Page 1

SINUMERIK 840C

Software Version 6

Operator’s Guide 09.2001 Edition

User Documentation

Page 2

Page 3

SINUMERIK 840C

Software Version 6

Operator’s Guide

Introduction 1

Operator Interface 2

Machine 3

Parameter 4

Programming 5

Valid for

Control Software Version

SINUMERIK 840C/CE

(Standard/Export version) 6

Services 6

Diagnosis 7

Maintenance 8

List of Abbreviations 9

09.2001 Edition

Page 4

SINUMERIK

documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . .

B Unrevised reprint with new Order No.. . . .

C Revised edition with new status. . . . .

If factual changes have been made on the page since the last edition, this is

indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

11.92 6FC5198–0AA00–1BP0 A

06.93 6FC5198–2AA00–0BP0 C

12.93 6FC5198–3AA00–0BP0 C

10.94 6FC5198–4AA00–0BP0 C

03.95 6FC5198–4AA00–0BP1 C

09.95 6FC5198–5AA00–0BP0 C

04.96 6FC5198–5AA00–0BP1 C

08.96 6FC5198–5AA00–0BP2 C

07.97 6FC5198–6AA00–0BP0 C

01.99 6FC5198–6AA00–0BP1 C

09.01 6FC5198–6AA00–0BP2 C

This manual is included in the documentation on CD-ROM (DOCONCD)

Edition Order No. Remarks

10.01 6FC5 198–6CA00–0BG2 C

Trademarks

R

SIMATIC

, SIMATIC HMIR, SIMATIC NETR, SIROTECR, SINUMERIKR and SIMODRIVER are trademarks

of Siemens AG. All other product and system names are registered trademarks of their respective

companies and must be treated accordingly.

For more information refer to the Internet under:

http://www.ad.siemens.de/sinumerik

This publication was produced with Interleaf V 7

The reproduction, transmission or use of this document or its

contents is not permitted wihout express written authority. Offenders

will be liable for damages. All rights, including rights created by patent

grant or registration of a utility model or design, are reserved.

Siemens AG 1992–2001.

All rights reserved.

Other functions not decribed in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist and therefore we cannot guarantee that they are completely

identical. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

Subject to change without prior notice.

Printed in the Federal Republic of Germany

Siemens–AktiengesellschaftOrder No. 6FC5198–6AA00–0BP2

Page 5

12.94

Preliminary Remarks

Notes for the reader The SINUMERIK documentation is organized in four parts:

S General documentation

S User documentation

S Manufacturer documentation and

S Service documentation

This documentation has been written for machine tool users. The

publication provides detailed information required by the user for

operating the SINUMERIK 840C control.

This Operator’s Guide only describes functions which belong to the

standard version. Options or modifications carried out by the machine

manufacturer, for example a special additional operator panel from the

machine manufacturer cannot be described in this Operator’s Guide.

More information on other SINUMERIK 840C publications and on

publications which are available for all SINUMERIK controls (e.g.

“Universal Interface”, “Measuring Cycles” ...) can be obtained from your

Siemens local branch office.

Other functions not described in this documentation might also be

executable in the control.

This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

The symbol shown here appears in this

documentation when facts of importance must be

observed.

The symbol shown here appears in this

documentation whenever the machine tool

manufacturer can influence or modify the

described function by changing a machine data

(MD). Please observe the machine

manufacturer’s specifications.

This Operator’s Guide applies to:

SINUMERIK 840 C/CE control

Software Version 6 (6.3)

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 6

Safety

12.94

09.01

Danger

!

!

!

This warning notice means that loss of life, severe

personal injury or substantial material damage will

result if the appropriate precautions are not taken.

Warning

This warning notice means that loss of life, severe

personal injury or substantial material damage can

result if the appropriate precautions are not taken.

Caution

This warning notice (with warning triangle) means

that a minor personal injury can result if the appropriate precautions are not taken.

Caution

This warning notice (without warning triangle) means

that a material damage can result if the appropriate

precautions are not taken.

Notice

This warning notice means that an undesired event

or an undesired state can result if the appropriate

notices are not observed.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 7

Contents

1 Introduction – The SINUMERIK 840C and its Operation 1–1. . . . . . . . . . . .

1.1 Switching on the control 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Structure of the operator interface 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Menu switchover 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Directory structure 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 The meaning of the SIEMENS and user directories 1–11. . . . . . . . . . . . . . . . . . .

1.6 Screen darkening 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Data backup options 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 Help displays 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operator Interface 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Operator panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Operating elements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Operator panel 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 PC standard keyboard (MF–2) 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Operating elements of the operator panel keyboard/full keyboard 2–7. . . . . . .

2.2.4 The operating elements of the machine control panel 2–12. . . . . . . . . . . . . . . . .

2.2.5 Operating elements on the hand-held unit 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Operating elements on the A–MPC hand-held unit 2–22. . . . . . . . . . . . . . . . . . .

2.2.7 Screen layout 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

3 Machine 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Operating modes 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Operating states – Operating state changes on change of operating mode 3–5

3.1.2 Machine functions – overview 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Status displays 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3.1 Channel-independent status display by means of icons 3–8. . . . . . . . . . . . . . .

3.1.3.2 Spindle utilization display 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 JOG: Set-up mode 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.1 Traversing in JOG mode 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.2 Approach reference point (REFPOINT) 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.3 User agreement (“Safety Integrated” option) 3–13. . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.4 Increment mode – selection 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.4.1 Indexed traversing 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.4.2 Indexed traversing with incremental dimension (INC) 3–15. . . . . . . . . . . . . . . . .

3.1.4.5 Repos (Repositioning) 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.6 Scratching 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.7 Finish thread 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5 TEACH IN mode 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.1 Set breakpoints 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.2 Edit mode 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.3 Block structure settings 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.4 Creating a TEACH IN program in the edit mode 3–27. . . . . . . . . . . . . . . . . . . . . .

3.1.5.5 Accepting axis positions 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.6 MDA in edit mode 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

3.1.5.7 Block by block teach-in 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.8 Modifying an existing part program with block by block teach-in 3–32. . . . . . . .

3.1.5.9 Examples 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 MDA mode 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6.1 Copying MDA programs 3–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7 AUTOMATIC mode 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7.1 Workpiece and program selection with the data selector 3–45. . . . . . . . . . . . . .

3.1.7.2 SELECT PROGRAM/JOB function 3–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7.3 Starting and interrupting a part program 3–51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7.4 Search for first letter function (from SW 6) 3–53. . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7.5 Program view (from SW 6) 3–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7.6 Expanded program view (from SW 6.3) 3–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Additional machine functions 3–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Overstore 3–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Extended overstore 3–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Altering F and S values on-line 3–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Program modification 3–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4.1 Description of the functions DRY, M01, ROV, ACR, DRF, DSB, PST, BRK,

CLR, EXT, NCY, SAV, SKP and predec. blocks 3–63. . . . . . . . . . . . . . . . . . . . . .

3.2.4.2 Single block/Decoding single block 3–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Block search 3–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Program correction 3–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Saving programs 3–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 PRESET (Set actual value)/DRF 3–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8.1 PRESET – Offset 3–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8.2 DRF offset 3–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Axis-specific G functions 3–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Extended stop and retract 3–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Multichannel display 3–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Parameter 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Editing data in the PARAMETER area 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Selecting data 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Entering and correcting data 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Entering PLC data in ASCII format 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Program parameters 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Tool offsets 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Zero offset 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Angle of rotation (coordinate rotation) 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 R parameters 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 Plane 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6 Setting data 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.1 Working area limitation 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.2 General setting data 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.3 Spindle setting data 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.4 Scale 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.5 General setting data bits 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.6 Axial setting data bits 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.7 Position measuring signals 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.8 Cycle setting data 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.9 Axis and spindle converter 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.10 Gearbox interpolation 4–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.11 Travel to fixed stop 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.7 Additional protection zone adjustment via setting data (from SW 6.3) 4–28. . .

4.2.8 Inch/metric conversion (from SW 6.3) 4–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

5 Programming 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Programming in the NCK memory area (directory NCK) 5–3. . . . . . . . . . . . . . .

5.1.1 Select program 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Editing an existing program 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Editing a new NC program 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Graphic tool path simulation 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Program input with operator support 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.6 Machining cycles 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.7 Plane 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8 Program management 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8.1 Changing the access rights 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8.2 Copy program 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8.3 Rename program 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8.4 Delete program 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.8.5 Move cycles 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.9 FANUC program converter (from SW 4.9) 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Programming with the ASCII editor in the hard disk data management 5–40. .

5.2.1 Creating a workpiece 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Creating a part program file 5–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Creating job lists 5–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.1 General 5–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.2 Creating the JOB LIST file 5–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.3 Editing job lists 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.4 Creating job lists 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.5 Syntax description for the job lists 5–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Shopfloor sheet 5–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Copy, paste and delete files in the data management area of the hard disk 5–57

5.2.6 Description of the ASCII editor 5–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6.1 Editing with the ASCII editor 5–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6.2 Input fields 5–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6.3 Selection fields (toggle fields) 5–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6.4 Double ASCII editor 5–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 Viewing IKA data 5–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Services 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 LOAD NC 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Loading workpieces and programs 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Loading data 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SAVE NC 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Saving NC data 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Saving part programs or NCK data in a workpiece in the local or

global directory 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Data input from an external device 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Insert data from the clipboard 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Continuous mode for data input via RS232C (V24) (from SW 5.6) 6–21. . . . . .

6.4 Data output to an external device 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Output formats 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1.1 Punch tape format 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1.2 PC format 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Outputting workpieces and archives 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Data output 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Data input and output with the FD–E2 floppy drive (option) 6–27. . . . . . . . . . . .

6.5.1 Data output with the FD–E2 floppy drive 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Data input from the FD–E2 floppy drive 6–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 Formatting diskettes 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Data input and output with the SINUMERIK FD–E1 floppy drive (option) 6–32.

6.7 Printing out files 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

6.8 Archive lists 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.1 Creating new archive lists 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.2 Editing existing archive lists 6–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.3 Edit, copy and delete archive lists 6–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Device settings (up to SW 6.2) 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.1 Selecting an interface 6–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.2 Editing interfaces 6–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.3 Device settings (from SW 6.3) 6–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Data management 6–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.1 Copy and paste in the SERVICES/MANAGEMENT area 6–48. . . . . . . . . . . . . .

6.10.2 Delete data in the SERVICES/MANAGEMENT area 6–49. . . . . . . . . . . . . . . . . .

7 Diagnosis 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Alarm and message displays 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Service displays 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Alarm logs 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 NC information 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Drift compensation 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Softkeys for the start-up engineer in the DIAGNOSIS basic display 7–6. . . . .

8 Maintenance 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Operating data 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Replacing the battery 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Handling modules 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Practical tips on remedying electromagnetic compatibility problems 8–6. . . . .

8.5 Cleaning 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 List of Abbreviations 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 11

10.94

1 Introduction – The SINUMERIK 840C

and its Operation

The SINUMERIK 840C is a CNC (Computer Numerical Control),

intended mainly for automation applications.

Generally, the CNC implements the following basic functions (in

conjunction with a machine tool or such like):

S Automatic workpiece machining

S Free programming of axes

S Programming of technological functions such as feed, spindle speed,

etc.

S Controlling of the axes and spindles in conjunction with the drives and

the measuring systems

S Scanning and controlling input and output signals via the PLC

program

S Machine operation via the machine control panel

S Storing user data in the CNC memory

S Organizing data exchange with I/O devices.

The operator interface (monitor displays, keyboard) is the connecting

element between operator action and the machine. This Operator’s

Guide describes only functions which are within the standard scope of

supply of Siemens. The machine manufacturer can also configure

functions and monitor displays and he can connect his own keyboard.

Please read the machine manufacturer’s Operator’s Guide in these

cases.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–1

Page 12

1 Introduction – The SINUMERIK 840C and its Operation

1.1 Switching on the control

1.1 Switching on the control

Switching on of the control can be implemented

in various ways by the machine manufacturer.

Please refer to the machine manufacturer’s

specifications.

Please note:

The control is switched on by switching on the input voltage at the power

supply of the central controller.

After the control has been switched on, different start-up images appear

for a few seconds. The control software is loaded, i.e. the NCK and the

MMC software is booted from the hard disk.

When the control is installed, the PLC software is loaded from the hard

disk into the battery-backed RAM memory, i.e. the PLC software is not

booted when the control is powered up.

10.94

Power-up of the control is performed in the following sequence:

1. The operating system software is loaded

2. The user data are loaded from the NC/DATA directory on the hard

disk. These might be IKA and GIA data. The machine data (TEA1,

TEA2, etc.) are not loaded during power-up. These data are stored in

battery-backed memory.

3. The system now loads all of the data assigned to the STANDARD

workpiece. The Siemens and user cycles can only be loaded with the

STANDARD workpiece (LOADCYC command in the job list).

The machine manufacturer can configure whether the last selected

workpieces are to be loaded from the hard disk at this stage. If, in the

3rd phase, the same data are loaded with a workpiece (e.g. RPA,

TOA etc.) as in the 2nd phase, these data are overwritten by the

workpiece-related data.

If not otherwise configured by the machine manufacturer, the main menu

of the JOG mode appears after power-up of the control. Operator

actions on the control can be performed after the screen has built up

completely.

1–2

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 13

10.94

1 Introduction – The SINUMERIK 840C and its Operation

1.2 Structure of the operator interface

1.2 Structure of the operator interface

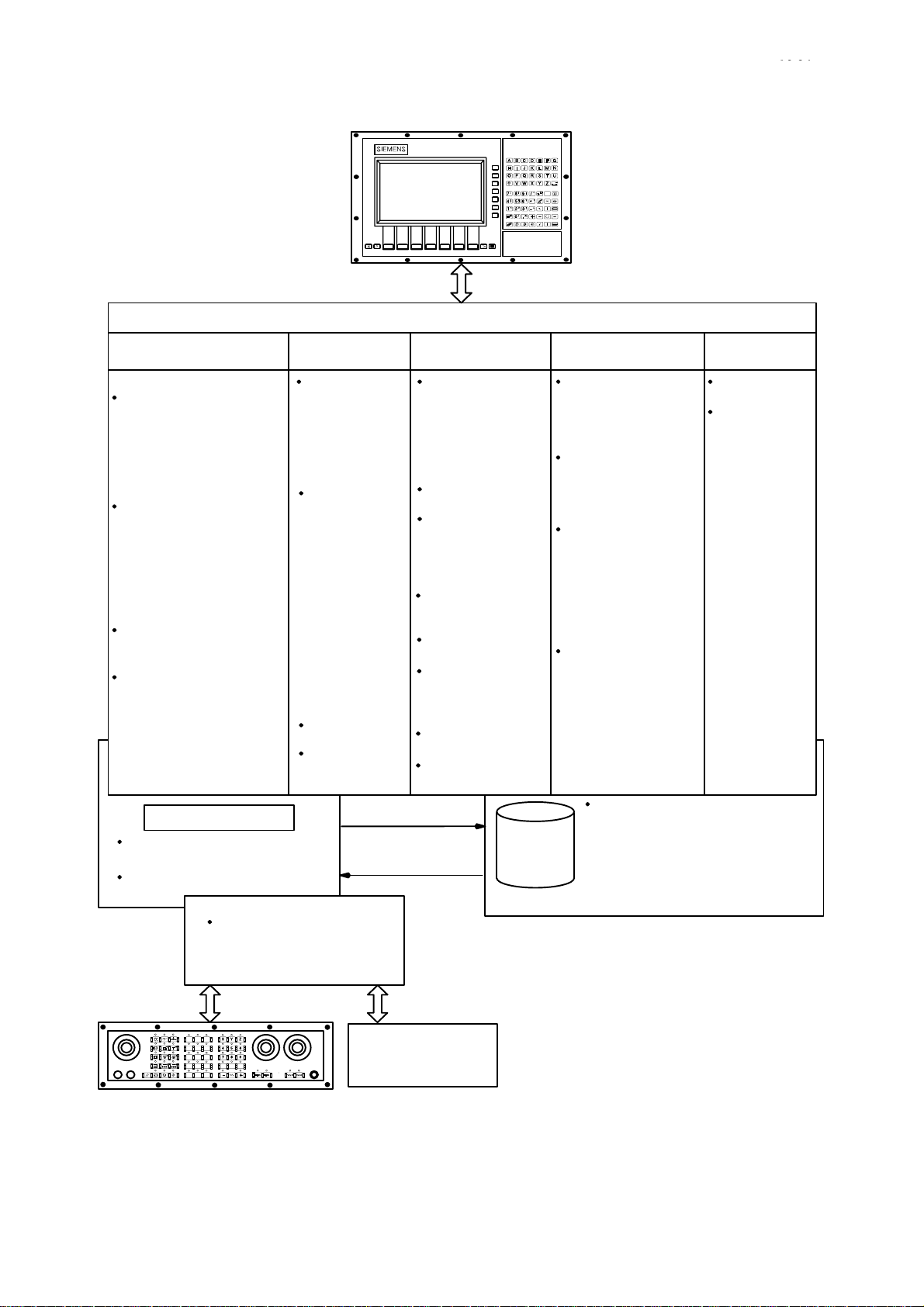

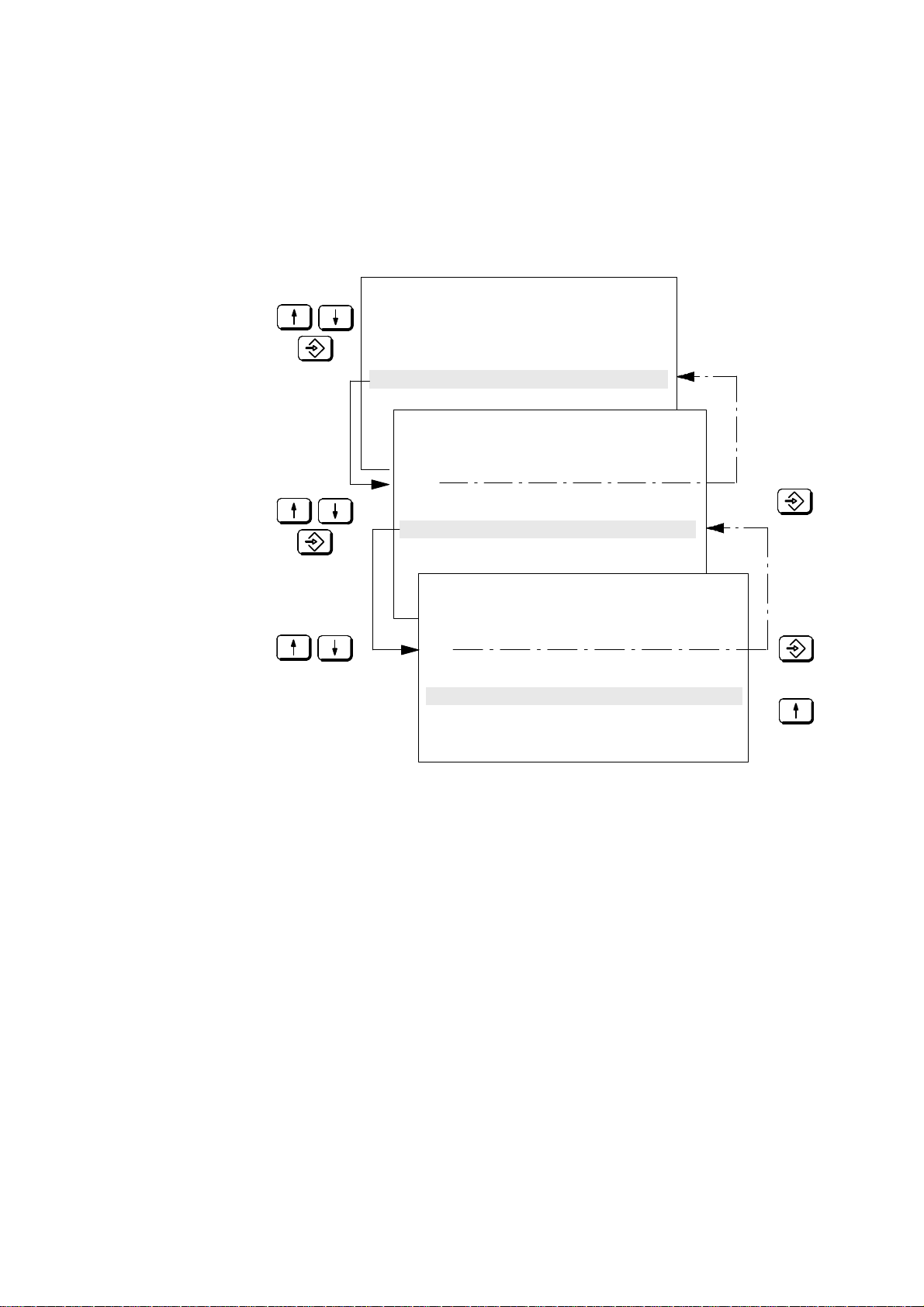

5 operating areas The SINUMERIK 840C operator interface is divided into 5 areas:

MACHINE, PARAMETER, PROGRAMMING, SERVICES and

DIAGNOSIS. The 5 areas will be displayed as softkey functions any time

you press the area switchover key.

Area switchover key

Machine Parameter Programm. Services Diagnosis

Fig. 1.1 shows you which operator actions are possible in the different

operating areas. With the SINUMERIK 840C, you can edit the part

programs in two different memories:

S in the NCK memory (volatile RAM memory)

S on the hard disk (MMC–CPU).

If you work on the volatile RAM memory, you must store the edited or

newly created programs on the hard disk if they are to be retained after

switching off the control.

If you edit a program on the hard disk, this program must be loaded in

the NCK memory in order to be executed.

For this purpose, the SAVE softkey function is provided in the MACHINE

and PROGRAM areas as well as the SAVE NC function in the

SERVICES area. The PROGRAM area optionally offers a graphic

programming system and a DIN code simulation. You will find a

description of this system in separate publications of the User’s Guide

Graphic Programming System for

S Drilling/Boring and Milling

S Turning

and in User’s Guide, Simulation: Milling and Turning.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–3

Page 14

1 Introduction – The SINUMERIK 840C and its Operation

1.2 Structure of the operator interface

Operator panel

Operating areas

10.94

07.97

Machine

Operating mode selection

JOG

– Set-up mode

– Approach reference point

– Incremental traversing

– REPOS

– Handwheel

– Man. traversing

– Overstore

TEACH IN

– Set-up mode

– Incremental traversing

– REPOS

– Handwheel

– Overstore

– Program modification

– Search

MDA

– Overstore

– Program modification

AUTOMATIC

– Overstore

– PRESET

– Program modification

– Search

– Workpiece selection

RAM memory

Part programs and IKA3

data on volatile memory

All other NC data buffered

NCK

Interface control

to the machine

Parameter

Program

parameters

– Tool

offset

– Zero

offset

– Angle of rot.

– R parameters

Setting data

– Working area

limitations

– Spindle data

– Scale

– General data

and bits

– Axial bits

– Position

signals

– Axis/spindle

converter

– Gearbox

interpolation

– Travel against

fixed stop

Computer

link (option)

User

function

(option)

Programming

Editing and

generating

part programs

– Editing in the

NCK area

– Editing on the

hard disk

Generating

workpieces

Delete,

copy and

insert

workpieces

and files

Creating

directories and

files

Generating

job lists

Graphic

programming

system WOP

(option)

DIN simulation

(option)

Graphic tool path

simulation

SAVE

LOAD

Services

Load NC

– Load data from

the hard disk

into the

NCK memory

Save NC

– Save data

from the

NCK memory

to the hard disk

Data in/out

– RS232C (V24) in/out

– Printing data

– Generating and

editing archive

lists

– Device settings

– Clipboard

Data management

– Copy, delete and

insert directories

and files

Storing data on the hard

disk with:

– SAVE NC softkey in the

SERVICES area

– SAVE TO HARD DISK or

SAVE UNDER softkey

Diagnosis

Alarm

displays

Start-up

functions

– NC diagnosis

– PC diagnosis

– PLC diagnosis

MMC–CPU

1–4

PLC

Input/output

machine

control

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 15

10.94

1.3 Menu switchover

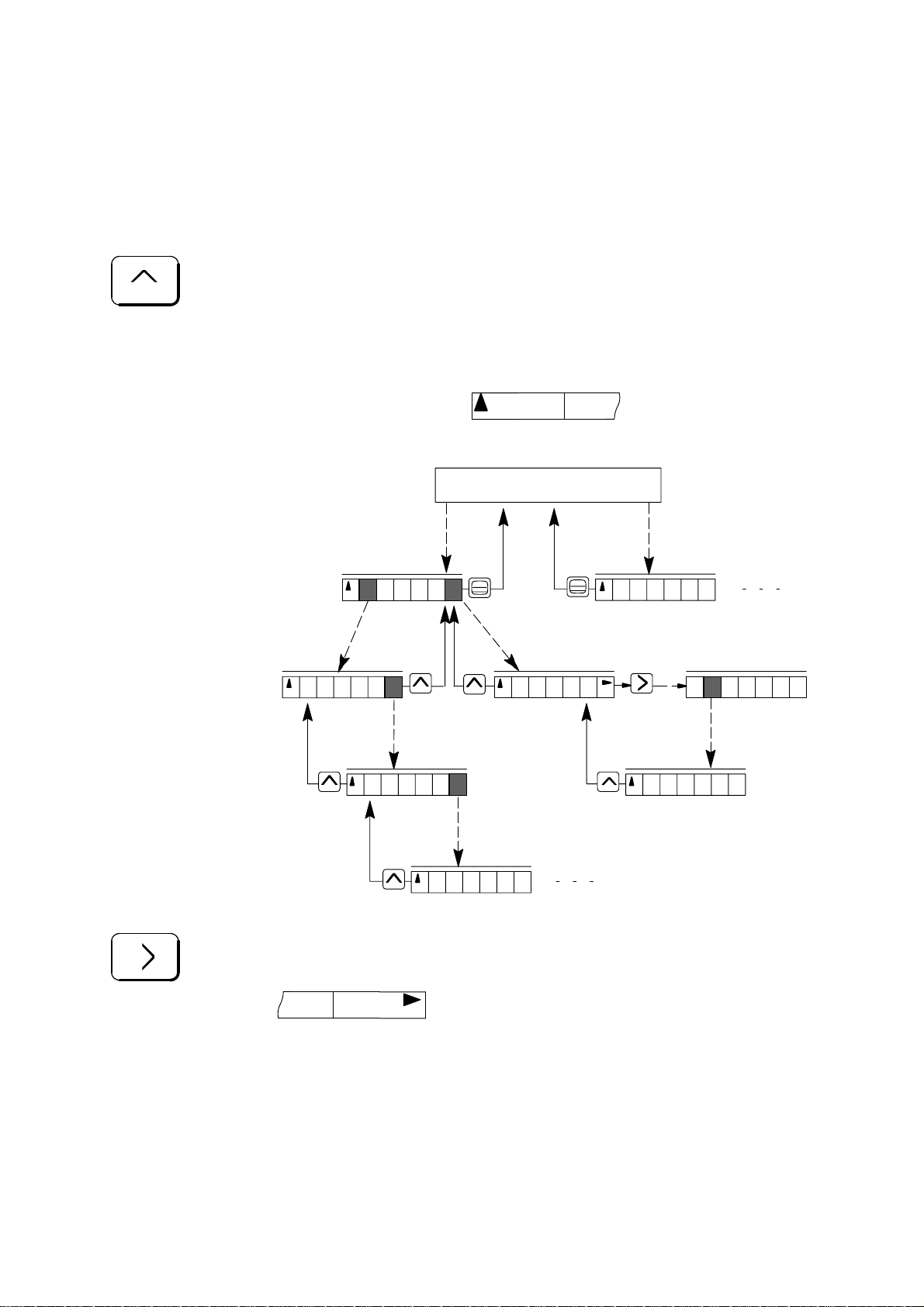

Softkeys are keys which are variably assigned with functions.

The 5 areas of the SINUMERIK 840C are selected via softkeys. Within

these areas further branching via softkeys is possible.

Operating the RECALL key brings you back to the next higher menu

level.

An arrow in the first softkey window indicates that you can return to a

menu:

1 Introduction – The SINUMERIK 840C and its Operation

1.3 Menu switchover

Area menu bar

With the ETC key, you can expand the softkey menu if an extension is

available.

If there is an arrow in the 7th softkey window

(on the right), this key is active.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–5

Page 16

1 Introduction – The SINUMERIK 840C and its Operation

1.3 Menu switchover

In each area, the menu last active is stored on area

switchover (exception: MACHINE area).

If you leave an area and do not wish to return to the

menu level currently selected, you switch over to the

main menu of the area with RECALL. This brings you

to the defined initial status of this area. This

procedure simplifies operation when first selecting

the area. By pressing the SHIFT and RECALL keys

you will obtain the basic display immediately from

any branch in the PARAMETER, SERVICES,

DIAGNOSIS and PROGRAMMING areas.

When leaving the area the control “remembers” the

deselected area. This area is selected again by

pressing the area switchover key twice.

10.94

1–6

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 17

10.94

04.96

1 Introduction – The SINUMERIK 840C and its Operation

1.4 Directory structure

1.4 Directory structure

Directories Structures from the PC world have been integrated in the SINUMERIK

840C. The PROGRAMMING, SERVICES and DIAGNOSIS areas as well

as program selection (DATA SELECTOR) contain directories. These

directories are a file management aid for sorting and storing files.

Directories can in turn contain subdirectories. Only one directory level is

displayed on the screen at any one time.

File The softkey bar does not change when you “page” through the

directories. Softkey function and directory are not directly related. A file

is a logical data unit which you can address with a name (e.g. MPF1,

TOA1, ...). Files can be assigned to directories according to specific

criteria, i.e. MPF1 to the workpiece (directory) SHAFT1 or TEA1 to the

directory NC. You can assign directories to other directories, which you

also address with a name (e.g. LOCAL directory).

Directory path This results in “directory paths” which you can page through as follows.

Using the vertical cursor keys, set the cursor on a directory and press

the INPUT key. The next subdirectoy in this directory is opened.

Continue doing this until you have reached the directory of the files. You

recognize files by the entry in the LENGTH column. You reach the next

higher level from a directory level by using the vertical cursor keys to

position the cursor on the line with the double dot

the directory and then acknowledge with INPUT. If you have reached the

highest level, the double dot is replaced by a hyphen.

at the beginning of

Data selector

Hotkeys

...

...

If you change the area by means of key or softkey functions (e.g.

change from SERVICES to DIAGNOSIS) from any directory, the

directory level last selected is stored. When reselecting the area, this

brings you back to the directory used previously. Switchover between

areas can be performed at any time, e.g. to look at a parameter or

machine data.

A program that interprets your keyboard entries (cursor, input) as a file

or directory selection, displays it on the screen (bar) and passes it on to

other programs (e.g. editor).

With 840C software version 5 and higher the data selector responds to

hotkeys. The first object (directory/file) in the current directory that starts

with the letter or number entered is found and selected.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–7

Page 18

1 Introduction – The SINUMERIK 840C and its Operation

1.4 Directory structure

10.94

Workpiece With the SINUMERIK 840C you can store part programs and NCK data

(TOA, SEA, RPA, ZOA) in a directory from now on referred to as

workpiece. You can then load this workpiece and its data completely into

the NCK area. Thus you can store all relevant data (part programs, tool

offsets) required for a workpiece under one workpiece name and load it

any time you wish.

Programming/Programs

User

Name Type Length Date

–

GLOBAL glup

LOCAL parts

NCK nck

Programming/Programs

User/LOCAL

Name Type Length Date

..

STANDARD part

PART part

SHAFT1 part

GEAR5 part

Programming/Programs

User/LOCAL

Name Type Length Date

..

MPF1 parp 301 18.04.92

MPF99 parp 256 18.04.92

SPF88 parp 76 18.04.92

TOA1 toa 10250 18.04.92

RPA0 rpa 5637 18.04.92

Fig. 1.1 Representation of the directory path PROGRAMMING/LOCAL/SHAFT1/SPF88

The directory path (e.g. User/LOCAL/SHAFT1) is

displayed each time.

Type In addition to being identified by name, workpieces and files are also

assigned a type identifier. This provides a unique assignment between

the variable name and the created file or directory type. The type

identifiers are as follows:

1–8

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 19

10.94

1 Introduction – The SINUMERIK 840C and its Operation

1.4 Directory structure

Designation

Alarm help text

Archive list

Archive lists

Basic settings

Boot strapper

Boot strapper

Boot strapper

Clipboard

Color assignment list

Color table

Comment

Comment text

Configuration

Configuration

Configuration

Configuration texts

Curve pointer

Curve points

Cycle

Cycle machine data (TEA4)

Cycle setting data (SEA4)

Data

Data areas

Data list

Data management

Data references

Device

Device assignment

Drive machine data (TEA3)

Drives

Empirical values

Error texts

Form element

Function

Functions

Function test parameter

Global geometries

Global programs

Graphics

Graphics macro

Graphics mask

Help

Help text

Help text

Help texts

Icons

IKA number

Interfaces

Intermediate save

Job list

Keyboard table

Kinematics

Type Designation Type

alrminf

arc

arcs

bdgl

nckcnf

plccnf

serbo

clip

colli

clut

comm

cmt

bdcnf

simcnf

sycnf

bdcnfl

ika2

ika3

zpf

tea 4

sea 4

mda

dber

lbd

dasy

daref

dev

secnf

tea3

servo

heur

simtxt

gpmk

func

funcs

fkt

glgeo

glup

grfk

gramk

grmsk

wophelp

bdht

texl

htex

ikon

ika1

devs

bak

jobl

kbtab

kine

Language

LB data lists

LB semantics lists

List module

Local programs

Log

Log

Logbook

Logs

Master control

Measured value diagram 1

Measured value diagram 2

Memory dump

Message descriptions

Message descriptions (bin)

Message texts

Message texts (bin)

Motor list

NC

NC machine data (TEA1)

NC macro

NC matching

OEM

Operator action

Options

Part program

PC

PC area

PC system

PC user memory submodule (UMS)

PLC

PLC machine data (TEA2)

Power section list

Programs

R parameter (RPA)

Scheme

Scheme source

Scheme texts

Screen dump

Screen dumps

Screen form

Screen forms

Semantics list

Services

Setting data (SEA)

Siemens

Simulation

Source program

Startup

Startup info texts

Status data (GIA)

System

lang

lbds

lbss

lb

parts

prot

prpr

rlog

prprs

reg

mdi1

mdi2

plcprg

alrmda

alrmd

alrmta

alrmt

motl

nck

tea1

nckmk

nckmd

oem

bedsy

mdd

parp

mmc

mode

sys

mmcasm

plc

tea 2

ltl

progs

rpa

metab

metac

metat

hcpy

hcpys

msk

msks

lbs

serv

sea

siem

simul

sour

ibn

ibninf

gia

ncks

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–9

Page 20

1 Introduction – The SINUMERIK 840C and its Operation

1.4 Directory structure

Designation Type Designation Type

10.94

System

System file

System file

System files

Templates

Temporary

Text list

Tool catalog

Tool geometry macro

Tool list

Tool offsets (TOA)

plcs

ncsysf

plcsysf

sersy

exam

temp

lbt

toolb

tomk

toli

UMS texts

User

User memory submodule (ASM)

Variable geometry

WOP

WOP control

WOP setup

Workpiece

Work schedule

Zero offsets (ZOA)

toa

250 directories or files can be created for each

directory.

e.g.: Directory LOCAL : 250 workpieces

Directory GLOBAL : 250 workpieces

Directory SHAFT1 : 250 files

etc.

text

user

asm

vgeo

wop

wopst

wopset

part

fainf

zoa

1–10

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 21

10.94

1 Introduction – The SINUMERIK 840C and its Operation

1.5 The meaning of the SIEMENS and user directories

1.5 The meaning of the SIEMENS and user directories

The directories are divided into a Siemens directory and a user directory

in the areas where it is sensible to do so:

Softkey

Softkey

SERVICES

DATA

MANAGEMENT

SIEMENS

List module

NC

WOP

Files

User

Operation

Data management

GLOBAL

Start-up

List module

LOCAL

NC

PLC

Master control

Services

Drives

Simulation

WOP

Files

Fig. 1.2 SIEMENS directory and user directory in the SERVICES/DATA

IN–OUT/DEVICES area

Siemens directory The Siemens directory includes all data which are relevant for the

control’s operating system. You cannot edit or read out data in the

Siemens directory; you can merely copy this data into the user directory,

where it can be handled in exactly the same way as user data.

User directory The user directory includes all user data. The fact that system data

copied into the user directory can be edited there makes it possible to

modify the configuration files of the control. The data of the user branch

(if available) are always used before any other for the system

configuration on powering up of the control. These possibilities are only

relevant in the start-up phase and are password-protected against

unauthorized operation.

You will find a possibility to use this structure in the SERVICES/DATA

IN–OUT/DEVICE SETTINGS.

Here you can copy a standard interface configuration from the Siemens

directory into the user directory and modify it in accordance with your

data save device.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–11

Page 22

1 Introduction – The SINUMERIK 840C and its Operation

1.6 Screen darkening

1.6 Screen darkening

The SINUMERIK 840C includes a function by which the screen is

darkened after an adjustable period of time.

The default value of this period is 2 hours, i.e. as a rule the screen

darkens 2 hours after a key has last been activated; this value can be

changed in the PC data basic settings in the DIAGNOSIS area. The

display is activated once any key on the alphanumeric keyboard or on

the machine control panel, is pressed. The first keystroke simply

reactivates the screen and does not initiate its normal function. With the

screen darkening function, only the monitor is switched off and all other

functions remain active.

By pressing the SHIFT and ACTUAL POSITION IN LARGE

CHARACTERS keys, you can darken the monitor yourself and reactivate

the display by pressing any key on the alphanumeric keyboard.

Screen darkening can also be implemented by the

machine manufacturer via the PLC program. In this

case, the operator actions mentioned above do not

apply. Refer to the machine manufacturer’s

Operator’s Guide.

10.94

09.95

Caution!

All internal processes which generate screen outputs

do not cancel screen darkening. This also applies to

alarms and operational messages.

1–12

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 23

10.94

09.95

1 Introduction – The SINUMERIK 840C and its Operation

1.7 Data backup options

1.7 Data backup options

The memory capacity of the hard disk on the MMC–CPU module

enables you to store large volumes of data in the SINUMERIK 840C. It is

advisable, however, to perform a data dump of all relevant data on an

external data device (programmer, PC, etc.) because the data will be

lost irretrievably if the MMC–CPU (which incorporates the hard disk)

develops a defect.

Archive list As a backup aid, the SINUMERIK 840C allows directories and files to be

archived in archive lists, i.e. you can store a list of all important files and

directories under a name that you specify and output this complete to an

external device (see Services section, “Creating archive lists”).

The SINUMERIK 840C has various hardware interfaces which can be

addressed by the software.

Output via The RS232C (V24)/20mA interface on the MMC–CPU enables you to

RS232C/V24 output your user data from the hard disk in PC format or in punched tape

format (see Services section, “Data input-output”). The interface

automatically changes over between RS232C (V24) and 20 mA mode,

depending on the connected device and corresponding cable.

Constantly update the backup data so that you have

the current data available externally should a fault

occur.

Via the RS232C (V24) interface, you can also print out data directly with

a printer (SERVICES/DATA IN–OUT/PRINT function).

The SINUMERIK FD–E2 diskette unit (option) can be used for backing

up data.

Computer link Optionally you can implement a computer link with the

SINUMERIK 840C (only in the NCK area) by using link modules.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

1–13

Page 24

1 Introduction – The SINUMERIK 840C and its Operation

1.8 Help displays

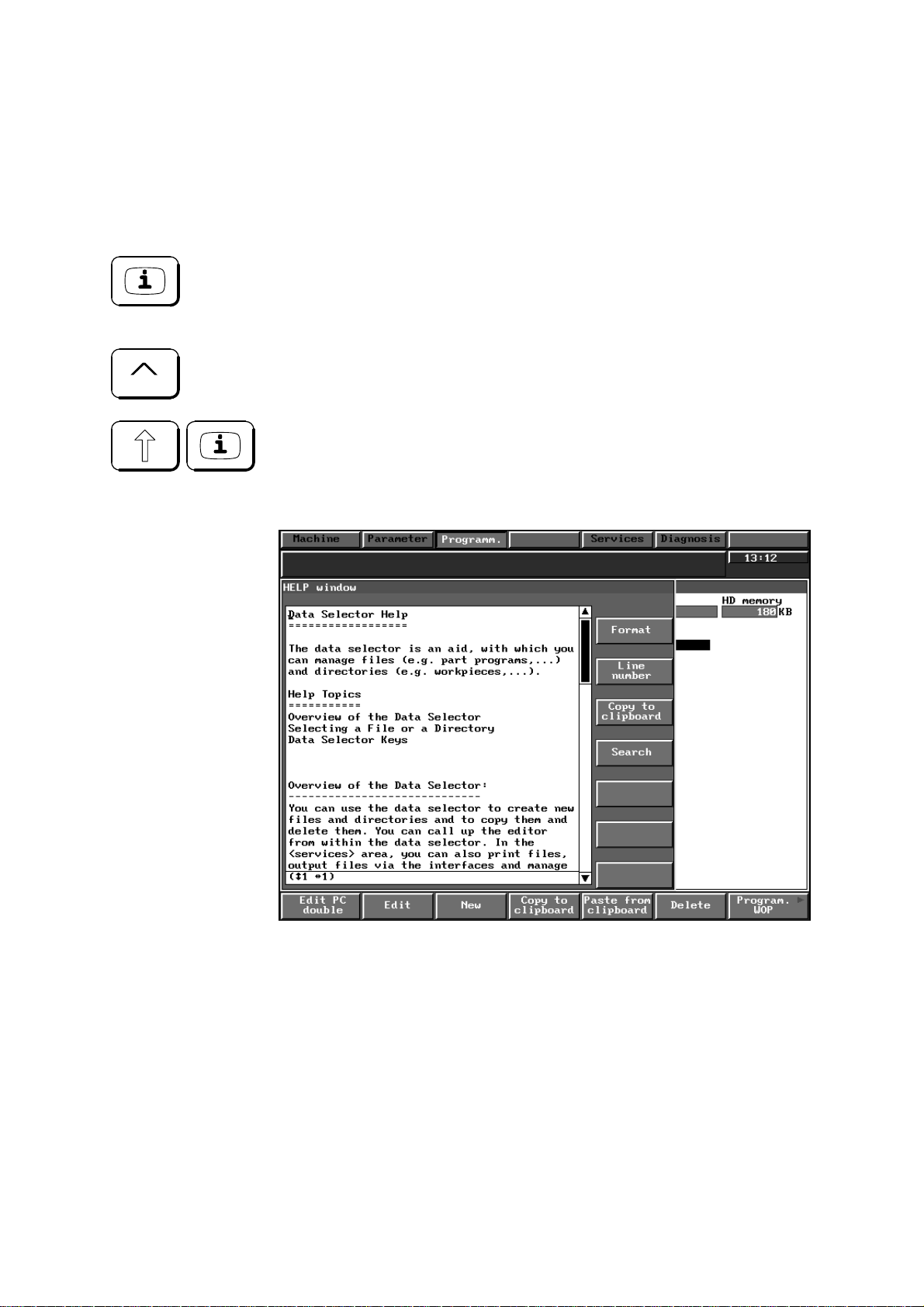

1.8 Help displays

You can call up help displays in the different operating areas of the

SINUMERIK 840C. The following is offered:

1. With this key you activate a help display for a special operation.

The possibility is indicated by the “i” in the 1st (left) softkey.

Press RECALL to deselect this help screen.

2. By pressing SHIFT + i you select or deselect a help screen

irrespective of an operator action, e.g. help screen for the data

selector:

10.94

1–14

Fig. 1.3 Help display

END OF SECTION

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 25

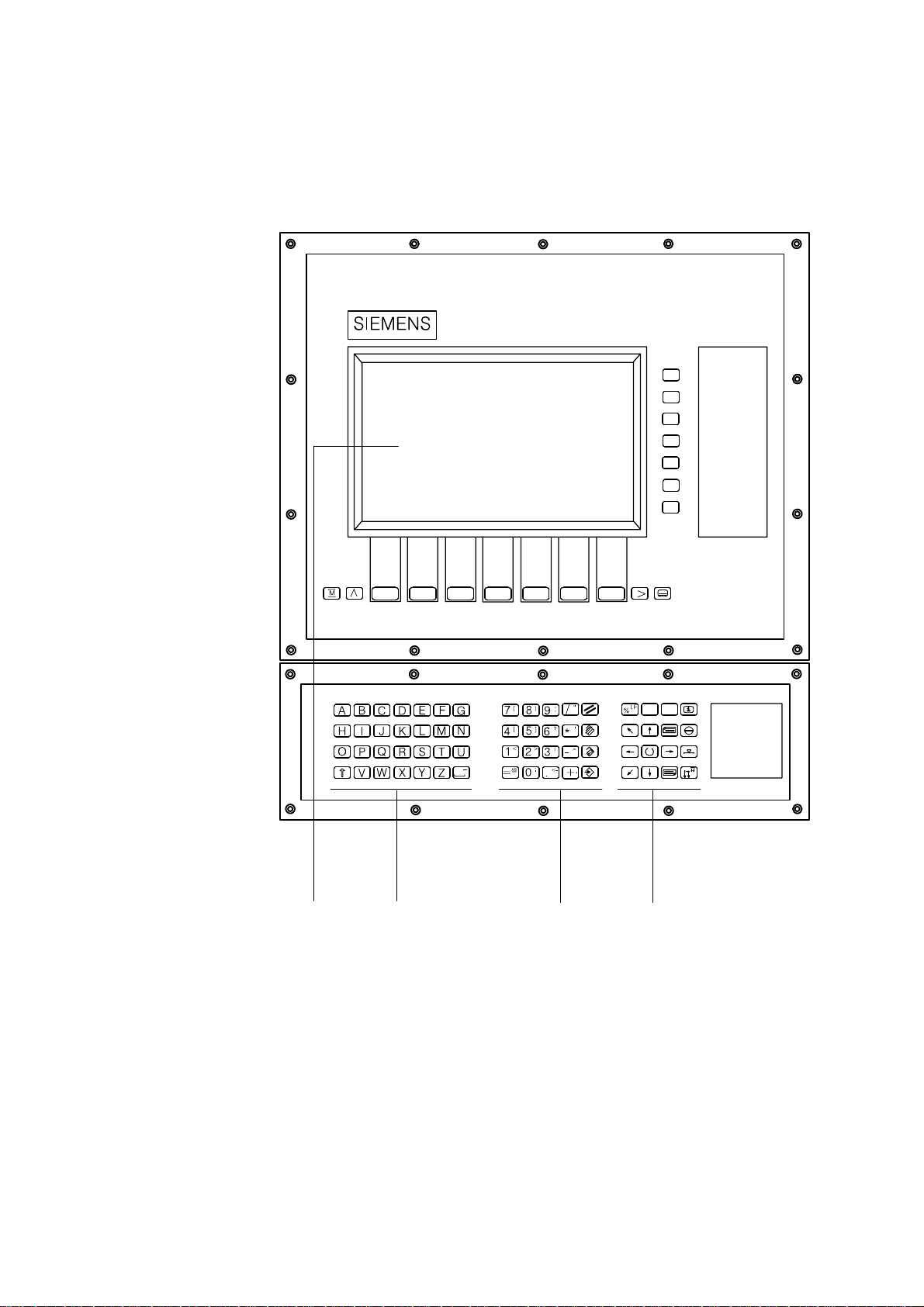

10.94

2 Operator Interface

2.1 Operator panel

Different operator panels can be connected to the SINUMERIK 840C.

The following components can be added: machine control panel, handheld unit and PC standard keyboard (MF–2).

S 19” operating panel with 14” colour monitor

(2x7 softkeys, switchover keys)

S 19” NC full keyboard

(alphabetic group of keys, numeric group of keys, cursor group of

keys)

S 19” slimline operator panel with 9.5” monochrome LC display

including NC full keyboard

(2x7 softkeys, switchover keys, alphabetic group of keys, numeric

group of keys, cursor group of keys)

S 19” slimline operator panel with 10” or 9.5” TFT display including NC

full keyboard

(2x7 softkeys, switchover keys, alphabetic group of keys, numeric

group of keys, cursor group of keys)

S PC standard keyboard (MF–2)

S 19” machine control panel, M version

S 19” machine control panel, T version

S Hand-held unit

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–1

Page 26

2 Operator Interface

2.2 Operator panel

2.2 Operating elements

2.2.1 Operator panel

10.94

03.95

AB C

Fig. 2.1 19” operator panel with 14” colour monitor

\

Alt

D

2–2

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 27

10.94

03.95

2 Operator Interface

2.2.1 Operator panel

SELECT

MENU

SELECT

\

Alt

D

MACHINE

CLEAR

DELETE

ALTER

SHIFT

INPUT

AB C

Fig. 2.2 19” operator panel with 14” colour monitor in US layout

ALARM

RESET

POSITION

GROUP

CHANNEL

HELP

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–3

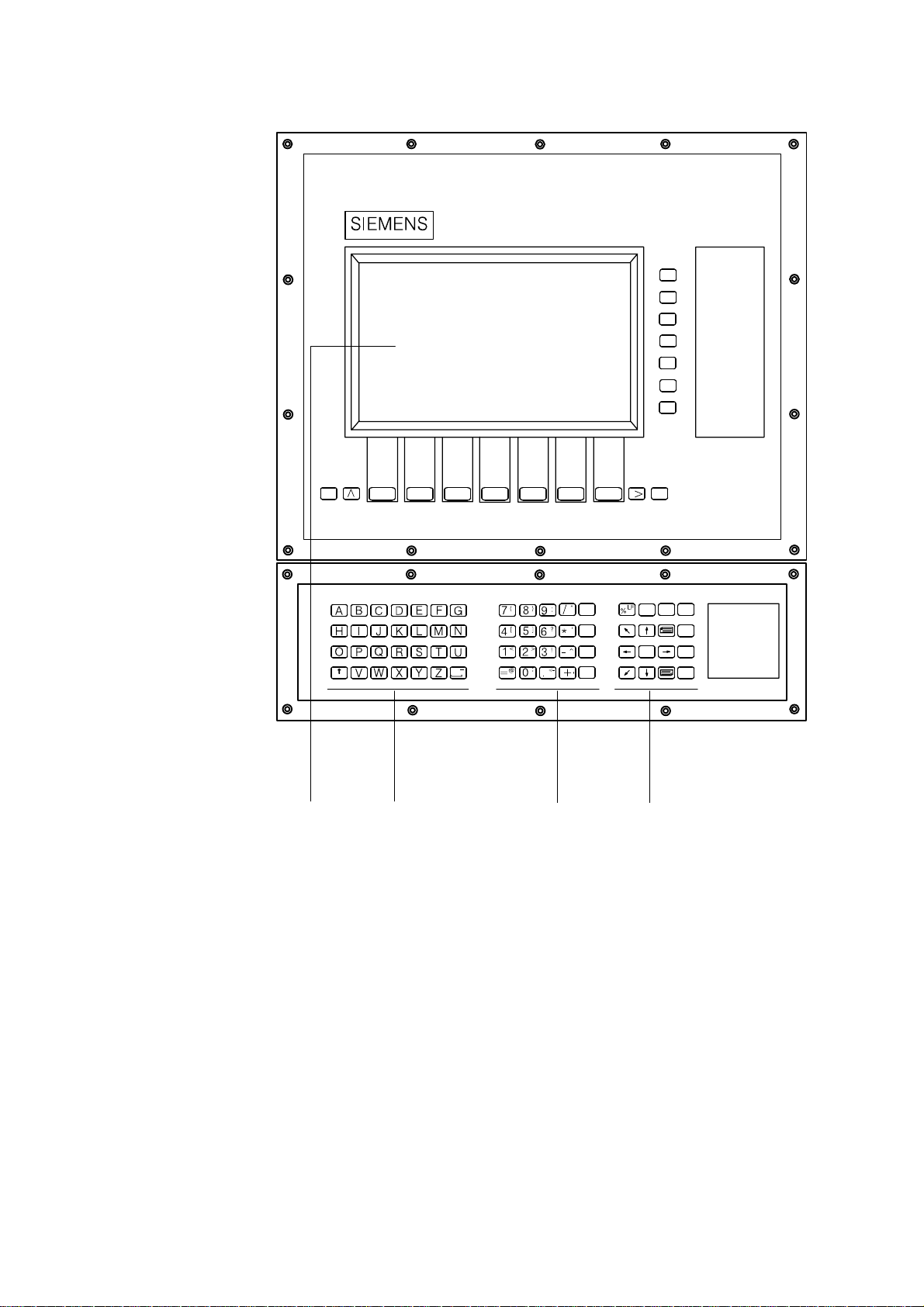

Page 28

2 Operator Interface

2.2.1 Operator panel

ABCD

Fig. 2.3 SINUMERIK slimline operator panel

10.94

07.97

\

Alt

SHIFT

GROUP

CHANNEL

CLEAR DELETE ALTER

MACHINE

MACHINE

A CD

MENU

SELECT

B

INPUT

Fig. 2.4 SINUMERIK slimline operator panel in US layout

A: 14”/10”/9.5” colour graphics monitor

14 softkeys

ETC key, Recall key

Machine area key

Area switchover key

B: Alphabetic group of keys

C: Numeric group of keys with editing and input keys

D: Cursor group of keys with control keyboard

POSITION

SELECT

HELP

\

Alt

ALARM

RESET

2–4

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 29

10.94

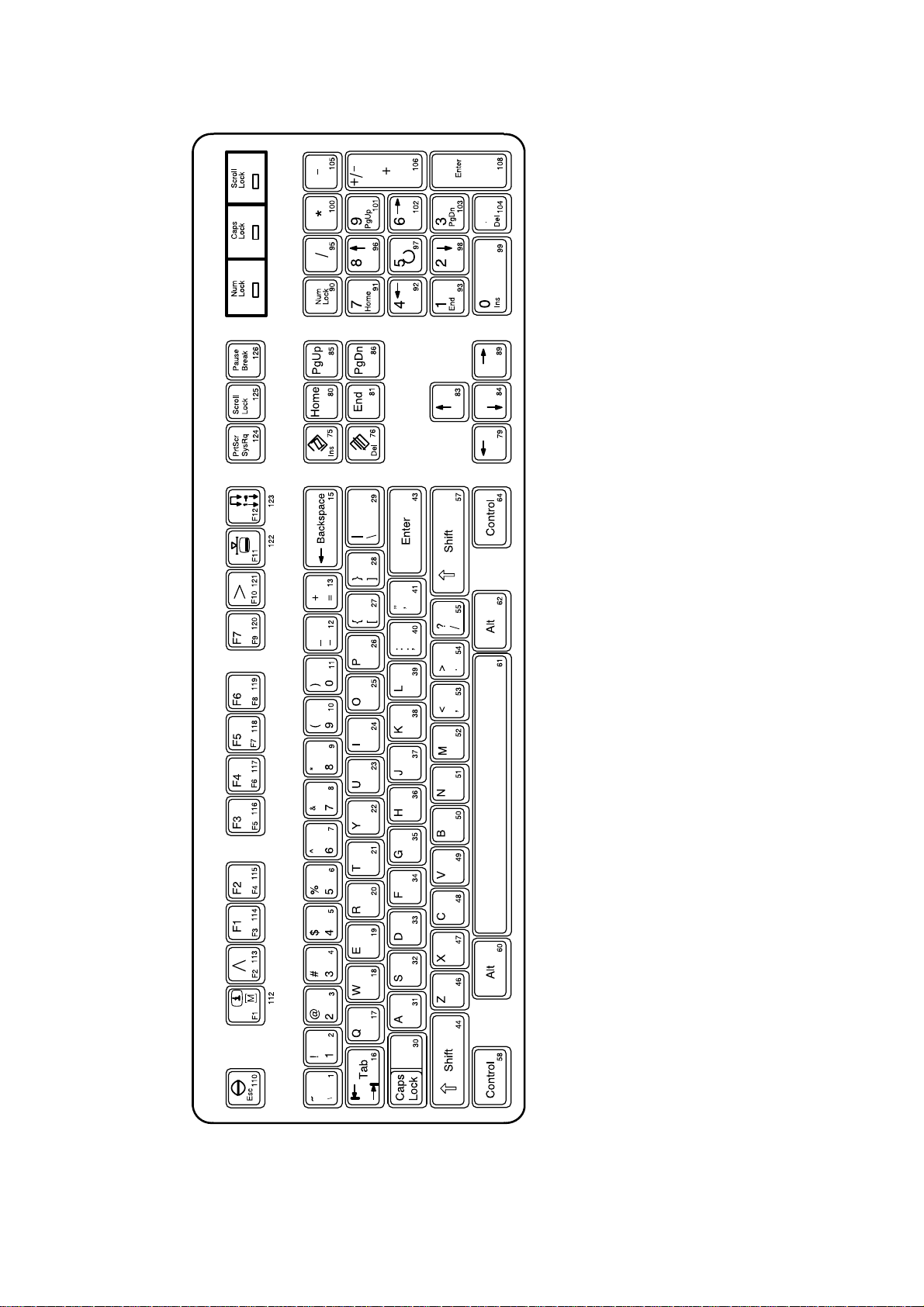

2.2.2 PC standard keyboard (MF–2)

An MF2 full standard keyboard can be connected. The machine control

panel functions, however, cannot be activated via this keyboard.

A set of key caps is supplied with the standard MF2 keyboard. These

key caps correspond to the symbols on the operating panel and can be

mounted on the standard keyboard as shown in the drawing.

The full standard keyboard does not comply with the

conditions (noise immunity) of a SINUMERIK control;

therefore it should be used only for start-up and

during servicing. The MF2 keyboard is connected to

the operator panel interface.

2 Operator Interface

2.2.2 PC standard keyboard (MF–2)

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–5

Page 30

2 Operator Interface

2.2.2 PC standard keyboard (MF–2)

10.94

Fig. 2.5 Full keyboard

2–6

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 31

10.94

2.2.3 Operator panel keyboard / full keyboard

2 Operator Interface

2.2.3 Operating elements of the operator panel keyboard/full keyboard

Softkey: Key which is assigned a variable function via a menu bar on the

screen.

Horizontal softkey bar (full keyboard)

Vertical softkey bar (full keyboard)

The designation F1 to F7 corresponds to the designation on the

additional key caps of the standard keyboard

(see also Figure “Full keyboard”).

MACHINE

or

1)

MENU

SELECT

SHIFT

Machine area

RECALL key: Return to the higher level menu

ETC key: Extension of the softkey bar in the same menu

1)

Area switchover

With this key, you can switch over to the area menu bar from every area.

When an area is deactivated the control “remembers” it. It is activated

again by pressing the area switchover key twice.

Shift: Switching over keys with double allocation; not self-retaining, i.e.

1)

two keys must be activated.

Lower case letter a ... z, activated with SHIFT

Upper case letter A ... Z

...

Underscore

Blank, space

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–7

Page 32

2 Operator Interface

2.2.3 Operator panel keyboard / full keyboard

Special character: less than

Digit 1

Special character: greater than

Digit 2

Exclamation mark

Digit 3

Square bracket

Digit 4

Square bracket

Digit 5

10.94

Question mark

Digit 6

Round bracket

Digit 7

Round bracket

Digit 8

Colon

Digit 9

Semicolon

Digit 0

2–8

Inverted commas

Oblique stroke, division

Apostrophe

Multiplication

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 33

10.94

03.95

2 Operator Interface

2.2.3 Operator panel keyboard / full keyboard

Special character

Hyphen, subtraction

Special character

Equal sign

Comma

Plus, addition

Change of sign

Fullstop (point/period)

or

1)

CLEAR

or

DELETE

ALTER

INPUT

or

Delete character/entry

1)

Delete word

Edit word

1)

1)

Confirm input (store an edited value in the memory)

Line Feed; identifier for end of block

Percent sign; identifier for beginning of main program

Backslash

\

Alt

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Alt

2–9

Page 34

2 Operator Interface

2.2.3 Operator panel keyboard / full keyboard

Help

1)

HELP

This key can be used to call up explanations and information on the

current operating state.

Pressing it a second time brings you back to the previous display (but

or

+

not in the graphic programming system). The “i” in the softkey bar

indicates the possibility of calling up information by pressing the “Help”

key.

Actual position in large characters

1)

POSITION

When you operate this key, the CRT display of “Actual position” is shown

in double-height characters.

Operating the key again brings you back to the previous full CRT display

or

(with standard size characters).

+

10.94

or

You “page” up by one display.

You change the current screen display by operating one of these keys if

further screen displays of the same layout (lists) are available.

or

You “page” down by one display. In a part program you can page down

the display (towards the end of the program), or up (towards the

beginning of the program).

With these keys, you move the cursor on the screen to the left or to the

right, upwards (back) or downwards (forward).

With the cursor keys, you can move the cursor in the input fields (toggle

fields, etc.) or in the various editors (ASCII editor; DIN editor). Further

information is given in the respective Sections of this Operator’s Guide.

Change to another input window

or

1) US layout

2–10

or

With this key you activate the cursor in the input line (NCK only), move it

by means of the cursor keys, in order to correct or insert. When

operating the key again, you deactivate the cursor.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Activate/deactivate cursor in the input line

Page 35

10.94

SELECT

Acknowledge alarm

ALARM

RESET

2 Operator Interface

2.2.3 Operator panel keyboard / full keyboard

1)

Selection key/Search key

(toggle fields select/mark text in editor/search text)

SHIFT + selection key

(reset a toggle field)

SHIFT + ALTER

Copy the contents of the screen into a file (hardcopy!)

You will find the TIF file “HCFn” (n = 0, 1, ...) in directory “Services/

Screen shots”

Memory requirement on the hard disk:

mono approx. 300 KB / screen

color (compressed) approx. 20 kB / screen

1)

By pressing this key you acknowledge the information from the NC

monitoring system displayed in the alarm line such as:

S Alarm text and

S Alarm number for CANCEL alarms

– The machine manufacturer can configure whether this key is to act

on all channel-specific CANCEL alarms or only on the channelspecific CANCEL alarms of the current channel.

1)

GROUP

CHANNEL

Change of mode groups

Channel switchover

Change of mode

groups The NC channels are grouped together in mode groups. With the

SINUMERIK 840C up to 6 mode groups can be selected.

Please note:

The channels are assigned to mode groups by

the machine manufacturer.

Channel switchover

S Pressing this key once switches to the next higher channel number,

referred to the number displayed in the channel status field.

S Pressing the key again switches on to the next

channel or back.

S The channel can be selected directly by entering the channel number

and then operating the key.

S The NC area of the SINUMERIK 840C is divided into a maximum of

six channels.

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–11

Page 36

2 Operator Interface

2.2.4 The operating elements of the machine control panel

2.2.4 The operating elements of the machine control panel

Machine control panel for a milling machine

10.94

Machine control panel for a milling machine in US layout

REPOS

[VAR]

CYCLE

STOP

REF

POINT

CYCLE

START

4th

5th

AXIS

AXIS

7th

8th

AXIS

AXIS

RAPID

RESET

JOG

TEACH IN

MDI

AUTO

SINGLE

BLOCK

Machine control panel for a turning machine

FEED

STOP

60

10

100

0

120

%

60

10

100

0

FEED

START

120

%

90

80

80

SPINDLE

START

100

110

120

%

90

100

110

120

%

70

60

50

6th

AXIS

9th

AXIS

70

60

SPINDLE

STOP

50

Machine control panel for a turning machine in US layout

REPOS

[VAR]

CYCLE

STOP

REF

POINT

CYCLE

START

RAPID

JOG

TEACH IN

MDI

AUTO

SINGLE

RESET

BLOCK

Fig. 2.6 Machine control panels

70

60

70

60

SPINDLE

STOP

FEED

STOP

60

10

100

0

120

%

60

10

100

0

FEED

START

120

%

90

80

100

110

120

50

%

90

80

100

110

120

50

%

SPINDLE

START

2–12

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 37

10.94

2 Operator Interface

2.2.4 The operating elements of the machine control panel

Machine tool operations such as traversing of the axes or program start

can only be triggered via a machine control panel.

The machine tool can be equipped with a standard Siemens machine

control panel or with a special machine control panel from the machine

tool manufacturer.

A maximum of two mode groups is possible.

The standard Siemens machine control panel is described. Should

another machine control panel be used, please refer to the Operator’s

Guide of the machine tool manufacturer.

The standard Siemens machine control panel has the following

operating elements:

S Emergency stop button

S Operating modes with function keys

S Spindle control

S Feed control

S Direction keys with rapid override

S Keyswitch

S Reset key

S Program control

Emergency stop You operate the red button in emergency situations:

button

S When there is a danger to life.

S When there is a danger that the machine or the workpiece could be

damaged.

Operation of the “Emergency stop” button generally brings all drives to a

stop with maximum braking torque.

For further or other reactions to “Emergency

stop”, refer to the machine tool manufacturer’s

documentation.

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–13

Page 38

2 Operator Interface

2.2.4 The operating elements of the machine control panel

Operating modes

10.94

Key symbol

JOG

The axes are traversed continuously in

1)

JOG mode using the direction keys or

incrementally using the direction keys or

Definition

the handwheel.

1)

Interactive creation of programs

TEACH IN

1)

The machine is controlled by executing a

MDI

block or a series of blocks. The operator

panel is used to input blocks.

1)

The machine is controlled by automatic

AUTO

execution of programs.

If a mode key is pressed, the corresponding mode is selected and all

other modes and functions are cancelled.

The active mode is indicated and confirmed by the associated LED

lighting up.

“REPOS” and “Approach reference point” functions

Designation of

operating mode

JOG

Set-up

(Jogging)

TEACH IN

MDA

Manual Data Automatic

AUTOMATIC

Key symbol

REPOS

REF

POINT

Definition

Designation of

function

1)

Repositioning, approach contour again in

JOG mode

1)

Approach reference point in JOG mode

REPOS

Reposition

REFPOINT

Approach reference point

The “REPOS” and “Approach reference point” functions are only active

in JOG mode and can be selected only in JOG mode.

The active function is indicated by the associated LED lighting up.

The function can be cancelled by pressing the function key again. The

function is cancelled automatically if there is a change of operating

mode.

1) US layout

2–14

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 39

10.94

09.95

INC function

2 Operator Interface

2.2.4 The operating elements of the machine control panel

Key symbol Definition

1)

Increment mode with variable step size

[VAR]

(setting data).

Increment mode with fixed step size of

1 increment

Increment mode with fixed step size of

10 increments.

Increment mode with fixed step size of

100 increments.

Increment mode with fixed step size of

1000 increments.

Increment mode with fixed step size of

10 000 increments.

The increment size depends on the display resolution that has been set.

Designation of

function

INC VAR

Incremental Feed variable

INC

Incremental Feed

Spindle override switch

9080

70

60

50

100

110

120

%

The INC functions can be activated in conjunction with the following

modes:

S JOG mode

S TEACH IN mode.

S The rotary switch with 16 notched positions (of which 15 are used)

enables you to reduce or increase the programmed spindle speed S

(corresponds to 100%).

S A machine data determines whether the switch function is active, i.e.

it is determined by the machine manufacturer.

S The set spindle speed value S is displayed as an absolute value in %

on the CRT display.

Control: 50% to 120% of the programmed spindle speed

Step size: 5% from position to position

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–15

Page 40

2 Operator Interface

2.2.4 The operating elements of the machine control panel

The given step size and the control range are

valid for standard machine data (MD). These

can be altered by the machine tool manufacturer

to suit a specific application.

Spindle stop When you press the SPINDLE STOP key:

SPINDLE

STOP

1)

S The spindle speed is reduced down to zero

S The associated LED lights up as soon as SPINDLE STOP is

accepted by the control.

Example for use of SPINDLE STOP

S To effect tool change

S To enter S, T, H, M functions while setting up (overstoring)

Spindle start When you press the “Spindle start” key:

1)

SPINDLE

START

S The spindle is enabled. If the spindle has been stopped with

SPINDLE STOP in a program, it can be started again with SPINDLE

START.

10.94

07.97

S The associated LED lights up as soon as SPINDLE START is ac-

cepted by the control.

The following values are specified by machine

data or setting data:

S The maximum spindle speed

S The values for spindle override positions

(refer to the machine tool manufacturer’s

documentation)

Feedrate control Feedrate/rapid override

The rotary switch with 23 notched positions allows you to reduce or

increase the programmed feedrate value F (corresponds to 100%).

90

100

The set feedrate value F is indicated on the CRT display in %.

110

Control range: 0% to 120% of the programmed feedrate.

The 100% value is not exceeded in rapid traverse.

10

6

60

70

40

20

2

0

80

120

%

Step size: 0%, 1%, 2%, 4%, 6%, 8%, 10%, 20%, 30%, 40%,

50%, 60%, 70%, 75%, 80%, 85%, 90%, 95%, 100%,

105%, 110%, 115%, 120%

1) US layout

2–16

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 41

10.94

2.2.4 The operating elements of the machine control panel

The given increment sizes and the control range

are valid for

standard machine data (MD)

These can be altered by the machine tool

manufacturer to suit a specific application.

Feed stop When you operate the FEED STOP key:

1)

FEED

STOP

S The program being executed is stopped

S The feed drives are brought to a controlled stop

S The associated LED lights up as soon as FEED STOP is accepted by

the control.

Examples for use of FEED STOP:

S During application in MDA mode, a block with a fault is discovered

S To effect tool change.

Feed start When you operate the FEED START key:

1)

FEED

START

S The part program continues in the current block

S The feedrate is increased to the value specified by the program

2 Operator Interface

S The associated LED lights up as soon as FEED START is accepted

by the control.

Direction keys, turning machine

You traverse the axis marked X.

You traverse the axis marked Z.

The following is configured by the machine

manufacturer:

S The speed and rapid traverse rates

S The values for feedrate and override positions

S Whether the feedrate override switch is also

active for rapid traverse

S The axis names

(see machine manufacturer’s specifications)

You traverse the axis marked C.

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–17

Page 42

2 Operator Interface

2.2.4 The operating elements of the machine control panel

Rapid traverse override

1)

RAPID

When you operate this key at the same time as any of the keys above,

the axis is traversed in rapid traverse mode.

Direction keys, milling machine

You select the axis marked X, Y, Z etc.

You traverse the selected axis in positive or in negative direction.

You traverse other assigned axes in the same way.

10.94

09.95

If an INC function has been set and the direction key is pressed

(whether for a long or a short time), the axis traverses by only one step

(1/10/100/1000/10000 increments depending on the setting).

If an INC function is not selected, the default setting “continuous” is active. The axis traverses as long as the

direction key is pressed.

Please take into consideration that when the safety interlocks are

enabled only the simple traverse movement via the JOG keys or via the

handwheel is permitted.

Rapid traverse When you operate this key at the same time as any of the keys above,

override the axis is traversed in rapid traverse mode.

1)

RAPID

1) US layout

2–18

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

Page 43

10.94

09.95

2.2.4 The operating elements of the machine control panel

2 Operator Interface

Keyswitch The SINUMERIK 840C keyswitch has 4 positions which are assigned

with functions via the control’s operating system. Three keys of different

colours belong to the keyswitch and these can be turned and removed

from the following positions:

Position of switch Withdraw position

Position 0

– Data on the hard disk are only displayed

Position 1

0 + 1 key 1

black

Position 2

0 + 1 + 2 key 2

green

Position 3 0+1+2+3 key 3

red

The key positions can be assigned with

additional functions by the machine

manufacturer. Please read the machine

manufacturer’s Operator ’s Guide.

Function

Generate, edit and delete workpiece data

Generate, edit and delete interface data,

archive lists and setting data

Siemens MMC standard data is loaded into

the system when powering up. All data in the

directory is password-protected. Note: Use

only for start-up and servicing!

Note If the PLC is in the STOP state the input display on the machine control

panel is not scanned. In this case the control can be powered up via

keyswitch position 3.

Reset key

1)

When you operate the “Reset” key:

RESET

S Execution of the current part program is interrupted if the key triggers

a mode group Reset (= Reset of all the channels of the mode group).

S Messages are cleared from the monitoring system unless they are

POWER ON or acknowledgment alarms.

S The control is switched to the “Reset” state, i.e.

– The NC control remains synchronized with the machine.

– All buffer and user memories are cleared (but the contents of the

part program memory are retained).

– The control is in the Reset state and ready for a new program run.

1) US layout

Siemens AG 2001 All rights reserved 6FC5198–jAA00

SINUMERIK 840C (BA)

2–19

Page 44

2 Operator Interface

2.2.4 The operating elements of the machine control panel

10.94

The machine manufacturer can configure the

RESET key such that it acts on channel/mode

group or on the whole NC.

Single block This function allows you to execute a part program on a block-by-block

1)

SINGLE

BLOCK

basis.

The SINGLE BLOCK function can be activated in the AUTOMATIC,

TEACH IN and MDA modes.

When SINGLE BLOCK operation is active:

S The SBL (Single Block) message is shown on the CRT display

S The current block of the part program is executed only when you

press the “NC start” key

S When the current block has been executed, processing is stopped

S The following block can be executed by pressing the “NC start” key

again.

The function does not work with calculation blocks. Calculation blocks

are part program blocks which execute programmed calculations (R

parameters calculation operations), but do not output anything to the

machine or to the PLC.

If SINGLE BLOCK is activated, the corresponding LED lights up on the

machine control panel.

The function can be deselected by pressing the key again.

NC Stop If you press the NC STOP key, processing of the current part program is

1)

CYCLE

STOP

interrupted. All axis movements are brought to a controlled stop. The

reactions of the H and M functions in the case of NC STOP are

configured by the machine manufacturer. For more information refer to

the machine manufacturer’s documentation. The associated LED lights

up.

Processing can then be continued by pressing NC START.

NC Start If you press the NC START key, the part program called is started at the

1)

CYCLE

START

current block; the associated LED lights up. Processing of a part

program interrupted with NC STOP is continued at the point of

interruption on pressing NC START.

The axis positions programmed in the current block

are approached with linear interpolation after the “NC

START” key has been activated.