Page 1

Overview of Controls

1

SINUMERIK 802S/C

Manual Machine

Operator’s Guide

Sequence of

Operations

Tool Data

Functions

Service Functions

Saving Data

Switching to the

Standard Operator

Interface

2

3

4

5

6

7

Valid for

Software Version

SINUMERIK 802S/C 3.1.0 or higher

Shutting Down the

Controller

Menu Tree

Messages

8

9

10

04/2005 Edition

Page 2

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is indicated by the code in the "Remarks" column.

Status code in the "Remarks" column:

A .... New documentation.

B .... Unrevised reprint with new order number

C .... Revised edition with new status

Edition Order No. Remarks

04/2005 ---

Trademarks

SIMATIC®, SIMATIC HMI®, SIMATIC NET®, SIROTEC®, SINUMERIK® and SIMODRIVE® are registered

trademarks of Siemens AG. Other names used in this publication may be trademarks, which, if used by third

parties for their own means, may violate the rights of their owners.

A

Additional information is available in the Internet at:

http://www.siemens.com/motioncontrol

This publication has been produced using WinWord V 8.0,

Designer V 7.0 and the DocuTool AutWinDoc.

© Siemens AG, 2005. All rights reserved

Order No. --Printed in Germany

Other functions not described in this documentation may be

executable in the control

obligation to supply such functions with a new control or when

servicing.

We have checked the contents of this manual for agreement with the

hardware and software described. Nevertheless, differences might

exist and we cannot, therefore, guarantee that they are completely

identical. However, the data in this manual are reviewed regularly and

any necessary corrections included in subsequent editions.

Suggestions for improvement are welcome.

Technical data subject to change.

Siemens Aktiengesellschaft

. This does not, however, represent an

Page 3

04/2005 Preface

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in 3 parts:

• General documentation

• User documentation

• Manufacturer/Service documentation

Please contact your local Siemens office for more detailed information about other

SINUMERIK 802D publications.

An overview of publications that is updated monthly is provided in a number of

languages in the Internet at:

http://www.siemens.com/motioncontrol

Follow menu items "Support" Æ "Technical Documentation" Æ "Overview of

Documents".

The Internet version of the DOConCD (DOConWEB) is available at:

http://www.automation.siemens.com/doconweb

Target readership

This Manual is intended for machine-tool users. This publication provides detailed

information that the user requires for operating the SINUMERIK 810D and 840D

controls.

Standard scope

This Operator’s Guide describes the functionality of the standard scope.

Extensions or changes made by the machine tool manufacturer are documented by

the machine tool manufacturer.

Other functions not described in this documentation may be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new module or when servicing.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

iii

Page 4

Preface 04/2005

Hotline

If you have any questions, please get in touch with our Hotline:

A&D Technical Support

Phone.: +49 (0) 180 / 5050 - 222

Fax: +49 (0) 180 / 5050 - 223

E-mail: mailto:adsupport@siemens.com

Internet: http://www.siemens.com/automation/support-request

If you have any queries (suggestions, corrections) in relation to this documentation,

please fax or e-mail us:

Fax: +49 (0) 9131 / 98 - 63315

E-mail: mailto:motioncontrol.docu@siemens.com

Fax form: See the reply form at the end of the document.

SINUMERIK Internet address

http://www.siemens.com/motioncontrol

Safety notes

This Manual contains information which you should carefully observe to ensure

your own personal safety and the prevention of material damage. The notices are

highlighted by a warning triangle The warnings are shown below in decreasing

order of danger.

!

!

!

Danger

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury or in substantial property damage.

Warning

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury or in substantial property damage.

Caution

Used with the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury or in property

damage.

© Siemens AG, 2005. All rights reserved

iv SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 5

04/2005 Preface

Caution

Used without safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Notice

Used without the safety alert symbol indicates a potential situation which, if not

avoided, may result in an undesirable result or state.

If several hazards of different degrees occur, the hazard with the highest degree

must always be given preference. If a warning note with a warning triangle warns of

personal injury, the same warning note can also contain a warning of material

damage.

Qualified personnel

Start-up and operation of the device/equipment/system in question must only be

performed using this documentation. The device/system must only be

commissioned and operated by qualified personnel. Qualified personnel as

referred to in the safety guidelines in this documentation are those who are

authorized to start up, earth and label units, systems and circuits in accordance

with the relevant safety standards.

Proper use

!

Note the following:

Warning

The device must only be used for the applications described in the Catalog and

only in combination with the equipment, components and devices of other

manufacturers as far as this is recommended or permitted by Siemens. It is

assumed that this product be transported, stored and installed as intended and

maintained and operated with care to ensure that the product functions correctly

and properly.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

v

Page 6

Preface 04/2005

Other information

!

Important

This notice indicates important facts that must be taken into consideration.

Note

This symbol always appears in this documentation where further, explanatory

information is provided.

Machine manufacturer

This pictorial symbol always appears in this document to indicate that the

machine manufacturer can affect or modify the function described. Note the

machine manufacturer’s instructions.

© Siemens AG, 2005. All rights reserved

vi SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 7

04/2005 Contents

Contents

1 Overview of Controls...................................................................... 1-9

1.1 Operator panel.............................................................................. 1-10

1.1.1 Key functions ............................................................................. 1-10

1.1.2 Controls on the machine............................................................ 1-11

2 Sequence of Operations ................................................................ 2-13

2.1 Powering-up the control................................................................ 2-14

2.2 Reference point approach ............................................................ 2-14

2.2.1 Preparations for reference point approach ................................ 2-14

2.2.2 Moving the axes ahead of the reference point .......................... 2-15

2.2.3 Reference point approach ......................................................... 2-16

2.3 Manual Machining......................................................................... 2-17

2.3.1 Displays on the main "Manual Machining" screen:.................... 2-18

2.3.2 Toggling the display................................................................... 2-19

2.3.3 Machining with the handwheels................................................. 2-20

2.3.4 Handwheel valuation setting...................................................... 2-20

2.3.5 Machining with the 4-way switch/axis direction keys................. 2-20

2.3.6 Spindle advance/reverse ........................................................... 2-21

2.3.7 Jog spindle................................................................................. 2-21

2.3.8 Tool change ............................................................................... 2-22

2.3.9 Machining technology data........................................................ 2-23

2.3.10 Changing the spindle/feedrate value ....................................... 2-24

2.3.11 Entering machining technology data: ...................................... 2-25

2.3.12 Spindle positioning................................................................... 2-27

3 Tool Data.......................................................................................... 3-29

3.1 Tool list.......................................................................................... 3-30

3.2 Tool calibration.............................................................................. 3-31

3.3 Geometry tool data ....................................................................... 3-32

3.4 Entering tool technology data ....................................................... 3-33

3.5 Deleting tool technology data ....................................................... 3-35

4 Functions......................................................................................... 4-37

4.1 Limit stops..................................................................................... 4-38

4.1.1 Setting limit stops....................................................................... 4-38

4.1.2 Activating/disabling limit stops ................................................... 4-40

4.1.3 Turning against mechanical stoppage....................................... 4-41

© Siemens AG, 2005. All rights reserved

Sinumerik 802S/C BA_MM (BA) – 04/2005 Edition

vii

Page 8

Contents 04/2005

4.2 Taper turning................................................................................. 4-42

4.3 Radius turning............................................................................... 4-44

4.4 Drilling - centered.......................................................................... 4-46

4.5 Tapping ......................................................................................... 4-49

4.6 Groove cycles/parting ................................................................... 4-53

4.6.1 Groove cycle - single ................................................................. 4-53

4.6.2 Groove cycle - multiple .............................................................. 4-57

4.6.3 Parting........................................................................................ 4-59

4.6.4 Multiple parting .......................................................................... 4-60

4.7 Thread cutting.............................................................................. 4-61

4.7.1 Longitudinal thread cutting......................................................... 4-61

4.7.2 Thread recutting......................................................................... 4-65

4.7.3 Thread shaving after thread cutting........................................... 4-67

4.8 Cutting cycles................................................................................ 4-68

4.8.1 Cutting cycle A........................................................................... 4-69

4.8.2 Cutting cycle B........................................................................... 4-73

4.8.3 Cutting cycle C........................................................................... 4-77

4.9 Setting the workpiece zero point................................................... 4-80

5 Service Functions........................................................................... 5-83

6 Saving Data ..................................................................................... 6-85

7 Switching to the Standard Operator Interface ............................. 7-87

7.1 General ......................................................................................... 7-88

7.2 "Reference Point Level" starting point .......................................... 7-88

7.3 "Manual Machining" starting point ................................................ 7-89

7.3.1 Switching back to the "Manual Machine" operator interface ..... 7-91

8 Shutting Down the Controller........................................................ 8-93

9 Menu Tree ........................................................................................ 9-95

10 Messages....................................................................................... 10-99

© Siemens AG, 2005. All rights reserved

viii Sinumerik 802S/C BA_MM (BA) – 04/2005 Edition

Page 9

04/2005 1 Overview of Controls

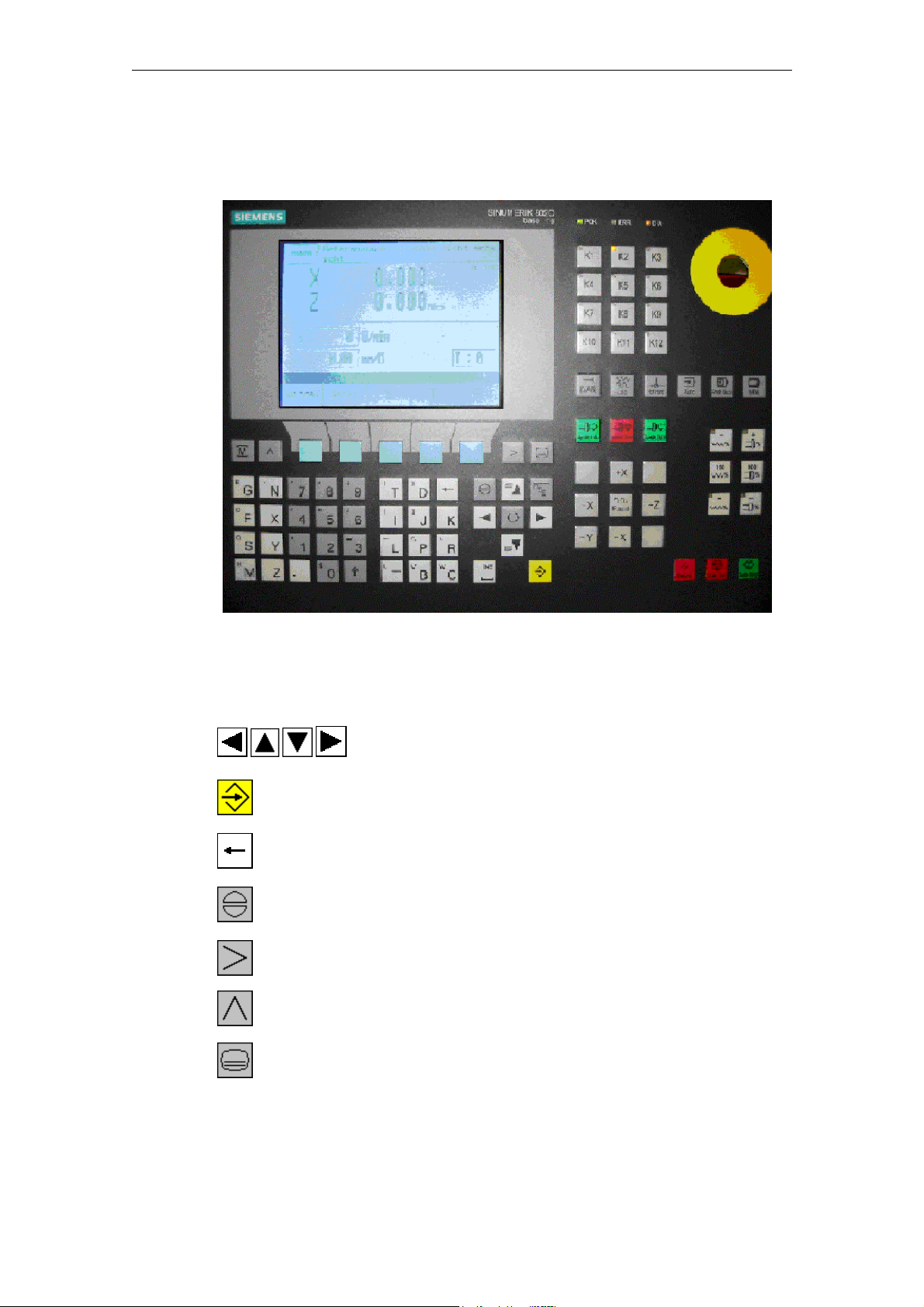

1.1 Operator panel

1

1 Overview of Controls

1.1 Operator panel.............................................................................. 1-10

1.1.1 Key functions ............................................................................. 1-10

1.1.2 Controls on the machine............................................................ 1-11

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

1-9

Page 10

1 Overview of Controls 04/2005

1.1 Operator panel

1.1 Operator panel

Fig. 1-1: Operator panel

1.1.1 Key functions

Move cursor in the direction of the arrow

Enter key (accept entry values)

Delete character (from right to left)

Acknowledge alarm

Extended menu (only if the corresponding symbol appears

on the screen)

Back key

(only if the corresponding symbol appears on the screen)

Monitor key, used exclusively for switching to the standard

operator interface (Sinumerik 802S/C base line).

© Siemens AG, 2005. All rights reserved

1-10 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 11

04/2005 1 Overview of Controls

1.1 Operator panel

Key not used for machine operation

Toggle key for handwheel valuation

JOG key for selecting “JOG” mode

1.1.2 Controls on the machine

(if provided by the machine manufacturer)

• NC start key

• NC stop key

• 4-way switch or axis direction keys (X+/X-/Z+/Z-) for axis movement

• Rapid traverse override switch or key for axis movement

• Spindle joystick or spindle direction keys for spindle control (clockwise or

counterclockwise rotation)

• Jog spindle key

• Handwheel for X and Z axis

• Emergency Stop button

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

1-11

Page 12

1 Overview of Controls 04/2005

1.1 Operator panel

© Siemens AG, 2005. All rights reserved

1-12 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 13

04/2005 2 Sequence of Operations

2.1 Powering-up the control

2

2 Sequence of Operations

2.1 Powering-up the control................................................................ 2-14

2.2 Reference point approach ............................................................ 2-14

2.2.1 Preparations for reference point approach ................................ 2-14

2.2.2 Moving the axes ahead of the reference point .......................... 2-15

2.2.3 Reference point approach ......................................................... 2-16

2.3 Manual Machining......................................................................... 2-17

2.3.1 Displays on the main "Manual Machining" screen:.................... 2-18

2.3.2 Toggling the display................................................................... 2-19

2.3.3 Machining with the handwheels................................................. 2-20

2.3.4 Handwheel valuation setting...................................................... 2-20

2.3.5 Machining with the 4-way switch/axis direction keys................. 2-20

2.3.6 Spindle advance/reverse ........................................................... 2-21

2.3.7 Jog spindle................................................................................. 2-21

2.3.8 Tool change ............................................................................... 2-22

2.3.9 Machining technology data........................................................ 2-23

2.3.10 Changing the spindle/feedrate value ....................................... 2-24

2.3.11 Entering machining technology data: ...................................... 2-25

2.3.12 Spindle positioning................................................................... 2-27

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-13

Page 14

2 Sequence of Operations 04/2005

2.1 Powering-up the control

2.1 Powering-up the control

Unless the machine manufacturer has set it up differently, the controller powers up

automatically when the power supply is switched on. Internal test routines are

performed during the power-up process. Once they have been successfully

completed, the controller opens and displays the Reference Point screen form.

2.2 Reference point approach

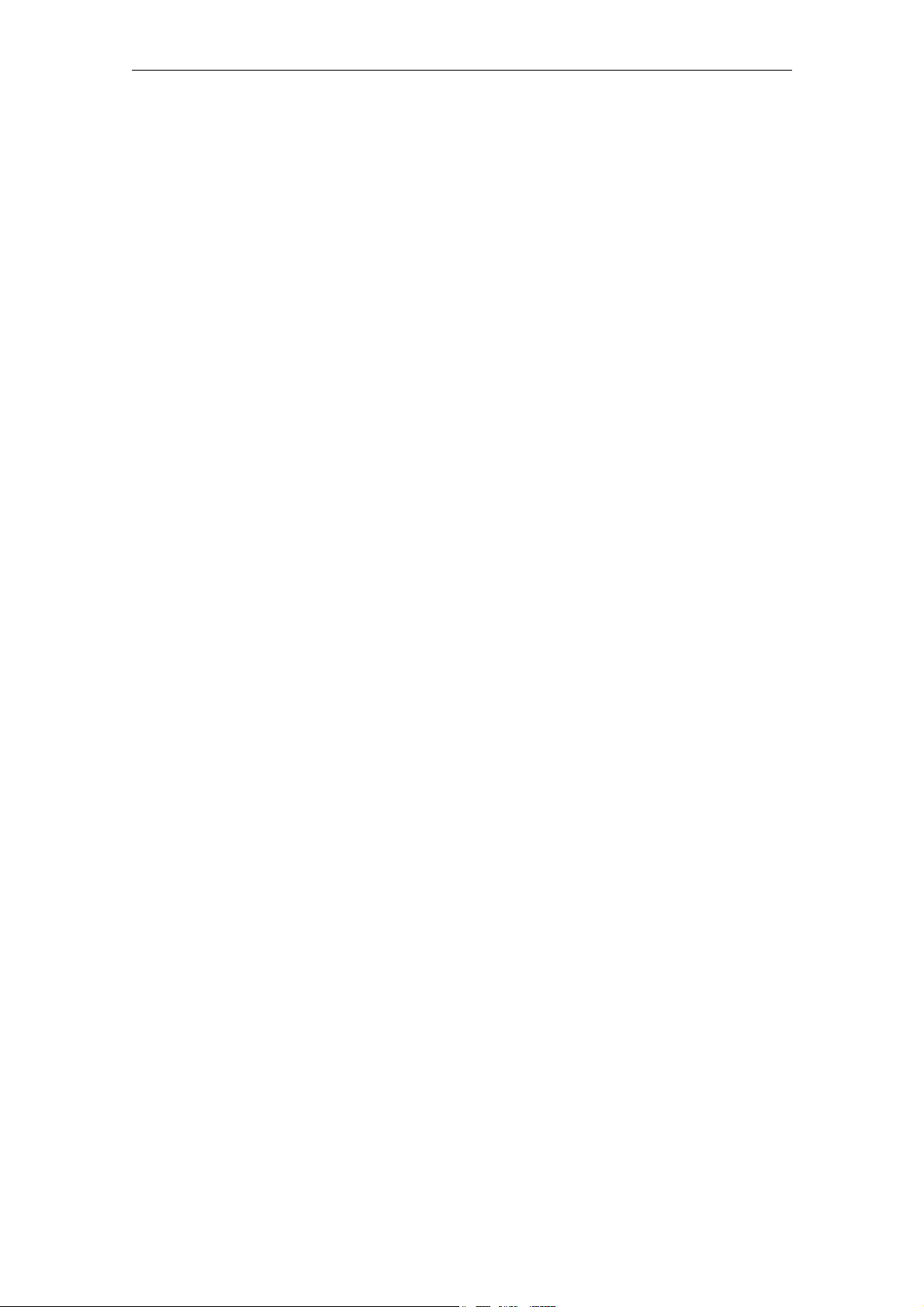

Once the controller has powered up, the Reference Point screen form appears:

Fig. 2-1: Reference point approach

!

Note

Before starting the reference point approach, be sure to move the machine slide

to a position from which the reference point can be approached in a positive axis

direction.

2.2.1 Preparations for reference point approach

Before you can approach the reference points for the two axes, the following

conditions must be met:

Prerequisite

• There must be no NC alarms pending!

→ Clear any that are pending by pressing the "Reset" function key.

• All machine axes must be in a position from which the reference point can be

reached in a positive traversing direction.

→ In manual mode, use the handwheels to move the axes to the appropriate

position ahead of the reference point.

© Siemens AG, 2005. All rights reserved

2-14 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 15

04/2005 2 Sequence of Operations

2.2 Reference point approach

2.2.2 Moving the axes ahead of the reference point

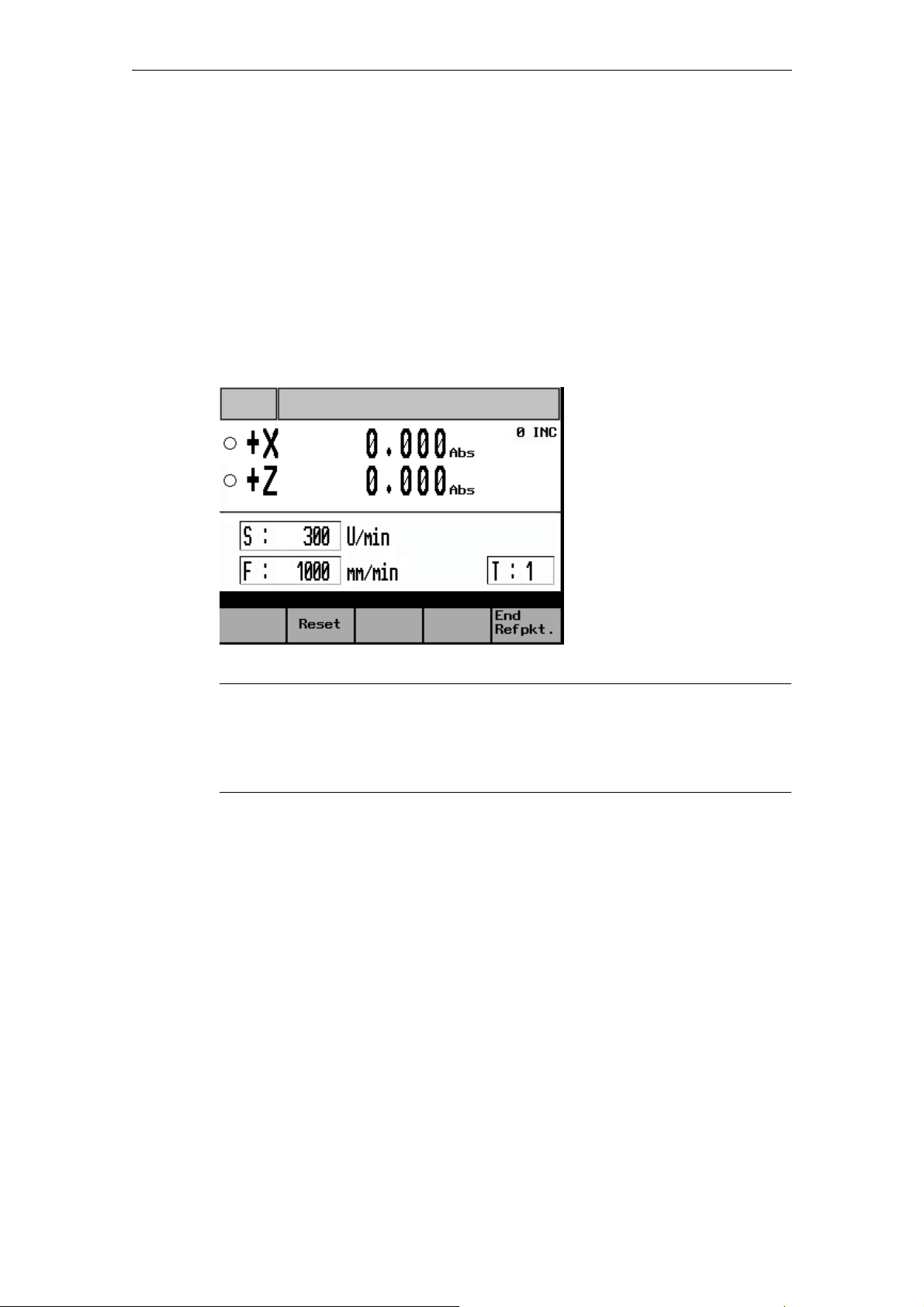

• Exit the Reference Point screen form by pressing the "End Refpkt" function key.

The following prompt appears:

Fig. 2-2: Exiting the Reference Point Approach screen

• Press "OK" to acknowledge the message and return to the main service

functions menu.

Fig. 2-3: Main Service Functions screen

• Press the “JOG” key once (otherwise, it will not be possible to switch to handwheel valuation).

• Then use the toggle key to set the handwheel valuation. The current setting will

appear on the top-right of the screen (e.g., 100 INC).

• Then use the handwheel to move the axes to a position from which they can

approach the reference point in a positive direction.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-15

Page 16

2 Sequence of Operations 04/2005

2.2 Reference point approach

Caution

In this operating mode the axes can only be approached using the handwheel.

Use of the 4-way switch or axis direction keys to move the axes is blocked. In

addition, the spindle cannot be started in this mode.

• Press the “Refer. Axes” function key to switch back to “Reference point

approach” mode.

2.2.3 Reference point approach

Displays

Axis has not yet been referenced

Axis has already reached the reference point (is referenced)

Once all the conditions have been met (→ Preparations for reference point

approach), reference point approach can be started for each axis as follows:

• Using the 4-way switch or axis direction key, start the X axis in the positive

direction (X+). The reference point for the X axis is then approached

automatically.

• At the end of this process the axis stops automatically and the symbol is

displayed in front of the axis name.

• Once the X axis has reached its reference point, the same process can be

repeated for the Z axis (Z+).

!

Note

The axes must be referenced in this sequence, i.e. the X axis first, followed by

the Z axis. Any other sequence will not be accepted by the controller.

Caution

If the machine manufacturer has not fitted an axis limit switch, there is a risk of a

mechanical collision if the axis is on the wrong side of the reference point cam

before the start of the reference point approach.

→ Preparations for reference point approach.

• Press the "End Refpkt." function key once both axes have been referenced to

return to the main "Manual Machining" screen.

© Siemens AG, 2005. All rights reserved

2-16 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 17

04/2005 2 Sequence of Operations

2.3 Manual Machining

2.3 Manual Machining

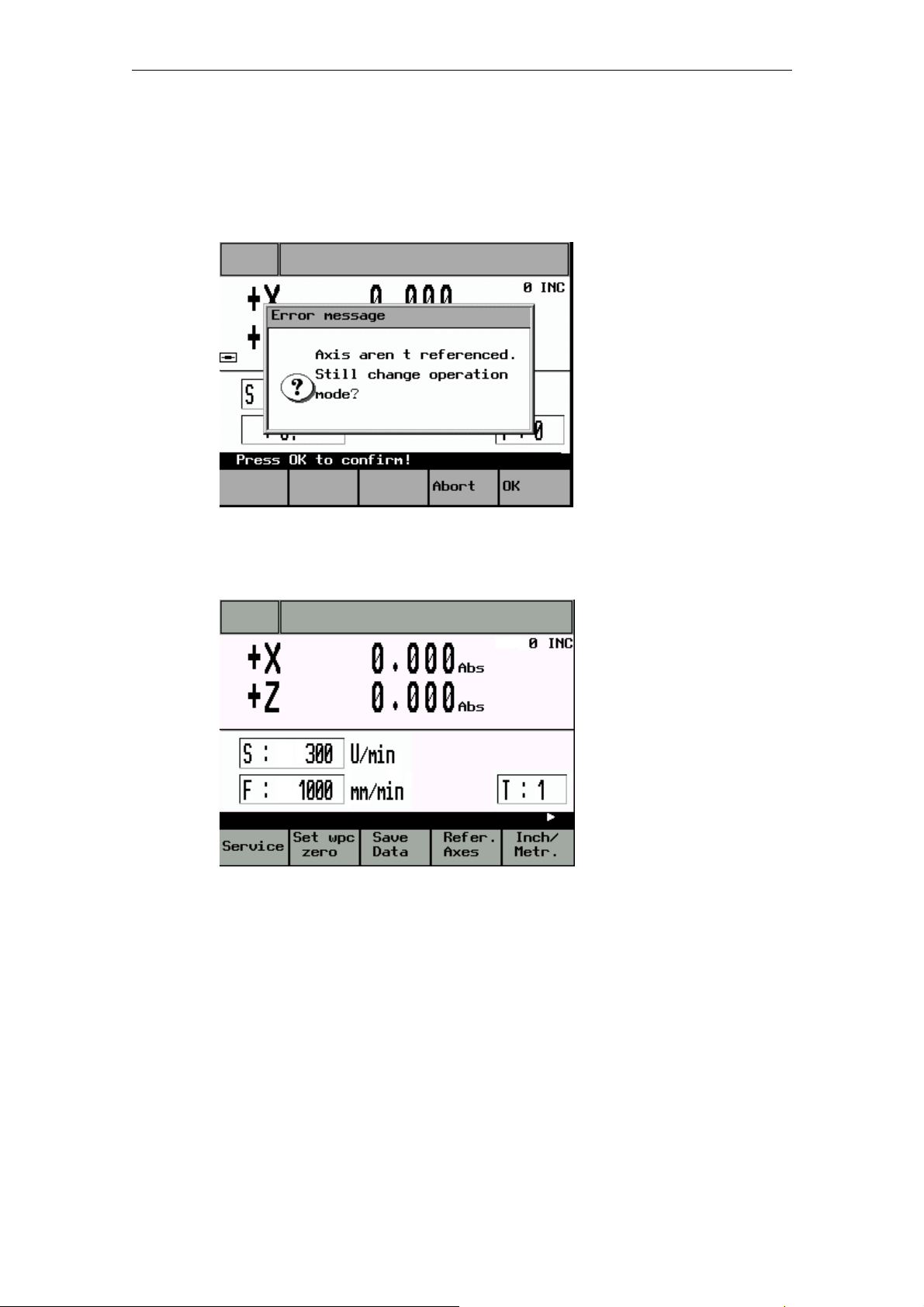

The main Manual Machining screen looks like this:

Fig. 2-4: Main "Manual Machining" screen

Manual workpiece machining is carried out in this operating mode.

Here the cross-slide is controlled either

• By means of the handwheels for the X and Z axis (→ Machining with the

handwheels) or

• By means of the 4-way switch or the axis direction keys (X+/X-/Z+/Z-)

(→ Machining with the 4-way switch/axis direction keys)

The spindle is controlled by means of

• The spindle joystick or the individual spindle advance and spindle reverse keys

(→ Spindle advance/reverse).

Machining technology data such as spindle speed, cutting speed and feedrate

must be set via special screen forms.

→ Machining technology data.

!

Note

Generally speaking the relevant machining technology data must be entered

before starting manual machining.

Caution

The maximum permissible spindle speed, which depends on the chucking device

fitted, must be entered in the Machining Technology Data screen form!

Failure to pay sufficient attention to this point can lead to serious damage as a

result of the chucking device speed being exceeded.

→ Machining technology data.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-17

Page 18

2 Sequence of Operations 04/2005

2.3 Manual Machining

2.3.1 Displays on the main "Manual Machining" screen:

Actual-value

display:

The current actual position for the X and Z axis is shown here.

If the abbreviation "Abs" appears after the position value, the

display shows the absolute machine position. If the

abbreviation "Rel" appears here, however, it is a relative

position reflecting the distance traversed since the display was

last reset.

→ Toggling the display.

Traversing

direction:

If the axis is moving, the current traversing direction is indicated

by the appropriate sign (+/-) in front of the axis letter (X/Z).

S value: The programmed value for either the spindle speed (Rev/min)

or the cutting speed (m/min) is shown here. The display

corresponds to the settings for the machining technology data.

→ Machining technology data.

F value: The programmed feedrate is displayed here in either "m/min" or

"mm/Rev", depending on the settings for the machining

technology data.

→ Machining technology data.

T value: The tool offset used by the controller is shown here.

→ Tool change.

INC value: Indicates the handwheel pulse weighting currently set.

→ Machining with the handwheels

© Siemens AG, 2005. All rights reserved

2-18 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 19

04/2005 2 Sequence of Operations

2.3 Manual Machining

2.3.2 Toggling the display

The radius turning function is accessed from the main "Manual Machining" screen

(Fig. 4) as follows:

• Change the function key bar by pressing the "Extended menu" key

Fig. 2-5: Main service “toggling the display”

Press the function keys shown to alter the display as follows:

“X NULL”: Press the "X=0" or "Z=0" key to change the actual value display

to "relative position display" and reset the display in the

corresponding axis.

“Z NULL”: Press the "X=0" or "Z=0" key to change the actual value display

to "relative position display" and reset the display in the

corresponding axis.

twice:

"X Abs./rel.”: Press the "abs./rel." key to toggle the actual value display

between "absolute position display" and "relative position

display" in the corresponding axis.

"Z Abs./rel.”: Press the "abs./rel." key to toggle the actual value display

between "absolute position display" and "relative position

display" in the corresponding axis.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-19

Page 20

2 Sequence of Operations 04/2005

2.3 Manual Machining

2.3.3 Machining with the handwheels

The handwheels for the X and Z axis are not mechanically connected to the feed

screws. Electronic pulse generators mounted on the handwheels generate the

information needed by the controller to execute the required traversing movement.

The handwheels are only active when the 4-way switch is in the zero position and

the individual axis control keys are disabled.

The distance traversed per handwheel pulse depends on the handwheel valuation

setting.

→ Handwheel valuation setting.

!

Note

If the handwheel valuation is set to "0" or if the feedrate override switch is in the

"0" position, the handwheels are disabled.

2.3.4 Handwheel valuation setting

Press the “Toggle key for handwheel valuation” in the main “Manual Machining”

screens to set the handwheel valuation.

The current setting will appear on the top-right of the screen (e.g., 100 INC).

If you are unable to adjust the handwheel valuation setting, it will be because the

controller's internal mode is incompatible with this process. Press the “JOG” key

once to resolve the problem.

Caution

An incorrect handwheel valuation setting can result in damage to the workpiece,

tool and machine.

2.3.5 Machining with the 4-way switch/axis direction keys

The axis can be traversed in the desired direction by turning the 4-way switch or

pressing the appropriate axis direction key. The feedrate at which the axis is

traversed depends on the settings in the Machining Technology Data screen form.

The axis feedrate is also influenced by the feedrate override switch setting and,

depending on the option selected in the Machining Technology Data screen form

(Rev. feedrate/cutting speed), by the spindle override switch.

© Siemens AG, 2005. All rights reserved

2-20 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 21

04/2005 2 Sequence of Operations

2.3 Manual Machining

If rapid traverse overlay is also actuated, the axis is moved at the maximum

possible speed unless a different value has been set at the feedrate override

switch.

!

Note

If the feedrate override switch is set to "0", any type of axis movement is blocked.

With the "Rev. feedrate" and "cutting speed" settings, the feed is blocked until the

spindle reaches the setpoint speed.

2.3.6 Spindle advance/reverse

The spindle is started in the appropriate direction (spindle advance/reverse) by

moving the spindle joystick or actuating the corresponding spindle direction key,

provided that the chuck guard switch is enabled (chuck guard closed).

!

Note

The spindle cannot be started unless the chuck guard switch is enabled.

→ Close the chuck guard.

Caution

Handling the chuck guard/chuck guard switch can lead to injury or mechanical

damage and should be avoided.

When the spindle is switched off it brakes and comes to a halt. If a spindle brake is

fitted, it is applied. If there is no spindle brake or it is switched off, the spindle can

be rotated freely once it has stopped.

If "Spindle Positi." is selected in the "Spindle Positioning" screen form, the spindle

is moved to the specified position after being switched off.

The spindle brake, if fitted, is then applied.

→ Spindle positioning.

The programmed spindle speed can be controlled by means of an appropriate

spindle override switch setting (e.g. 50%).

2.3.7 Jog spindle

The jog spindle key (if provided by the machine manufacturer) can be used to

rotate the spindle at low speed, for example to move a workpiece to a specific

angular position.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-21

Page 22

2 Sequence of Operations 04/2005

2.3 Manual Machining

2.3.8 Tool change

In the case of conventional/cycle-controlled machines of this order of magnitude,

with just a few exceptions, a manual tool change will generally be required. For this

reason, the correct tool number (tool compensation) must be notified to the control

by hand once the real tool change has taken place at the machine.

This is done as follows:

• Press function key "T" in the main Manual Machining screen form.

• The entry field for the T value is highlighted.

• Use the numeric keypad to enter the required tool number (tool offset)

(permissible values 1-15).

• Press "Enter" to complete the process.

If no further messages appear, the controller has completed the tool change.

!

Note

The tool number (tool offset) can only be changed, if all axes and the spindle are

stationary.

Caution

The tool number (tool offset) entered in the T value field must correspond to the

tool fitted in the machine. Otherwise, the tool will have to be re-calibrated (→ Tool

calibration). An uncalibrated or incorrectly calibrated tool can lead to dimensional

errors or to incorrect cutting values.

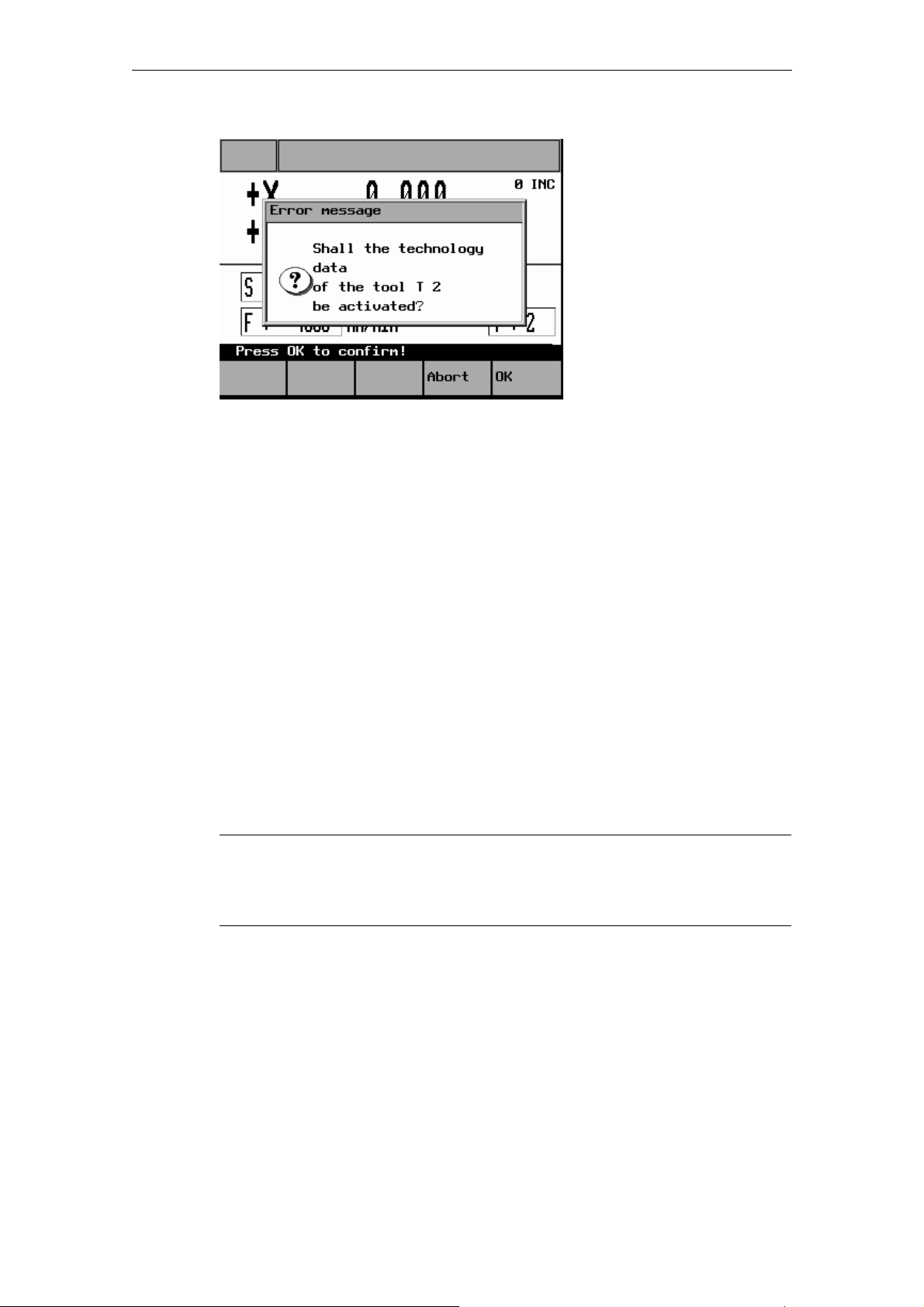

If machining technology data settings for the tool number (tool offset) to be

activated are found in the “Tool Data” screen form (→ Entering tool technology

data), the following message appears (relating to T4, in this example):

© Siemens AG, 2005. All rights reserved

2-22 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 23

04/2005 2 Sequence of Operations

2.3 Manual Machining

Fig. 2-6: Tool technology data acceptance message

The question can be answered by pressing one of these function keys:

"OK" The tool offsets for the X and Z axis corresponding to the last tool

calibration operation are applied. The actual-value display changes,

if necessary.

The previous machining technology data is also overwritten by the

tool technology data (which has been saved for this tool) (feedrate,

spindle speed, cutting speed)

→ Entering tool technology data.

“Abort” The tool offsets for the X and Z axis corresponding to the last tool

calibration operation are applied. The actual-value display changes,

if necessary.

The previous machining technology data is retained.

2.3.9 Machining technology data

Machining technology data, such as spindle speed, cutting speed and feedrate,

defines the settings that the controller needs for the machining of workpieces.

!

Note

The machining technology data can only be changed, if all axes and the spindle

are stationary.

There are two ways of changing the machining technology data:

• Simple changes to the spindle and feedrate values (S value/F value) can be

made directly in the "Manual Machining" screen form.

→ Changing the spindle/feedrate value

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-23

Page 24

2 Sequence of Operations 04/2005

2.3 Manual Machining

• A separate screen form is provided for entering the full set of machining

technology data.

→ Entering machining technology data

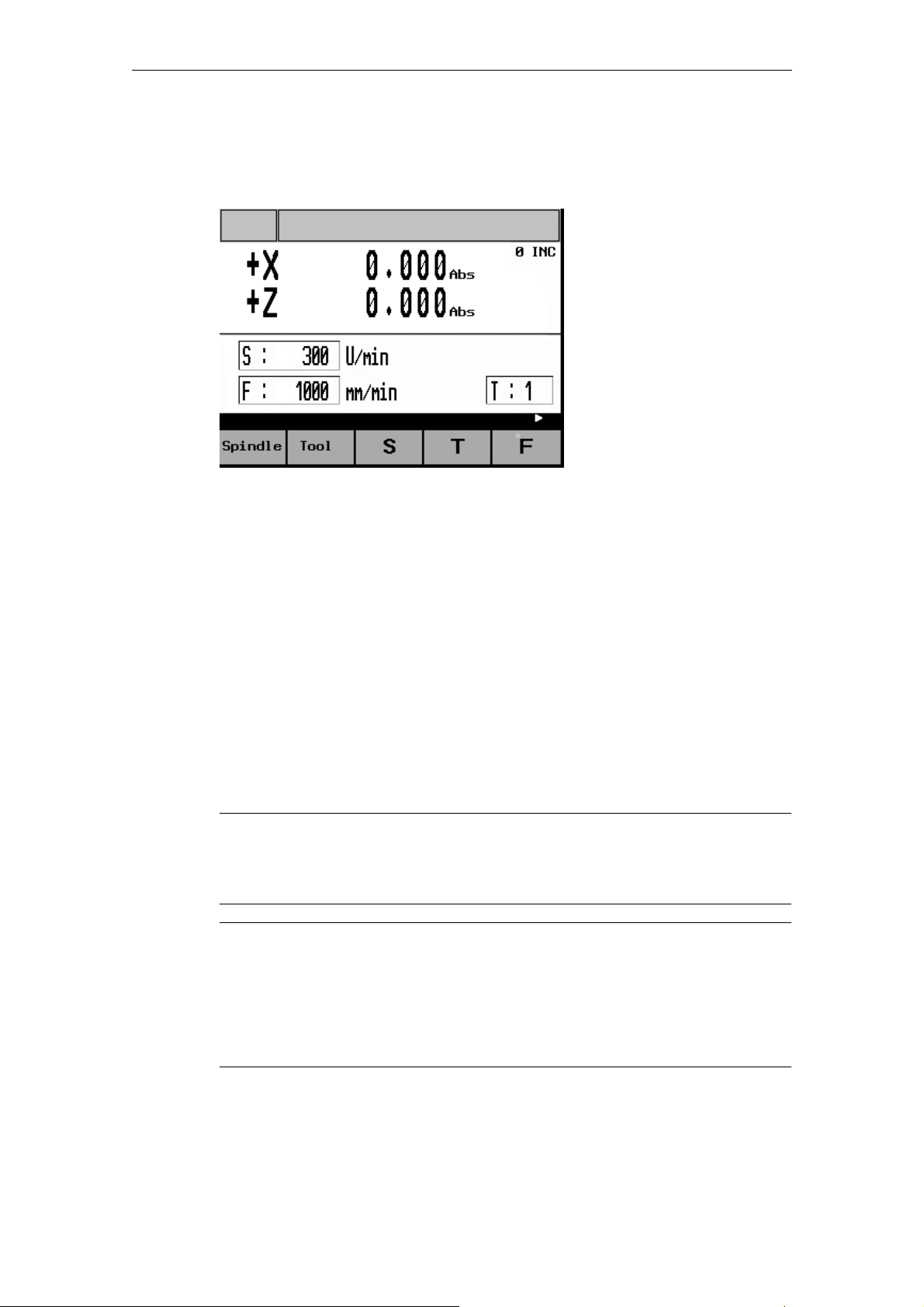

2.3.10 Changing the spindle/feedrate value

This method of adapting technology data can be used to change values quickly

during machining.

The values are changed using the appropriate function keys in the "Manual

Machining" screen form.

However, it is not possible to switch between "m/min" and "rev/min" (spindle) or

"mm/min" and "mm/rev" (axis) here (→ Entering machining technology data).

Changing

the S

value:

Changing

the F

value:

!

Note

The S value or F value can only be changed if all axes and the spindle are

stationary.

Press function key "S" to highlight the display field showing the

current programmed spindle value. The programmed value can now

be changed via the numeric keypad. Then press Enter to accept

(activate) the change. The entry field is deselected and the process

is complete.

To abort the change, press function key "S" or the Alarm reset key

instead of Enter. In this case the entry field is again deselected, the

new value is cleared and the previously programmed spindle value

is restored.

You cannot switch between "m/min" and "rev/min" here.

Press function key "F" to highlight the display field showing the

current programmed feedrate value. The programmed value can

now be changed via the numeric keypad. Then press Enter to

accept (activate) the change. The entry field is deselected and the

process is complete.

To abort the change, press function key "F" or the Alarm reset key

instead of Enter. In this case the entry field is again deselected, the

new value is cleared and the previously programmed feedrate value

is restored.

You cannot switch between "mm/min" and "mm/rev" here.

© Siemens AG, 2005. All rights reserved

2-24 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 25

04/2005 2 Sequence of Operations

2.3 Manual Machining

2.3.11 Entering machining technology data:

To open the screen form for machining technology data, press the "Spindle"

function key in "Manual Machining".

The following screen form appears:

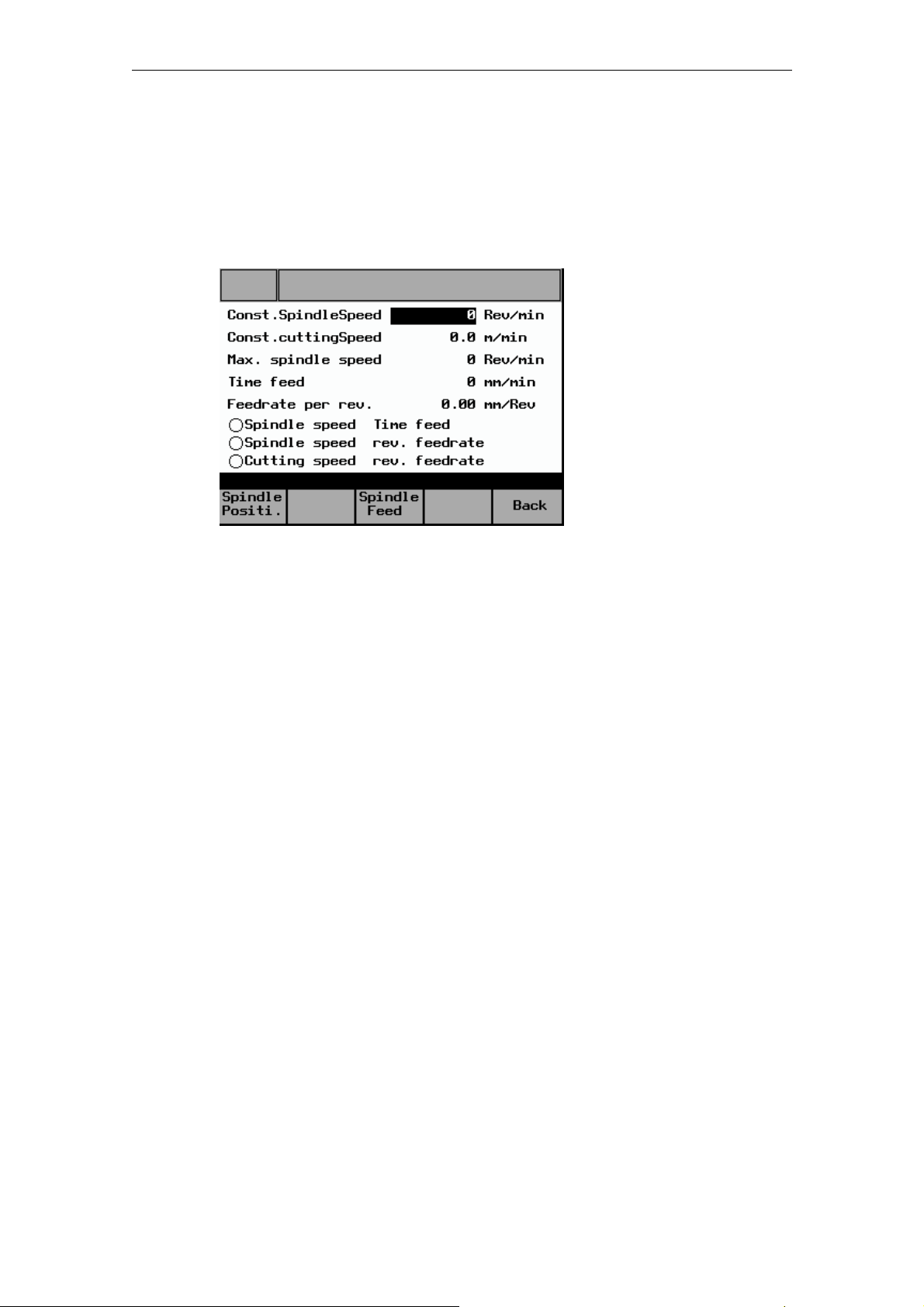

Fig. 2-7: Machining technology data input

When the screen form appears, the last entry field to have been edited is

highlighted and a new value can be entered. To change a value in a different entry

field, use the cursor keys to move to that field. Enter the value via the numeric

keypad and then press Enter to accept (activate) the value. To abort the change

and restore the previous entry value, use the cursor keys to move to a different

entry field or exit the screen form (by pressing the "Back" function key), without

pressing Enter.

The meanings of the individual entry fields are defined as follows:

Const. Spindle

Speed

This entry value defines the programmed spindle speed for

machining with "Spindle speed + Time feed" or "Spindle

speed + Rev. feedrate". The value is only fully reached if no

reduction is specified via the spindle override valuation or the

spindle speed limit parameter ("Max. spindle speed").

Const. cutting

Speed

Cutting speed entry value for machining with "Cutting speed +

Rev. feedrate". The spindle speed is adjusted to the

machining diameter of the workpiece so that uniform cutting

conditions are achieved. Since the spindle would theoretically

have to rotate at an "infinitely high" speed at the rotational

center point in this mode, it has to be limited via the "Max.

spindle speed" parameter. The constant cutting speed can

also be influenced by means of the feedrate and spindle

override valuation settings.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-25

Page 26

2 Sequence of Operations 04/2005

2.3 Manual Machining

Max. spindle

speed

It is vital to enter the maximum permissible spindle speed

here. The spindle speed is then limited to this value under all

circumstances, so that the permissible chucking device

speed, for example, cannot be exceeded.

Time feed If Time feed is selected, the axes are moved at the speed

entered here (mm/min) (unless rapid traverse override is

activated). It can be influenced by the feedrate override

switch setting.

Feedrate per

rev.

The value entered here determines the axis velocity in

“Spindle speed + Rev. feedrate” or “Const. cutting speed +

Rev. feedrate” modes (if no rapid traverse override is set). It

is influenced directly by the feedrate override valuation setting

and indirectly by the spindle override valuation setting.

Caution

In the entry field for the maximum permissible spindle speed, you must enter the

value specified by the manufacturer for the chucking device that is fitted!

Failure to pay sufficient attention to this point can lead to serious damage as a

result of the chucking device speed being exceeded.

• To select the desired machining mode, press the "Spindle Feed" function key

one or more times:

"Spindle speed + Time feed" → "Spindle speed + Rev. feedrate" → "Cutting

speed + Rev. feedrate"

The symbols displayed next to the text have the following meaning:

Display:

Machining mode deselected

Machining mode active (selected)

© Siemens AG, 2005. All rights reserved

2-26 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 27

04/2005 2 Sequence of Operations

2.3 Manual Machining

2.3.12 Spindle positioning

The Spindle positioning function is intended purely for stopping the spindle in a

specific position to facilitate fitting of the chuck guard. It is not intended for positionrelated machining.

If the Spindle positioning function is selected, the spindle is switched off and then

moved to the position specified in the "Set spindle pos." entry field. If fitted, a

spindle brake is then applied.

To open the “Spindle Positioning” screen form, press the "Spindle Positi." function

key in the "Machining Technology Data" screen form.

The following screen form appears:

Fig. 2-8: Spindle positioning

When the screen form appears, there are two ways to enter the position:

• Use the numeric keypad to enter the position directly in the highlighted entry

field for the "Set spindle pos.". Then press Enter to accept the value. Only

values from 0 to 359.9 are permitted; otherwise, an error message appears and

the value is not accepted.

• After switching off the spindle, rotate it manually into the required position and

press Enter. The current spindle position is displayed in the "Set spindle pos."

entry field and automatically accepted. If the spindle has not completed a full

rotation since the controller was last powered up, the spindle is not yet

synchronized and the position will therefore not be accepted. In this case, a

corresponding message is displayed.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

2-27

Page 28

2 Sequence of Operations 04/2005

2.3 Manual Machining

Press "ON" to activate spindle positioning and "OFF" to deactivate it.

The current status is indicated as shown below:

Display:

Function deselected

Function active (selected)

© Siemens AG, 2005. All rights reserved

2-28 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 29

04/2005 3 Tool Data

3.1 Tool list

3

3 Tool Data

3.1 Tool list.......................................................................................... 3-30

3.2 Tool calibration.............................................................................. 3-31

3.3 Geometry tool data ....................................................................... 3-32

3.4 Entering tool technology data ....................................................... 3-33

3.5 Deleting tool technology data ....................................................... 3-35

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

3-29

Page 30

3 Tool Data 04/2005

3.1 Tool list

3.1 Tool list

The controller is supplied with a tool list for 15 tools as standard. However, the

individual tools must be calibrated prior to initial use.

→ Tool calibration.

Caution

An uncalibrated or incorrectly calibrated tool can lead to dimensional errors or to

incorrect cutting values! If the values entered are very different from the actual

tool values, there is a risk that the tool may break or the mechanism or workpiece

may be damaged.

To open the "Tool Data Overview", press the "Tool" function key in the main

"Manual Machining" screen form.

The following screen form appears:

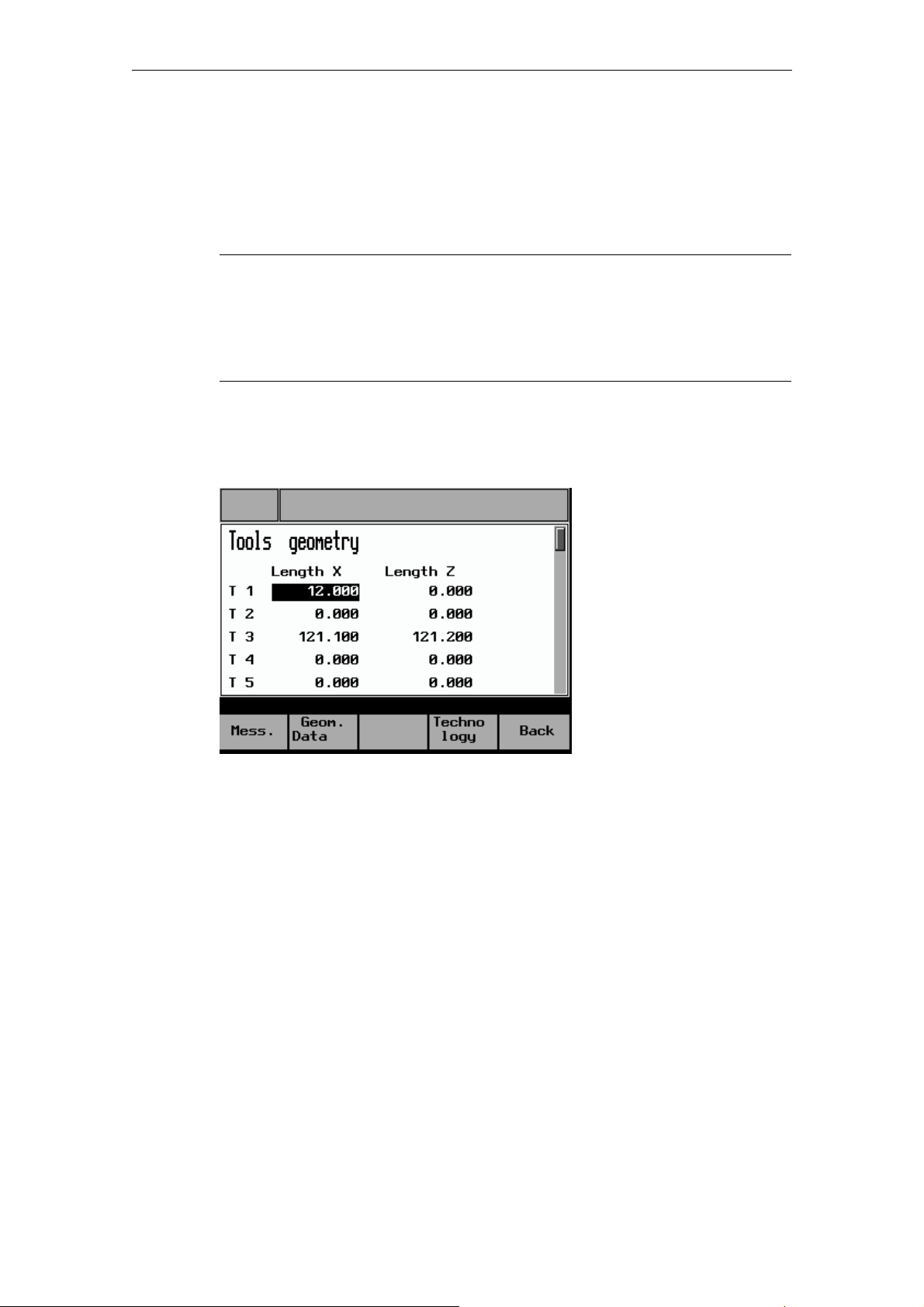

Fig. 3-1: Tool data overview

The active offsets for each tool, known as the tool offsets for the X and Z axis, are

displayed in this screen form. Experienced lathe operators can use this screen

form to enter the tool offsets, as on CNC controllers. Other operators should simply

refer to this screen form for information about the current offsets. The actual tool

measuring process takes place in the "Tool Measuring" screen form.

→ Tool calibration.

Data can be entered in the "Tool Data Overview" as follows:

• Use the cursor keys to select the required field (field is highlighted)

• Select the required tool type (turning tool or drilling tool) by pressing the

"Turn-/Boretool" function key

• Enter the values and press Enter to accept. The actual value display on the

machine (in "Manual Machining") is now updated to reflect the change. If you do

not wish to accept the value entered, either use the cursor key to leave the

entry field or switch to another screen form without pressing Enter.

© Siemens AG, 2005. All rights reserved

3-30 SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

Page 31

04/2005 3 Tool Data

3.2 Tool calibration

3.2 Tool calibration

The supported tool calibration function is described below by reference to the X

axis of a turning tool:

• Fit the tool to be calibrated into the machine.

• In the "Manual Machining" screen form select the appropriate tool number.

→ Tool selection

• Switch to the "Tool Data Overview" screen form.

• Keep on pressing the cursor key until the relevant tool number is highlighted.

• Press the “Mess.” function key; in the case of turning tools, the following screen

form will appear:

Fig. 3-2: Tool calibration (turning tools)

• Check that the current tool number appears in the display field for the tool, since

the calibration operation will relate to this tool. If not, press the "Back" function

key to return to the "Tool Data Overview" and select the correct tool.

• With the spindle running, adjust the X handwheel carefully to "scratch" a

workpiece and then (without changing the X position) traverse the slide in the Z

axis with the handwheel (axial turning).

• Switch off the spindle.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

3-31

Page 32

3 Tool Data 04/2005

3.3 Geometry tool data

• Enter the diameter measured at the workpiece in entry field "d1".

• Press Enter to accept the value. The controller then automatically calculates the

corresponding tool offset (in the radius) and displays this as value "L1" in the

screen form.

!

Note

If you exit the screen form at this point, the new offset will not take effect!

• Press the "Enter value" function key to apply the new tool offset for the selected

tool in the X axis. Provided that the "scratch position" in the X axis has not been

moved, the measured diameter is now displayed as the actual position in the

"Manual Machining" screen form.

• Press the "Z axis" function key to change the screen form so that the process

can be repeated for the Z axis.

• Press "Back" to return to the higher-level screen form.

3.3 Geometry tool data

In the "Geometry Tool Data" screen form, experienced lathe operators can enter

tool offsets, as on CNC controllers, or correct a calibrated tool wear value without

having to calibrate the tool again.

Other operators should simply refer to this screen form for information about the

current offsets. The actual tool measuring process takes place in the "Tool

Measuring" screen form. (→ Tool calibration)

However, here it is necessary to change the tool position “Change position” and

enter the "Radius" value to ensure that the cycles are executed correctly.

Press the "Geom. data" function key in the "Tool Data Overview" screen form to

open the following screen form for turning tools:

© Siemens AG, 2005. All rights reserved

3-32 SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

Page 33

04/2005 3 Tool Data

3.4 Entering tool technology data

Fig. 3-3: Geometry tool data (turning tools)

The displays for "Length 1" always relate to the X axis, those for "Length 2" to the Z

axis.

If the geometry tool data for a drilling tool is invoked, the following screen form

appears. The use and meaning of the values displayed are the same as those

shown in the “Geometry Tool Data” screen form for turning tools, except that some

of the values are not available for drilling tools.

Fig. 3-4: Geometry tool data (drilling tools)

3.4 Entering tool technology data

This function allows the machine operator to store the cutting technology data for a

tool, known as the tool technology data, together with the tool offset. The

advantage of this function is that when the tool is selected in "Manual Machining",

the machining technology data does not have to be changed; it can simply be

copied from the tool technology data memory. The decision lies with the machine

operator.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

3-33

Page 34

3 Tool Data 04/2005

3.4 Entering tool technology data

Press the "Technology" function key in the "Tool Data Overview" screen form to

open the following screen form:

Fig. 3-5: Tool technology

The following data can be entered in the “Tool Technology” screen form:

Spindle

value

Depending on which operating mode is selected (see below), you

can enter either the spindle speed in "Rev/min" or the cutting rate

in "m/min".

Feed value Depending on which operating mode is selected (see below) this

parameter requires the desired axis speed to be entered in either

"mm/min" or "mm/Rev".

Inactive "Inactiv" indicates that no tool technology data has been entered

yet for the corresponding tool.

The tool technology data should be entered as follows:

• Use the cursor keys to select an entry field for the tool in question (spindle or

feedrate entry field is irrelevant).

• To select the desired machining mode, press the "Spindle Feed" function key

one or more times:

(for a more detailed description: → Entering machining technology data)

• "Spindle speed + Time feed" ("Rev/min" + "mm/min") →

"Spindle speed + Rev. feedrate" ("Rev/min" + "mm/Rev") →

"Cutting speed + Rev. feedrate" ("m/min" + "mm/U")

• Use the numeric keypad to enter data in the entry fields for the spindle and

feedrate value. Then press Enter to accept the data. If you leave the entry field

or change the screen form without pressing Enter, the original value will be

retained (the new value is not saved).

© Siemens AG, 2005. All rights reserved

3-34 SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

Page 35

04/2005 3 Tool Data

3.5 Deleting tool technology data

3.5 Deleting tool technology data

Data in the "Tools Technology" screen form can be deleted as follows:

• Use the cursor keys to select an entry field for the tool in question (spindle or

feedrate entry field is irrelevant).

• Press the "Cancel Techno" function key

The following prompt appears:

Fig. 3-6: Deleting tool technology

The question can be answered by pressing one of these function keys:

"OK" The tool technology data for the tool in question is deleted (spindle

and feedrate value) and the system returns automatically to the

"Tools Technology" screen form. The display "Inactive" indicates

that the spindle and feedrate values have been deleted.

"Abort" The tool technology data for the tool in question is retained (spindle

and feedrate value) and the system returns automatically to the

"Tools Technology" screen form. The existing tool technology data

is retained.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

3-35

Page 36

3 Tool Data 04/2005

3.5 Deleting tool technology data

© Siemens AG, 2005. All rights reserved

3-36 SINUMERIK 802S/802C BA_MM (BA) – 04/2005 Edition

Page 37

04/2005 4 Functions

4.1 Limit stops

4

4 Functions

4.1 Limit stops..................................................................................... 4-38

4.1.1 Setting limit stops....................................................................... 4-38

4.1.2 Activating/disabling limit stops ................................................... 4-40

4.1.3 Turning against mechanical stoppage....................................... 4-41

4.2 Taper turning................................................................................. 4-42

4.3 Radius turning............................................................................... 4-44

4.4 Drilling - centered.......................................................................... 4-46

4.5 Tapping ......................................................................................... 4-49

4.6 Groove cycles/Parting................................................................... 4-53

4.6.1 Groove cycle - single ................................................................. 4-53

4.6.2 Groove cycle - multiple .............................................................. 4-57

4.6.3 Parting........................................................................................ 4-59

4.6.4 Multiple parting .......................................................................... 4-60

4.7 Thread cutting.............................................................................. 4-61

4.7.1 Longitudinal thread cutting......................................................... 4-61

4.7.2 Thread recutting......................................................................... 4-65

4.7.3 Thread shaving after thread cutting........................................... 4-67

4.8 Cutting cycles................................................................................ 4-68

4.8.1 Cutting cycle A........................................................................... 4-69

4.8.2 Cutting cycle B........................................................................... 4-73

4.8.3 Cutting cycle C........................................................................... 4-77

4.9 Setting the workpiece zero point................................................... 4-80

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-37

Page 38

4 Functions 04/2005

4.1 Limit stops

4.1 Limit stops

Limit stops are used to stop the axes in a specific position. If an axis stops in the

limit stop position, it cannot be moved again until the triggering limit stop is reset.

This function can be used in "Manual Machining" mode to turn simple steps

(including tapers) without the need for any further cycle parameterization.

→ Turning against mechanical stoppage

Boundary conditions

• The trip position is always an absolute dimension, i.e. it always corresponds to

the position of the absolute actual value display in "Manual Machining". A

relative limit stop position is not possible.

• A limit stop position can only be entered or accepted when the axes are

stationary; otherwise, an error message appears.

4.1.1 Setting limit stops

The screen form for setting trips is opened from the main "Manual Machining"

screen (Fig. 2-4) as follows:

• Change the function key bar by pressing the "Extended menu" key

Fig. 4-1: Extended "Manual Machining“

:

© Siemens AG, 2005. All rights reserved

4-38 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 39

04/2005 4 Functions

4.1 Limit stops

• Press the "Tripping" function key. The following screen form appears:

Fig. 4-2: Setting limit stops

The displays in the "Tripping" screen form have the following meanings:

ON The limit stop shown in this line is switched on, so it is active.

OFF The limit stop shown in this line is switched off, so it is inactive.

-X Negative limit stop for the X axis. If the limit stop is active, the axis

stops automatically when the absolute limit stop position (entered in

this line) is reached by traversing the axis in the negative direction.

+X Positive limit stop for the X axis. If the limit stop is active, the axis

stops automatically when the absolute limit stop position (entered in

this line) is reached by traversing the axis in the positive direction.

-Z Negative limit stop for the Z axis. If the limit stop is active, the axis

stops automatically when the absolute limit stop position (entered in

this line) is reached by traversing the axis in the negative direction.

+Z Positive limit stop for the Z axis. If the limit stop is active, the axis

stops automatically when the absolute limit stop position (entered in

this line) is reached by traversing the axis in the positive direction.

When the screen form appears there are two ways to enter the limit stop position:

• Direct position entry: Use the cursor keys to highlight the entry field for the

appropriate trip. Now use the numeric keypad to enter the absolute position you

require. Then press Enter to accept the value. If you do not wish to accept the

value entered, either leave the entry field by pressing the cursor key or change

the screen form by pressing the "Back" function key, without pressing Enter. In

both cases the original entry value is retained.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-39

Page 40

4 Functions 04/2005

4.1 Limit stops

• Accepting the current actual position: Use the cursor keys to highlight the entry

field for the appropriate trip. Now press Enter to copy the position of the

corresponding axis into the entry field.

!

!

Note

A limit stop position can only be entered or accepted when the axes are

stationary; otherwise, an error message appears.

Note

The trip position is always an absolute dimension, i.e. it always corresponds to

the position of the absolute actual value display in "Manual Machining". A relative

limit stop position is not possible.

4.1.2 Activating/disabling limit stops

Trips can be activated or disabled by means of the function keys in the "Tripping"

screen form, provided that all axes are stationary when the function key is pressed.

Otherwise, an error message appears.

The function keys have the following functions:

"Single ONOFF"

Pressing this function key activates or disables the limit stop

whose entry field is highlighted. Use the cursor keys to select the

appropriate entry field. If a trip is shown as "OFF" in the display,

it can be activated by pressing the "Single ON-OFF" function

key. It will then be shown as "ON" in the display. It can be

disabled in the same way: If a trip is shown as "ON", pressing the

function key changes it to "OFF". It is now disabled.

"All ON" Pressing the "All ON" function key activates all trips, regardless

of their previous status. The display is then set to "ON" for all

trips.

"All OFF" Pressing the "All OFF" function key disables all trips, regardless

of their previous status. The display is then set to "OFF" for all

trips.

© Siemens AG, 2005. All rights reserved

4-40 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 41

04/2005 4 Functions

4.1 Limit stops

4.1.3 Turning against mechanical stoppage

The example below is intended to clarify how the limit stops work. Machining can

generally also be carried out using the handwheel (rather than the 4-way switch or

axis direction keys as described here):

A step of 100 mm in the Z direction and a 50 mm end diameter in the X direction is

required, with a final machining allowance of 0.2 mm. The blank diameter is 70 mm

and the end face is at 0 mm in the Z direction (→ Tool calibration).

• Position the axes in front of the workpiece (e.g., X +75 mm/Z +5 mm).

• Check the machining technology data.

• Set the limit stops: -X at 50.4 mm/-Z at –99.8 mm (because of the final

machining allowance), +Z at +5 mm. Disable the limit stop for +X; it is not

required.

• Start spindle.

st

• Using the handwheel, infeed to the 1

depth of cut in the X direction.

• Start machining in the Z axis in the negative direction, using the 4-way switch or

the axis direction key.

• When the -Z trip position at –99.8 mm is reached, the Z axis stops automatically

and the "-Z trip reached" message appears.

• Switch off the 4-way switch or the axis direction key.

• Retract with the handwheel.

• Using the 4-way switch or axis direction key and rapid traverse overlay, traverse

in front of the workpiece in the positive Z direction until the axis stops and the

"+Z trip reached" message appears.

• Switch off the 4-way switch or the axis direction key.

• Using the handwheel, infeed to the next depth of cut in the X direction.

• Start machining in the Z axis in the negative direction, using the 4-way switch or

the axis direction key.

Repeat the process until the roughing depth is reached (the "-X trip reached"

message appears as the infeed motion is executed). Once this cut has been

completed, adjust the limit stops to the finished dimension, provided that the axes

are ahead of the workpiece.

• Set the stops to the finished dimension: -X to 50.0 mm/-Z to –100.0 mm

• Using the handwheel, infeed in the X direction until the "-X trip reached"

message appears.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-41

Page 42

4 Functions 04/2005

4.2 Taper turning

• Start machining in the Z axis in the negative direction, using the 4-way switch or

the axis direction key.

• When the -Z trip position at –100,.0 mm is reached, the Z axis stops

automatically and the "-Z trip reached" message appears.

• Switch off the 4-way switch or the Z direction axis direction key and start in the

positive X direction (finishing the end face).

• Switch off the 4-way switch or the X direction axis direction key as soon as the

tool tip leaves the workpiece.

• Machining is now complete and the limit stops can be disabled again.

4.2 Taper turning

The Taper turning function is intended for the simple production of tapered

workpieces. The procedure is basically the same as for "Manual Machining" apart

from the addition of an angle (angle of taper). The angle input rotates the

controller’s internal coordinate system according to the angle value. When the 4way switch or an axis direction key is actuated, the controller then uses the angle

input to interpolate (and traverse) the X and Z axis accordingly.

The programmed axis feed then applies to the path being traversed and not to the

corresponding axis.

If tapers with defined end points are to be turned, the use of limit stops is a helpful

addition to this function. Limit stops

!

!

Note

A taper can only be traversed using the 4-way switch or the axis direction keys.

Handwheel traversing is always a paraxial traverse and will not produce a taper.

Note

Taper turning can only be selected when the spindle is running; otherwise, an

error message appears.

The Taper turning function is accessed from the main "Manual Machining" screen

(Fig. 2-4) as follows:

• Change the function key bar by pressing the "Extended menu" key

.

© Siemens AG, 2005. All rights reserved

4-42 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 43

04/2005 4 Functions

4.2 Taper turning

• Press the "Taper turn" function key. The following screen form appears:

Fig. 4-3: Taper turning

As soon as the screen form appears, the entry field for the angle of taper is

highlighted to enable the angle to be entered using the numeric keypad. A positive

angle rotates the coordinate system towards the spindle when viewed in the X+

traverse direction, a negative angle rotates it towards the tailstock. Press Enter to

accept the value. The taper angle remains active until the "Taper Turning" screen

form is closed by pressing the "End Taper" function key.

The diagrams below show the relationship between the sign of the angle and the

rotation of the coordinate system.

Positive angle:

Fig. 4-4: Rotation of coordinates with a positive angle

Negative angle:

Fig. 4-5: Rotation of coordinates with a negative angle

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-43

Page 44

4 Functions 04/2005

4.3 Radius turning

4.3 Radius turning

The radius turning function is intended for the simple production of inside and

outside radii. All the technology data needed for the machining operation is

automatically taken from "Manual Machining". The positions of the axes at the time

the NC start key is pressed form the starting point for the radii to be traversed.

!

!

Note

The required radius is executed by pressing NC start and can be interrupted at

any time by pressing NC stop.

The 4-way switch or the axis direction keys and the handwheels are always disabled when

using this function.

Note

Radius turning can only be selected when the spindle is running; otherwise, an

error message appears.

The Taper turning function is accessed from the main "Manual Machining" screen

(Fig. 2-4) as follows:

• Change the function key bar by pressing the "Extended menu" key

• Press the "Radius turn" function key. The following screen form appears:

.

Fig. 4-6: Radius turning

© Siemens AG, 2005. All rights reserved

4-44 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 45

04/2005 4 Functions

4.3 Radius turning

The entry fields have the following meanings:

This entry value describes the position of the circle end position in the X

x1

axis. The value should be the "relative linear measurement" (in the radius)

whose starting point is the circle start position (= current X axis position in

the diameter).

This entry value describes the position of the circle end position in the Z

z1

axis. The value should be the "relative linear measurement" whose starting

point is the circle start position (= current Z axis position).

This entry value describes the radius to be traversed.

r

The function key assignments are as follows:

Arc

Direct.

This key is used to specify whether a clockwise or counterclockwise

circle should be traversed. The chosen direction is indicated by a

diagram in the screen form.

Abort This key can be used to abort a non-executable radius machining

operation without having to leave the "Radius turning" screen form.

The relevant entry value can then be corrected. For the operation to

be aborted successfully, the only requirement is that the spindle

must have been switched off before the function key is pressed. If

not, a corresponding message will appear and the function will be

disabled.

Caution

Omitting or using the wrong sign for the entry values (x1, z1) or entering the

wrong arc direction ("Arc Direct." function key) can lead to a collision and may

destroy the tool or the workpiece.

Once all the entry values have been entered correctly, radius turning can be

started by pressing the NC start key. Since the starting point for the radius is

always the current axis position, a kind of "surface texture" can be achieved by

pressing the NC start key repeatedly.

Any radius execution can be interrupted immediately by pressing the NC stop key.

Execution can only be continued by pressing the NC Start key before exiting the

"Radius turning" screen form, since exiting the screen form terminates the function.

If the screen form is opened again, the system assumes that you wish to execute a

new radius starting from the current axis position (in this case, the point of

interruption) and calculates it accordingly. An interrupted radius will not be

completed.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-45

Page 46

4 Functions 04/2005

4.4 Drilling - centered

Note

Any limit stops that are activated should be disabled before starting radius turning

or set to a value outside the traversing range needed for radius turning.

Otherwise an error message is transmitted by the controller which prevents the

"Radius turning" function being started.

→ Setting limit stops

4.4 Drilling - centered

The "Drilling" function is designed to produce deep-hole drill holes in the vicinity of

the turning center. Before the start of the cycle, the tool should be positioned in the

turning center so that the hole can be machined by infeeding in the longitudinal

axis only.

The technology data needed for the machining operation is automatically taken

from the entry fields in "Manual Machining".

!

Note

"Drilling" can only be selected when the spindle is running, otherwise an error

message appears.

Caution

In drilling operations, a spindle rotating in the wrong direction can cause serious

damage to the tool, workpiece or machine!

→ Check the direction of rotation of the spindle before pressing NC start!

Caution

Before starting the drilling operation, ensure that the tool is correctly positioned in

the turning center; otherwise, the drilling tool or workpiece may be damaged!!

→ Check that the tool is in the turning center before pressing NC start!!

The "Drilling - centered" function is accessed from the main "Manual Machining"

screen (Fig. 2-4) as follows:

• Change the function key bar by pressing the "Extended menu" key

.

© Siemens AG, 2005. All rights reserved

4-46 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 47

04/2005 4 Functions

4.4 Drilling - centered

• Press the "Drilling" function key. The following screen form appears:

Fig. 4-7: Drilling - centered

The entry fields have the following meanings:

Bezug z0 Start position for the drill hole in the longitudinal axis

(absolute position of the Z axis).

Tiefe l Enter the depth of the drill hole to be created, taking the start

position for the drill hole ("Refer. z0") as the starting point.

The drilling direction is always towards the chuck and cannot

be reversed.

Zust. Max Maximum infeed value for the 1

st

infeed in the longitudinal

axis.

Min Minimum infeed value in the longitudinal axis, which must be

observed for the final infeed.

Faktor Degression factor: the value by which the 2

nd

and all

subsequent infeeds in the longitudinal axis must be

multiplied. The following general rule applies: an entry value

greater than 1 increases the infeed depth with each infeed,

an entry value of less than 1 reduces it with each infeed. To

switch off degression, enter 1 (or 0) here.

Zeit t Dwell time on reaching the drilling depth.

Rückhub R Length of the return stroke in the longitudinal axis for chip

breaking. This parameter is not displayed if "deswarfing" is

selected.

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-47

Page 48

4 Functions 04/2005

4.4 Drilling - centered

Meaning of the function keys:

"Spanbr./

Entsp"

This key is used to toggle between machining with "swarf

breaking" and with "deswarfing". With "swarf breaking", on

reaching the corresponding infeed depth the tool is retracted in

the axial axis by a defined value (swarf breaking) before the

next infeed. With "deswarfing" on the other hand, the tool is

withdrawn from the drill hole on reaching the corresponding

infeed depth. The next infeed then continues as usual. The

current selection is shown as a graphic in the left-hand section

of the screen. If "deswarfing" is selected, no value is shown for

the "return".

"Achspos

übern.”

The current actual position of the relevant axis can be accepted

by selecting an input parameter (entry field is highlighted) and

pressing this function key. If you try to accept the axis position

in entry fields for which this type of value input is not viable,

however, an error message appears, which must be

acknowledged by pressing the function key.

"Ausführen" This function key opens the screen form in which the actual

machining operation takes place:

Fig. 4-8: Execute drilling

Once all the entry values have been entered correctly and the screen form shown

above has been opened, drilling can be started by pressing the NC start key. The

spindle must already be rotating in the correct direction and the drilling tool

positioned in the turning center.

Machining proceeds as follows:

• Starting from the current axis position, the tool is traversed to the cycle start

point in the longitudinal axis. This is calculated internally from the value for the

"Referenc z0" parameter (taking into account the clearance distance).

© Siemens AG, 2005. All rights reserved

4-48 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 49

04/2005 4 Functions

4.5 Tapping

• The first infeed in the axial axis (as defined in the "Infeed Max." parameter) is

then performed.

• The subsequent traversing movement in the axial axis depends on whether

"swarf breaking" or "deswarfing" has been selected. With "swarf breaking" the

tool is retracted in the axial axis by the value set in the "return" parameter; with

"deswarfing" the axial axis is positioned at the cycle start point.

• The subsequent infeeds in the longitudinal axis are always calculated in the

same way: new infeed value = last infeed value x factor + return stroke value

The new infeed value is monitored to ensure that it complies with the value for

the "Infeed Min." parameter. If the infeed value is below the minimum infeed,

this value is imposed, provided that the drilling depth allows it. The calculation is

followed by the infeed in the longitudinal axis.

• Infeed motion and "swarf breaking/deswarfing" then alternate until the drilling

depth specified in the "Length I" parameter is reached.

• Once the required drilling depth is reached, the waiting time specified in the

"Dwell t" parameter begins.

• At the end of this waiting time, the tool is traversed to the cycle start point in the

longitudinal axis.

Machining is now complete and once the spindle has been switched off the

"Execution" screen form can be closed by pressing the "Cycle finish" function key.

4.5 Tapping

The "Tapping" function is designed to produce internal threads in the vicinity of the

turning center using a compensating chuck.

Before the start of the cycle, the tool should be positioned in the turning center so

that the hole can be machined by infeeding in the longitudinal axis only.

The technology data needed for the machining operation is automatically taken or

calculated from the entry fields in "Manual Machining", as follows:

Spindle

speed

The cycle takes the spindle speed setting directly from the entry

field for "Const. spind. speed".

→ Entering machining technology data

© Siemens AG, 2005. All rights reserved

SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

4-49

Page 50

4 Functions 04/2005

4.5 Tapping

Pitch The pitch is formed as follows according to the option selected in

the "Machining Technology Data" screen form:

- "Spindle speed + Time feed":

In this case, the pitch (mm/rev) is calculated as follows from the

entry value for the Time feed (mm/min) and the current spindle

speed (rev/min):

The calculation is made when the NC start key is pressed in the

“Execution” screen form for tapping. Since the actual speed

forms part of the calculation, it is essential that the spindle

override valuation is already set to "100%" at this point.

Otherwise, a defined pitch cannot be set.

- "Spindle speed + Rev. feedrate":

Here the pitch is taken directly from the "Rev. feedrate" value

(mm/Rev) in the Machining Technology Data screen form.

- "Cutting speed + Rev. feedrate":

Here the pitch is taken directly from the "Rev. feedrate" value

(mm/Rev) in the Machining Technology Data screen form.

!

Note

"Tapping" can only be selected when the spindle is running, otherwise an error

message appears.

Caution

In tapping operations, a spindle rotating in the wrong direction can cause serious

damage to the tool, workpiece or machine.

→ Check the direction of rotation of the spindle before pressing NC start.

Caution

Before starting the tapping operation, ensure that the tool is correctly positioned

in the turning center; otherwise, the tapping tool or workpiece may be damaged.

→ Check that the tool is in the turning center before pressing NC start.

© Siemens AG, 2005. All rights reserved

4-50 SINUMERIK 802S/C BA_MM (BA) – 04/2005 Edition

Page 51

04/2005 4 Functions

4.5 Tapping

Caution

If "Time feed" is selected in the “Machining Technology Data” screen form, in

order for the pitch to be calculated correctly, the spindle override valuation must

be set to "100%". Otherwise, the tapping tool or workpiece may be damaged.

Prior to NC start, check that the spindle override valuation is set to 100%!!