Page 1

TAC Vista

TAC Pangaea

WorkStation

TAC Xenta 120

Technical Manual

Page 2

Page 3

TAC Vista

TAC Xenta 120

Technical Manual

Page 4

Copyright © 2011 Schneider Electric Buildings. All rights reserved.

This document, as well as the product it refers to, is only intended for licensed users. Schneider Electric Buildings owns the copyright of this

document and reserves the right to make changes, additions or deletions. Schneider Electric Buildings assumes no responsibility for possible

mistakes or errors that might appear in this document.

Do not use the product for other purposes than those indicated in this document.

Only licensed users of the product and the document are permitted to use the document or any information therein. Distribution, disclosure,

copying, storing or use of the product, the information or the illustrations in the document on the part of non-licensed users, in electronic or

mechanical form, as a recording or by other means, including photo copying or information storage and retrieval systems, without the express

written permission of Schneider Electric Buildings, will be regarded as a violation of copyright laws and is strictly prohibited.

Trademarks and registered trademarks are the property of their respective owners.

Page 5

TAC Xenta, TAC Xenta 120 Contents

Contents

INTRODUCTION

1 About this Manual 11

1.1 Structure..................................................................................................................... 11

1.2 Typographic Conventions.......................................................................................... 12

1.3 Prerequisites............................................................................................................... 12

1.4 Terminology............................................................................................................... 13

GETTING STARTED

2 Planning the Project 19

2.1 Folder Structure.......................................................................................................... 19

2.1.1 Creating a Project Folder ........................................................................................... 19

2.2 Case Study.................................................................................................................. 20

2.2.1 Description of Facility................................................................................................ 20

2.2.2 Device Description and Naming Convention ............................................................ 21

2.2.3 Devices in the Example.............................................................................................. 22

2.2.4 Network Structure and Naming Convention in the Example..................................... 23

3 Creating the TAC Xenta 120 Configuration 25

3.1 ZBuilder Example Overview ..................................................................................... 25

3.2 Starting ZBuilder.......................................................................................... .... ..... ..... 25

3.3 Selecting a Template.................................................................................................. 26

3.4 Adjusting the Configuration....................................................................................... 26

3.4.1 Adjusting the Heating/Cooling Parameters................................................................ 27

3.4.2 Adjusting the Fan Parameters .................................................................................... 29

3.4.3 Adding a Room Unit.................................................................................................. 30

3.4.4 Adding an Occupancy Signal..................................................................................... 31

3.4.5 Adding a Window Contact......................................................................................... 32

3.4.6 Adjusting the Control Parameters for the Fan............................................................ 33

3.5 Specifying an Exception Mode.................................................................................. 34

3.6 Changing the Inputs/Outputs configuration............................................................... 35

3.7 Documenting and Saving the Configuration.............................................................. 37

3.7.1 Documenting the Configuration on a Printout........................................................... 37

3.7.2 Saving the Configuration File.................................................................................... 38

4 Installing TAC Xenta 120 in a Classic Network 39

4.1 Adding and Configuring the TAC Xenta 120............................................................ 39

4.1.1 Adding a LonWorks Group........................................................................................ 39

4.1.2 Adding a TAC Xenta 120 .......................................................................................... 40

4.1.3 Configuring a TAC Xenta 120................................................................................... 42

Schneider Electric Buildings, Dec 2011 5 (126)

04-00035-02-en (EN)

Page 6

Contents TAC Xenta, TAC Xenta 120

4.2 Commissioning and Downloading ............................................................................. 45

REFERENCE

5 ZBuilder - the Configuration Tool 49

5.1 Usage.......................................................................................................................... 49

5.2 ZBuilder Overview........................................................................................ .... ..... .... 49

5.3 Templates and Applications ....................................................................................... 52

5.3.1 Selecting a File ...........................................................................................................52

5.4 The Configuration Window........................................................................................ 52

5.5 Documenting the Configuration................................................................................. 53

5.5.1 Printing the Configuration Parameters....................................................................... 53

5.5.2 Associating a Graphic with the Configuration........................................................... 54

5.5.3 Saving the Configuration............................................................................................ 55

6 TAC ZBuilder as a Plug-in 57

6.1 As a Plug-in in TAC Vista.......................................................................................... 57

6.1.1 Starting ZBuilder from TAC Vista............................................................................. 57

6.1.2 Resetting a Neuron ..................................................................................................... 58

6.2 As a Plug-in in LonMaker.......................................................................................... 58

6.2.1 Starting ZBuilder from LonMaker ............................................................................. 58

6.2.2 Configuring a TAC Xenta 120................................................................................... 59

6.2.3 Updating a LonMaker Device Shape ......................................................................... 60

6.2.4 Registering ZBuilder as a Plug-in ............................................... ............................... 61

6.2.5 Resetting a Neuron ..................................................................................................... 62

7 Application Types (Configuration) 63

7.1 Terminal Load and the Heating/Cooling Sequence.................................................... 63

7.2 The 4-pipe Fan-Coil ................................................................................................... 64

7.3 The 2-pipe Fan-Coil ................................................................................................... 64

7.4 The Heat Pump........................................................................................................... 65

7.5 Different Control Signals ........................................................................................... 66

7.6 Peripheral Units and Additional Functions ................................................................ 70

8 Fan Control 71

8.1 General ....................................................................................................................... 71

8.2 Analog Control........................................................................................................... 71

8.3 On/off and Multistage Control ............................................... ..... .... ..... ...................... 72

8.4 Fan Hysteresis ............................................................................................................ 72

8.5 Other Fan Parameters ................................................................................................. 72

8.5.1 Boost........................................................................................................................... 72

8.5.2 Conditioning...............................................................................................................72

8.5.3 Cooling delays........................... ..... .... ...................................................... .................. 73

8.5.4 Heating delays ............................................................................................................ 73

8.5.5 Feedback..................................................................................................................... 73

8.5.6 Interlock...................................................................................................................... 73

8.5.7 Run in deadband................................. ..... .... ...................................................... ..... .... 74

8.6 Fan Control from STR Wall units .............................................................................. 74

9 Connected Devices and Network Parameters 75

9.1 Room Unit .................................................................................................................. 75

9.1.1 STR Modules: I/O Usage ........................................................................................... 76

6 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 7

TAC Xenta, TAC Xenta 120 Contents

9.1.2 STR Modules: Additional functions .......................................................................... 76

9.2 Occupancy sensor....................................................................................................... 76

9.3 Window Contact......................................................................................................... 77

9.4 Air Quality Equipment............................................................................................... 77

9.4.1 OAD, Outside Air Damper ........................................................................................ 78

9.4.2 CO

Control......................................................................................... .... ..... .............. 78

2

9.4.3 Dehumidification, %RH............................................................................................. 78

9.4.4 Economizer ................................................................................................................ 79

9.5 Free I/O ...................................................................................................................... 80

9.5.1 General....................................................................................................................... 80

9.5.2 Push-button Signals.................................................................................................... 81

9.6 L

ON Properties.......................................................... .... ..... ......................................... 82

9.6.1 Node........................................................................................................................... 82

9.6.2 SNVT ......................................................................................................................... 83

9.6.3 Common SNVT Properties .......................................................................... .... ..... ..... 84

10 Control Issues 85

10.1 Room Temperature Setpoints..................................................................................... 85

10.2 PI parameters........................................................................................... ..... .... .......... 86

10.3 Cascade control.......................................................................................................... 88

10.4 Master-Slave Considerations ..................................................................................... 89

10.5 Actuator Resync and End-points Adjustment............................................................ 90

11 Exception Modes 93

11.1 General....................................................................................................................... 93

11.2 Exception Mode Activation ....................................................................................... 93

11.3 Status when Active..................................................................................................... 95

11.4 Reset Condition.......................................................................................................... 96

11.5 “Other events” explained ........................................................................................... 96

11.5.1 Compressor Lock-out................................................................................................. 96

11.5.2 Fan feedback failure................................................................................................... 96

11.5.3 Flow feedback error ................................................................................................... 97

11.5.4 Loss of space temp input signal ................................................................................. 97

11.5.5 Loss of water temp input signal ................................................................................. 97

11.5.6 Bypass button used as on/off set to off ...................................................................... 97

11.5.7 Exception Mode status............................................................................................... 97

11.6 Some Exception Mode Examples .............................................................................. 98

12 I/O Setup 103

12.1 Hardware Platforms ................................................................... .... ............................ 103

12.2 Digital Input Polarity.................................................................................................. 103

12.3 I/O Ports ..................................................................................................................... 104

12.3.1 Default Usage.............................................................................................................104

12.3.2 Re-arranging the Ports................................................................................................ 104

12.4 Functions Bound to SNVTs....................................................................................... 104

12.5 Temperature Offsets................................................................................................... 105

Schneider Electric Buildings, Dec 2011 7 (126)

04-00035-02-en (EN)

Page 8

Contents TAC Xenta, TAC Xenta 120

APPENDIX

A Setpoint Calculation 109

B SNVT-lists 113

B.1 The Node Object Inputs and Outputs (nvi, nvo) ........................................................ 113

B.2 The Control Object Inputs (nvi)................................................................................. 113

B.3 The Control Object Outputs (nvo).............................................................................. 117

Index 121

8 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 9

INTRODUCTION

1 About this Manual

Page 10

Page 11

TAC Xenta, TAC Xenta 120 1 About this Manual

1 About this Manual

This manual describes a particular process. For information on certain

products, we refer you to the manual or the Help for the product in question.

For information on how to install software, we refer you to the instructions delivered with the software.

For information on third party products, we refer you to the instructions

delivered with the third party product.

If you discover errors and/or unclear descriptions in this manual, please

contact your TAC representative.

Note

1.1 Structure

We are continuously improving and correcting our documentation.

This manual may have been updated.

Please check our product documentation site at www.tac.com for the

latest version.

The manual is divided into the following parts:

• Introduction

The Introduction section contains information on how this manual

is structured and how it should be used to find information in the

most efficient way.

• Getting Started

The Getting Started section contains a step-by-step description of

how to engineer or carry out different tasks. It also gives you

guided instructions on how to complete a sample project. If you

want more information, see the corresponding chapter in the Reference section of the manual.

• Reference

The Reference section contains more comprehensive information

about various parts of the Getting Started section. It also provides

you with information on alternative solutions not covered by the

Getting Started section.

• Appendix

At the end of the manual we have collected some detailed descrip-

Schneider Electric Buildings, Dec 2011 11 (126)

04-00035-02-en (EN)

Page 12

1 About this Manual TAC Xenta, TAC Xenta 120

!

tions and lists. This information may be useful during special circumstances, but is normally not required.

1.2 Typographic Conventions

Throughout the manual the following specially marked texts may occur.

Warning

Alerts you that failure to take, or avoid, a specific action might result

in physical harm to you or to the hardware.

Caution

Alerts you to possible data loss, breaches of security, or other more

serious problems.

Important

Alerts you to supplementary information that is essential to the completion of a task.

Note

Alerts you to supplementary information.

Tip

Alerts you to supplementary information that is not essential to the

completion of the task at hand.

Advanced

Alerts you that the following information applies to complex tasks or

tasks restricted by access.

1.3 Prerequisites

To be able to profit from the contents in this manual, it is recommended

that you read the following documentation:

• TAC ZBuilder Programming Tool for TAC Xenta 120, Datasheet,

0-003-3010.

12 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 13

TAC Xenta, TAC Xenta 120 1 About this Manual

• TAC Xenta 121-FC Programmable Fan Coil Application,

Datasheet, 0-003-3057.

• TAC Xenta 121-HP Programmable Heat Pump Application,

Datasheet, 0-003-3058.

• TAC Xenta 121/24 24 VAC Hardware Platform Installation

Instruction, 0FL-4234.

• TAC Xenta 121/230 230 VAC Hardware Platform Installation

Instruction, 0FL-4235.

• TAC Vista IV Engineering Classic Networks, manual, 0-004-7841.

• TAC Vista IV Engineering LNS Network, manual, 0-004-7842.

1.4 Terminology

TAC Xenta Devices

• All programmable T AC Xentas, 280/300/401, will be called Xenta

devices throughout this manual.

• The Xenta 422, 452, and so on will be referred to as I/O modules.

LonWorks Devices

• All other devices will be called LonWorks devices, including the

Xenta 100.

Classic Network

•A Classic Network refers to a TA C Vista system with a Lon-

Works network, TAC Xenta devices and/or LonWorks devices,

using an LTA port connection/communication to the network and

no LNS database. A Classic Network does NOT use any SNVT

bindings.

LNS Network

•An LNS Network refers to a TAC Vista system with a LonWorks

network, TAC Xenta devices and/or LonWorks devices, using an

LTA port with a VNI as the Network Interface (NI) application,

LonMaker 3 and an LNS database. This type of LTA port is

referred to as an LNS port in TAC Vista IV.

TAC Vista Modes

• Engineering Mode. This mode is used when commissioning the

network. In this mode, you can send information to the network

devices as well as service pin each device.

• Operating Mode. This mode provides full communication

between the server and the network device. If the connection

between the server and the device on the network is disrupted, you

will receive an alarm.

Schneider Electric Buildings, Dec 2011 13 (126)

04-00035-02-en (EN)

Page 14

1 About this Manual TAC Xenta, TAC Xenta 120

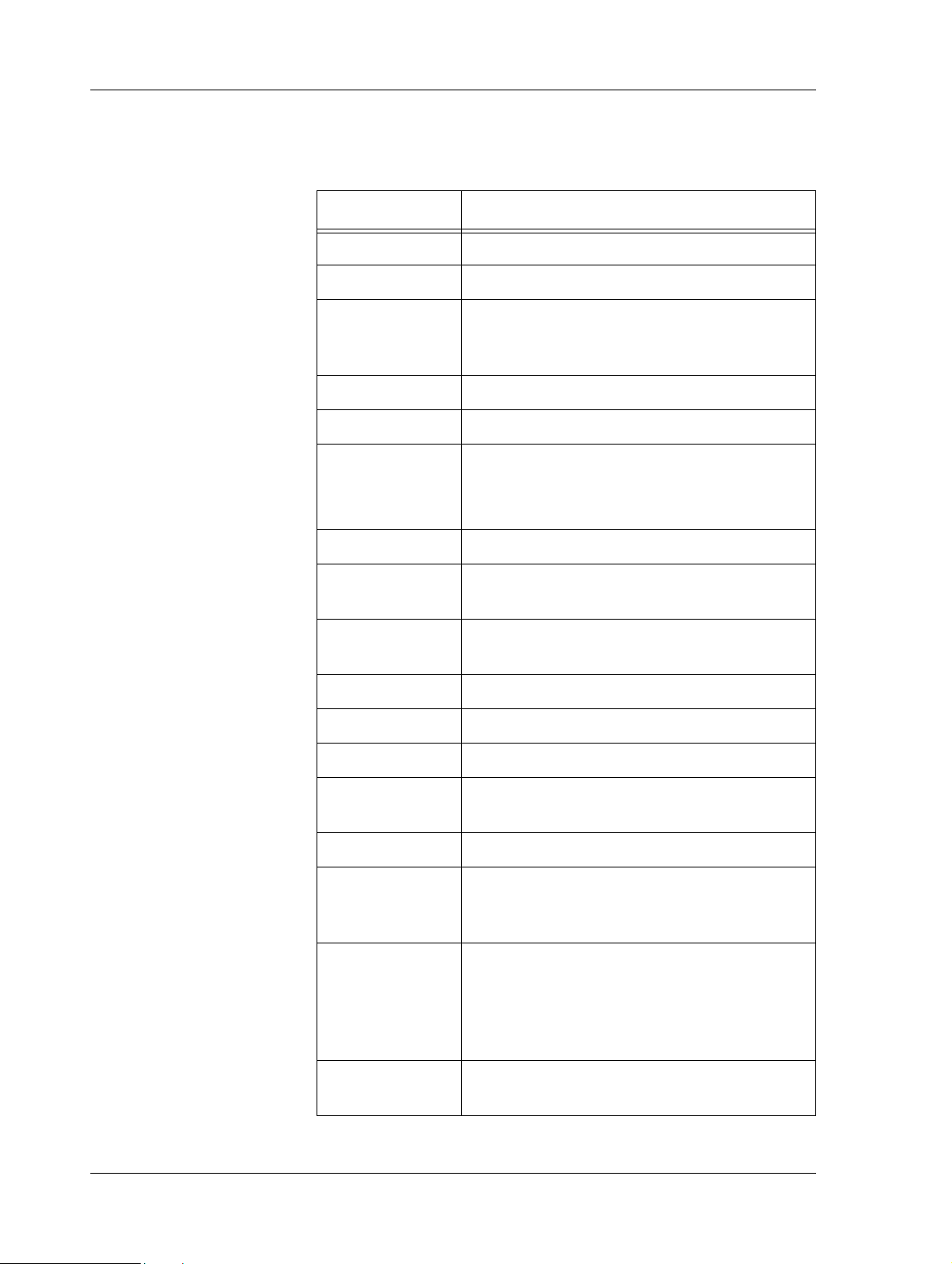

Some useful terms and abbreviations regarding the zone controller's

application and network communication are explained in the table

below.

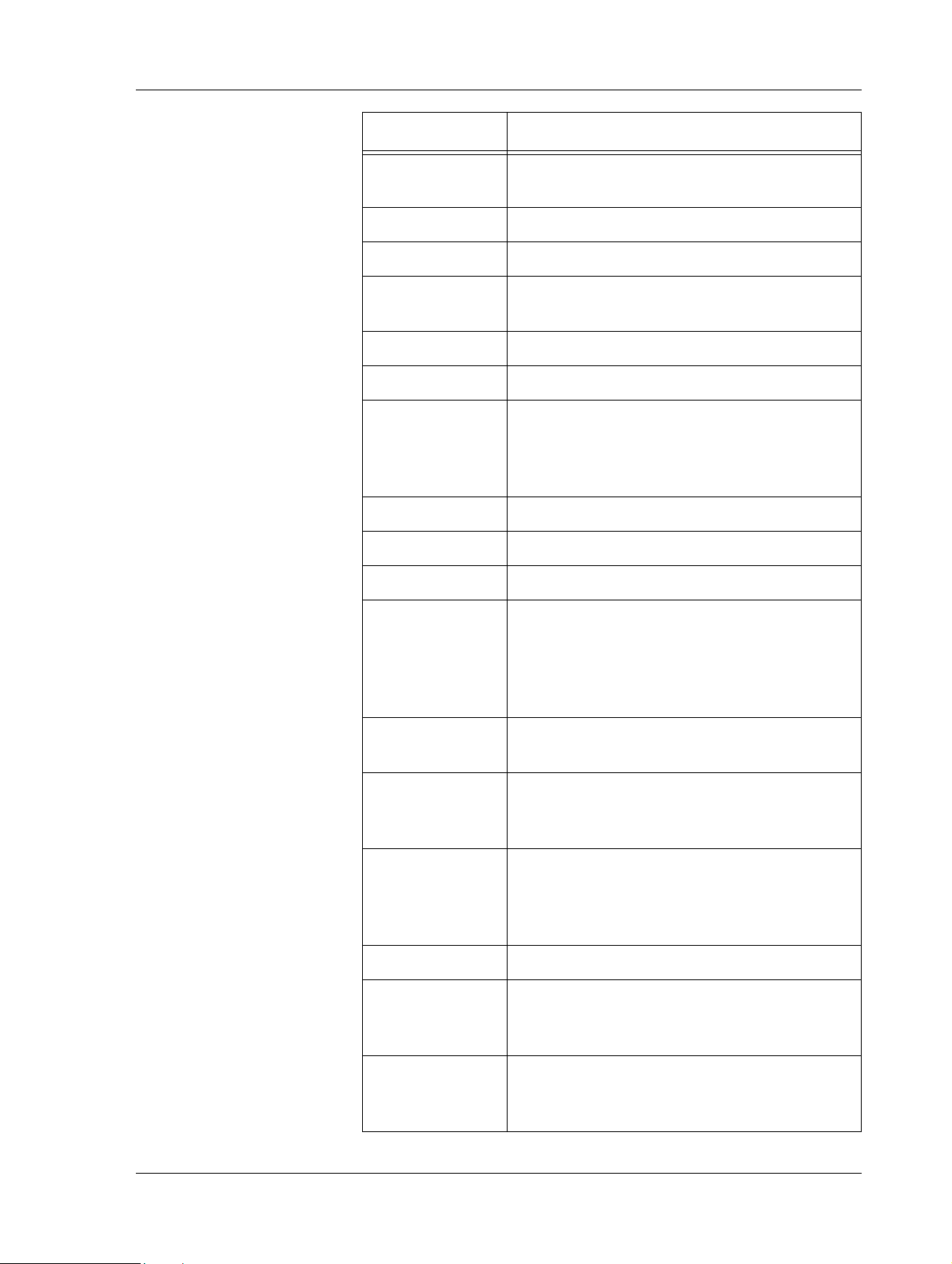

Term Description

ASC Application Specific Controller

CCD Climate Control Device

CFR Configuration record, a file included with the

XIF file for devices with many configuration

parameters. Example: TAC Xenta 120 series.

configuration Procedure to design the software for an ASC

DAT Discharge Air Temperature

device plug-in TAC Vista: controller configuration tool

LNS: application to provide custom user inter-

face for devices.

FB Functional Block

Exception Mode Special, configurable behavior of the controller

triggered by certain events.

hardwired an I/O that is physically connected, as opposed

to a SNVT binding

HP Heat Pump

FC Fan Coil

I/O Input/Output

LNS L

ONWORKS Network Servic es; network man-

agement software for L

ONWORKS networks

MS MultiStage

nci configuration parameter; variable that gets its

value from a configuration tool and keeps it

during a power failure

Neuron A microprocessor optimized for control net-

works. Neuron chips have three 8-bit inline

processors: two are dedicated to the communi-

cations protocol and one is a general-purpose

applications processor.

nvi variable that normally gets its value from

another unit on the network through binding

14 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 15

TAC Xenta, TAC Xenta 120 1 About this Manual

Term Description

nvo variable that is sent to another unit on the net-

work

OAD Outside Air Damper

OAT Outside Air Temperature

PWM (Pulse Width Modulat ion) One type of actuator

control signal

SCC Space Comfort Controller

scpt Standard Configuration Property Type

sequence dia-

gram

A diagram with the Terminal Load on the x-

axis and the (symbolical) controller output sig-

nals on the y-axis. The principal usage of the

TCDs depending on the TL value is shown.

SPID Standard Program ID

SNVT Standard Network Variable Type

STR Room temperature sensor (STR series)

stand-alone The T AC ZBuilder does not run directly ag ainst

a controller or as a plug-in. Generated configu-

rations can only be saved to a file, not down-

loaded to a physical controller or saved to a

database.

TCD Temperature Control Device - Heating and/or

cooling equipment

template A standard configuration file that can be used

as a starting-point for a specific ZBuilder appli-

cation. File name: *.zbt.

TL,

Terminal Load

Terminal Load is a value in the range –100% to

+100%. The value indicates the amount of

power (<0: heating, >0: cooling), needed to

reach the required temperature.

ucpt User Configuration Property Type

XFB-file / XFO-

file

When the XIF-file is imported to L

ONMAKER

Integration Tool it is compiled into two files:

the XFB-file and the XFO-file.

XIF file eXternal InterFace file is a file that, in short,

describes which network variables the device

can handle.

Schneider Electric Buildings, Dec 2011 15 (126)

04-00035-02-en (EN)

Page 16

1 About this Manual TAC Xenta, TAC Xenta 120

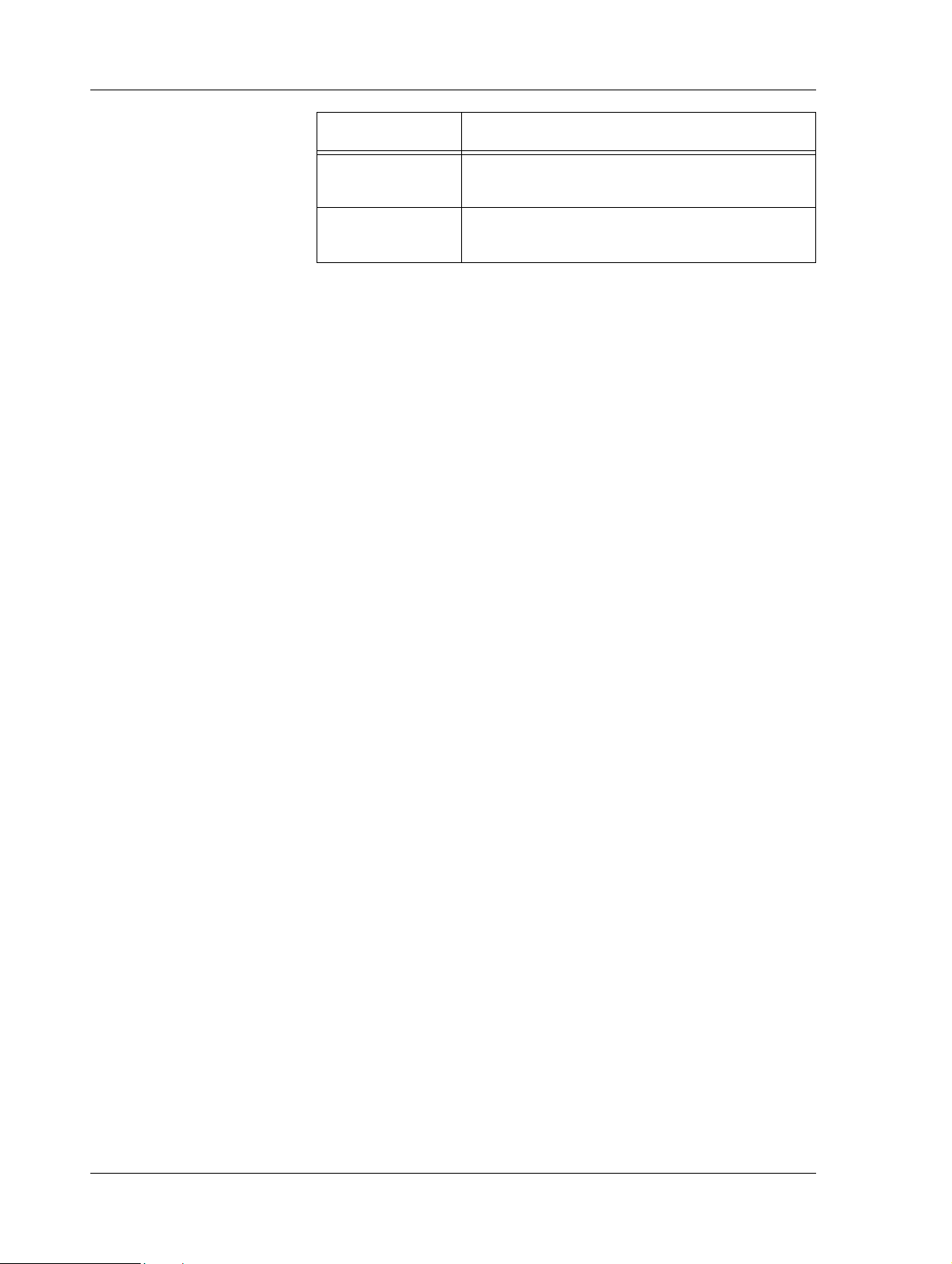

Term Description

.zbc File name extension for ZBuilder configuration

files.

.zbt File name extension for ZBuilder template

files. See also template.

16 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 17

GETTING STARTED

2 Planning the Project

3 Creating the TAC Xenta 120 Con-

figuration

4 Installing TAC Xenta 120 in a

Classic Network

Page 18

Page 19

TAC Xenta, TAC Xenta 120 2 Planning the Project

2 Planning the Project

Planning the LonWorks Network in advance saves a lot of time and

effort later in the process. Issues like network structure (groups),

device-naming conventions, and so on should be considered before

actually creating the network.

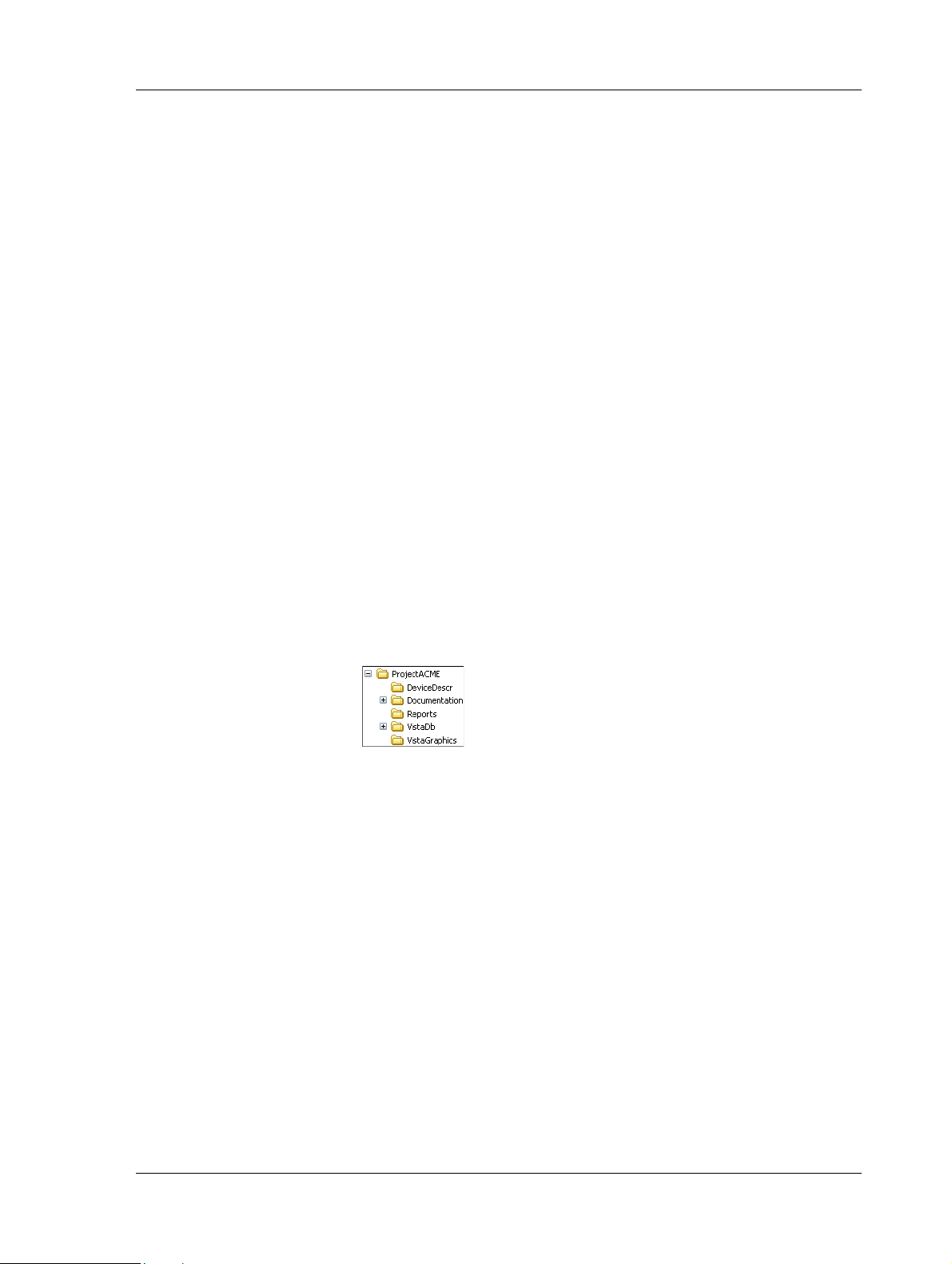

2.1 Folder Structure

Another consideration is the location(s) on the hard drive where files are

stored. A well-organized project requires a well-organized file structure.

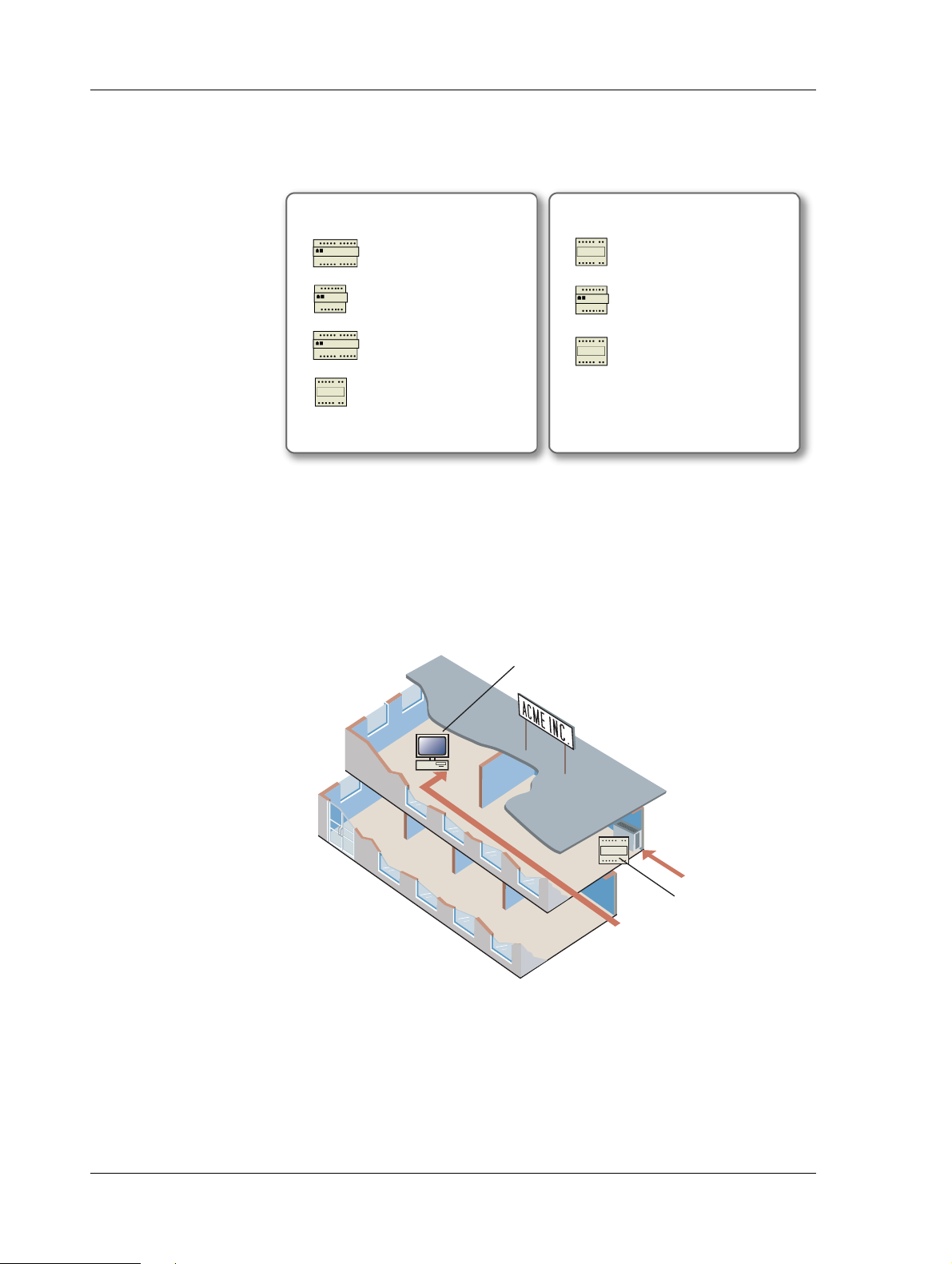

2.1.1 Creating a Project Folder

When starting a new project, you should prepare a directory containing

folders and subfolders as shown below. In this example, we call our

project ACME.

A short description of their intended use and content:

• DeviceDescr – *.mta-files and *.xif-files for the LonWorks net-

work devices.

• Documentation – subfolder with more general information. For

example, useful manuals, data sheets, and technical product information (TPI). I/O-lists, functional descriptions, and other files created by DesignBuilder could also be saved here.

• Reports – reports from Vista Server.

• VistaDb – the Vista database.

• VistaGraphics – Vista graphics files.

Once the engineering work is finished, the complete project folder is

transferred from the engineering PC to the site PC. Save the folder

structure as a compressed file (*.zip) to avoid problems with the readonly attributes when storing on a CD.

Schneider Electric Buildings, Dec 2011 19 (126)

04-00035-02-en (EN)

Page 20

2 Planning the Project TAC Xenta, TAC Xenta 120

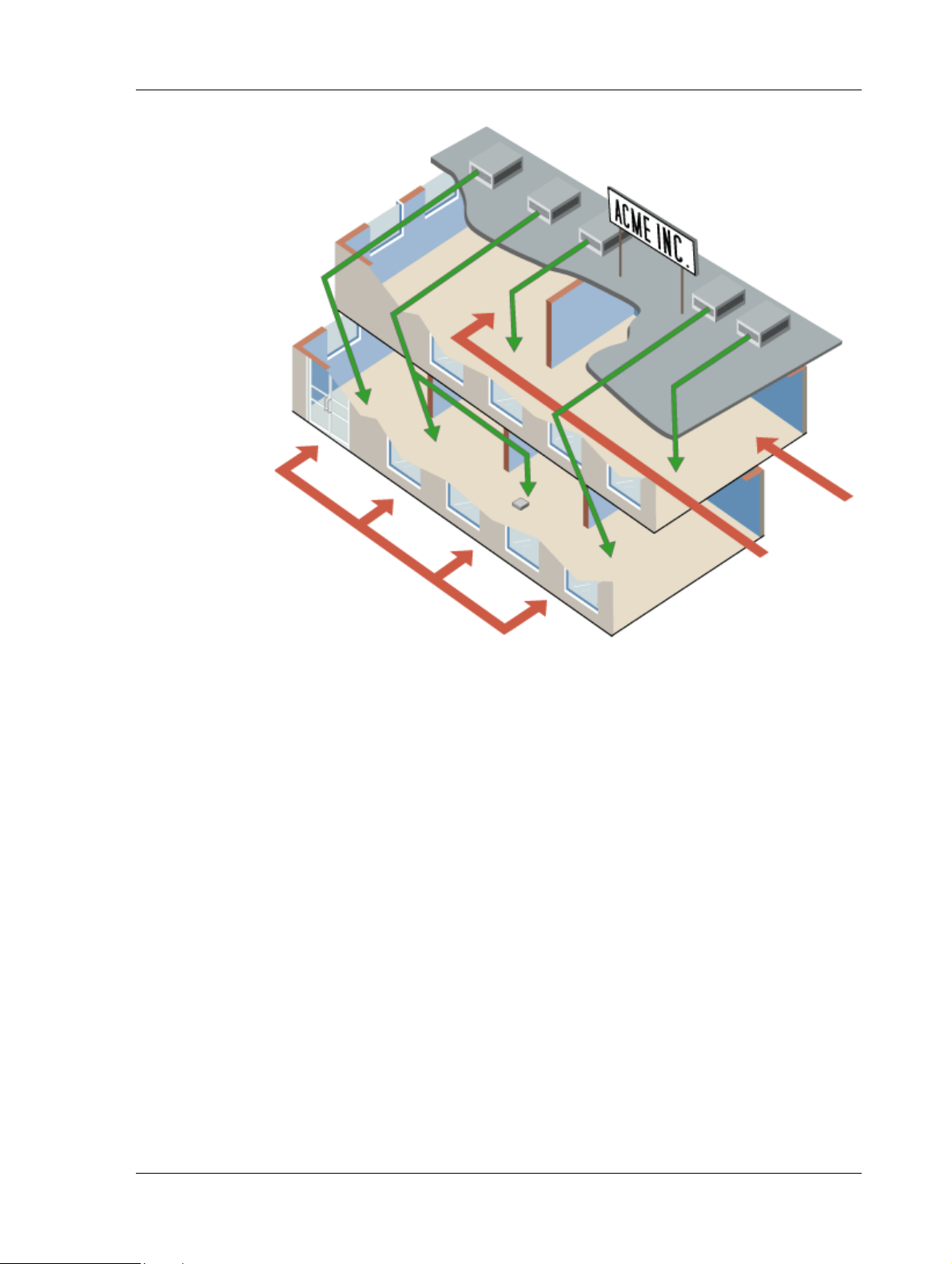

2.2 Case Study

The following chapters describe how to configure and add a TAC Xenta

120 to a LonWorks network using TAC ZBuilder. Our network example is based on the case described below.

2.2.1 Description of Facility

We are creating a system for a fictional company that we call ACME

Inc.

The facility is a typical, small two-story office building, served by packaged rooftop equipment. The first floor area serves Marketing,

Accounts, Senior Management and the entrance lobby. The second

floor area serves Engineering and Customer Support.

Within the first floor area, the Accounting area is served by a constant

volume rooftop air handling unit. This unit has central station cooling

and central station heating. The space is divided into control zones; the

Accounting area and a conference room with secondary air handling.

The Marketing and Senior Management areas are served by a single

rooftop variable air volume (VAV) air handling unit. The first floor

lobby area is served by a rooftop constant-volume single zone air handling unit.

On the second floor, the Customer Support area is served by a single

zone, rooftop constant-volume air handling unit. The Engineering area

is served by a Rooftop VAV air handling unit. A laboratory within the

engineering area is temperature-controlled by a fan-coil unit. The staff

can supervise the system from a PC-based presentation system.

20 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 21

TAC Xenta, TAC Xenta 120 2 Planning the Project

RTU1

RTU3

RTU2

RTU4

Engineering

Support

Lobby

Accounts

Conference Room

Marketing and Management

Lobby

Conf_Room

2.2.2 Device Description and Naming Convention

Within the first floor area, the rooftop unit serving the Accounting area

is controlled by a Xenta 301, called RTU1.

The secondary air handling unit serving Marketing and Senior Management is controlled by a Xenta 281, called Conf_Room.

The rooftop unit serving Marketing and Senior Management is controlled by a Xenta 401, called RTU2, using four I/O modules.

The air handling unit serving the lobby area is controlled by a Xenta

104, called Lobby.

Within the second floor area, the rooftop unit serving the Customer Support area will be controlled by a Xenta 104, named RTU3.

The rooftop unit serving the Engineering area is controlled by a Xenta

401, called RTU4, using five I/O modules.

The fan-coil unit in the engineering lab area is controlled by a Xenta

121-FC, called Engr_Lab, configured with TAC ZBuilder.

Schneider Electric Buildings, Dec 2011 21 (126)

04-00035-02-en (EN)

Page 22

2 Planning the Project TAC Xenta, TAC Xenta 120

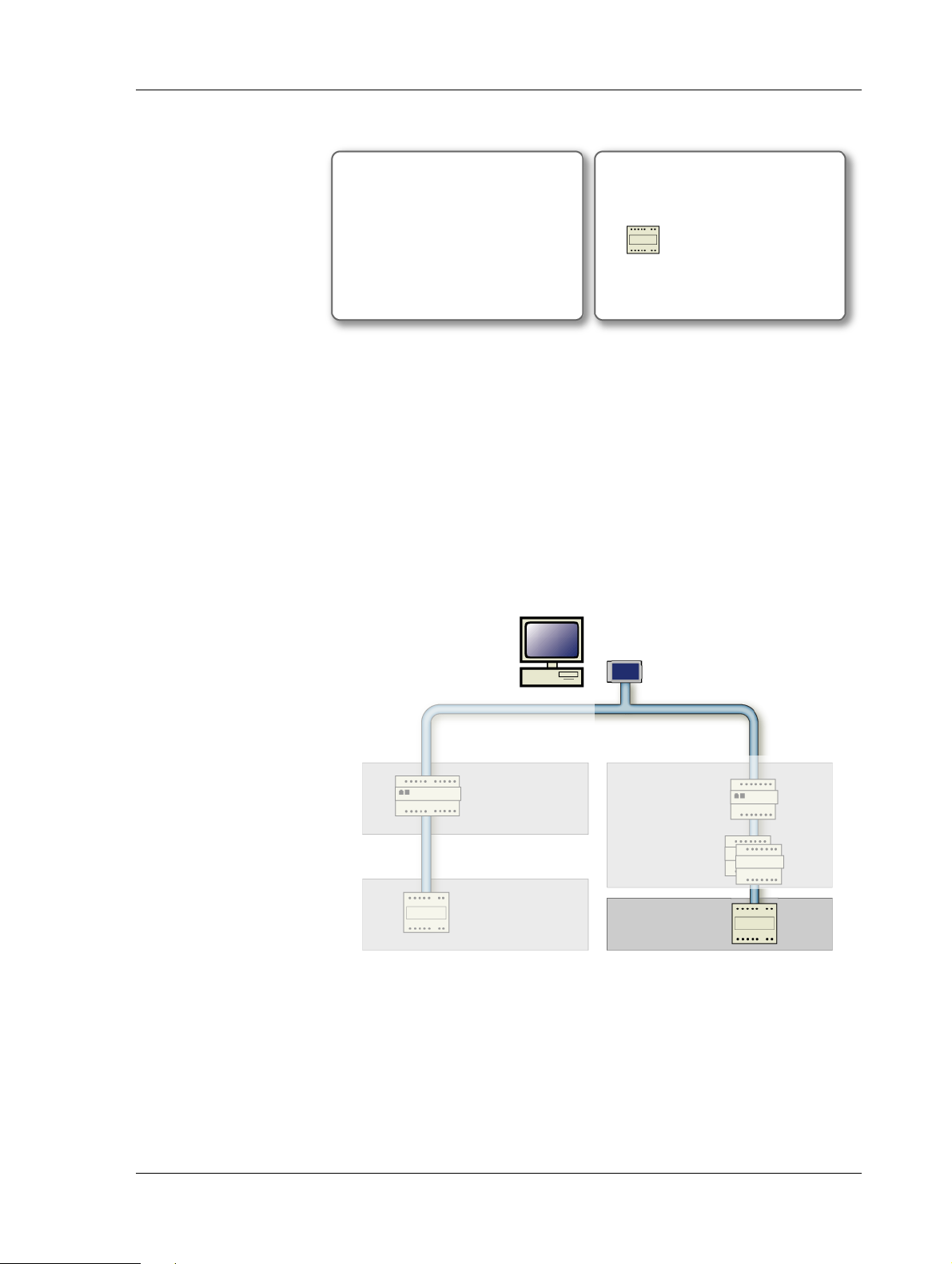

First Floor Second Floor

RTU1

Xenta 301

Conf_Room

Xenta 281

Lobby

Xenta 104

RTU3

Xenta 104

RTU4

Xenta 401

RTU2

Xenta 401

Engr_Lab

Xenta 121-FC

VistaSRV1

Engr_lab

The PC where the presentation system is installed is called VistaSRV1

(in some pictures called VistaSrv_1, but the character “_” should be

avoided) and is located in the Support area.

2.2.3 Devices in the Example

In our example, we use a part of the above network to illustrate how a

Xenta 120 is added.

On the second floor, we have selected the engineering lab fan-coil unit

to illustrate how to configure and install a TAC Xenta 120.

22 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 23

TAC Xenta, TAC Xenta 120 2 Planning the Project

First Floor Second Floor

Engr_Lab

Xenta 121-FC

RTU4

Xenta 401

VistaSRV1

LTA Card

I/O Modules

(1 & 3)

Conf_Room

Lobby

LonWorks Group 1st_Floor_LW

Xenta Group 1st_Floor

Xenta Group 2nd_Floor

LonWorks Group 2nd_Floor_LW

Engr_Lab

We work with the following device:

2.2.4 Network Structure and Naming Convention in the Example

When adding the Xenta 120 using Vista Workstation, the name of the

network is the name of the company – ACME_Inc. Since the building

has two floors, the network is built with the devices divided into two

Xenta groups called 1st_Floor and 2nd_Floor.

Xenta devices placed on the first floor belong to the Xenta group

1st_Floor and Xenta devices placed on the second floor belong to the

Xenta group 2nd_Floor.

The Xenta 104 is a member of the LonWorks group 1st_Floor_LW and

the Xenta 121-FC is a member of the LonWorks group 2nd_Floor_LW.

Schneider Electric Buildings, Dec 2011 23 (126)

04-00035-02-en (EN)

Page 24

2 Planning the Project TAC Xenta, TAC Xenta 120

24 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 25

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

3 Creating the TAC Xenta 120

Configuration

3.1 ZBuilder Example Overview

ZBuilder is a software tool designed to create a set of configuration

parameters for a specific application, for example a fan-coil with an

electric reheater or a heat pump with a reversing valve.

The parameters are saved in a configuration file which is used by TAC

Vista or LonMaker to install and commission the corresponding TAC

Xenta 120 controller.

For a thorough description of the tool and the working methods, please

refer to Chapter 5, “ZBuilder - the Configuration Tool”, on page 49, and

the other chapters in the Reference section of the manual.

In this chapter you will learn how to use ZBuilder to:

• Start ZBuilder stand-alone

• Select a configuration template

• Adjust the Configuration

• Specify an Exception Mode

• Configure the Inputs/Outputs

• Save and Document the Configuration

3.2 Starting ZBuilder

ZBuilder can be run stand-alone, but can also be started as a plug-in

from TAC Vista or L

To start ZBuilder as a plug-in, the Xenta 120 must be added to a LonWorks network:

• For more information on how to start ZBuilder as a plug-in from

Vista Workstation, see Section 6.1.1, “Starting ZBuilder from

TAC Vista”, on page 57.

• For more information on how to start ZBuilder as a plug-in from

LonMaker, see Section 6.2.1, “Starting ZBuilder from LonMaker”, on page 58.

ONMAKER.

Schneider Electric Buildings, Dec 2011 25 (126)

04-00035-02-en (EN)

Page 26

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

In the example, we start ZBuilder stand-alone to create the configuration file before the Xenta 120 is added to the Lonworks network.

To start ZBuilder as a stand-alone tool

• Click Start, point to All Programs, point to T A C, point to

TAC ZBuilder, and then click TAC ZBuilder.

The TAC ZBuilder Select File window now opens.

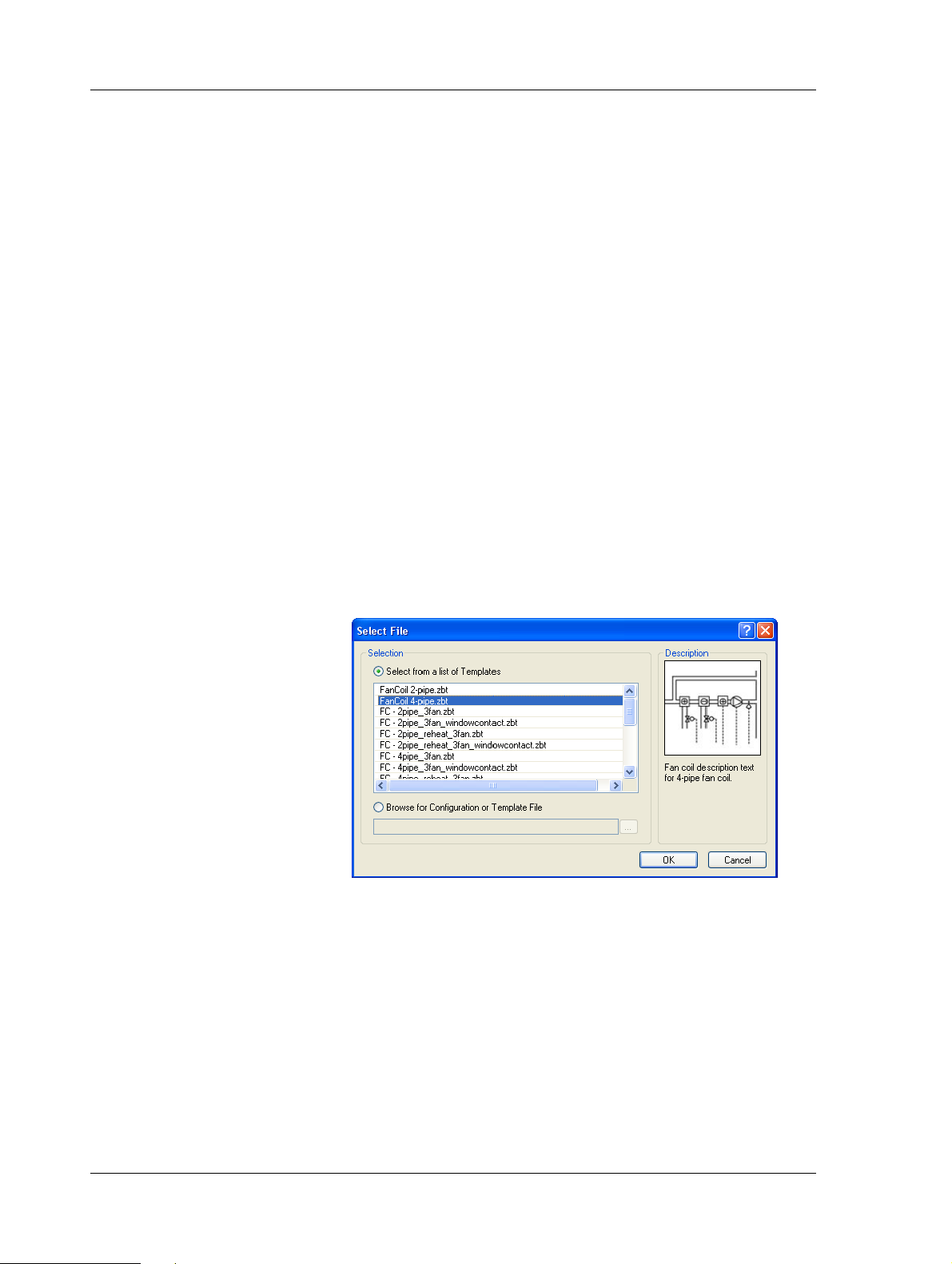

3.3 Selecting a Template

To simplify the configuration procedure, you start with a template or

another configuration file similar to the application that you are going

to create.

For more information on how to select files, see Chapter 5.3.1, “Selecting a File”, on page 52.

In the example, you will start with a template for a 4-pipe fan-coil.

To select a Template

1 In the Select File dialog box, make sure the Select from a list of

Templates option is selected.

2 In the templates list select the required template. In the example,

FanCoil 4-pipe.zbt.

3 Click OK.

3.4 Adjusting the Configuration

Normally you need to adjust the default configuration for the current

application.

In the example, we will adjust the settings to achieve the following:

• The fan will always run for at least 30 seconds when the second

heating stage is turned off.

• When the window is opened, the controller will be turned off.

26 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 27

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

• The secondary heating will start at 80% Terminal Load.

• The second fan stage will start at 70% Terminal Load in cooling.

• The Occupancy state will be signalled via a SNVT; all other

inputs/outputs will be hardwired, that is, physically connected.

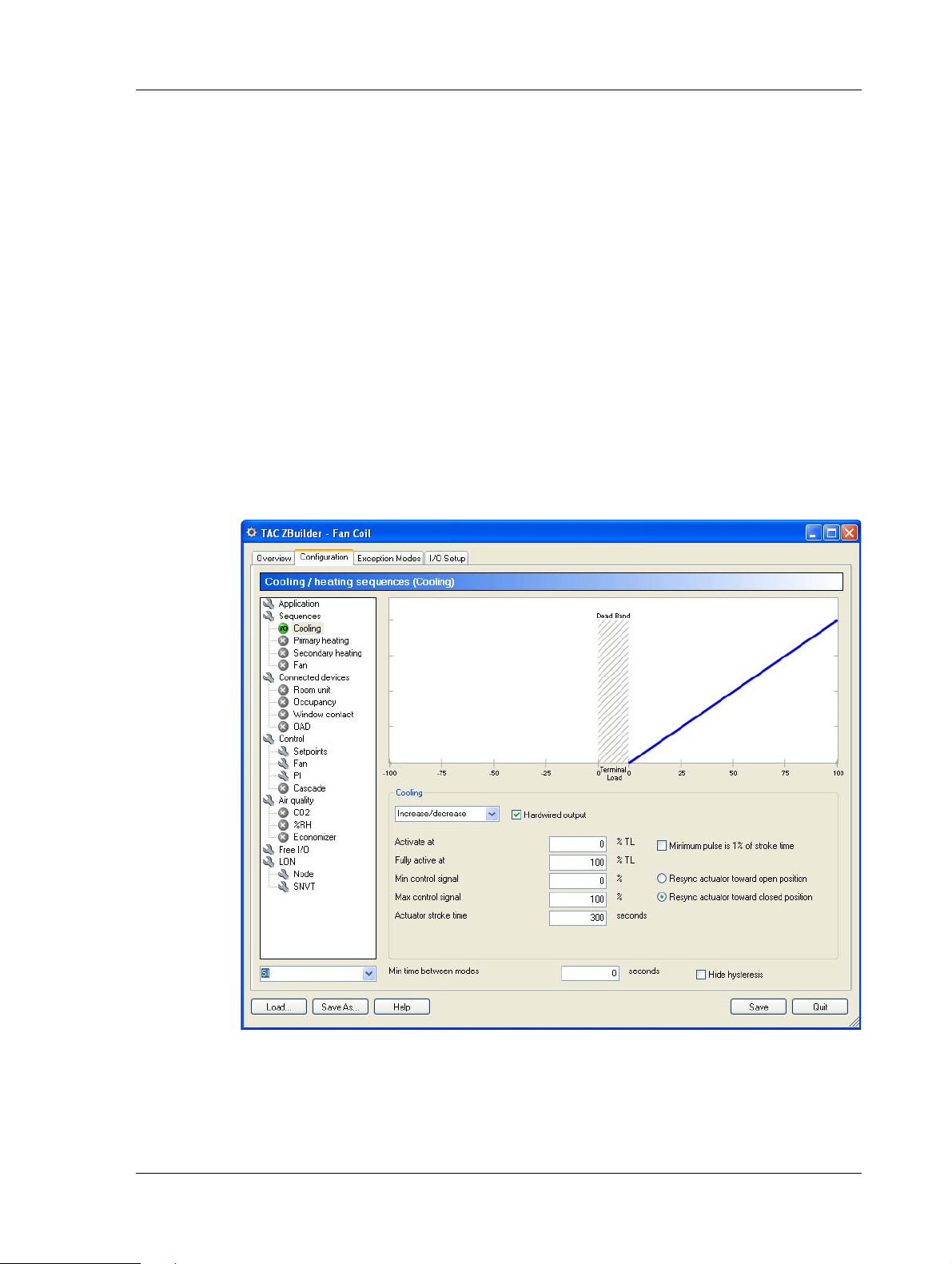

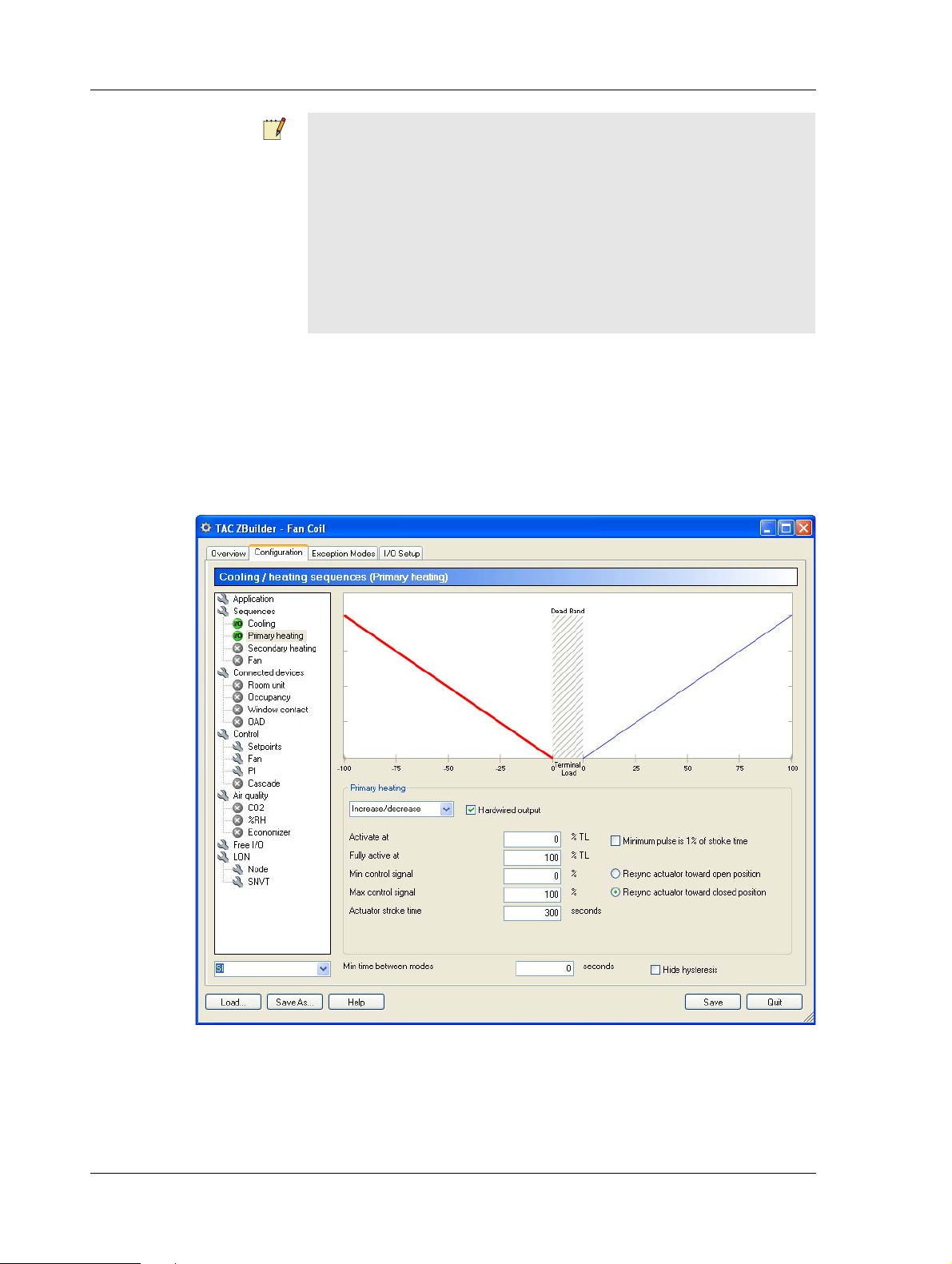

3.4.1 Adjusting the Heating/Cooling Parameters

For more information on the control sequence, see Chapter 7.1, “Terminal Load and the Heating/Cooling Sequence”, on page 63.

To adjust the Heating/Cooling Parameters

1 Click the Configuration tab.

2 In the tree structure, select Sequences\Cooling.

3 In the Cooling area, in the device type list, select the required

device type. In the example, Increase/decrease

4 Make sure the Hardwired output checkbox is selected.

Schneider Electric Buildings, Dec 2011 27 (126)

04-00035-02-en (EN)

Page 28

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

Notes

• Increase/decrease actuators need to be resynchronized. This can

be done towards the open or closed position. The specified direction will be used for all active increase/decrease actuators in the

configuration. The default value is Resync actuator towa rd

closed position. For more information, see Section 10.5, “Actuator Resync and End-points Adjustment”, on page 90.

• The Cooling icon in the tree to the left has been changed to a

green I/O icon.

You will now have a blue sloping line, showing how the valve will

open with increasing Terminal Load (increasing need of cooling).

5 In the tree structure, select Sequences\Primary heating.

6 In the Primary heating area, in the device type list, select the

required device type. In the example, Increase/decrease.

7 Make sure the Hardwired output checkbox is selected.

Note that you will get a red sloping line, showing how the valve

will close with increasing Terminal Load (decreasing need of heating).

28 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 29

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

8 In the Fully active at box, enter the required value. In the exam-

ple, “80”.

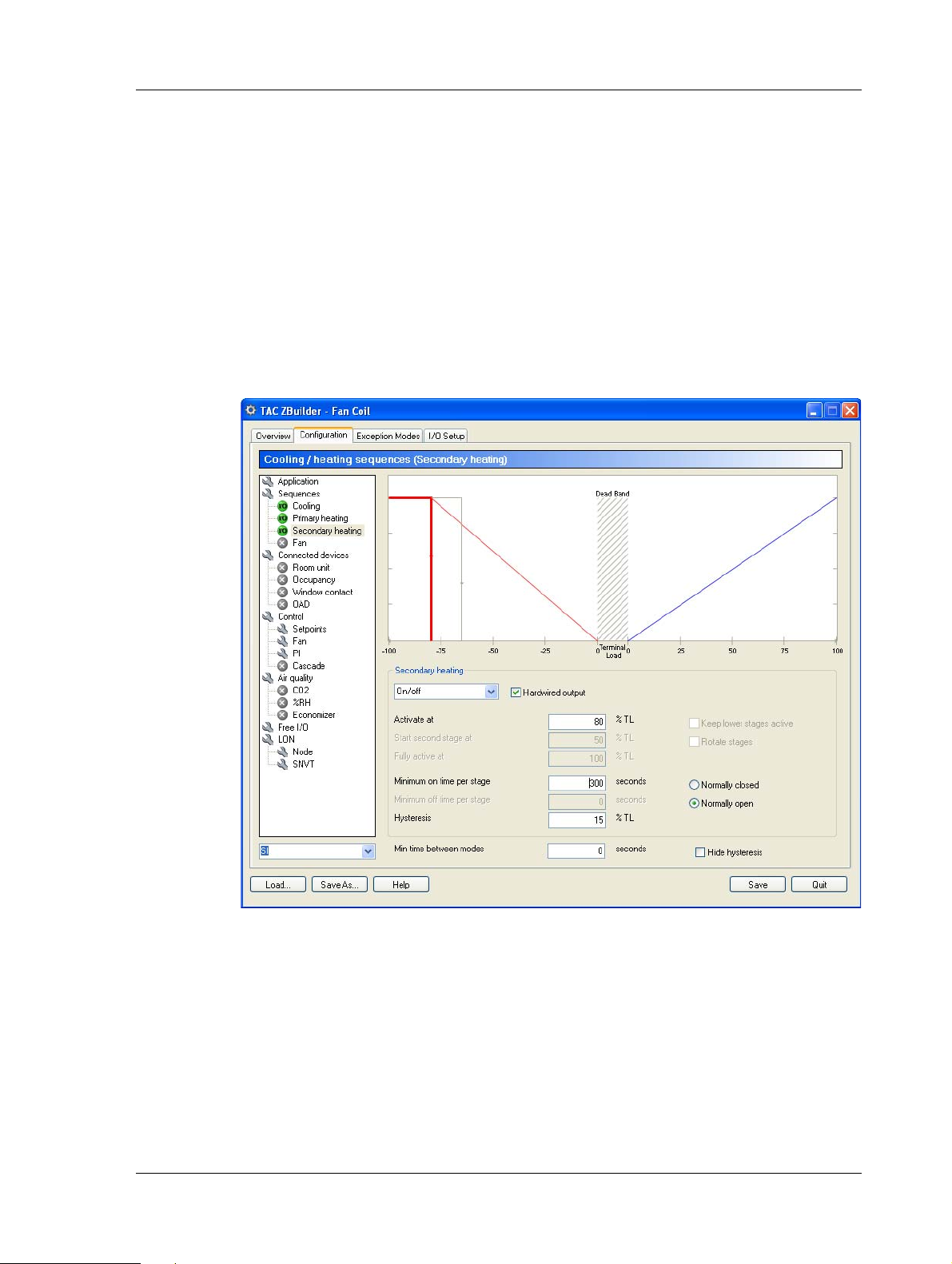

9 In the tree structure, select Sequences\Secondary heating.

10 In the Secondary heating area, in the device type list, select the

required device type. In the example, On/off to include the On/off

reheater.

11 Select the Hardwired output checkbox.

12 In the Activate at box, enter the required value. In the example,

“80”, to determine at what point the reheater will turn on.

13 In the Hysteresis box, enter the required value. In the example,

“15”, to determine the hysteresis before the reheater is turned off.

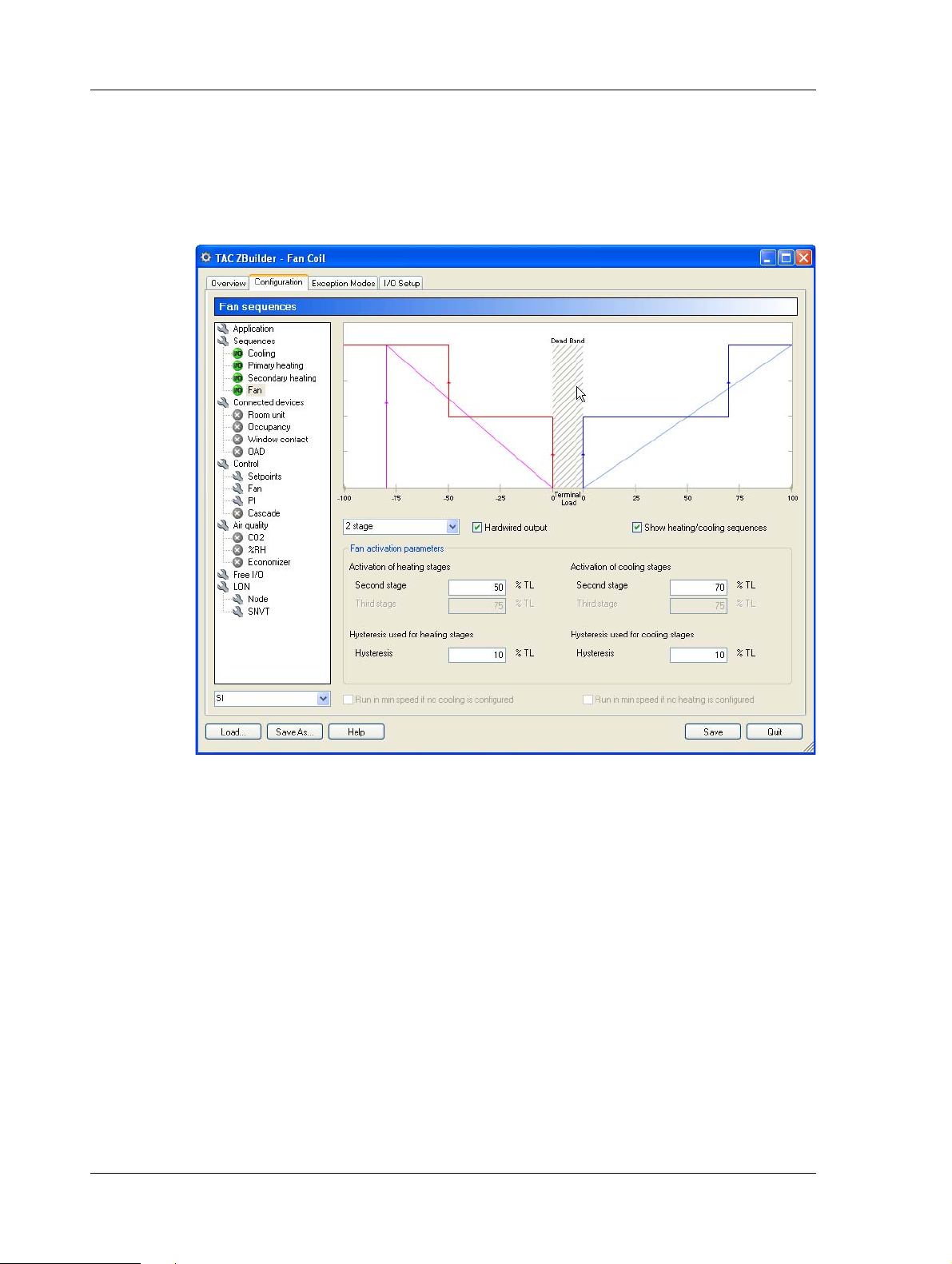

3.4.2 Adjusting the Fan Parameters

In the example, we use the template’s 2-stage fan, but adjust the on/off

delay times and the deadband.

To adjust the Fan parameters

1 In the tree structure, select Sequences\Fan.

2 In the fan type list, select the required fan type. In the example,

2 stage.

Schneider Electric Buildings, Dec 2011 29 (126)

04-00035-02-en (EN)

Page 30

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

3 Make sure the Hardwired output checkbox is selected.

4 In the Activation of cooling stages, Second stage box, enter the

required value. In the example, “70”.

5 Select the Show heating/cooling sequence checkbox, to superim-

pose the heating/cooling sequence on the fan sequence.

3.4.3 Adding a Room Unit

Several types of room temperature sensor units can be connected to the

TAC Xenta 120 controller series.

In the example, we want to add the STR 106 to the controller.

To add a Room unit

1 In the tree structure, select Connected devices/Room unit.

30 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 31

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

2 In the Select hardwired room unit area, click the required room

unit. In the example, STR 106 to include that room unit.

3.4.4 Adding an Occupancy Signal

In order to let the controller change between occupancy modes, an occupancy signal must be activated.

In the example, we specify an occupancy signal via a SNVT.

To add an Occupancy Signal

1 In the tree structure, select Connected devices\Occupancy.

2 Select the Active checkbox.

3 Make sure the Hardwired occupancy sensor checkbox is cleared ,

which means the SNVT will be used.

Schneider Electric Buildings, Dec 2011 31 (126)

04-00035-02-en (EN)

Page 32

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

Note that the Occupancy icon in the tree to the left has been

changed to a yellow ‘SNVT’ icon.

3.4.5 Adding a Window Contact

In order to define an Exception Mode, the corresponding hardware

device must be activated.

In the example, we specify a hardwired window contact.

To add a window contact

1 In the tree structure, select Connected devices\Window contact.

2 Select the Active checkbox.

32 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 33

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

3 Select the Hardwired window contact checkbox.

3.4.6 Adjusting the Control Parameters for the Fan

To protect the reheater, it is common to let the fan run some time after

the reheater has been turned off.

In the example, we increase the Off delay time.

To adjust the control parameters for the fan

1 In the tree structure, select Control\Fan.

2 Click the Heating delays text to display the parameters.

Tip

Y ou can also click the + -icon next to the text to display the parameters.

3 In the Off delay heating mode box, enter the required value. In

the example, “30”.

4 Click the Run in deadband text to display the parameters.

Schneider Electric Buildings, Dec 2011 33 (126)

04-00035-02-en (EN)

Page 34

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

5 Select the Run in deadband when in occupied mode checkbox.

3.5 Specifying an Exception Mode

Exception Modes are used to describe a number of events which in

some way may interfere with normal control.

In the example, we want to turn off all heating/cooling if the window

has been left open for more than two minutes. We describe this case in

an Exception Mode.

To specify an Exception mode

1 Click the Exception Modes tab.

2 Click the Exception Mode 1 text to display the parameters.

3 In the left Activation input list, select the required input. In the

example, Window contact.

4 In the right Activation input list, select the required condition. In

the example, Input is inactive.

5 In the Delays area, in the Delay on box, enter the required value.

In the example, “120”.

34 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 35

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

6 In the Exception mode description area, enter a descriptive text.

In the example, “Window contact”.

Note

The information text can display max. 110 characters.

7 Click the Exception Mode 1 text to hide the parameters.

The information text is now displayed as a label for this exception.

3.6 Changing the Inputs/Outputs configuration

When hardwired inputs and outputs are used in the application,

ZBuilder automatically selects suitable I/O terminals on the controller.

Schneider Electric Buildings, Dec 2011 35 (126)

04-00035-02-en (EN)

Page 36

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

However, the inputs and outputs can be manually changed to other suitable ports, if that is required.

ZBuilder also lists SNVTs for functions that you have enabled, but chosen not to use hardwired I/O for. These SNVTs need to be bound.

In the example, we choose relay contact K4 for our Secondary heating.

To change the Inputs/Outputs configuration

1 Click the I/O Setup tab.

2 In the IO ports area, in the Output list, click the suggested output

port. In the example, K1, Sec. Heating 1 - 1st stage.

3 Point at K1 and drag the output to the required port. In the exam-

ple to K4.

In the Functions bound to SNVTs list, used SNVTs are displayed as a

reminder that they need to be bound.

In the example, the SNVT nviOccSensor is displayed since the occupancy sensor is not hardwired but is signalled via a SNVT.

36 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 37

TAC Xenta, TAC Xenta 120 3 Creating the TAC Xenta 120 Configuration

3.7 Documenting and Saving the Configuration

The configuration process is now complete. Only documenting and saving the result remains. The saved file is later used for download of the

configuration into the controller.

In the example, this is done in Chapter 4, “Installing TAC Xenta 120 in

a Classic Network”, on page 39.

3.7.1 Documenting the Configuration on a Printout

For archiving purposes, the I/O Setup and some other details of the configuration can be easily printed in a standardized form.

To learn more about how to document the configuration, see

Chapter 5.5, “Documenting the Configuration”, on page 53.

In the example, we add some lines of description and make a standard

printout.

To print out the Configuration

1 Click the Overview tab. In the Selected devices area an overview

of the application is shown.

2 In the Description box, enter a descriptive text. In the example,

“4-pipe fan-coil application for the lab in the Engineering area”.

Schneider Electric Buildings, Dec 2011 37 (126)

04-00035-02-en (EN)

Page 38

3 Creating the TAC Xenta 120 Configuration TAC Xenta, TAC Xenta 120

3 Click Print preview.

A Print preview window opens, showing the configuration name,

date and time, the descriptive comment, the I/O connections, and a

list of the used user configuration parameters (UCPTs).

4 Click the Print button in the tool bar to get a printout on the default

printer.

5 Click Close.

3.7.2 Saving the Configuration File

The current configuration may be saved either as an ordinary configuration file (*.zbc), or as a configuration template (*.zbt), but in the latter

case only by using the Save as button.

To learn more about how to save the configuration file, see

Chapter 5.5.3, “Saving the Configuration”, on page 55.

In the example, we will save the application as an ordinary configuration file.

To save the configuration file

1 Click the Overview tab, click Save.

2 Browse to the folder where the file will be saved. In the example,

C:\ProjectACME\DeviceDescr .

3 Enter the configuration file name. In the example, Engr_Lab.zbc.

4 Click Quit to quit ZBuilder.

38 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 39

TAC Xenta, TAC Xenta 120 4 Installing TAC Xenta 120 in a Classic Network

4 Installing TAC Xenta 120 in a Classic

Network

The Xenta 120 has to be added to the LonWorks network to be able to

download the parameters from the configuration file to the TAC Xenta

120 using ZBuilder. The Xenta 120 can be added at the same time as the

other devices on the LonWorks network, or it can be added later to an

existing network.

For more information on how to create LonWorks networks, see the

Engineering Classic Networks and/or Engineering LNS Networks.

Before downloading the parameters, you load an already created configuration into ZBuilder. At this stage you can make changes to the configuration file and save them to the configuration file if required.

The configuration file is then transferred to the Vista database and from

there downloaded to the Xenta 120.

2a. Load

Config files

(2b. Save as)

ZBuilder

Fig. 4.1: Using ZBuilder as a plug-in for TAC Vista

1. Edit

TAC Xenta 120

3. OK or Apply

Engineering

(and Operating)

TAC Vista

Vista db

Operating

(online)

In the example, we will add one TAC Xenta 120 to an existing Classic

network.

4.1 Adding and Configuring the TAC Xenta 120

You can add and configure Xenta 120 devices in Vista without be ing

connected to the devices.

From the Vista point of view, TAC Xenta 120 is like a LonWorks

device with configuration parameters that can be edited.

TAC Xenta 121

with basic

application sw

4.1.1 Adding a LonWorks Group

The Xenta 120 is added to a LonWorks group in the LonWorks network.

Schneider Electric Buildings, Dec 2011 39 (126)

04-00035-02-en (EN)

Page 40

4 Installing TAC Xenta 120 in a Classic Network TAC Xenta, TAC Xenta 120

In the example, we add the LonWorks group, 2nd_Floor_LW to the

LonWorks network, ACME_Inc.

To add a LonWorks group

1 In Vista workstation, change the Vista mode to Engineering.

2 In the Folders pane, right-click the LonWorks network object that

the LonWorks group belongs to. In the example, VistaSRV1ACME_Inc.

3 Point to New, point to Device, and then click LonWorks Group.

4 Name the LonWorks group. In the example, 2nd_Floor_LW.

4.1.2 Adding a TAC Xenta 120

You need to add the Xenta 120 to a LonWorks gro up on the LonWork s

network.

In the example, we name the Xenta 120 “Engr_Lab” and add it to the

LonWorks group 2nd_Floor_LW on the ACME_Inc Lonworks network.

To add a TAC Xenta 120

1 In Vista Workstation, in the Folders pane, right-click the Lon-

Works group the Xenta 120 belongs to. In the example,

VistaSRV1-ACME_Inc-2nd_Floor_LW.

2 Point to New, point to Device, and then click on TAC Xenta 120.

3 Click Next.

40 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 41

TAC Xenta, TAC Xenta 120 4 Installing TAC Xenta 120 in a Classic Network

4 In the Name box, enter a name for the Xenta 120. In the example,

Engr_Lab.

5 Click Next.

6 In the Neuron ID box, enter the neuron ID of the Xenta 120.

7 In the File system box, browse to the Xenta 120 external interface

file (.xif). In the example,

C:\ProjectACME\DeviceDescr\X120FCw1.xif.

Notes

• The external interface files used together with Xenta 120 are

delivered with V ista. If Vista is installed in the default folder, the

files are found in the C:\Program Files\TAC\TAC Vista [version]\$ini folder.

• For a Xenta 121-HP (Heat Pump), the external interface file

X120HPw1.xif is used.

Schneider Electric Buildings, Dec 2011 41 (126)

04-00035-02-en (EN)

Page 42

4 Installing TAC Xenta 120 in a Classic Network TAC Xenta, TAC Xenta 120

8 Click Finish.

9 Click Close.

The TAC Xenta 120 device has now been added to the network .

4.1.3 Configuring a TAC Xenta 120

We need to start ZBuilder from TAC Vista and load a configuration file

in order to transfer the parameters from the configuration file to the

Vista database.

In the example, we load the configuration file, Engr_Lab.zbc, created in

the previous chapter.

To configure a TAC Xenta 120

1 In TAC Vista, right-click the new Xenta 120 device. In the exam-

ple, VistaSRV-2nd_Floor_LW-Engr _Lab.

2 Click Edit.

TAC ZBuilder starts.

3 In ZBuilder click Load.

4 In the Select File dialog box, click Browse for Configuration or

Template File.

42 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 43

TAC Xenta, TAC Xenta 120 4 Installing TAC Xenta 120 in a Classic Network

5 In the Browse for Configuration or Template File, browse to the

configuration file. In the example,

C:\ProjectAcme\DeviceDescr\Engr_Lab.zbc.

6 Click OK.

Schneider Electric Buildings, Dec 2011 43 (126)

04-00035-02-en (EN)

Page 44

4 Installing TAC Xenta 120 in a Classic Network TAC Xenta, TAC Xenta 120

7 Click OK.

Note

The contents of the configuration file have now been loaded into

ZBuilder. Last minute changes may be done in ZBuilder and if so,

you may want to Save as these changes to the existing configuration file, or to a new configuration file.

8 Click OK to transfer the configuration parameters to the Vista

database and close ZBuilder.

Tip

You can click Apply to transfer the configuration parameters to the

Vista database without closing ZBuilder.

44 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 45

TAC Xenta, TAC Xenta 120 4 Installing TAC Xenta 120 in a Classic Network

Note

When editing the configuration file for a Xenta 120 that is already

installed on the LonWorks network and Vista is in Operating mode,

the configuration download to the Xenta 120 will have already

occurred at the ZBuilder Apply/OK command and no download and

commission is needed.

A reset of the neuron of the Xenta 120 is performed by Vista after a

configuration change to make the changes valid. If the reset fails, you

have to perform a manual restart. For more information on how to

reset a neuron, see Section 6.1.2, “Resetting a Neuron”, on page 58.

4.2 Commissioning and Downloading

The configuration parameters have to be downloaded from the Vista

database to the TAC Xenta 120. To be able to do a commission and

download, you have to be connected to the LonWorks network.

To Commission and Download

1 In Vista Workstation, in the folders pane, right-click the Xenta

120. In the example, VistaSRV1-2nd_Floor-Engr_Lab.

2 Click Commission and Download.

3 Click Download parameters from Vista to device.

4 Click OK.

Schneider Electric Buildings, Dec 2011 45 (126)

04-00035-02-en (EN)

Page 46

4 Installing TAC Xenta 120 in a Classic Network TAC Xenta, TAC Xenta 120

5 In the TAC Vista Load – Upload Parameters dialog, click .

6 Click Continue.

7 Click Close.

8 Change the Vista mode to Operating.

9 In the folders pane, refresh the tree structure and check that the

Xenta 120 is online.

Important

A reset of the neuron of the Xenta 120 is performed by Vista after a

configuration change to make the changes valid. If the reset fails, you

have to perform a manual restart. For more information on how to

reset a neuron, see Section 6.1.2, “Resetting a Neuron”, on page 58

46 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 47

REFERENCE

5 ZBuilder - the Configuration Tool

6 TAC ZBuilder as a Plug-in

7 Application Types (Configuration)

8 Fan Control

9 Connected Devices and Network

Parameters

10 Control Issues

11 Exception Modes

12 I/O Setup

Page 48

Page 49

TAC Xenta, TAC Xenta 120 5 ZBuilder - the Configuration Tool

Fan-Coil

or

Heat pump

Room temperature

Offset temp. dial

Bypass button

Occupancy sensor

CO

2

sensor

%RH sensor

Outdoor

temp.

sensor

Duct temp.

sensor

Water temp.

sensor

Outside Air

Damper

Electrical

Heater

Door/

Window

contact

Glass break

sensor

TAC Xenta 120

5 ZBuilder - the Configuration Tool

5.1 Usage

The TAC Xenta 120 series controllers are used for applications that can

be designed and configured in a very flexible way, using ZBuilder.

The tool is a software package that can be run stand-alone or as a device

plug-in to TAC Vista® or L

ONMAKER®.

Fig. 5.1: A TAC Xenta 120 series controller and examples of peripherals

The configuration created by this tool is transferred to LNS or Vista and

is loaded into a TAC Xenta® 120 controller, which has the required set

of Inputs and Outputs and the basic software for the relevant applica-

5.2 ZBuilder Overview

tion.

The purpose of the ZBuilder is to create a software configuration file,

where hardware and/or SNVT input signals are used to affect a specific

Climate Control Device (CCD), resulting in signals directed to hardware and/or SNVT outputs.

Schneider Electric Buildings, Dec 2011 49 (126)

04-00035-02-en (EN)

The contents of the configuration file are used by TAC Vista or L

M

AKER to download the configuration in a Xenta 120 unit, which

ON-

Page 50

5 ZBuilder - the Configuration Tool TAC Xenta, TAC Xenta 120

Template

(*.zbt)

Config

parameters

Config file

(*.zbc)

TAC Vista/

LNS

Modified

config file

ZBuilder

TAC Xenta 121

with basic

application sw

already contains the required software for the intended application (for

example Fan-Coil or Heat Pump).

.

Fig. 5.2: Creating and downloading a modified configuration file for a

TAC Xenta 121 application.

ZBuilder has a start page, where the user can start with a template

(*.zbt) or edit a previously saved configuration file (*.zbc).

The configuration is then customized in three tabbed pages:

• Configuration

• Exception Modes

• I/O Setup

The Configuration page lists the available Configuration Modules and

the corresponding parameters.

In the Exception Modes page, up to eight exceptions can be defined, that

is, special action at certain events, for example the desired action when

a window is opened.

The I/O Setup page shows how the inputs and outputs for the selected

Xenta 120 hardware are used. This can also be reconfigured here.

A fourth page, Overview is a graphic presentation of the application,

with a list of the most important parameters and a print function for documentation purposes.

The result is saved as a customized Configuration file.

TAC Vista or LonMaker is used to download the configuration file in

the TAC Xenta 120.

TAC Xenta OP can be used to inspect nvi and nvo values. Due to the

many configuration possibilities, the OP cannot be used to configure the

controller.

50 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 51

TAC Xenta, TAC Xenta 120 5 ZBuilder - the Configuration Tool

About TAC ZBuilder

The current version of TAC ZBuilder is found in the About TAC

ZBuilder window, which appears if you click on the icon in the upper

left corner.

Fig. 5.3: Finding version information of TAC ZBuilder

Terminal Load

In the Xenta the control program calculates the Terminal Load, a value

in the range –100% to +100%. This value indicates the amount of heating or cooling power required at the moment.

A negative Terminal Load means that heating is required.

A positive Terminal Load means that cooling is required.

The configuration procedure tells the controller how the CCD (Climate

Control Device) should act at different levels of Terminal Load.

This is shown in a sequence diagram, with the Terminal Load on the X-

axis and the output signals to the CCD on the Y-axis.

In ZBuilder a CCD can consist of up to three heating or cooling devices:

• Primary heating

• Secondary heating

• Cooling

Schneider Electric Buildings, Dec 2011 51 (126)

04-00035-02-en (EN)

Page 52

5 ZBuilder - the Configuration Tool TAC Xenta, TAC Xenta 120

Item tree

Units selection:

SI (metric) or

US (inch-pound)

5.3 Templates and Applications

5.3.1 Selecting a File

At start-up, a template (*.zbt) from a list or a configuration file (*.zbc;

or another template) is selected:

The modified result can then be saved as a new template or file.

There are two basic templates: Fan-Coil and Heat pump.

Once an application type (F-C or HP) has been selected, it is not possi-

ble to Load another type.

If you need another type, you will first have to Save the current type or

restart the tool.

5.4 The Configuration Window

In the left part of the Configuration window, there are an item tree and

a drop-down Units selection menu.

52 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 53

TAC Xenta, TAC Xenta 120 5 ZBuilder - the Configuration Tool

By clicking on a menu in the list, you will be able to inspect and modify

different parameters of the application.

The icons in the tree indicate what kind of parameters are displayed and

some of the properties for the configured devices.

Table 5.1: Icons in Menu tree

Icon Meaning

‘Main’ window, or

Window with additional functions and settings

Window for a configured device that has a hardwired

connection

Window for a configured device that is connected via a

SNVT

Window for a non-used device

5.5 Documenting the Configuration

For documentation and future use, the configuration can be:

• exported as a text file

• printed as a parameter list in a pre-defined format

• associated with a graphical description

• saved as a configuration or a template file

5.5.1 Printing the Configuration Parameters

For documenting and future use, the I/O Setup and other parameter

details of the configuration can be easily printed.

To print the Configuration parameters

1 Click the Overview tab.

2 In the Description field, enter a suitable text.

3 Click Content to select which parts to include with the printout

(or text file export).

4 Click Print preview.

A Print preview window will open, showing the following

(depending on the Content selection):

• Header (application type, configuration file name, and date

and time of preview)

• Description: the text from the Description field.

• Connections: the IO Ports from the I/O Setup.

Schneider Electric Buildings, Dec 2011 53 (126)

04-00035-02-en (EN)

Page 54

5 ZBuilder - the Configuration Tool TAC Xenta, TAC Xenta 120

• SNVTs expected to be bound: the list of SNVTs from the I/O

Setup.

• Exception Mode descriptions: for each defined Exception

Mode the Information text is presented.

• Configuration parameters: a list of the used UCPTs (user configuration parameters), their Name, Position (order in table),

Index (bit no., 0 is most significant), and Value.

5.5.2 Associating a Graphic with the Configuration

To give a quick visual cue, a graphic can be shown in the Description

area of the Select File window. Below the picture, the descriptive text

from the Overview Description field also appears.

Fig. 5.4: Graphic and text description of selected Configuration file

Any .jpg-file with the same name and residing in the same folder will

appear in the window.

Example: If the configuration file resides as

C:\Program Files\TAC\TAC ZBuilder\Templates\HeatPump2.zbc

then the graphic

C:\Program Files\TAC\TAC ZBuilder\Templates\HeatPump2.jpg

will appear in the square Description window.

The resolution of the .jpg file should not exceed 120x120 pixels.

Note

In the Overview window there is a graphical view of the Selected

devices. This is a dynamically drawn graphic, updated with any

change in the configuration. This graphic cannot be saved separately

at this stage.

54 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 55

TAC Xenta, TAC Xenta 120 5 ZBuilder - the Configuration Tool

5.5.3 Saving the Configuration

The current configuration can be saved

• as an ordinary configuration file (*.zbc), or

• as a configuration template (*.zbt),

but in the latter case only by using the Save as button.

Zbuilder is always started with a configuration selected by the user. As

soon as a change has been made, the Save button is made available.

Clicking on Save will immediately overwrite the selected configuration

(unless a template has been used).

In order to preserve the original configuration, use the Save as button,

as this will ask for a file name, folder, and format (.zbc or .zbt). After

this, Save can be used.

Before making the final Save or Save as, you may consider these

points:

•In Overview, enter a descriptive text in the Description field. This

text will appear in the Configuration Parameters printout and the

Select File window described above.

• Associate a descriptive graphic with the same name as the configuration file, as shown above.

• Decide if the current configuration shall be used as a template or

an ordinary file.

Schneider Electric Buildings, Dec 2011 55 (126)

04-00035-02-en (EN)

Page 56

5 ZBuilder - the Configuration Tool TAC Xenta, TAC Xenta 120

56 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 57

TAC Xenta, TAC Xenta 120 6 TAC ZBuilder as a Plug-in

6 TAC ZBuilder as a Plug-in

TAC Xenta 120 can be treated as a LONWORKS device with configuration parameters that can be edited, using ZBuilder as a plug-in to

TAC Vista or L

6.1 As a Plug-in in TAC Vista

ZBuilder is used as a Plug-in in Vista when Xenta 120 devices are

installed on a classic network.

6.1.1 Starting ZBuilder from TAC Vista

As described in Chapter 4, “Installing TAC Xenta 120 in a Classic Network”, on page 39, we start ZBuilder from TAC Vista in order to transfer the parameters from the existing configuration file to the Vista

database.

ONMAKER.

To start ZBuilder from TAC Vista

1 In TAC Vista, right-click the new Xenta 120 device and select

Edit.

Fig. 6.1: Starting ZBuilder with an Edit command

TAC ZBuilder should now start.

2 In the ZBuilder Select File window, click Browse for Configura-

tion or Template File and select the configuration file from the

previous chapter, Engr_Lab.zbc.

The contents of the configuration file are now loaded into ZBuilder.

Last minute changes may be done in ZBuilder and, if so, you may

want to Save as these changes to the existing configuration file or

to a new configuration file.

Schneider Electric Buildings, Dec 2011 57 (126)

04-00035-02-en (EN)

Page 58

6 TAC ZBuilder as a Plug-in TAC Xenta, TAC Xenta 120

6.1.2 Resetting a Neuron

A reset of the neuron of the Xenta 120 is performed by Vista after a configuration change to make the changes valid. If the reset fails, you must

perform a manual reset.

To reset the neuron

1 In Vista Workstation, in the folders pane, right-click the Xenta 120

device.

2 Point to Advanced Operations and then click Reset Neuron.

3 Click Yes.

6.2 As a Plug-in in LonMaker

ZBuilder is used as a Plug-in in LonMaker when Xenta 120 devices are

installed on an LNS network.

6.2.1 Starting ZBuilder from LonMaker

ZBuilder is started from LONMAKER in order to transfer the parameters

from the existing configuration file to the LNS database.

Important

Do not use the LonMaker Browser to inspect or change the nci, scpt,

or ucpt values. These values can be interpreted in different ways and

only ZBuilder has the logic to interpret the Xenta 120 applications.

To start ZBuilder from LonMaker

1 In LonMaker, in the drawing, right-click the Xenta 120 device.

58 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 59

TAC Xenta, TAC Xenta 120 6 TAC ZBuilder as a Plug-in

2 Click Configure.

Fig. 6.2: Starting ZBuilder from LonMaker with a Configure command

TAC ZBuilder should now start.

Tips

• Y o u can also click System Plug-Ins on the LonMaker menu and

start TAC ZBuilder from the Plug-Ins window

• If ZBuilder does not start (LonMaker Browser starts instead),

you must register ZBuilder as a plug-in. For more information on

how to register a plug-in, see Section 6.2.4, “Registering

ZBuilder as a Plug-in”, on page 61.

6.2.2 Configuring a TAC Xenta 120

Configuration of the Xenta 120 in ZBuilder transfers the parameters to

the LNS database. If the device is commissioned at the time, the parameters will also be downloaded to the Xenta 120; otherwise, the parameters will be downloaded when the Xenta 120 is commissioned.

For information on how to commission a device, see the Engineering

LNS Networks manual.

To configure a TAC Xenta 120

1 In ZBuilder, in the Select File dialog box, click Browse for Con-

figuration or Template File.

2 Select the required template or browse to the required configura-

tion file.

Schneider Electric Buildings, Dec 2011 59 (126)

04-00035-02-en (EN)

Page 60

6 TAC ZBuilder as a Plug-in TAC Xenta, TAC Xenta 120

The contents of the template/configuration file are now loaded into

ZBuilder. Last minute changes may be done in ZBuilder and, if so,

you may want to Save as these changes to the existing configura-

tion file or to a new configuration file.

3 Edit the configuration parameters as required.

4 Click Save as.

5 Browse to a suitable folder.

6 Click Save.

7 Click OK to transfer the parameters to the LNS database and close

ZBuilder.

If several Xenta 120 devices are to have the same configuration, there

is a great advantage in updating the LonMaker device shape with the

complete configuration. For more information on how to Update a LonMaker device shape, see Section 6.2.3, “Updating a LonMaker Device

Shape”, on page 60.

Tip

You can click Apply to transfer the configuration parameters to the

LNS database without closing ZBuilder.

Note

When editing the configuration file for a Xenta 120 that is installed on

the LonWorks network and commissioned, the configuration download to the Xenta 120 will occur at the ZBuilder Apply/OK command.

A reset of the neuron of the Xenta 120 is performed by LonMaker after

a configuration change to make the changes valid. If the reset fails, you

must perform a manual restart. For more information on how to reset

a neuron, see Section 6.2.5, “Resetting a Neuron”, on page 62.

6.2.3 Updating a LonMaker Device Shape

If several Xenta 120 controllers are to use the same configuration, you

should use the complete, updated LonMaker Xenta 120 device template

to simplify the download procedure.

To use the LonMaker template for Configuration Download

1 Start ZBuilder from the configured device in LonMaker.

2 Click the Configuration tab.

3 In the tree structure, select LON.

4 Click Update Template.

60 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 61

TAC Xenta, TAC Xenta 120 6 TAC ZBuilder as a Plug-in

The LonMaker Xenta 120 device template is now updated with the

complete configuration, including the extension records (the specified STR, the Exception Modes texts, and so on).

5 In LonMaker, drag the required number of Xenta 120 shapes to the

drawing. Select Default values as Configuration property source.

The correct parameters will be associated with the new Xenta 120

devices.

6 Commission each Xenta 120 device.

7 Perform a node reset, see Section 6.2.5, “Resetting a Neuron”, on

page 62.

Important

When this configuration method is used, the last step is mandatory to

complete the commissioning procedure.

Note

In order to streamline the work with multiple devices, the Xenta 120

shapes do not contain any Functional Blocks with nvi:s/nvo:s

included. The reason is that the Update Template button does not

update the nci:s connected to that/those FBs that exist in the shape.

To create your own shape containing FBs, make sure the device is configured in ZBuilder and that the LNS database is updated (Update

Template), before the shape is created. An SCC FanCoil FB, containing the required variables for binding, can easily be created using the

LonMaker basic Shapes.

6.2.4 Registering ZBuilder as a Plug-in

Normally, TAC ZBuilder is registered together with all other plug-ins

when the network drawing is created. However, it may be necessary to

repeat the registration.

To register ZBuilder as a Plug-in

1 In LonMaker, on the LonMaker menu, click Network Pr operties

2 Click the Plug-in Registry tab.

3 In Already Registered list, select TAC ZBuilder (Version x.x.x).

Schneider Electric Buildings, Dec 2011 61 (126)

04-00035-02-en (EN)

Page 62

6 TAC ZBuilder as a Plug-in TAC Xenta, TAC Xenta 120

4 Click Add.

5 Click OK.

6 Wait until the ZBuilder is registered.

6.2.5 Resetting a Neuron

A reset of the neuron of the Xenta 120 is performed by LonMaker after

a configuration change to make the changes valid. If the reset fails, you

will need to perform a manual reset.

To reset a neuron

1 In LonMaker, in the drawing, right-click the Xenta 120 device.

2 Click Manage.

3 Click Reset.

4 Quit the LonMaker Device Manager dialog box.

62 (126) Schneider Electric Buildings, Dec 2011

04-00035-02-en (EN)

Page 63

TAC Xenta, TAC Xenta 120 7 Application Types (Configuration)

-100 -83 -50 0

0 33 100

Output

signal

Terminal

Load

Cooling

Fan

Primary

Secondary

heating

7 Application Types (Configuration)

7.1 Terminal Load and the Heating/Cooling Sequence

The function of the TAC Xenta 120 is determined by the Terminal

Load, that is, how much of the heating/cooling power is needed at each

point in time.

It is possible to configure up to two heating devices and one cooling

device. Each of these can be a multistage, pwm, analog, or increase/

decrease device.

The user defines the sequence in relation to the Terminal Load, and the

resulting process is displayed in a diagram with the Terminal Load on

the x-axis and the output signal on the y-axis.

An example of a Heating/Cooling sequence is shown below.

Fig. 7.1: The Heating/Cooling sequence as a function of the Terminal

Load

Schneider Electric Buildings, Dec 2011 63 (126)

04-00035-02-en (EN)

Page 64

7 Application Types (Configuration) TAC Xenta, TAC Xenta 120

Window contact

Heating

coil

1-, 2- or

3-speed Fan

Wall module

Occupancy

sensor

Discharge air

sensor

Incr./decr. or

thermal actuators

Reheating

stage

Economizer Cooling

coil

Humidity

sensor

Outside temp.

sensor

Window contact

Heating/cooling

coil

1-, 2- or

3-speed Fan

Wall module

Occupancy

sensor

Discharge air

sensor

Incr./decr. or

thermal actuator

Water temp.

sensor

Reheating

stage

Economizer

CO2 sensor

Outside temp.

sensor

7.2 The 4-pipe Fan-Coil

An example of a 4-pipe Fan-Coil system:

Fig. 7.2: 4-pipe Fan-Coil

7.3 The 2-pipe Fan-Coil

An example of a 2-pipe Fan-Coil system:

Fig. 7.3: 2-pipe Fan-Coil

Change-over Temperature

In a 2-pipe Fan-Coil unit there is a water temperature sensor for the

incoming flow. When the controller is in Auto mode it will change

between heating and cooling, based on a configurable change-over tem-

64 (126) Schneider Electric Buildings, Dec 2011

perature level.

There is a heating/cooling change-over hysteresis. With the change-

over temperature at 20 °C (68 °F) and change-over hysteresis of 3 °C

(5.4 °F), the fan-coil, coming from heating, will change to cooling at

04-00035-02-en (EN)

Page 65

TAC Xenta, TAC Xenta 120 7 Application Types (Configuration)

2726252423222120191817161514

C

o

13

heating start

change-over temp.

cooling start

change-over

hysteresis

(from cooling)

(from heating)

Window contact

Heating/cooling

compressor

1-, 2- or

3-speed Fan

Wall module

Occupancy

sensor

Discharge air

sensor

Isolation

valve

Water temp.

sensor

Reheating

stage

Economizer

CO2 sensor

Outside temp.

sensor

Reversing

valve

21.5 °C (70.7 °F). Coming from cooling it will start heating at 18.5 °C

(65.3 °F).

Fig. 7.4: 2-pipe Fan-Coil changeover temperature parameters

If no water temperature sensor is used, the mode has to be set to HEAT

or COOL by a superior system.

Note

It is possible to allow heating by a secondary heating stage, even if the

mode indicates that the water temperature is too low to allow heating

by the fan-coil itself.

7.4 The Heat Pump