Page 1

Legal information

Warning notice system

DANGER

will

WARNING

may

CAUTION

NOTICE

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

SINUMERIK

SINUMERIK 808D ADVANCED

Programming and Operating Manual (Turning)

User Manual

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The

notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage

have no safety alert symbol. These notices shown below are graded according to the degree of danger.

indicates that death or severe personal injury

indicates that death or severe personal injury

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of

injury to persons with a safety alert symbol may also include a warning relating to property damage.

result if proper precautions are not taken.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their

training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

for the specific task in accordance with

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products

and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage,

installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any

problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

© Siemens AG 2014. All rights reserved

6FC5398-5DP10-0BA1, 01/2014

1

Page 2

Preface

Applicable products

Control system

Software version

Documentation components and target groups

Component

Recommended target group

User documentation

Manufacturer/service documentation

My Documentation Manager (MDM)

Standard scope

Technical support

Hotline:

Service and Support:

EC Declaration of Conformity

15257461

This manual is applicable to the following control system:

SINUMERIK 808D ADVANCED T (Turning) V4.6

Programming and Operating Manual (Turning) Programmers and operators of turning machines

Programming and Operating Manual (Milling) Programmers and operators of milling machines

Programming and Operating Manual (ISO Turning/Milling) Programmers and operators of turning/milling

machines

Programming and Operating Manual (Manual Machine Plus Turning) Programmers and operators of turning machines

Diagnostics Manual Mechanical and electrical designers,

commissioning engineers, machine operators,

and service and maintenance personnel

Commissioning Manual Installation personnel, commissioning engineers,

and service and maintenance personnel

Function Manual Mechanical and electrical designers, technical

professionals

Parameter Manual Mechanical and electrical designers, technical

professionals

PLC Subroutines Manual Mechanical and electrical designers, technical

professionals, and commissioning engineers

Under the following link you will find information to individually compile your documentation based on the Siemens content:

www.siemens.com/mdm

This manual only describes the functionality of the standard version. Extensions or changes made by the machine tool

manufacturer are documented by the machine tool manufacturer.

● Global support hotline:

+49 (0)911 895 7222

● Support hotline in China:

+86 4008104288 (china)

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at

http://support.automation.siemens.com

Here, enter the number

Programming and Operating Manual (Turning)

2 6FC5398-5DP10-0BA1, 01/2014

● Chinese Web site:

http://www.siemens.com.cn/808D

● Global Web site:

http://support.automation.siemens.com

as the search term or contact your local Siemens office.

Page 3

Table of contents

Preface ................................................................................................................................................................... 2

1 Introduction............................................................................................................................................................. 7

2 Turning on, reference point approach .................................................................................................................... 15

3 Setting-up ............................................................................................................................................................. 16

4 Part programming ................................................................................................................................................. 29

5 Automatic machining ............................................................................................................................................. 35

6 Saving system data ............................................................................................................................................... 46

7 Data backup ......................................................................................................................................................... 48

8 Programming principles ........................................................................................................................................ 49

1.1 SINUMERIK 808D ADVANCED operator panels .......................................................................................... 7

1.1.1 Overview ....................................................................................................................................................... 7

1.1.2 Control elements on the PPU ........................................................................................................................ 8

1.2 Machine control panels ............................................................................................................................... 10

1.2.1 Overview ..................................................................................................................................................... 10

1.2.2 Control elements on the MCP ..................................................................................................................... 11

1.3 Screen layout .............................................................................................................................................. 13

1.4 Protection levels .......................................................................................................................................... 14

1.5 Setting user interface language .................................................................................................................. 15

3.1 Coordinate systems .................................................................................................................................... 16

3.2 Setting up tools ........................................................................................................................................... 18

3.2.1 Creating a new tool ..................................................................................................................................... 18

3.2.2 Activating the tool ........................................................................................................................................ 20

3.2.3 Assigning the handwheel ............................................................................................................................ 20

3.2.4 Activating the spindle .................................................................................................................................. 22

3.2.5 Measuring the tool (manually) ..................................................................................................................... 22

3.2.6 Verifying the tool offset result in "MDA" mode ............................................................................................. 26

3.2.7 Entering/modifying the tool wear data ......................................................................................................... 27

3.3 Operating area overview ............................................................................................................................. 28

4.1 Creating a part program .............................................................................................................................. 30

4.2 Editing part programs .................................................................................................................................. 31

4.3 Managing part programs ............................................................................................................................. 33

5.1 Performing the simulation ........................................................................................................................... 36

5.2 Program control .......................................................................................................................................... 38

5.3 Program test ............................................................................................................................................... 39

5.4 Starting and stopping/interrupting a part program ....................................................................................... 41

5.5 Executing/transferring a part program through the RS232 interface ........................................................... 42

5.5.1 Configuring RS232 communication ............................................................................................................. 42

5.5.2 Executing from external (through RS232 interface) .................................................................................... 43

5.5.3 Transferring from external (through RS232 interface) ................................................................................. 44

5.6 Machining at a specific point ....................................................................................................................... 45

8.1 Fundamentals of programming ................................................................................................................... 49

8.1.1 Program names .......................................................................................................................................... 49

8.1.2 Program structure ....................................................................................................................................... 49

8.2 Positional data ............................................................................................................................................ 50

8.2.1 Programming dimensions ........................................................................................................................... 50

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

3

Page 4

8.2.2 Absolute/incremental dimensioning: G90, G91, AC, IC .............................................................................. 51

8.2.3 Dimensions in metric units and inches: G71, G70, G710, G700 ................................................................. 52

8.2.4 Radius/diameter dimensions: DIAMOF, DIAMON, DIAM90 ....................................................................... 52

8.2.5 Programmable work offset: TRANS, ATRANS ........................................................................................... 53

8.2.6 Programmable scaling factor: SCALE, ASCALE ........................................................................................ 56

8.2.7 Workpiece clamping - settable work offset: G54 to G59, G500, G53, G153 ............................................... 57

8.2.8 Kinematic transformation ............................................................................................................................ 58

8.2.8.1 Milling on turned parts (TRANSMIT) ........................................................................................................... 58

8.2.8.2 Cylinder surface transformation (TRACYL) ................................................................................................ 60

8.3 Linear interpolation ..................................................................................................................................... 67

8.3.1 Linear interpolation with rapid traverse: G0 ................................................................................................ 67

8.3.2 Feedrate F .................................................................................................................................................. 68

8.3.3 Linear interpolation with feedrate: G1 ......................................................................................................... 69

8.4 Circular interpolation ................................................................................................................................... 70

8.4.1 Circular interpolation: G2, G3 ..................................................................................................................... 70

8.4.2 Circular interpolation via intermediate point: CIP ........................................................................................ 73

8.4.3 Circle with tangential transition: CT ............................................................................................................ 73

8.5 Thread cutting ............................................................................................................................................. 74

8.5.1 Thread cutting with constant lead: G33 ...................................................................................................... 74

8.5.2 Programmable run-in and run-out path for G33: DITS, DITE ...................................................................... 76

8.5.3 Thread cutting with variable lead: G34, G35 ............................................................................................... 77

8.5.4 Thread interpolation: G331, G332 .............................................................................................................. 78

8.6 Fixed point approach .................................................................................................................................. 79

8.6.1 Fixed point approach: G75 ......................................................................................................................... 79

8.6.2 Reference point approach: G74 .................................................................................................................. 79

8.7 Acceleration control and exact stop/continuous path .................................................................................. 80

8.7.1 Exact stop/continuous-path control mode: G9, G60, G64 ........................................................................... 80

8.7.2 Acceleration pattern: BRISK, SOFT............................................................................................................ 82

8.7.3 Dwell Time: G4 ........................................................................................................................................... 82

8.8 The third axis ................................................................................................

8.9 Spindle movements .................................................................................................................................... 83

8.9.1 Spindle speed S, directions of rotation ....................................................................................................... 83

8.9.2 Spindle positioning...................................................................................................................................... 84

8.9.2.1 Spindle positioning (SPOS, SPOSA, M19, M70, WAITS) ........................................................................... 84

8.9.2.2 Spindle positioning (SPOS, SPOSA, M19, M70, WAITS): Further information ........................................... 89

8.9.3 Gear stages ................................................................................................................................................ 90

8.10 Special turning functions ............................................................................................................................. 91

8.10.1 Constant cutting rate: G96, G97 ................................................................................................................. 91

8.10.2 Rounding, chamfer ..................................................................................................................................... 92

8.10.3 Contour definition programming ................................................................................................................. 94

8.11 Tool and tool offset ..................................................................................................................................... 96

8.11.1 General information (turning) ...................................................................................................................... 96

8.11.2 Tool T (turning) ........................................................................................................................................... 96

8.11.3 Tool offset number D (turning) .................................................................................................................... 97

8.11.4 Selecting the tool radius compensation: G41, G42 ................................................................................... 100

8.11.5 Corner behavior: G450, G451 .................................................................................................................. 102

8.11.6 Tool radius compensation OFF: G40 ........................................................................................................ 102

8.11.7 Special cases of the tool radius compensation ......................................................................................... 103

8.11.8 Example of tool radius compensation (turning) ......................................................................................... 104

8.11.9 Special handling of tool compensation (turning) ....................................................................................... 105

8.12 Miscellaneous function M ......................................................................................................................... 105

8.13 H function ................................................................................................................................................. 106

8.14 Arithmetic parameters, LUD and PLC variables ....................................................................................... 107

8.14.1 Arithmetic parameter R ............................................................................................................................. 107

8.14.2 Local User Data (LUD) ............................................................................................................................. 108

8.14.3 Reading and writing PLC variables ........................................................................................................... 109

8.15 Program jumps ......................................................................................................................................... 110

8.15.1 Unconditional program jumps ................................................................................................................... 110

.............................................. 83

Programming and Operating Manual (Turning)

4 6FC5398-5DP10-0BA1, 01/2014

Page 5

9 Cycles ................................................................................................................................................................ 120

10 Typical turning program ...................................................................................................................................... 198

A Appendix ............................................................................................................................................................ 204

8.15.2 Conditional program jumps ....................................................................................................................... 111

8.15.3 Program example for jumps ...................................................................................................................... 112

8.15.4 Jump destination for program jumps ......................................................................................................... 113

8.16 Subroutine technique ................................................................................................................................ 113

8.16.1 General information................................................................................................................................... 113

8.16.2 Calling machining cycles (turning)............................................................................................................. 115

8.16.3 Executing external subroutines (EXTCALL) .............................................................................................. 116

8.17 Timers and workpiece counters ................................................................................................................ 117

8.17.1 Runtime timer ............................................................................................................................................ 117

8.17.2 Workpiece counter .................................................................................................................................... 118

9.1 Overview of cycles .................................................................................................................................... 120

9.2 Programming cycles .................................................................................................................................. 120

9.3 Graphical cycle support in the program editor ........................................................................................... 122

9.4 Drilling cycles ............................................................................................................................................ 123

9.4.1 General information................................................................................................................................... 123

9.4.2 Requirements ............................................................................................................................................ 123

9.4.3 Drilling, centering - CYCLE81 ................................................................................................................... 126

9.4.4 Drilling, counterboring - CYCLE82 ............................................................................................................ 128

9.4.5 Deep-hole drilling - CYCLE83 ................................................................................................................... 130

9.4.6 Rigid tapping - CYCLE84 .......................................................................................................................... 134

9.4.7 Tapping with compensating chuck - CYCLE840 ....................................................................................... 138

9.4.8 Reaming1 - CYCLE85 ............................................................................................................................... 142

9.4.9 Boring - CYCLE86..................................................................................................................................... 144

9.4.10 Boring with stop 1- CYCLE87 ................................................................................................................... 147

9.4.11 Drilling with stop 2 - CYCLE88 .................................................................................................................. 148

9.4.12 Reaming 2 - CYCLE89 .............................................................................................................................. 150

9.5 Turning cycles ........................................................................................................................................... 152

9.5.1 Requirements ............................................................................................................................................ 152

9.5.2 Cutoff - CYCLE92 ..................................................................................................................................... 153

9.5.3 Groove - CYCLE93 ................................................................................................................................... 155

9.5.4 Undercut (forms E and F to DIN) - CYCLE94 ........................................................................................... 163

9.5.5 Cutting with relief cut - CYCLE95 .............................................................................................................. 166

9.5.6 Thread undercut - CYCLE96 ..................................................................................................................... 181

9.5.7 Thread chaining - CYCLE98 ..................................................................................................................... 184

9.5.8 Thread cutting - CYCLE99 ........................................................................................................................ 189

9.6 Error messages and error handling ........................................................................................................... 197

9.6.1

General Information .................................................................................................................................. 197

9.6.2 Error handling in the cycles ....................................................................................................................... 197

9.6.3 Overview of cycle alarms .......................................................................................................................... 197

9.6.4 Messages in the cycles ............................................................................................................................. 197

A.1 Creating a new cutting edge ..................................................................................................................... 204

A.2 Setting up the workpiece ........................................................................................................................... 205

A.2.1 Entering/modifying work offsets ................................................................................................................ 206

A.3 Entering/modifying the setting data ........................................................................................................... 207

A.4 Setting R parameters ................................................................................................................................ 209

A.5 Setting user data ....................................................................................................................................... 210

A.6 Other settings in "JOG" mode ................................................................................................................... 211

A.6.1 Setting the relative coordinate system (REL) ............................................................................................ 212

A.6.2 Setting the JOG data ................................................................................................................................. 212

A.7 The help system ........................................................................................................................................ 213

A.8 Operation wizard ....................................................................................................................................... 215

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

5

Page 6

A.9 Editing Chinese characters ....................................................................................................................... 216

A.10 Pocket calculator ...................................................................................................................................... 217

A.11 Calculating contour elements ................................................................................................................... 218

A.12 Free contour programming ....................................................................................................................... 222

A.12.1 Programming a contour ............................................................................................................................ 223

A.12.2 Defining a start point ................................................................................................................................. 224

A.12.3 Programming contour element ................................................................................................................. 225

A.12.4 Parameters for contour elements.............................................................................................................. 227

A.12.5 Undercuts for turning technology .............................................................................................................. 230

A.12.6 Specifying contour elements in polar coordinates..................................................................................... 231

A.12.7 Cycle support ............................................................................................................................................ 233

A.12.8 Programming example for turning application .......................................................................................... 233

A.13 Word structure and address ..................................................................................................................... 237

A.14 Character set ............................................................................................................................................ 238

A.15 Block format .............................................................................................................................................. 238

A.16 List of instructions ..................................................................................................................................... 240

Programming and Operating Manual (Turning)

6 6FC5398-5DP10-0BA1, 01/2014

Page 7

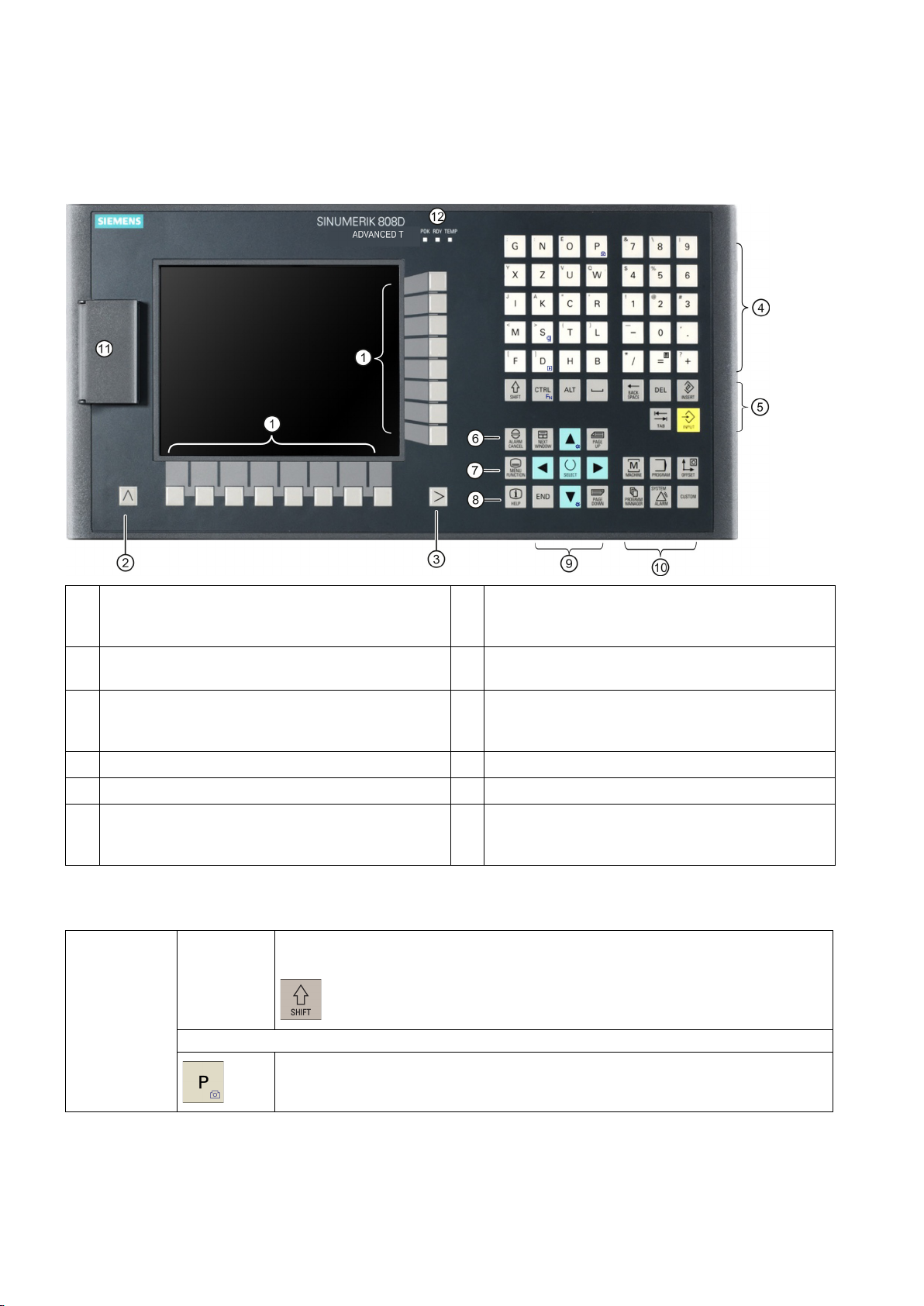

1

Introduction

1.1

SINUMERIK 808D ADVANCED operator panels

1.1.1

Overview

PPU161.2 (horizontal panel layout)

PPU160.2 (vertical panel layout)

The SINUMERIK 808D ADVANCED PPU (Panel Processing Unit) is available in the following variants:

● PPU161.2

● PPU160.2

Horizontal panel layout, applicable for the SINUMERIK 808D ADVANCED T (turning) or SINUMERIK 808D ADVANCED

M (milling) control system

Vertical panel layout, applicable for the SINUMERIK 808D ADVANCED T (turning) or SINUMERIK 808D ADVANCED M

(milling) control system

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

7

Page 8

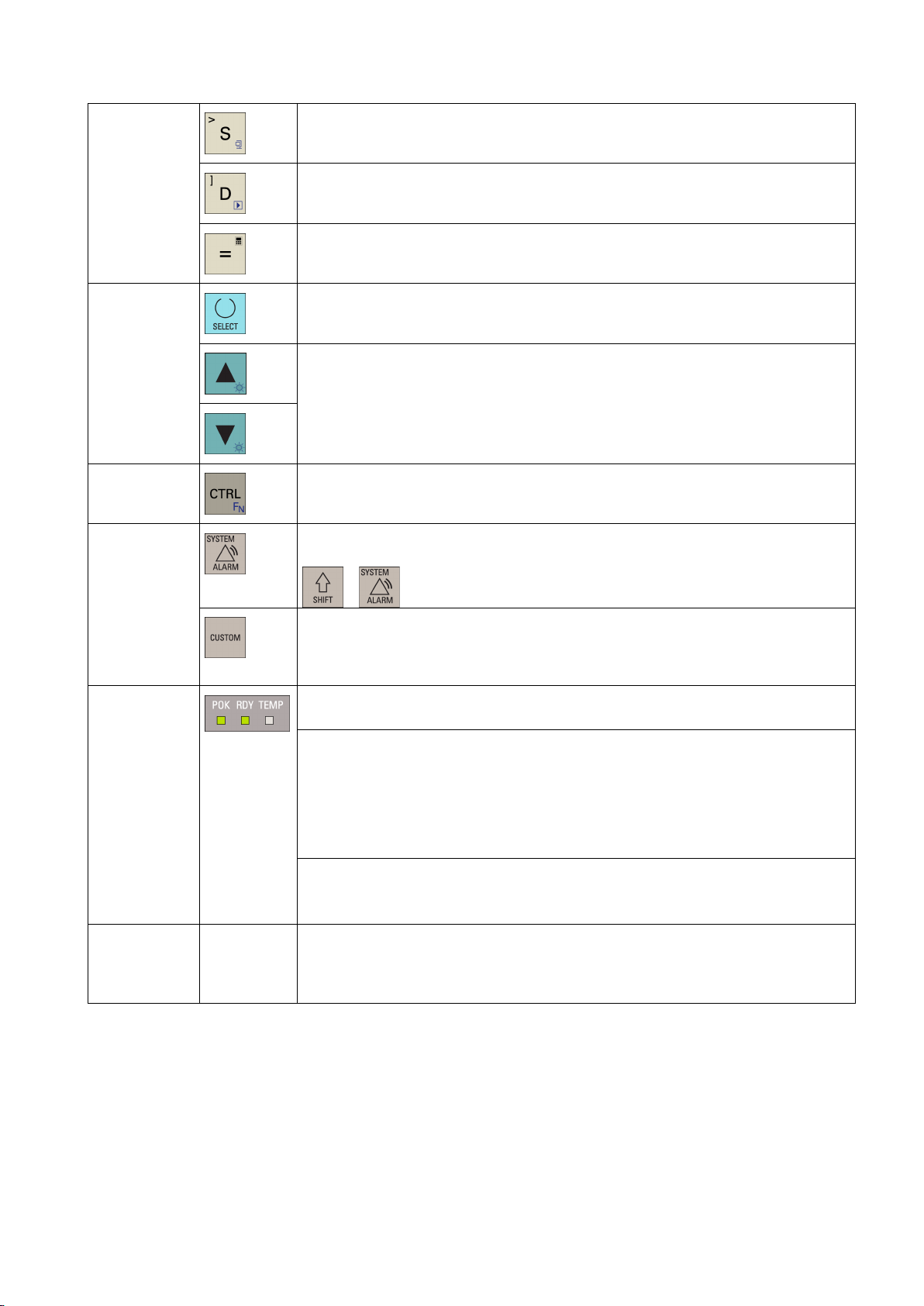

1.1.2

Control elements on the PPU

Elements on the PPU (Panel Processing Unit) front

Vertical and horizontal softkeys

On-board wizard key

Return key

Help key

Menu extension key

Cursor keys

Alphabetic and numeric keys

Operating area keys

Control keys

USB interface

Alarm cancellation key

Status LEDs

Further information

The following illustration uses PPU161.2 as an example to show control elements available on the PPU:

①

Calls specific menu functions

②

Returns to the next higher-level menu

③

Opens the next lower-level menu or navigate between

the menus of the same level

④

⑤

⑥

Cancels alarms and messages that are marked with

this symbol

* For more information, refer to the table below.

Alphabetic and

numeric keys

*

To enter the upper character on an alphabetic/numeric key, keep the following key

*

pressed:

⑦

Provides step-by-step guides on basic commissioning

and operation procedures

⑧

Calls help information

⑨

*

⑩

⑪

⑫

*

*

*

The icons on the following keys are available only with PPU161.2 and PPU160.2.

Programming and Operating Manual (Turning)

8 6FC5398-5DP10-0BA1, 01/2014

The icon on the key is a hint that you can press both <CTRL> and this key as shortcuts

for capturing screens.

Page 9

● An external USB keyboard which functions as an external NC keyboard

Cursor keys

The icon on the key is a hint that you can press both <CTRL> and this key as shortcuts

for saving start-up archives.

The icon on the key is a hint that you can press both <CTRL> and this key as shortcuts

for displaying pre-defined slides on the screen.

The icon on the key is a hint that you can press this key to call the calculator function.

● Toggles between entries in the input field

● Enters the "Set-up menu" dialog at NC start-up

Icons on both keys are available only with PPU161.2 and PPU160.2. The icon on the

key is a hint that you can press both <CTRL> and the key to adjust the screen backlight

brightness.

Control keys

The icon on the key is available only with PPU161.2 and PPU160.2. The icon is a hint

that this key can be used together with another key to function as a key combination.

Operating area

keys

To open the system data management operating area, press the following key

combination:

+

Enables user-defined extension applications, for example, generation of user dialogs

with the EasyXLanguage function.

For more information about this function, refer to SINUMERIK 808D ADVANCED

Function Manual.

Status LEDs

LED "POK"

Lights up green: The power supply for the CNC is switched on.

LED "RDY"

Lights up green: The CNC is ready and the PLC is in running mode.

Lights up orange:

● On: The PLC is in stop mode.

● Flashing: The PLC is in power-up mode.

Lights up red: The CNC is in stop mode.

LED "TEMP"

Unlit: The CNC temperature is within the specified range.

Lights up orange: The CNC temperature is out of range.

USB interface Connects to a USB device, for example:

● An external USB memory sticker, to transfer data between the USB sticker and the

CNC

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

9

Page 10

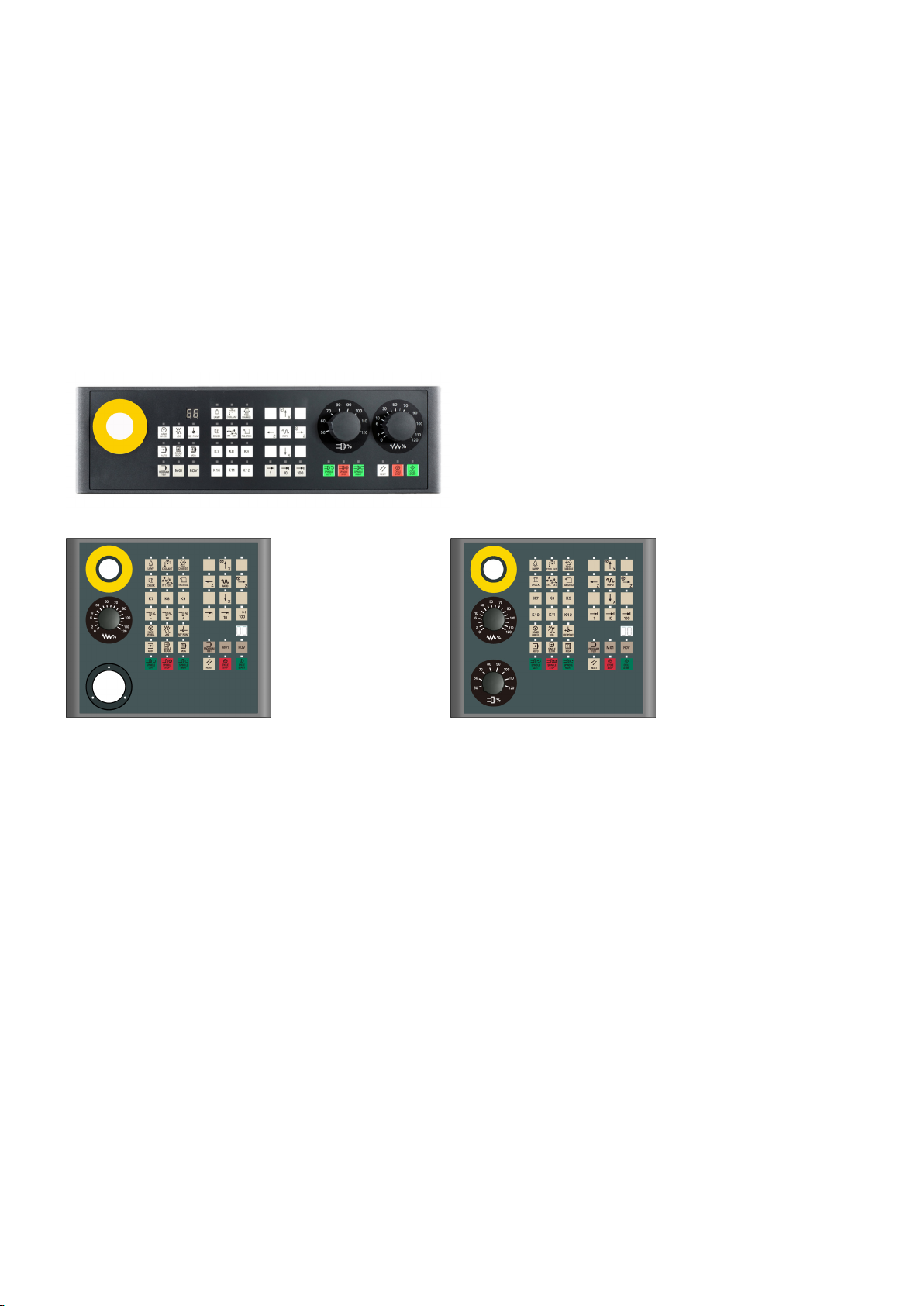

1.2

Machine control panels

1.2.1

Overview

Elements on the MCP (Machine Control Panel) front

The MCP for the SINUMERIK 808D ADVANCED PPU is available in the following variants:

● Horizontal MCP variant

● Vertical MCP variant with a reserved slot for the handwheel

● Vertical MCP variant with an override switch for the spindle

Horizontal MCP

Vertical MCP with reserved handwheel slot Vertical MCP with spindle override switch

Programming and Operating Manual (Turning)

10 6FC5398-5DP10-0BA1, 01/2014

Page 11

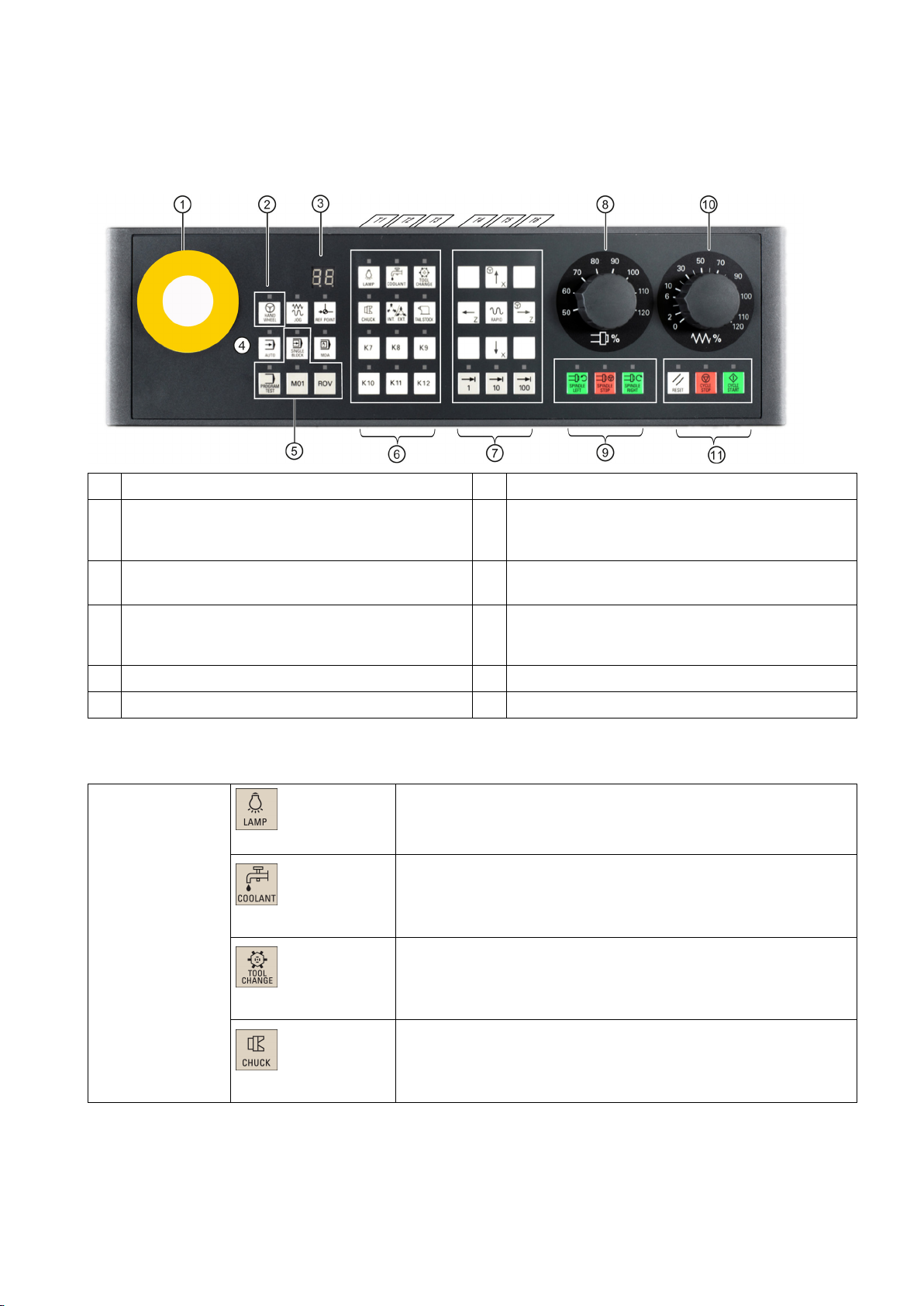

1.2.2

Control elements on the MCP

Elements on the MCP (Machine Control Panel) front

Reserved hole for emergency stop button

Axis traversing keys

Handwheel key

Spindle override switch

Tool number display

Spindle state keys

Operating mode keys

Feedrate override switch

Program control keys

Keys for program start, stop, and reset

User-defined keys

Further information

User-defined keys

The following illustration uses a horizontal MCP as an example to show control elements available on the MCP:

* For more information, refer to the table below.

①

②

Controls the axis movement with external handwheels

③

Displays the current tool number

④

⑤

⑥

*

⑦

⑧

(unavailable for the vertical MCP with reserved

handwheel slot)

⑨

⑩

Traverses the selected axis at the specified feedrate

override

⑪

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

Pressing this in any operating mode switches on/off the lamp.

LED lit: The lamp is switched on.

LED unlit: The lamp is switched off.

Pressing this key in any operating mode switches on/off the coolant

supply.

LED lit: The coolant supply is switched on.

LED unlit: The coolant supply is switched off.

Pressing this key starts sequential tool changes (active only in "JOG"

mode).

LED lit: The machine starts sequential tool changes

LED unlit: The machine stops sequential tool changes

Pressing this key in any operating mode activates the chuck to

clamp/unclamp the workpiece.

LED lit: Activates the chuck to clamp the workpiece

LED unlit: Activates the chuck to unclamp the workpiece

11

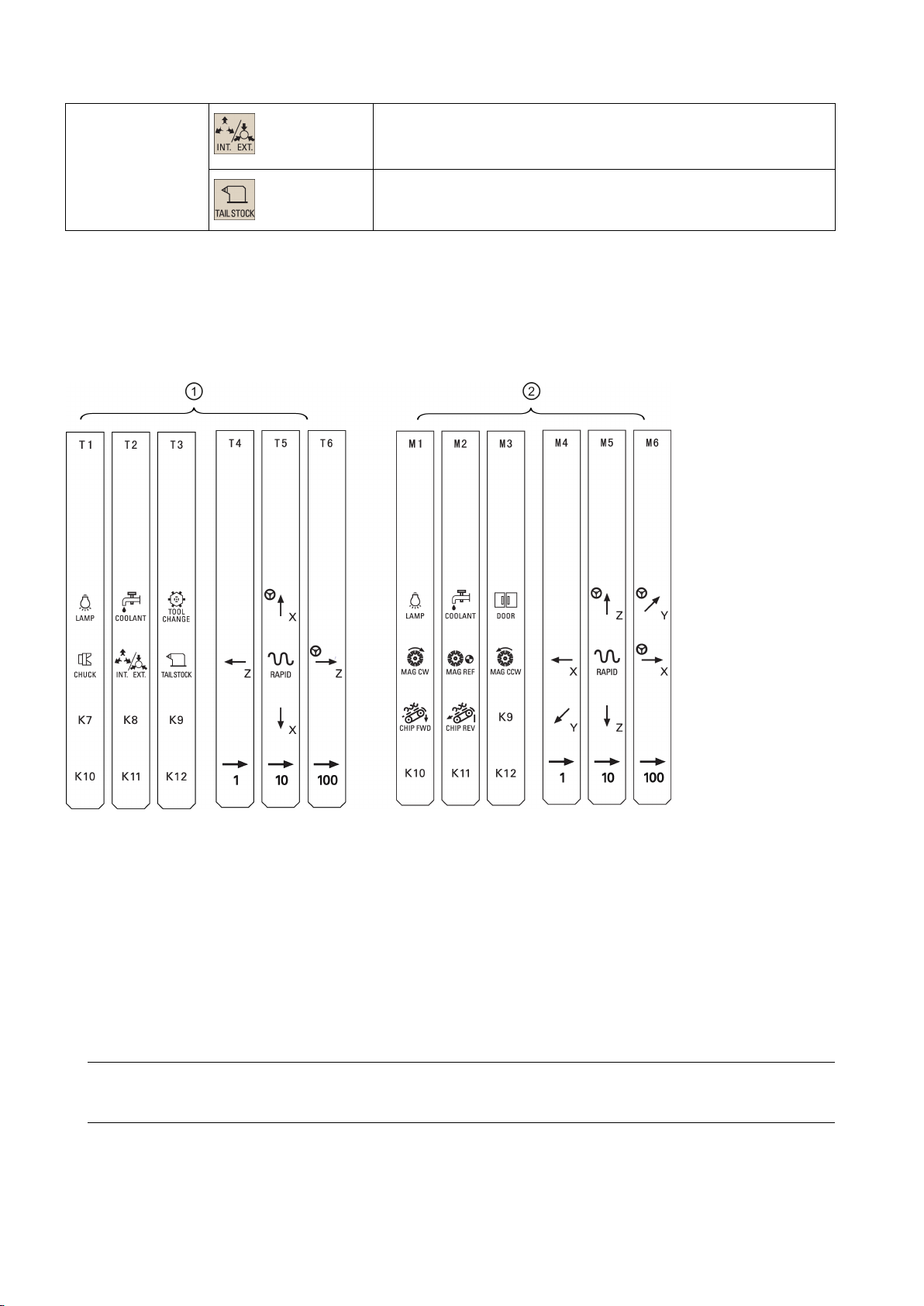

Page 12

Pre-defined insertion strips

Customized insertion strips

Note

Pressing this key only when the spindle stops operation.

LED lit: Activates the external chuck to clamp the workpiece inwards

LED unlit: Activates the internal chuck to clamp the workpiece outwards

Pressing this key in any operating mode advances/retracts the tailstock.

LED lit: Advances the tailstock towards the workpiece until it firmly

engages with the end of the workpiece

The MCP (machine control panel) package includes two sets (six pieces each) of pre-defined insertion strips. One set is for

the turning variant of the control system and is pre-inserted on the back of the MCP. The other set is for the milling variant of

the control system.

If your control system is of the SINUMERIK 808D ADVANCED milling variant, replace the pre-inserted strips with the millingspecific insertion strips.

The MCP package also includes an A4-sized blank plastic sheet with detachable strips. You can customize insertion strips if

the pre-defined strips can not meet your needs.

In the \examples\MCP folder of the Toolbox DVD for the SINUMERIK 808D ADVANCED, there is a symbol library file and an

insertion strip template file. To make customized insertion strips, follow the steps below:

1. Copy the desired symbols from the symbol library file to the desired locations in the insertion strip template.

2. Print the template to the A4-sized blank plastic sheet.

3. Detach the insertion strips from the blank plastic sheet.

4. Pull out the pre-inserted strips from the MCP.

5. Insert the customized strips on the back of the MCP.

This manual assumes an 808D standard machine control panel (MCP). Should you use a different MCP, the operation

may be other than described herein.

Programming and Operating Manual (Turning)

12 6FC5398-5DP10-0BA1, 01/2014

Page 13

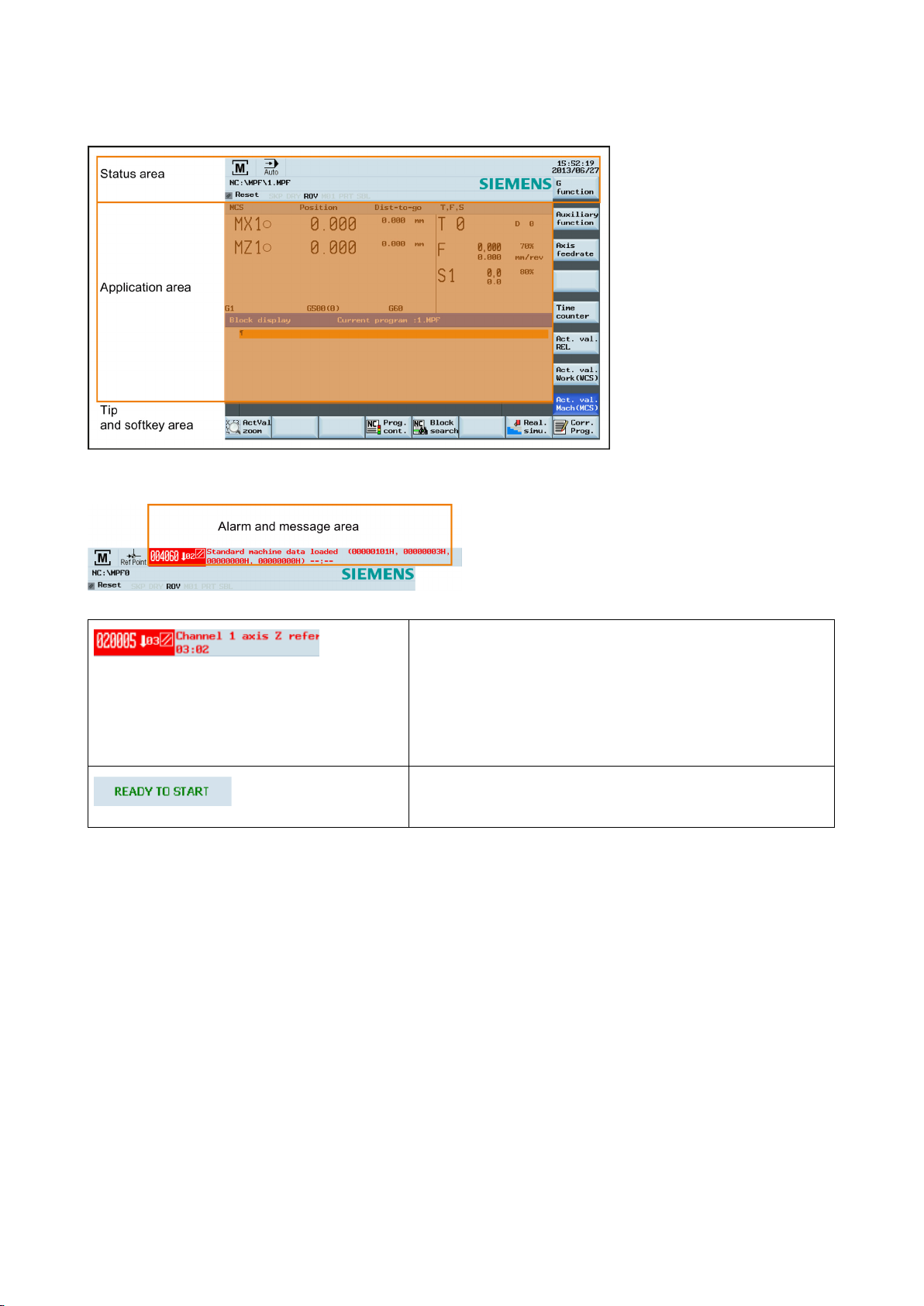

1.3

Screen layout

Alarms and messages

Displays active alarms with alarm text

Displays messages from NC programs

The alarm number is displayed in white lettering on a red

background. The associated alarm text is shown in red lettering.

An arrow indicates that several alarms are active. The number to

the right of the arrow indicates the total number of active alarms.

When more than one alarm is active, the display scrolls through

the alarms in sequence. An acknowledgement symbol indicates

the alarm cancel criterion.

Messages from NC programs do not have numbers and appear in

green lettering.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

13

Page 14

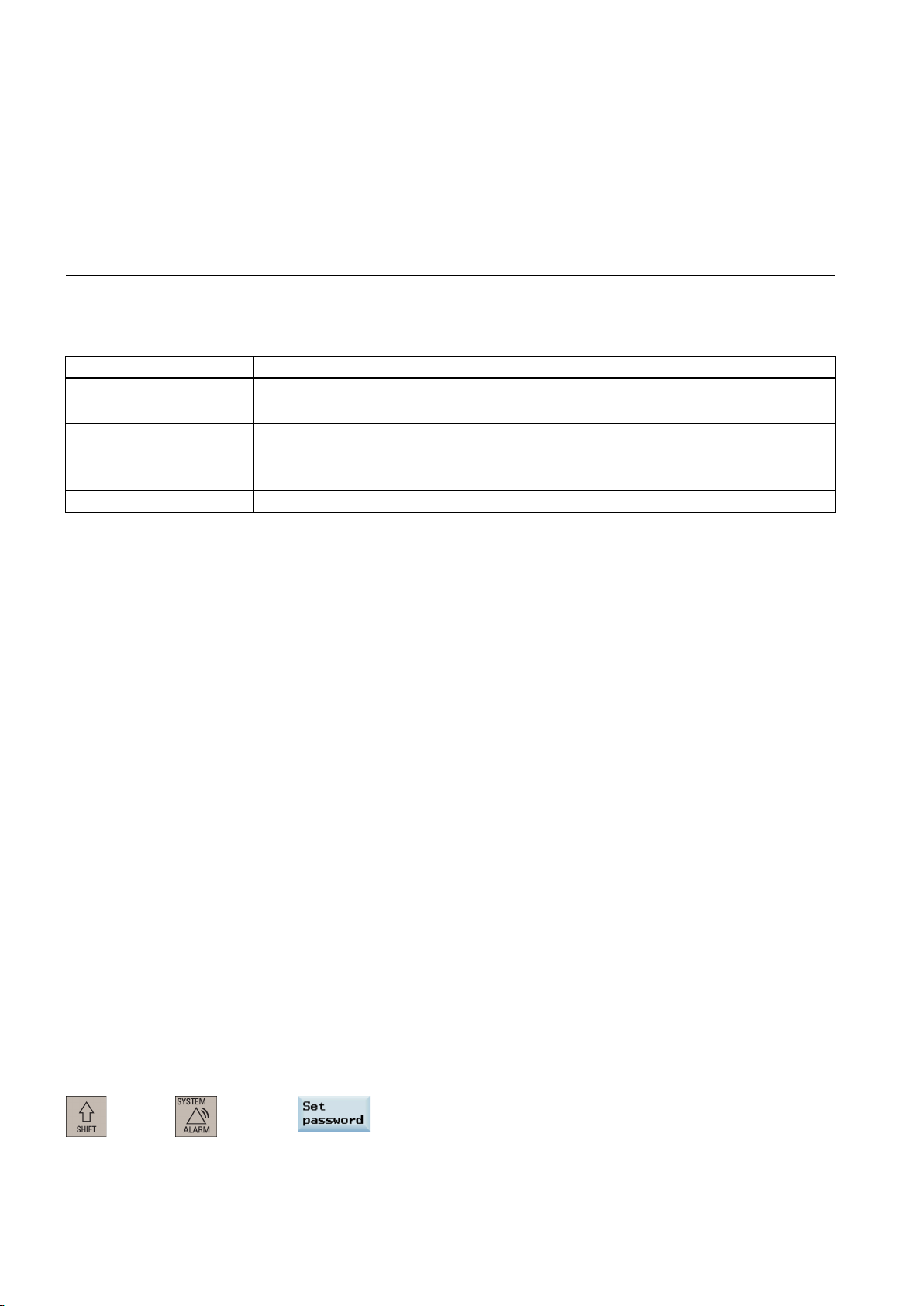

1.4

Protection levels

Overview

Note

Before you boot the control system with default machine/drive data, make sure that you have backed up your machine/drive

Protection level

Locked by

Area

0

1

2

3-6

7

Protection level 1

Protection level 3-6

Protection level 7

USER_CLASS

Setting password

The SINUMERIK 808D ADVANCED provides a concept of protection levels for enabling data areas. Different protection

levels control different access rights.

The control system delivered by SIEMENS is set by default to the lowest protection level 7 (without password). If the

password is no longer known, the control system must be reinitialized with the default machine/drive data. All passwords are

then reset to default passwords for this software release.

data; otherwise, all data are lost after rebooting with default machine/drive data.

Siemens password Siemens, reserved

Manufacturer password Machine manufacturers

Reserved

End user password

(Default password: "CUSTOMER")

No password End users

Protection level 1 requires a manufacturer password. With this password entry, you can perform the following operations:

● Entering or changing part of the machine data and drive data

● Conducting NC and drive commissioning

Protection level 3-6 requires an end user password. With this password entry, you can perform the following operations:

● Entering or changing part of the machine data and drive data

● Editing programs

● Setting offset values

● Measuring tools

Protection level 7 is set automatically if no password is set and no protection level interface signal is set. The protection level

7 can be set from the PLC user program by setting the bits in the user interface.

In the menus listed below the input and modification of data depends on the set protection level:

● Tool offsets

● Work offsets

● Setting data

● RS232 settings

● Program creation/program correction

The number of machine data and drive data which can be read or modified depends on the protection level. You can set the

protection level for these function areas with the display machine data (

End users

...).

You can set the desired password through the following operating area:

Programming and Operating Manual (Turning)

+

→

14 6FC5398-5DP10-0BA1, 01/2014

Page 15

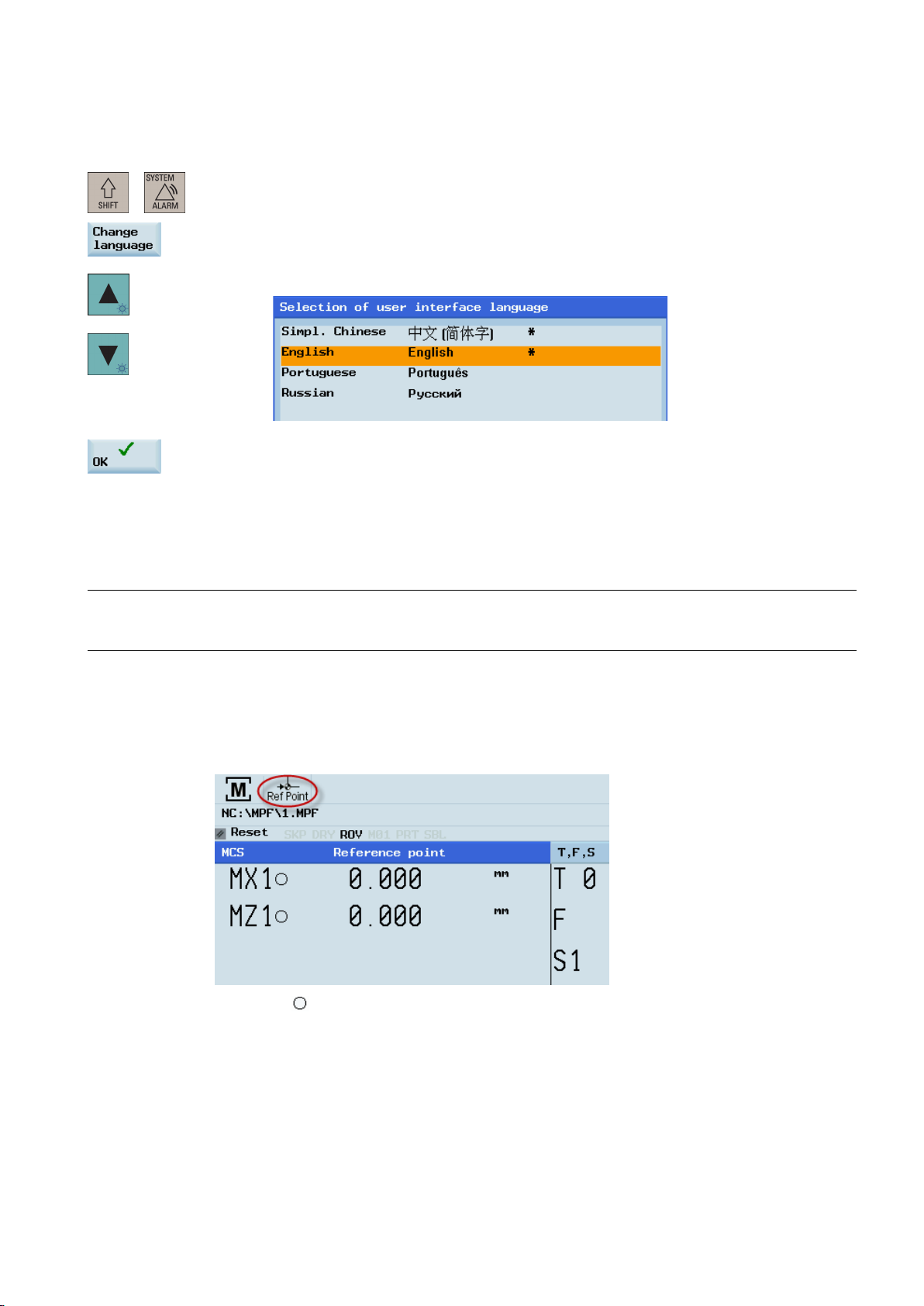

1.5

Setting user interface language

Operating sequence

Note:

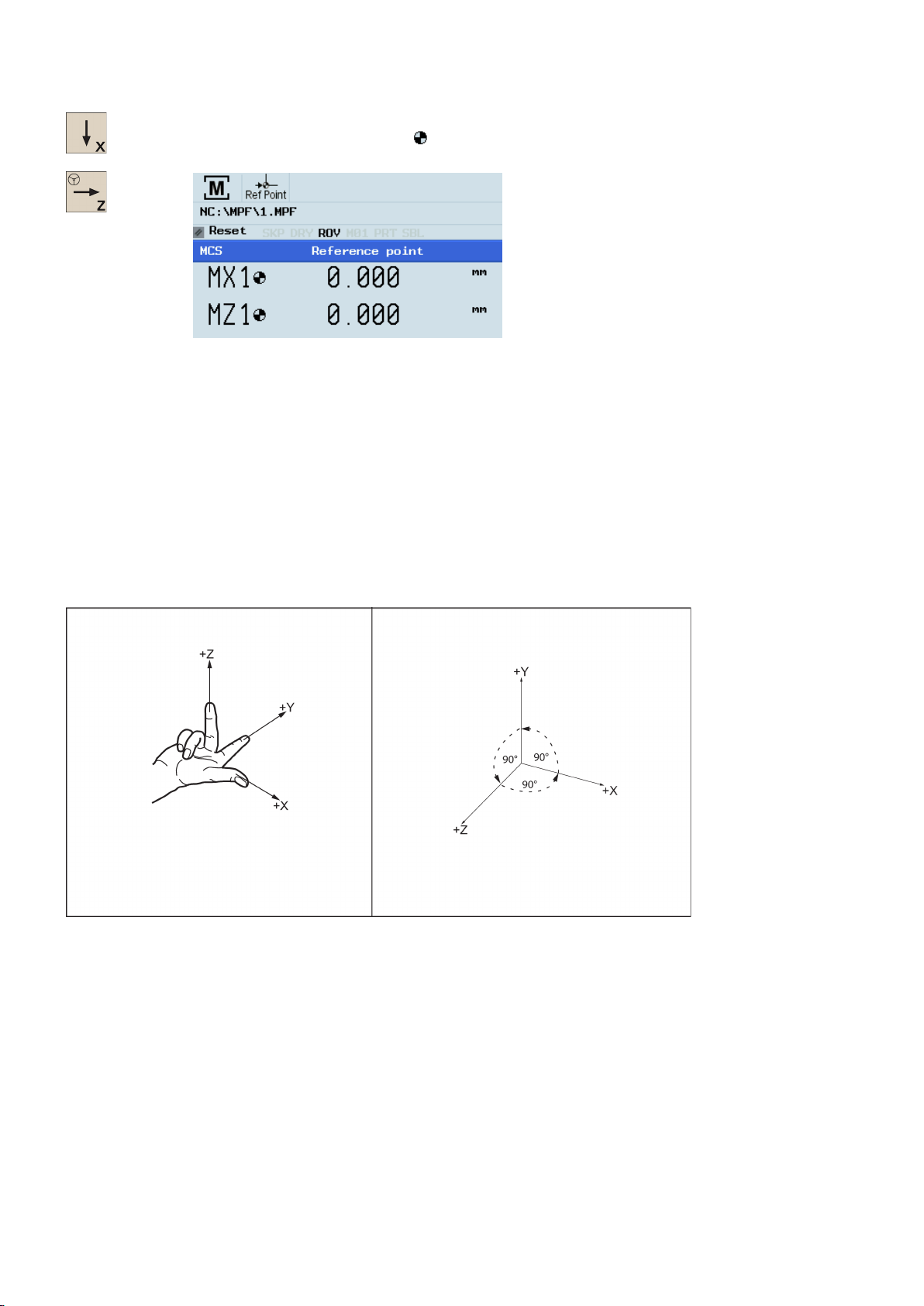

2

Turning on, reference point approach

Note

Operating sequence

identifier indicates that the axis is not yet referenced. If an axis is

+

1. Select the desired operating area.

2. Press this softkey to open the user interface language selection window.

3. Use the cursor keys to select the desired language.

4. Press this softkey to confirm your selection.

The HMI (Human Machine Interface) is automatically restarted when a new language is

selected.

When turning on the CNC and the machine, also observe the machine tool manufacturer's documentation, since turning-on

and reference point approach are machine-dependent functions.

1. Switch on the power supply for the control system and the machine.

2. Release all emergency stop buttons on the machine.

By default, the control system is in the "REF POINT" window after booting.

The symbol

not referenced, the symbol is always visible in the current (machining) operating area.

shown next to the axis

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

15

Page 16

) appears next to the axis identifier and is visible only in the "REF

3

Setting-up

3.1

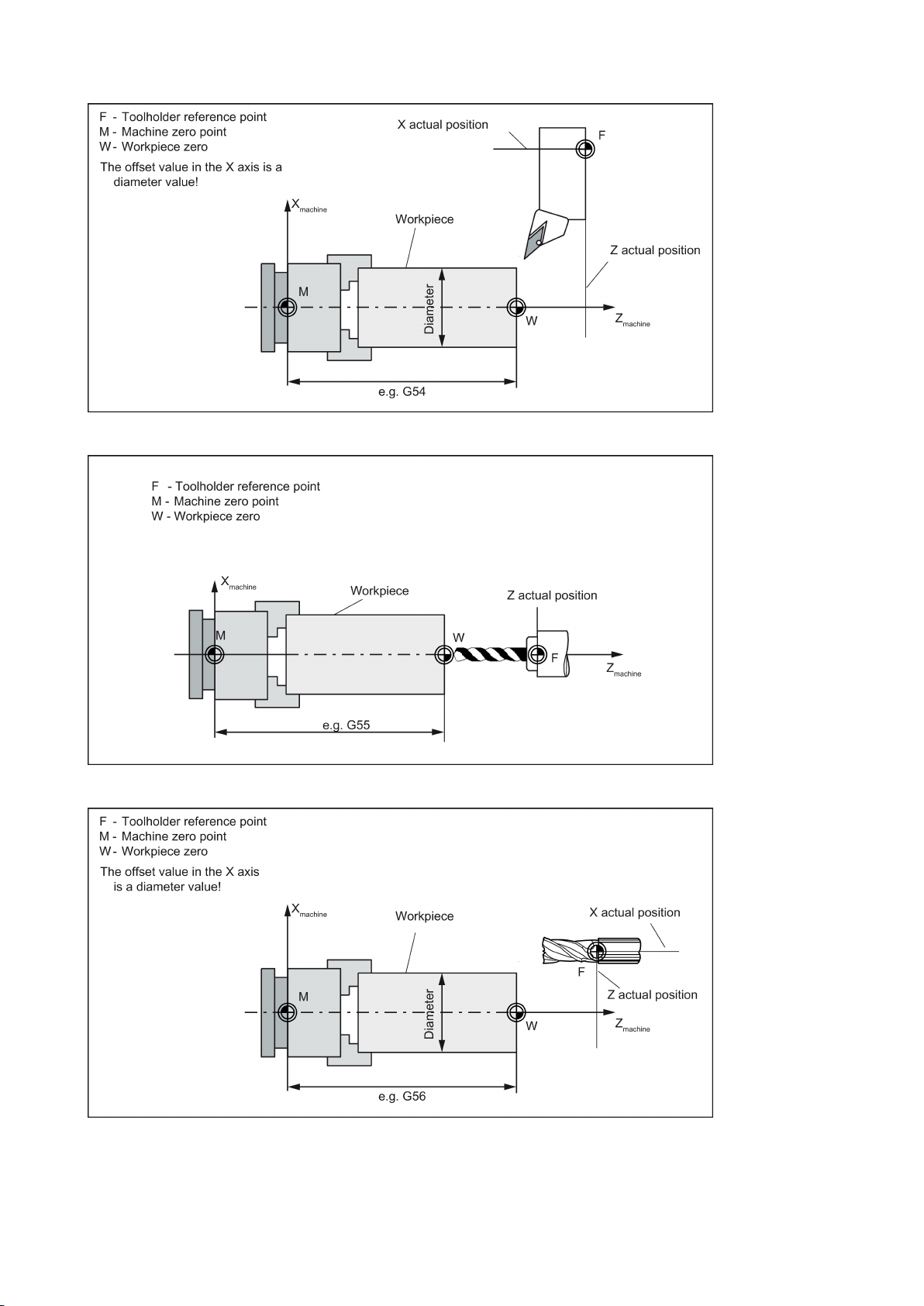

Coordinate systems

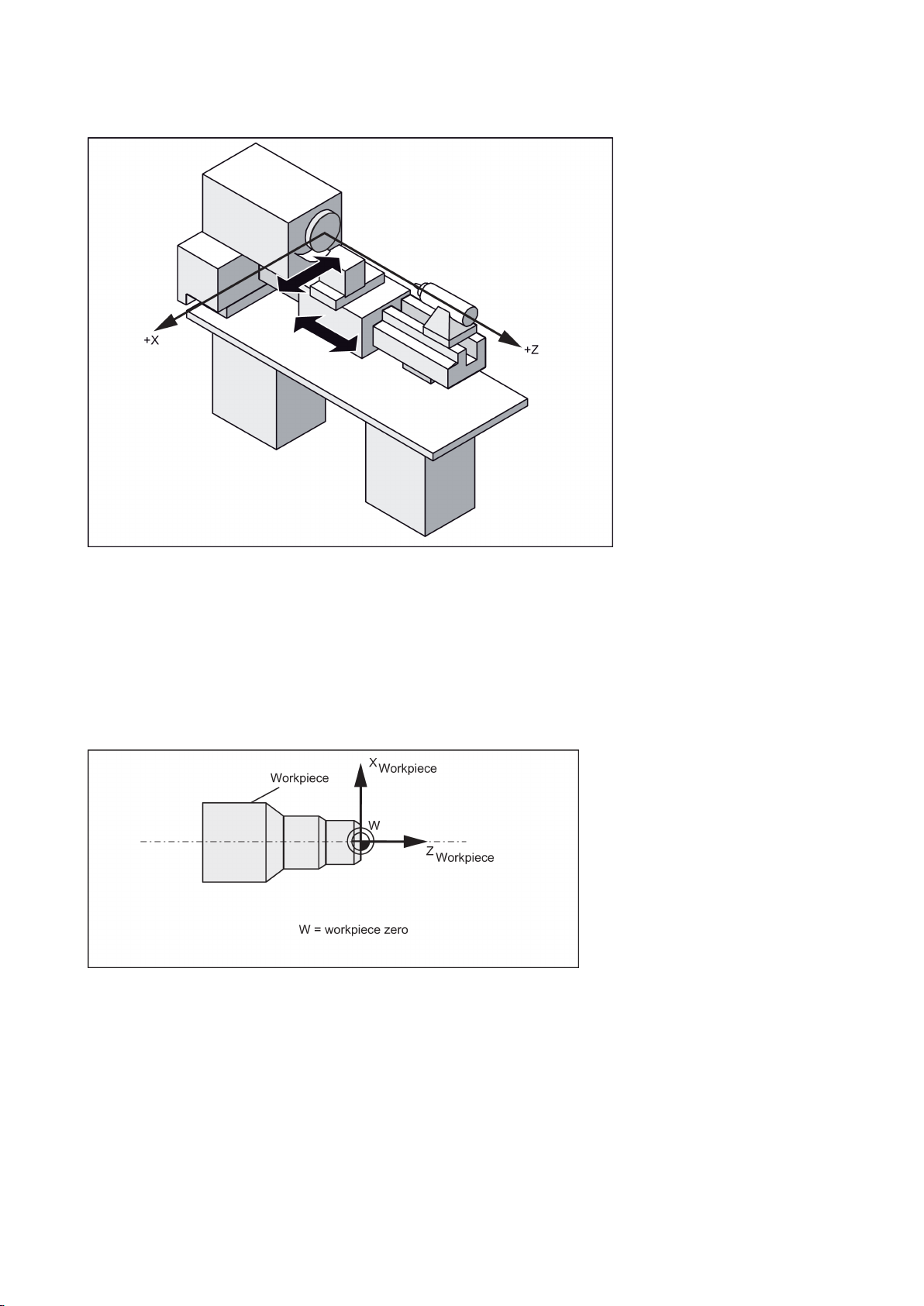

Machine coordinate system (MCS)

3. Press the corresponding axis traversing keys on the MCP to traverse each axis to the reference point.

If the axis is referenced, a symbol (

POINT" window.

Note that axis traversing directions and axis key functions are defined by the machine manufacturer.

As a rule, a coordinate system is formed from three mutually perpendicular coordinate axes. The positive directions of the

coordinate axes are defined using the so-called "3-finger rule" of the right hand. The coordinate system is related to the

workpiece and programming takes place independently of whether the tool or the workpiece is being traversed. When

programming, it is always assumed that the tool traverses relative to the coordinate system of the workpiece, which is

intended to be stationary.

The figure below illustrates how to determine the axis directions.

The orientation of the coordinate system relative to the machine depends on the machine type. It can be rotated in different

positions.

The directions of the axes follow the "3-finger rule" of the right hand. Seen from the front of the machine, the middle finger of

the right hand points in the opposite direction to the infeed of the spindle.

Programming and Operating Manual (Turning)

16 6FC5398-5DP10-0BA1, 01/2014

Page 17

machine zero.

machine axes

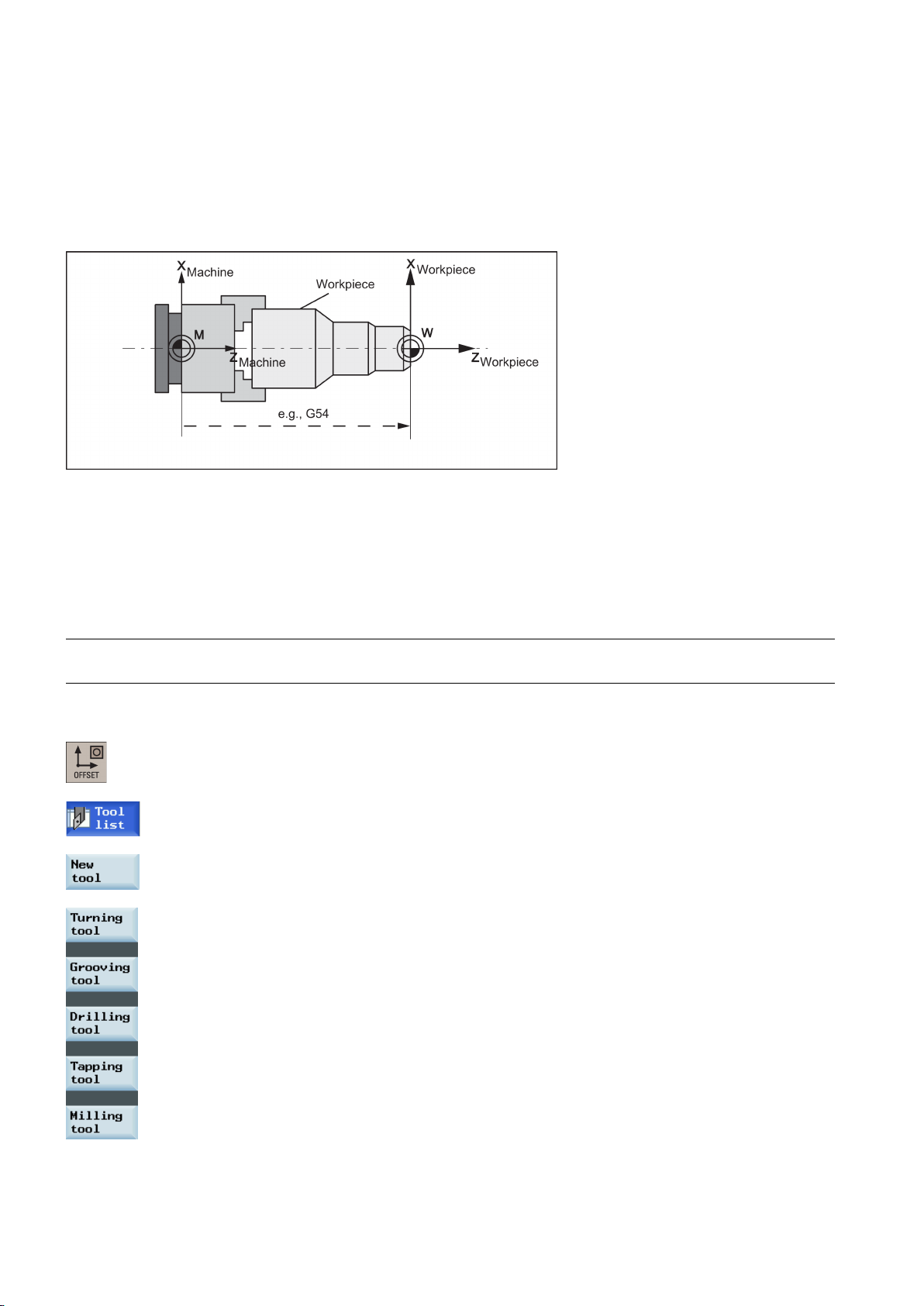

Workpiece coordinate system (WCS)

workpiece zero

Relative coordinate system (REL)

The figure below shows an example of the machine coordinate system of a turning machine.

The origin of this coordinate system is the

This point is only a reference point which is defined by the machine manufacturer. It does not have to be approachable.

The traversing range of the

can be in the negative range.

To describe the geometry of a workpiece in the workpiece program, a right-handed, right-angled coordinate system is also

used.

The

can be freely selected by the programmer in the Z axis. In the X axis, it lies in the turning center.

The figure below shows an example of the workpiece coordinate system.

In addition to the machine and workpiece coordinate systems, the control system provides a relative coordinate system. This

coordinate system is used to set reference points that can be freely selected and have no influence on the active workpiece

coordinate system. All axis movements are displayed relative to these reference points.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

17

Page 18

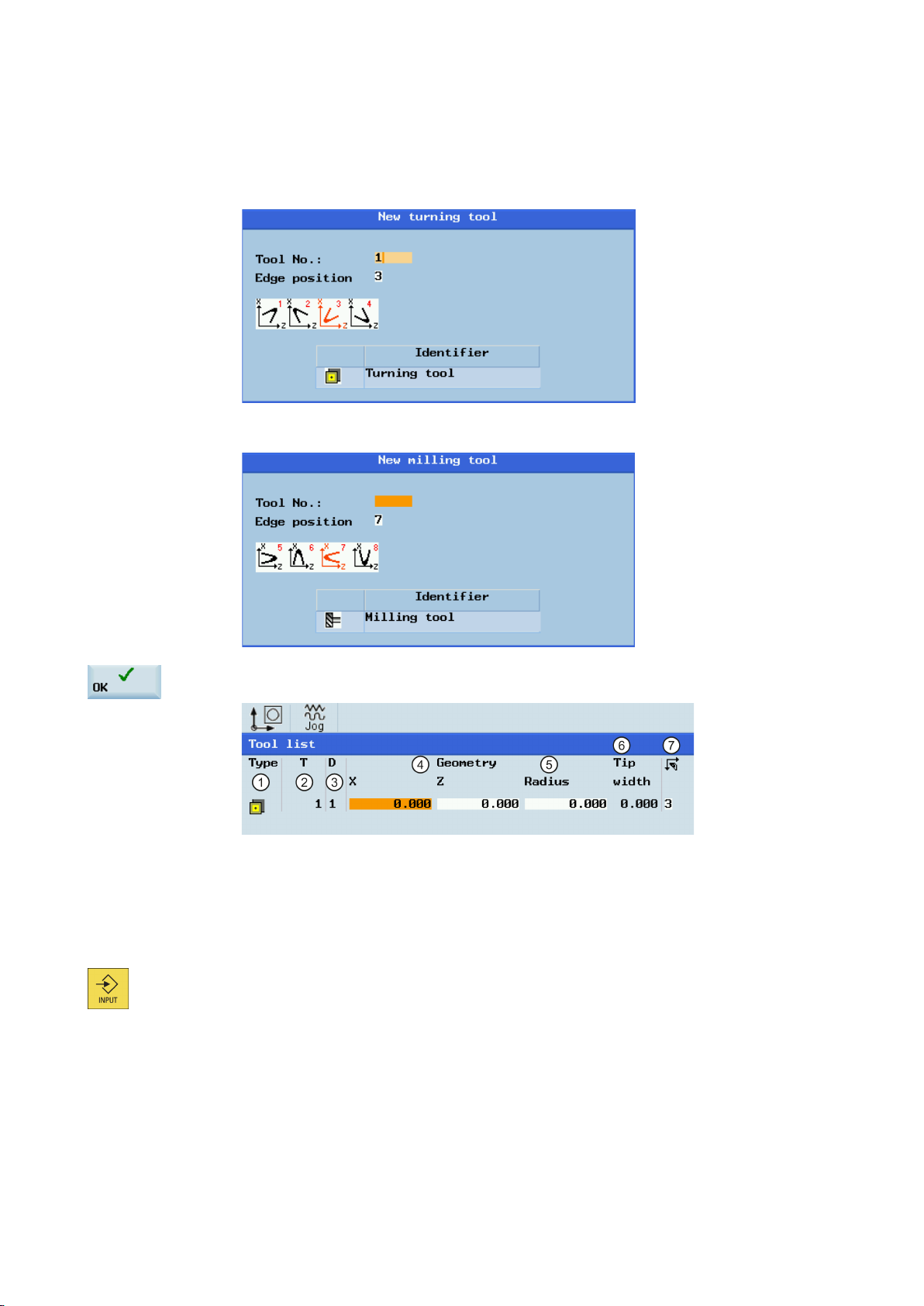

Clamping the workpiece

settable work

offset

G54

Current workpiece coordinate system

3.2

Setting up tools

3.2.1

Creating a new tool

Note

Operating sequence

For machining, the workpiece is clamped on the machine. The workpiece must be aligned such that the axes of the

workpiece coordinate system run in parallel with those of the machine. Any resulting offset of the machine zero with

reference to the workpiece zero is determined along the Z axis and entered in a data area intended for the

. In the NC program, this offset is activated during program execution, for example, using a programmed

command.

The figure below shows an example of the workpiece clamped on the machine.

The programmed work offset TRANS (Page 53) can be used to generate an offset with reference to the workpiece

coordinate system, resulting in the current workpiece coordinate system.

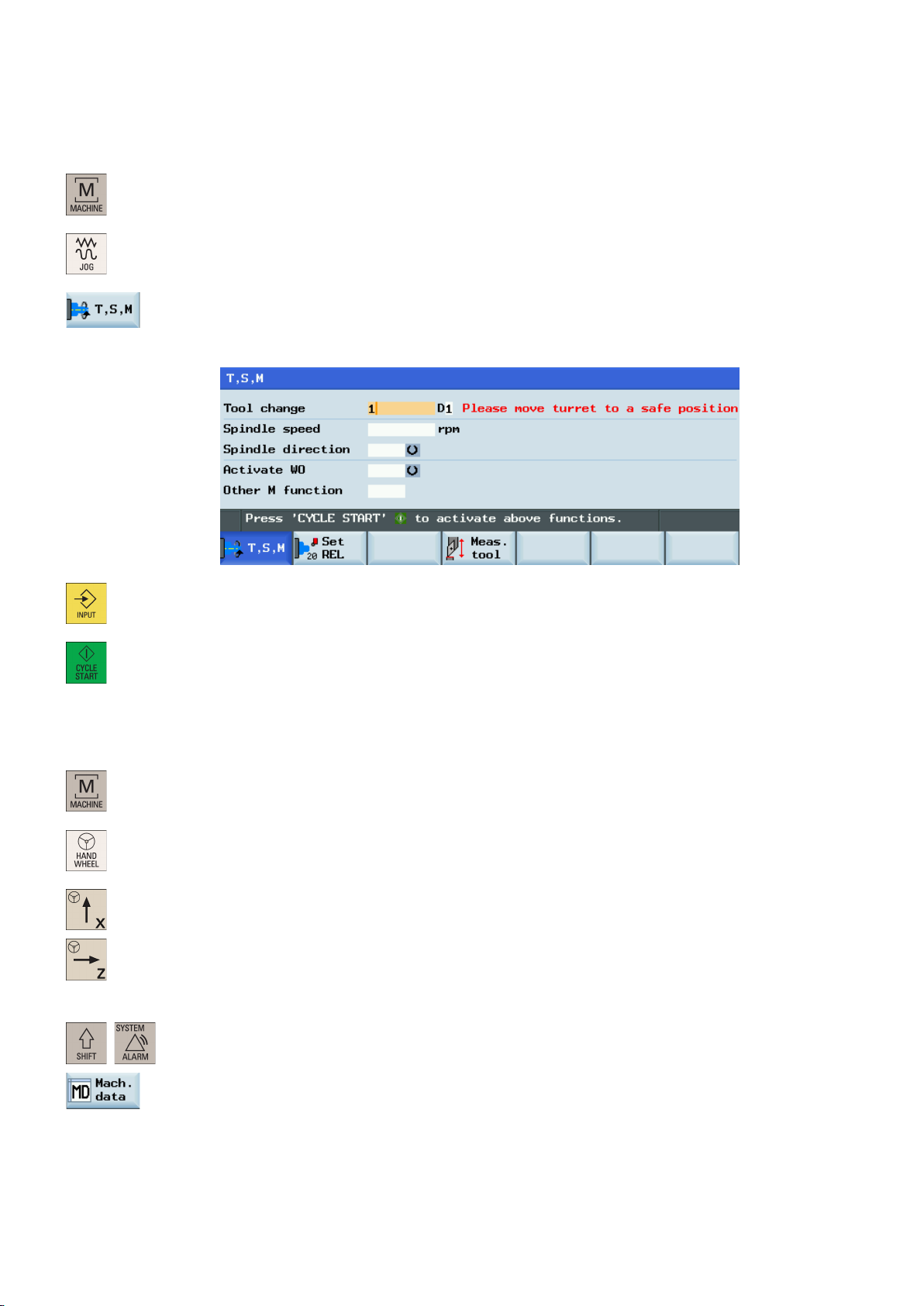

The control system supports a maximum of 64 tools or 128 cutting edges.

1. Select the desired operating area.

2. Open the tool list window.

3. Open the lower-level menu for tool type selection.

4. Select a desired tool type with the corresponding softkey.

Programming and Operating Manual (Turning)

18 6FC5398-5DP10-0BA1, 01/2014

Page 19

Available edge positions for turning tool and grooving tool: 1, 2, 3 and 4 (taking new turning tool

5. Enter the tool number (value range: 1 to 31999; preferentially enter a value less than 100) and

select the corresponding tool edge position code according to the actual tool point direction in the

following windows:

●

as an example)

● Available edge positions for drilling tool, tapping tool and milling tool: 5, 6, 7 and 8 (taking new

milling tool as an example)

6. Use this softkey to confirm your settings. The window below shows the information of the new tool

created.

①

②

③

④

7. Enter the tool radius data or tool tip width as desired and confirm your settings.

Tool type

Tool number

Cutting edge number

Tool length in the X and Z axes

⑤

⑥

⑦

Tool radius

Tip width of the cutting edge, which is

only active for the grooving tool

Cutting edge direction

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

19

Page 20

3.2.2

Activating the tool

Operating sequence

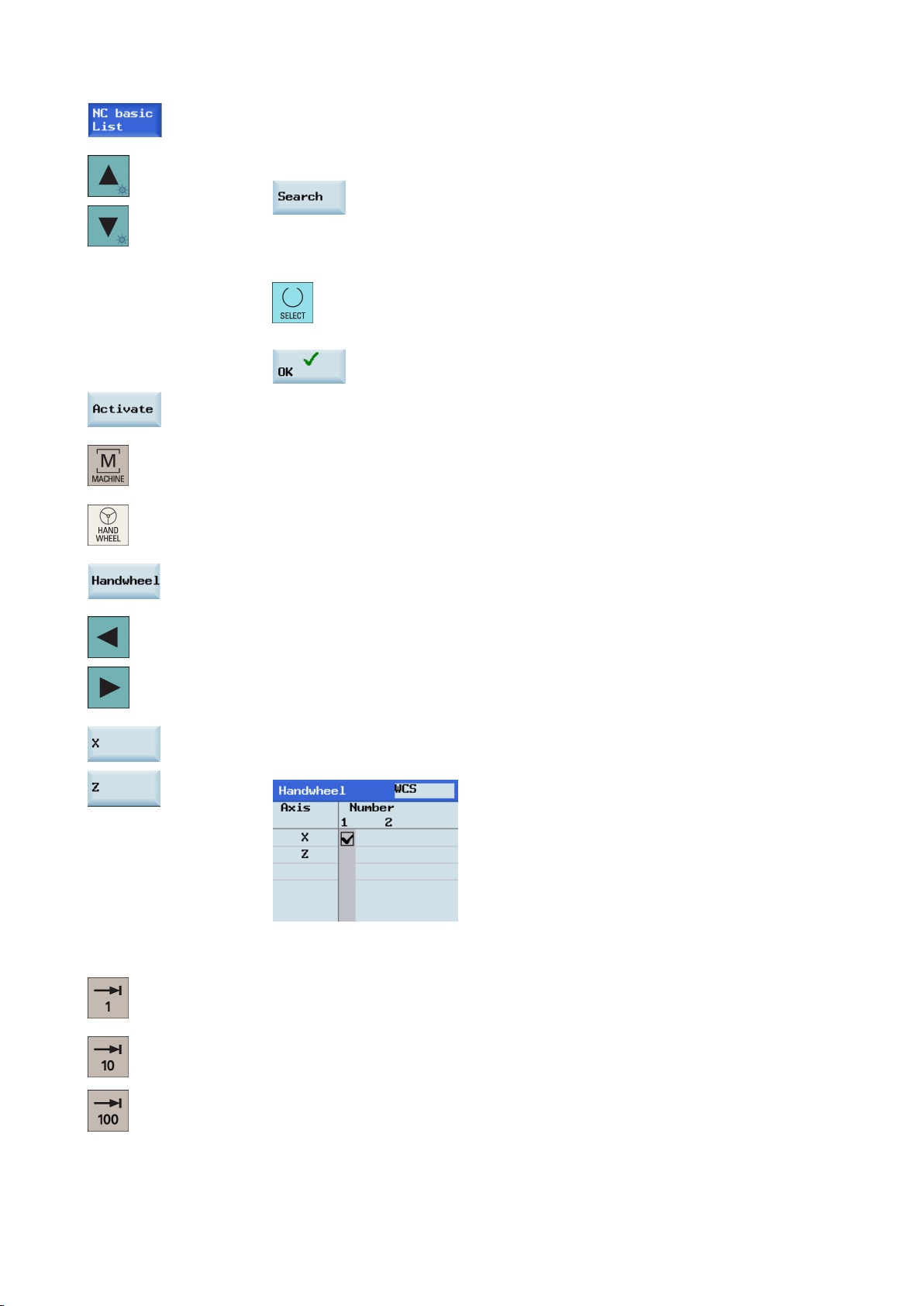

3.2.3

Assigning the handwheel

Method 1: Assigning through the MCP

Method 2: Assigning through the PPU

4. Enter the desired tool number (for example, 1) in the "T, S, M" window.

1. Select the desired operating area.

2. Switch to "JOG" mode.

3. Open the "T, S, M" window.

5. Use this key or move the cursor to confirm your entries.

6. Press this key on the MCP to activate the tool.

+

1. Select the desired operating area.

2. Press this key on the MCP to control the axis movement with external handwheels.

3. Press the desired axis traversing key with the handwheel icon. The handwheel is assigned.

1. Select the desired operating area.

2. Open the machine data window.

Programming and Operating Manual (Turning)

20 6FC5398-5DP10-0BA1, 01/2014

Page 21

3.

Press this softkey to open the basic machine data list.

4.

Use the cursor keys or the following softkey to search for the general machine data "14512

5.

Select "Bit7" by using the following key and cursor keys:

Press the following softkey to confirm your input.

6.

Press this vertical softkey to activate the value change. Note that the control system restarts to

7.

After the control system has booted, select the desired operating area.

8.

Press this key on the MCP.

USER_DATA_HEX[16]".

accept the new value.

Press this vertical softkey to open the handwheel assignment window.

9.

Select the desired handwheel number with the cursor left/right key.

10.

Press the relevant axis softkey for handwheel assignment or deselection.

11.

The symbol "☑" that appears in the window indicates a handwheel has been assigned to the

specific axis.

12.

Select the required override increment. The selected axis can now be moved with the

handwheel.

The override increment is 0.001 mm.

The override increment is 0.010 mm.

The override increment is 0.100 mm.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

21

Page 22

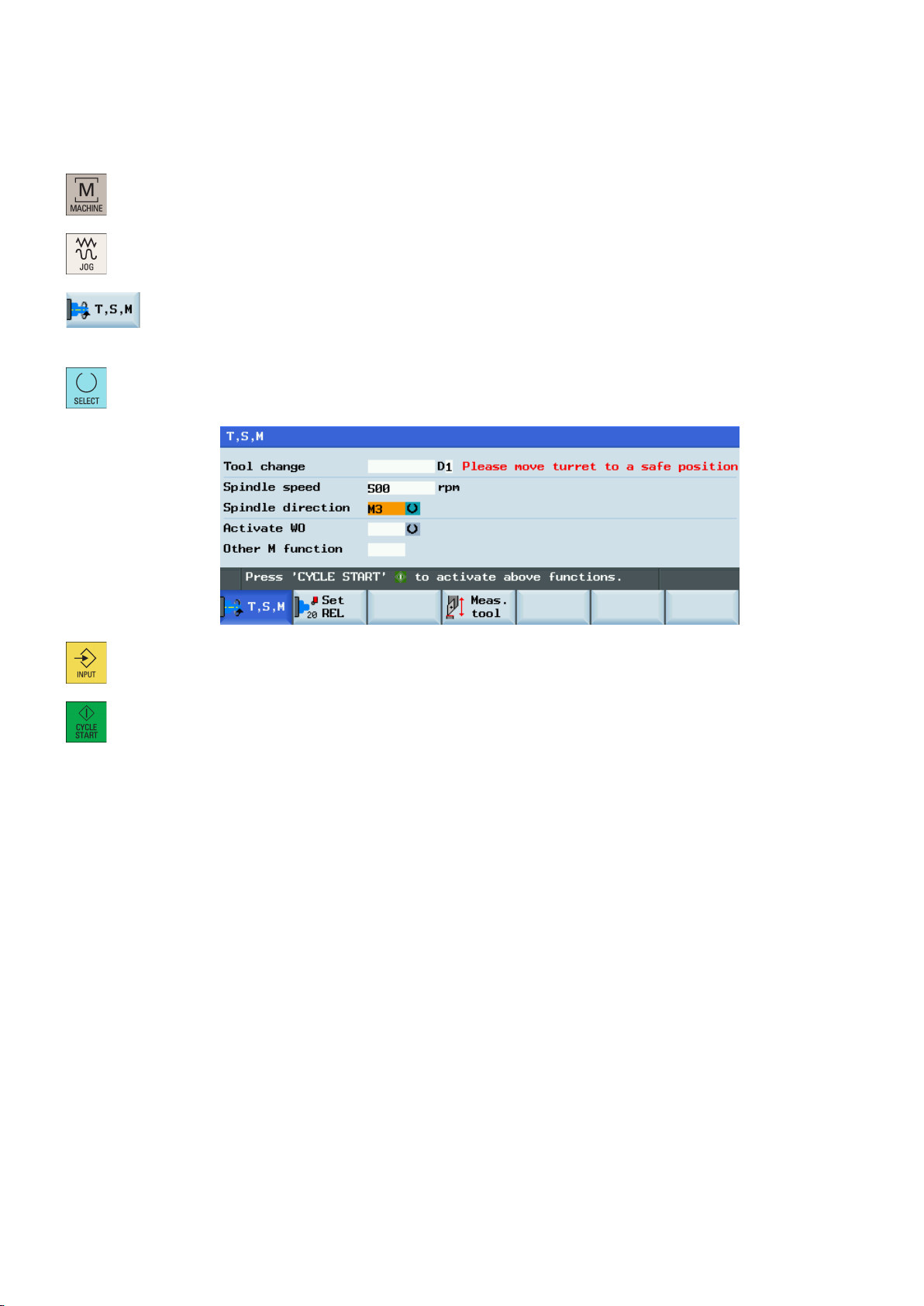

3.2.4

Activating the spindle

Operating sequence

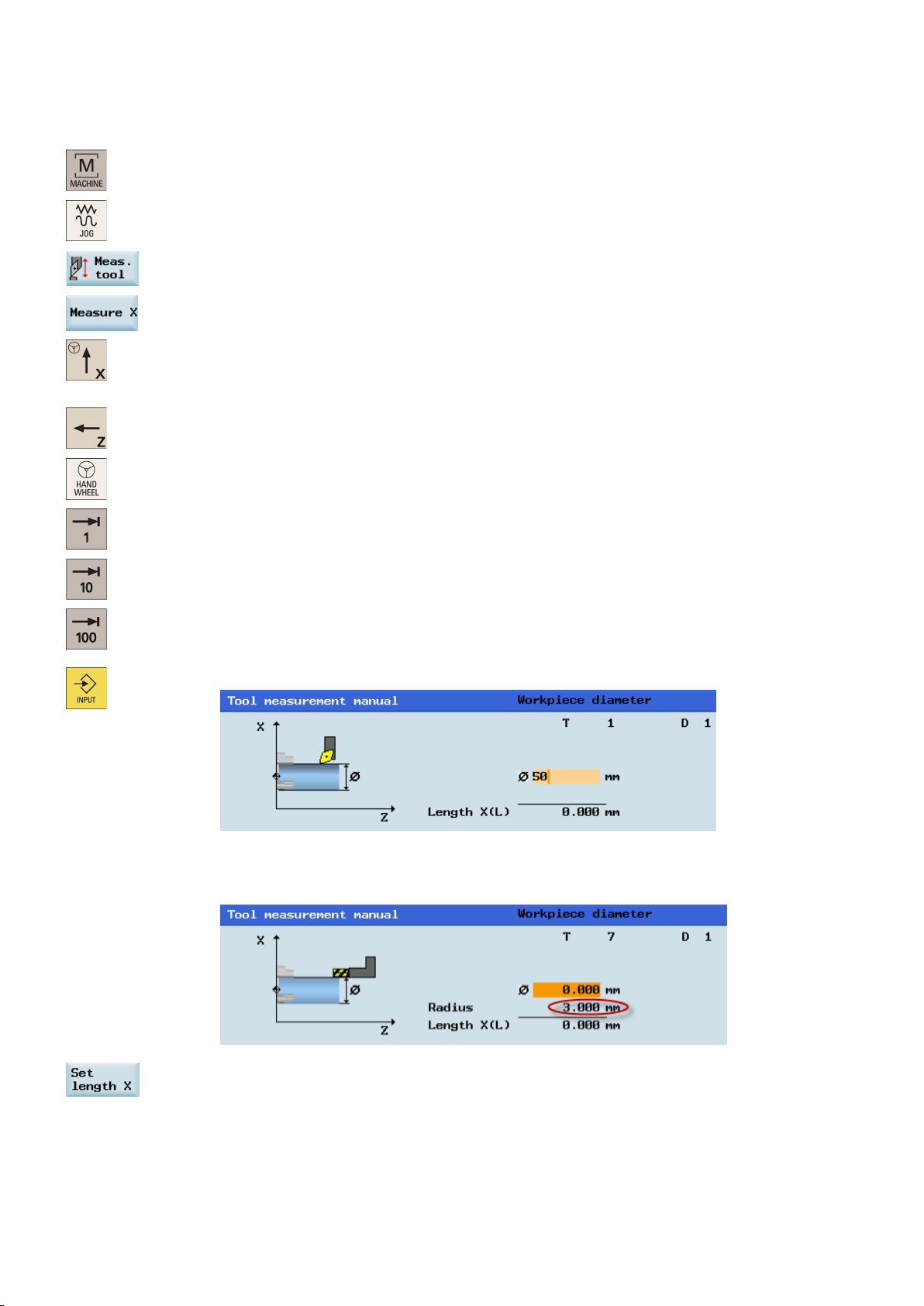

3.2.5

Measuring the tool (manually)

Overview

4. Enter the desired value for the spindle speed in the "T, S, M" window.

1. Select the desired operating area.

2. Switch to "JOG" mode.

3. Open the "T, S, M" window.

5. Press this key to select the spindle direction.

6. Use this key or move the cursor to confirm your entries.

7. Press this key on the MCP to activate the spindle.

The geometries of the machining tool must be taken into consideration when you execute a part program. These are stored

as tool offset data in the tool list. Each time the tool is called, the control considers the tool offset data.

You can determine the tool offset data, including the length, radius and diameter by either measuring the tool or entering the

values in the tool list (see Section "Creating a new tool (Page 18)" for more information).

As per the actual position of the point F (the machine coordinate) and the reference point, the control system can calculate

the offset value assigned to the lengths for the X and Z axes.

Programming and Operating Manual (Turning)

22 6FC5398-5DP10-0BA1, 01/2014

Page 23

Figure 3-1 Determining the length offsets using the example of a turning tool

Figure 3-2 Determining the length offsets using the example of a drill: Length 1/Z axis

Figure 3-3 Determining the length offsets using the example of a milling tool

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

23

Page 24

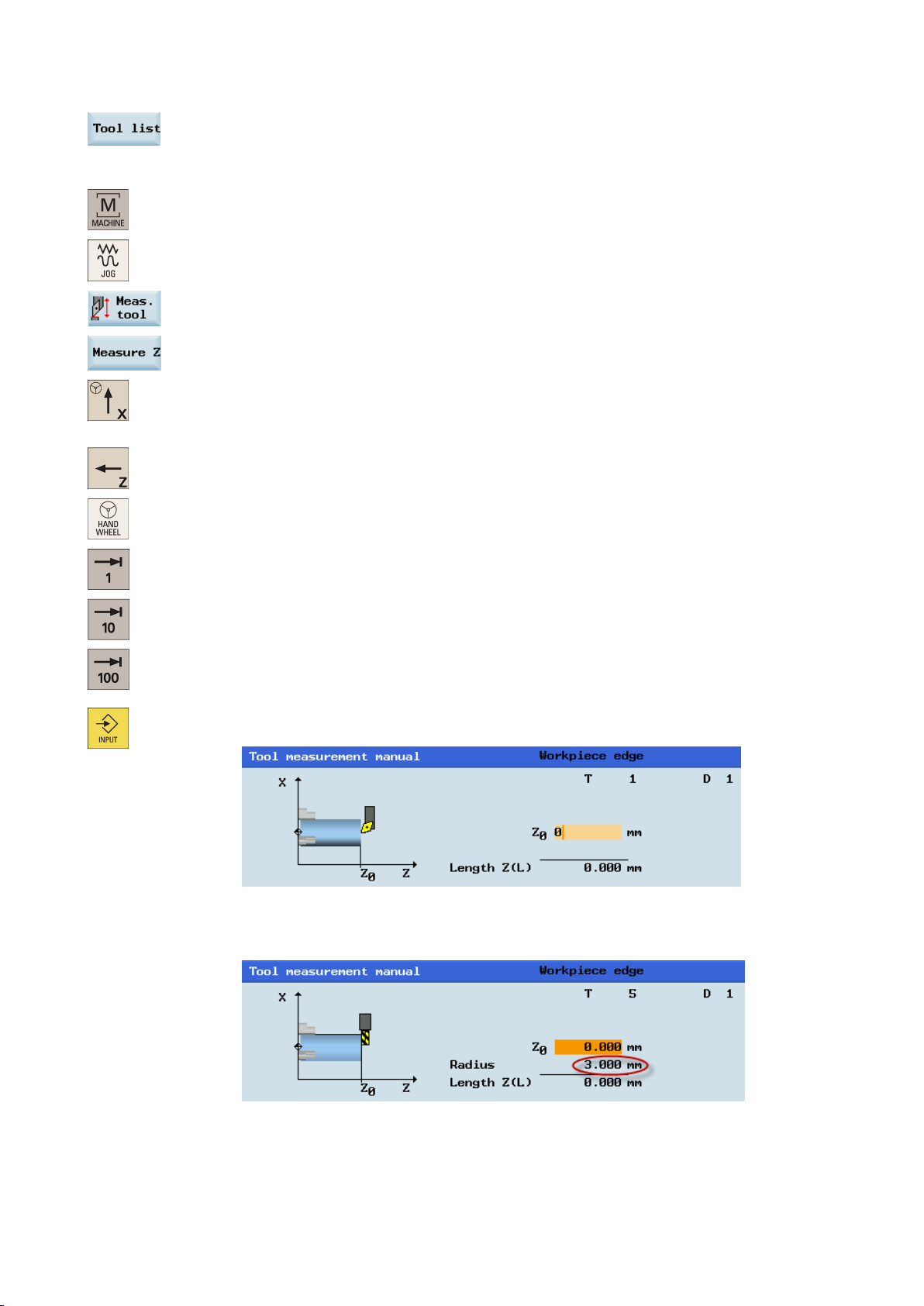

Operating sequence

Measuring the tool in the X direction

1.

Select the desired operating area.

2.

Switch to "JOG" mode.

3.

Open the manual tool measurement window.

4.

Press this vertical softkey to measure the tool in the X direction.

5.

Move the tool to approach the workpiece in the X direction.

6.

Switch to handwheel control mode.

7.

Select a suitable override feedrate, and then use the handwheel to move the tool to scratch the

Note:

...

required workpiece edge (or the edge of the setting block, if it is used).

8. Enter the workpiece diameter in the "Ø" field (for example, 50).

For a milling tool with edge position 5 or 7, the radius of the tool itself is displayed in the following

window:

9. Save the length value in the X axis. The tool diameter, radius, and cutting edge position are all

taken in to account.

Programming and Operating Manual (Turning)

24 6FC5398-5DP10-0BA1, 01/2014

Page 25

Measuring the tool in the Z direction

1.

Select the desired operating area.

2.

Switch to "JOG" mode.

3.

Open the manual tool measurement window.

4.

Press this vertical softkey to measure the tool in the Z direction.

5.

Move the tool to approach the workpiece in the Z direction.

6.

Switch to handwheel control mode.

7.

Select a suitable override feedrate, and then use the handwheel to move the tool to scratch the

Note:

10. Press this softkey and you can see that the compensation data values have been automatically

added to the tool data.

...

required workpiece edge (or the edge of the setting block, if it is used).

8. Enter the distance between the tool tip and the workpiece edge in the "Z0" field, for example, "0".

(This value is the thickness of a setting block if it is used.)

For a milling tool with edge position 6 or 8, the radius of the tool itself is displayed in the following

window:

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

25

Page 26

9.

Save the length value in the Z axis.

10.

Press this softkey and you can see that the compensation data values have been automatically

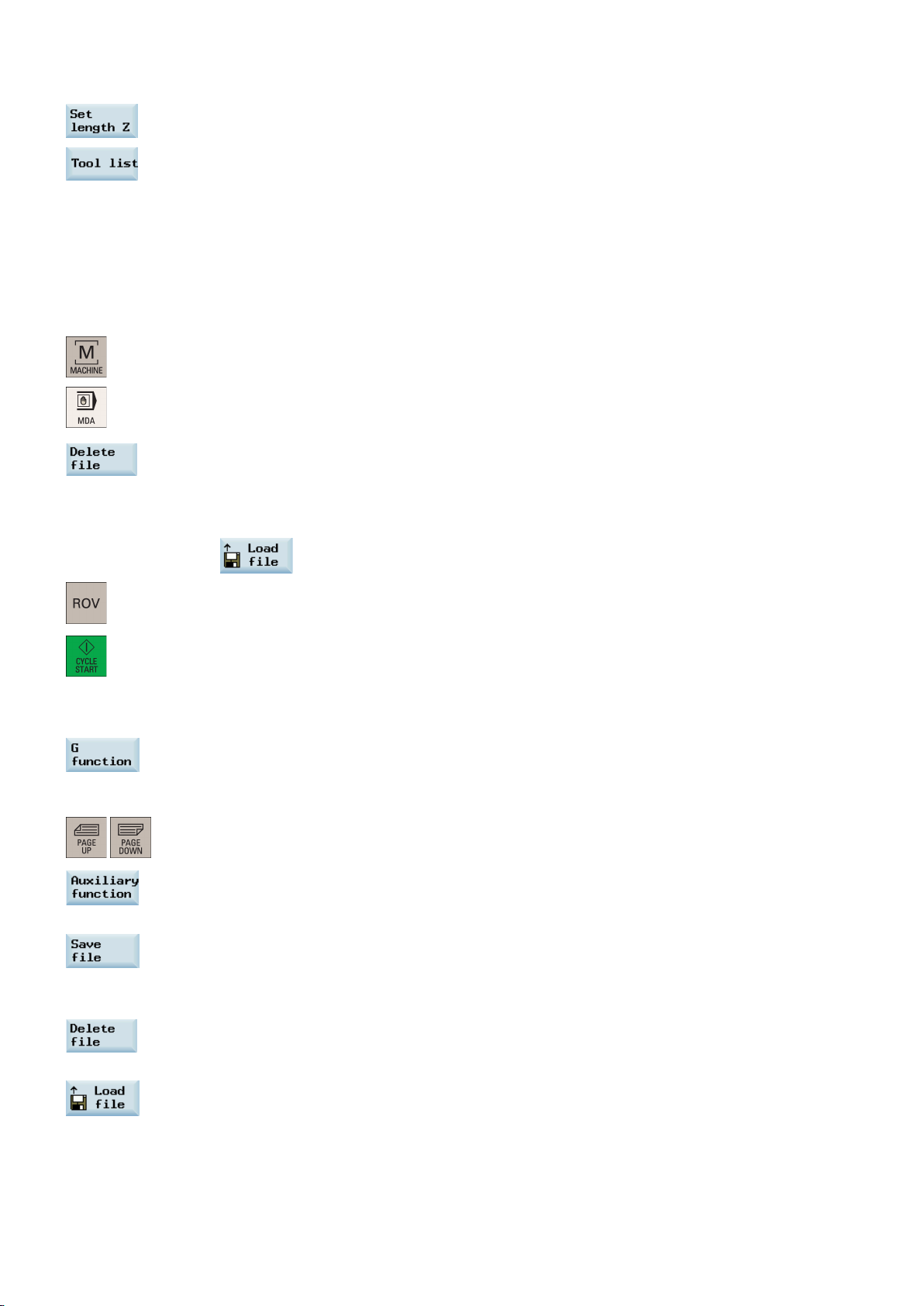

3.2.6

Verifying the tool offset result in "MDA" mode

Operating sequence

1.

Select the desired operating area.

2.

Switch to "MDA" mode.

3.

Press this softkey on the PPU.

4.

Enter the test program, for example: G500 T1 D1 G00 X0 Z5.

You can alternatively load an existing part program from a system directory using the following

5.

Press this key to ensure the "ROV" function is active (lit up).

Note:

6.

Press this key on the MCP.

Further softkey functions in "MDA" mode

Note:

Repeat the above operations for other tools and make sure you measure all the tools before machining, which also eases

the tool changing process.

In order to ensure the machine safety and correctness, you must test the results of the tool offset appropriately.

added to the tool data.

softkey if desired:

The "ROV" function activates the feedrate override switch under the G00 function.

To display additional G functions, use the following keys:

If you do not save with this softkey, the program edited in "MDA" mode is actually a temporary file.

Increase the feedrate override gradually to avoid accidents caused by an axis moving too fast and

observe whether the axis moves to the set position.

This window displays important G functions whereby each G function is assigned to a group and has a

fixed position in the window. To close the window, press this softkey once again.

This window displays the auxiliary and M functions currently active. To close the window, press this

softkey once again.

This softkey opens the file saving window where you can specify a name and a storage medium for the

program displayed in the MDA window. To save your program, either enter a new program name in the

input field or select an existing program for overwriting.

Pressing this softkey deletes all the blocks displayed in the MDA window.

This softkey opens a window where you can select an existing program file from a system directory to

load into the MDA buffer.

For the explanation of other softkeys in this mode, refer to Section "Other settings in "JOG" mode (Page 211)".

Programming and Operating Manual (Turning)

26 6FC5398-5DP10-0BA1, 01/2014

Page 27

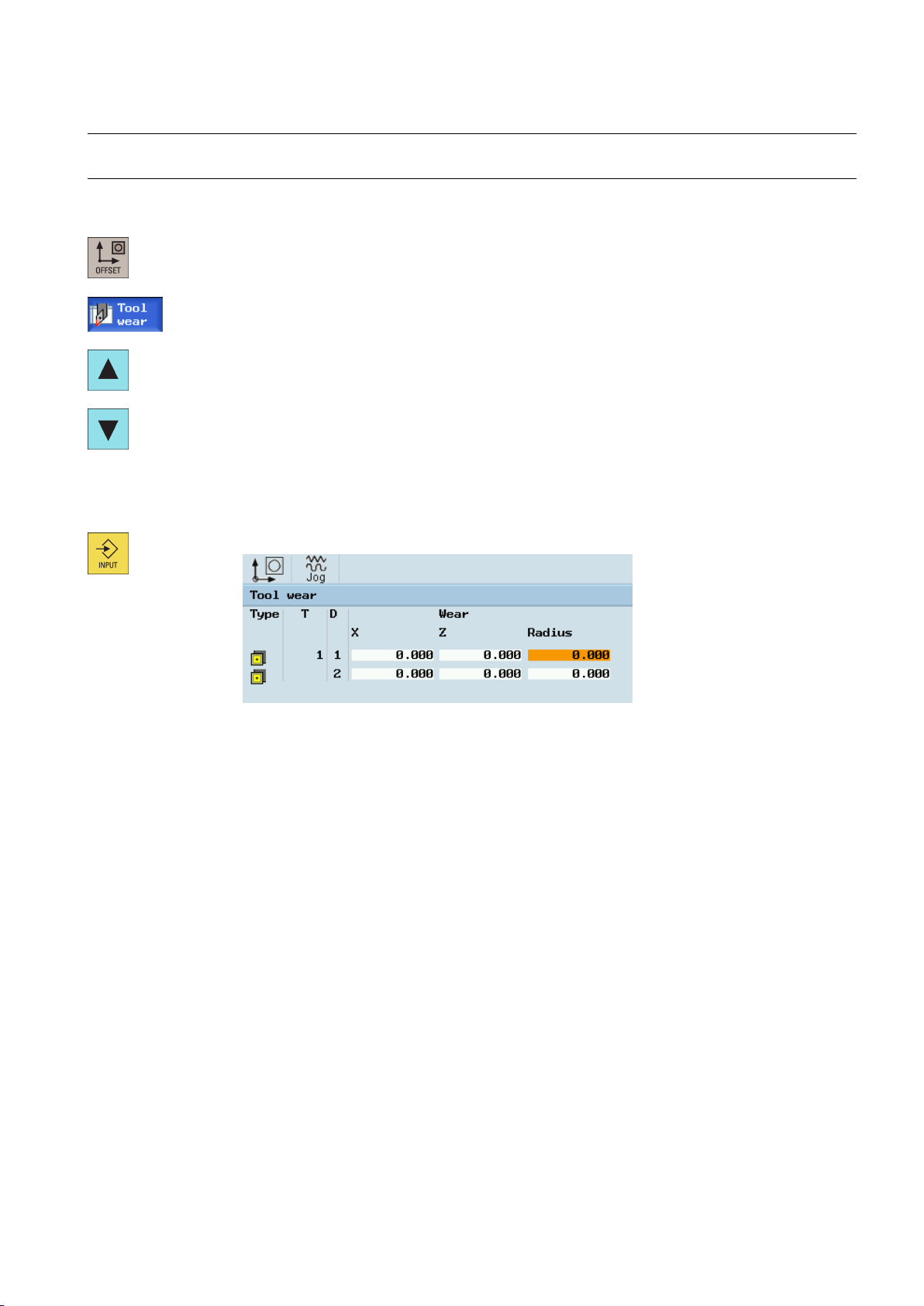

3.2.7

Entering/modifying the tool wear data

Note

Operating sequence

Enter the tool length wear parameter of axis X and axis Z as well as the tool radius wear parameter.

You must distinguish the direction of tool wear compensation clearly.

4.

1. Select the desired operating area.

2. Open the tool wear window.

3. Use the cursor keys to select the required tools and their edges.

Positive value: The tool moves away from the workpiece.

Negative value: The tool moves closer to the workpiece.

5. Press this key or move the cursor to activate the compensation.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

27

Page 28

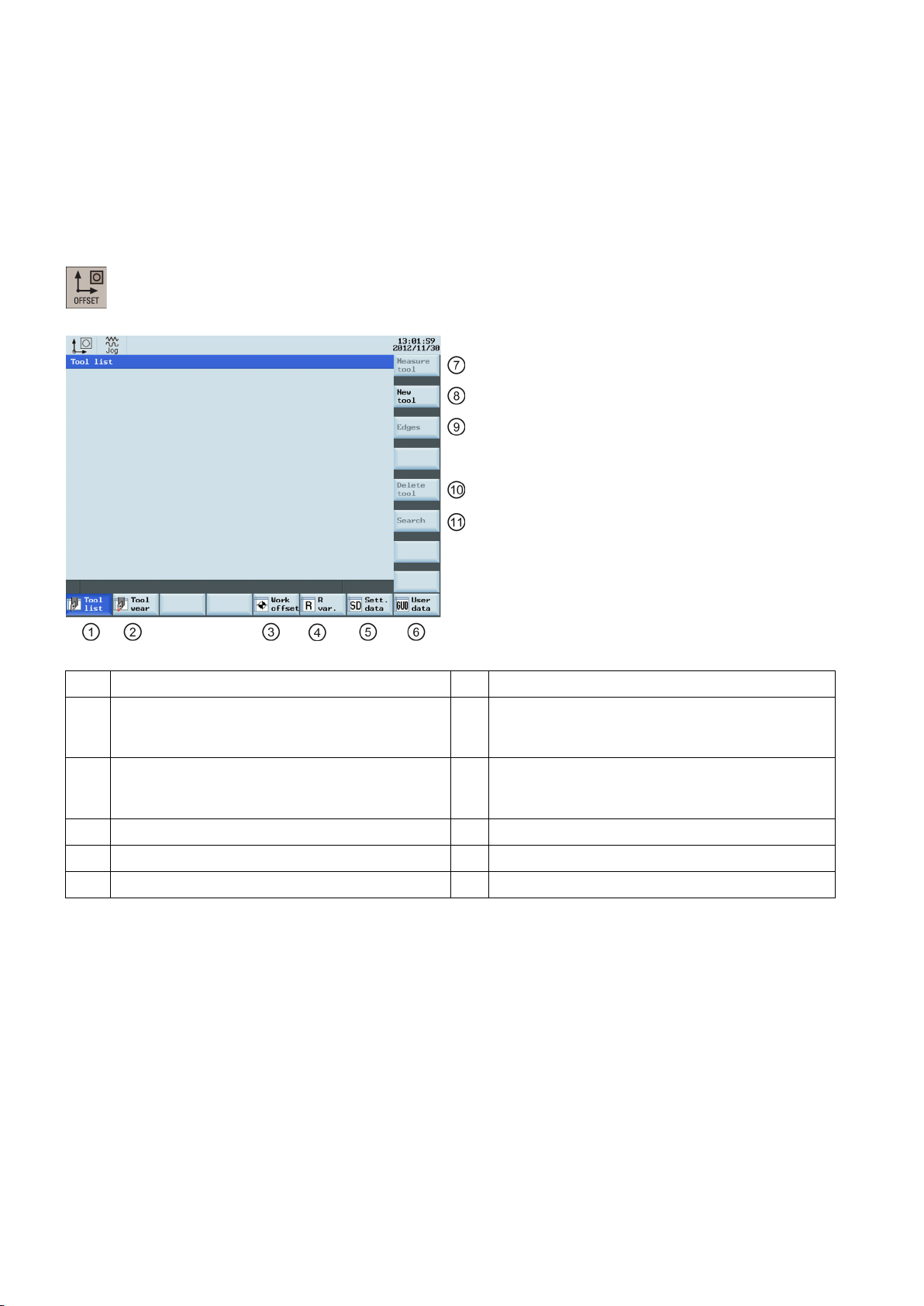

3.3

Operating area overview

Softkey functions

When working with the CNC, you need to set up the machine and the tools, etc. as follows:

● Create the tools and cutting edges.

● Enter/modify the tool and work offsets.

● Enter the setting data.

Pressing this key on the PPU allows you to open the following window:

Displays and modifies the tool offsets

①

Displays and modifies the tool wear data

②

Displays and modifies the work offsets

③

Displays and modifies the R variables

④

Configures and displays lists of setting data

⑤

Displays the defined user data

⑥

Measures the tool manually

⑦

Creates a new tool

⑧

For more information, see Section "Creating a new

tool (Page 18)".

Opens a lower-level menu for cutting edge settings

⑨

For more information, see Section "Creating a new

cutting edge (Page 204)".

Removes the currently selected tool from the tool list

⑩

Searches for your desired tool with the tool number

⑪

Programming and Operating Manual (Turning)

28 6FC5398-5DP10-0BA1, 01/2014

Page 29

4

Part programming

Softkey functions

The SINUMERIK 808D ADVANCED control system can store a maximum of 300 part programs which include those created

by the control system for certain functions such as MM+, TSM, and so on.

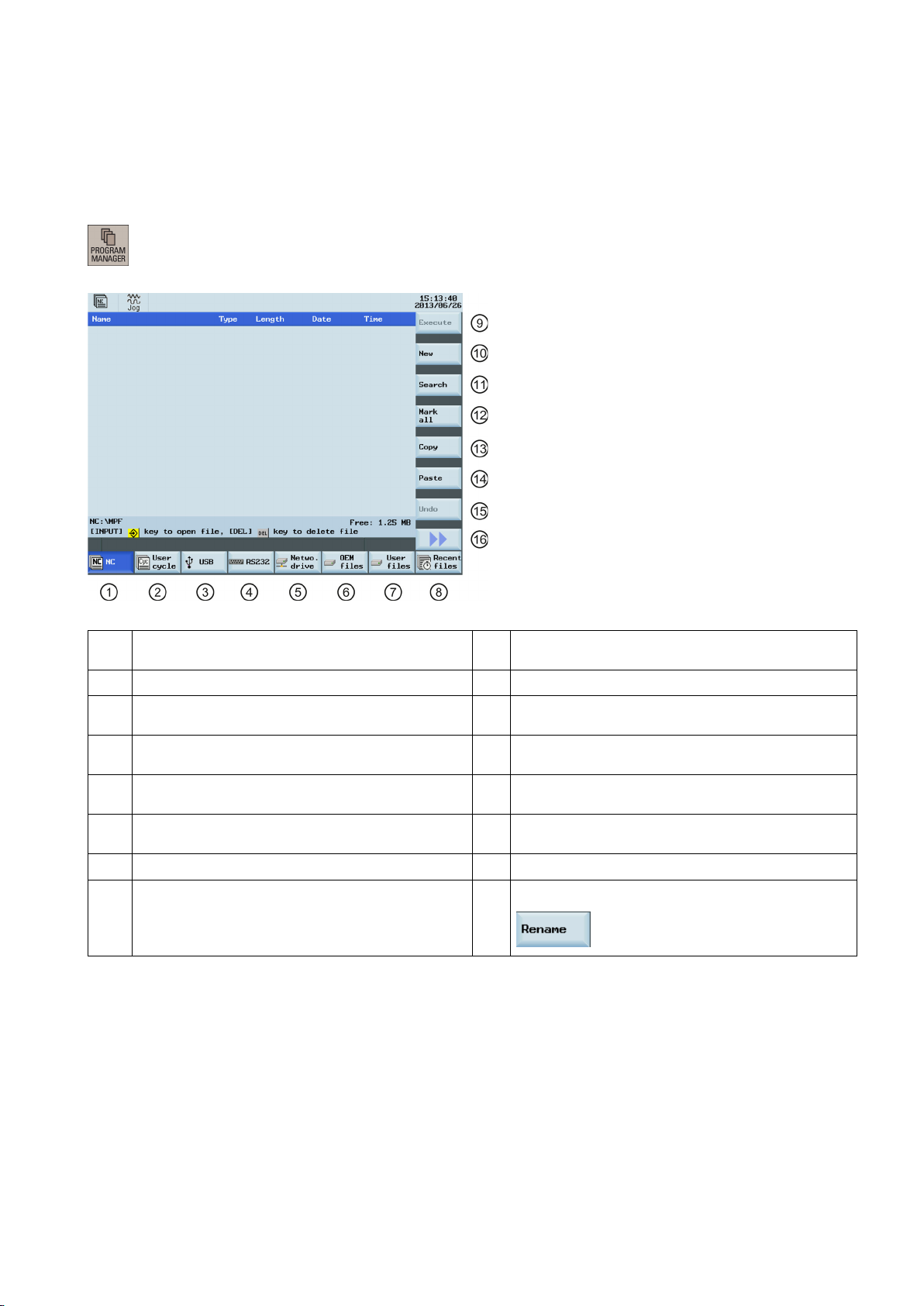

Pressing this key on the PPU allows you to open the following window:

Stores the NC programs for subsequent operations

①

Manages and transfers the manufacturer cycles

②

Reads in/out files via the USB drive and executes the

③

program from the external storage media

Reads in/out files via the RS232 interface and

④

executes the program from an external PC/PG

Reads in/out files via the Ethernet interface and

⑤

executes the program from an external PC/PG

Backs up manufacturer files

⑥

Backs up user files

⑦

Shows the recently accessed files

⑧

Executes the selected file. No editing is allowed in the

⑨

execution process

Creates new files or directories

⑩

Searches for files

⑪

Selects all files for the subsequent operations

⑫

Copies the selected file(s) to the clipboard

⑬

Pastes the selected file(s) from the clipboard to the

⑭

current directory

Restores the deleted file(s)

⑮

Opens the second-level softkeys, for example:

⑯

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

29

Page 30

4.1

Creating a part program

Operating sequence

Note:

gram name is limited to 24 English characters or 12

Press this softkey to confirm your entry. The part program editor window opens. Enter the blocks in

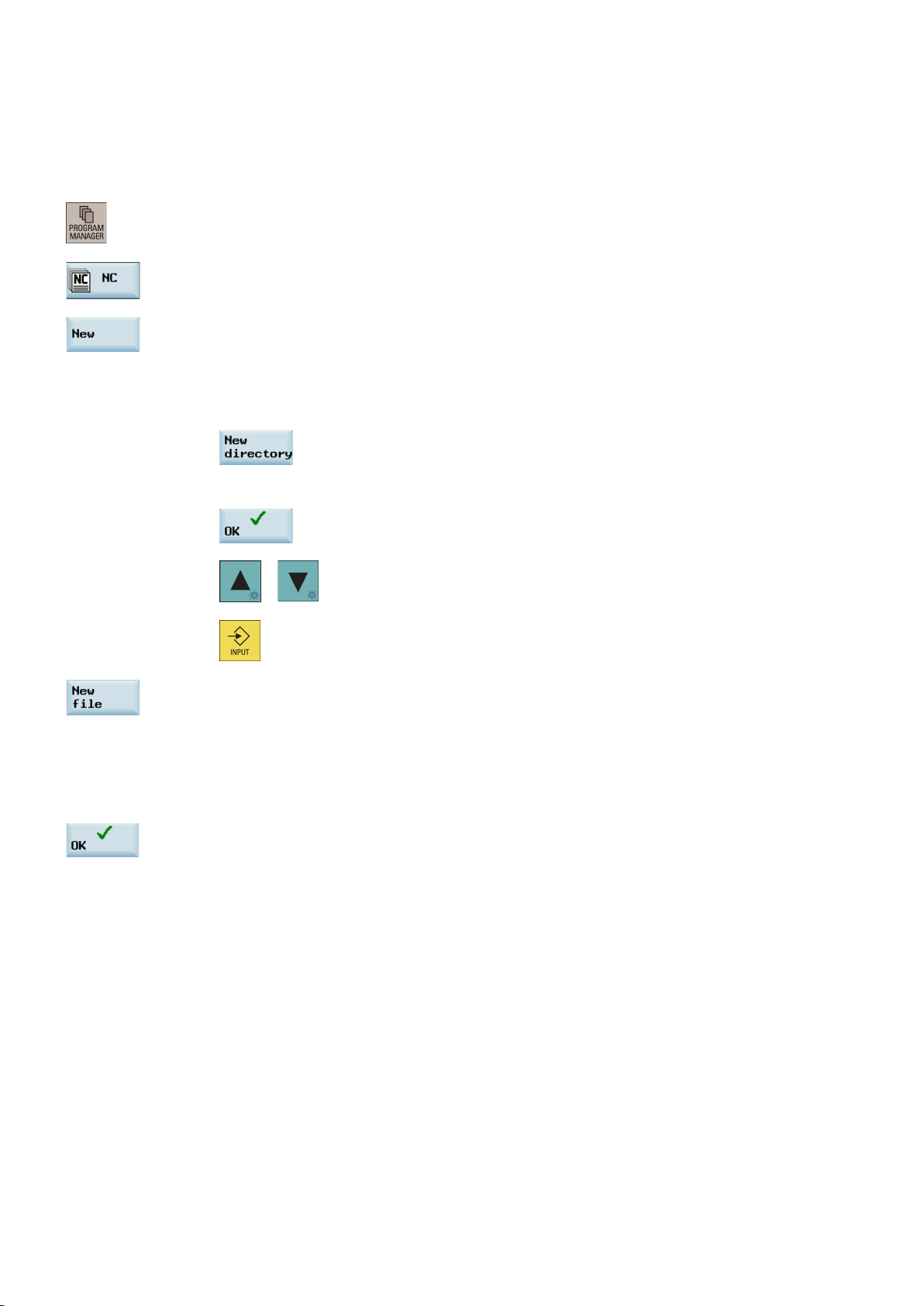

To create a part program, follow these steps:

1. Select the desired operating area.

2. Enter the folder for the new program to be created.

3. If you desire to directly create a new program file, press this softkey and proceed to Step 4.

4. Press this softkey to activate the window for creating a new program.

5. Enter the name of the new program. If you desire to create a main program, it is unnecessary to

6.

If you desire to create a new program directory first, press this softkey and proceed as follows

before you go to Step 4:

Press this softkey to activate the window for creating a new directory.

①

Enter a desired name for the new directory.

②

Press this softkey to confirm your entry.

③

Select the new directory with the cursor keys.

④

enter the file extension ".MPF". If you desire to create a subprogram, you must enter the file

extension ".SPF". The character length of a pro

Chinese characters. It is recommended that you do not use any special characters in the program

name.

the window, which are saved automatically.

Press this key on the PPU to open the directory.

⑤

Programming and Operating Manual (Turning)

30 6FC5398-5DP10-0BA1, 01/2014

Page 31

4.2

Editing part programs

Overview

Operating sequence

Note:

Renumbering blocks

A part program or sections of a part program can only be edited if currently not being executed. Any modifications to the part

program are stored immediately.

1. Select the desired operating area.

2. Enter the program directory.

3. Select the program file you desire to edit. You can also search for a file or directory by either:

● Pressing the following softkey and specifying the desired criteria in the search dialog:

file.

Or:

● Entering the first character on the main screen of the program directory. The system directly

navigates to the first file starting with that character.

4. Press this key to open the program file. The system switches over to the program editor window.

5. Edit the blocks in the window as required. Any program changes are automatically stored. See

below for the detailed description of the editing options.

6. After finishing the editing, you can press this softkey to execute the program. The system switches

to the "AUTO" mode in the machining area.

the file extension ".MPF" or ".SPF" must be entered if you desire to search for a program

With this softkey, the system automatically assigns block numbers to each block. The block

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

numbers are inserted in front of each block in the ascending order in a step of 10.

31

Page 32

Searching for blocks

Copying, cutting, and pasting blocks

Or

Proceed through the following steps to search for a block:

1. Press this softkey in the opened program editor window.

2. Press this softkey to search via text. Alternatively, you can search with a given line number by

Proceed through the following steps to copy, cut, and paste blocks:

pressing the following softkey:

2. Enter the search text or line number in the input field. Press this key to select a starting point for

search if you choose to search via text.

4. Press this softkey to start the search, or otherwise, press the following softkey to cancel the search:

1. Press this softkey in the opened program editor window to insert a marker.

2 Use the cursor keys to select the desired program blocks.

3. Press the following softkey to copy the selection to the buffer memory:

Press the following key to cut the selection to the buffer memory:

4. Place the cursor on the desired insertion point in the program and press this softkey.

The data is successfully pasted.

Programming and Operating Manual (Turning)

32 6FC5398-5DP10-0BA1, 01/2014

Page 33

4.3

Managing part programs

Searching for programs

Note:

Copying and pasting programs

1. Select the desired operating area.

2. Select the storage medium in which you wish to perform the search.

The following two folders are visible with the manufacturer password:

3. Press this vertical softkey to open the search window.

4. Enter the complete name with extension of the program file to be searched in the first input field in

the search window. To narrow your search, you can enter the desired text in the second field.

5. Use this key to choose whether to include subordinate folders or observe upper/lower case.

6. Press this softkey to start the search, or otherwise, press the following softkey to cancel the search:

1. Select the desired operating area.

2. Open the desired directory.

3. Select the program file that you would like to copy.

4. Press this softkey to copy the selected file.

5. Select the target directory with the horizontal softkeys.

6. Press this softkey to paste the file from the clipboard to the current directory.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

33

Page 34

Deleting/restoring programs

Renaming programs

1. Select the desired operating area.

2. Open the desired directory.

3. Select the program file that you would like to delete.

4. Press this key, and the following message appears on the screen:

5. Press this softkey to confirm the deletion, or press the following softkey to cancel:

If you want to restore the last deleted file, press the following softkey:

1. Select the desired operating area.

2. Open the desired directory.

3. Select the program file that you would like to rename.

4. Press the extension softkey to access more options.

5. Press this vertical softkey to open the window for renaming.

6. Enter a desired new name with the extension in the input field.

7. Press this softkey to confirm your entry, or press the following softkey to cancel:

Programming and Operating Manual (Turning)

34 6FC5398-5DP10-0BA1, 01/2014

Page 35

Viewing and executing recent programs

1.

Select the desired operating area.

2.

Press this softkey to open the list of recent files. Note that even the deleted files are also displayed

3.

Select the program file that you would like to execute.

4.

Press this vertical softkey to start executing the selected program.

To clear the current file list, press the following softkey:

5

Automatic machining

Overview

Softkey functions

③

⑧

④

⑨

Switches over the coordinate system in the actual value

The machine must have been set up for "AUTO" mode according to the specifications of the machine manufacturer. You can

perform such operations as program start, stop, control, block search, and real-time simulation, etc.

Pressing key on the PPU and then key on the MCP allows you to open the following window:

in the list.

Zooms in the actual value window

①

Performs the program test, dry run, conditional stop,

②

block skipping, and auxiliary function lock

Finds the desired block location

Activates the simulation function

Corrects a wrong program block. Any changes will be

⑤

stored immediately.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

Displays important G functions

⑥

Displays currently active auxiliary and M functions

⑦

Displays the axis feedrate in the selected coordinate

system

Displays the information of part machining time (part

timer) and part counter

⑩

window

35

Page 36

Parameters

5.1

Performing the simulation

Functionality

Operating sequence

Displays the axes that exist in the machine coordinate

①

system (MCS), workpiece coordinate system (WCS), or

relative coordinate system(REL).

Displays the current position of the axes in the selected

②

coordinate system.

By using the broken-line graphics, the programmed tool path can be traced. Before the automatic machining, you need to

perform the simulation to check whether the tool moves in the right way.

1. Select the desired operating area.

2. Select a part program for simulation.

3. Press this key to open the program.

Displays the remaining distance for the axes to

③

traverse.

Displays seven subsequent blocks of the currently

④

active part program. The display of one block is limited

to the width of the window.

4. Switch to "AUTO" mode.

Programming and Operating Manual (Turning)

36 6FC5398-5DP10-0BA1, 01/2014

Page 37

Softkey functions

5. Press this softkey to open the program simulation window, and the program control mode PRT is

The following describes the functions of the softkeys on the simulation main screen.

automatically activated.

If the control system is not in the correct operating mode, a message will appear at the bottom of

the screen as follows. If this message appears, repeat Step 4.

6. Press this key to start the standard simulation for the execution of the selected part program. Note

that the simulation function can be executed only when the control system is in "AUTO" operating

mode!

Shows the simulation track automatically.

①

Enters the lower-level menu for block displaying. Three

②

displaying options are available:

Zooms in the whole screen.

③

Zooms out the whole screen.

④

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

Deletes the current simulation track.

⑤

Makes the cross hair move in large or small steps with

⑥

the cursor.

Shows more options:

⑦

Returns to the program editor window.

⑧

Enables the material removal

simulation of a defined blank

Selects whether to show the blocks

or not

37

Page 38

5.2

Program control

Operating sequence

Press the corresponding vertical softkey to activate or deactivate the desired program control option

Softkey functions

1. Select the desired operating area.

2. Switch to "AUTO" mode.

3. Press this softkey to open the lower-level menu for program control.

4.

(see table below for detailed softkey functions). The softkeys selected are highlighted in blue.

Disables the output of setpoints to axes and spindles. The setpoint display "simulates" the traverse

movements.

It functions the same as pressing the following key:

After activating this option, the icon "PRT" appears immediately in the program status bar and this

softkey is highlighted in blue.

For more information of the program test, refer to Section "Program test (Page 39)".

All traversing motions are performed with the feedrate setpoint specified via the "Dry run feed" setting

data. Instead of the programmed motion commands, the dry run feed rate is effective.

After activating this option, the icon "DRY" appears immediately in the program status bar and this

softkey is highlighted in blue.

Stops processing of the program at every block in which miscellaneous function M01 is programmed.

It functions the same as pressing the following key:

After activating this option, the icon "M01" appears immediately in the program status bar and this

softkey is highlighted in blue.

Skips program blocks that are identified with a slash in front of the block number (e.g. "/N100").

After activating this option, the icon "SKP" appears immediately in the program status bar and this

softkey is highlighted in blue.

Available only in the following state:

Each block is decoded separately, and a stop is performed at each block. However, for the thread

blocks without dry run feedrate, a stop is only performed at the end of the current thread block.

It functions the same as pressing the following key:

After activating this option, the icon "SBL" appears immediately in the program status bar and this

softkey is highlighted in blue.

Programming and Operating Manual (Turning)

38 6FC5398-5DP10-0BA1, 01/2014

Page 39

5.3

Program test

Testing the program with dry run

The feedrate override switch also acts on the rapid traverse override.

It functions the same as pressing the following key:

After activating this option, the icon "ROV" appears immediately in the program status bar and this

softkey is highlighted in blue.

Performs program test before real machining by checking the axis movement on the machine. It

disables the output of setpoints to spindles and suppresses all auxiliary functions.

After activating this option, the icon "AFL" appears immediately in the program status bar and this

softkey is highlighted in blue.

Note that the display is toggled between "AFL" and "PRT" by pressing the corresponding softkey. Only

one of these two functions can be active at the same time.

You can test a part program using three different methods before machining pieces.

With dry run, all programmed motion commands are replaced by a defined dry run feedrate (refer to Section

"Entering/modifying the setting data (Page 207)"). Before executing the dry run, first remove the workpiece from the

machine.

Proceed as follows to test a part program with dry run.

1. Select the desired operating area.

2. Switch to "AUTO" mode.

3. Press this softkey to open the lower-level menu for program control.

4. Press this vertical softkey to activate the feedrate settings for the dry run.

5. Press this key on the MCP to close the door in the machine (if you do not use this function, just

close the door in the machine manually).

6. Make sure the feedrate override is 0%. Check that correct tool is in spindle before continuing.

7. Press this key on the MCP to run the program.

8. Turn the feedrate override switch slowly to the desired value.

9. Press this key to stop the program test.

Programming and Operating Manual (Turning)

6FC5398-5DP10-0BA1, 01/2014

39

Page 40

Testing the program with PRT

1.

Select the desired operating area.

2.

Switch to "AUTO" mode.

3.

Press this key on the MCP to activate the PRT mode.

4.

Press this key on the MCP to run the program. The setpoint display "simulates" the traverse

5.

Press this key to stop the program test.

Testing the program with AFL