Page 1

Operation and Programming 08/2003 Edition

sinumerik

SINUMERIK 802S base line

SINUMERIK 802C base line

Turning

Page 2

Page 3

SINUMERIK 802S base line

SINUMERIK 802C base line

Operation and Programming

Introduction

Turning On, Reference

Point Approach

1

2

Turning

Setting Up

Manually Controlled Mode

Automatic Mode

Part Programming

Services and Diagnosis

Programming

3

4

5

6

7

8

Valid for

Control system Software version

SINUMERIK 802S base line 4

SINUMERIK 802C base line 4

2003.08 Edition

Cycles

9

Page 4

SINUMERIK

®

Documentation

Key to editions

The editions listed below have been published prior to the current edition.

The column headed “Note” lists the amended sections, with reference to the previous edition.

Marking of edition in the “Note” column:

A ... ... New documentation.

B ... ... Unchanged reprint with new order number.

C ... ... Revised edition of new issue.

Edition Order No. Note

1999.02 6FC5598-2AA00-0BP1 A

2000.04 6FC5598-3AA00-0BP1 A

2002.01 6FC5598-3AA00-0BP2 C

2003.08 6FC5598-4AA01-0BP0 A

Trademarks

SIMATIC

®

, SIMATIC HMI®, SIMATIC NET®, SIMODRIVE®, SINUMERIK®, and SIMOTION® are registered

trademarks of SIEMENS AG.

Other names in this publication might be trademarks whose use by a third party for his own purposes may violate

the registered holder.

Copyright Siemens AG 2003. All right reserved

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will

be liable for damages. All rights, including rights created by patent

grant or registration of a utility model, are reserved.

Exclusion of liability

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences

might exist and we cannot therefore guarantee that they are completely identical. The information contained in this document is reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

© Siemens AG, 2003

Subject to technical changes without notice.

Siemens-Aktiengesellschaft. SINUMERIK 802S/802C base line

Page 5

Safety Guidelines

This Manual contains notices intended to ensure your personal safety , as well

as to protect products and connected equipment against damage. Safety

notices are highlighted by a warning triangle and presented in the following

categories depending on the degree of risk involved:

!

Indicates an imminently hazardous situation which, if not avoided, will result in

!

Indicates a potentially hazardous situation which, if not avoided, could result in

!

Used with safety alert symbol indicates a potentially hazardous situation which,

Used without safety alert symbol indicates a potentially hazardous situation

Danger

death or serious injury or in substantial property damage.

Warning

death or serious injury or in substantial property damage.

Caution

if not avoided, may result in minor or moderate injury or in property damage.

Caution

which, if not avoided, may result in property damage.

Indicates important information relating to the product or highlights part of the

Qualified person

Proper use

The unit may be used only for the applications described in the catalog or the

!

This product must be transported, stored and installed as intended, and

Please observe the following:

Notice

documentation for special attention.

The unit may only be started up and operated by qualified person or persons.

Qualified personnel as referred to in the safety notices provided in this

document are those who are authorized to start up, earth and label units,

systems and circuits in accordance with relevant safety standards.

Warning

technical description, and only in combination with the equipment, components

and devices of other manufacturers as far as this is recommended or p ermitted

by Siemens.

maintained and operated with care to ensure that it functions correctly and

safely.

Page 6

Page 7

Contents

Contents

SINUMERIK 802S/C base line Operator Panel OP

1. Introduction

1.1 Screen Layout 1-1

1.2 Operating areas 1-4

1.3 O verview of the most important softkey functions 1-5

1.4 Pocket calculator 1-6

1.5 Coordinate systems 1-10

III

1-1

2. Turning On and Reference Point Approach

2-1

3. Set Up

3.1 Entering tools and tool offsets 3-1

3.1.1 Creating a new tool 3-3

3.1.2 Tool compensation data 3-4

3.1.3 Determining the tool offsets 3-5

3.2 Entering/modifying the zero offset 3-7

3.2.1 Determining the zero offset 3-8

3.3 Programming the setting data - “Parameters” operating area 3-10

3.4 R parameters – “Parameters” operating area 3-12

3-1

4. Manually Operated Mode

4.1 Jog mode – “Machine” operating area 4-1

4.1.1 Assigning handwheels 4-4

4.2 MDA mode (Manual Data Input) – “Machine” operating area 4-5

5. Automatic Mode

5.1 Selecting/starting a part program – “Machine” operating area 5-4

5.2 Block search – “Machine” operating area 5-5

5.3 Stopping/aborting a part program – “Machine” operating area 5-6

5.4 Repositioning after interruption – “Machine” operating area 5-7

5.5 Program execution from external (RS232 interface) 5-8

5.6 Teach-in 5-9

4-1

5-1

6. Part Programming

6.1 Entering a new program – “Program” operating area 6-3

6.2 Editing a part program – “Program” operating area 6-4

6.3 Programming support 6-7

6.3.1 Vertical menu 6-7

6.3.2 Cycles 6-8

6.3.3 Contour 6-9

6.3.4 Free softkey assignment 6-24

6-1

7. Services and Diagnosis

7.1 Data transfer via the RS232 Interface 7-1

7.1.1 Interface parameters 7-4

7.1.2 Special functions 7-5

7.1.3 Interface parameterization 7-6

7.2 Diagnosis and start-up – ”Diagnostics” operating area 7-8

7-1

8. Programming

8.1 Fundamentals of NC programming 8-1

8.1.1 Program structure 8-1

8.1.2 Word structure and address 8-2

8.1.3 Block structure 8-3

8.1.4 Character set 8-5

8.1.5 Overview of instructions 8-6

8-1

SINUMERIK 802S/C base line

Operation and Programming Turning

I

Page 8

Contents

8.2 Position data 8-13

8.2.1 Absolute/incremental dimensions: G90, G91 8-13

8.2.2 Metric/inch dimensions: G71, G70 8-14

8.2.3 Radius/diameter dimensions: G22, G23 8-15

8.2.4 Programmable zero offset: G158 8-16

8.2.5 Workpiece clamping - settable zero offset: G54 to G57, G500, G53 8-17

8.3 Axis movements 8-18

8.3.1 Linear interpolation at rapid traverse: G0 8-18

8.3.2 Linear interpolation at feedrate: G1 8-19

8.3.3 Circular interpolation: G2, G3 8-20

8.3.4 Circular interpolation via intermediate point: G5 8-23

8.3.5 Thread cutting with constant lead: G33 8-24

8.3.6 Fixed-point approach: G75 8-27

8.3.7 Reference point approach: G74 8-28

8.3.8 Feedrate F 8-28

8.3.9 Exact stop / continuous path mode: G9, G60, G64 8-29

8.3.10 Dwell time: G4 8-31

8.4 Spindle movements 8-32

8.4.1 Spindle speed S, directions of rotation 8-32

8.4.2 Spindle speed limitation: G25, G26 8-33

8.4.3 Spindle positioning: SPOS 8-34

8.5 Special turning functions 8-35

8.5.1 Constant cutting rate: G96, G97 8-35

8.5.2 Rounding, chamfer 8-37

8.6 Tool and tool offset 8-39

8.6.1 General notes 8-39

8.6.2 Tool T 8-40

8.6.3 Tool offset number D 8-41

8.6.4 Selection of tool radius compensation: G41, G42 8-46

8.6.5 Behavior at corners: G450, G451 8-48

8.6.6 Tool radius compensation OFF: G40 8-49

8.6.7 Special cases of tool radius compensation 8-50

8.6.8 Example of tool radius compensation 8-52

8.7 Miscellaneous function M 8-53

8.8 Arithmetic parameters R 8-54

8.9 Program branches 8-56

8.9.1 Labels - destination for program branches 8-56

8.9.2 Unconditional program branches 8-57

8.9.3 Conditional branches 8-58

8.9.4 Example of program with branches 8-60

8.10 Subroutine technique 8-61

9. Cycles

9.1 General Information about Standard Cycles 9-1

9.1.1 Overview of Cycles 9-1

9.1.2 Error messages and error handling in cycles 9-2

9.2 Drilling, counter boring - LCYC82 9-4

9.3 Deep hole drilling – LCYC83 9-6

9.4 Tapping with compensating chuck - LCYC840 9-10

9.5 Boring - LCYC85 9-12

9.6 Recess cycle – LCYC93 9-14

9.7 Undercut cycle – LCYC94 9-18

9.8 Stock removal cycle – LCYC95 9-20

9.9 Thread cutting – LCYC97 9-25

II

SINUMERIK 802S/C base line

Operation and Programming

9-1

Turning

Page 9

Contents

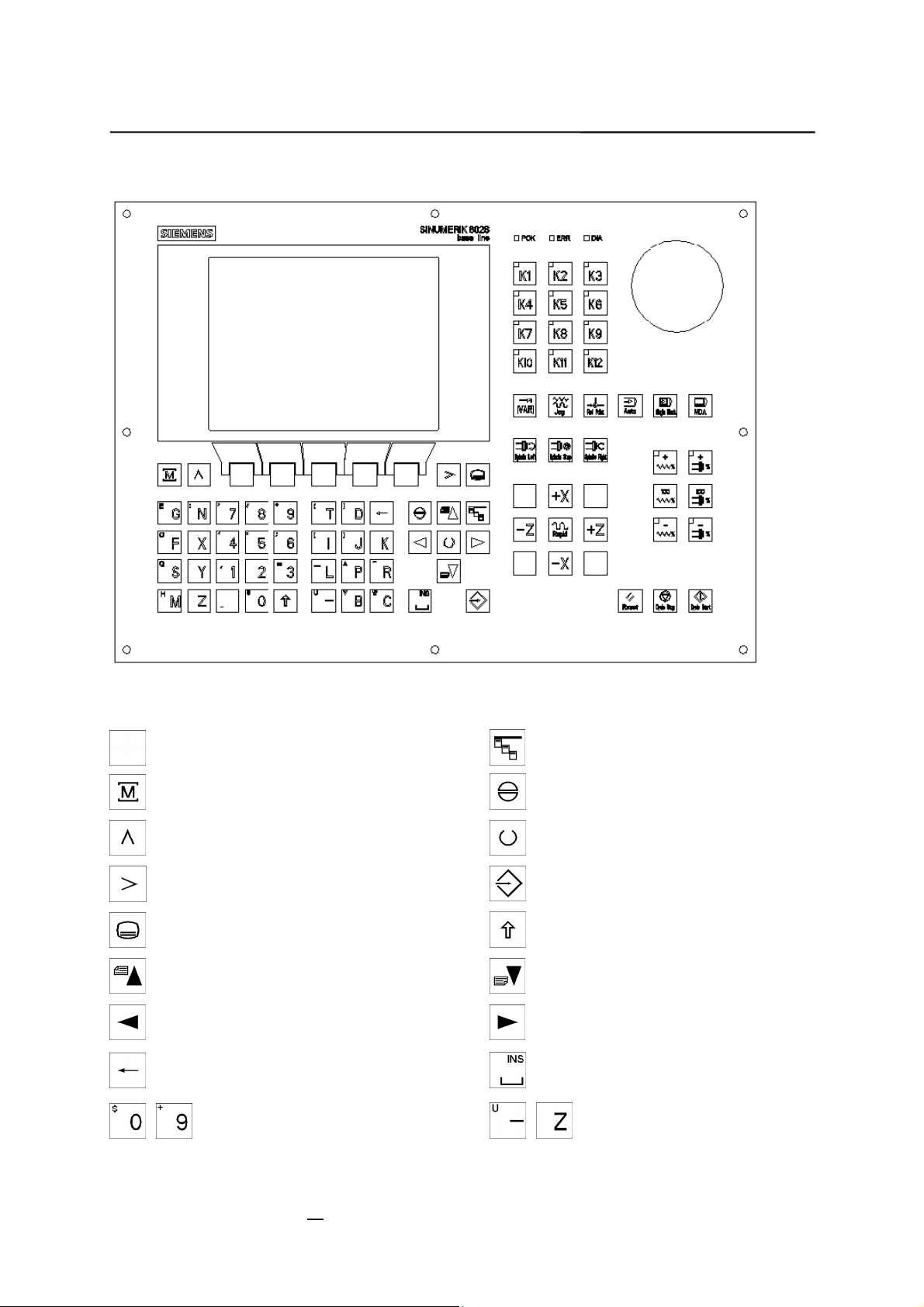

SINUMERIK 802S/C base line Operator Panel OP

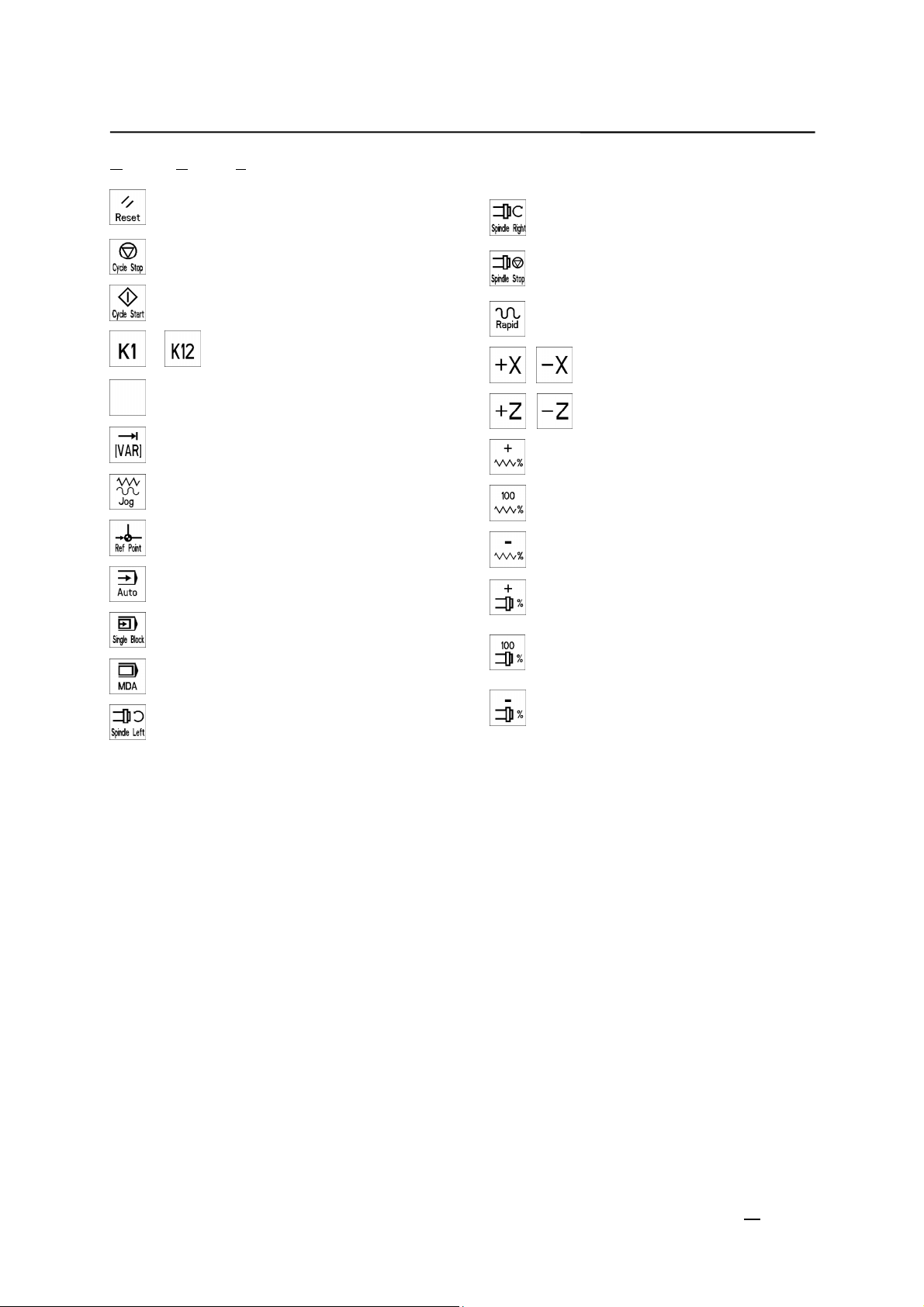

NC keyboard area (left side):

Softkey

Machine area key

Recall key

ETC key

Area switchover key

Cursor UP

with shift: page up

Cursor LEFT

Delete key (backspace)

Numerical keys shift for

alternative assignment

Vertical menu

Acknowledge alarm

Selection key/toggle key

ENTER / input key

Shift key

Cursor DOWN

with shift: page down

Cursor RIGHT

SPACE (INSERT)

Alphanumeric keys shift for

alternative assignment

SINUMERIK 802S/C base line

Operation and Programming Turning

III

Page 10

Contents

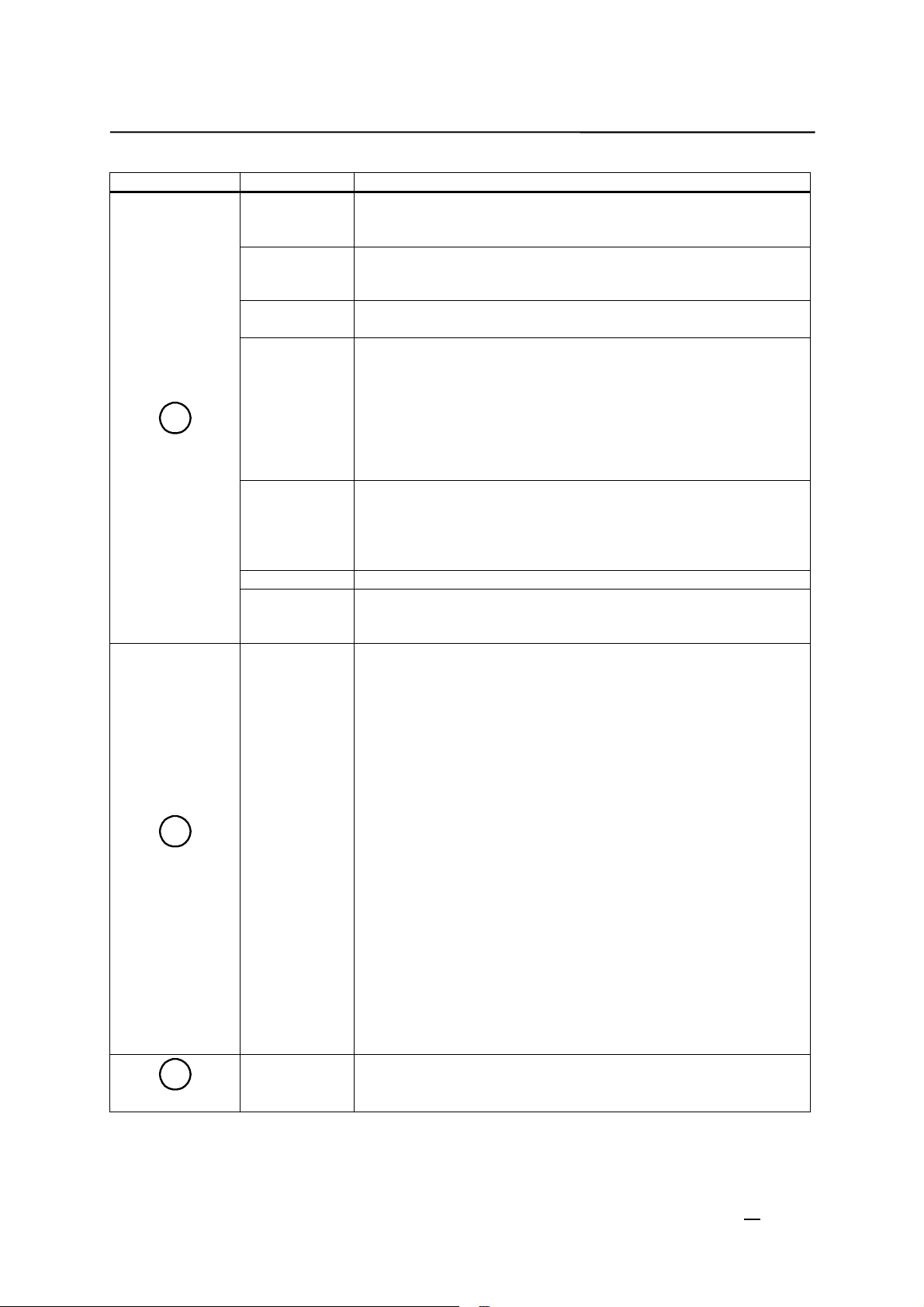

Machine Control Panel area (right side):

RESET

NC STOP

NC START

User-defined key with LED

…

User-defined key without LED

INCREMENT

JOG

REFERENCE POINT

AUTOMATIC

SINGLE BLOCK

MANUAL DATA

SPINDLE START LEFT

Counterclockwise direction

SPINDLE START RIGHT

Clockwise direction

SPINDLE STOP

RAPID TRAVERSE OVERLAY

X axis

Z axis

Feedrate override plus with LED

Feedrate override 100% without

LED

Feedrate override minus with LED

Spindle speed override plus with

LED

Spindle speed override 100%

without LED

Spindle speed override minus with

LED

IV

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 11

Introduction

1.1 Screen layout

1

Fig.1-1 Screen layout

The abbreviations on the screen stand for the following:

Table 1–1 Explanation of display elements

Display Element Abbreviation Meaning

MA Machine

Active operating area

Program status

Operating mode

PA Parameter

PR Programming

DI Services

DG Diagnosis

STOP Programm stopped

RUN Program running

RESET Program aborted

Jog Manual traverse

MDA Manual input with automatic function

Auto Automatic

SINUMERIK 802S/C base line

Operation and Programming Turning

1-1

Page 12

Introduction

Display Element Abbreviation Meaning

SKP Skip block

Program blocks marked by a slash in front of the block number

are ignored during program execution.

DRY Dry run feed

Traversing movements are executed at the feed specified in the

Dry Run Feed setting data.

ROV Rapid traverse override

The feed override also applies to rapid feed mode.

SBL Single block with stop after each block

When this function is active, the part program blocks are

processed separately in the following manner:

Each block is decoded separately, the program is stopped at the

Status display

Operational

message

M1 Programmed stop

PRT Program test

1…1000

INC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

end of each block. The only exception are thread blocks without

dry run feed. In this case, the program is stopped only when the

end of the current thread block is reached. SBL can only be

selected in the RESET state.

When this function is active, the program is stopped at each block

in which the miscellaneous function M01 is programmed.

In this case, the message “5 stop M00/M01 active“ appears on

the screen.

Incremental mode

If the control is in the Jog mode, incremental dimension is

displayed instead of the active program control function.

Stop: No NC Ready

Stop: EMERGENCY STOP active

Stop: Alarm active with stop

Stop: M0/M01 sctive

Stop: Block ended in SBL mode

Stop: NC STOP active

Wait: Read-in enable missing

Wait: Feed enable missing

Wait: Dwell time active

Wait: Auxiliary function acknowl. missing

Wait: Axis enable missing

Wait: Exact stop not reached

Wait: For spindle

Wait: Feed override to 0%

Stop: NC block incorrect

Wait: Block search active

Wait: No spindle enable

Wait: Axis feed value 0

Program name

1-2

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 13

Introduction

Display Element Abbreviation Meaning

Alarm line

Working window

Recall symbol

Menu extension

The alarm line is only displayed if an NC or PLC alarm is active.

The alarm line contains the alarm number and reset criterion of

the most recent alarm.

Working window and NC display

This symbol is displayed above the softkey bar when the operator

is in a lower-level menu.

When the Recall key is pressed, you can return to the next-higher

menu without saving data.

ETC is possible If this symbol appears above the softkey bar,

further menu functions are provided. These functions can be

activated by the ETC key.

Softkey bar

If this symbol is displayed above the softkey bar, further menu

Vertical menu

functions are provided. When the VM key is pressed, these

functions appear on the screen and can be selected by Cursor

UP and Cursor DOWN.

Here the current actual feedrate override is shown.

Feedrate

override

Gear box

Spindel speed

override

Here the current spindle gear stage 1…5 is shown.

Here the current spindel speed override is shown.

SINUMERIK 802S/C base line

Operation and Programming Turning

1-3

Page 14

Introduction

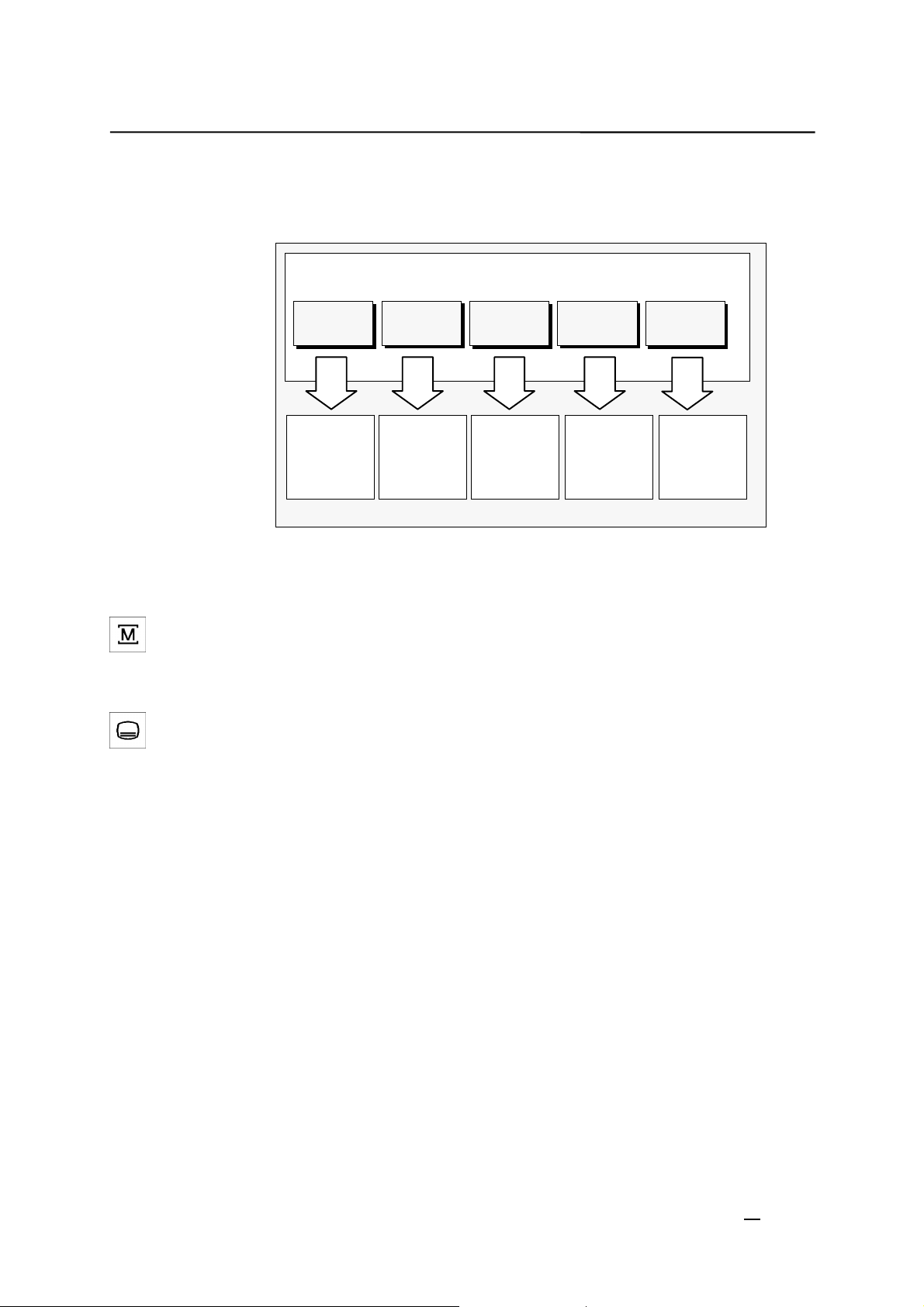

1.2 Operating areas

The basic functions are grouped in the CNC into the following operating areas:

Operatin g ar eas

Machine Parameters

Executing

part

programs

Manual

control

Editing

program

data

Program

Creating

part

programs

Services

Reading

in / reading

out data

Diagnostics

Alarm

display

Start-up

Fig.1-2 SINUMERIK 802S/C base line operating areas

Switching between the operating

Press the “Machine” area key for direct access to the “Machine” operating

area.

Use the area switching key to return from any operating area to the main

menu.

Press the area switching key twice to return to the previous operating area.

After turning on the control system, the Machine operating area will appear by

default.

Protection levels

Sensible points of the control system are password-protected against entering

and modifying data.

However, the operator can alter the protection levels in the “Machine Data”

display menu in the “Diagnostics” operating area.

Default: Protection level 3.

In the following menus, entering and modifying data depends on the set class

of protection:

tool offsets

z

zero offsets

z

setting data

z

RS232 settings

z

1-4

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 15

Introduction

1.3 Overview of the most important softkey functions

Machine Parameter Program Services Diagnosis

Alarms

Display

bright.

Data In

Start

Programs Cycles Selection Open

R

Parameter

Data Out

Start

New Copy Delete Rename

Tool

correction

Service

display

Display

darker

RS232

setting

Execut. f.

ext.

Setting

data

Start-up

Change

lang.

Error log show

Zero

offset

Machine

data

Memory

info

Program

control

Hand wheel Axis feed.

Zoom block Search

Axis feed.

Zoom block

Axis feed.

SINUMERIK 802S/C base line

Operation and Programming Turning

Execut.f.

ext.

Act.val

WCS

Zoom G

funct

Act.val

WCS

Zoom G

funct

Act.val

WCS

Zoom

act.val

Zoom M

funct

Zoom

act.val

Zoom M

funct

Zoom

act.val.

1-5

Page 16

Introduction

1.4 Pocket calculator

This function can be activated for all input fields intended for entry of numerical

values by means of the “=” character. To calculate the required value, you can

use the four basic arithmetic operations, and the functions sine, cosine,

squaring, as well as the square root function.

If the input field is already loaded with a value, this function writes the value in

the input line of the pocket calculator.

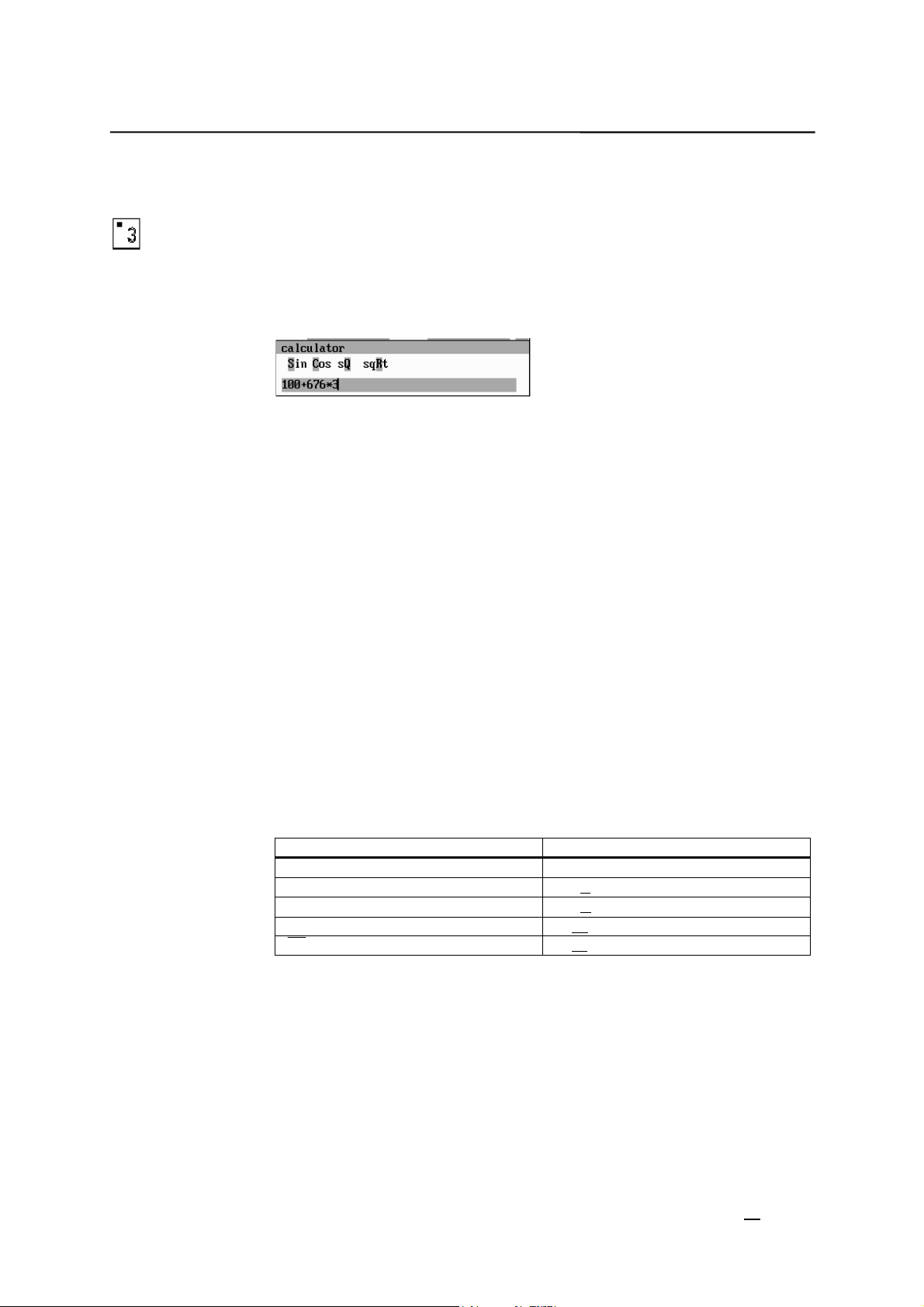

Fig. 1-3 Pocket calculator

Permissible characters

The following characters are permitted for input:

+ Value X plus value Y

- Value X minus value Y

* Value X multiplied with value Y

/ Value X divided by value Y

6 6LQHIXQFWLRQ

7KHYDOXH;LQIURQWRIWKHLQSXWFXUVRULVUHSODFHGE\WKHYDOXH

VLQ;

C Cosine function

The value X in front of the input cursor is replaced by the value cos(X).

Q Square function

The value X in front of the input cursor is replaced by the value X

R Square root function

The value X in front of the input cursor is replaced by the value √X.

2.

Calculation examples

Task Input

100 + (67*3) 100+67*3

sin(45°)

cos(45°)

2

4

√ 4

45 S -> 0.707107

45 C -> 0.707107

4 Q -> 16

4 R -> 2

The calculation is carried out by pressing the Input key. The softkey function OK

will accept the result into the input field, quitting the calculator automatically .

To calculate auxiliary points on a contour, the calculator provides the following

functions:

calculating the tangential transition between a circle sector and a straight

z

line

moving a point in a plane

z

converting polar coordinates into Cartesian coordinates

z

adding the second end point of a contour section ‘straight line - straight

z

line’ given via angular interrelation.

1-6

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 17

Introduction

These functions are directly linked with the input fields of the programming

support. Any values in this input field are written by the pocket calculator into

the input line, and the result is automatically copied into the input fields of the

programming support.

Softkeys

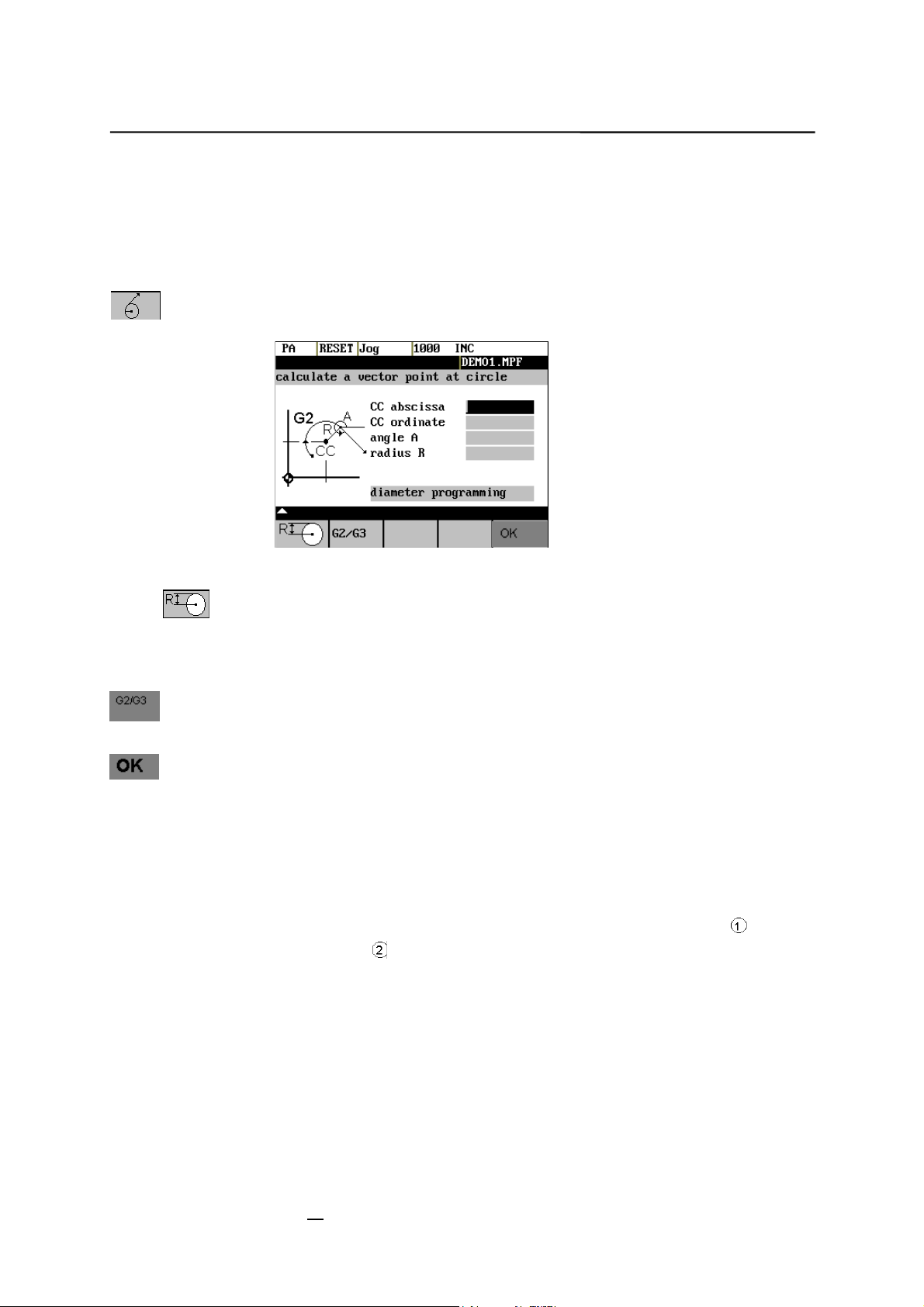

This function is used to calculate a point on a circle. The point results from the

angle of the created tangent and the direction of rotation of the circle.

Fig.1-4 Calculation of a point on a circle

Enter the circle center, the angle of the tangent and the radius of the circle.

The function switches the screen form from diameter programming to radius

programming.

Use softkey G2 / G3 to define the direction of rotation of the circle.

The abscissa and ordinate values are calculated; the abscissa is the first axis

of the plane, and the ordinate is the second axis of the plane.

If plane G18 is active, the abscissa is the Z axis, and the ordinate is the X axis.

The value of the abscissa is copied into that input field from which the pocket

calculator function has been called, and the ordinate value into the next

following input field.

Example

Given: Radius: 10

Calculating the intersection point between the circle sector and the

straight line

Circle center point: Z 147 X103

Ongoing angle of the straight line: -45°

.

SINUMERIK 802S/C base line

Operation and Programming Turning

1-7

Page 18

Introduction

Result: Z = 154.071

X = 117.142

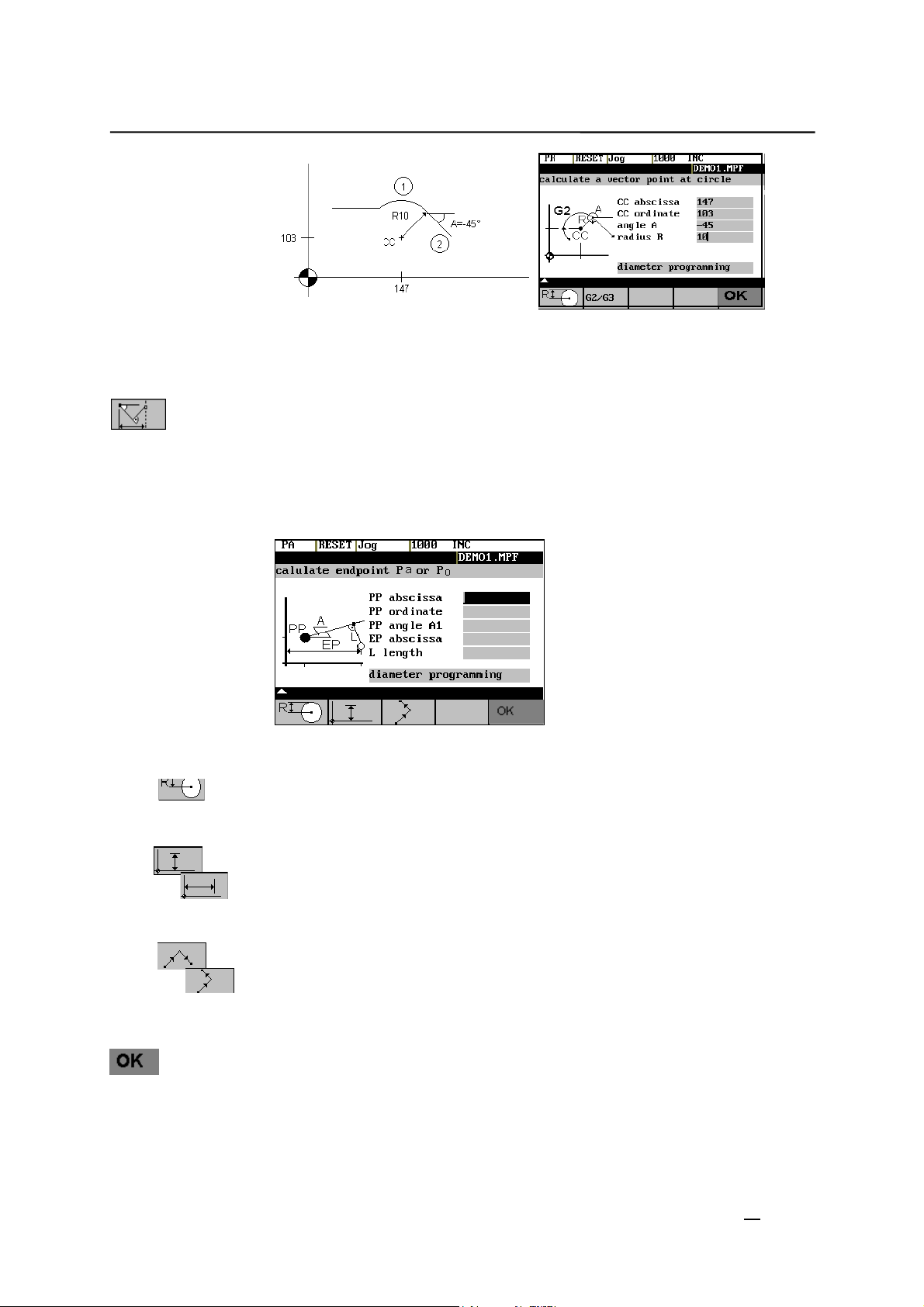

The function calculates the missing end point of the contour section straight

line - straight line, with the second straight line standing vertically on the first

straight line.

The following values of the straight line are known:

Straight line 1: Start point and rise angle

Straight line 2: Length and one end point in the Cartesian coordinate system

Fig.1-5

The function switches the screenform from diameter programming to radius

programming.

The function chooses the given coordinate of the end point. The value of

ordinate and/or abscissa is given.

The second straight line is rotated in clockwise direction or, with refer to the

first straight line, rotated by 90 degrees in counter-clockwise direction.

The function chooses the appropriate setting.

The missing end point is calculated. The value of the abscissa is copied into

that input field from which the pocket calculator function has been called, and

the ordinate value into the next following input field.

1-8

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 19

Introduction

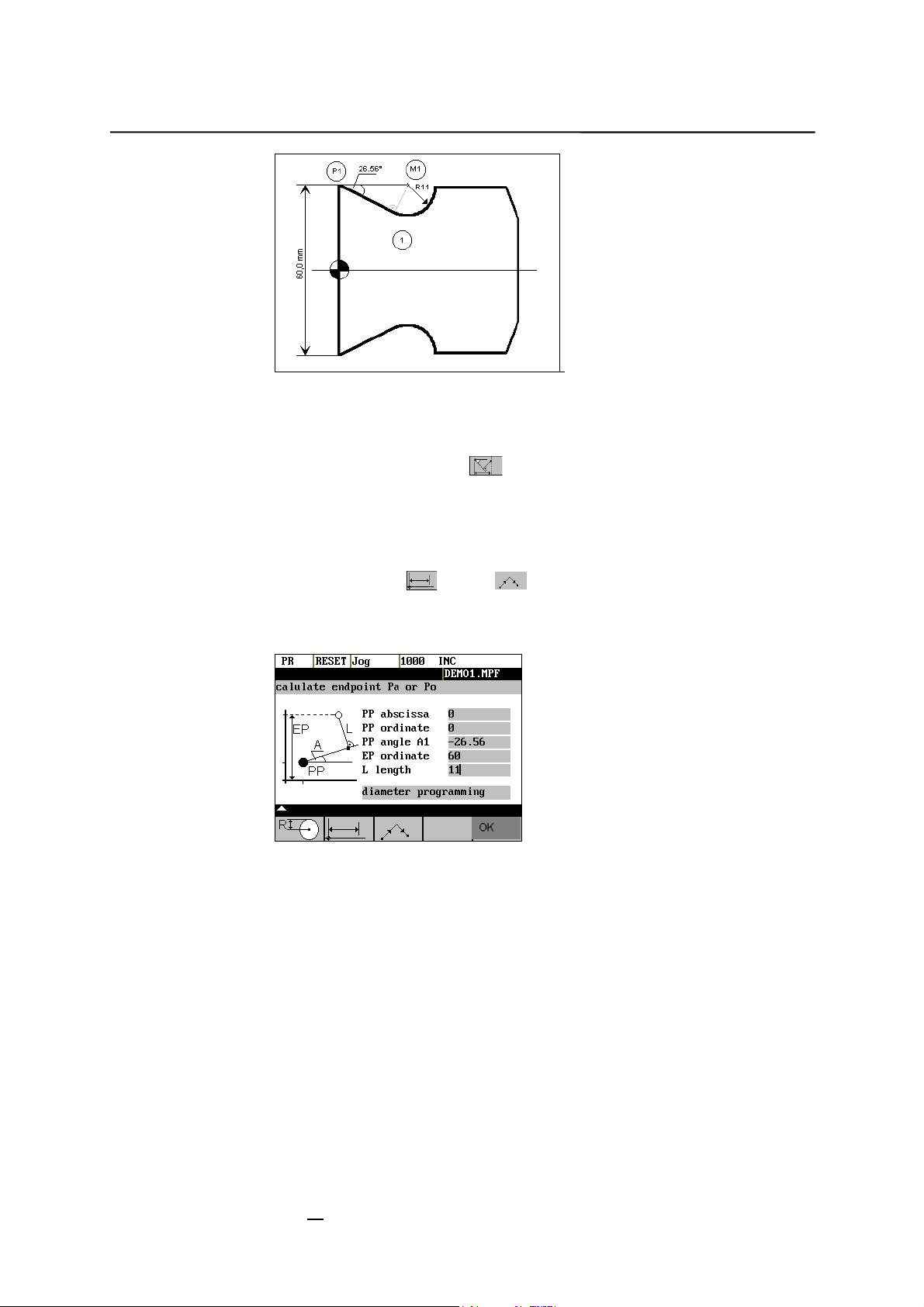

Fig.1-6

The drawing above must be added by the value of the circle center point to be

able to calculate the intersection point between the circle sector of the straight

line. The missing coordinate of the center point is calculated by means of the

pocket calculator function

stands vertical on the straight line.

Calculating M1 in section 1:

In this section, the radius stands on the straight line section rotated in counter-

clockwise direction.

, since the radius in the tangential transition

Use the softkeys

Enter the coordinates, the pole point P1, the rise angle of the straight line, the

given ordinate value and the circle radius as the length.

Fig.1-7

Result: Z = 24.601

X = 60

and to select the given constellation .

SINUMERIK 802S/C base line

Operation and Programming Turning

1-9

Page 20

Introduction

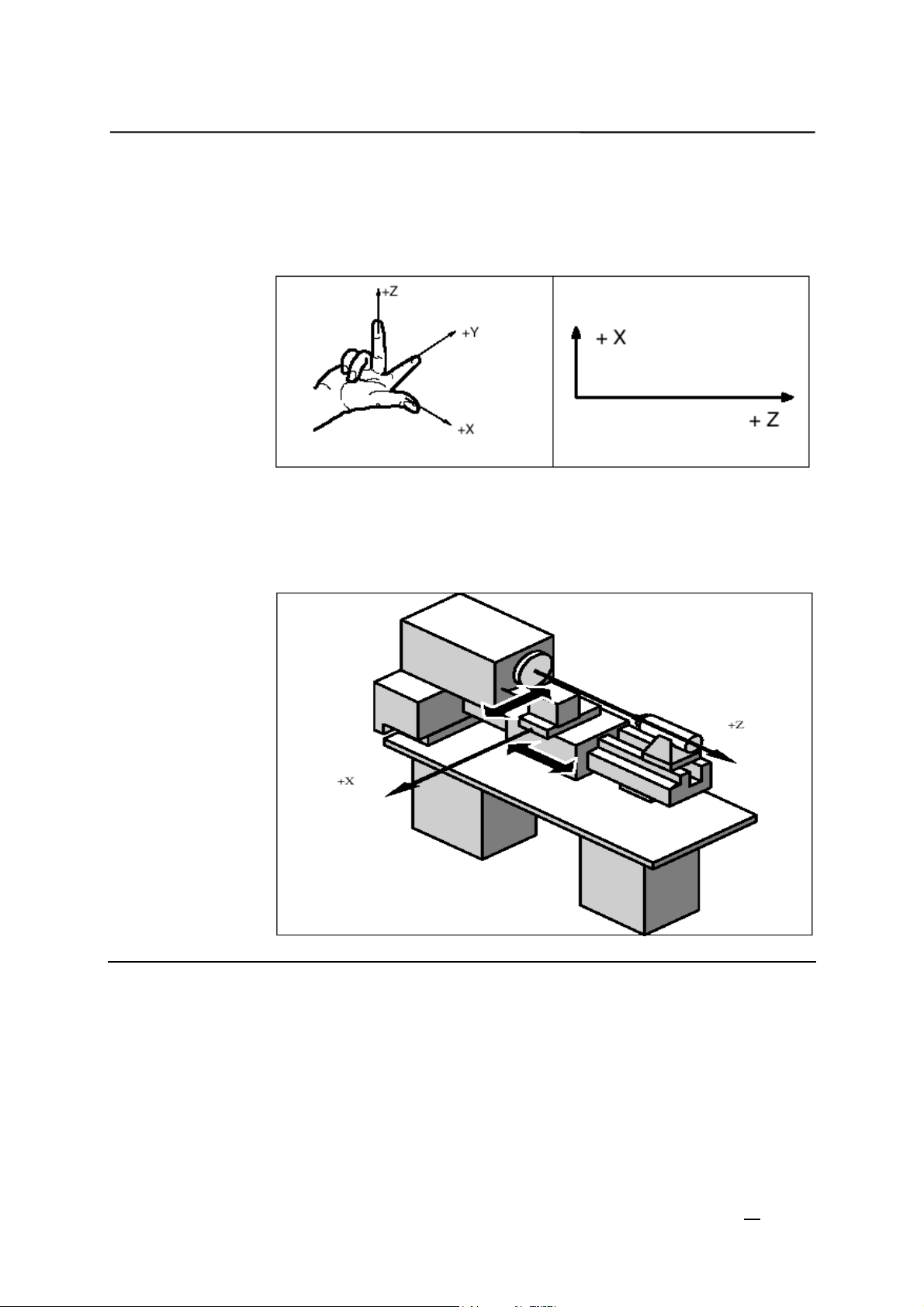

1.5 Coordinate systems

Right-handed, rectangular coordinate systems are used for machine tools.

Such systems describe the movements on the machine as a relative motion

between tool and workpiece.

Fig.1-8 Specification of the axis directions to one another; coordinate system

when programming for turning

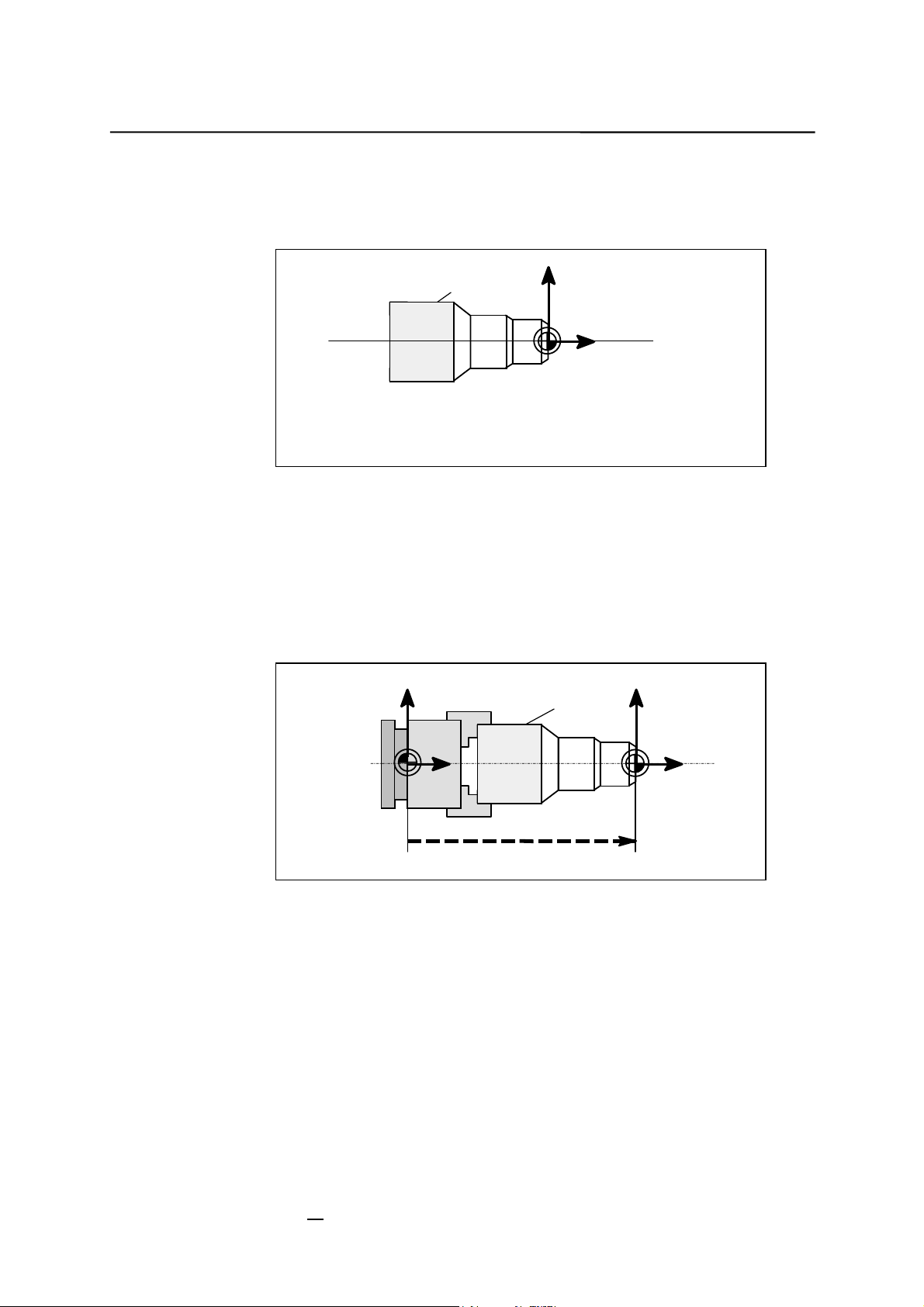

Machine coordinate

system (MCS)

Fig. 1-9 Machine coordinates/axes on a turning machine

The origin of this coordinate system is the machine zero.

All axes are in the zero position at this point. This point is merely a reference

The traversing range of the machine axes can be negative.

The orientation of the coordinate system on the machine depends on the particular

machine type. It can be turned to various positions.

point determined by the machine manufacturer. It does not need to be

approachable.

1-10

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 21

Introduction

Workpiece coordinate system (WCS)

The coordinate system described above (see Fig. 1–8) is also used to describe

the geometry of a workpiece in the workpiece program.

The workpiece zero can be freely selected in the Z axis by the programmer. In

the Z axis, the zero point corresponds to the turning center.

Workpiece

X

Workpiece

W

Z

Workpiece

- wo rkpiece z ero

W

Fig.1-10 Workpiece coordinate system

Workpiece clamping

To machine the workpiece, it is clamped in the machine. The workpiece must

be aligned such that the axes of the workpiece coordinate system are in

parallel with the machine axes. Any resultant offset of the machine zero to the

workpiece zero is determined in the Z axis and entered in a specially provided

data area for the settable zero offset. This offset is activated during the NC

program execution by means, for example, of a programmable G54 (see

Section “Workpiece Clamping - Settable Zero Offset ...”).

X

Machine

M

Z

Machine

z.B.

Fig.1-11 Workpiece on the machine

Current workpiece

coordinate system

An offset in relation to the workpiece coordinate system can be generated by

means coordinate system of the programmable zero offset G158. The result is

the current workpiece (see Section “Programmable Zero Offset: G158”).

Workpiece

G54

X

Workpiece

W

Z

Workpiece

SINUMERIK 802S/C base line

Operation and Programming Turning

1-11

Page 22

Introduction

1-12

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 23

Turning On and Reference Point

2

Approach

Notice

Before you switch on the SINUMERIK and the machines, you should also have

read the machine documentation, since turning on and reference point

approach are machine-dependent functions.

Operating sequence

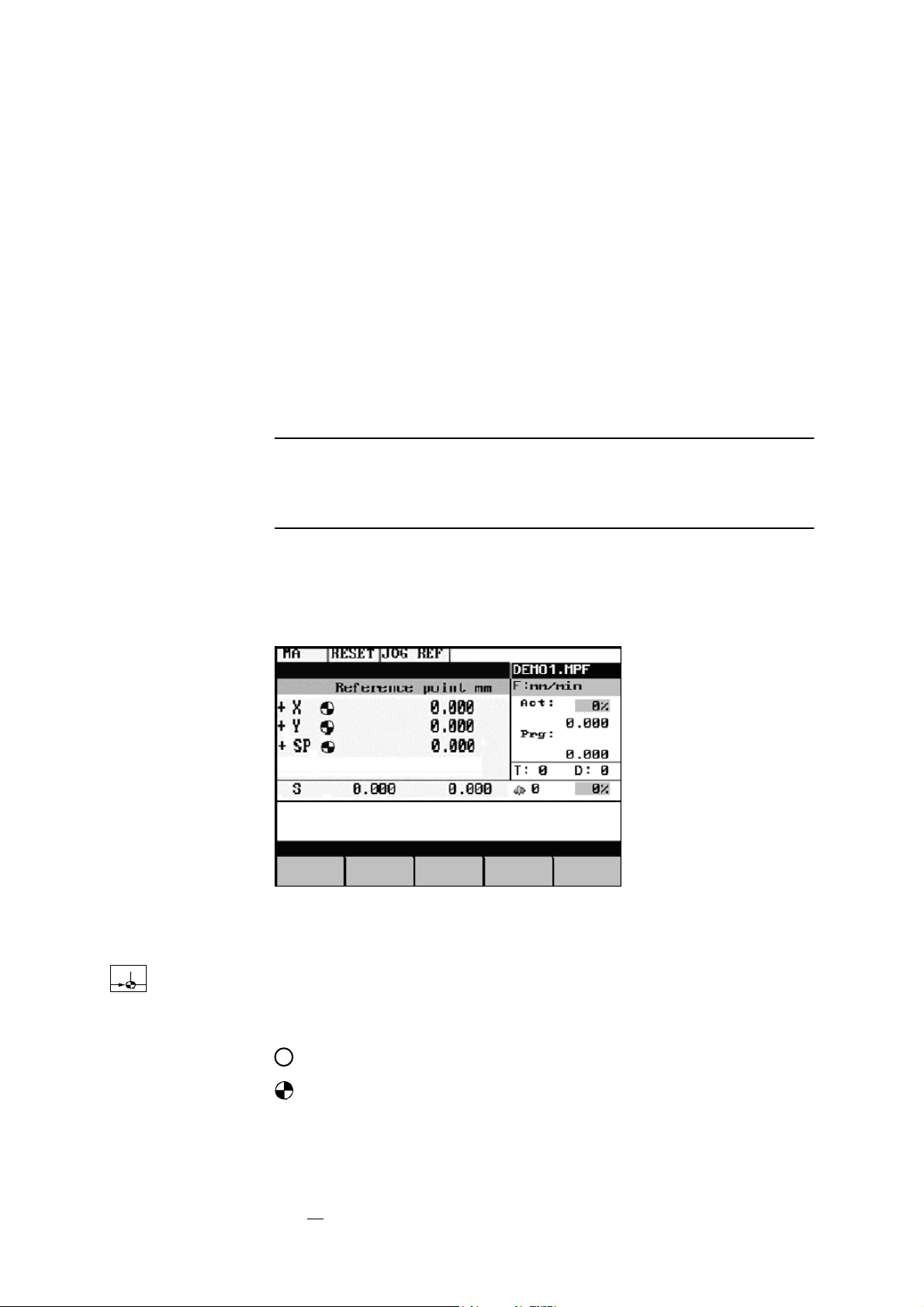

The Reference point approach window is active.

Fig.2-1 Jog Ref basic screen

Reference-point approach can only be executed in the Jog mode.

Activate the “Approach reference point” function by selecting the Ref key on

In the “Reference point approach” window (Fig. NO TAG), it is displayed

First switch on the power supply of the CNC and of the machine. After the

control system has booted, you are in the “Machine” operating area, in the Jog

operating mode.

the machine control panel area.

whether or not the axes have to be referenced.

Axis has to be referenced

SINUMERIK 802S/C base line

Operation and Programming

Axis has reached the reference point

Turning

2-1

Page 24

Turning On and Reference Point Approach

… Press the direction keys.

The axis does not move if you select the wrong direction.

Approach the reference point in each axis successively.

You can quit the function by selecting another operating mode (MDA,

Automatic or Jog).

2-2

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 25

Set Up

3

Preliminary remarks

Before you can use the CNC, set up the machine, tools, etc. on the CNC by:

entering the tools and tool offsets

z

entering/modifying the zero offset

z

entering the setting data

z

3.1 Entering tools and tool offsets

Functionality

Each tool has a defined number of parameters depending on the tool type.

Each tool is identified by its own tool number (T number).

See also Section 8.6 “Tool and Tool Offset“.

Operating sequences

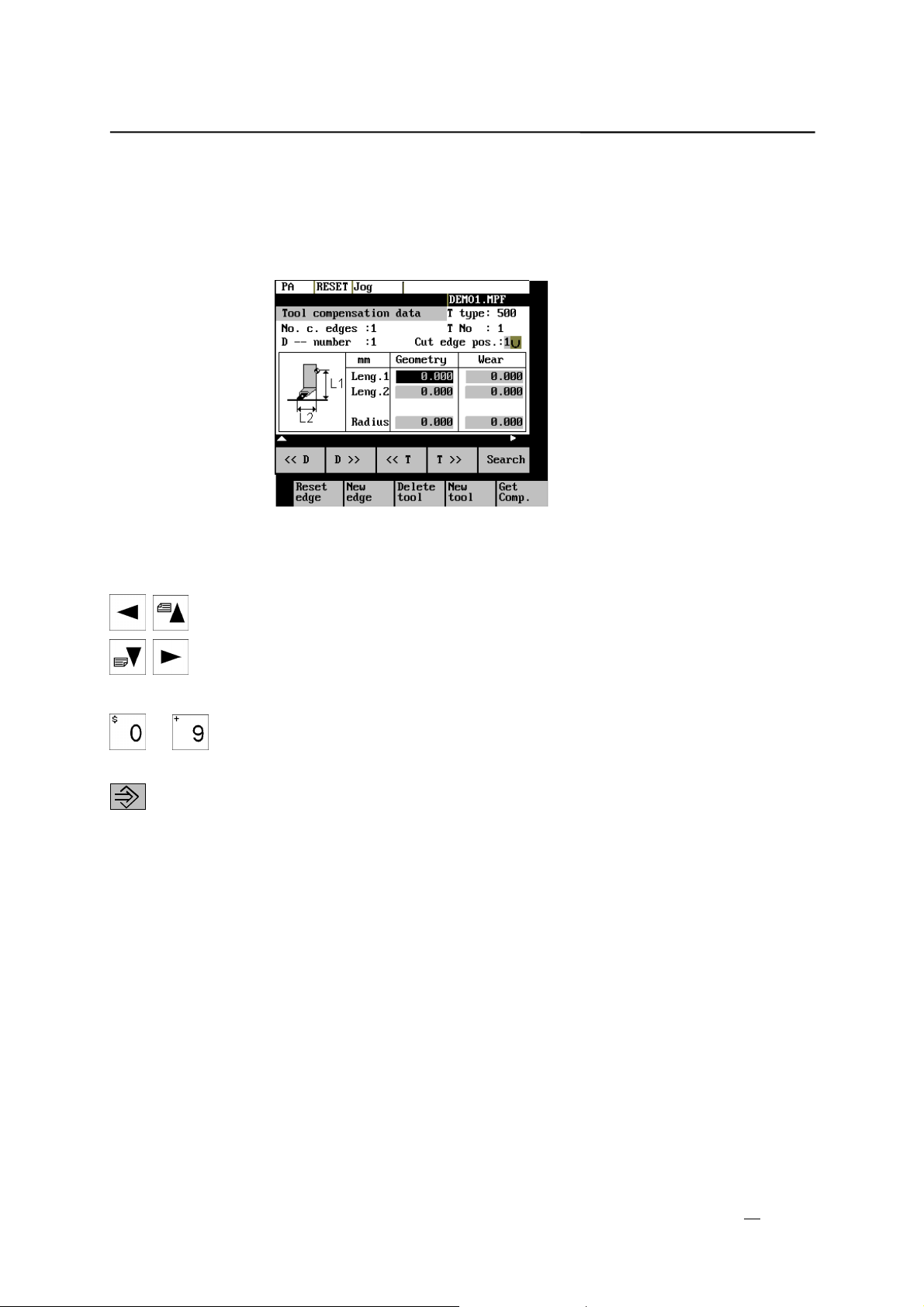

This function opens the Tool Compensation Data window, which contains the

Parameter

The tool offsets consist of several data that describe the geometry, wear and

tool type.

offset values of the currently active tool. If you select another tool using the <<T

or T>> softkeys, the setting remains when you quit the window.

Tool

Corr.

Fig.3-1 Tool com pensation data window

SINUMERIK 802S/C base line

Operation and Programming Turning

3-1

Page 26

Set Up

Softkeys

Select next lower or next higher edge number.

<< D

D >>

<< T

T >>

Get

Determine length compensation values.

Comp.

Select next lower or next higher tool.

Use the ETC key to extend the softkey functions.

Reset

edge

All edge compensation values are reset to zero.

New

edge

Creates a new edge and loads it with the appropriate parameters.

The new edge is created for the currently displayed tool; it is automatically

Delete

tool

assigned the next higher edge number (D1 – D9).

Max. 30 edges (in total) can be stored in the memory.

Deletes the tool compensation data of all edges of the selected tool.

New

tool

Creates new tool compensation data for a new tool.

Note: Max. 15 tools can be created.

Pressing this softkey opens the dialog box and the overview of the tool

Search

numbers assigned. Enter the tool number you search for in the input window

and start search with OK. If the searched tool exists, the search function opens

the tool offset data box.

3-2

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 27

Set Up

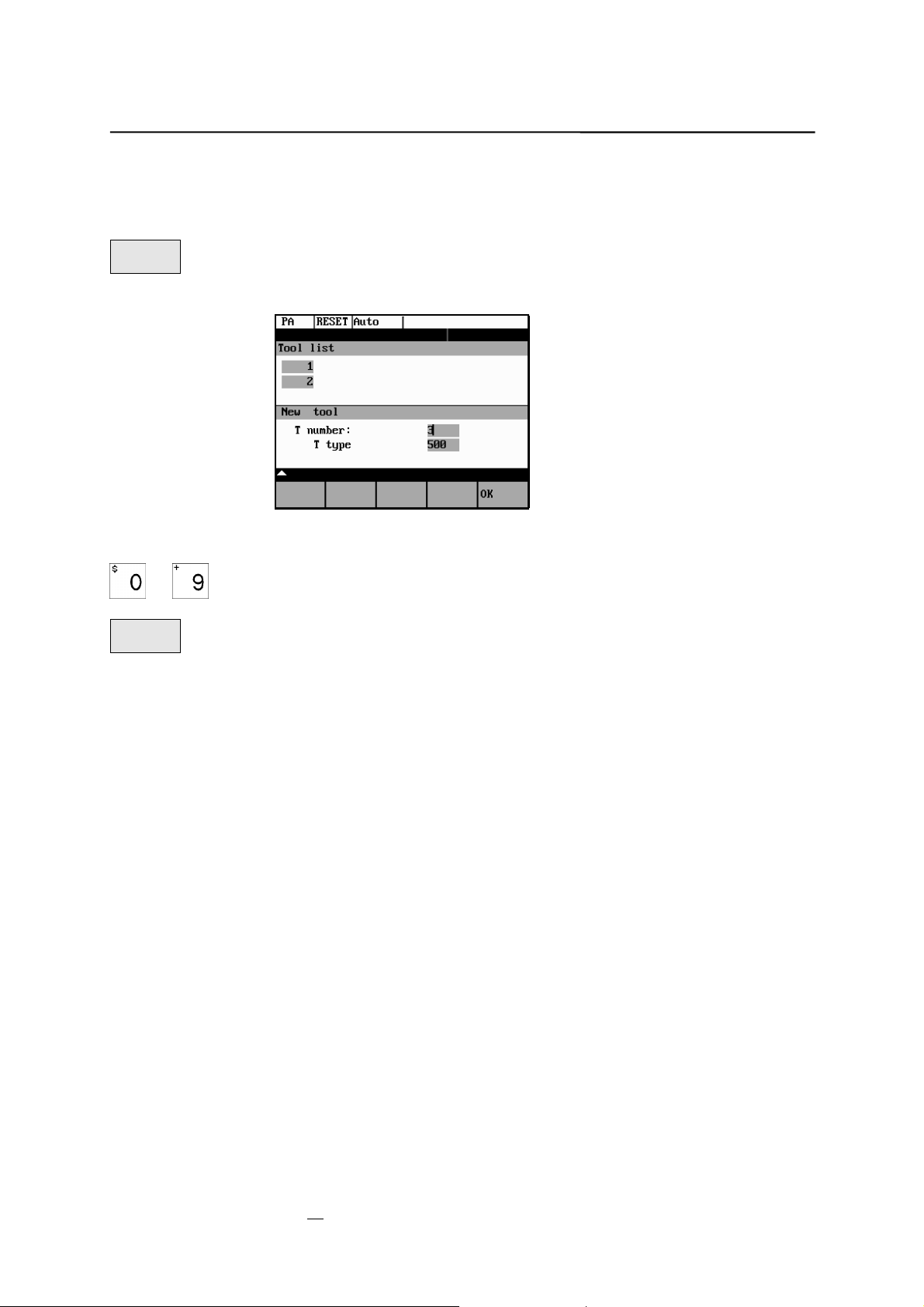

3.1.1 Creating a new tool

Operating sequence

Press this softkey to create a new tool.

New

tool

Fig 3-2 New Tool window

Pressing this softkey opens the input window and an overview of the tool

numbers assigned.

… Enter the new T number (maximal only three digits) a nd specify the tool type.

OK

Press OK to confirm your entry; the Tool Compensation Data window is

opened.

SINUMERIK 802S/C base line

Operation and Programming Turning

3-3

Page 28

Set Up

3.1.2 Tool compensation data

The tool compensation data are divided into length and radius compensation

data.

The list is structured according to the tool type.

Fig.3-3 Tool com pensation data window

Operating sequence

Enter the offsets by

positioning the cursor on the input field to be modified,

… entering value(s)

and confirming your entry by pressing Input or a cursor selection.

3-4

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 29

Set Up

?

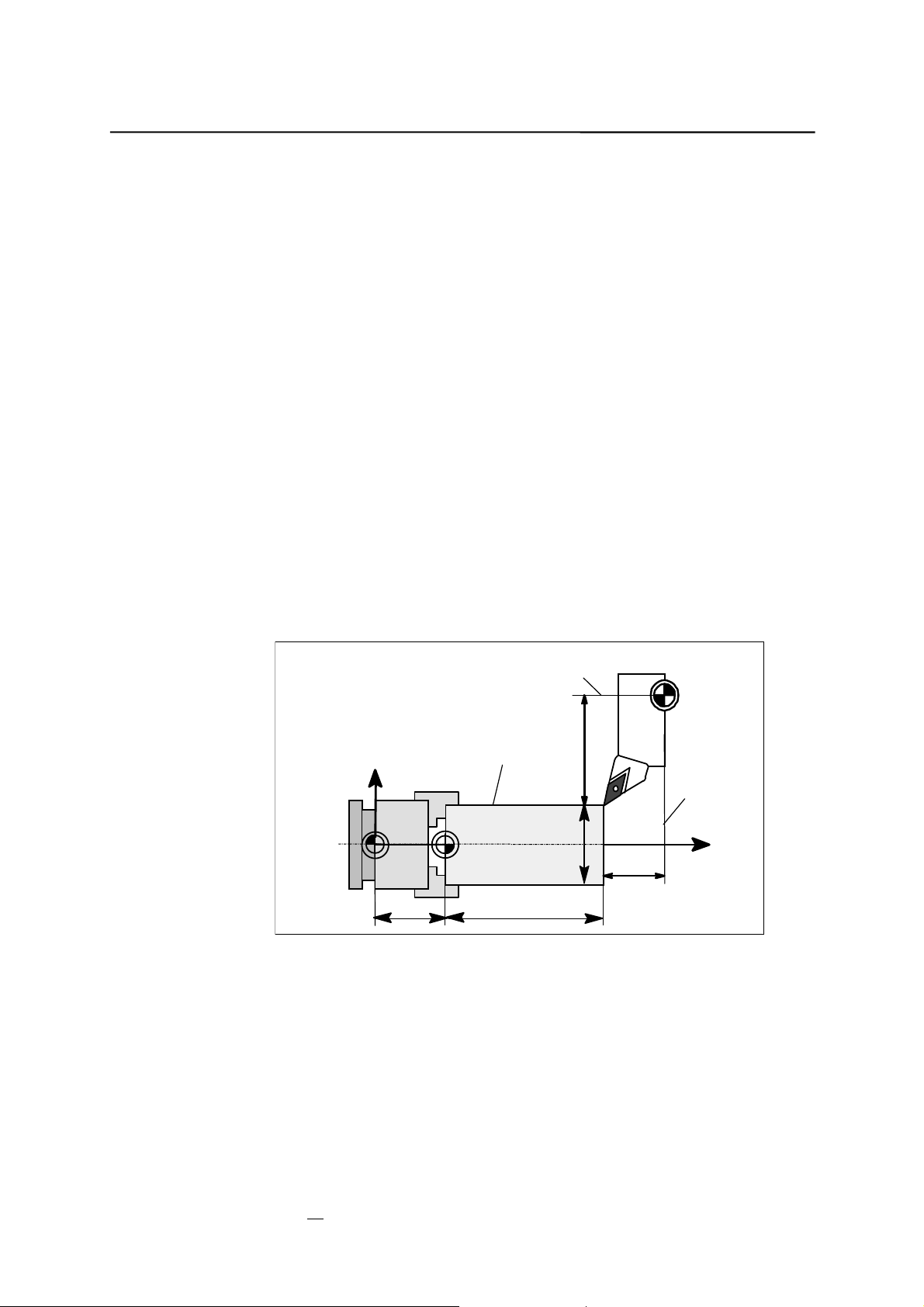

3.1.3 Determining the tool offsets

Functionality

Prerequisite

This function can be used to determine the unknown geometry of a tool T.

The appropriate tool has been changed. In JOG mode, approach a point on the

machine, from which you know the machine coordinates, with the edge of the

tool.This can be a tool with a known position. The machine coordinate value

can be split into two components: stored zero offset and offset.

Procedure

Enter the offset value into the intended Offset field. Then select the required

zero offset (e.g. G54) or G500 if no zero offset is to be calculated. These

entries must be made for each selected axis (see Fig. 3-6).

Please note the following:

The assignment of length 1 or 2 to the axis

depends on the type of tool (turning tool, drill)..

For the turning tool, the offset value for the X axis is a diameter dimension.

Using the actual position of point F (machine coordinate), the offset entry and

the selected zero offset Gxx (position of the edge), the control system can

calculate the assigned compensation value of length 1 or length 2 for the

preselected axis.

Note

: You can also use a zero offset already determined (e.g. G54 value) as

the known machine coordinate. In this case, approach to workpiece zero with

the edge of the tool. If the edge stands directly at the workpiece zero, the offset

value is zero.

F - tool carrier reference point

M - m a c h in e ze ro

W - workpiece zero

The offset value of the X axis is a

diameter value.

Actual position X

F

Workpiece

X

Machine

M

Gxx

Length 1=

W

Offset

Offset

Actual position Z

Length 2=?

Z

Machine

Fig.3-4 Determination of the length compensation values using the example of

a cutting tool

SINUMERIK 802S/C base line

Operation and Programming Turning

3-5

Page 30

Set Up

F- workpiece reference point

M-machine zero

W -workpiece zero

X

Machine

Workpiece

Actual position Z

M

Gxx

W

Offset

Length 1=?

F

Z

Machine

Fig.3-5 Determination of length compensation value using the example of a

drill: Length 1/Z axis

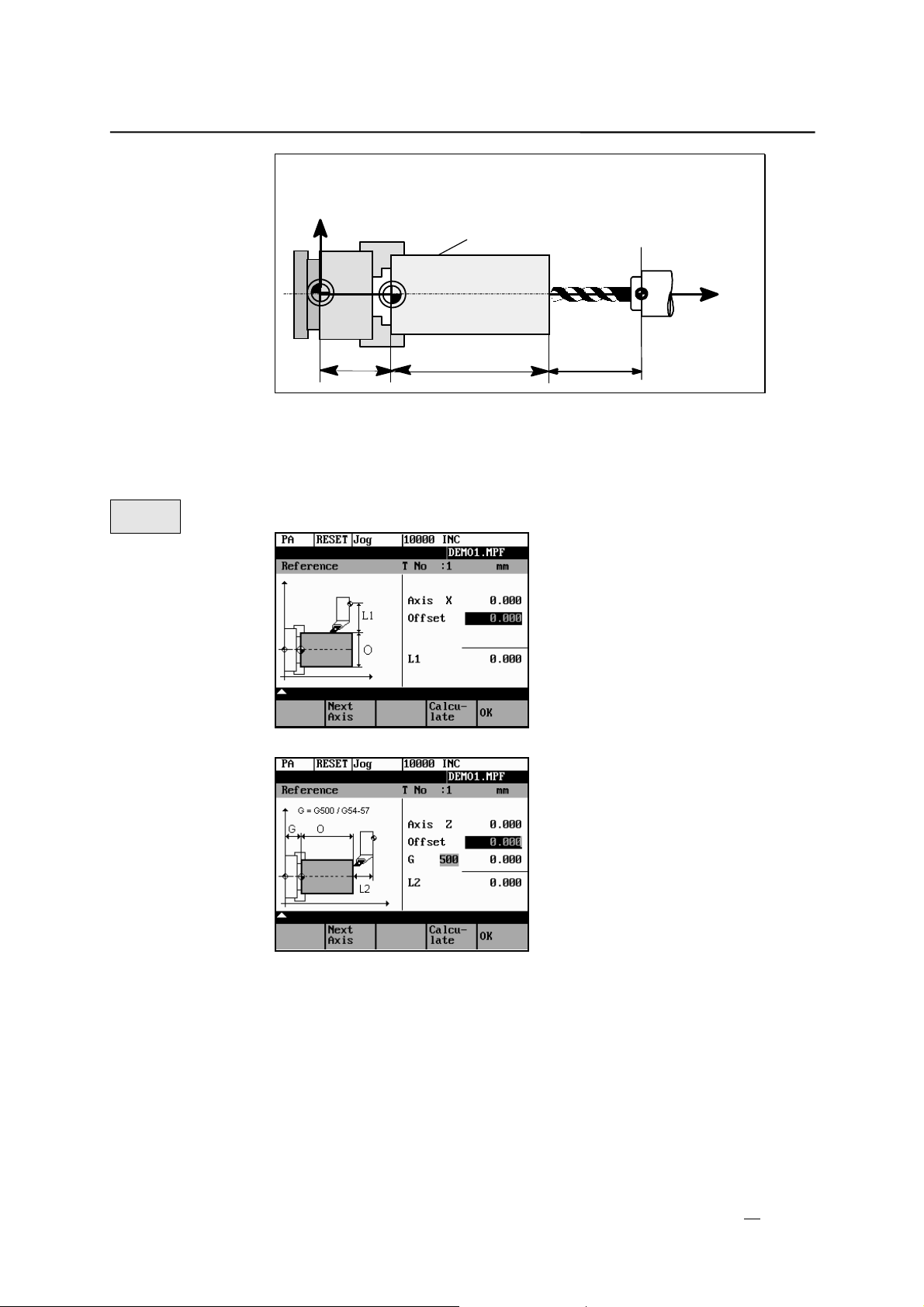

Operating sequence

Get

Comp.

Select the softkey Get Comp. The window Compensation values opens.

Fig.3-6 Compensation values window

Enter offset if the tool edge cannot approach the zero point Gxx. If you

z

work without zero offset, select G500 and enter offset.

When the softkey Calculate is pressed, the control system determines the

z

searched geometry length 1 or 2 depending on the preselected axis. This

geometry is calculated on the basis of the approached actual position, the

selected Gxx function and the entered offset value.

The determined compensation value is stored.

3-6

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 31

Set Up

3.2 Entering/modifying the zero offset

Functionality

The actual-value memory and thus also the actual-value display are referred to

the machine zero after the reference-point approach. The workpiece machining

program, however, refers to the workpiece zero.

This offset must be entered as the zero offset.

Operating sequences

Parameter

Use the Parameter and Zero Offset softkeys to select the zero offset.

An overview of settable zero offsets appears on the screen .

Zero

offset

Fig.3-7 Zero offset window

Position the cursor bar on the input field to be altered,

… enter value(s).

The next zero offset overview is displayed by Page down. G56 and G57 are

now displayed.

Return to next-higher menu level, without saving the zero offset values.

Softkeys

Determine

Use this function to determine the zero offset with refer to the coordinate origin

of the machine coordinate system. When you have selected the tool, which you

want to use for measuring, you can set the appropriate conditions in the

Determine window.

SINUMERIK 802S/C base line

Operation and Programming Turning

3-7

Page 32

Set Up

Programmed

Sum

A window with the programmed zero offset is displayed. The values in the

window cannot be edited.

Displays the sum of all active zero offsets. The values cannot be edited.

3.2.1 Determining the zero offset

Prerequisite

You have selected the window with the corresponding zero offset (e.g. G54)

and the axis for which you want to determine the offset.

F - tool support reference point

M - machine zero

W - workpiece zero

X

Machine

M

Workpiece

W

Length 2

F

Actual

Z position

Z

Machine

Zero offset Z=?

Fig.3-8 Determining the zero offset for the Z axis

Approach

A zero offset can only be determined with a known tool. Enter the active

z

tool in the dialog box. Press OK to take over the tool; the

window is then opened.

The selected axis appears in the Axis area.

z

The actual position of the tool support reference point (MCS) associated

to the axis is displayed in the adjacent field.

D number 1 is displayed for the tool edge.

z

If you have entered the valid offsets for the used tool under a D number

other than D1, enter that D number here.

The stored tool type is displayed automatically.

z

The effective length compensation value (geometry) is displayed.

z

Select the sign (-, +) for calculating the length offset, or select “without”

z

taking the length offset into account.

A negative sign subtracts the length offset value from the actual position.

The zero offset in the selected axis is the result.

Offset

z

If the tool does not reach zero, an offset can be entered to specify an

additional offset to a point which can be approched by the tool.

Determine

3-8

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 33

Set Up

Fig.3-9 Select Tool screen form

Fig.3-10 Determine zero offset form

Softkey can be used to select the zero offsets G54 to G57. The selected zero

Next

UFrame

Selects the next axis.

Next

Axis

Calculate

offset is displayed on the selected softkey.

Pressing the Calculate softkey calculates the zero offset.

Press the OK softkey to quit the window.

OK

SINUMERIK 802S/C base line

Operation and Programming Turning

3-9

Page 34

Set Up

3.3 Programming the setting data - “Parameters” operating area

Functionality

Use the setting data to define the settings for the operating states. These can

also be modified if necessary.

Operating sequences

Parameter

Sett.

The Setting Data softkey branches to another menu level in which various

data

Use the Parameter and Setting Data softkeys to select Setting Data.

control options can be set.

Fig.3-11 Setting data main screen

Use the paging keys to position the cursor on the desired line within the display

areas.

… Enter the new value in the input fields.

Use Input or the cursor keys to confirm.

Softkeys

Jog

data

This function can be used to change the following settings:

Jog feed

Feed value in Jog mode

If the feed value is zero, the control system uses the value stored in the

machine data.

Spindle

Spindle speed

Direction of rotation of the spindle

3-10

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 35

Set Up

Spindle

data

Limits for the spindle speed set in the Max. (G26)/Min. (G25) fields must be

Minimum / Maximum

within the limit values specified in the machine data.

Programmed (LIMS)

Programmable upper speed limitation (LIMS) at constant cutting speed (G96).

Dry-run feedrate for dry-run operation (DRY)

Dry

feed

The feedrate you enter here is used in the program execution instead of the

programmed feed during the Automatic mode when the Dry-Run Feedrate is

active (see Program Control, Fig. 5–3).

Start

angle

A start angle representing the starting position for the spindle is displayed for

Start angle for thread cutting (SF)

thread cutting operations. It is possible to cut a multiple thread by altering the

angle and repeating the thread cutting operation.

SINUMERIK 802S/C base line

Operation and Programming Turning

3-11

Page 36

Set Up

3.4 R parameters – “Parameters” operating area

Functionality

Fig.3-12 R Parameters window

All R parameters (arithmetic parameters) that exist in the control system are

displayed on the R Parameters main screen as a list (see also Section 8.8

“Arithmetic Parameters /R Parameters”). These can be modified if necessary.

Operating sequence

Parameters

R Parameters

Use the Parameter and R Parameter softkeys

to position the cursor on the input field that you want to edit.

… Enter value(s).

Press Input or use the cursor keys to confirm.

3-12

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 37

Manually Operated Mode

Preliminary remarks

The manually operated mode is possible in the Jog and MDA mode.

In the Jog mode, you can traverse the axes, and in the MDA mode, you can

enter and execute individual part program blocks.

4

4.1 Jog mode – “Machine” operating area

Functionality

Operating sequences

… Press the appropriate key for the X or Z axis to traverse the desired axis.

As long as the direction key is pressed and hold down, the axes traverse

… If necessary use the override button key to set the traversing speed.

It can be adjusted by settable increments:

0%, 1%, 2%, 4%, 8%, 10%, 20%, 30%, 40%, 50%, 60%, 75%, 80%, 85%, 90%,

In Jog mode, you can

traverse the axes and

z

set the traversing speed by means of the override switch, etc.

z

Use the Jog key on the machine control panel area to select the Jog mode.

continuously at the speed stored in the setting data. If this setting is zero, the

value stored in the machine data is used.

95%, 100%, 105%, 110%, 115%, 120%.

If you press the Rapid Traverse Overlay key at the same time, the selected

axis is traversed at rapid traverse speed as long as both keys are pressed

down.

SINUMERIK 802S/C base line

Operation and Programming Turning

4-1

Page 38

Manually Operated Mode

In the Incremental Feed operating mode, you can use the same operating

sequence to traverse the axis by settable increments. The set increment is

displayed in the display area. Jog must be pressed again to cancel the

Incremental Feed.

The Jog main screen displays position, feed and spindle values, including the

feedrate override and spindle override, gear stage status as well as the current

tool.

Fig.4-1 Jog main screen

Parameters

Table 4–1 Description of parameters in the

Parameter Explanation

MCS

X

Display of addresses of existing axes in machine

coordinate system (MCS).

Z

+X– Z If you traverse an axis in the positive (+) or negative (–)

direction, a plus or minus sign appears in the respective

field.

No axis is displayed, if the axis is in position.

Act.

mm

Repos

offset

The current position of the axes in the MCS or WCS is

displayed in these fields.

If the axes are traversed in the

Interrupted condition, the distance traversed by each axis

in relation to the break point is displayed in this column.

Spindle S

Display of actual value and setpoint of spindle speed

rpm

Feed F mm/min Display of path feed actual value and setpoint

Tool Display of currently active tool with the current cutting

edge number

Actual feedrate

Display of current feedrate override

override

Actual spindle

Display of current spindlel speed override

override

Gear stage Display of current gear stage in the machine

Jog

main screen

Jog

mode in the Program

Softkeys

Handwheel

4-2

Call the Handwheel window .

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 39

Manually Operated Mode

Axis

feed

Interp./

feed

Call the Axis Feed or Interp. Feed window .

Use this softkey to change between the Axis Feed window and the Interp. Feed

window.

The softkey label changes to Interp. feed when the Axis/Feed window is

opened.

Act. val.

WCS

Act.val.

MCS

The softkey changes between MCS and WCS. When doing this, the softkey

The actual values are displayed as a function of the selected coordinate

system. There are two different coordinate systems, i.e. the machine

coordinate system (MCS) and the workpiece coordinate sy stem (WCS).

label changes as follows:

The values of the machine coordinate system are selected, the softkey

z

label changes to Act. val. WCS.

When the workpiece coordinate system is selected, the label changes to

z

Act. val. MCS.

Zoom

act.val.

Enlarged view of actual values.

Pressing Recall key , return to the next-higher menu level.

SINUMERIK 802S/C base line

Operation and Programming Turning

4-3

Page 40

Manually Operated Mode

4.1.1 Assigning handwheels

An axis is assigned to the respective handwheel and becomes active as soon

as you press OK.

Operating Sequence

In Jog mode, call the Handwheel window.

Hand–

After the window has opened, all axis identifiers are displayed in the Axis

wheel

Place the cursor on the line with the handwheel to which you wish to assign an

column and also appear in the softkey bar. Depending on the number of

connected handwheels, it is possible to change from handwheel 1 to

handwheel 2 using the cursor.

axis. Then select the softkey that contains the name of the axis.

The symbol

appears in the window.

Fig.4-2 Handwheel window

WCS

MCS

OK

The WCS/MCS softkey is used to select the axes from the machine or

workpiece coordinate system for assignment to the handwheel. The current

setting is displayed in the handwheel window.

Use the OK softkey to take over the selected setting; the window is then

closed.

Menu extension

Deselect

4-4

The assignment you have made is reset for the selected handwheel.

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 41

Manually Operated Mode

4.2 MDA mode (Manual Data Input) – “Machine” operating area

Functionality

Contours that require several blocks (e.g. roundings, chamfers) cannot be

This mode is protected by the same safety interlocks as fully automatic mode.

!

Furthermore, the MDA mode is subject to the same prerequisites as the fully

Before NC-start of an input NC-program in the mode MDA is to wait till the

You can create and execute a part program block in the MDA mode.

executed/programmed.

Caution

automatic mode.

message “Block store active” displays on the screen.

Operating sequences

Use the MDA key in the machine control panel area to select the MDA mode.

Fig.4-3 MDA main screen

… Enter a block using the control keybo ard.

The entered block is executed by pressing NC START. The block cannot be

executed while machining is taking place.

SINUMERIK 802S/C base line

Operation and Programming Turning

4-5

Page 42

Manually Operated Mode

Parameters

Table 4–2 Description of the parameters in the MDA working window.

Parameter Explanation

MCS

Display of existing axes in MCS or WCS

X

Z

+X

– Z

If you traverse an axis in the positive (+) or negative (–)

direction, a plus or minus sign appears in the respective

field.

No sign is displayed if the axis is in position.

Act. value

mm

Spindle S

The current position of the axes in the MCS or WCS is

displayed in these fields.

Display of actual value and setpoint of spindle speed

rpm

Feed F Display of path feed actual value and setpoint in

mm/min or mm/rev.

Tool Display of currently active tool with the current tool edge

number (T..., D...).

Edit window In the Stop or Reset program state, an edit window is

provided for input of the part program block.

Actual feedrate

Display of current feedrate override

override

Actual spindle

Display of current spindlel speed override

override

Gear stage Display of current gear stage in the machine

Softkeys

The actual values for the MDA mode are displayed as a function of the

Act.val.

WCS

Act.val.

There are two different coordinate systems, i.e. the machine coordinate sy stem

MCS

Enlarged view of the actual values

Zoom

act.val.

selected coordinate system.

(MCS) and the workpiece coordinate system (WCS).

Menu extension

Display of Axis Feed or Interp. Feed window

Axis

feed

Interp.

feed

this softkey can be used to change between the two windows. The softkey

label changes to Interp. Feed when the Axis Feed window is opened.

The G function window contains all active G functions whereby each G function

Zoom

G funct.

is assigned a group and has its own fixed positon in the window.

Further G functions can be displayed using the Page Up or Page Down keys

together with Shift key. Select Recall to quit the window.

4-6

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 43

Manually Operated Mode

The window shows the currently edited block full length.

Zoom

block

Opens the M function window to display all active M functions of the block.

Zoom

M funct.

SINUMERIK 802S/C base line

Operation and Programming Turning

4-7

Page 44

Manually Operated Mode

4-8

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 45

Automatic Mode

5

Functionality

Preconditions

Operating sequence

The Automatic main screen appears that displays the position, feed, spindle,

In Automatic mode, part programs can be executed fully automatically, i.e. this

is the operating mode for standard processing of part programs.

The preconditions for executing part programs are:

Reference point approached.

z

You have already stored the required part program in the control system.

z

You have checked or entered the necessary offset values, e.g. zero

z

offsets or tool offsets.

The required safety interlocks are activated.

z

Use the Automatic key to select the Automatic mode.

override and tool values, the gear stage status as well as the current block.

Fig.5-1 Automatic main screen

SINUMERIK 802S/C base line

Operation and Programming Turning

5-1

Page 46

Automatic Mode

Parameters

Table 5–1 Description of the parameters in the working window

Parameter Explanation

MCS

Display of existing axes in MCS or WCS.

X

Z

+ X

– Z

If you traverse an axis in the positive (+) or negative (–)

direction, a plus or minus sign appears in the respective field.

No sign is displayed if the axis is in position.

Act. val.

mm

Distance

to go

Spindle S

The current position of the axes in the MCS or WCS is displayed

in these fields.

The remaining distance to be traversed by these axes in the

MCS or WCS is displayed in these fields.

Display of actual value and setpoint of spindle speed

rpm

Feed F

Display of path feed actual value and setpoint

mm/min or

mm/rev

Tool Display of currently active tool with the current cutting edge

number (T..., D...).

Current

block

Actual

The block display contains the current block. The block is output

in one line only and truncated if necessary.

Display of current feedrate override

feedrate

override

Actual

Display of current spindlel speed override

spindle

override

Gear stage Display of current gear stage in the machine

Softkeys

The window to select Program Control (e.g. skip block, program test) appears

Progr.

control

The window shows the previous, current and next block full length. In addition,

Zoom

block

Use the Block Search function to jump to the desired point in the program.

Search

The Search softkey provides the functions “Find line” and “Find text”.

Search

The cursor is positioned to the main program block of the breakpoint (”interrupt

Interr.

point

Continue Search

Contin.

search

on the screen.

the names of the current program or subroutine are displayed.

point”). The search target is automatically set in the subroutine levels.

5-2

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 47

Automatic Mode

O

The Start B Search softkey starts the search process in which the same

Start B

search

calculations are carried out as in normal program mode, but without axis

movements.

The block search can be canceled by NC Reset.

The values of the machine or workpiece coordinate system are selected. The

Act.val.

WCS

Act.val.

MCS

softkey label changes to Act. val. WCS or Act. val. MCS.

Zoom

act.val.

Enlarged view of actual values

Menu extension

Axis

feed

Interp.

This softkey can be used to change between the windows. The softkey label

feed

Execute

f. ext.

Zoom

G Funkt.

The G Function window contains all active G functions. Each G function is

When pressing these softkeys, the Axis Feed or Interp. Feed window appears.

changes to Interp. feed when the Axis Feed window is opened.

An external program is transferred into the control system via the RS232

interface and executed immediately by pressing NC START.

Opens the G Function window to display all active G functions.

assigned to a group and has a fixed position in the window. More G functions

can be displayed by pressing the PAGE UP or PAGE DOWN keys together

with Shift key.

DEM

Fig.5-2 Active G functions window

Zoom

M funct.

Opens the M Function window to display all active M functions.

SINUMERIK 802S/C base line

Operation and Programming Turning

5-3

Page 48

Automatic Mode

5.1 Selecting/starting a part program – “Machine” operating area

Functionality

The control system and the machine must be set up before the program is

started. Please note the safety instructions provided by the machine

manufacturer.

Operating sequence

Use the Automatic key to select the Automatic mode.

Programs

An overview of all programs stored in the control system is displayed.

Position the cursor bar on the desired program.

Select

Progr.

If necessary you can now make settings on program execution.

control

Use the Select softkey to select the program for execution. The selected

program name appears in the Program Name screen line.

The following program control functions can be activated and deactivated:

Fig.5-3 Program control window

The part program is executed when NC START is pressed.

5-4

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 49

Automatic Mode

M

5.2 Block search – “Machine” operating area

Operating sequence

Precondition: The desired program has already been selected (cf. Section 5.1),

and the control system is in the reset state.

Search

The block search function can be used to advance the program up to the

desired point in the part program. The search target is set by positioning the

cursor directly on the desired block in the part program.

DEMO.

Fig.5-4 Block search window

This function starts program advance and closes the Search window.

Start B

search

Result of the search

The desired block is displayed in the Current Block window.

SINUMERIK 802S/C base line

Operation and Programming Turning

5-5

Page 50

Automatic Mode

5.3 Stopping/aborting a part program – “Machine” operating area

Functionality

Part programs can be stopped and aborted.

Operating Sequence

The execution of a part program can be interrupted by selecting NC STOP.

The interrupted program can be continued by NC START .

The current program can be aborted by pressing RESET.

When you press NC START again, the aborted program is restarted and

executed from the beginning.

5-6

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 51

Automatic Mode

5.4 Repositioning after interruption – “Machine” operating area

Functionality

After a program interruption (NC STOP), you can move the tool away from the

Operating sequence

Search

Interr.

Point

Start B

search

contour in the manual mode (Jog). The control system stores the coordinates

of the breakpoint (”interrupt point”). The path differences traversed by the axes

are displayed.

Select the Automatic mode.

Open the Block Search window to load the breakpoint.

The breakpoint is loaded. The routine is adjusted to the start position of the

interrupted block.

A block search to the breakpoint is started.

Continue execution of the program by NC START.

SINUMERIK 802S/C base line

Operation and Programming Turning

5-7

Page 52

Automatic Mode

5.5 Program execution from external (RS232 interface)

Functionality

An external program is transferred to the control system via the RS232

interface and executed immediately by pressing NC START.

While processing the contents of the buffer memory, the program is

automatically reloaded. For example, as an external device, a PC can be used,

on which the WinPCIN tool for data transfer is installed.

Operating sequence

Prerequisite: The control system is reset.

The RS232 interface is parameterized correctly (see Chapter 7) and not

occupied by any other application (DataIn, DatatOut, STEP7).

Execute

f. ext.

Use WinPCIN (or PCIN) on the external device (PC) to set the program for

Press this softkey.

data output active.

The program is transferred to the buffer memory and automatically selected

and displayed in the program selection.

For the program execution, it is advantageous to wait until the buffer memory is

filled.

The program execution starts with NC START. The program is reloaded

continuously.

Either at the end of the program or when pressing RESET, the program is

automatically removed from the control system.

Note

As an alternative, External Program Execution can also be activated in

z

the Services area.

Any transfer errors are displayed in the Services area when you press the

z

Error log softkey.

5-8

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 53

Automatic Mode

5.6 Teach-in

Functionality

Use the submode Teach In to accept the axis position values directly into a

parts program block to be generated or modified.

The axis positions are approached either in Automatic mode by traversing the

JOG keys or by using the handwheel. However, first press the appropriate

softkey (see below) in the Programming operating area to enable the submode

Teach In.

Operating sequence

Prerequisite:

Teach-in option is set (display MD 278=4)

The control system is either in the state Stop or Reset.

Programs

open

A list of all programs existing in the control system is displayed.

Pressing Open calls the editor for the selected program and opens the editor

window.

Menu extension

Edit

Select

Menu extension

Teach In

Select

on

Fig.5-5 Teach in main screen

Softkeys

Use this softkey to generate a block with technological data.

Technol

. Data

SINUMERIK 802S/C base line

Operation and Programming Turning

5-9

Page 54

Automatic Mode

Use this screen form to enter

feed value

z

spindle speed and direction of rotation

z

tool and edge number

z

Feed mode (active; mm/min corresponds to G64; mm/rev. of spindle

z

corresponds to G96)

Positioning behavior (active; exact stop G60; continuous-path control

z

mode G64)

Fig.5-6 Input screen form for technological data

When you press OK, a block with the technological data entered is generated

and inserted in front of the block to which the cursor is positioned. Pressing

RECALL cancels your entry and lets you return to the Teach In main screen.

Teach In

Records

Use this softkey to generate NC blocks using the traversing keys or the

handwheel.

Simple NC blocks are generated by traversing with parallel axes using either

the traversing keys of the axes or the handwheel. It is also possible to correct

the values of an existing blocks.

Fig.5-7 Teach in of NC blocks

Fast

Trav.

Linear

Circul.

Use this softkey to generate a rapid traverse block (G0).

Use this softkey to generate a linear feed block (G1).

Use this softkey to generate a circular block (G5 with intermediate point and

end point).

5-10

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 55

Automatic Mode

Accept

Insert

Accept

Change

Use this softkey to generate a block with the values taught. The new block is

inserted in front of the block to which the cursor is positioned.

Values are corrected in the block (accepted from the screen form) to which the

cursor is positioned.

Use RECALL to return to the Teach In main screen. Any amendments you wish

to make can be later inserted manually.

Finish

Record

Progr.

run

The machine screen set in Automatic mode appears again. Use NC Start to

Use this softkey to generate an M2 block to be inserted after the current block

(cursor position).

Use this softkey to traverse the programmed block.

continue the selected but interrupted program from the block selected last (if

the control system has not been in Reset state). Teach In remains enabled.

Block search with Teach In active is not possible.

Teach

In Off

Use this softkey to turn off the submode Teach In.

Note

After turning off Teach In, the interrupted program can no longer be edited.

Example

Teaching a G5 block

Fig.5-8 Teach in of a circular blo c k

The program block with G5 is selected by the cursor.

z

Press the softkey Circul.

z

The circle start point is the end point of the previous block.

Approach to the intermediate point of the contour and press Accept

z

Change.

Approach to the end point of the contour and press Accept Change.

z

SINUMERIK 802S/C base line

Operation and Programming Turning

5-11

Page 56

Automatic Mode

5-12

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 57

Part Programming

6

Functionality

The standard cycles can also be displayed provided you have the required

Operating sequence

You are in the main menu.

Programs

Fig.6-1 Programming main screen

When the Program operating area is selected for the first time, the directory for

This Section describes how to create a new part program.

access authorization.

The Programming main screen appears.

part programs and subroutines is automatically selected (see above).

Softkeys

Cycles

This softkey is only displayed if the operator has the appropriate access

Select

Open

SINUMERIK 802S/C base line

Operation and Programming Turning

The Standard Cycles directory is displayed by pressing the Cycles softkey.

authorization.

This function selects the program highlighted by the cursor for execution. The

program is started on next NC START.

Opens the files selected by the cursor for editing.

Menu extension

6-1

Page 58

Part Programming

New

Use the New softkey to create a new program. A window appears in which you

are prompted to enter program name and type.

After you have confirmed your inputs by OK, the program editor is called, and

you can enter part program blocks. Select RECALL to cancel this function.

Copy

Delete

Use the Copy softkey to copy the selected program into another program.

The program highlighted by the cursor is deleted after the system has

requested confirmation of the delete operation.

Press OK to confirm the Delete request and RECALL to cancel it.

Rename

When you select the Rename softkey, a window appears in which you can

rename the program that you have already highlighted by the cursor.

After you have entered the new name, confirm your rename request by OK or

cancel by RECALL.

The Programs softkey can be used to change to the program directory.

Memory

Info

When you press this softkey, the totally available NC memory (in kbytes) is

displayed.

6-2

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 59

Part Programming

.

6.1 Entering a new program – “Program” operating area

Functionality

This Section describes how to create a new file for a part program. A window

appears in which you are prompted to enter program name and type.

DEMO

Fig.6-2 New program input screen form

Operating sequences

Program

You have selected the Program operating area. The Program Overview

window showing the programs already stored in the CNC is displayed on the

screen.

New

Press the New softkey. A dialog window appears in which you enter the new

main program or subroutine program name. The extension .MPF for main

programs is automatically entered. The extension .SPF for subroutines must

be entered with the program name.

… Enter the new name.

OK

Complete your input by selecting the OK softkey. The new part program file is

generated and is now ready for editing.

The creation of the program can be interrupted by RECALL; the window is the n

closed.

SINUMERIK 802S/C base line

Operation and Programming Turning

6-3

Page 60

Part Programming

6.2 Editing a part program – “Program” operating area

Functionality

Part programs or sections of a part program can only be edited if not being

executed.

Fig. 6-3 Editor window

Operating sequence

Programs

Y ou are in the main me nu and have selected the Program s operating area. The

program overview appears automatically.

DEMO.MPF

Use the paging keys to select the program you wish to edit.

open

Pressing the open softkey calls the editor for the selected program and pulls

down the editor window.

The file can now be edited. All changes are stored immediately.

Softkeys

User-assignable softkeys

You can assign predefined functions to the softkeys 1 - 4 (see Section 6.3.4

“User-Assignable Softkeys”).

The softkeys are assigned process-specific functions by the control

manufacturer.

Contour

The contour functions are described in Section 6.3 ”Programming Support”.

Menu extension

Edit

Mark

6-4

This function selectes section of text up to the current cursor position.

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 61

Part Programming

Delete

Copy

Past

Recomp.

cycles

This function deletes the selected text.

This function copies selected text to the clipboard.

This function inserts text from the clipboard at the current cursor poisition.

For re-compilation, the cursor must stand on the cycle call line in the program.

The required parameters must be arranged directly in front of the cycle call and

may not be separated by instruction or comment lines. The function decodes

the cycle name and prepares the screen form with the respective parameters.

If there are any parameters are outside the validity range, the function

automatically uses standard values. When the screen form has been quitted,

the original parameter block is automatically replaced by the corrected one.

Note: Only automatically generated blocks can be recompiled.

Note

To carry out these functions outside the Edit menu, it is also possible to use the

key combinations <SHIFT> and

softkey 1 Select

softkey 2 Delete block

softkey 3 Copy block

softkey 4 Insert block.

Menu extension

Assign

SK

This function can be used to change the assignment of the softkey functions 1 -

4.

For more detail description refer to Section NO TAG.

Search

Text

The softkeys Search and Contin. search can be used to search for a string

chain in the program file displayed on the screen.

Type the text you wish to find in the inp ut line and start the Sea rch operation by

selecting the OK softkey.

If the character string you have specified cannot be found in the program file,

an error message appears that must be acknowledged with OK.

You can exit the dialog box without starting the search by selecting RECALL.

Line no.

Type the line numbe r in the inp ut line.

The search is started by pressing OK.

You can quit the dialog box without starting the search by selecting RECALL.

Contin.

Search

The functions searches through the file to find another character string that

matches the target string.

SINUMERIK 802S/C base line

Operation and Programming Turning

6-5

Page 62

Part Programming

Close

This function stores the changes in the file system and automatically closes the

file.

Editing cyrillic letters

This function is only avaiable if the Russian language option is selected.

Procedure

The control system offers a window for cyrillic letters to choose from. This is

enabled/disabled using the Toggle key.

Fig.6-4

To select a character,

use the letters X, Y or Z to choose the line

z

and then enter the digit or the letter assigned to the corresponding

z

column.

When you enter the digit, the character will be copied into the edited file.

6-6

SINUMERIK 802S/C base line

Operation and Programming

Turning

Page 63

Part Programming

6.3 Programming support

Functionality

The programming support facility contains various help levels simplifying the

programming of part programs without constraining your choice of inputs.

6.3.1 Vertical menu

Functionality

The vertical menu allows you to quickly insert certain NC instructions into the

Operating sequence

You are in the program editor.

The vertical menu is displayed in the program editor.

part program.

Press the VM key and select the desired instruction from the list.

Fig.6-5 Vertical menu

Lines that end in “...” contain a collection of NC instructions. You can list these

instructions by pressing the Input key or entering the number of the line.

Fig.6-6 Vertical menu

Use the paging keys to browse through the list.

SINUMERIK 802S/C base line

Operation and Programming Turning

6-7

Page 64

Part Programming

Confirm your entry by pressing Input.

Alternatively, the number of the lines from 1 to 7 can be entered to select

instructions and take them over into the part program.

6.3.2 Cycles

Functionality

You can either specify your own machining cycles on assigning parameters or,

alternatively, use input forms in which you set all the necessary R parameters.

Operating sequences

LCYC 93

LCYC 94

The screen forms are selected either with the available softkey functions or by

means of the vertical menu.

Fig.6-7

The cycle support provides a screen form in which you can fill in all the

necessary R parameters. A graphic and a context-sensitive help will assist you

to fill in the form.

Select the OK softkey to transfer the generated cycle call to the part program.

OK

6-8

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 65

Part Programming

6.3.3 Contour

Functionality

The control system provides you with various contour forms to assist you in

creating part programs quickly and reliably. Enter the necessary parameters in

the screen forms and confirm your inputs.

The contour screen forms can be used to program the following contour

elements and contour sections:

Straight section with specification of end point or angle

z

Circle sector with specification of center point / end point

z

Circle sector with specification of center point / opening angle

z

Circle sector with specification of center point / radius

z

Straight line/straight line contour section with specification of angle and

z

end point

Straight line/circle contour section with tangential transition; calculated

z

from angle, redius and end point

Straight line/circle contour section with any transition; calculated from

z

angle, center point and end point

Circle/straight line contour section with tangential transition; calculated

z

from angle, radius and end point

Circle/straight line contour section with any transition; calculated from

z

angle, center point and end point.

Circle/circle contour section with tangential transition; calculated from

z

center point, radius and end point

Circle/circle contour section with any transition; calculated from center

z

point and end positon

Circle - straight line - circle contour section with tangential transitions

z

Circle - circle - circle contour section with tangential transitions

z

Fig.6-8

Softkeys

The sofkey functions branch to the contour elements.

Programming aid for programming straight line sections.

SINUMERIK 802S/C base line

Operation and Programming Turning

6-9

Page 66

Part Programming

Fig.6-9

Enter the end point of the straight line.

The block is traversed either at rapid traverse or with the programmed

G0/G1

feedrate.

The end point can be entered either in the absolute dimension, as an

incremental dimension (referred to the starting point) or in polar coordinates.

The current setting is displayed in the interactive dialog screenform.

The end point can also be specified by a coordinate and the angle between the

1st axis and the straight line.

If the end point is determined using polar coordinates, the length of the vector

between pole and end point is required, as well as the angle of the vector with

reference to the pole. When using the possibility, first a pole must be set.

Fig.6-10

Pressing the OK softkey takes over the block into the part program and

OK

displays the Additional Functions form in which you can extend the block by

adding more instructions.

6-10

Operation and Programming

SINUMERIK 802S/C base line

Turning

Page 67

Part Programming

Additional functions

Fig.6-11 Additional functions screen form

Enter additional commands in the fields. The commands can be separated by

means of blanks, commas or semi-colons.

This screen form is available for all contour elements.

OK

The OK softkey transfers the commands to the part program.

Select RECALL if you wish to exit the interactive form without saving the

values.

The dialog screen form is used to create a circular block by means of the end

and center point coordinates.

Fig.6-12

Enter the center point coordinates in the input fields.

To enter the coordinates, there are three variants:

absolute

z

incremental

z

polar

z

This softkey changes the direction of rotation from G2 to G3. G3 appears on

G2/G3

the display.

When you press the softkey again, you will return to G2.