TAC Vista

TAC Xenta® 121-FC

Programmable Fan Coil Application

TAC Xenta 121-FC is an easily programmable controller intended for both 2-pipe and 4-pipe applications, with or without re-heat.

It can be configured for use with a multitude of valve actuator types, such as on/off, multistage, increase/decrease, PWM, and so

on. The controller has different types of fan control and advanced fan control functions, including on/off delays, boosting, and

conditioning.

The sequences for cooling, heating, and fan are completely user-programmable, allowing for numerous applications. For energy

savings the controller has built-in economizer functionality. Use TAC Xenta 121-FC with any TAC STR (1.8 kohm) room unit.

Set-up is done using the programming tool TAC ZBuilder, which can be run stand-alone or as a device plug-in to either TAC Vista®

or an LNS-based tool. Using Vista or an LNS-based tool, the configuration settings are downloaded into a TAC Xenta 121, prepared

with the necessary basic application software.

The controller is a LonMark® compliant device aimed at communicating on a LonTalk® TP/FT-10 channel. It is able to operate both

as a stand-alone device and as part of a system. In- and output net work variables can be monitored via the TAC Xenta OP, but

programming relies on the use of the TAC ZBuilder.

TECHNICAL DATA

Supply Voltage

FC/24 .......................24 V AC ±20%, 50–60 Hz

FC/230 ......................230 V AC ±10%, 50–60 Hz

Power Consumption

FC/24:

Controller with TAC Xenta OP ....................5 VA

Digital outputs ..................max. 4×19 VA = 76 VA

Total...................................max. 81 VA

FC/230:

Controller with TAC Xenta OP ....................5 VA

Digital outputs, individual outputs and total.....max. 12 VA

Total...................................max. 20 VA

Ambient Temperature

Operation ................0 °C to +50 °C (32 °F to 122 °F)

Storage ................ –20 °C to +50 °C (–4 °F to 122 °F)

Humidity ..................max. 90% RH non-condensing

Enclosure

Material................................ABS/PC plastic

Enclosure rating.................................IP 20

Flammability class, materials ...................UL 94 5VB

Color ...................................... gray/red

Dimensions, mm (in.)............. 122×126×50 (4.8x5.0x2)

Weight, kg (lb..) ....... FC/24: 0.3 (0.66), FC/230: 0.6 (1.3)

Inputs X1–X3

Voltage across open contact .............23 V DC ± 1 V DC

Current through closed contact .....................4 mA

Minimum pulse input duration ................... 250 ms

Inputs for Sensors B1–B2

Thermistor type ..............NTC, 1800 W at 25 °C (77 °F)

Measuring range .........–10 °C to +50 °C (14 °F to 122 °F)

Accuracy .............................±0.2 °C (±0.4 °F)

Universal Input U1

As temperature input..................... same as B(1–2)

As digital input .........................same as X(1–3)

As analog input ............................ 0–10 V DC

Input R1

Type ........................10 kW linear potentiometer

Adjustment range .................. software configurable

Triac Outputs V1–V4 for heating/cooling valve actuators, 24 V

AC Internally Supplied

Maximum load per output.......FC/24: 0.8 A, FC/230: 0.5 A

Total output load ..............FC/24: 3.2 A, FC/230: 0.5 A

Relay Outputs K1–K3

Maximum voltage ........................... 250 V AC

Maximum resistive load............................ 3 A

Relay Output K4

Maximum voltage .......FC/24: 24 V AC, FC/230: 250 V AC

Maximum resistive load...........FC/24: 3 A, FC/230: 12 A

Voltage Output Y1

Range ................................... 0–10 V DC

Maximum load .................................2 mA

Indication LED Colors

Power ........................................green

Service..........................................red

Interoperability

Standard ..................TAC Xenta 121-FC conforms to

Lo n Ma r k Interoperability Guidelines 3.4 and

Lo n Ma r k Functional Profile: 8501 SCC – Fan Coil

Communication protocol ........................LonTalk

Physical channel ......................TP/FT-10, 78 kbps

Neuron type ............................3150, 10 MHz

Agency Compliances

Emission: CE ............EN 61000-6-3, C-Tick, FCC Part 15

Immunity: CE............................EN 61000-6-1

Safety: CE ................................EN 61010-1

UL 916, C-UL US, Open Energy Management Equipment

(TAC Xenta 121-FC/24): . .Approved for plenum installations

Energy (TAC Xenta 121-FC/230 only, see p. 6):

eu.bac, certificate no. 020711 ................ EN 15500

RoHS directive............................ 2002/95/EG

Part Numbers

Contr Zone TAC Xenta 121-FC/24 .............007306210

Contr Zone TAC Xenta 121-FC/230 ............007306220

Manual ..................................0-004-7692

Plug-in Terminal Blocks TAC Xenta 100 ..........007309140

Adapter RJ10 to Terminals ....................007309210

03-00134-05-en

2

03-00134-05-en

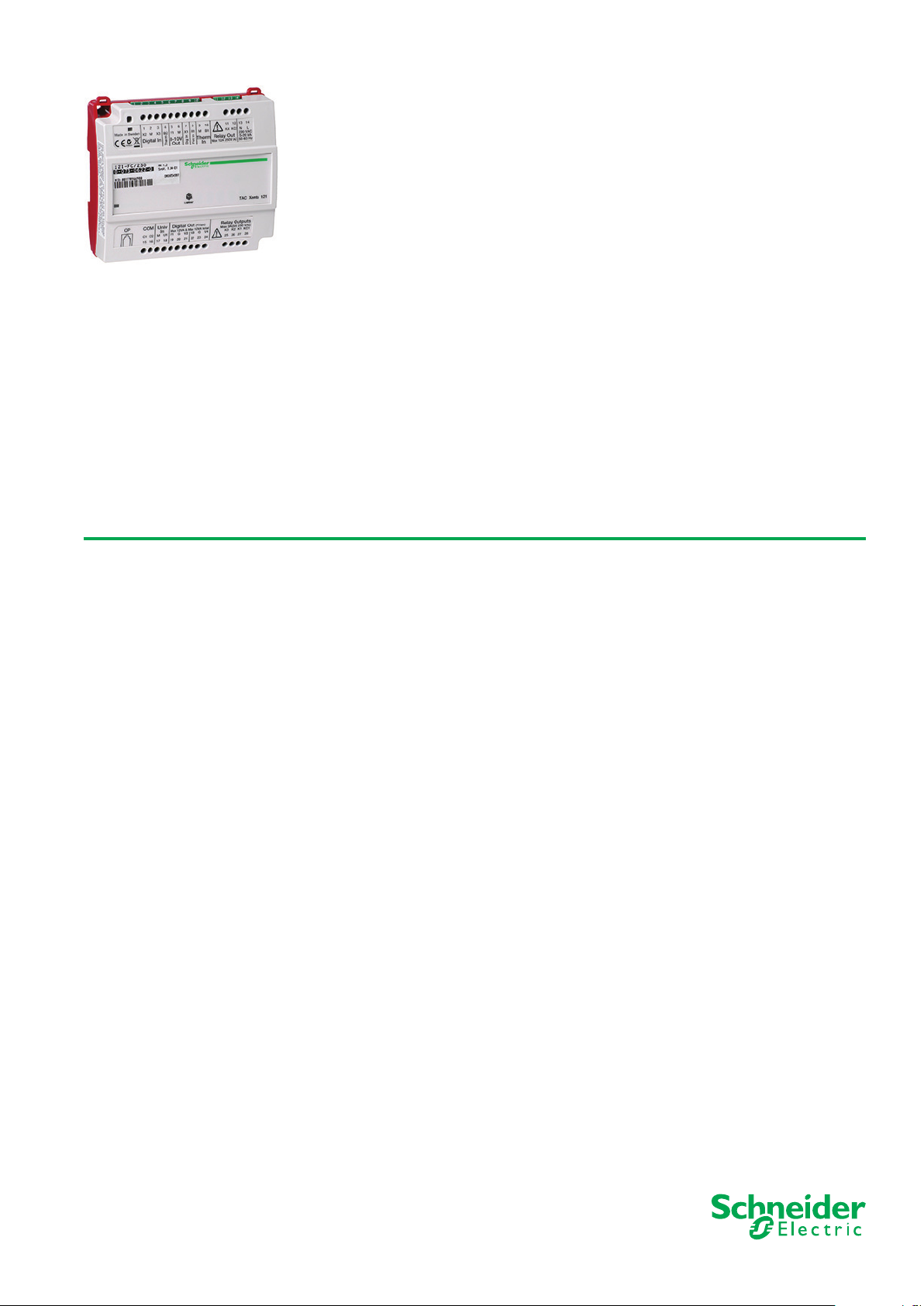

APPLICATION EXAMPLES

Window sensor

1-, 2- or

3-speed Fan

Wall module

Occupancy sensor

Discharge air sensor

Reheating stage

Outside temp. sensor

Economizer

Humidity sensor

Heating coil Cooling coil

Incr./decr. or

thermal actuators

Window sensor

1-, 2- or

3-speed fan

Wall module

Occupancy sensor

Discharge air sensor

Reheating stage

Outside temp. sensor

Economizer Heating/Cooloing coil

Incr./decr. or

thermal actuators

CO

2

sensor

Water temp. sensor

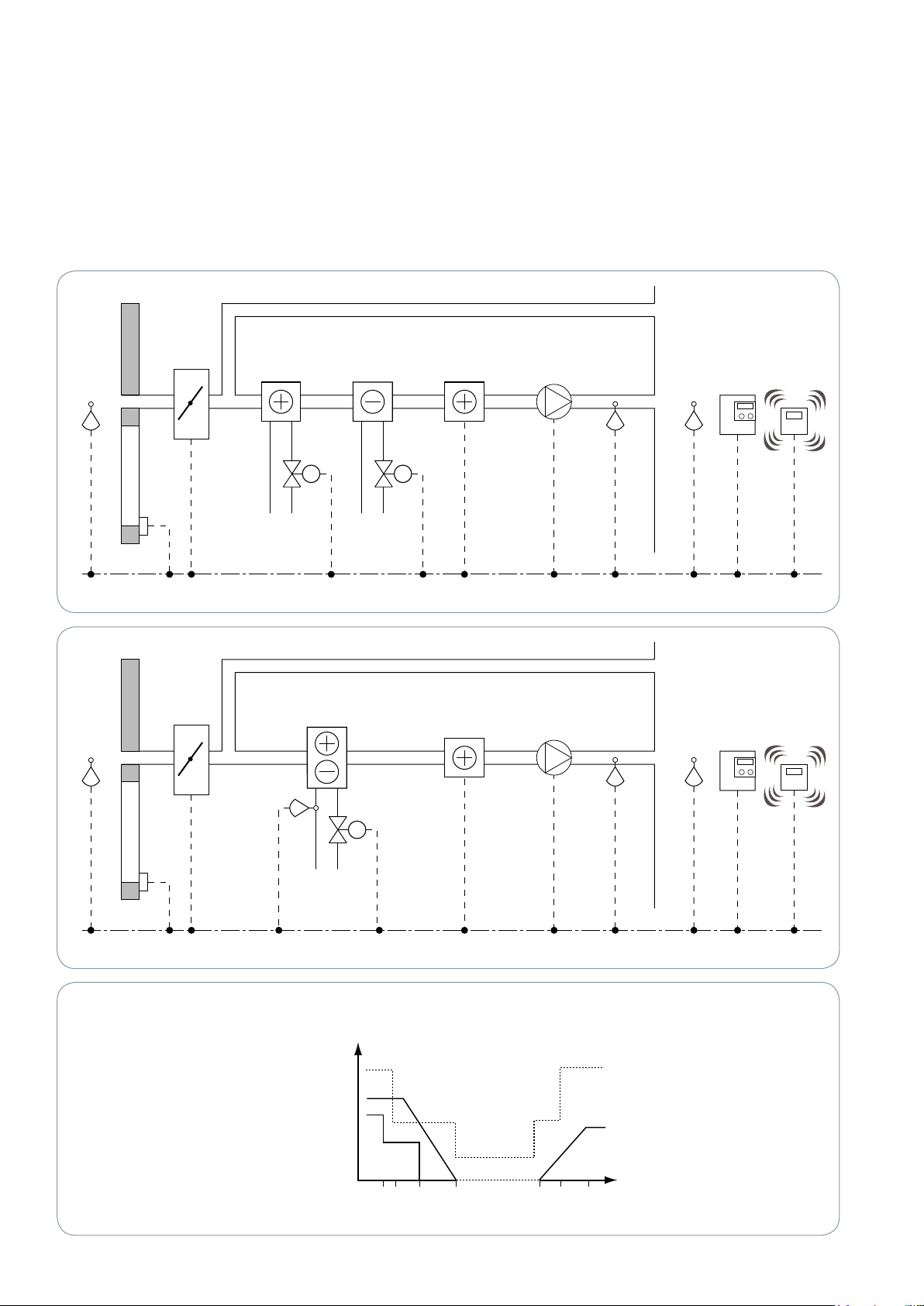

-100 -83 -50 0

0 33 100

Fan

Primary Heating

Secondary Heating

Output

signal

Cooling

Terminal

Load

Control sequence fan coil (example)

TAC Xenta 121-FC can be programmed

to have up to two heating devices and

one cooling device. Each of these can be

a multistage, pwm, analog, or increase/

decrease device.

A Fan Coil unit can have a heating coil

and a cooling coil (4-pipe, Fig. 1a).

It can also be a combined cooling and

heating coil (2-pipe, Fig. 1b). For the

2-pipe application, a water temperature

sensor is required for crossover.

An electrical heater is common as the

second device.

The user defines the sequence; there are

no restrictions that a specific device be

activated first, in parallel, in series, or so

on.

Fan control outputs are always either a

multi stage output (1, 2, or 3 stages) or an

analog output.

Economizer control using an outside air

damper, as well as CO2 control and %RH

control are available.

When the temperature in the zone increa ses, the heating valve closes, see

Fig. 2. If there is still a cooling de mand,

the cooling valve opens and the fan

speed increa ses in steps until the highest

fan speed is reached.

This sequen ce is reversed when the temperature drops.

Figure 1a: Fan Coil unit, 4-pipe

Figure 1b: Fan Coil unit, 2-pipe

Figure 2

Loading...

Loading...