Page 1

TAC Vista

TAC Pangaea

WorkStation

TAC Xenta 104-A

Product Manual

Page 2

Page 3

TAC Vista

TAC Xenta 104-A

Product Manual

Page 4

Copyright © 2004-2010 Schneider Electric Buildings AB. All rights reserved.

This document, as well as the product it refers to, is only intended for licensed users. Schneider Electric Buildings AB owns the copyright of

this document and reserves the right to make changes, additions or deletions. Schneider Electric Buildings AB assumes no responsibility for

possible mistakes or errors that might appear in this document.

Do not use the product for other purposes than those indicated in this document.

Only licensed users of the product and the document are permitted to use the document or any information therein. Distribution, disclosure,

copying, storing or use of the product, the information or the illustrations in the document on the part of non-licensed users, in electronic or

mechanical form, as a recording or by other means, including photo copying or information storage and retrieval systems, without the express

written permission of Schneider Electric Buildings AB, will be regarded as a violation of copyright laws and is strictly prohibited.

Trademarks and registered trademarks are the property of their respective owners.

Page 5

Zone Controller, TAC Xenta 104-A Contents

Contents

INTRODUCTION

1 Documentation and Terminology 9

1.1 Documentation........................................................................................................... 9

1.2 Terminology............................................................................................................... 10

REFERENCE

2 Zone Controller TAC Xenta 104 13

2.1 General....................................................................................................................... 13

2.2 Wall Modules............................................................................................................. 14

2.2.1 STR350/351 ............................................................................................................... 14

2.2.2 STR150 ...................................................................................................................... 15

2.2.3 STR100-104............................................................................................................... 16

2.2.4 Wall Module Configuration....................................................................................... 17

2.2.5 General....................................................................................................................... 18

2.2.6 HVAC Controller, Network Installation.................................................................... 18

2.2.7 HVAC Controller, Stand-alone Installation............................................................... 19

3 Installation 21

3.1 Mechanical Installation.............................................................................................. 21

3.1.1 Fitting......................................................................................................................... 21

3.2 Electrical Installation ................................................................................................. 22

3.2.1 General....................................................................................................................... 22

3.2.2 Wiring of TAC Xenta 104 as Typical RTU or HVAC Unit ..................................... 25

3.2.3 Wiring of TAC Xenta 104 as Typical Packaged RTU.............................................. 26

3.2.4 Wiring of TAC Xenta 104 as Controller Applied to Small AHU............................. 27

3.2.5 Connecting to STR150............................................................................................... 28

3.3 Commissioning .......................................................................................................... 28

3.3.1 General....................................................................................................................... 28

3.3.2 Node Status ................................................................................................................29

3.3.3 Configuration Parameters (nci’s)............................................................................... 30

3.3.4 Network Installation.............................................................. ..... .... ............................ 30

3.3.5 Network Variable Binding.................................................... ..... .... ............................ 30

3.3.6 Function Test..............................................................................................................31

4 Configuration Parameters 33

4.1 Basic Parameters...................................................... .................................................. 34

4.2 Other Configuration Parameters ................................................................................ 35

5 Functional Description 39

5.1 General....................................................................................................................... 39

Schneider Electric Buildings AB, Mar 2010 5 (74)

04-00068-01-en

Page 6

Contents Zone Controller, TAC Xenta 104-A

5.2 The Controller’s Basic Functions............................................................................... 40

5.2.1 Operation Modes ......................................................................... .... ........................... 40

5.2.2 Application and Emergency Modes ........................................................................... 41

5.2.3 Measuring Zone Temperature .................................................................................... 42

5.2.4 Setpoint Calculation ................................................................................................... 43

5.2.5 Control Sequence with TAC Xenta 104-A................................................................. 44

5.2.6 Fan Control................................................................................................................. 44

5.3 More About Functions................................................................................................ 45

5.3.1 Heating ....................................................................................................................... 45

5.3.2 Cooling....................................................................................................................... 46

5.3.3 Economizer.................................................................................................................47

5.3.4 Cascade Control.......................................................................................................... 48

5.3.5 Networked Applications............................................................................................. 48

5.3.6 Stand-alone Applications............................................................................................ 49

5.3.7 Sensor Options............................................................................................................ 49

5.3.8 Auxiliary Alarm Contact............................................................................................ 50

5.3.9 Fan Status Contact...................................................................................................... 50

5.3.10 Alarm.......................................................................................................................... 51

6 Troubleshooting 53

6.1 General ....................................................................................................................... 53

6.2 Inputs and Outputs (nvi/nvo’s)................................................................................... 53

6.3 Troubleshooting Guide............................................................................................... 54

7 Technical Data 55

7.1 Technical Data............................................................................................................ 55

7.2 Dimensions................................................................................................................. 58

8 Communication 59

8.1 General ....................................................................................................................... 59

8.2 Default Settings and Power on................................................................................... 59

8.3 Monitoring Network Variables, Heartbeat................................................................. 60

8.4 Not Accepted Values.................................................................................................. 60

8.5 The Node Object......................................................................................................... 61

8.5.1 The Node Object’s Inputs (nvi).................................................................................. 62

8.5.2 The Node Object’s Outputs (nvo) .............................................................................. 62

8.5.3 The Node Object’s Configuration Parameters (nci)................................................... 62

8.6 The Controller Object................................................................................................. 62

8.6.1 The Controller Object’s Inputs (nvi).......................................................................... 64

8.6.2 The Controller Object’s Outputs (nvo)....................................................................... 65

8.6.3 The Controller Object’s Configuration Parameters (nci)........................................... 66

APPENDIX

A Commissioning Protocol 69

Index 71

6 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 7

INTRODUCTION

1 Documentation and Terminology

Page 8

Page 9

Zone Controller, TAC Xenta 104-A 1 Documentation and Terminology

1 Documentation and Terminology

1.1 Documentation

Enclosed Documentation

TAC Xenta 104 is delivered with an installation instruction:

• Installation instruction, TAC Xenta 104

Other Documentation

There is additional information about TAC Xenta 104 in the following

documents:

• Data sheet for TAC Xenta 104

• Data sheet for ZS 101–ZS 105

• Data sheet for STR100–STR107

• Data sheet for STR150

• Data sheet for STR350/351

• TAC Xenta Network Guide

• TAC Xenta OP Handbook

All the above mentioned documents can be found on the internet at

or can be ordered from your

nearest Schneider Electric service point.

Schneider Electric Buildings AB, Mar 2010 9 (74)

04-00068-01-en

Page 10

1 Documentation and Terminology Zone Controller, TAC Xenta 104-A

1.2 Terminology

This handbook contains some abbreviations and terms, which are specific for the zone controller’s applications and network communication.

The most common terms are explained in Table 1.1, “Terminology”.

Table 1.1: Terminology

neuron

A communication processor with built-in

protocol

node

A communication unit on the network

SNVT Standard Network Variable Type

nvixxx Variable that gets its value from another

unit on the network

nvoxxx Variable that is sent to another unit on the

network

ncixxx Configuration parameter; variable that

gets its value from another unit on the network and keeps it during a power failure

service pin Function that can be used during installa-

tion on the network

wink

A confirmation that the connection to a

controller via the network is working (a

LED is lit for appr. 20 seconds)

LNS

LonWork

®

Network Services. System tool

for installation, configuration and maintenance of LonWorks network

10 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 11

REFERENCE

2 Zone Controller TAC Xenta 104

3 Installation

4 Configuration Parameters

5 Functional Description

6 Troubleshooting

7 Technical Data

8 Communication

Page 12

Page 13

Zone Controller, TAC Xenta 104-A 2 Zone Controller TAC Xenta 104

2 Zone Controller TAC Xenta 104

2.1 General

The TAC Xenta® 104-A is a zone controller intended for roof top unit,

small AHU, and unit ventilator applications which have heating, cooling, and economizer functions. The controller maintains a constant zone

temperature by sequenced control of the heating, cooling, and OA/RA

dampers. By using a discharge air temperature sensor, the discharge and

zone temperatures may be controlled in cascade if the TAC Xenta 104A configuration properties are set accordingly.

Cascade control also allows minimum and maximum limiting of the discharge air temperature. The fan On/Off is controlled by a 24 VAC isolated relay contact. The fan mode may be selected to operate continuous

during the Occupied mode, or cycle with heating or cooling demand

from the zone.

The Controller’s Basic Functions

The controller has a number of built-in functions that are designed to

handle normal control situations. There are two operating modes to

choose from (occupied and unoccupied) and five application modes

(heating only, cooling only, auto changeover, fan only and off).

The zone temperature is measured using a permanent thermistor sensor

or a temperature node connected to the network. Setpoint calculations

are made in line with defined methods. Fan control during the comfort

mode can be either continuous or cycling with heating or cooling functions. The economizer will only function in the cooling or auto

changeover modes. If the outdoor air is useful for cooling, the economizer will use it and provide energy savings and prevent damper hunting when cooling is cycling on and off.

For a detailed functional description of all the basic please see

Chapter 5.2, “The Controller’s Basic Functions”, on page 40.

More About Functions

Apart from the controller’s basic functions, there are a number of other

functions for controlling the climate in the zone; these are described in

detail in Chapter 5.3, “More About Functions”, on page 45. Additional

external functions that can be connected are also described in this chapter, these include window contact sensor and occupancy sensor.

Schneider Electric Buildings AB, Mar 2010 13 (74)

04-00068-01-en

Page 14

2 Zone Controller TAC Xenta 104 Zone Controller, TAC Xenta 104-A

Communication

The controller can work either as a stand-alone unit, without being connected to a network during operation, or be a part of a larger system with

several other units such as TAC Xenta 300/400 and other zone controllers in the TAC Xenta family.

TAC Vista is an excellent tool for reading variables as well as a configuration tool for commissioning and/or operation purposes. When TAC

Vista is not part of the system, reading and configuration of variables

can be made from the operating panel TAC Xenta OP, version 3.11 or

later.

The controller is LonMark

®

TP/FT-10 network via a twisted-pair, unpolarized cable. If you

Talk

want to know more about the LonWorks

®

approved and communicates on a Lon-

®

technology visit www.eche-

lon.com or www.lonmark.org.

2.2 Wall Modules

A temperature sensor must be mounted within in the zone to be controlled. In the STR series of wall modules the temperature sensor is

combined with various types of user interface. Several STR models can

be used with the TAC Xenta 104-A; the choice is determined by the

desired functionality and user interface.

2.2.1 STR350/351

• STR350/351. Wall unit with temperature sensor and LCD display.

Extensive functionality for zone control. Communicates with the

controller over LonWorks.

• STR150. Wall unit with temperature sensor and LCD display.

Incorporates the most common functions for zone control. Oneway serial communication with the controller.

• STR100-104. Wall module with temperature sensor and controls

for the most common zone control functions. STR100-104 signals

are hard-wired to TAC Xenta 104-A I/O.

STR350/351 communicates over LonWorks. LonWorks is used for all

data exchanges between the room unit and the controller.

STR350/351 has the following functionality when used with

TAC Xenta 104-A:

• Temperature sensor . Use either the built in thermistor element or

any other temperature sensor available on the LonWorks network

• Actual temperature display. The actual zone temperature ca n be

displayed on the LCD. It can also be hidden if preferred.

• Temperature setpoint display. The temperature setpoint can be

displayed, either as an absolute value or as an offset.

14 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 15

Zone Controller, TAC Xenta 104-A 2 Zone Controller TAC Xenta 104

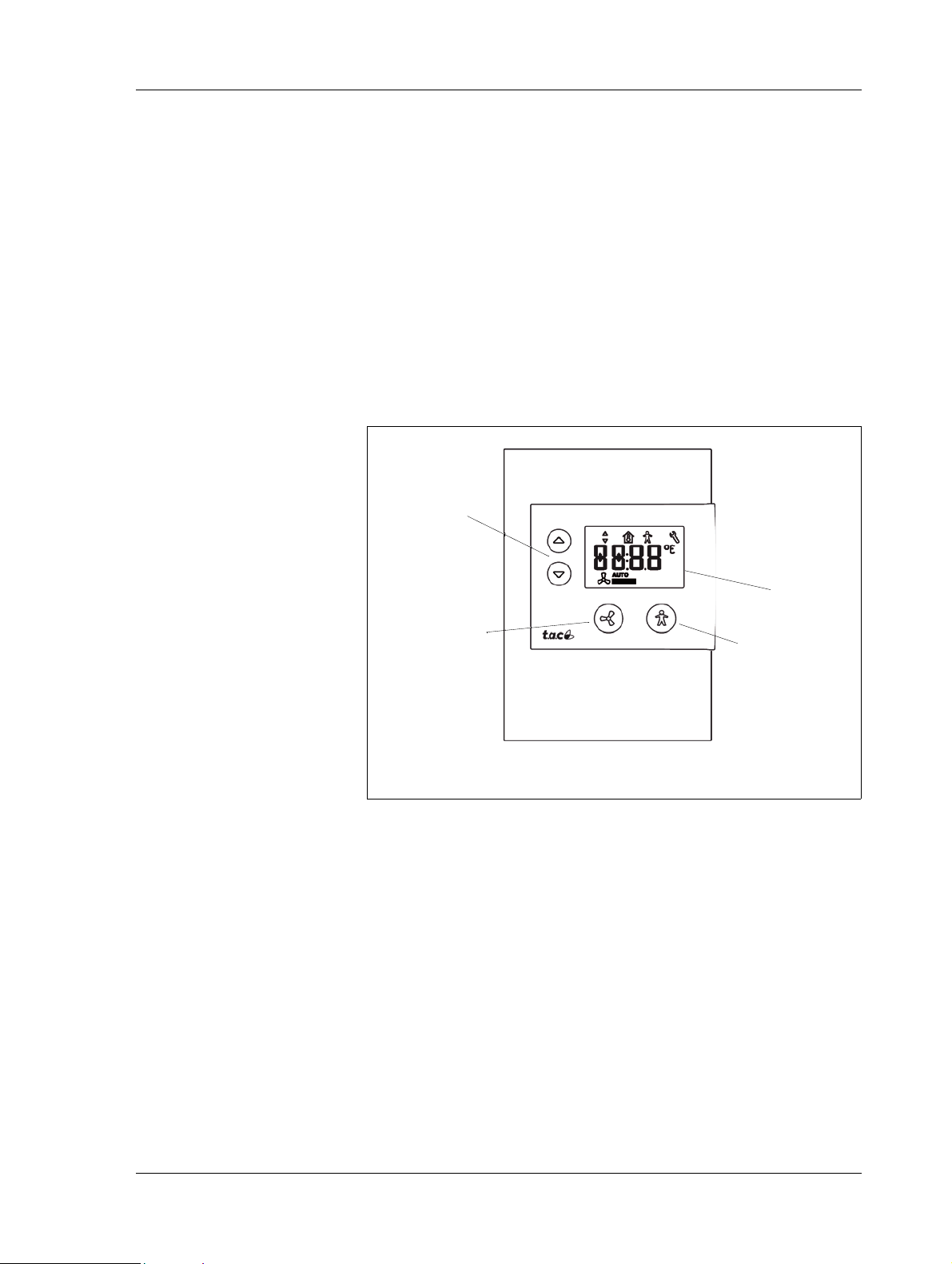

Fig. 2.1: Wall module STR150

Bypass button

Increase/Decrease

buttons

Fan speed control

Display

• Temperature setpoint adjustment. The temperature setpoint can

be adjusted, either as an absolute value or as an offset.

• Bypass or on/off button. The bypass function forces the control-

ler to comfort mode for a configurable period of time. The same

button can also be used as an on/off button.

• Mode Indicator. An On/Off symbol in the LCD indicates the

mode of the control.

See STR350/351 configuration and data sheets for more details about

the technical characteristics listed above, additional functions and configuration details.

Use the LNS plug-in to configure STR350/351.

2.2.2 STR150

STR150 is connected to TAC Xenta 104-A using two or three wires; the

third wire is used if mode indication in the LCD is required. On the other

two wires information is sent from the wall unit to the controller:

• Zone temperature. The temperature sensed by the thermistor ele-

ment.

• Temperature setpoint. The temperature setpoint is displayed as

an absolute temperature, but transmitted as an offset to the configured reference temperature.

• Bypass button. The bypass button forces the controller to comfort

mode for a fixed period of time (2h).

The mode indication signaled on the third wire is connected to the symbol of a man in the LCD:

• Comfort mode (On) is indicated by a steady symbol

Schneider Electric Buildings AB, Mar 2010 15 (74)

04-00068-01-en

Page 16

2 Zone Controller TAC Xenta 104 Zone Controller, TAC Xenta 104-A

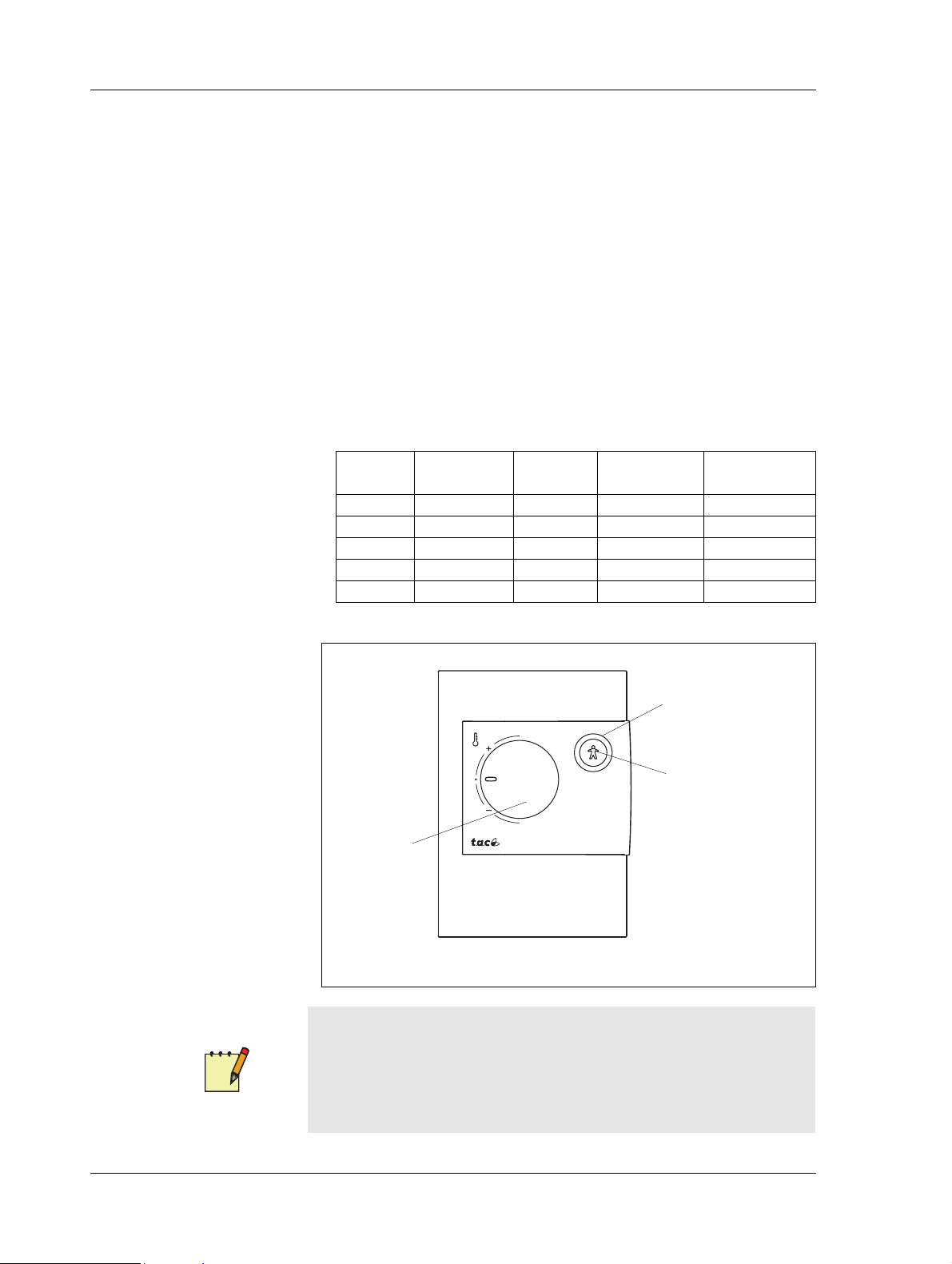

Fig. 2.2: Wall module STR104 as an example

Mode indicator

On/Off

Bypass button

Temperature

setting wheel

• Economy (Standby) mode is indicated by a flashing symbol.

• If the symbol is not shown (off) the zone is unoccupied.

There is no communication from the controller to the unit. This means

that if a setpoint is changed using TAC Vista, the new value cannot be

displayed on STR150.

STR150 is configured using the buttons and display on the unit. See

STR150 configuration and data sheets for details.

2.2.3 STR100-104

STR100-104 is a series of room units that connect to the I/O terminals

of TAC Xenta 104-A. The functionality of the various models are

shown in the Table 2.1, “STR100-104 functionality”.

Table 2.1: STR100-104 functionality

Model Temp Sensor

STR100 X

STR101 X X

STR102 X X X

STR103 X X X

STR104 X X X X

Mode

Indicator

Setpoint

Adjustment

Bypass Button

Note

• The TAC Xenta OP is normally connected directly to the controller, not the wall module. The TAC Xenta 101-VF has a TAC

Xenta OP access connecter (type RJ-10) on the controller instead

of dedicated terminals for the wall module.

16 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 17

Zone Controller, TAC Xenta 104-A 2 Zone Controller TAC Xenta 104

Depending on model the following functionality may also be present:

• Temperature Sensor. All models have a 1.8Kohms@25°C ther-

mistor element.

• Temperature Adjustment. The temperature setpoint can be

adjusted. Using the plastic keys on the rear of the core panel the

adjustment range can be set.

• Mode Indicator. The green LED indicates the control mode:

• Comfort mode (On) is indicated by a steady green light

• If the LED is off the zone is unoccupied.

• Bypass button. The bypass button forces the controller to comfort

mode for fixed period of time (2h).

Refer to STR100-107 data sheet and installation sheet for details.

2.2.4 Wall Module Configuration

Wall Module Choice

STR150 is enabled by nciAppOptions bit 14:

• 0 = ZS, STR100-104 or STR350/351 (default)

•1 = STR150

This can be set using the LonMaker Xenta100 plug-ins in Toolpack ver-

sion 2.01 or higher, or by means of TAC Xenta OP.

Initial Start Up Status

• SpaceTemp in the application is set to +20.00 Celsius (This can

not be read in the nviSpaceTemp, however it can be read in

nvoSpaceTemp)

• Fan is set to Fan Auto

TAC Xenta can now accept for data from the STR module.

If no room temperature readings are received within 10 minutes, the

SpaceTemp in the application is set to “invalid”. This is shown as

“invalid” in nvoSpaceTemp.

When the first update is received then the 10-minute limit is changed to

5 minutes.

Unless there is a restart, the Offset + Fan values are not cleared and the

last value is valid.

Note

• Fore more information on how to configure and engineer the

STR series of wall modules see respective product documents.

Schneider Electric Buildings AB, Mar 2010 17 (74)

04-00068-01-en

Page 18

2 Zone Controller TAC Xenta 104 Zone Controller, TAC Xenta 104-A

2.2.5 General

The controller is suitable for a variety of applications such as RTU

(Roof Top Units), small Unit Ventilators and small AHU (Air Handling

Units).

Cooling control is achieved by one or two cooling stages in sequence

based on zone temperature from the wall module.

Heating control is achieved by one or two heating stages based on zone

temperature or as an alternative tri-state valve control based on discharge air temperature.

For economizer control a sensor is connected in the mixed- or discharge

air stream depending of application.

A fan is controlled according to configuration settings.

Different configuration options can be chosen to fit both networked and

stand-alone applications.

The TAC Xenta 104 controller incorporates several features:

• a fan status switch to stop the heating and cooling functions, c an

be connected.

• an auxiliary alarm sensor can be connected.

• the fan can be configured to run continous or cycle on a call for

heating or cooling.

• A discharge air temperature sensor can be connected for controlling the discharge air temperature and the zone temperature in

cascade.

2.2.6 HVAC Controller, Network Installation

In networked applications a SNVT supplies the out-door air temperature for economizer and compressor lockout functions.

For economizer control a sensor is connected in the mixed air stream in

both two stage and tri-state modes.

For detailed description about networked applications, please see

Chapter 5.3.5, “Networked Applications”, on page 48.

In stand-alone applications the outdoor air temperature for economizer

and compressor lockout functions is supplied by a physical input.

For economizer control a sensor is connected in the discharge air stream

in both two stage and tri-state modes.

18 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 19

Zone Controller, TAC Xenta 104-A 2 Zone Controller TAC Xenta 104

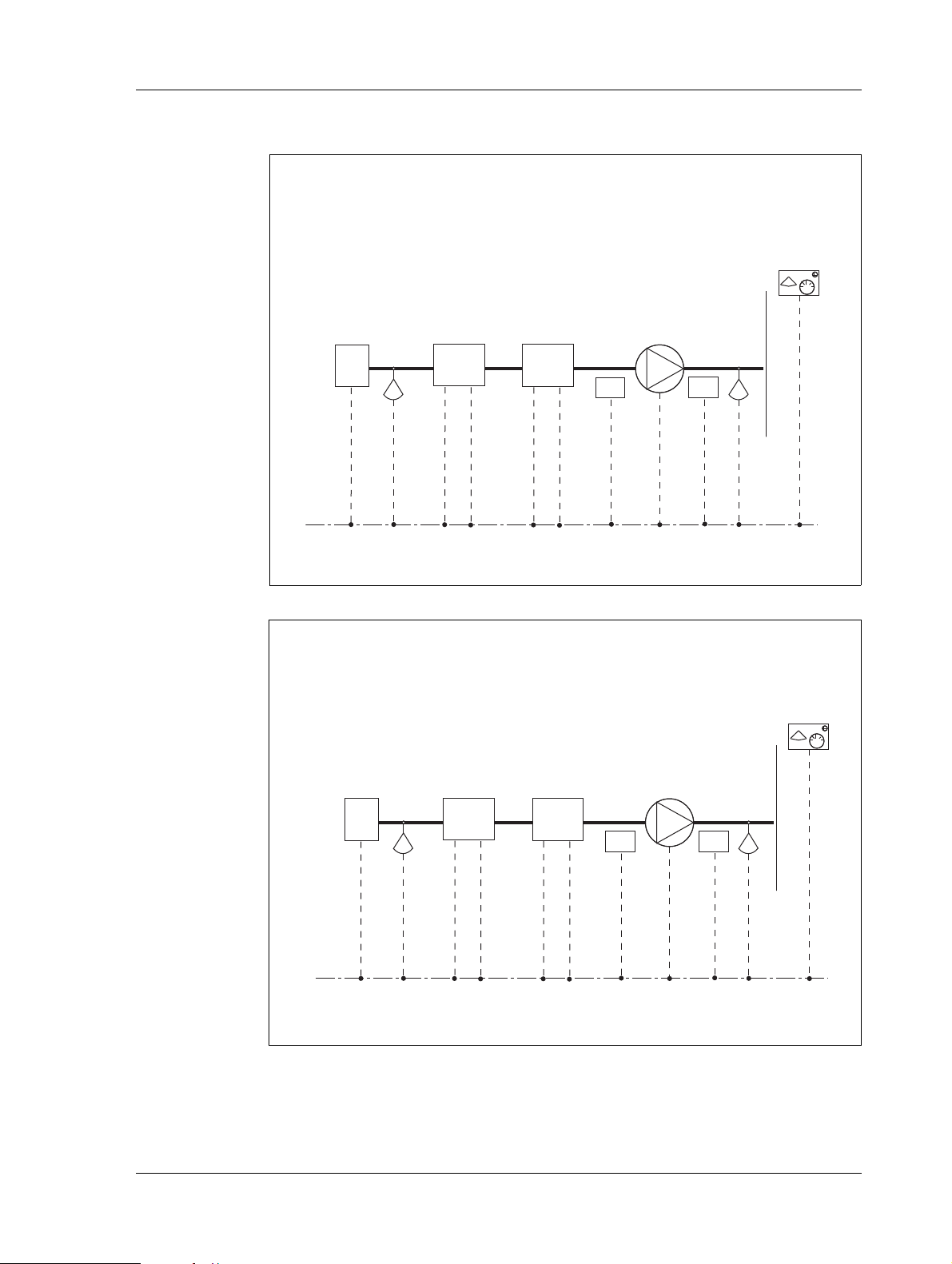

H1 H2 C1 C2

Fig. 2.3: RTU application for HVAC controller network installation

Economizer

Mixed air temperature sensor

(input B2)

Heating

stage

Cooling

stage

Alarm

Fan

Fan

Status

Discharge air temperature sensor

(optional at input U1)

Wall

module

Fig. 2.4: AHU or Unit Ventilator applications for HVAC controller

network installation

Economizer

Mixed air temperature sensor

(input B2)

Heating

stage

Cooling

stage

Alarm

Fan

Fan

Status

Discharge air temperature sensor

(input U1)

Wall

module

For detailed description about stand-alone applications, please see

Chapter 5.3.6, “Stand-alone Applications”, on page 49.

Inc. Dec. C1 C2

2.2.7 HVAC Controller, Stand-alone Installation

In stand-alone applications the outdoor air temperature for economizer

and compressor lockout functions is supplied by a physical input.

Schneider Electric Buildings AB, Mar 2010 19 (74)

04-00068-01-en

Page 20

2 Zone Controller TAC Xenta 104 Zone Controller, TAC Xenta 104-A

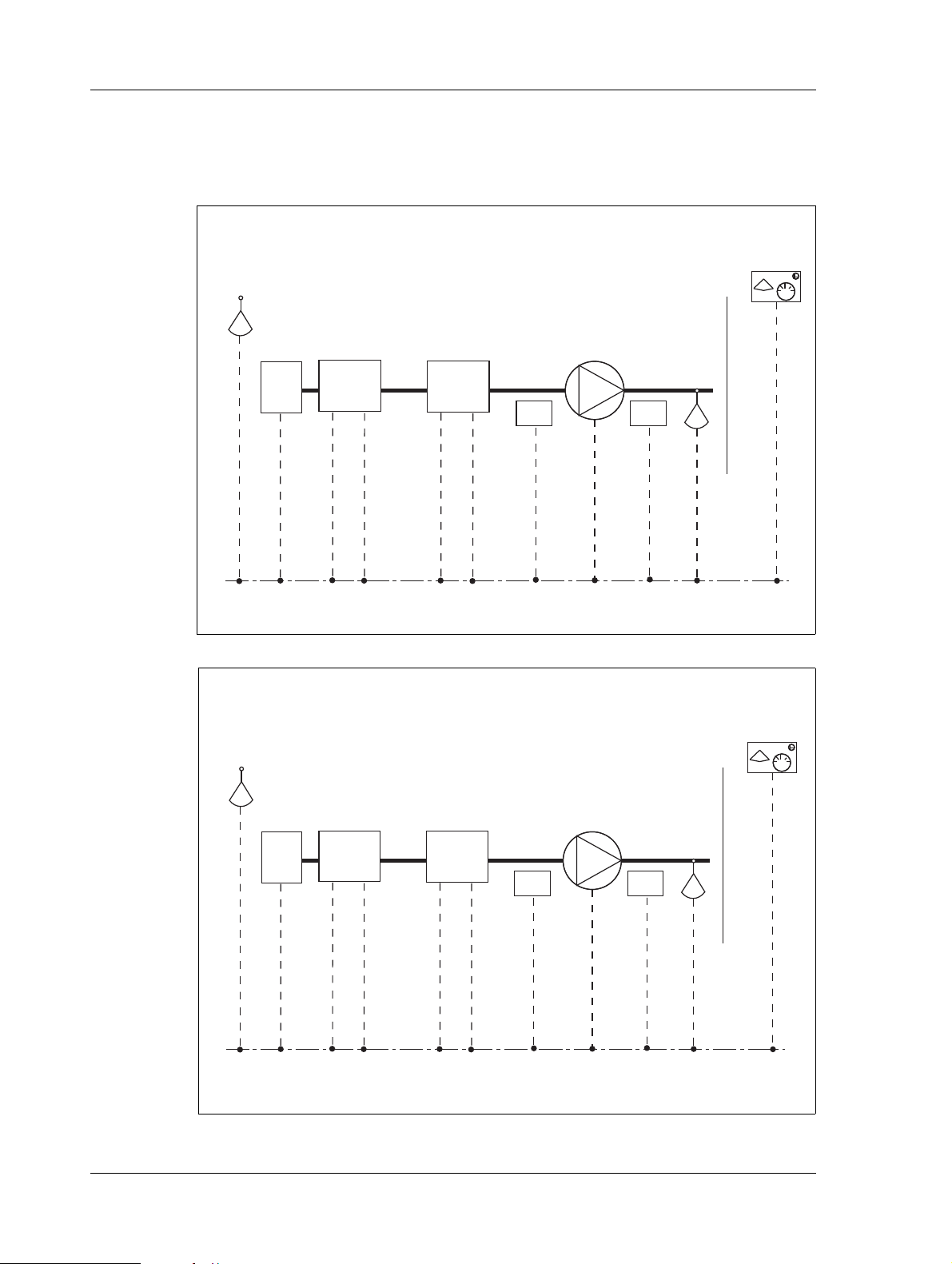

H1 H2 C1 C2

Economizer

Outdoor air

sensor

(input U1)

Heating

stage

Cooling

stage

Alarm

Fan

Fan

Status

Discharge air temperature

sensor (input B2)

Wall

module

Fig. 2.5: RTU application for HVAC controller, stand-alone

Economizer

Outdoor air

sensor

(input U1)

Heating

stage

Cooling

stage

Alarm

Fan

Fan

Status

Discharge air temperature

sensor (input B2)

Wall

module

Fig. 2.6: AHU or Unit Ventilator application for HVAC controller, stand-alone

For economizer control a sensor is connected in the discharge air stream

in both two stage and tri-state modes.

For detailed description about stand-alone applications, please see

Chapter 5.3.6, “Stand-alone Applications”, on page 49.

Inc. Dec. C1 C2

20 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 21

Zone Controller, TAC Xenta 104-A 3 Installation

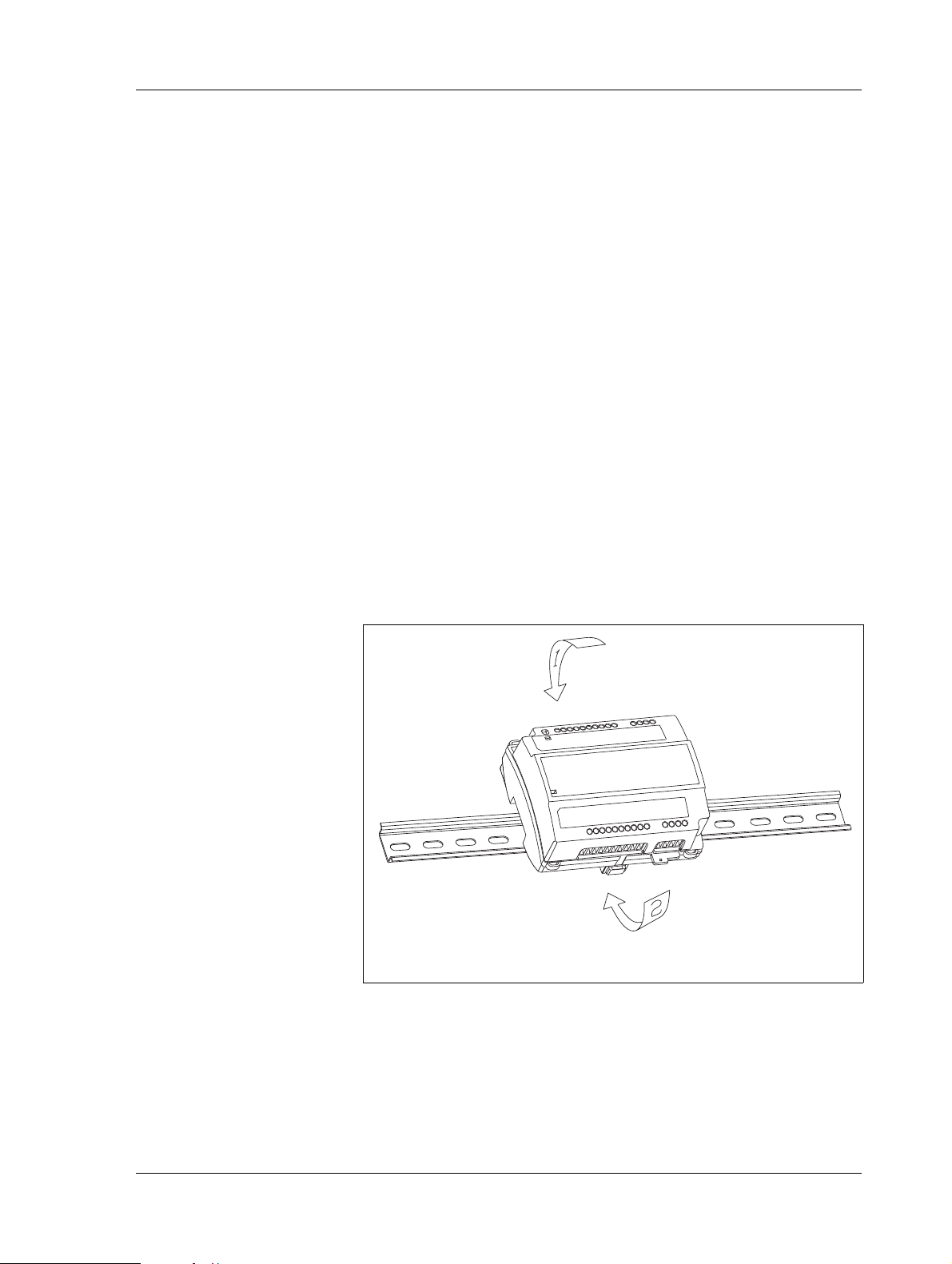

Fig. 3.1: TAC Xenta 104-A fixed on a DIN rail

3 Installation

3.1 Mechanical Installation

3.1.1 Fitting

The TAC Xenta 104-A can either be snapped onto a DIN rail (Fig. 3.1)

or fixed to a level surface with two screws. (Fig. 3.2).

Fastening the controller onto a DIN rail:

1 Place the controller on the top of the rail as shown by arrow 1.

2 Twist the controller downwards until it snaps onto the rail as

shown by arrow 2.

3 T o remove use place a screwdriver to locate the lock on the bottom

of the controller and pull down. Lift the controller diagonally

upwards and off the rail.

Schneider Electric Buildings AB, Mar 2010 21 (74)

04-00068-01-en

Page 22

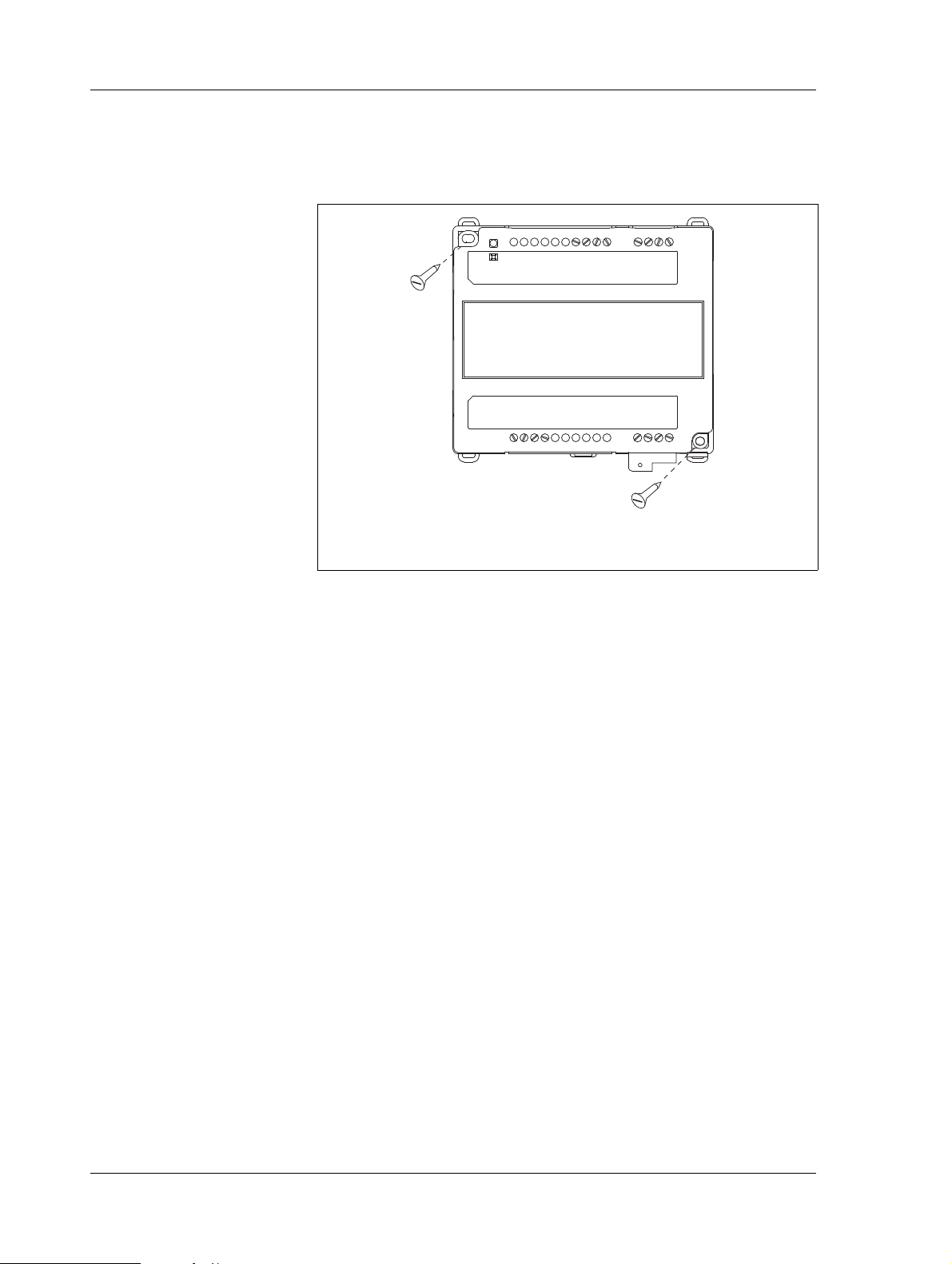

3 Installation Zone Controller, TAC Xenta 104-A

Fig. 3.2: TAC Xenta 104-A fixed to a level surface

Fixing the controller to a level surface:

Use the two sockets provided for fixing the controller; the maximum

screw size is M4 or ST 3,5 (Ø 0.15"). The head of the screw should not

exceed 7,5 mm (0.3") in diameter.

3.2 Electrical Installation

3.2.1 General

1 Each controller or group of controllers must use max. 6 A fuses.

2 Avoid hanging or loose cables by using clamps to secure them to

the controller.

3 A switch to cut off the power supply to the controller or compete

unit must be easily accessible.

4 Connect U1 and M with a jumper when not used.

5 When several Xenta controllers receive power from a common

transformer, it is important that all Gs are connected to each other

and that all G0s are connected to each other. They must not be

interchanged. An important exception: G0 on the wall module

should not be connected with the other G0’s. Instead it should be

connected to the terminal OP on the controller. At the transformer,

G0 should be connected to protective earth. This is to get an

grounding point for interference diversion.

6 To ensure that the specified measuring accuracy is achieved, the

two M terminals must be connected to the wall module.

NOTE: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

22 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 23

Zone Controller, TAC Xenta 104-A 3 Installation

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Safety Standard

Transformers supplying the controller must comply to the safety standard EN 60 742 or any other relevant safety standard for ELV, 24 V AC.

ETL listing: UL 3111-1, first edition and CAN/CSA C22.2 No. 1010.1-

92. When connecting equipment that has an independent power supply,

the power supply must also comply with this norm.

Cable Lengths

For information on communication cable lengths, see TAC Xenta Network Guide, part number 0-004-7460. For all other cables, maximum

length is 30 m (100 feet) and min. area is 0,7 mm

2

(AWG-19).

The Wall Modules

The STR100-104 is primarily intended for use with the Xenta 104-A.

For more information about how to connect and configure wall modules, please refer to the documentation for each respective product.

Schneider Electric Buildings AB, Mar 2010 23 (74)

04-00068-01-en

Page 24

3 Installation Zone Controller, TAC Xenta 104-A

Connection Terminals

The designation of the connection terminals can be seen in two places

on the controller: on the edge of the printed circuit board, and on the

label on the front of the controller.

Table 3.1: Connection Terminals

Termin. Design. Function Type

1 C1 TP/FT-10 communication channel -

2 C2 TP/FT-10 communication channel -

3 X3 Alarm (option) Digital input

4 M Measurement neutral -

5 X2 Fan status Digital input

6 B2 Discharge/mixed air temperature sensor Thermistor input

7 M Measurement neutral -

8 U1 OA/discharge air temperature

9 D1 LED on wall module Digital output

10 M Measurement neutral -

11 X1 Bypass button on wall module Digital input

12 R1 Setpoint offset dial on wall module 10 k

sensor Thermistor input

Ω linear potentiometer

13 M Measurement neutral -

14 B1 Room temperature sensor Thermistor input

15 G 24 V AC (G) Input

16 G0 24 V AC (G0) Input

a

17

18 G 24 V AC supply for TAC Xenta OP -

19 V1 Heating actuator: increase Triac output

20 VC1 24 V AC (G) supply for V1, V2 -

21 V2 Heating actuator: decrease Triac output

22 V3 Cooling stage 1 1st stage output

23 VC2 24 V AC (G) supply for V3, V4 -

24 V4 Cooling stage 2 2nd stage output

25 M Measurement neutral -

26 Yl Economizer actuator Analog output

27 K1 Fan relay Relay output

28 KC1 Fan relay Relay output

OP 24 V AC supply for TAC Xenta OP -

a. Connected to G0 on the wall module. Do not connect to G0 on the controller.

24 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 25

Zone Controller, TAC Xenta 104-A 3 Installation

20

VC1

Junction Box

3

2

1

24 VAC

G0

C

Ty pical RTU

Te r minal Str

ip

R

G

15

16

Heat

Stage 1

W1

G

OP

17

18

19

V1

C2

TAC Xenta

104-A

C1

1

2

X3

3

4

X2

5

6

Lon Talk

TP/FT-10

FAN

24

Stage 1

Heat

Stage 2

W2

Cool

Y1

22

21

V2

23

V3

VC2

Efma24

actuator

Cool

Stage 2

Y2

econ

G

V4

25

Y1

26

27

K1

KC1

28

10

8

7

B2

9

U1

D1

X1

11

R1

12

13

B1

14

Alarm

Fan

Status

Mixed air*/Discharge air**

Fan

Relay

Typical RTU

or HVAC Unit Connections

* When networked

** When stand-alone

Discharge air*/Outdoor air**

M

M

M

M

M

STR101-1

04

G

OP

C1

C2

Wall Module

12

11

13

14

15

16

M

LED

Pot/Pot+R

Mx

Switch

Therm

23

24

21

22

Fig. 3.3: Wiring of TAC Xenta 104: typical RTU or HVAC unit

3.2.2 Wiring of TAC Xenta 104 as Typical RTU or HVAC Unit

Read Chapter 3.2.1, “General”, on page 22 before you connect the

cables as shown in the wiring diagram in Fig. 3.3.

Schneider Electric Buildings AB, Mar 2010 25 (74)

04-00068-01-en

Page 26

3 Installation Zone Controller, TAC Xenta 104-A

15

G

16

G0

17

OP

18

G

19

V1

20

VC1

21

V2

22

V3

23

VC2

24

V4

25

26

Y1

27

K1

28

KC1

1

2

3

4

5

6

7

8

9

10

12

13

14

C1

C2

X3

X2

B2

U1

D1

X1

R1

B1

G

R

C

Y1

Y2

Cool

Stage 2

Cool

Stage 1

Efma24

actuator

econ

FAN

Junction Box

COM

TAC Xenta

104-A

3

2

1

INC.

Actuator,

heating valve

DEC.

Alarm

Fan Status

Fan

Typical RTU

Terminal

Lon Talk

TP/FT-10

Typical Packaged RTU

Cooling only with reheat valve

24 VAC

* When networked

** When stand-alone

Discharge air*/Outdoor air**

Mixed air*/Discharge air**

M

M

M

M

M

11

STR101-104

G

OP

C1

C2

Wall Module

12

11

13

14

15

16

M

LED

Pot/Pot+R

Mx

Switch

Therm

23

24

21

22

Fig. 3.4: Wiring of TAC Xenta 104: typical packaged RTU

3.2.3 Wiring of TAC Xenta 104 as Typical Packaged RTU

Read section Chapter 3.2.1, “General”, on page 22 before you connect

the cablesas shown in the wiring diagram in Fig. 3.4.

26 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 27

Zone Controller, TAC Xenta 104-A 3 Installation

20

VC1

Junction Box

Actuator,

Heating v

alve

24 VAC

Size Transformer

For Total Load

G0

G

15

16

G

OP

17

18

19

V1

C2

C1

1

2

X3

3

4

X2

5

6

Lon Talk

TP/FT-10

FAN

24

Cond. Unit

COM

Y1

R

22

21

V2

23

V3

VC2

Efma24

actuator

Y2

econ

V4

25

Y1

26

27

K1

KC1

28

Controller Applied to Small AHU

or Unit Ventilator

10

8

7

B2

U1

D1

9

X1

1

1

R1

12

13

B1

14

3

2

1

DEC.

INC.

Alar

Fan

Status

Fan Relay

TAC Xenta

104-A

* When networked

** When stand-alone

Discharge air*/Outdoor air**

Mixed air*/Dischargeair**

STR101-104

G

OP

C1

C2

Wall Module

12

11

13

14

15

16

M

LED

Pot/Pot+R

Mx

Switch

Therm

23

24

21

22

Fig. 3.5: Wiring of TAC Xenta 104:

controller applied to small AHU

3.2.4 Wiring of TAC Xenta 104 as Controller Applied to Small AHU

Read section 3.2.1 “General” before you connect the cables as shown in

the wiring diagram in Fig. 3.5.

Schneider Electric Buildings AB, Mar 2010 27 (74)

04-00068-01-en

Page 28

3 Installation Zone Controller, TAC Xenta 104-A

Fig. 3.6: Connecting to STR150

3.2.5 Connecting to STR150

Wall Module

STR150

1

C1

TAC Xenta

104-A

G

15

3.3 Commissioning

3.3.1 General

Once the mechanical and electrical installations have been completed

the controller can be commissioned. This means:

• Installing the controller on the network, setting the node status and

giving it an address.

Mode

11 1213

4

3

2

C2

X3

OP

G0

17

16

5

X2

M

G

V1

19

18

7

6

M

B2

VC1

V2

20

21

9

8

D1

U1

VC2

V3

23

22

Data

M

12

11

10

M

V4

24

R1

X1

Y1

M

26

25

14

13

M

B1

KC1

K1

28

27

28 (74) Schneider Electric Buildings AB, Mar 2010

• Setting the controller's configuration parameters.

• Bind network variables.

• Test the functions.

Before commissioning a complete zone system, read the “TAC Xenta Zone Systems Guideline”.

The TAC Xenta OP can be used to set the basic parameters. Use a network management tool or TAC Vista for commissioning the controller

on the network.

How to use the TAC Xenta 100 as a stand-alone unit:

1 Use TAC Xenta OP to set the node status to "Configured".

2 Use TAC Xenta OP to set the basic parameters.

3 Use TAC Xenta OP to set all other parame ters and variables.

Commissioning can also be achieved using a network management tool.

04-00068-01-en

Page 29

Zone Controller, TAC Xenta 104-A 3 Installation

3.3.2 Node Status

The node status indicates which network configuration or program

mode the controller is in. The node status can be changed using

TAC Vista (version 3.1 or later) and the network management tool.

TAC Xenta OP can also be used on some occasions. The controller can

be in these states:

Unconfigured

The controller is not configured when it leaves the factory. Neither the

program nor the network communication are running. The service light

emitting diode is flashing.

The controller must be configured before it can operate in a network (on

line) see below.

You cannot set configuration parameters or network variables in this

state.

Configured, Online

Use the TAC Xenta OP, TAC Vista or a network management tool to

change the status to configured. When this has been done, the program

and the network communication will be fully operational. The service

LED is off. This is the normal state for a controller when it is operating.

The controller will use the address given by the tool during configuration. As TAC Xenta OP cannot be used to set an address, all controllers

are given a default address. Therefore all controllers get default

addresses. This means that TAC Xenta 100 can only be used as a standalone controller and cannot be used in a network.

The parameters and variables can now be set.

Configured, Soft Online

A network management tool is needed for this operation. The controller

is programed and configured for a network, but the program and communications are idle. The light emitting diode is off. If the controller is

reset, it will go into configured, online.

Configured, Hard Online

A network management tool is needed for this operation. The controller

is programed and configured for a network, but the program and communications are idle. The light emitting diode is off. If the controller is

reset, it will remain in this state.

Without a Program and Not Configured

This states indicates that there is something wrong with the controller.

No program can be detected. The light emitting diode is lit.

Schneider Electric Buildings AB, Mar 2010 29 (74)

04-00068-01-en

Page 30

3 Installation Zone Controller, TAC Xenta 104-A

3.3.3 Configuration Parameters (nci’s)

TAC Xenta 100 has a number of configuration parameters that can be

used to set the parameters of the controller. See Chapter 4, “Configuration Parameters”, on page 33. There are also network variables to control the controller during when it is operating.

Use the commissioning protocol in Appendix B to write down your settings when commissioning. Chapter 8, “Communication”, on page 59

contains information about all parameters and variables, such as their

index, accepted values, normal values. Detailed descriptions of the

parameters and variables can be found in Chapter 4, “Configuration

Parameters”, on page 33, in Chapter 5, “Functional Description”, on

page 39 and in Chapter 6, “Troubleshooting”, on page 53.

3.3.4 Network Installation

For network installation, you need either a network management tool

(LNS based or not) or TAC Vista. Examples of network management

tools are MetraVision and ICELAN-G. Here you find brief information

on how this is made.

The installation has two steps:

1 Feed information about the controllers’ unique neuron-ID into the

network management tool’s data base.

2 Allow the network management tool to install the controller on the

network. The controller will automatically be given an addre ss.

There are two ways to feed the neuron-ID into the data base:

1 Manually feed the neuron-ID into the network management tool.

To make this easier you can use a bar code reader to read the

detachable ID-neuron label that is attached to every controller. It

can be a good idea to collect these labels when you make the basic

configuration, and stick them to a form, drawing or similar. There

is a form for this purpose in the manual “TAC Xenta, Guidelines

for zone applications” .

2 Use the service pin function. You can only do this when the con-

troller is connected to the network. There is a service pin key in a

hole in the upper left hand corner of the controller by terminal C1.

Push the key to instruct the controller to send out its neuron-ID.

The network management tool can then read the neuron-ID from

the network and save it in its data base.

Fore more information see “TAC Xenta, Guidelines for zone applications”.

3.3.5 Network Variable Binding

The binding method is determined by the type of network management

tool to be used. Detailed information can be found in the tool’s docu-

30 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 31

Zone Controller, TAC Xenta 104-A 3 Installation

mentation. A description of how network variables are bound with

Metra Vision can be found in the "TAC Xenta Network manual".

Binding network variables is not an issue when the controller is used in

a stand-alone operation.

3.3.6 Function Test

Check that the controller works as intended.

All the controller’s functions are described in Chapter 5, “Functional

Description”, on page 39.

Trouble-shooting is described in Chapter 6, “Troubleshooting”, on

page 53.

Schneider Electric Buildings AB, Mar 2010 31 (74)

04-00068-01-en

Page 32

3 Installation Zone Controller, TAC Xenta 104-A

32 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 33

Zone Controller, TAC Xenta 104-A 4 Configuration Parameters

4 Configuration Parameters

All communication with the controller is made using network variables.

• nci’s are used to configure the controller. nci’s are normally set

during commissioning, and are not altered during normal operation (the parameters are stored in a special memory, and can be

changed a maximum of 10 000 times).

• nvi’s control the controller during operation,

• nvo’s are output variables, which the controller sends out on the

network.

Chapter 8, “Communication”, on page 59 contains detailed information

about accepted values and normal values for all parameters. All configuration parameters have default values on delivery.

Schneider Electric Buildings AB, Mar 2010 33 (74)

04-00068-01-en

Page 34

4 Configuration Parameters Zone Controller, TAC Xenta 104-A

4.1 Basic Parameters

nciAppOptions

These parameters are used to set selectable functions in the controller.

The parameter consists of 16 bits, where each bit represents one function choice. The bits 10 through 13 are not used. When you look at

nciAppOptions with TAC Xenta OP, bit 0 is shown to the left.

Table 4.1: The function of different bits in nciAppOptions.

Bit no. Function

Bit 0 Not used

Bit 1 Not used

Bit 2 0 2-stage heating

1 Tri-state heating

Bit 3 0 Fan cycling on room temperature

1 Continuous fan

Bit 4 0 Read outdoor temperature (U1)

1 Read SNVT nviOutsideTemp

Bit 5 0 Read outdoor or discharge temperature. Econo Lockout using nviOutsideTemp (Deg).

1 Read enthalpy value. Econo Lockout using nviOutsideTemp (Ent).

Bit 6 - 13 Not used

Bit 14 0 ZS, STR101-104 or STR350/351wall modules

1 STR150 wall module with display

Bit 15 Reserved for production test. Should not be altered!

Bit 6 through bit 13 are not used.

34 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 35

Zone Controller, TAC Xenta 104-A 4 Configuration Parameters

4.2 Other Configuration Parameters

The controller’s other configuration parameters are listed below

together with a short description. See also Chapter 8, “Communication”, on page 59.

Index Name Description

0 nciLocation Location label

18 nciSetpoints Occupancy temperature setpoints

19 nciSpaceTempLow Low limit of zone temperature

20 nciSpaceTempHigh High limit of zone temperature

21 nciSpaceTempOfst Offset of zone temperature

22 nciGainEcon Gain for economizer controller

23 nciItimeEcon Integral time economizer controller

24 nciGainHeat Gain for heating controller

25 nciItimeHeat Integral time heating controller

26 nciGainCool Gain for cooling controller

27 nciItimeCool Integral time cooling controller

28 nciClgLocStpt Cooling lock-out setpoint

29 nciEcoLocStptDeg Economizer lock-out setpoint degrees

30 nciEcoLocStptEnt Economizer lock-out setpoint enthalpy

31 nciEconoMin Minimum position economizer

32 nciHeatActStTime Stroke time for heating actuator

33 nciShrtCycleTime Minimum compressor intervals

34 nciMixAirTempLow Low limit of temperature for mixed air

35 nciDischAirMin Min. limit discharge air

36 nciDischAirMax Max. limit discharge air

37 nciInstallType Source for network configuration

38 nciSndHrtBt Send heartbeat

39 nciRcvHrtBt Receive heartbeat

nciLocation

nciLocation is used to make a label for the actual place where the controller is installed. In the operating panel, this parameter is shown as the

first variable.

nciSetpoints

nciSetpoints is used to set the setpoint temperatures for heating and

cooling in the different operation modes: occupied and off mode (see

section Section 5.2.1, “Operation Modes”, on page 40 and

Section 5.2.4, “Setpoint Calculation”, on page 43).

Schneider Electric Buildings AB, Mar 2010 35 (74)

04-00068-01-en

Page 36

4 Configuration Parameters Zone Controller, TAC Xenta 104-A

nciSpaceTempLow, nciSpaceTempHigh

nciSpaceTempLow and nciSpaceTempHigh are used to set an alarm setpoint, lowest and highest zone temperatures. Default value 50/86 °F

(10/30 °C).

nciSpaceTempOfst

nciSpaceTempOfst is used to adjust the reading from the temperature

sensor or nviSpaceTemp. Default value 0.

nciGainEcon, nciGainHeat, nciGainCool

nciGainEcon, nciGainHeat and nciGainCool are used for setting the

gain for the economizer and heating/cooling controllers. Default value

25.

nciItimeEcon, nciItimeHeat, nciItimeCool

nciItimeEcon, nciItimeHeat and nciItimeCool are used to sett the I-time

for the economizer and heating/cooling controllers. Default value 900 s

(15 min).

nciClgLocStpt

nciClgLocStpt is used to set the cooling lock-out setpoint.

nciEcoLocStptDeg, nciEcoLocStptEnt

nciEcoLocStptDeg and nciEcoLocStptEnt contains the lock-out setpoints for the economizer, in degrees and enthalpy. Default values 64 °F

/ 0 (18 °C / 0).

nciEconoMin

nciEconoMin contains the minimum position for the economizer

damper. Default value 0%.

nciHeatActStTime

nciHeatActStTime is set according to the stroke time of the actuator.

nciShrtCycleTime

nciShrtCycleTime is used to set a minimum allowed time between compressor run sessions.

nciMixAirTempLow

Alarm setpoint for low mixed air temp. Default value 46 °F (8 °C).

nciDischAirMin, nciDischAirMax

nciDischAirMin and nciDischAirMax are used to set the allowed maximum/minimum temperatures. Effective in cascade tri-state control as

well as two stage (see Section 5.3.2, “Cooling”, on page 46). Default

values 50/95 °F (10/35 °C).

36 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 37

Zone Controller, TAC Xenta 104-A 4 Configuration Parameters

nciInstallType

nciInstallType is only used during free-standing operation and is set to

show that the node itself should define its address (see Section 8.5.3,

“The Node Object’s Configuration Parameters (nci)”, on page 62).

nciSndHrtBt

nciSndHrtBt is used to decide how often the nvo’s, which are sent out

on the network regularly, should be sent (see Section 8.3, “Monitoring

Network Variables, Heartbeat”, on page 60).

nciRcvHrtBt

nciRcvHrtBt is used to decide the maximum time there can be between

updating the nvi’s, for which the controller expects continuous updating

(see Section 8.3, “Monitoring Network Variables, Heartbeat”, on

page 60).

Schneider Electric Buildings AB, Mar 2010 37 (74)

04-00068-01-en

Page 38

4 Configuration Parameters Zone Controller, TAC Xenta 104-A

38 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 39

Zone Controller, TAC Xenta 104-A 5 Functional Description

5 Functional Description

5.1 General

The controller’s function is determined by its node status (Section 3.3.2,

“Node Status”, on page 29), operations (Section 5.2.1, “Operation

Modes”, on page 40) and the methods used to force the controller

(Section 5.2.2, “Application and Emergency Modes”, on page 41) for

well-adapted zone temperature control.

The controller measures the zone temperature, the outside or mixed air

temperature and uses various methods to calculate setpoints. Apart from

the basic functions the controller can also use a variety of methods to

control the climate in the zone. These are described in Section 5.3,

“More About Functions”, on page 45.

Each section in this chapter ends with information about how network

variables are used in the current control situation. If you need details

about the network variables’ characteristics, such as default values and

accepted values see Chapter 8, “Communication”, on page 59.

Schneider Electric Buildings AB, Mar 2010 39 (74)

04-00068-01-en

Page 40

5 Functional Description Zone Controller, TAC Xenta 104-A

5.2 The Controller’s Basic Functions

5.2.1 Operation Modes

The controller has three operation modes:

•Occupied

• Bypass

• Unoccupied

The operation mode is controlled by nviManOccCmd, but is also influ-

enced by the bypass button on the wall module. The relationship

between operation modes is shown in Table 5.1, “The relationship

between desired operation, bypass timer and current operation mode.”

The controller’s values during stand-alone operation are also shown.

Table 5.1: The relationship between desired operation, bypass timer and current operation mode.

Desired operation

nviManOccCmd

Occupied OC_OCCUPIED

OC_OCCUPIED

Unoccupied Enabled OC_BYPASS

OC_UNOCCUPIED At a stand-still OC_UNOCCUPIED

Stand-alone OC_OCCUPIED

OC_NUL

a. Activated by the bypass button on the wall module

Bypass timer

a

nvoEffectOccup

Occupied Mode

Occupied Mode is default mode that is to say when someone is in the

zone the controller should ensure that the climate in the room is comfortable. The controller is in this mode when nviManOccCmd =

OC_OCCUPIED (or OC_NUL after a power down).

The LED on the wall module is lit with a steady red light and the setpoint knob on the wall module can be used to make manual settings. The

setpoints used are found in nciSetpoints (can be modified).

The fan is on continously or during heating/cooling.

Bypass Mode

Change temporarily from unoccupied to occupied mode using the

bypass button on the wall module.

The nviOccManCmd variable is used to bypass an old value, which is

stored, and start a timer, which will run according to nciBypassTime.

When nciBypassTime has elapsed, nviOccManCmd resumes it’s previous state.

40 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 41

Zone Controller, TAC Xenta 104-A 5 Functional Description

Heating

Case

Cooling

Case

Heating

Setpoint

Cooling

Setpoint

Cooling

Demand

Fig. 5.1: Changeover between heating and cooling cases

If the nviOccManCmd SNVT is updated thi s will have a higher priority,

and the Bypass mode is left.

To avoid this, the nvo bound to the nviOccManCmd should not propagate on periond (set to 0). Only on Delta.

Unoccupied Mode

When the zone is not used for a longer period of time, the controller can

be set in unoccupied mode. The controller is in this mode when nvi-

ManOccCmd = OC_UNOCCUPIED.

The light emitting diode on the wall module is out, and the fan is off, if

there is no demand for heating or cooling. In such cases, the fan is running. The setpoint knob is blocked, but the bypass button is not. The setpoints used are found in nciSetpoints, unoccupied mode.

Index Variable name Description

1 nvoEffectOccup Actual occupancy output

14 nviManOccCmd Occupancy scheduler input

18 nciSetpoints Occupancy temperature setpoints

5.2.2 Application and Emergency Modes

TAC Xenta 104-A is designed to control both heating, cooling, economizing, and to automatically change from heating to cooling as necessary..

You can force the controller to heat only or cool only, just as you can

force it to neither heat nor cool, and to run the fan only. This is achieved

using nviApplicMode, see Table 5.2, “The relation between nviApplicMode and forcing.”.

Table 5.2: The relation between nviApplicMode and forcing.

nviApplicMode Mode Description

HVAC_AUTO Automatic (no forcing) The controller automatically change s over b etween heating and cooling

HVAC_HEAT Heating only The controller can only heat. The cooling setpoint is neglected.

HVAC_COOL Cooling only The controller can only cool. The heating setpoint is neglected.

Schneider Electric Buildings AB, Mar 2010 41 (74)

04-00068-01-en

Page 42

5 Functional Description Zone Controller, TAC Xenta 104-A

Table 5.2: The relation between nviApplicMode and forcing.

nviApplicMode Mode Description

HVAC_FAN_ONLY Fan only The controller neither cools nor heats. The fan is running constantly.

HVAC_OFF Off The controller neither cools nor heats. The fan is at a stand-still.

Emergency Mode

In some situations, the damper has to be forced fully opened or closed.

This is done with nviEmergCmd. The heating and fan control are disabled in emergency mode. The emergency mode has higher priority

than all the other modes.

Table 5.3: The relation between nviEmergCmd and forcing.

nviEmergCmd Description

EMERG_NORMAL Normal control

EMERG_SMOKE_PURGE Fully open damper (100%)

EMERG_SHUTDOWN Fully closed damper (0%)

Index Variable name Description

10 nviApplicMode Application mode input

11 nviEmergCmd Emergency command input

5.2.3 Measuring Zone Temperature

You can measure the zone temperature either with a permanent thermistor sensor (usually the wall module) or with a LonTalk temperature

sensor node connected to nviSpaceTemp. If nviSpaceTemp has a valid

value the controller will use it, if it doesn't the thermistor value will be

used. The thermistor value (or a value from the network) can be

adjusted by nciSpaceTempOfst having received a value; the value is

added to the thermistor value. The value the controller uses is also put

out on nvoSpaceTemp. If neither value is valid, nvoSpaceTemp will

receive the off value.

nvoSpaceTemp is sent when it has changed by at least 0.1°C.

Table 5.4: Measuring Zone Temperature

Index Variable name Description

6 nvoSpaceTemp Zone temperature output

12 nviSpaceTemp Zone temperature input

21 nciSpaceTempOfst Zone temperature sensor adjustment

42 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 43

Zone Controller, TAC Xenta 104-A 5 Functional Description

5.2.4 Setpoint Calculation

Zone Temperature Setpoints

nciSetpoints define four temperature setpoints; heating setpoint occupied mode, cooling setpoint occupied mode, heating setpoint unoccupied mode and cooling setpoint unoccupied mode.

The smallest accepted deviation between the heating and cooling setpoints is 0.5 °C, and the heating setpoints must be lower than the cooling setpoints. If the heating setpoints are higher or equal to the cooling

setpoints, the controller resets the heating setpoint to 0,5 °C lower than

the cooling setpoint. Table 5.5, “The setpoints in nciSet points” shows

accepted values and default values for the four temperature setpoints in

nciSetpoints.

The setpoints for occupied mode are basic setpoints, which can be

changed with nviSetpoint, nviSetPntOffset and the setpoint knob. The

unoccupied mode setpoints are always valid.

Table 5.5: The setpoints in nciSetpoints

Setpoint Min. Max. Normal

Cooling setpoint occupied 10 °C 35 °C 24 °C

Heating setpoint occupied 10 °C

Cooling setpoint unoccupied 10 °C 35 °C 28 °C

Heating setpoint unoccupied 10 °C

a. If the cooling setpoint is 10 °C, the heating setpoint is set to 9,5 °C.

a

a

35 °C 22 °C

35 °C 16 °C

Calculation

The current setpoint, nvoEffectSetpt, depends on the current operation

mode, nvoUnitStatus, the desired operation mode, nviApplicMode, and

nviSetpoint, nviSetpntOffset, nciSetpoints and a possible local setpoint

adjustment via the wall module.

nviSetpoint is used to allow the temperature setpoints in occupied mode

to be changed via the network. If there is a valid value on nviSetpoint,

the controller uses this value as a new basic setpoint when calculating

effective setpoints. Heating and cooling setpoints will thus be half of the

deadband ((Occupied Heat – Occupied Cool)/2) apart from nviSetpoint.

nviSetPntOffset can be seen as a setpoint adjustment from a wall module

connected to the network. Its value is added to setpoints for occupied

mode.

Index Variable name Description

2 nvoUnitStatus Unit status output

5 nvoEffectSetpt Actual setpoint output

10 nviApplicMode Application mode input

13 nviSetPoint Temperature setpoint input

14 nviSetPntOffset Setpoint offset input

Schneider Electric Buildings AB, Mar 2010 43 (74)

04-00068-01-en

Page 44

5 Functional Description Zone Controller, TAC Xenta 104-A

Heating

Cooling

Cooling demand

100%

0%

Fig. 5.2: Control sequence for TAC Xenta 104-A without economizer

Neutral

zone

Heating

Cooling

Cooling demand

100%

0%

Economizer lockout

Economizer

Output

Fig. 5.3: Control sequence for TAC Xenta 104-A with economizer

Index Variable name Description

18 nciSetpoints Occupancy temperature setpoints

5.2.5 Control Sequence with TAC Xenta 104-A

Without Economizer

The zone temperature is controlled by one or two stages, which either

heats or cools. The fan is normally only on during heating or cooling,

but can also be configured to run continously. Figure 5.2 shows the control sequence:

5.2.6 Fan Control

With Economizer

The zone temperature is controlled by a combination of one or two

stages of heating and cooling aided by an economizer.

The fan can be in two different modes, chosen in bit 3 of

nciAppOptions:

Continuous Operation

The fan is on continuously during occupied and by pass modes.

44 (74) Schneider Electric Buildings AB, Mar 2010

Cycling with Heating/Cooling

When fan configuration is set for cycling, the fan will be off until the

zone temperature controller calls for heating or cooling and the zone

04-00068-01-en

Page 45

Zone Controller, TAC Xenta 104-A 5 Functional Description

Heating

Cooling

Cooling demand

100%

0%

Economizer lockout

Economizer

Output

Neutral zone

Fig. 5.4: Control sequence for TAC Xenta 104-A with economizer

temperature and effective setpoint deviates more than 0.5 °C. The fan

will be turned off when the deviation is less than 0.2 °C.

Index Variable name Description

17 nciAppOptions Application options

5.3 More About Functions

5.3.1 Heating

General

When the zone temperature falls below the present heating setpoint,

heating outputs will be staged On in sequence. If tri-state heating is

selected, the increase output will begin to pulse On to open the tri-state

heating valve. When the heating setpoint is satisfied, the two stage heating outputs will sequence off. If tri-state heating is selected, the

decrease output will begin to pulse On to close the tri-state heating

valve. When the zone temperature rises above the present cooling setpoint, cascade mixed air temperature control will modulate the economizer damper if the economizer is enabled via the floating lockout

setpoint. When the economizer reaches 100%, or if the economizer is

locked out, the two cooling outputs will be staged On in sequence. This

cooling sequence is reversed as the room temperature falls below the

cooling setpoint.

Staged Heating Control

The heating outputs are controlled by a PI regulator that looks at room

temperature as its input. If heating is allowed it will sequence on the two

outputs. The heating outputs do not have a fixed delay set point. The

timing and delay function is a result of the PI regulator.

Tri-state Heating Control

Schneider Electric Buildings AB, Mar 2010 45 (74)

04-00068-01-en

The heating outputs can be configured as tri-state control for controlling

a heating valve in Unit Ventilator or small AHU applications. When tristate is selected and the outdoor temp. is supplied as an NV (in a net-

Page 46

5 Functional Description Zone Controller, TAC Xenta 104-A

worked system), the heating controller looks at the sensor connected to

terminal U1.

When used as a stand alone controller (U1 used for outdoor air), the

heating controller instead looks at the sensor connected to terminal B2

and uses this value for heating as well as economizer control.

If a thermal actuator is used for heating and some modulation is desired

then it must be connected to the increase output. Also the P and I band

must be set very low to cause the output to be operating as soon as a

need for heat exists. When heating demand is 100% the output will be

on continually.

Lockout

The heating control is locked out on a loss of fan p roof. If tri-state heating control is selected, tri-state valve control remains enabled for heating coil protection.

Heating controller

Type: PI

Gain: 0-32,75; normal value: 25

I-time: 0-60 minutes; normal 15 minutes

Dead band: 0,2 °C

Run time: 5-600 s; normal 165 s

Control interval: 15 s

5.3.2 Cooling

Control

The cooling outputs are controlled by a PI regulator that uses room temperature as its input. If cooling is allowed and outdoor temperature is

above cooling lockout setpoint it will sequence on the two outputs. The

outputs have an adjustable anti-cycle timer for short cycle protection.

An NV is available to read on the network to indicate the percent of

cooling called for by the cooling regulator. The PI regulator tuning

parameters can be adjusted via the TAC Xenta OP or an NV.

Night Free Cooling Mode

This can be accomplished by sending the opertaing mode “cooling

only”, then sending an NV for reduced room temperature set-points, and

sending an NV for cooling lockout.

46 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 47

Zone Controller, TAC Xenta 104-A 5 Functional Description

Lockout

If the outdoor temperature sensor is connected and configured it will be

used to determine cooling lockout. Cooling is locked out on a loss of fan

proof.

Cooling controller

Type: PI

Gain: 0-32.75; normal value: 25

I-time: 0-60 minutes; normal 15 minutes

Dead band: 0.2 °C

Run time: 5-600 s; normal 165 s

Control interval: 15 s

5.3.3 Economizer

Control

The economizer will only function in the cooling or Auto changeover

modes. The economizer will stay at the minimum position setpoint

while heating in occupied or bypass mode. In unoccupied mode, the

damer is closed. The economizer output is controlled via a PI regulator

that normally uses the sensor connected to B2 as its input.

The economizer is active during cooling. There is a built in software

lock to hold the economizer at 100% outdoor air position if the outdoor

air is useful for cooling when any stage of mechanical cooling is on.

This will provide maximum energy savings and prevent economizer

damper hunting when the mechanical cooling is cycling on and off.

Lockout

There are three economizer lockout options. First, if the outdoor temperature sensor is connected and configured it will be used to determine

economizer lockout. Second, if the outdoor sensor is not connected, an

NV must be sent to give the controller the outdoor air temperature.

Third, an enthalpy NV may be sent to the controller and an enthalpy

lockout setpoint used to determine economizer operation. The economizer is also locked out on a loss of fan proof.

When the economizer reaches 100%, or if the economizer is locked out,

the two cooling outputs will be staged On in sequence. This cooling

sequence is reversed as the room temperature falls below the cooling

setpoint.

A minimum economizer damper position is set to maintain minimum

ventilation requirements.

Schneider Electric Buildings AB, Mar 2010 47 (74)

04-00068-01-en

Page 48

5 Functional Description Zone Controller, TAC Xenta 104-A

Controller zone

temperature

Controller

heat./econ.

Setpoint

Room temp.

Discharge air temp

Setpoint discharge

air temperature

Valve/

economizer

Fig. 5.5: Principal diagram cascade control

5.3.4 Cascade Control

Cascade temperature control allows the zone temperature setpoint deviation to establish an inversely reset discharge and/or mixed air temperature setpoint decrease and vice versa. The minimum and maximum

discharge and/or mixed air temperature setpoints can be adjusted using

configuration parameters. Economizer and tri-state heating control are

always based on cascade control.

Zone temperature controller

Type: PI

Gain: 0-32,75; normal value: 25

I-time: 0-60 minutes; normal 15 minutes

Dead band: 0,2 °C

Control interval: 15 s

5.3.5 Networked Applications

48 (74) Schneider Electric Buildings AB, Mar 2010

Index Variable name Description

7 nvoDischAirTemp Discharge air temperature output

24 nciAppOptions Application options

29 nciDischAirMax Max. limit discharge air

30 nciDischAirMin Min. limit discharge air

In networked applications the outdoor air temperature is fed to the controller by nviOutsideTemp. Configuration variable nciAppOptions bit 4

set to 1. The outdoor temperature controls the economizer and compressor lockout functions.

The input B2 is connected to a sensor in the mixed air stream for economizer control. The temperature value is presented in

nvoDischMixTemp.

Cooling control by stage 1 and stage 2 in sequence always use roomtemperature (input B1) as real value and controls against nvoEffectSetpt.

Two Stage-application (RTU)

Economizer control uses mixed air temperature (input B2) as real value

and controls against setpoint from the cascade controller (set-value discharge air).

04-00068-01-en

Page 49

Zone Controller, TAC Xenta 104-A 5 Functional Description

Heating control uses roomtemperature (input B1) as real value and controls against nvoEffectSetpt.

The input U1 can, if desired, be used for monitoring discharge air temperature in nvoDischAirTemp but no controlling functions will depend

on this input.

Tri-State-application (Small Unit Ventilator- or Small AHU)

Economizer control uses mixed air temperature (input B2) as real value.

Controls against setpoint from the cascade controller.

The input U1 should in this case be connected to a discharge air sensor.

The value will be presented in nvoDischAirTemp. Heating control uses

discharge air temperature as real value and controls against setpoint

from the cascade controller.

5.3.6 Stand-alone Applications

In stand-alone applications the input U1 is used for measuring outdoor

air temperature. This is selected by nciAppOptions bit 4 set to 0. The

purpose is to control the economizer and compressor lockout functions.

The outdoor temperature can be monitored (from software version 1.01

onwards) in nvoDischAirTemp.

Cooling control by stage 1 and stage 2 in sequence is always using

roomtemperature (input B1) as real value and controls against

nvoEffectSetpt.

Two Stage- application (RTU)

The input B2 is used for a discharge air sensor and can be monitored in

nvoDischMixTemp. It supplies real value for the economizer loop and

controls against setpoint from the cascade controller (set-value discharge air).Heating control uses roomtemperature (input B1) as real

value and controls against nvoEffectSetpt.

Tri-State- application (Small Unit Ventilator- or Small AHU)

The input B2 is used for a discharge air sensor and will be used as real

value for economizer control against setpoint from the cascade controller. The temperature value can be monitored in nvoDischMixTemp.

Heating control also uses discharge air temperature (input B2) as real

value and controls against setpoint from the cascade controller.

5.3.7 Sensor Options

If the controller is networked, the sensor connected to terminal B2

should be used as a mixed air sensor for economizer control and a sensor

connected to U1 should be used as a di scharge air sensor if set up for tristate heating control. Then an NV for outdoor air temperature has to be

used.

Schneider Electric Buildings AB, Mar 2010 49 (74)

04-00068-01-en

Page 50

5 Functional Description Zone Controller, TAC Xenta 104-A

If a controller is set up as a stand-alone RTU control, then the sensor

connected to terminal U1 must be outdoor air temperature. This is used

for economizer and compressor lockout. The sensor connected to terminal B2 is used for discharge air temperature.

If set up as a stand-alone small Unit Ventilator controller (tri-state), the

sensor connected to terminal B2 must be installed in the discharge air

stream since it will in this case be used as real value for both heating and

economizer control.

If the controller is set-up using an NV for outdoor air temperature, the

discharge air temperature can be monitored and displayed at the TAC

Xenta OP (nvoDischAirTemp), TAC Vista

®

or bound to a NV in a TAC

Xenta 300 or TAC Xenta 400.

This will allow you to provide a fully functional RTU control system

either stand-alone or networked. In a network system you can display

both the mixed and discharge air temperature for monitoring and diagnostics.

Index Variable name Description

7 nvoDischAirTemp Discharge air temperature

24 nciAppOptions Application options

5.3.8 Auxiliary Alarm Contact

TAC Xenta 104-A has an option for connecting an auxiliary alarm contact to input X3. An alarm is activated when the contact has been active

for more than 3 minutes. See nvoAlarmStatus, bit 3 (Table 5.6,

“nvoAlarmStatus”).

5.3.9 Fan Status Contact

To insure the function of the fan while heating and cooling, a fan status

contact can be connected to input X2. An alarm is activated when there

is no fan proof for more than 5 minutes while the fan is running. See

nvoAlarmStatus, bit 0 (Table 5.6, “nvoAlarmStatus”). The alarm is activated also if the the fan proof signal is present for more than 5 minutes

when the fan is supposed not to be running.

50 (74) Schneider Electric Buildings AB, Mar 2010

04-00068-01-en

Page 51

Zone Controller, TAC Xenta 104-A 5 Functional Description

5.3.10 Alarm

When TAC Xenta 104-A reports alarms to a monitoring systemit it is

achieved using the network variable nvoAlarmStatus. The variable has

16 bits, which corresponds to different alarm situations.

Table 5.6: nvoAlarmStatus

Bit no Alarm Cuts out when... Is reset when...

0 Fan failure No fan proof for more than 5 min.

while running (all modes).

1 High zone temperature The zone temp. is higher than the

value in nciSpaceTempHigh for more

than 60 min (all modes).

2 Low zone temperature The zone temp. is lower than the

value in nciSpaceTempLow for more

than 60 min (all modes).

3 Auxiliary alarm Alarm contact (X3) is active for more

than 3 min.

4 Low discharge air tem-

perature

10 Start not bound nvi:s Power on. When the first not bound network vari-

11 Adaptation of thermistor Internal writing error in the controller

12 Bound network variables

not received

13 Not valid value on input An input network variable gets out-