system ensures great

flexibility and cost-effective network-capability for the entire control system. With the pr ogramming tools

available on the market, the machine-tool manufacturer has the option of developing his own

applications and integrating them into the control.

With Visual Basic for Windows, Microsoft has developed a programming tool that cleverly combines the

advantages of Windows with the programming language Basic. There is scarcely another programming

system with which it is so easy to write Windows programs. Using predefined "Custom Controls", even

a beginner can develop professional Windows user interfaces in a simple way. Windows and menus

can be opened and closed with simple program commands and the input and output of the program

user can be managed and visualized.

However, anyone aiming at professional development cannot do without Visual C++. C++ is currently

the first choice when it comes to solving complex programming problems in a simple way. With visual C

it is possible not only to write programs for Windows but also under Windows, and that faster and more

easily then ever before. Integrated tools such as AppWizard and ClassWizard save the programmer a

lot of time-consuming and error-prone administration work, allowing him to concentrate on the actual

problem to be solved.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 1-1

SINUMERIK 840C OEM Version for Windows (BN)

Page 16

1 Introduction

09.01

Windows applications can exchange data with the NCK, PLC and 611D via the DDE interface defined

by Microsoft (Dynamic Data Exchange). Via the DDE server, which is also part of the OEM package,

data are transferred from the applications and from and to the NCK, PLC and 611D. The methods

"POKE" (write data), "REQUEST" (read data) and "EXECUTE" (commands for file transfer) are

implemented. Towards the PLC the "ADVISE" method is also implemented. The data that can be

accessed via the DDE server include machine data, setting data, PLC data blocks, part programs etc.

Simply by entering applications in an initialization file, they are integrated into the area switchover and

can be started either automatically when the control is booted or by the user by means of softkey or

PLC command. Examples of such customer applications include:

• Tool management and visualization

• Pallet management

• Job management

• Machine diagnosis

With the OEM package, the machine-tool manufacturer obtains not only the DDE server and a few

library routines but also a complete simulation and test environment for an external PC. With a

commercially available programming tool (e.g. Visual Basic, Visual C++, etc.) the machine-tool

manufacturer can develop and test his own applications on an external PC.

The following section of this documentation deals with the requirements for and the installation of the

OEM test environment and the OEMFORM alarm tool.

Chapter 3 provides a system description of SINUMERIK 840C OEM Version for Windows. This

description includes both the hardware architecture of the control and the method of operation and

parameterization of the Siemens basic modules.

The alarm concept described in previous editions in Chapter 4 has been taken out to form a separate

documentation from the current software version on.

The next section contains a brief introduction to the method of operation of the Windows DDE and a

detailed discussion of the various communications options of OEM applications with the NCK and PLC.

The DDE section is completed with a description of some sample programs that show the reader how

to integrate his own applications and serve as a guide for the development of custom applications.

■

1-2

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 17

2 Overview and Installation

09.01

2 Overview and Installation

The OEM package comprises a PC test and simulation environment of the SINUMERIK 840C with

which customer applications can be tested before they are loaded into the control. The package also

contains several test utilities and sample programs including all the source files and resources to

introduce you to program development for SINUMERIK 840C OEM Version for Windows. You can also

load the sample programs directly into the control, for example, to perform runtime measurements of

the data transfer between the MMC and the NCK or the MMC and the PLC. You will find the simulation

and test environment on the four diskettes labeled:

"SINUMERIK 840 C/CE OEM Package Windows DISK x V06.04.01"

The installation programs will expand each of the necessary files and copy them into the correct

directory so that the programs function correctly.

If you have any questions regarding installation, please contact you local Siemens branch office or

Siemens national company.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 2-1

SINUMERIK 840C OEM Version for Windows (BN)

Page 18

2 Overview and Installation

09.01

2.1 System requireme nts

Your PC must fulfil the minimum requirements listed below if the test environment is to function

correctly.

Hardware: 25 MHz 386 or larger

Memory: 4 MB RAM, approx. 21 MB free space on the hard disk

Monitor adapter: VGA resolution (640

Operating system: MS Windows 3.1 or MS Windows for Workgroups 3.11, Windows 95,

Windows NT

MS-DOS 6.22 or higher

You must also enter the Windows directory in the PATH of the AUTOEXEC.BAT. Please note that in

addition to the OEM package you will also need a programming tool for pr ogramming under Windows

(e.g. MS Visual Basic, MS Visual C++, Borland Pascal, etc.) to create your own applications which you

must purchase on the open market. Please consult the documentation supplied with it for the system

resources required (processor, RAM and hard disk memory, operating system etc.).

×480 pixels)

2.2 Installation proce dure

The OEM test environment is installed under menu guidance under the Windows operating system.

1. First start Windows if it is not yet active.

2. Place installation diskette 1 (labeled: OEM Package Windows V06.01.01) in your disk drive.

3. Read the README.TXT file and perform the installation according to the specifications.

Caution:

If a new database that has been created with OEMFORM is to be linked into the test

environment, after copying the requested databases into directory c:\oem\<language>, the

program DBTXTUPD.EXE must be called up in a DOS box (or directly under DOS) in the

directory C:\MMCWIN\PE with the selected language as parameter, e.g. DBTXTUPD for

German.

2-2

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 19

2 Overview and Installation

09.01

2.3 Additional notes on the OEM t est environment

• When you copy the keyboard drivers you might find that Windows is currently using one of

these drivers. You can acknowledge the message that appears on the screen with the

button "IGNORE".

• The font in the editor "WEdit" might differ slightly from the font on the control. An

equivalent font is not loaded in the test environment.

• The OEM test environment has been developed for a VGA resolution of (640×480 pixels).

If you use a higher resolution, the OEM test environment uses an equivalent portion of the

full screen. The OEM test environment is, however, still fully functional.

• The softkey bar that displays the menu list for the application currently active can be

hidden by calling the softkey manager SOFTMAN.EXE again in directory C:\MMCWIN\PC.

• The appearance of several applications can be altered in the installation file SIN840C.INI

(see Section 3.5) in directory C:\MMCWIN\PC. The window size and foreground/

background behavior of applications can be altered with the following options:

- Window always on top: topmost=on/off

- Window size: position[ ... ]

• In the MACHINE basic display of the test environment, the 1st softkey on the NC control

panel corresponds to function key F2. In all other applications, the 1st softkey corresponds

to function key F3.

Machine basic display:

[∆]

F1 [M]

Other applications:

• You can switch between test environment tasks using the standard MS Windows mecha-

nism (<Alt> + <Tab> etc.).

SK1

F2

SK1

F3

SK2

F3

SK2

F4

SK3

F4

SK3

F5

SK4

F5

SK4

F6

SK5

F6

SK5

F7

SK6

F7

SK6

F8

SK7

F8

SK7

F9

i

>

>

F1 (Help)

F10

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 2-3

SINUMERIK 840C OEM Version for Windows (BN)

Page 20

2 Overview and Installation

PCMCIA

h

09.01

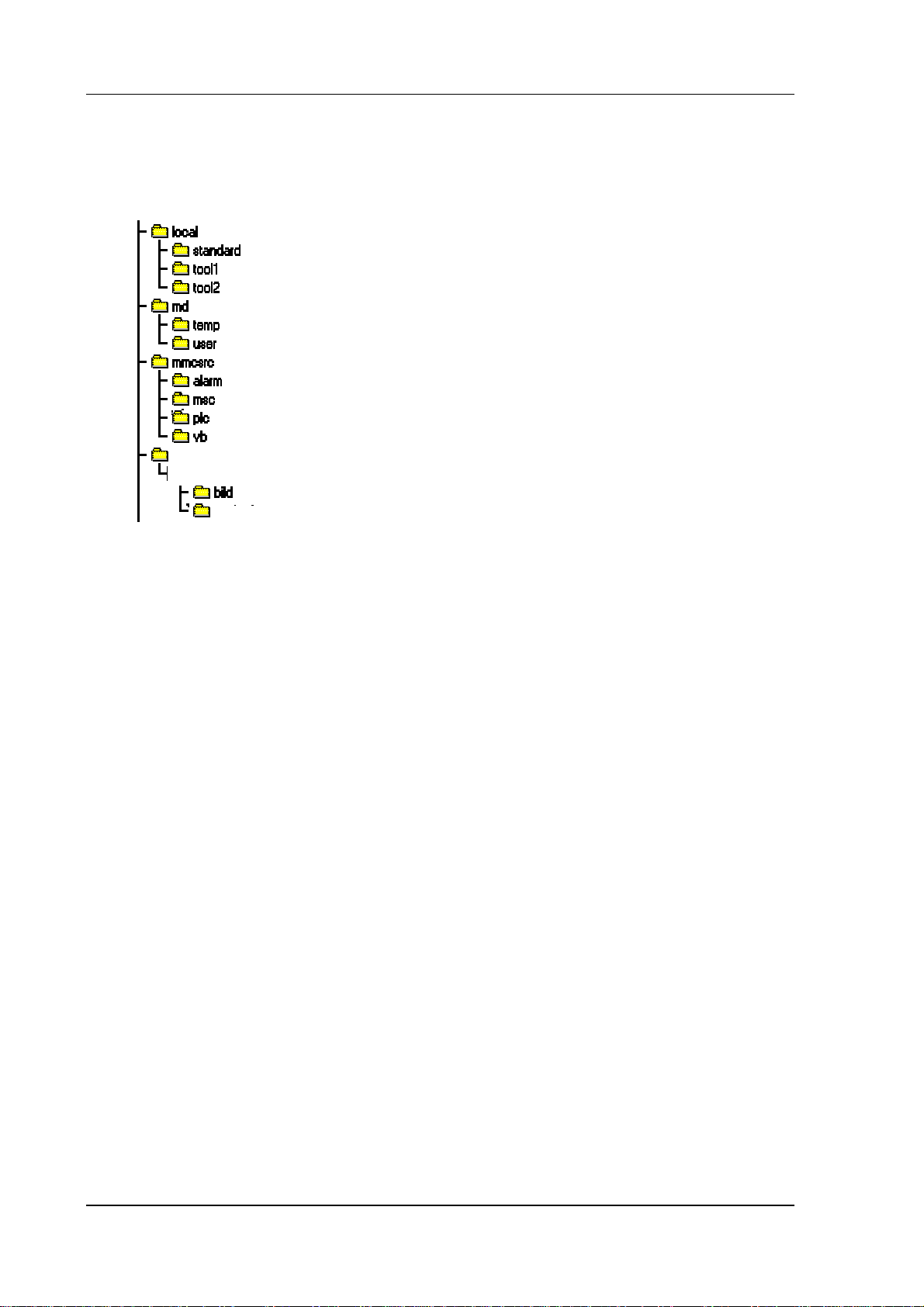

2.4 Directory structure of the OEM test environment

When you have installed the OEM test environment you will find the following directory structure on

drive C: of your hard disk:

mmcwin

—

— PC

englis

The OEM test environment contains the following subdirectories:

• Directory "local". This directory contains the workpieces that have been created

(subdirectories) together with all the files (mpf...,spf..., toa, etc.) required for machining a

workpiece. This directory is also part of the system software of the contr ol. After installation,

only the workpiece with the name "standard" exists.

• Directory "md" usually contains the machine data of the control. As no real NCK or PLC exist

in the OEM test environment, the associated subdirectories are "empty", i.e. they only contain

the obligatory "dummy" files. Both the workpieces and the directory with the machine data

can be selected and edited under the data management of the OEM test environment.

• Directory "mmcsrc" contains a number of sample programs including all the source and

resource files. These sample programs are intended to provide you with help in developing

your own applications.

The sample programs have either been developed with Microsoft Windows 3.1 SDK or

MFC 2.0 (C:\MMCSRC\MSC) or with Microsoft Visual Basic 3.0 (C:\MMCSRC\VB). They are

available either as executable *.EXE files or as entire projects with resources, source code,

libraries and header files.

The sample programs VSASER.EXE, ADVTEST.EXE and TACHO.EXE are already linked

into the OEM test environment and can be started directly from it. You will find a

description of the sample programs in Chapter 6.

• Directory C:\MMCWIN\PCMCIA contains 3 com driver floppy disks, XIRCO M driver floppies

and PC-CARD HD Patch.

• Directory C:\MMCWIN\PC contains all the basic modules of 840C OEM Version for Windows.

This directory exists both in the OEM test environment as well as in the contr ol. In addition to

the basic components such as area switchover, data management, the editor "WEdit" etc.,

this directory contains the actual DDE server (DDESRV.EXE) for linking Windows

applications to the NCK, PLC and 611D. This directory also contains a multiport RAM

simulator (MPRSIM.EXE) for PC use. You will find a description of the basic modules in

Section 3.3.

• Directory \mmcwin\pc\bild contains the machine displays that are displayed in the OEM test

environment when a machine area is called.

■

2-4

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 21

3 System Structure of 840C

09.01

3 System Structure of 840C

3.1 Overview

The product SINUMERIK 840C OEM Version for Windows provides the machine-tool manufacturer

with a sophisticated and modern control which is used as a basis for integrating additional function

expansions and customer-specific solutions.

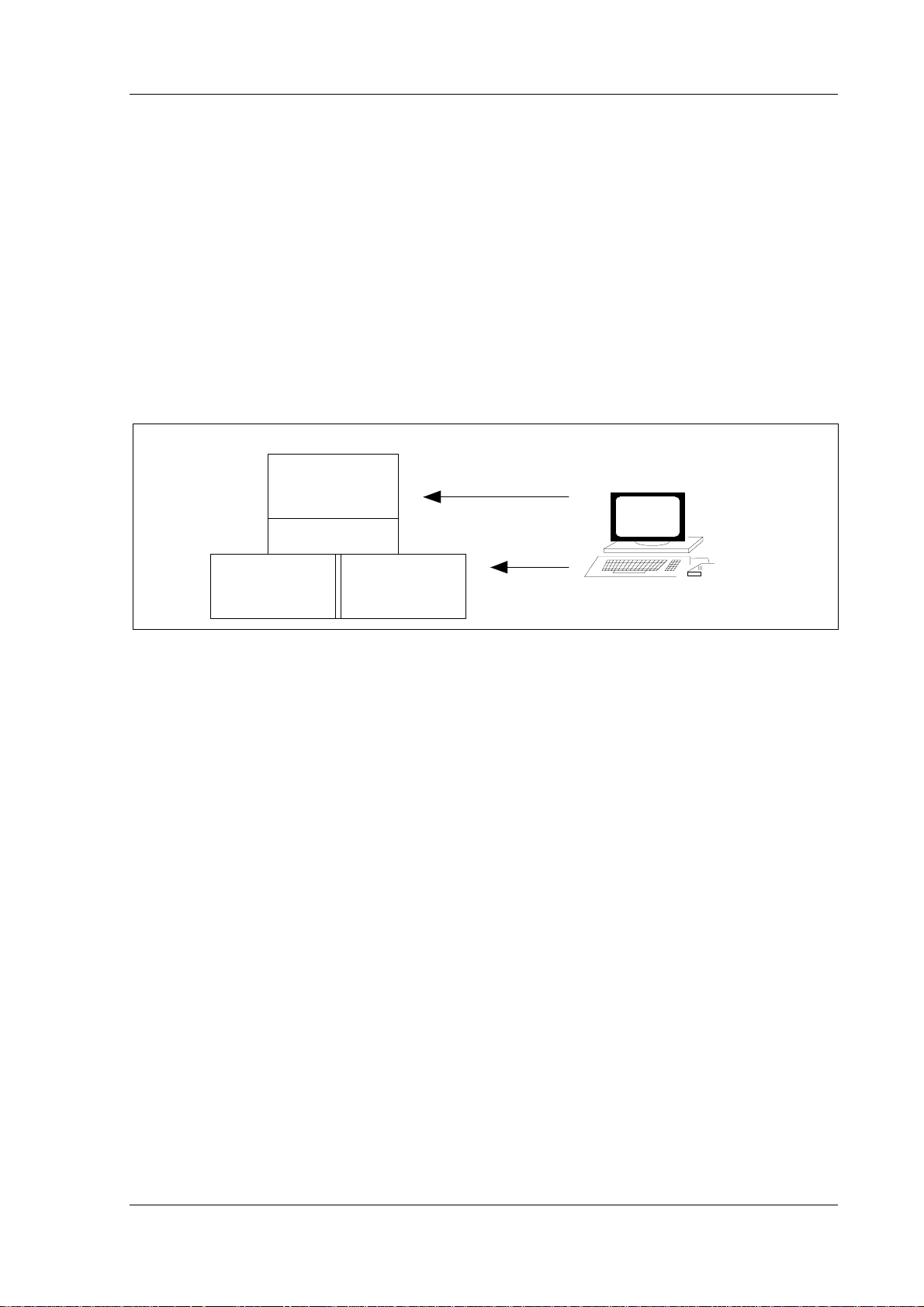

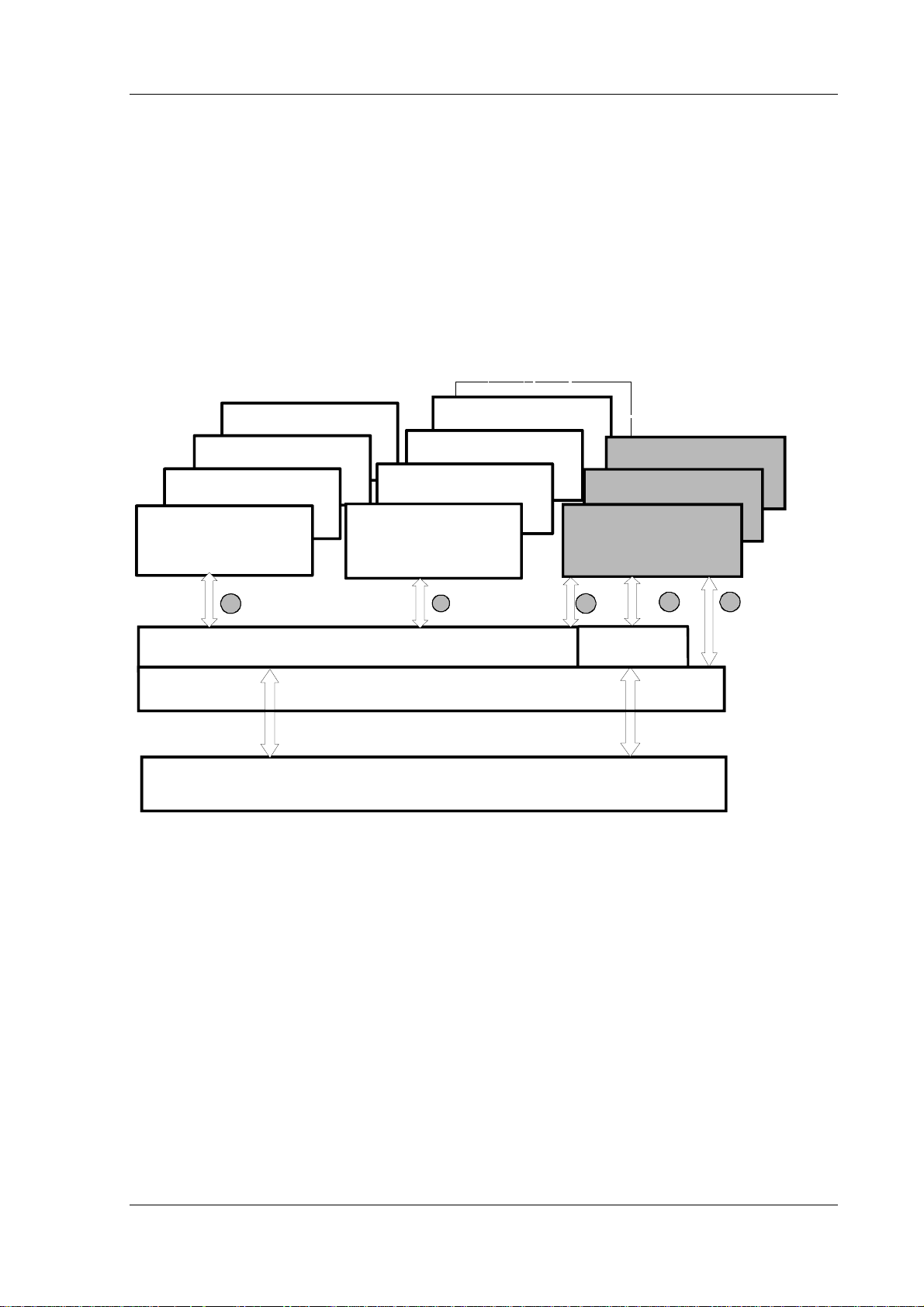

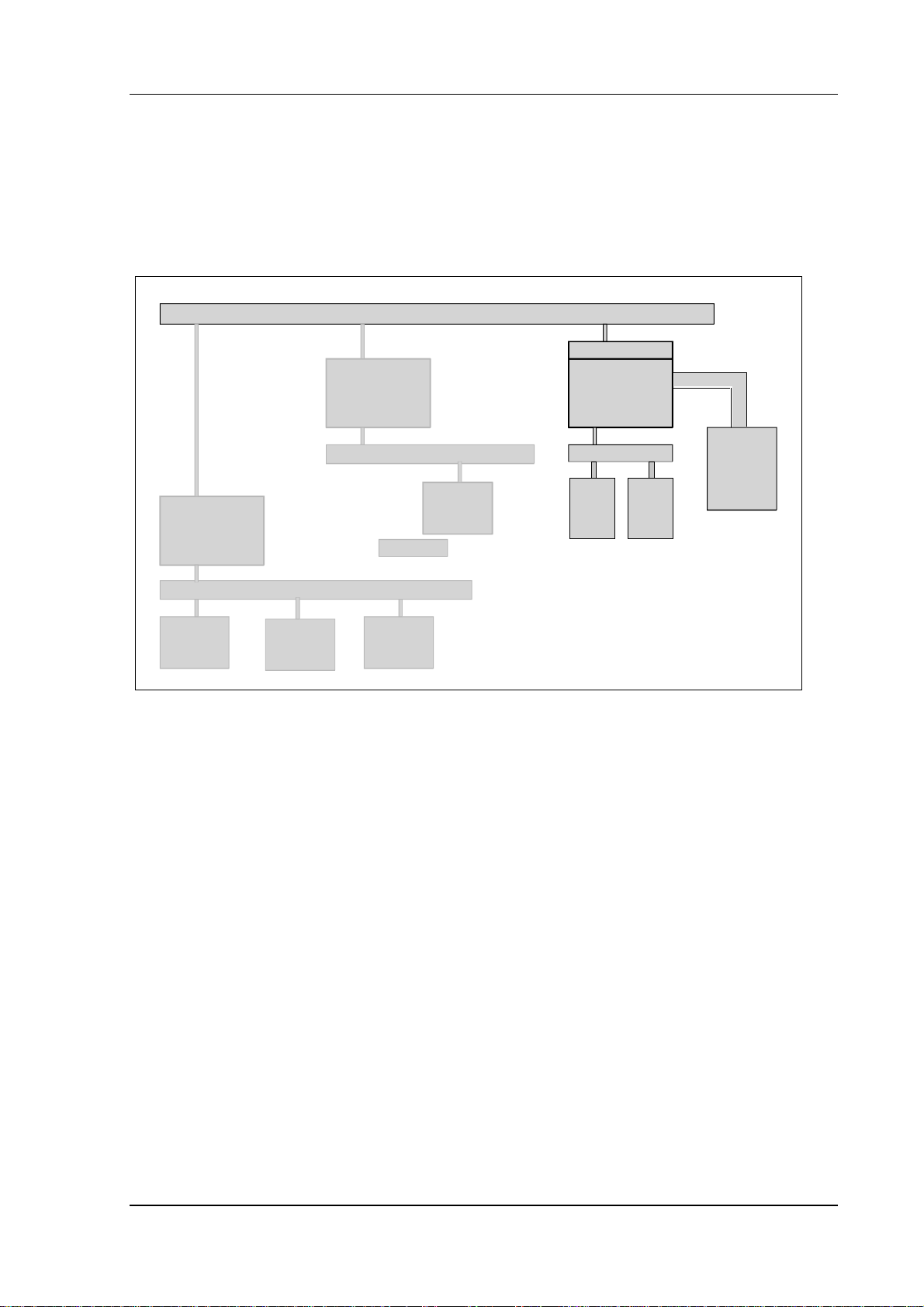

3.1.1 Hardware concept

The following hardware configuration was chosen to meet the demands for "open architecture" and

adaptability.

External

programm ing

MMC

device or

Comm unication

NCK PLC

A T-compatib le PC

Fig. 3.1: Functional st ructure of SINUMERIK 840C OEM Version for Windows

The CNC 840C control can be divided into the following three components:

MMC=PC: With this integrated AT-compatible PC with the operating system Windows for

Workgroups 3.11, the machine-tool manufacturer can make individual

adaptations and develop his own solutions on all levels of the user interface

(MMC=Man Machine Communication) including communication with the NCK

and the PLC. The AT box of central controller 3 also provides the user with open

architecture hardware.

NCK: The actual NC kernel works with a 32-bit word size and an NC memory of 1 MB.

Up to 6 spindles can be operated from its 15 servo loops. Several programs can

be executed simultaneously due to its channel structure. Data can be exchanged

with the MMC and the PLC via the DDE interface and the VDI interface. Using

program package WS800 A, machine displays can be configured in the NCK

and customized machining cycles created and the control therefore adapted to

the individual tasks of the machine tool.

PLC: The PLC section of the SINUMERIK 840C is responsible for the entire machine

control and always contained the essential know-how of the machine-tool

manufacturer. 1024 inputs and outputs, a 256-KB user memory and a

processing speed of less than 1 ms per 1000 instructions are the salient features

of the freely programmable PLC.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 3-1

SINUMERIK 840C OEM Version for Windows (BN)

Page 22

3 System Structure of 840C

09.01

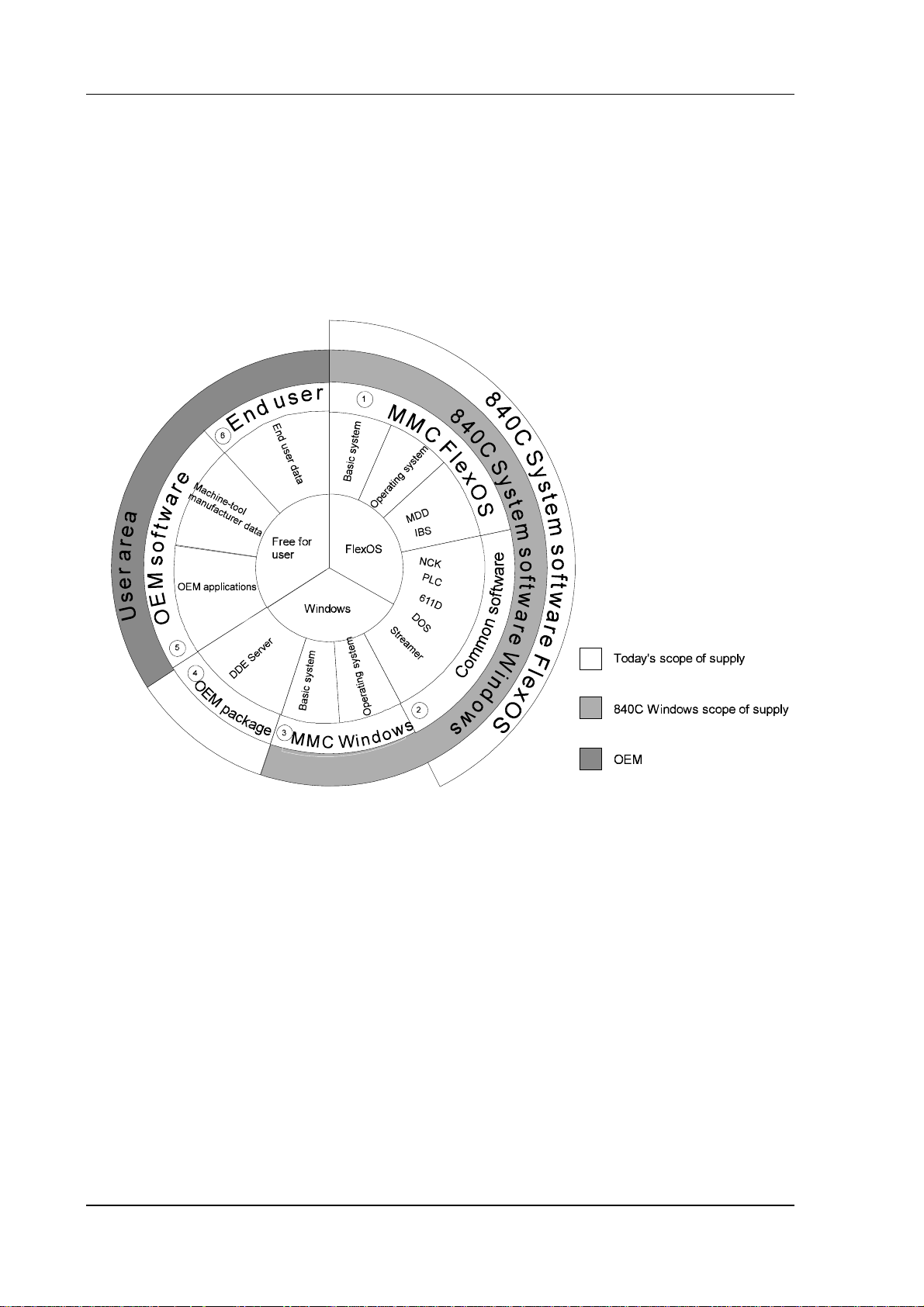

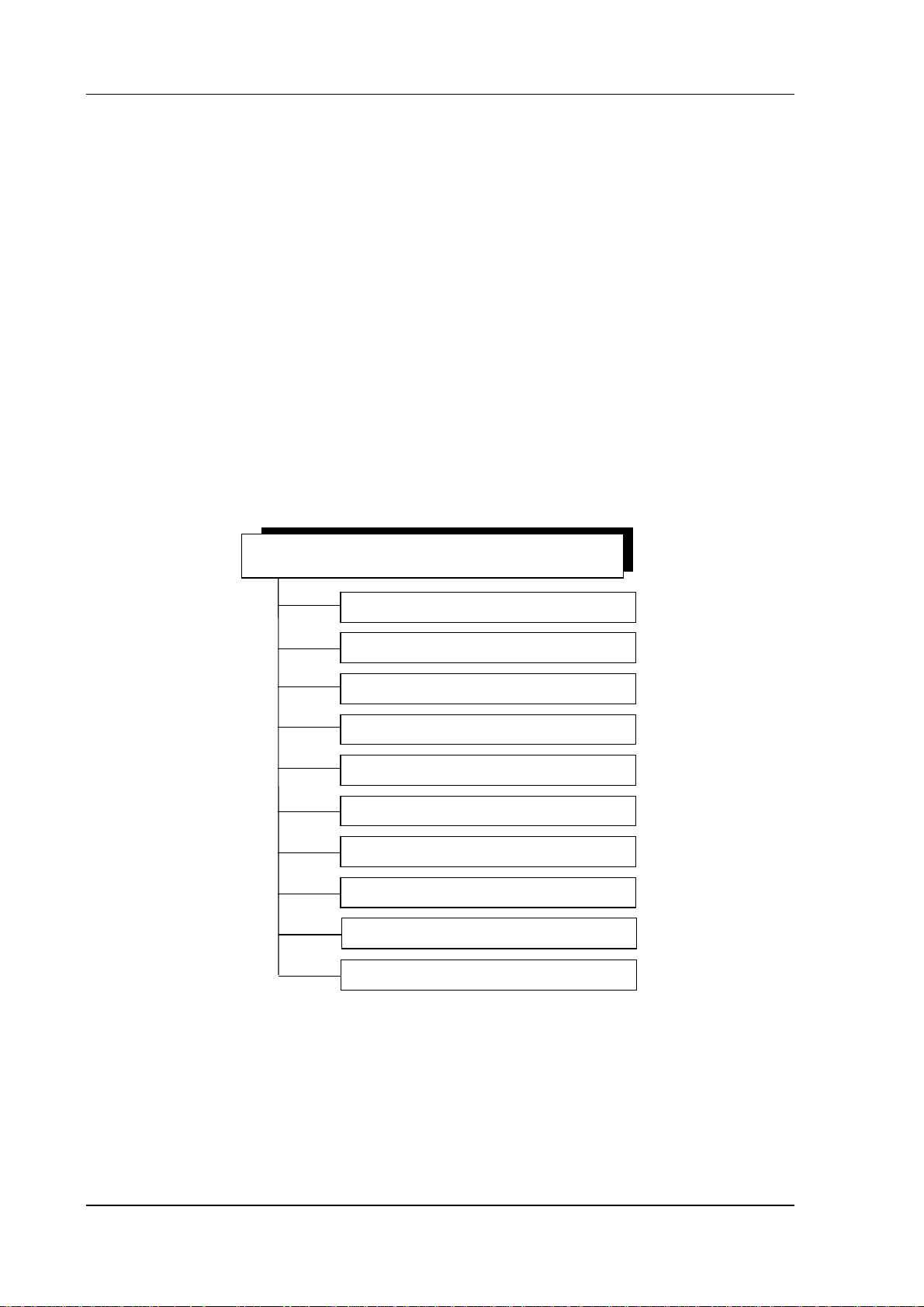

3.1.2 Software structure of the integrated PC

The system software of the CNC control 840C OEM Version for Windows comprises the 840C system

software basic version (FlexOS) which has been expanded by a Windows MMC. The OEM test

environment essentially consists of modified MMC Windows software installed on the hard disk which

enables simulation of the Windows SINUMERIK 840C interface on an external PC. The diagram below

shows the distribution of the entire control software on the hard disk.

Fig. 3.2: Main divisi on of the software on the hard disk of the 840C OEM Version for Windows

1. The installation functions (MD dialog, drive/servo installation) in the Diagnosis area can only be

executed under MMC FlexOS. The operating system FlexOS can be selected in the

backup/restore menu.

2.

Common software includes DOS, Valitek and NCK, PLC and drive software. This software r uns

with the Windows MMC without any restrictions.

The Windows MMC consists of the operating system Windows for Workgroups 3.11 and a

3.

Windows basic system (basic modules) which, like the basic version (FlexOS), is responsible for

the basic functions of the Windows control panel and operation. The user can also install the

software in the five standard languages (English, German, French, Italian and Spanish) and

switch between the individual languages.

4.

The DDE server (Dynamic Data Exchange) is the data interface to the NCK, PLC and 611D. The

DDE server is both part of the OEM package and the control software. However, it can only be

executed with the library MEMBER.DLL supplied with the OEM package.

3-2

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 23

3 System Structure of 840C

09.01

The user area can be used both by the machine-tool manufacturer and the end user. The OEM

5.

can use the part of the hard disk that is not used by Siemens which is paid for when the MMC

Windows licence is purchased. A memory size of at least 40 MB is guaranteed. As it is possible

to integrate OEM software under Windows, space on the hard disk is provided for customized

programs that can be developed using commercially available tools.

6.

The user area can also be used for end user data such as part pr ograms, measurement data,

order data, MDA/PDA data etc.

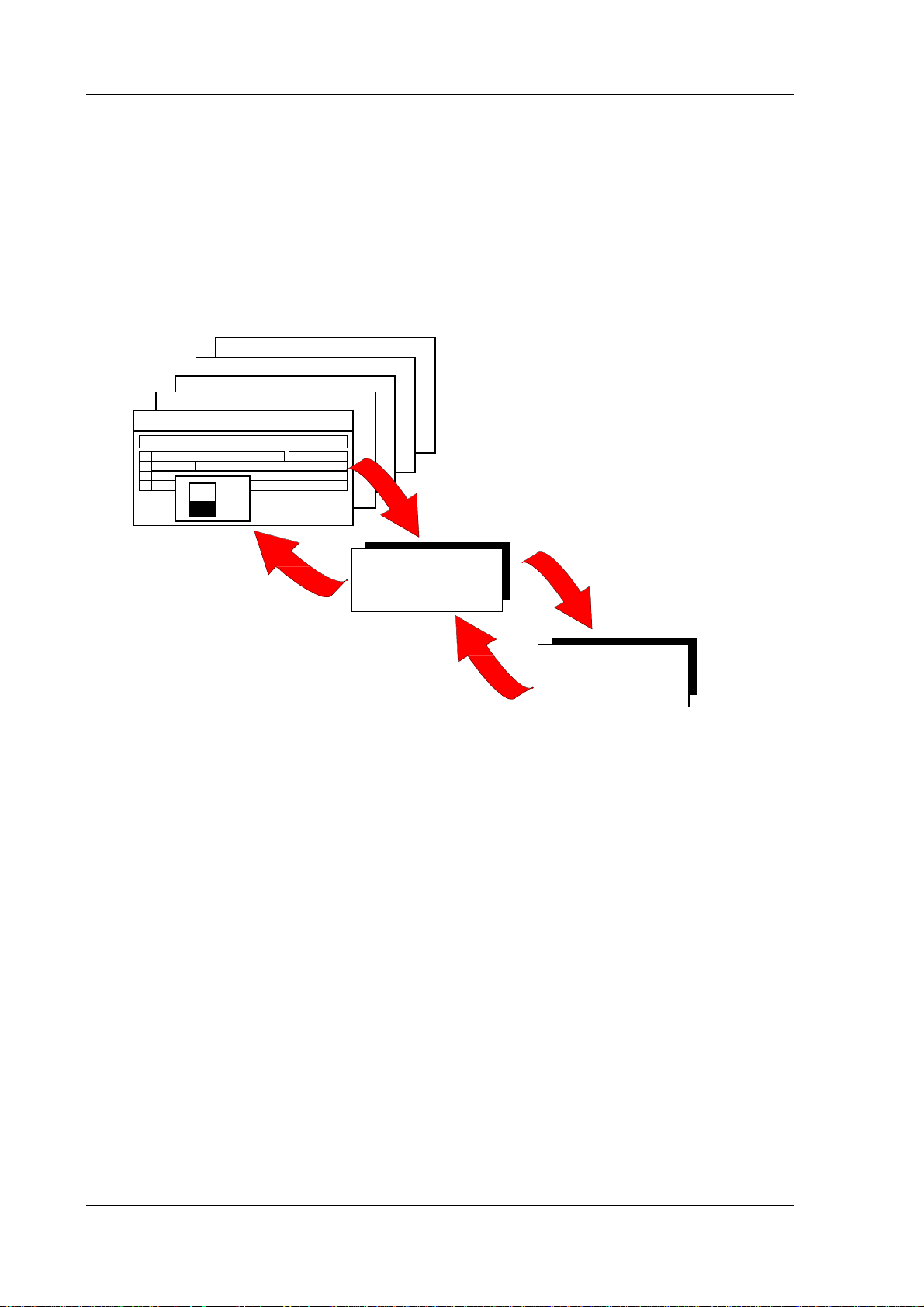

The individual operating system components, as well as the Siemens basic modules and the OEM

applications can interact as shown below and exchange information with the NCK/PLC and the 611- D.

Fig. 3.3. clearly shows the interaction between the Windows system software and the basic modules

and OEM applications.

NCK/PLC service

NCK programming

Parameters

Machine operation

1

V24 parameterization

Data management

Area switchover

235

WEdit

Basic system

DOS / WINDOWS

NCK / PLC / 611-D

Fig. 3.3: Interaction bet ween M M C Wi ndows and OEM applications

OEM appl.

< . . . . > . exe

4

DDE

server

1. The machine displays created in the NC kernel with WS800 A are passed directly to the user

interface via a graphics converter (NCK task), i.e. the operator receives the information directly

from the NCK/PLC and 611-D. Conversely, (nearly) all the entries made via the keyboard on the

control panel or the MF2 keyboard are passed onto the NCK.

2.

In addition to the NCK task, other Siemens basic modules carry out numerous functions in the

MMC area. The area switchover is therefore used to start additional applications and the data

management to manage the files on the hard disk and to transfer data between the MMC and

the NCK or peripheral device.

3.

The OEM applications like the Siemens applications (e.g. machine operation, parameters, etc.)

are initiated via the area switchover. Some of the basic modules also contain special function

calls (e.g. workpiece transfer via serial interface) which can also be used by OEM applications.

The OEM applications can be operated in the usual way via the operator panel or keyboard.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 3-3

SINUMERIK 840C OEM Version for Windows (BN)

Page 24

3 System Structure of 840C

09.01

Data on NCK, PLC, 611D is accessed using the DDE server via the DDE interface defined by

4.

Microsoft. This interface is supported by nearly all Windows programs (EXCEL, WORD, etc.) and

development tools (MS-Visual Basic, Visual C++, etc.) and guarantees a high degree of

development safety and stability due to its fixed definition and widespread use.

5.

OEM applications can also directly access services in the DOS/Windows oper ating system. File

manager, printer, Windows API (Windows Application Programmers Interface), etc. calls can be

used in the usual way.

3.1.3 Basic modules

The MMC Windows basic system together with the operating system are r esponsible for operation of

the integrated PC. The MMC Windows basic modules and the OEM test environment are largely

identical. All the standard modules have a compatible structure and a uniform appearance which can

be modified by making entries in the initialization files. Basic modules that run in the background (e.g.

multiport RAM driver, keyboard driver, DDE server etc.) are configured in such a way that they do not

appear in the task list. This ensures that the user only accesses applications that he can see in the task

list.

The following diagram provides an overview of the most important modules in the basic system

840C WINDOWS Basic system

Start up

Area switchover

Graphics converter (NCK task)

Data management ASCII editor

V24 parameterization

Alarm module

NCK/PLC communication

Softkey manager

Keyboard driver

Backup/Restore

Fig. 3.4: Basic system OEM Version for Windows

• The start-up module (AUTOEXEC.BAT, REG_AUTO.CFG) organizes the loading of the MPR

server, the booting of the PLC/NCK and 611-D software. The user can also define in the

initialization file C:\MMCWIN\LOAD840C.INI which user files are to be transferred to the NCK

during start-up.

3-4

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 25

3 System Structure of 840C

09.01

• Individual applications can be started by the operator via softkey with the area switchover

(REGIE.EXE) which replaces the Windows program manager. It is activated via the data area

key. As far as the area switchover is concerned, the Siemens areas, "Machine", "Par ameter", ...,

are ordinary applications.

The menu line and the entries in the associated pull-down menus including the application to be

initiated (*.EXE files) can be freely defined in the initialization file (REGIE.INI). Applications can

also be protected with a password, keyswitch position and cycle disable. The area switchover is

preconfigured by Siemens and can be changed as necessary (e.g. removing the Machine area

and adding OEM applications). It can be operated either via the control panel keys, softkeys or

mouse.

• NCK task (NCKTASK.EXE) groups together the entire control of the NCK. Th is includes both the

display of graphic information that is processed in the NCK area as well as the transfer of

keyboard entries to the NCK. NCK task is also responsible for managing the current menus of

the various data areas of the NCK. In the OEM test environment where ther e is no link to an

NCK, NCK task visualizes machine displays that are stored on the hard disk.

• The data manager (DATENMAN.EXE) contains a user interface for transferring files between the

MMC, NCK, diskette drive and serial interface. A workpiece manager and an editor "WEdit"

(WEDIT.EXE) with which part programs can be edited directly in the NCK memory are also

provided.

With the workpiece manager it is possible to integrate network drives, making transparent

selection of workpieces that are stored on a remote computer possible. "Part program execution

from the hard disk or network" is also implemented. Files can also be edited directly in the NCK

memory with the editor.

• With the Parameterization V24 module (PAR_V24.EXE), serial interfaces can be par ameterized

for the transmission of data in tape format. Up to 10 interface settings can also be managed.

• The alarm module (ALARM.EXE) accepts alarms and messages from the NCK/PLC/drive,

visualizes them in the alarm or message line and lists the current alarms and messages in the

alarm window. The position at which the alarm is displayed on the screen is defined in the alarm

text database. An OEM application can obtain the current active alarms and messages via the

Windows DDE mechanism (Dynamic Data Exchange) and initiate its own.

• The NCK/PLC communication essentially consists of the DDE server (DDESRV.EXE) and the

MPR server (SERVER.EXE) which allow the modules described above and the OEM

applications to exchange data with the NCK/PLC and the 611D. In the OEM test environment,

the multiport RAM server is replaced by an MPR server simulator (MPRSSIM.EXE).

• The softkey manager (SOFTMAN.EXE) displays the menu line of Windows applications and the

buttons of non-system modal dialog boxes on the horizontal softkey bar. It is thus also possible

to operate any Windows application via softkey.

• The keyboard driver (KYRU.EXE) converts signals coming from the 840C operator panel into

codes which can be evaluated by Windows or DOS. This same thing happens when a full MF2

keyboard is connected to the operator panel. A keyboard can only be connected to the central

controller for OEM servicing because of the lack of EMC of the keyboard connection.

The user can also freely assign various keys on the NC operator panel.

• Data can be saved and read back in via the Valitek streamer or via PC link as on the 840C Basic

Version. The streamer is connected to the parallel interface of the MMC CPU module. You must

close Windows and return to the MS DOS level to operate the streamer.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 3-5

SINUMERIK 840C OEM Version for Windows (BN)

Page 26

3 System Structure of 840C

09.01

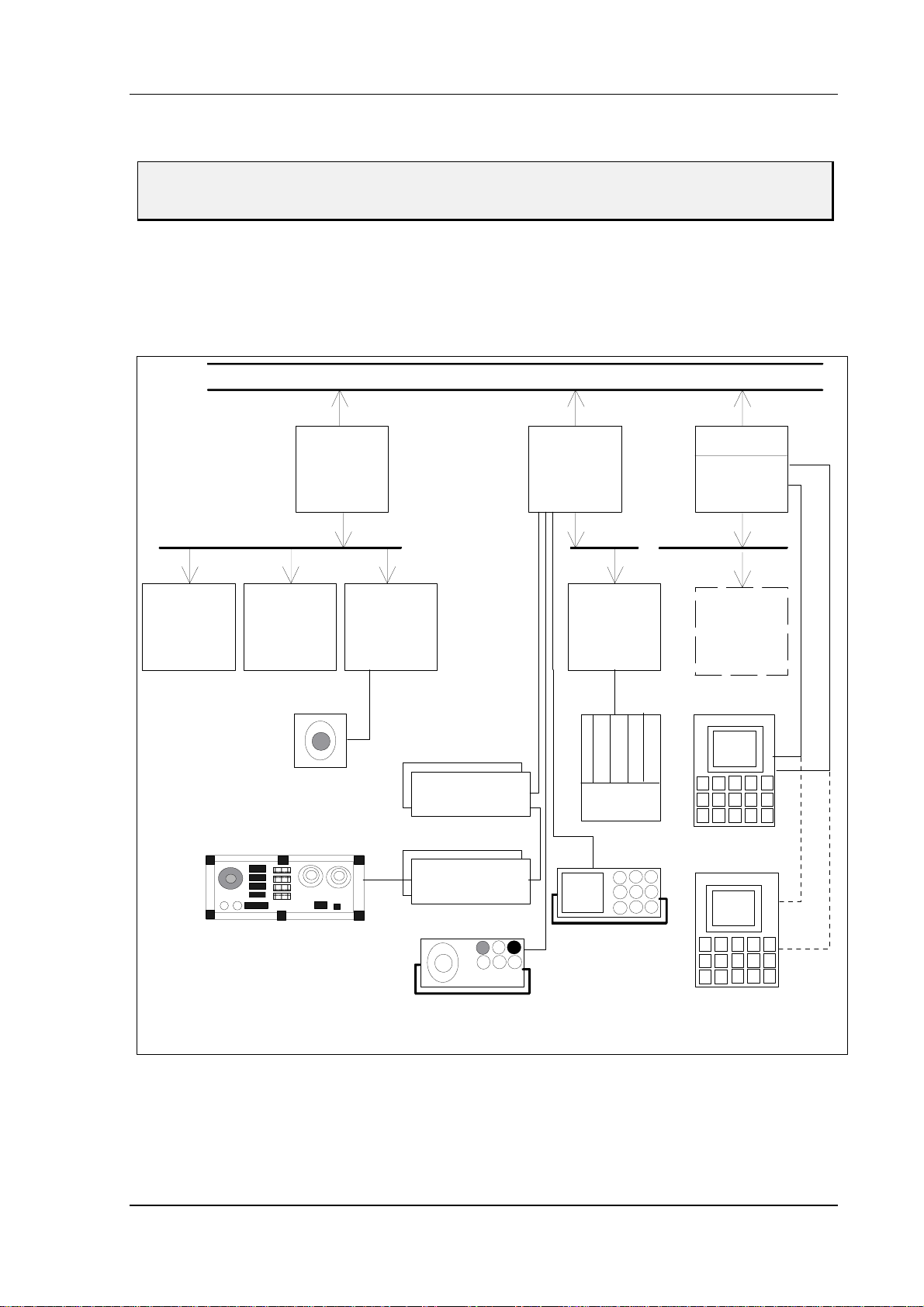

3.1.4 NCK / PLC / SIMODRIVE 611-D interface

Data/files of the NCK/PLC/611D are accessed via the DDE interface (Dynamic Data Exchange) defined

by Microsoft for Windows applications. The DDE server collects the data and makes them available to

the applications. The functions "POKE" (write data), "REQUEST" (read data) and "EXECUTE"

(commands for file transfer) are implemented. The function "ADVISE" is also implemented for the PLC.

Data exchange with standard Windows programs such as Excel, Visual Basic, etc. is possible via this

interface. The DDE server can access, for example, machine data, setting data, PLC data blocks, part

programs and current values.

. . .

BORLAND C++

VISUAL C++

VISUAL BASIC

E X C E L

1

= NC DDE NCK PLC ! NC_0X125_1_1_2_2_0

2

3

AB

100

Speed

50

spindle

0

Read and write

data, programs

DDE server

NCK/PLC/611-D

Fig. 3.5: Data exchange via DDE server

The DDE server converts the data request into an I code protocol and passes it on to the NCK. There,

a software module sends the requested data to the DDE server.

Two function blocks exist in the PLC, FX74 (read data from DDE server and write to a data block) and

FX73 (read data from a data block and write to the DDE server). The user can fr eely select the for mats

and the protocols. For this, he must write a function block that reads out the data with the help of FX74,

interprets them and writes back the requested data with FX73.

Service and drive data can be accessed for the SIMODRIVE 611-D. The DDE server is only used for

data exchange and is not a control interface.

You will find a detailed description of the DDE server and the I code interface with its various features

in Chapter 5 and Appendix A1.

3-6

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 27

3 System Structure of 840C

09.01

3.2 Hardware configuration

You will find additional information on this subject in the SINUMERIK 840C documentation:

Interface Part 2, Connection Conditions.

The hardware of the 840C OEM Version for Windows is based on the 840C Basic Version.

3.2.1 Brief description of hardware

The SINUMERIK 840C OEM Version for Windows is a modular control with the following structure:

Link bus

Dual Port

NCK CPU

PLC CPU

MMC CPU

Servo

loops

NCK bus bus busPLC

Computer

link

Handwheel

CSB INT. EU

DMP mod.

DMP mod.

Handheld unit

SIMATIC EU

PG

AT96

AT box

OP

2nd

OP

RGB

RS232

Fig. 3.6: Block diagram of SINUMERIK 840C OEM Version for Windows

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 3-7

SINUMERIK 840C OEM Version for Windows (BN)

Page 28

3 System Structure of 840C

The system uses the following hardware components:

• NCK CPU

- NCK CPU 486 DX 33MHz or 486 DX2 66MHz with 4 and 8 MB RAM,

486 DX4 66MHz with 8 MB RAM

486 DX4 100 MHz with 8 MB RAM

- Servo loops

up to 30 servo loops (axes/spindles) analog and digital drive interfaces,

max. 2 electronic handwheels.

- Computer link

computer link via RS 232C (V.24), SINEC H1 or MAP 3.0

- Central service board (CSB)

central monitoring functions,

handwheel inputs,

NC inputs

- 230V AC / 24V DC power supply (occupies three slots)

• PLC

- PLC CPU 135 WD

80186 / 16 MHz

PLC coprocessor

MPC interface for distributed machine I/Os

RS 232C (V.24) interface to PG

rapid interrupt inputs

- Interface EU, 16-bit

16-bit link to SIMATIC EU (IM314)

- Distributed machine I/Os

standard DMP

compact DMP

machine control panel

- In 329

L2-DP Profibus

09.01

•••• MMC

- MMC CPU (version B), 486 SX 33 MHz, 486 DX 33 MHz, 486 DX2 66 MHz

with 8 or 16 MB RAM

2 serial interfaces (operator panel connection or freely assignable)

Centronics interface to streamer

MF/2 keyboard interface

- Interface MMC

Connection for FD-E2 3.5" diskette drive

2 serial interfaces

PCMCIA slot

- Operator panel versions

9.5/10 inch slimline operator panel monochrome incl. NC keyboard

9.5/10 inch slimline operator panel color incl. NC keyboard

14 inch monitor with separate NC keyboard

• AT box with 3 slots

3-8

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70

SINUMERIK 840C OEM Version for Windows (BN)

Page 29

3 System Structure of 840C

09.01

3.2.2 Integrated PC

The PC is integrated into the system and is a system component that communicates via the internal

link bus.

Visualization and communication tasks and database functions are chiefly performed on this industrial

PC.

SINU M E RIK 840 C

Link bus

Multiport RAM

MMC

PLC CPU

CPU

(SBC)

NCKCPU

NCK local bus

Servo

loops

Fig. 3.7: MMC in the hardware of the 840C

Computer

link

PLC local bus

Int. EU

MSTT

CSB

AT 96

INT

MMCATBox

Operator

panel

The PC integrated in the 840C OEM Version for Windows provides all the functions of an AT

motherboard. The entire set of chips of an AT is integrated on one printed circuit board, which gives

rise to the name SBC (single board computer). The SBC is an industry-standard and noise-fr ee ver sion

of an integrated industrial PC. It is linked to the internal SINUMERIK bus via a dual-por t RAM and via

this link is able to exchange data with the NCK, PLC and SIMODRIVE 611-D.

An MMC interface module can be slotted into the central rack directly next to the MMC CPU module via

the AT96 bus. This module has two additional serial interfaces, two PCMCIA slots (type II) and a floppy

bus extension for connecting diskette drive FD-E2.

Central controller 3 also contains an AT box whose ISA bus is linked to the AT96 bus. A maximum of 3

standard 16-bit PC cards can be slotted into this AT box, providing the user with many options for

connecting peripherals (networking via standard PC modules) or integrating existing external solutions

directly to the control (measuring computer for quality assurance).

In contrast to a standard PC, however, the integrated SBS of the SINUMERIK 840C does not have a

loudspeaker.

©

Siemens AG 2001. All Rights Reserved 6FC5198-6AA70 3-9

SINUMERIK 840C OEM Version for Windows (BN)

Page 30

3 System Structure of 840C

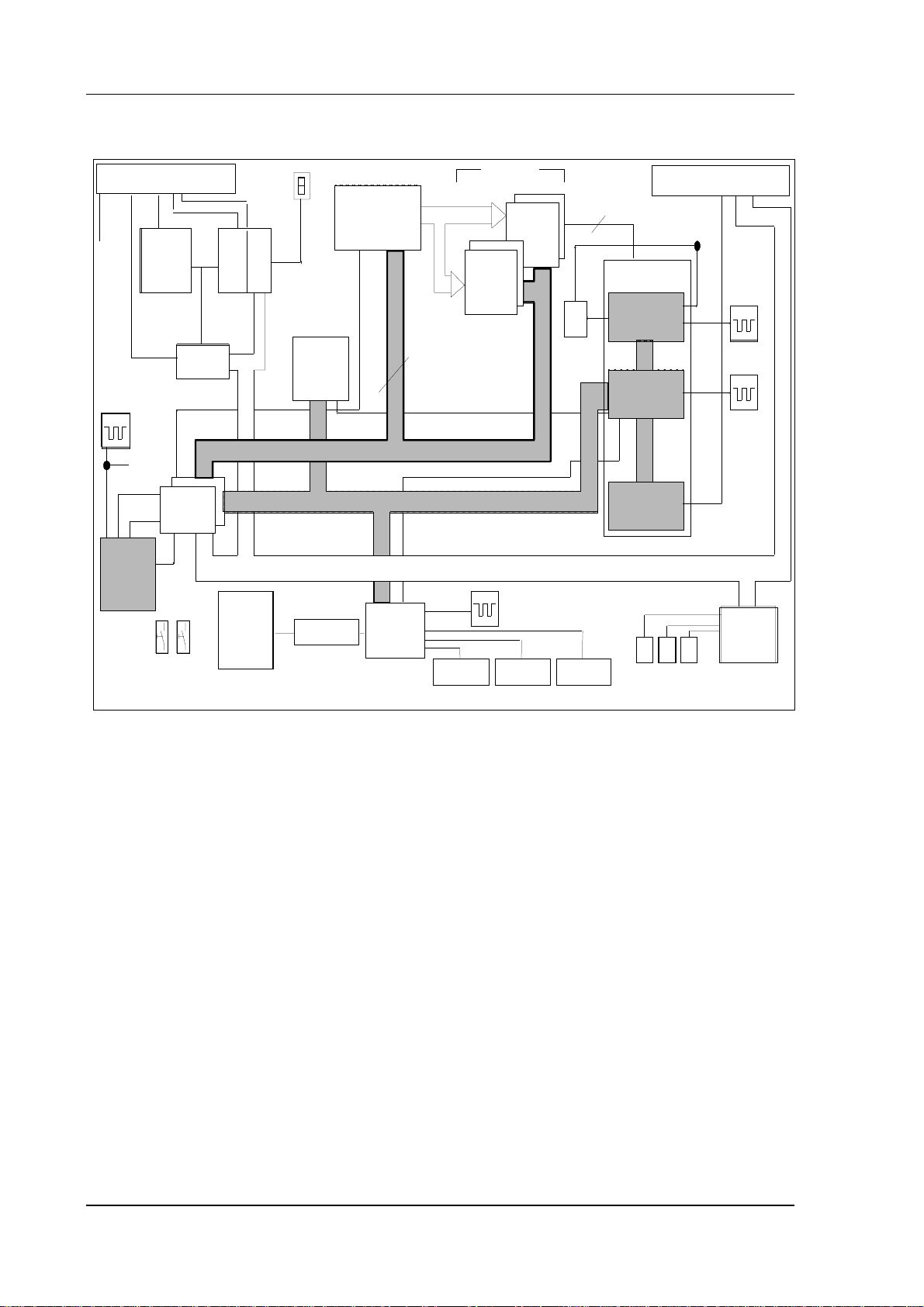

3.2.2.1 Block diagram

09.01

32K

Status

EPROM

MCU

mem or y c ontr ol

BIOS

64 Kx8

ED BU S (32 bit)

XD BUS (8 b it)

+5V

+15V

BATT

U

66 MHz

80486

Link bus X11

DPR

contr.

66 MHz

32 bit

CD BUS

Dual port

RAM

32K

Stat . cont.

2 DPUs

data path

CPU

NMI

Winchester

drive

RESET

IDE interface

Fig. 3.8: Block diagram of the MMC 486 CPU module

Com bo

16 bit

SD BUS (16 bit)

X 111

RS232/TTY

max. 32 MB

DRAM

x3 6

bank 0

18.432 MHz

*with adapter

DRAM

x36

bank 1

X 121 X 1 32

4 bit parit y

: 2

Keyboard i nterfaceRS232/RS42 2*

ATU

TIMING

control

PERIPHERA LS

RTC

AT BUS I /F

R G B

Video interface

AT96 Bus X21

66 MHz

14.3181 MHz

32.768 kHz

VGA

graphic

un it

3.2.2.2 Processor 80486

- External 33MHz clock, internal 33 or 66 MHz clock

- 100% software-compatible with 80386

- 32-bit data bus

- 4 GB linear address space

- Real and protected mode

- Integrated floating point unit

- Integrated 8 KB cache

3.2.2.3 System memory

- Two slots with x36 organized SIM modules

- Max. 16 MB dynamic memory, 8 MB in the basic version

- Modifiable DRAM parameters in the set-up

- 4 bit parity monitoring

- EMS (version 4.0) support