Page 1

Zone controller

TA C Xenta 102

Handbook

TAC impr oves indoor c limate

and reduces operating costs.

0-004-7516-1 (GB), 1999-08-18

Air flow

Heating

Changeover via

network variable

Cooling

Cooling

demand

Page 2

Page 3

TAC Xenta 102 Handbook Foreword

Foreword

This is the technical handbook for the TAC Xenta 102 controller, a

zone controller for VAV applications in offices and other larger

buildings.

In this second edition of the handbook, sections that were earlier

complicated to the user, have been made clearer, and most of the

content has been reorganized. The trouble-shooting section has been

made into its own chapter, and there are now appendices in the end of

the handbook; one containing setpoint calculating examples, and one

containing a commissioning protocol which can be used together with

chapter 3 when commissioning.

The programs in TAC Xenta 102 now have new versions. For both the

system program and the application program in the controller, the

versions are 1.10. If there is a service replacement in the system, all

variable bindings—if the controller is run on a network—must be

remade when an older or newer version of the controller is fitted. Th is

is because the controller has got a new “Standard Program ID”. There

are also three new network variables.

TAC AB, 1999-08-18

0-004-7516-1 (GB), i (ii)

Page 4

TAC Xenta 102 Handbook Foreword

Copyright © 1999 TAC AB

This document contains information which is the property of TAC and is therefore only available for those using and maintaining TAC’s equipment. Disclosure,

reproduction or use of either the document or the information within for any other purpose are strictly prohibited.

TAC reservs the right to make necessary changes of and additions to the material.

Echelon, Lon, LonWorks, LonTalk, Neuron, 3150, LonMark and the LonMark logo are registered trademarks for Echelon Corporation, USA. TAC Xenta® is a

registered trademark for TAC AB in Sweden and other countries. All other trademarks are the property of their respective owners.

Revisions list

Part number Comment Editor Date

0-004-7516-0 First edition. KRRO 1997-09-11

0-004-7516-1 Second edition. System and application program in a new SUWA 1999-08-18

version 1.10.

ii (ii), 0-004-7516-1 (GB)

TAC AB, 1999-08-18

Page 5

TAC Xenta 102 Handbook Contents

Zone controller TAC Xenta 102

Handbook

Reservations for changes.

Contents

1 Introduction .................................................................................................................. 1:1

1.1 The content of the handbook ............................................................................................................... 1:1

1.2 Documentation .................................................................................................................................... 1:2

1.3 Terminology ........................................................................................................................................ 1:3

2 The zone controller T A C Xenta 102 ............................................................................ 2:1

2.1 General ................................................................................................................................................ 2:1

2.2 Wall modules ....................................................................................................................................... 2:3

2.3 Applications ......................................................................................................................................... 2:4

2.3.1 General ............................................................................................................................................... 2:4

2.3.2 Air flow control only (TAC Xenta 102-B) ................................................................................... ..... 2 : 4

2.3.3 Air flow control with modulating valve reheat (TAC Xenta 102-VF) ................................................ 2:5

2.3.4 Air flow control with modulating valve water reheat and fan (TAC Xenta 102-VF) .................... 2: 5

2.3.5 Air flow control with one stage electric reheat (TAC Xenta 102-EF) ............................................. 2: 6

2.3.6 Air flow control with one stage electric reheat and fan (TAC Xenta 102-EF) ............................... 2: 6

2.3.7 Air flow control with thermo-actuator for radiators (TAC Xenta 102-EF) ................................... 2:7

3 Installation .................................................................................................................... 3:1

3.1 Mechanical installation ....................................................................................................................... 3:1

3.1.1 Fitting.................................................................................................................................................. 3:1

3.2 Electrical installation.......................................................................................................................... 3:3

3.2.1 General ............................................................................................................................................... 3:3

3.2.2 Wiring of TAC Xenta 102-B............................................................................................................. 3 :5

3.2.3 Wiring of TAC Xenta 102-EF ............................................................................................... ........... 3 :6

3.2.4 Wiring of TAC Xenta 102-VF ............................................................................................... ........... 3 : 7

3.3 Commissioning ................................................................................................................................... 3:8

3.3.1 General ............................................................................................................................................... 3 :8

3.3.2 Node status.......................................................................................................................................... 3:8

3.3.3 Configuration parameters (nci’s)...................................................................................................... 3: 9

3.3.4 Network installation ......................................................................................................................... 3:10

3.3.5 Network variable binding ................................................................................................................ 3:10

3.3.6 Function test ..................................................................................................................................... 3:10

4 Configuration parameters ............................................................................................ 4:1

4.1 Basic parameters ................................................................................................................................ 4:2

4.2 Other configuration parameters ......................................................................................................... 4:3

TAC AB, 1999-08-18

0-004-7516-1 (GB), 1 (2)

Page 6

TAC Xenta 102 Handbook Contents

5 Functional description................................................................................................. 5:1

5.1 General ................................................................................................................................................ 5:1

5.2 The controller’s basic functions ......................................................................................................... 5:2

5.2.1 Operation modes ................................................................................................................................ 5:2

5.2.2 Operation mode, manual mode and emergency mode .................................................................... 5:4

5.2.3 Measuring zone temperature ............................................................................................................ 5: 5

5.2.4 Setpoint calculation ........................................................................................................................... 5:6

5.2.6 Control sequence with TAC Xenta 102-B ......................................................................................... 5:8

5.2.5 Control sequence with TAC Xenta 102-EF and 102-VF .................................................................. 5: 8

5.3 More about functions......................................................................................................................... 5:10

5.3.1 Air flow control ................................................................................................................................ 5:10

5.3.2 Heating and fan control ................................................................................................................... 5:11

5.3.3 Air quality control ........................................................................................................................... 5:12

5.3.4 Window contact ................................................................................................................................ 5:13

5.3.5 Occupancy sensor ............................................................................................................................ 5 :13

5.3.6 Minimum value for heating valve (TAC Xenta 102-VF only) ...................................................... 5:14

5.3.7 Alarm ................................................................................................................................................ 5:15

5.3.8 Master/slave operation .................................................................................................................... 5:16

6 Trouble-shooting ........................................................................................................... 6:1

6. 1 General ................................................................................................................................................ 6:1

6.2 Inputs and outputs (nvi/nvo’s).............................................................................................................. 6:2

6.3 Problems and solutions ....................................................................................................................... 6:3

7 T echnical data............................................................................................................... 7:1

7.1 T echnical data...................................................................................................................................... 7:1

7.2 Dimensions.......................................................................................................................................... 7:3

7.2.1 With semi-protection ......................................................................................................................... 7 :3

7.2.2 Without semi-protection .................................................................................................................... 7 :3

8 Communication ............................................................................................................. 8:1

8. 1 General ................................................................................................................................................ 8:1

8.2 Default settings and power on ............................................................................................................. 8:1

8.3 Monitoring network variables, Heartbeat ........................................................................................... 8:2

8.4 Not accepted values.............................................................................................................................. 8:3

8.5 The node object .................................................................................................................................... 8:3

8.5.1 The node object’s inputs (nvi)............................................................................................................ 8 :3

8.5.2 The node object’s outputs (nvo)......................................................................................................... 8 :4

8.5.3 The node object’s configuration parameters (nci) ........................................................................... 8:4

8.6 The controller object ........................................................................................................................... 8:4

8.6.1 The controller object’s inputs (nvi) ...................................................................................... ............. 8 :6

8.6.2 The controller object’s outputs (nvo) ................................................................................................ 8: 7

8.6.3 The controller object’s configuration parameters (nci) .................................................................. 8 :8

Appendix A: Setpoint calculation

Appendix B: Commissioning protocol

Index

Reply form

2 (2), 0-004-7516-1 (GB)

TAC AB, 1999-08-18

Page 7

TAC Xenta 102 Handbook About this handbook

1 Introduction

1.1 The content of the handbook

• Chapter 1 Introduction,

gives an overview over the structure of this handbook,

additional information about the product, and has a short

terminology section.

• Chapter 2 The zone controller TAC Xenta 102,

briefly describes the wall module, the controller’s functions

and control examples of the three different models of TAC

Xenta 102.

• Chapter 3 Installation,

contains instructions on mechanical and electrical

installation of the controller, and instructions on

commissioning and network installation.

• Chapter 4 Configuration parameters,

describes the setting of the zone controller’s configuration

parameters.

• Chapter 5 Functional description,

gives detailed information about the zone controller’s basic

functions, operating modes, and other functions.

• Chapter 6 Trouble-shooting during operation and

commissioning,

contains trouble-shooting measures you can use to find and

remedy possible faults in the system.

• Chapter 7 Technical data,

lists all technical data and dimensions for TAC Xenta 102.

• Chapter 8 Communication,

describes the zone controller’s communication with other

units via the network by means of network variables.

• Appendix A, Setpoint calculation

contains calculating examples for the setpoint calculation in

chapter 5.

• Appendix B

contains a commissioning protocol, which can be used

together with chapter 3 during installation and

commissioning.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 1:1 (4)

Page 8

TAC Xenta 102 Handbook About this handbook

• Index and Reply form,

are in the end of the handbook. Use the index to make your

search for information easier, and the reply form to let us

know whether there is something wrong or unclear in this

handbook.

1.2 Documentation

Enclosed documentation

TAC Xenta 102 is delivered with an installation instruction for

each of the controllers below:

• TAC Xenta 102-B,

Installation instruction, part number 0FL-3857

• TAC Xenta 102-EF,

Installation instruction, part number 0FL-3859

• TAC Xenta 102-VF,

Installation instruction, part number 0FL-3861

Other documentation

There is additional information about TAC Xenta 102 in the

following documents:

• Data sheet for TAC Xenta 102-B,

part number 0-003-1611

• Data sheet f or TAC Xenta 102-EF,

part number 0-003-1617

• Data sheet f or TAC Xenta 102-VF,

part number 0-003-1623

• Data sheet for ZS 101–ZS 105,

part number 0-003-1661. Here the wall modules are described.

• TAC Xenta Network Guide,

part number 0-004-7460. Here you can find additional information on network installation.

• TAC Xenta OP Handbook,

part number 0-004-7506. Here you find information on how to

use TAC Xenta OP together with TAC Xenta 102 and the wall

modules.

• TAC Xenta, Zone System Guidelines

part number 0-004-7637. Here you find information on how a

zone system is built with TAC Xenta components.

• TAC Xenta 102 Handbook,

part number 0-004-7516-0. Here you find information on the

earlier version of the zone controller.

All the above mentioned documents can be found on the internet:

www.tac.se or they can be ordered from the nearest TAC service

point.

1:2 (4), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 9

TAC Xenta 102 Handbook About this handbook

1.3 Terminology

In this handbook there are some abbreviations and terms which

are specific for the zone controller’s applications and network

communication. Therefore, the most common terms have been

gathered, together with a short explanation, in the list below.

neuron .................. communication processor with built-in

protocol

node ..................... communication unit on the network

SNVT ................... Standard Network Variable Type

nvixxx .................. variable which gets its value from another

unit on the network

nvoxxx ................. variable which value is sent out to another

unit on the network

ncixxx .................. configuration parameter; variable which gets

its value from another unit on the network

and which keeps it during a power failure

service pin ........... function which can be used during installation

on the network

wink ..................... confirmation that the connection to a controller

via the network is working (a light emitting

diode is lit for appr. 15 seconds)

LNS ...................... LonWork Network Services. System tool for

installation, configuration and maintenance of

LonWorks network

TAC AB, 1999-08-18 0-004-7516-1 (GB), 1:3 (4)

Page 10

TAC Xenta 102 Handbook About this handbook

This page is intentionally left blank.

1:4 (4), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 11

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

2 The zone controller TAC Xenta 102

2.1 General

The zone controller TAC Xenta 102 is intended for “Variable

Air Volume” (VAV) applications in offices and other large

buildings. A VAV controller usually controls the temperature in

a given zone by controlling the volume sub-tempered air which

is supplied to the zone.

The controller’ s basic functions

All controller models have a number of built-in functions which

handle the normal control situation. There are four operating

modes to choose from (comfort, economy, bypass, and off) and

five modes to force the controller (only heating allowed, only

cooling allowed, night cooling, auto, and off).

Measuring the zone temperature is made by means of a

permanent thermistor sensor or a temperature node connected

to the network, and setpoint calculation is made according to

special methods.

There is a detailed functional description of all the basic

functions in chapter 5.2.

More about functions

Apart from the controller’s basic functions, there are

additional possibilities to control the climate in the zone. In

section 5.3, these are described in detail, and also which

external functions that may be connected, e.g. window contact

sensor and occupancy sensor.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 2:1 (8)

Page 12

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

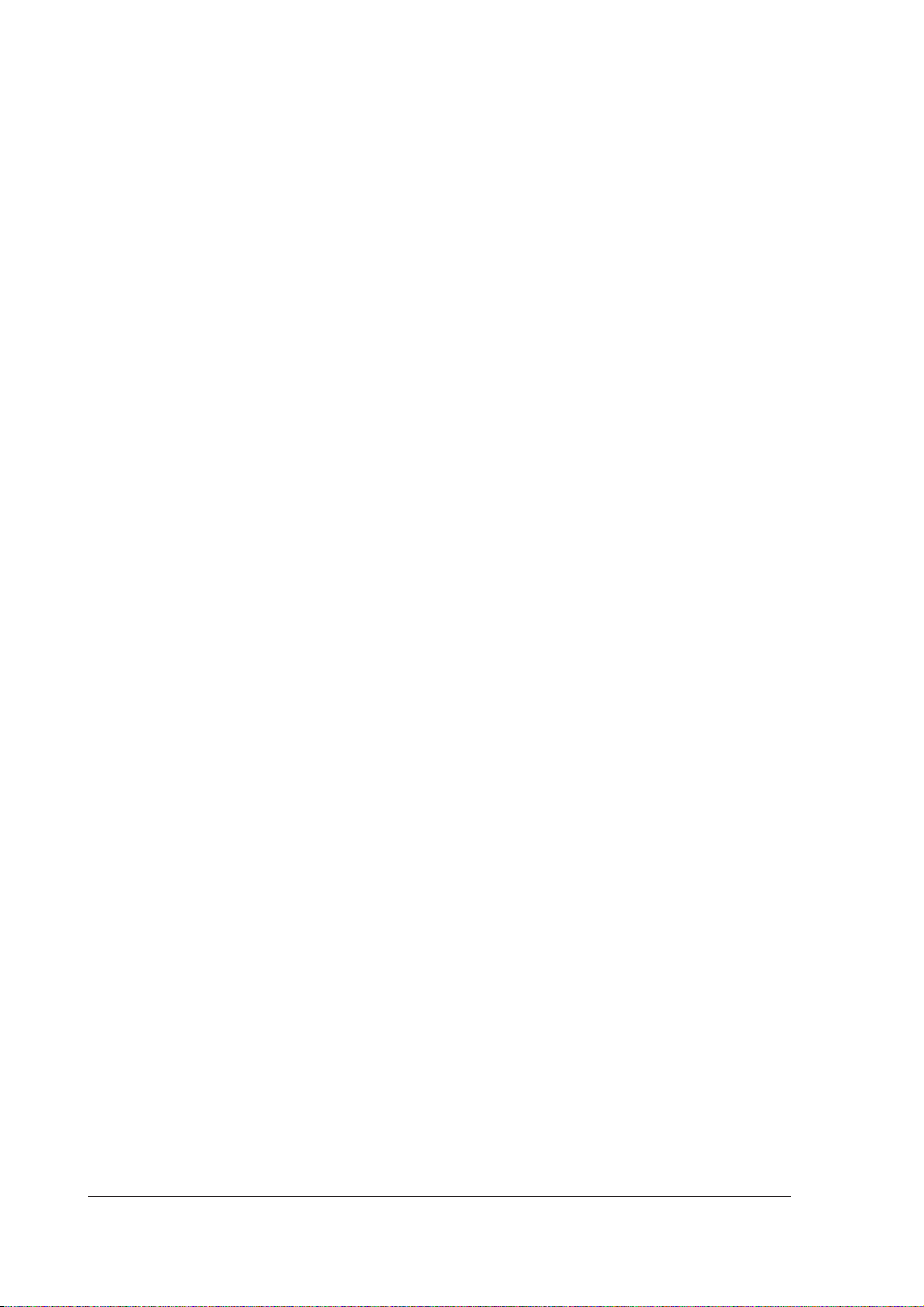

Communication possibilities

The controller can work either as a free-standing unit, without

being connected to a network during operation, or be a part of

a larger system with several other units such as TAC Xenta

300/400 and other zone controllers in the TAC Xenta family

(figure 2.1). A detailed description of how units work together

in a larger zone system, is found in “Guide lines for zone

applications”, part number 0-004-7637.

TAC Vista is an excellent tool for reading variables and as a

configuration tool during commissioning and/or operation.

When TAC Vista is not a part of the system, reading and

configuration of variables can be made from the operating

panel TAC Xenta OP, version 3.11 or later.

4th

floor

3rd

floor

Office 3:1 Office 3:2

Office 3:3 Office 3:4

TAC

Xenta

300

Office 3:5

Analog

Digital

I/O

I/O

Office 3:6 Office 3:7 Office 3:8 Office 3:9

TAC

Xenta

400

2nd

floor

1st

floor

Router

Router

Router

Room

Slave

1:1

101-1VF 101-2VF101-1VF101-1VF101-1VF101-1VF101-1VF101-1VF101-1VF

Master

Room 1:2

Slave

Room 2:2

Slave

102-B 102-B102-B

Room 1:3

Slave

TAC Vista

Room 2:3

Room

1:4

Slave

Slave

Office 2:1

Room 1:5

Master

102-EF102-EF102-EF102-EF102-EF

Office 2:2

Office 1:1

Office 2:3

Office 1:2

Office 2:4 Office 2:5

Office 1:4

Office 1:3

103-A103-A103-A103-A

Office 2:6Room 2:1

101-2VF101-2VF101-2VF101-2VF101-2VF101-2VF

Ground

floor

TAC

Xenta

400

Figure 2.1 Zone controller in a larger system together with TA C Vista

2:2 (8), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 13

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

The controller is LONMARK® approved and communicates on a

LONTALK® TP/FT-10 network via a twisted-pair, unpolarized cable.

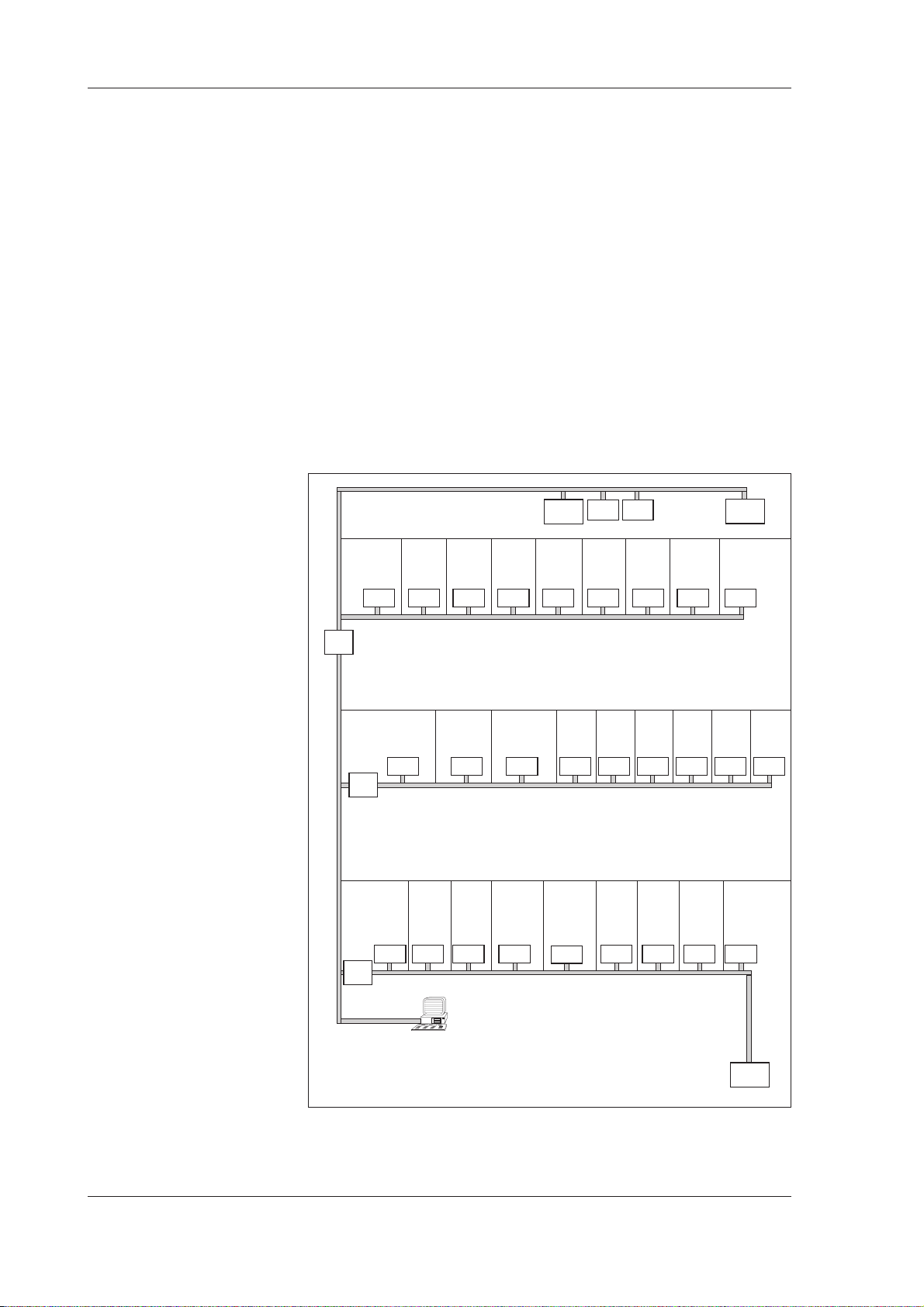

2.2 Wall modules

Locking screw

COMFORT

Bypass key

ECONOMY

OFF

OP connection

Figure 2.2 Wall module in the ZS100 series

Position

indicator

Setpoint knob

In the controlled zone, there is usually a wall module from the

ZS 100 series, which measures the temperature. The wall

modules ZS 101–ZS 105 may very well be used together with

all controller models. On the wall module (figure 2.2) there are

among other things a setpoint knob and a bypass key with

setting possibilities.

The setpoint knob is used to adjust the zone temperature

setpoint with a maximum of ± 5 °C.

The bypass key is used to change the operating mode, and by

pressing the key, an internal timer in the controller, which runs

for two hours, is started. Read more about different operating

modes and ways to force the controller in sections 5.2.1–5.2.2.

On all ZS 100 wall modules, the current operating mode is

indicated by the position indicator (red light emitting diode) as

follows:

· Steady light: Comfort or bypass mode

· Slow flashing: Economy mode

· Fast flashing for appr. 15 s: Answer to “wink” command.

Confirmation that the OP is

connected to the correct

controller

· Off: Other operating modes

There is additional information on the wall modules and how the

temperatures can be adjusted locally in the zone by means of the

keys in “Data sheet for ZS 101–ZS 105”, part number 0-003-

1661.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 2:3 (8)

Page 14

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

2.3 Applications

2.3.1 General

All models have this in common:

• they are intended for use together with a Belimo® VAV-Compact

air flow controller. TAC Xenta 102 sends air flow setpoints to the

VAV-Compact, and reads measured air flow from the air flow controller.

• they have air quality control as an option, which means that the

controller can control the air flow to keep down the carbon dioxide concentration in the zone. However, the function needs a carbon dioxide sensor to be connected to the controller, electronically or via the network.

• a window contact to stop the heating and cooling functions,

should a window be opened, can be connected. An occupancy

sensor can detect the presence of a person in the controlled zone

and change the controller from economy to comfort mode.

The window contact sensor, occupancy sensor, and air quality

control are described in detail in section 5.3.2–5.3.4.

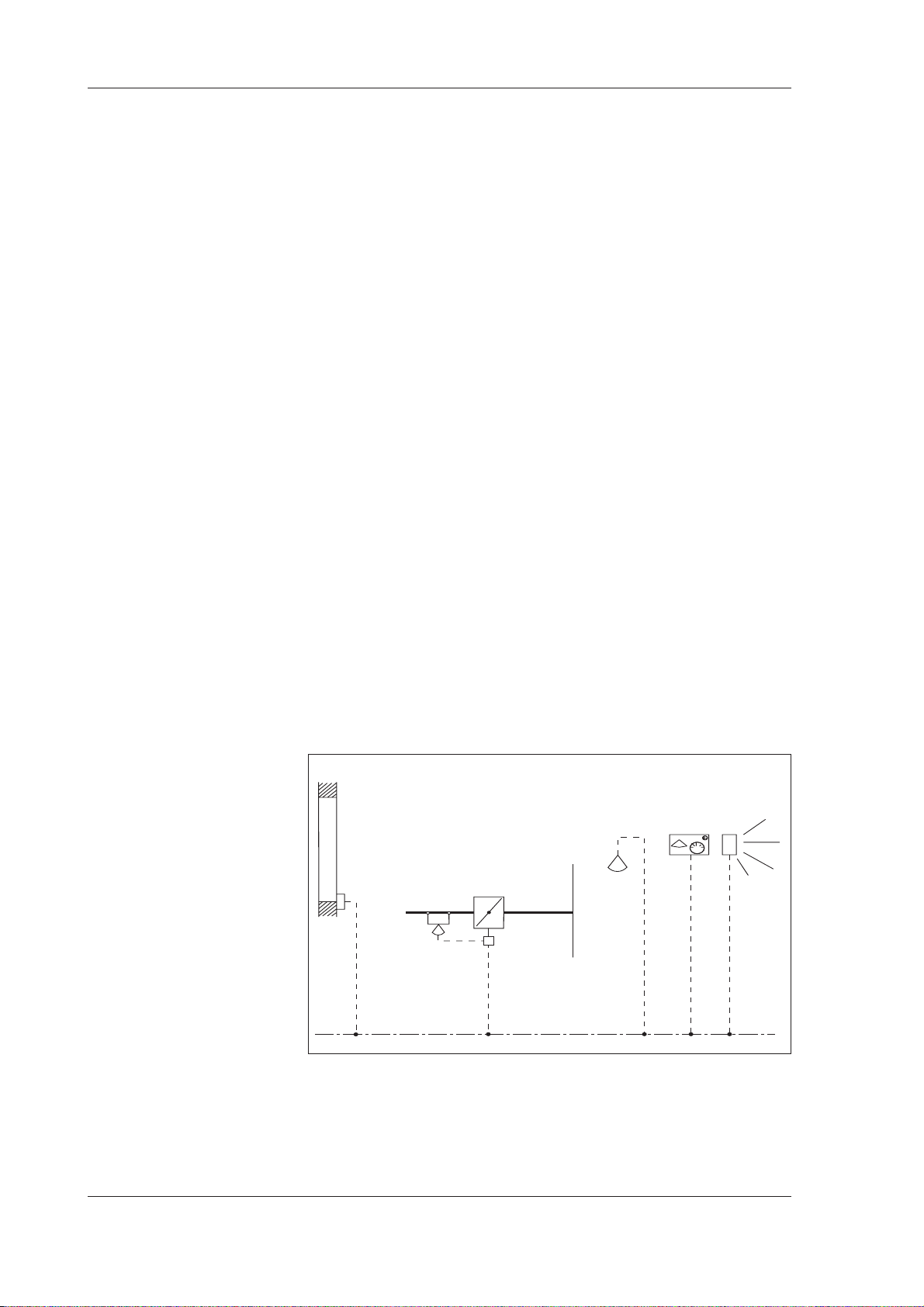

2.3.2 Air flow control only (TAC Xenta 102-B)

The controller controls the zone temperature by means of the

air damper via VAV-Compact. The air flow is minimum and

maximum limited. Usually the controller only uses one cooling

sequence (sub-tempered air in the duct), but it can be changed

to heating (hot air in the duct) given a central command.

Window

contact

Damper and air

flow controller

Wall

sensor

module

Carbon dioxide

Occupancy

sensor

Figure 2.3 Control application for TA C Xenta 102-B

2:4 (8), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 15

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

2.3.3 Air flow control with modulating valve water reheat

(TAC Xenta 102-VF)

The controller controls the zone temperature by sequence controlling the air flow controller (VAV-Compact) and the heating coil.

The air flow is minimum and maximum limited. The heating

sequence controls the valve and minimum limits the air flow.

Wall

module

Carbon dioxide

sensor

Occupancy

sensor

Window

contact

Damper and air

flow controller

Heating

water coil

Valve and

actuator

Figure 2.4 Control application for TA C Xenta 102-VF

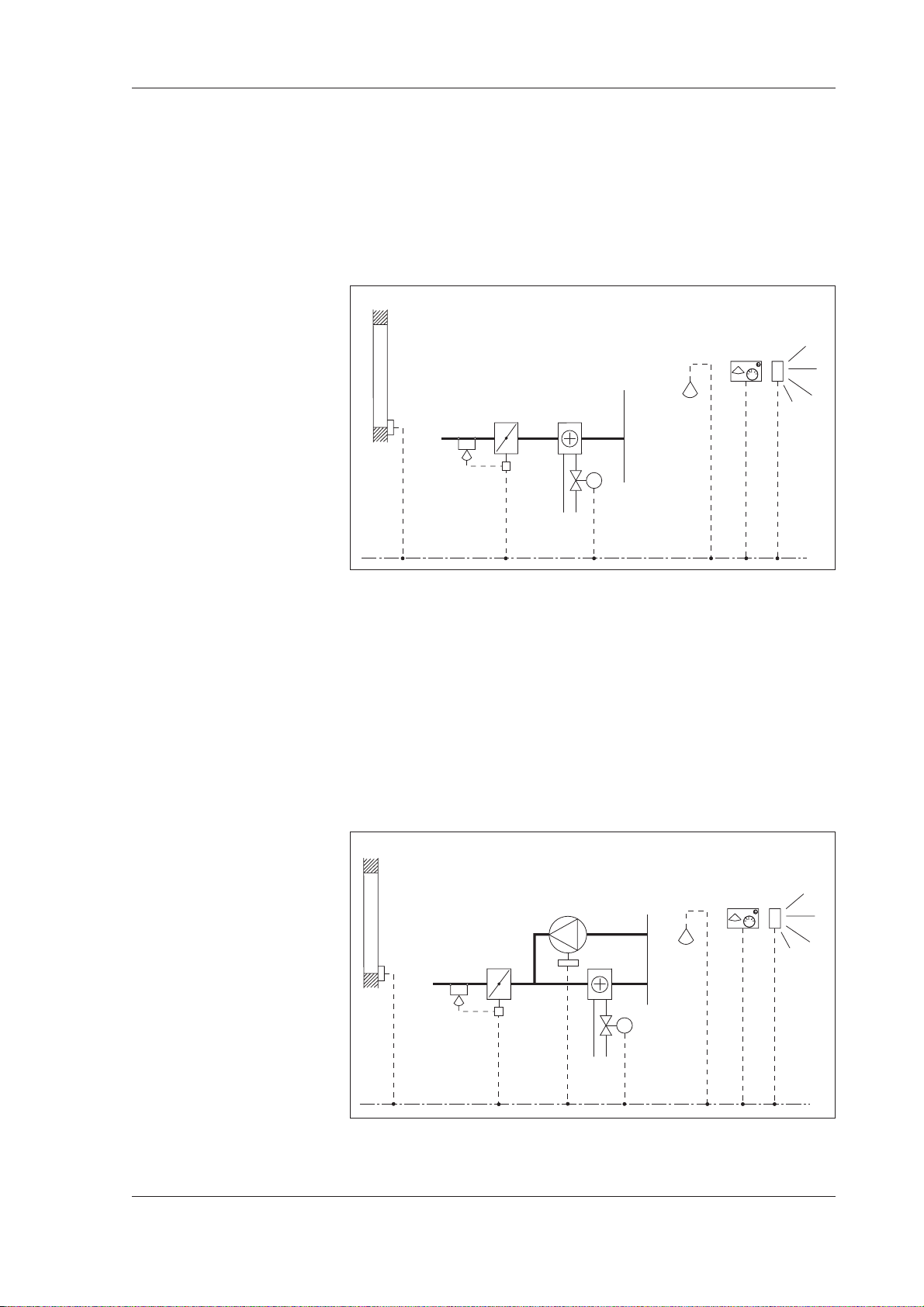

2.3.4 Air flow control with modulating valve water reheat and fan

(TAC Xenta 102-VF)

The controller controls the zone temperature by sequence controlling the air flow controller (VAV-Compact) and the heating coil.

The airflow is minimum and maximum limited. The heating combines the valve control with the fan to increase the air circulation

through the heating coil.

Window

contact

Damper and air

flow controller

Fan

Heating

water coil

Wall

module

Carbon dioxide

sensor

Occupancy

sensor

Valve and

actuator

Figure 2.5 Control application for T A C Xenta 102-VF

TAC AB, 1999-08-18 0-004-7516-1 (GB), 2:5 (8)

Page 16

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

2.3.5 Air flow control with one stage electric reheat (TAC Xenta

102-EF)

The controller maintains the zone temperature by sequence controlling the air flow controller (VAV-Compact) and the electric

heating coil. The air flow is minimum and maximum limited.

When heating, the controller controls the electric heating coil via a

relay in combination with setting the air flow to its minimum

value.

Window

contact

Damper and air

flow controller

Electric

heating coil

Wall

module

Carbon dioxide

sensor

Occupancy

sensor

Figure 2.6 Control application for T A C Xenta 102-EF

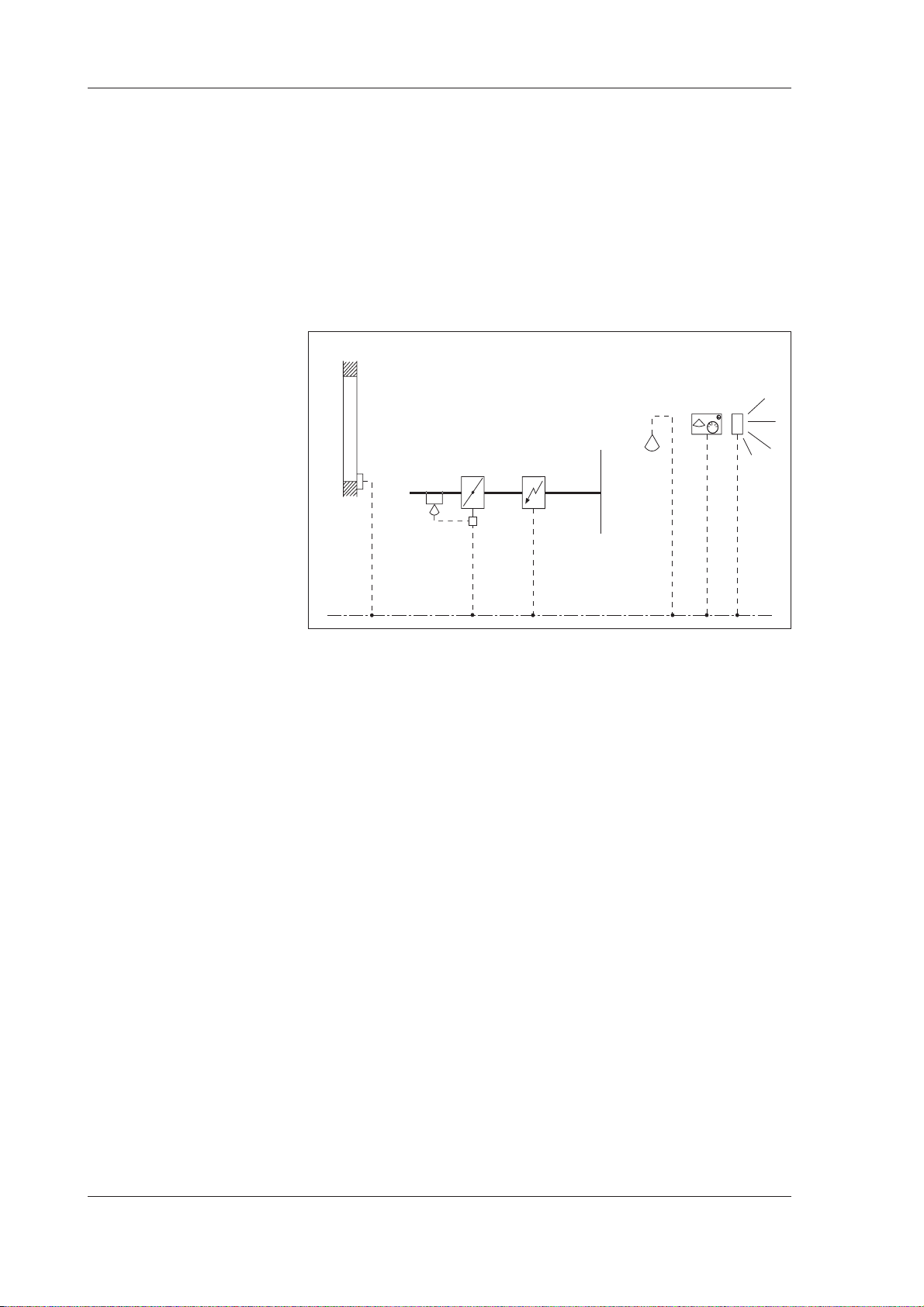

2.3.6 Air flow control with one stage electric reheat and fan (TAC

Xenta 102-EF)

The controller controls the zone temperature by sequence

controlling the air flow controller (VAV-Compact) and the

electric heating coil. The air flow is minimum and maximum

limited. When heating, the controller controls the electric

heating coil by means of a relay in combination with the fan

running to increase the air circulation through the heating coil.

In this application (electric reheat + fan), the minimum limitation

may have separate settings for cooling and heating.

2:6 (8), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 17

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

Wall

Fan

module

Carbon dioxide

sensor

Occupany sensor

Window

contact

Damper and air

flow controller

El. heating

coil

Figure 2.7 Control application for T A C Xenta 102-EF

2.3.7 Air flow control with thermo-actuator for radiators

(TAC Xenta 102-EF)

The controller controls the zone temperature by sequence

controlling the air flow controller (VAV-Compact) and the

themo-actuators for radiators. The air flow is minimum and

maximum limited.

Carbon dioxide

Window

contact

Damper and air

flow controller

Valve

Radiators

Figure 2.8 Control application for T A C Xenta 102-EF

Wall module

sensor

Occupancy

sensor

TAC AB, 1999-08-18 0-004-7516-1 (GB), 2:7 (8)

Page 18

TAC Xenta 102 Handbook The zone controller TAC Xenta 102

This page is intentionally left blank.

2:8 (8), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 19

TAC Xenta 102 Handbook Installation

3 Installation

3.1 Mechanical installation

3.1.1 Fitting

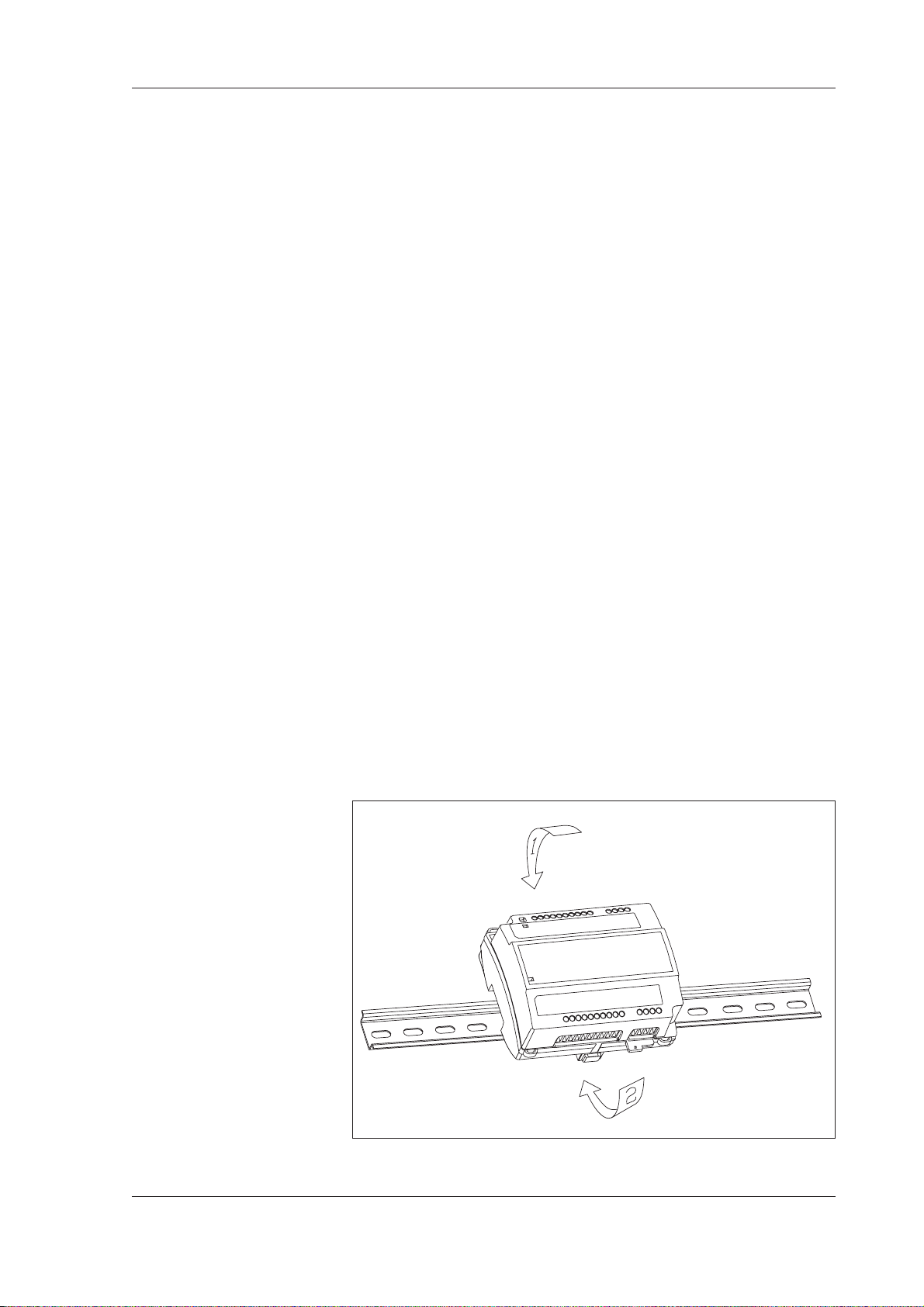

TAC Xenta 102 can either be snapped onto a DIN rail (figure

3.1) or fastened with two screws to a level surface (figure 3.2).

On the controllers which controls equipment with 230 V supply,

a semi-protection which covers the relay terminals, should be

fitted (figure 3.3). A semi-protection is delivered together with

these controllers.

T o fasten the contr oller onto a DIN rail:

1. Place the controller on the top of the rail as is shown by arrow 1.

2. Turn the controller downwards until it snaps onto the rail as

is indicated by arrow 2.

3. To remove, place a screwdriver in the lock on the bottom of

the controller and pull down. Then it is possible to lift the

controller diagonally upwards and off the rail.

Figure 3.1 TA C Xenta 102 fastened on a DIN ra il

TAC AB, 1999-08-18 0-004-7516-1 (GB), 3:1 (10)

Page 20

TAC Xenta 102 Handbook Installation

Fastening the controller on a level surface:

Use the two sockets provided for fastening the controller; the

maximum screw size is M4 or ST 3,5. The head of the screw

should not exceed 7,5 mm in diameter.

Figure 3.2 TA C Xenta 102 f astened on a le v el surface

T o fit the semi-protection:

When the cables are secured, the protection is fitted by means of

the enclosed screw.

Figure 3.3 Fitting the semi-protection

3:2 (10), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 21

TAC Xenta 102 Handbook Installation

3.2 Electrical installation

3.2.1 General

Warning! All 230 V supply cables must be

!!

1. Each controller or group of controllers must be fitted with

max. 6 A fuses.

2. Secure the cables to the controller by means of clamps or

similar, to limit their mobility.

3. Wire straps or shrinking tubing must prevent loose 230 V

cables from getting in contact with ELV cables—supply or

signal cables—and vice versa.

4. It must be simple to break the power supply for the

controller or for the complete installation.

5. When several Xenta controllers are supplied from a

common transformer, it is important that all G’s are

connected with each other and that all G0’s are connected

with each other. They must not be interchanged. An

important exception

connected with the other G0’s. Instead it should be

connected to the terminal OP on the controller. At the

transformer, G0 should be connected to protective earth.

This is to get an grounding point for interference diversion.

installed by authorised electricians.

: G0 on the wall module should not be

6. Connect the two M terminals to the wall module to get the

specified measuring accuracy for the room temperature.

Safety standard

Transformers supplying the controller must comply to the safety standard EN 60 742 or any other relevant safety standard

for ELV, 24 V AC. When equipment with a power supply of its

own is connected, e.g. an occupancy sensor, this power supply

must also comply with this norm.

Cable lengths

For information on communication cable lengths, see TAC

Xenta Network Guide, part number 0-004-7460. For all other

cables, maximum length is 30 m and min. area is 0,7 mm

2

.

Wall modules ZS 101–ZS 104

It is mainly the wall modules ZS 101–ZS 104 which are intended for use together with TAC Xenta 102. The wall module ZS

105 can also be used, but then the fan switch on this unit is not

used. The wiring diagrams on the following pages show how wiring with ZS 104 should be done, as this is the model that has all

connections.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 3:3 (10)

Page 22

TAC Xenta 102 Handbook Installation

Connection terminals

The designation of the connection terminals can be seen in two

places on the controller: on the edge of the printed circuit board,

and on the label on the front of the controller.

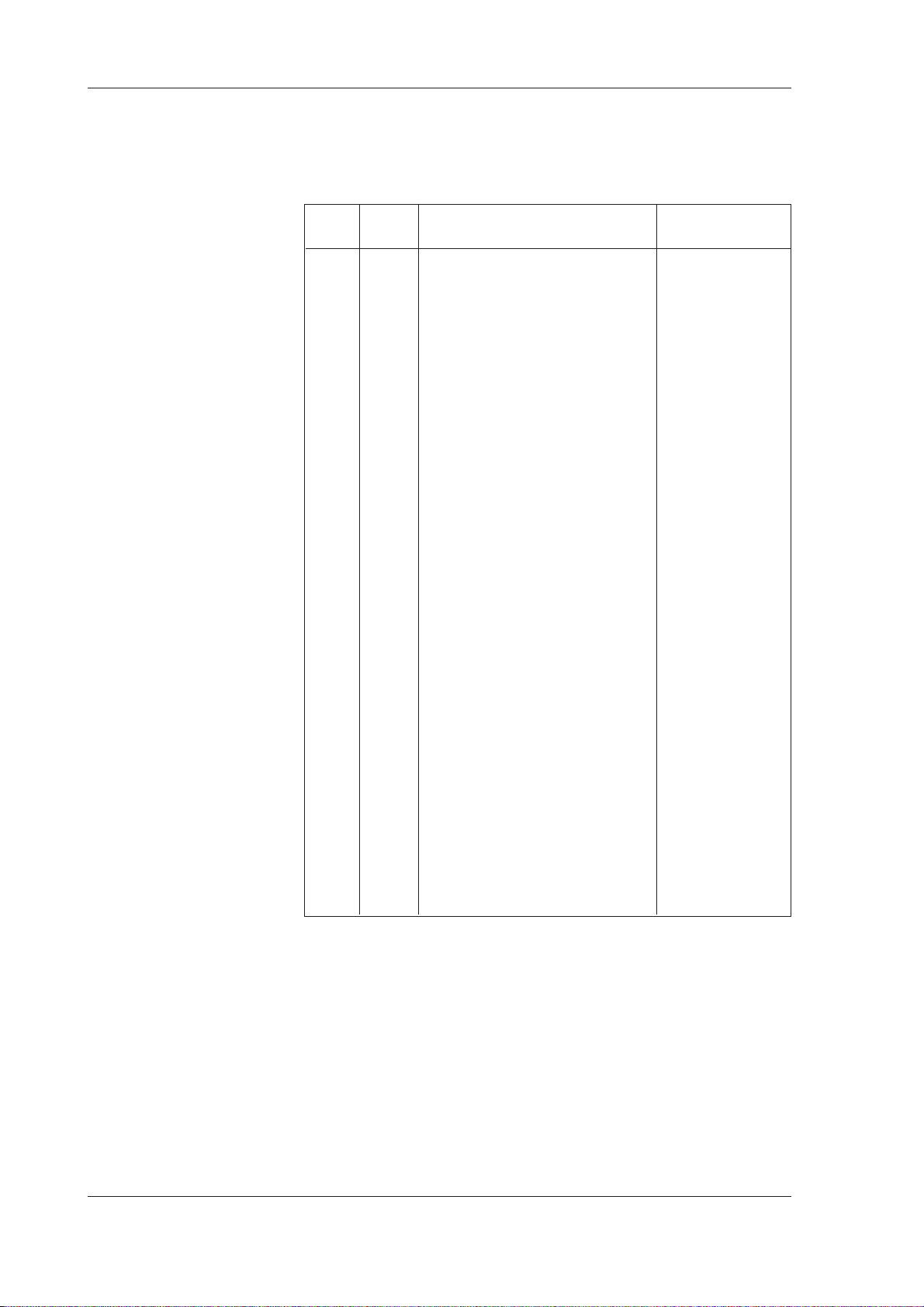

Termin Design. Function Type

no.

1 C1 TP/FT-10 communication channel 2 C2 TP/FT-10 communication channel -

*1

3

4 M Measurement neutral -

*1

5

*1

6

7 M Measurement neutral -

8 Z1 Air flow from VAV-Compact Analogue input

9 D1 LED on wall module Digital output

10 M Measurement neutral 11 X1 Bypass key on wall module Digital input

12 R 1 Setpoint adjustment on wall 10 k

X3 Window contact Digital input

(Closed contact=closed window)

X2 Occupancy sensor Digital input

Z2 Carbon dioxide sensor Analogue input

Ω linear

module potentiometer

13 M Measurement neutral 14 B1 Room temperature sensor Thermistor input

15 G 24 V AC (G) Input

16 G0 24 V AC (G0) Input

*2

17

OP 24 V AC supply for TAC Xenta OP -

18 G 24 V AC supply for TAC Xenta OP 19 V 1 Fan on/off (102-EF and 102-VF)

20 G 24 V AC (G) supply for V1 and V2 Output

21 G0 24 V AC (G0) Output

22 Y 2 Control signal 0–10 V for heating Analogue output

valve (only 102-VF)

23 M Measurement neutral 24 Y1 Control signal, air flow controller Analogue output

25 — Not in use 26 — Not in use 27 K 1 On/off, electric heating coil or

thermo-actuator (only 102-EF),

24 V or 230 V AC Relay

28 K C1 Supply for K1 -

*1

See chapter 4 Configuration parameters

*2

Connected alone to G0 on the wall module. Must not be connected to G0 on

the controller.

3:4 (10), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 23

TAC Xenta 102 Handbook Installation

3.2.2 Wiring of TAC Xenta 102-B

Note! Read section 3.2.1 “General” before you connect the

cables according to the wiring diagram in figure 3.4.

LONT

ALK

TP/FT-10

15 16 17 18 19 20 21 22 23 24 25 26 27 28

®

Junction box

Wall module

Window

contact

Occupancy

GW1 GQ1GX1

1234567891011121314

C2 X3 M M MMZ1 X1R1 B1

sensor

X2

+–

Z2

Carbon dioxide

sensor e.g. GKD 2001

V... 24 V AC/DC

10)(9

ZS 104

6

7

D1C1

5

1

3

2

Xenta 102-B

G0

G

OP V1 Y1

GG

G0

M

C1

G

C2

G0

13

Belimo

VAV-Compact

2

5

Air flow controller

with damper

24 V AC (G)

24 V AC (G0)

Figure 3.4 Wiring of TA CXenta 102-B

TAC AB, 1999-08-18 0-004-7516-1 (GB), 3:5 (10)

Page 24

TAC Xenta 102 Handbook Installation

3.2.3 Wiring of TAC Xenta 102-EF

Note! Read section 3.2.1 “General” before you connect the

cables according to the wiring diagram in figure 3.5.

LONTALK

TP/FT-10

15 16 17 18 19 20 21 22 23 24 25 26 27 28

®

Junction box

Wall module

Occupancy

contact

sensor

Carbon dioxide

+–

Z2

X2

sensor, e.g. GKD 2001

V... 24 V AC/DC

10)(9

ZS 104

6

7

D1C1

5

1

3

2

Window

GW1 GQ1GX1

1234567891011121314

C2 X3 M M MMZ1 X1R1 B1

Xenta 102-EF

G0

G

OP V1 Y1

GG

G0 K1 KC1

13

M

Belimo

On/off, fan

VAV-Compact

2

5

Air flow

controller with

Electric

heating

coil

damper

27 28

24 V AC

C1

G

C2

G0

!

230 V AC (L)

230 V AC (N)

CAT III

(IEC 664)

Class II

(EN 61010-1)

Thermal actuator,

e.g. TSE 150 NC/NO

24 V AC (G)

24 V AC (G0)

Figure 3.5 Wiring of TACXenta 102-EF

3:6 (10), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 25

TAC Xenta 102 Handbook Installation

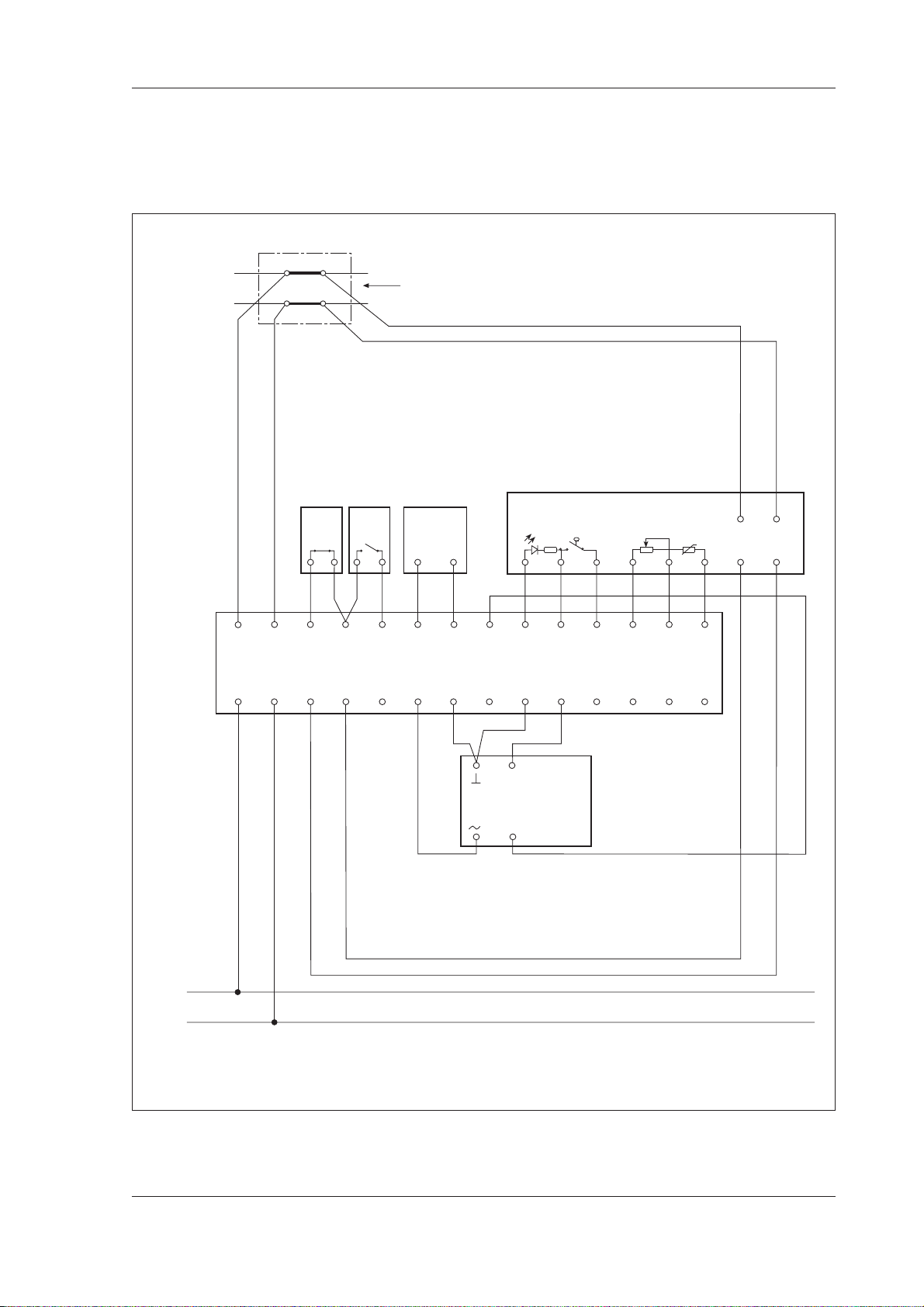

3.2.4 Wiring of TAC Xenta 102-VF

Note! Read section 3.2.1 “General” before you connect the

cables according to the wiring diagram in figure 3.6.

LONT

ALK

TP/FT-10

15 16 17 18 19 20 21 22 23 24 25 26 27 28

®

Junction box

Wall module

Window

contact

Närvaro-

givare

Koldioxidgi vare,

t.ex. GKD 2001 V...

24 V A C/DC

GW1 GQ1GX1

10)(9

+–

1234567891011121314

Z2

C2 X3 M M MMZ1 X1R1 B1

X2

6

7

D1C1

5

ZS 104

3

1

2

Xenta 102-VF

G0

G

OP V1 Y2 Y1

GG

G0

M

C1

G

C2

G0

13

G G0 X1/X2M

Belimo

On/off,

fan

EM52L

Actuator, water

heating coil

VAV-Compact

2

5

Air flow

controller with

damper

24 V AC (G)

24 V AC (G0)

Figure 3.6 Wiring of TA C Xenta 102-VF

TAC AB, 1999-08-18 0-004-7516-1 (GB), 3:7 (10)

Page 26

TAC Xenta 102 Handbook Installation

3.3 Commissioning

3.3.1 General

When the mechanical and electrical installation has been made,

you can commission the controller. This means:

· Installing the controller on the network, set node status

and give it an address.

· Set the controller's configuration parameters.

· Bind network variables.

· Test the function.

When it comes to commissioning of complete zone systems,

read the manual “TAC Xenta–Zone Systems Guideline”. Here

you will find a short description of what to do and when to do

it. In short: you could use TAC Xenta OP for setting the basic

parameters. Use a network management tool or TAC Vista for

commissioning the controller on the network and do the rest of

the commissioning.

3.3.2 Node status

When TAC Xenta 100 should be used stand-alone, this is how:

1. Set node status to “Configured” with TAC Xenta OP.

2. Set the basic parameters with TAC Xenta OP.

3. Set the other parameters and variables with TAC Xenta

OP.

You could also use a network management tool for the commissioning.

The node status indicates which mode the controller is in, when

it comes to network configuration and program. The status can

be changed with TAC Vista (version 3.1 or later), network

management tool, or, to some extent, TAC Xenta OP. The

controller can be in these states:

Unconfigured

The controller is in this state when delivered from the factory.

Neither the program nor the network communication are

running. The service light emitting diode is flashing.

The controller cannot work on a network in this state. To do

so, it must be in configured, online state, see below.

You cannot set configuration parameters or network variables

in this state.

3:8 (10), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 27

TAC Xenta 102 Handbook Installation

Configured, online

By means of TAC Xenta OP, TAC Vista or a network

management tool, the status can be changed to configured.

Then, both the program and the network communication are

running. The service LED is off. This is the normal state for a

controller in operation.

Now the controller uses the address which it was given by the

tool during configuration. With TAC Xenta OP you cannot,

however, set an address. Therefore all controllers get default

addresses. This means that such a TAC Xenta 100 cannot

work on a network. It can only work stand-alone.

In this state you can set parameters and variables.

Configured, soft online

To get the controller into this state, you need a network

management tool. The controller has a program and a network

configuration, but the program and the communication are at a

standstill. The light emitting diode is off. If the controller is

reset, it will go into configured, online.

Configured, hard online

To get the controller into this state, you need a network

management tool. The controller has a program and a network

configuration, but the program and the communication are at a

standstill. The light emitting diode is off. If the controller is

reset, it will remain in this state.

Without a program and not configured

This states indicates that there is something wrong with the

controller. No program can be detected. The light emitting

diode is lit.

3.3.3 Configuration parameters (nci’s)

TAC Xenta 100 has a number of configuration parameters,

where you can set how the controller should be working. Read

about them in chapter 4. There are also network variables

which controls the controller during operation.

Use the commissioning protocol in Appendix B to write down

your settings at commissioning. In chapter 8, there is

information on all parameters and variables, such as their

index, accepted values, default values. There are detailed

descriptions of the parameters and variables in chapter 4, 5,

and 6.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 3:9 (10)

Page 28

TAC Xenta 102 Handbook Installation

3.3.4 Network installation

For network installation, you need a network management tool

(LNS based or not). Examples of network management tools

are MetraVision and LonMaker for Windows. Here you find

brief information on how this is made. You find more

information in “TAC Xenta, Guidelines for zone applications”.

The installation has two steps:

1. Feed information about the controllers’ unique neuron-ID

into the network management tool’s data base.

2. Let the network management tool install the controller on

the network. The controller will then also get an address.

There are two ways to feed the neuron-ID into the data base:

1. Manually feed the neuron-ID into the network management

tool. To make this easier you can use a bar code reader to

read the detachable ID-neuron label, which you find on all

controllers. It is convenient to gather these labels when you

go around and make the basic configuration, and stick them

to a form, drawing or similar. In the manual “TAC Xenta,

Guidelines for zone applications” there is a form for this

purpose.

2. Use the service pin function. You can only do this when the

controller is connected to the network. On the controller

there is a service pin key in a hole in the upper left corner, at

terminal C1. When you push this, the controller sends out its

neuron-ID. The network management tool can then read the

neuron-ID from the network, to save it in its data base.

3.3.5 Network variable binding

How binding is done depends on which network management

tool is used. To get exact information, you should use the tool’s

documentation. In “TAC Xenta Network manual”, there is

however a description of how network variables are bound

with Metra Vision.

To bind network variables is not an issue when the controller is

used in stand-alone operation.

3.3.6 Function test

You should also make sure that the control works as intended.

In chapter 5 all the controller’s functions are described.

In chapter 6 you find help, should a problem occur.

3:10 (10), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 29

TAC Xenta 102 Handbook Configuration parameters

4 Configuration parameters

All communication with the controller is made by means of

network variables. nci’s are used to configure the controller,

nvi’s controls the controller during operation, and nv o’s are

output variables, which the controller sends out on the network.

nci’s are normally set during commissioning, and are not

altered during normal operation (the parameters are stored in

a special memory, and can be changed a maximum of 10 000

times). In chapter 8, there is detailed information on accepted

values and default values for all parameters. All configuration

parameters have default values on delivery.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 4:1 (4)

Page 30

TAC Xenta 102 Handbook Configuration parameters

4.1 Basic parameters

nciAppOptions

These parameters are used to set selectable functions in the controller. The parameter consists of 16 bits, where each bit

represents one functional choice. The bits 10 through 14 are

not used. When you look at nciAppOptions with TAC Xenta OP,

bit 0 is shown to the left.

There is an overview of all the bits’ functions in table 4.1 below.

Table 4.1 The function of different bits in nciAppOptions.

Bit no. Function

Bit 0 0 Occupancy sensor not connected, terminal X2

1 Occupancy sensor connected, terminal X2

Bit 1 0 Energy hold off device (window contact) not connected,

terminal X3

1 Energy hold off device (window contact) connected,

terminal X3

Bit 2 0 Cooling sequence only disabled (only valid for

TAC Xenta 102-B)

1 Cooling sequence only enabled (only valid for

TAC Xenta 102-B)

Bit 3 0 Fan disabled

1 Fan enabled (not valid for TAC Xenta 102-B)

Bit 4 0 Ther mo-actuators normally closed (NC) (only valid for TAC

Xenta 102-EF)

1 Ther mo-actuators normally open (NO) (only valid for TAC

Xenta 102-EF)

Bit 5 0 Air quality control disabled

1 Air quality control enabled

Bit 6 0 Electric heating coil (only valid for TAC Xenta 102-EF)

1 Thermo-actuator for radiators (only valid for

TAC Xenta 102-EF)

Bit 7 0 Slave mode disabled

1 Slave mode enabled

Bit 8 0 Occupancy sensor: closed contact indicates occupancy

1 Occupancy sensor: open contact indicates occupancy

Bit 9 0 If

setpoints for the comfort and economy modes are

calculated using method B (see section 5.2.4).

1 If

setpoints for the comfort and economy modes are

calculated using method A (see section 5.2.4).

nviSetpoint

nviSetpoint

has a valid value, the heating/cooling

has a valid value, the heating/cooling

Bit 15 Reserved for production test. Should not be altered!

Bits 10 through 14 are not used.

4:2 (4), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 31

TAC Xenta 102 Handbook Configuration parameters

4.2 Other configuration parameters

The controller’s other configuration parameters are listed below together with a short description. See also chapter 8.

T ab le 4.2 Configuration parameters.

Index Name Description

0

nciLocation

25

nciSetpoints

26

nciSpaceTempDev

27

nciSpaceTempLow

28

nciVAVGain

29

nciVAVItime

30

nciGainHeat

31

nciItimeHeat

32

nciSpaceTempOfst

33

nciMinFlow

34

nciMaxFlow

35

nciMinFlowHeat

36

nciMinFlowStand

37

nciNomFlow

38

nciFlowOfstSlave

Location label

Occupancy temperature setpoints

Max. deviation of zone temperature

Low limit of zone temperqature

Gain fo VAV

Integral time for VAV

Gain for heating controller

Integral time for heating controller

Zone temperature sensor adjustment

Minimum flow

Maximum flow

Minimum flow heating

Minimum flow standby

Nominal flow

Flow offset for slave

39

nciCO2PerVolt

40

nciSpaceCO2Low

41

nciSpaceCO2High

44

nciHeatPrimMin

45

nciInstallType

46

nciSndHrtBt

47

nciRcvHrtBt

Conversion factor ppm CO2 per volt

Space CO2 level for closed damper

Space CO2 level for open damper

Minimum output heating controller

Network configuration source

Send heartbeat

Receive heartbeat

nciLocation

The parameter is used for naming the place where the controller is installed. In the operating panel, this parameter is shown

as the first variable (see section 8.1).

nciSetpoints

The parameter is used for setting the setpoint temperatures for

heating and cooling in comfort and economy mode (see section

5.2.1 and 5.2.4).

nciSpaceTempDev

The parameter is used for setting the maximum allowed deviation of the zone temperature (see section 5.3.7). Default value 2

°C.

nciSpaceTempLow

The parameter is used for setting the lowest allowed zone temperature (see section 5.3.7). Default value 10 °C.

nciV AVGain, nciGainHeat

The parameters give the cooling and heating sequence gain. Default value 25.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 4:3 (4)

Page 32

TAC Xenta 102 Handbook Configuration parameters

nciIV A Vtime, nciItimeHeat

The parameters holds the integral time for the cooling and heating sequence gain. Default value 900 s (15 min).

nciSpaceTempOfst

The parameter is used for adjusting the temperature setpoint.

Default value 0.0 °C.

nciMinFlow, nciMaxFlow

The parameters are used for setting the minimum and maximum flow allowed. Default values 0 l/s and 65535 l/s.

nciMinFlowHeat, nciMinFlowStand

The parameters are used for setting the min. flow allowed at active

heating (only relevant for applications with electrical reheat but

without a fan) and standby respectively. Default value 0 l/s.

nciFlowOfstSlave

The parameter is used for adjusting the flow of the slave controller (see section 5.3.8). Default value 0 l/s.

nciCO2PerVolt

The parameter is used for setting a conversion factor for the

signal from the carbon dioxide sensor to a concentration in

ppm. Default value 200 ppm/V.

nciSpaceCO2Low, nciSpaceCO2High

The parameters are used for setting the air quality control limits (se section 5.3.3). Default value 400 and 1000 ppm.

nciHeatPrimMin (only TAC Xenta 102-VF)

The parameter is used for setting the smallest heating valve

opening allowed (se section 5.3.6). Default value 0%.

nciInstallType

The parameter is used only at free-standing operation and is set

to show that the node should define its own address (see section

8.5.3).

nciSndHrtBt

The parameter is used for determining how often the nvo’s,

which are transmitted continuously on the net, should be sent

(see section 8.3).

nciRcvHrtBt

The parameter is used for determining how long time max. there may be between updating those nvi’s, for which the controller expects continuous updating (see section 8.3).

4:4 (4), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 33

TAC Xenta 102 Handbook Functional description

5 Functional description

5.1 General

The controller’s function is determined by its node status

(section 3.3.2), different operation modes (section 5.2.1) and the

ways to force the controller (section 5.2.2) for well-adapted

zone temperatur control. The controller measures the zone

temperature and uses different methods to calculate setpoints.

The air flow is controlled by an external air flow controller.

Apart from the basic functions in chapter 5.2, the controller

has a number of other possibilies to control the climate in the

zone. There are information about these functions in chapter

5.3.

Each section in this chapter is ended with information on which

network variables are used in the current control situation. If

you need details about the network variables’ characteristics,

such as default values and accepted values, you find this in

chapter 8.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:1 (16)

Page 34

TAC Xenta 102 Handbook Functional description

5.2 The controller’s basic functions

5.2.1 Operation modes

The controller has four selectable operation modes:

• Comfort

• Economy

• Bypass

• Off

The operation mode is controlled by nviManOccCmd, but is also

influenced by occupancy sensors and the bypass key on the wall

module. The connection between these is shown in table 5.1.

There you also find the controller’s values during stand-alone

operation.

T a ble 5.1 The relation betw een desired operation mode, bypass timer , occupancy sensor and current

operation mode.

Desired op. mode Bypass timer

nviManOccCmd operation mode

Comfort Enabled Without signific. Comfort OC_OCCUPIED

At a standstill Occupancy detect. Comfort OC_OCCUPIED

OC_OCCUPIED No occupancy Economy OC_STANDBY

1

Occupancy sensor2Current

nvoEffectOccup

Economy Enabled Without signific. Bypass OC_BYPASS

OC_STANDBY At a standstill Without signific. Economy OC_STANDBY

Off Enabled Without signific. Bypass OC_BYPASS

OC_UNOCCUPIED At a standstill Without signific. Off OC_UNOCCUPIED

Stand-alone Enabled Occupancy detect. Comfort OC_OCCUPIED

operation No occupancy Bypass OC_BYPASS

At a standstill Occupancy detect. Comfort OC_OCCUPIED

OC_NUL No occupancy Off OC_UNOCCUPIED

1

Activated by the bypass key on the wall module

2

See section 5.3.5 about occupancy sensors

Comfort mode

This is the default mode, when someone is in the zone, and the

controller should give the room a comfortable climate. The

controller is in this mode when nviManOccCmd=OC_OCCUPIED (or OC_NUL after a power down).

The LED on the wall module is lit with a steady red light and

you can use the setpoint knob on the wall module to make a

manual setting and air quality control is enabled. The setpoints

used are found in nciSetpoints (can be modified).

The alarms for the zone temperature deviation, high carbon

dioxide levels, and flow deviation can cut out, but the alarms

for window contact and low zone temperature are blocked.

5:2 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 35

TAC Xenta 102 Handbook Functional description

Economy mode

In economy mode, the controller lowers the energy

consumption in the zone by using the heating and cooling

setpoints for economy in nciSetpoints (could be modified). The

controller is in this mode when nviManOccCmd =

OC_STANDBY and the bypass key has not been pressed.

The LED of the wall module flashes slowly. The bypass key can

be used, and also the setpoint knob, if you want to make a

manual setting.

The alarms for the zone temperature deviation, high carbon

dioxide levels, and flow deviation are blocked, but the alarms

for low zone temperature and window contact can cut out.

Bypass mode

The bypass key on the wall module is used if you want to turn

to comfort mode occasionally from economy or off mode.

When someone presses the bypass key on the wall module, the

bypass timer is started and the controller turns to bypass mode.

The bypass timer runs for two hours, and after those two hours

the controller changes operation mode according to table 5.1.

The controller’s bypass mode acts as the comfort mode during

those two hours. Both setpoints and alarms work as in comfort

mode.

Off mode

When the zone is not used for a longer period of time, the controller can be set in off mode. The controller is in this mode

when nviManOccCmd=OC_UNOCCUPIED.

The light emitting diode on the wall module is out. The setpoint

knob is blocked, but the bypass key is not. The alarms for the

zone temperature deviation, high carbon dioxide levels, and

flow deviation are blocked, but the alarms for low zone

temperature and window contact are enabled.

Index Variable name Description

1

nvoEffectOccup

13

nviManOccCmd

nciSetpoints

25

Effective occupancy output

Occupancy scheduler input

Occupancy temperature setpoints

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:3 (16)

Page 36

TAC Xenta 102 Handbook Functional description

5.2.2 Operation mode, manual mode and emergency mode

TAC Xenta 102 is designed to control both heating and cooling,

and to switch automatically between heating and cooling.

Heating

case

Heating

setpoint

Cooling

setpoint

Cooling

case

Cooling

demand

Figure 5.1 Changeover between heating and cooling cases.

It is possible to force the controller to heating only, cooling

only or night cooling. This is done with nviApplicMode,

according to the table below.

T a ble 5.2 The relation between nviApplicMode and f orcing.

nviApplicMode

HVAC_AUTO Automatic The controller automatically changes over between heating

HVAC_HEAT

HVAC_COOL Cooling only The controller can only cool. The heating setpoint is

Forcing Description

(no forcing) and cooling by controlling with heating and cooling setpoints.

Heating only The controller can only heat. The cooling setpoint is

neglected.

neglected.

HVAC_NIGHT_

PURGE completely open.

HV AC_OFF Off The controller neither cools nor heats.

Night cooling The controller can only cool with night air and the damper is

Manual mode

In this mode, the air flow can be set manually by means of

nviManOverride. The variable has three values, see the table

below. The heating sequence is disabled. The manual mode has

a higher priority than operation and operation mode.

T ab le 5.3 The relation betw een nviManOverride and forcing.

nviManOverride

HVO_OFF Normal operation

HVO_FLOW_VALUE Optional flow is set (l/s)

HVO_PERCENT The damper is set to desired position (%)

5:4 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Description

Page 37

TAC Xenta 102 Handbook Functional description

Emergency mode

In an emergency, the controller can force the damper to

completely opened or closed by means of nviEmergCmd, see the

table below. The heating sequence and the fan are disabled. The

emergency mode has a higher priority than all other modes.

T able 5.4 The relation between nviEmergCmd and f orcing.

nviEmergCmd

EMERG_NORMAL Normal operation

EMERG_PURGE Completely open damper (100%)

EMERG_SHUTDOWN Completely closed damper (0%)

EMERG_PRESSURIZE Completely open damper (100%)

EMERG_DEPRESSURIZE Completely closed damper (0%)

Description

Index Variable name Description

14

nviApplicMode

20

nviManOverride

21

nviEmergCmd

Application mode input

VAV manual override input

Emergency command input

5.2.3 Measuring zone temperature

You can measure the zone temperature either with the wall

module (thermistor sensor) or with a LonTalk temperature

sensor node connected to nviSpaceTemp. If nviSpaceTemp has a

valid value, the controller will use this, otherwise the thermistor

value will be used. The thermistor value (or via the network)

can be adjusted by nciSpaceTempOfst having received a value;

this is added to the thermistor value. The value the controller

uses is also put out on nvoSpaceTemp. If neither value is valid,

nvoSpaceTemp gets the off value. nvoSpaceTemp is sent out

when it has changed at least 0,1°C.

Index Variable name Description

5

nvoSpaceTemp

15

nviSpaceTemp

32

nciSpaceTempOfst

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:5 (16)

Zone temperature output

Zone temperature input

Zone temperature sensor adjustment

Page 38

TAC Xenta 102 Handbook Functional description

5.2.4 Setpoint calculation

Zone temperature setpoints

nciSetpoints defines temperature setpoints; heating setpoint

comfort mode, cooling setpoint comfort mode, heating setpoint

economy mode, cooling setpoint economy mode.

Table 5.5 Setpoints in nciSetpoints.

Setpoint Min. Max. Default

Cooling setpoint comfort 10 °C 35 °C 23 °C

Heating setpoint comfort 10 °C

Cooling setpoint economy 10 °C 35 °C 25 °C

Heating setpoint economy 10 °C

1

If the cooling setpoint is 10 °C, the heating setpoint is set to 9,5 °C.

1

1

The smallest accepted deviation between the heating and cooling

setpoints is 0,5 °C, and the heating setpoints must be lower than

the cooling setpoints. If the heating setpoints are higher or equal

to the cooling setpoints, the controller resets the heating setpoint

to 0,5 °C lower than the cooling setpoint. Table 5.2 shows accepted values and default values for the four temperature setpoints in

nciSetpoints.

35 °C 21 °C

35 °C 19 °C

The setpoints for comfort and economy mode are basic

setpoints, which can be changed with nviSetpoint,

nviSetPntOffset and the setpoint knob.

Calculation

The current setpoint, nvoEffectSetpt, depends on the current op-

eration, nvoUnitStatus, the desired operation mode, nviApplic-

Mode, and nviSetpoint, nviSetpntOffset, nciAppOptions, nciSetpoints and a possible local setpoint adjustment via the wall

module. Figure 5.2 shows an overview over the relation

between the variables used for setpoint calculation.

nviSetpoint is used to allow the temperature setpoints in comfort

and economy mode to be changed via the network. If there is a

valid value on nviSetpoint, the controller calculates the setpoints

for comfort and economy mode with method A or method B

(the methods are described in Appendix A). The choice of

method is made via nciAppOptions, bit 9. If bit 9=0 method B is

used, and if 9=1 method A is used. If there is no valid value on

nviSetPoint, no recalculation of the temperature setpoints in

nciSetpoints is made.

5:6 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 39

TAC Xenta 102 Handbook Functional description

nviSetPntOffset can be r egarded as a setpoint adjustment from a

wall module connected to the network. Its value is added to

setpoints for comfort and economy mode.

In Appendix A there are detailed calculation examples of

setpoint calculation.

Figure 5.6 The relation between variables for the setpoint calculation.

nviSetpntOf fset

Wall module

setpoint knob

nviSetpoint

nciAppOptions bit 9

1

Calculation

according to

method A or B

nciSetpoints

Comf., ool.setp.

2

Comf., heat.setp.

Econ., cool.setp.

if nviSetpoint

has a valid

2

value, otherwise

no recalculation

Addition Addition

Econ., heat. setp.

1

The wall module’s setpoint knob only affects comfort and economy mode.

2

In comfort mode, the setpoints for method A and method B are the same.

Index V ariable name Description

2

4

14

16

17

24

25

nvoUnitStatus

nvoEffectSetpt

nviApplicMode

nviSetpoint

nviSetpntOffset

nciAppOptions

nciSetpoints

Controller

Unit status output

Effective setpoint output

Application mode input

Temperature setpoint input

Setpoint offset input

Application options

Occupancy temperature setpoints

nvoEffectSetpt

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:7 (16)

Page 40

TAC Xenta 102 Handbook Functional description

5.2.5 Control sequence with TAC Xenta 102-B

The controller changes between the heating and the cooling

sequence by a central command from the network. The heating

sequence is enabled when the variable nviApplicMode has the

value HVAC_HEAT. The cooling sequence is enabled when

nciAppOptions bit 2=1 or when the variable nviApplicMode has

the value HVAC_AUTO, HVAC_COOL or HVAC_NIGHT_-

PURGE. The diagram below shows the heating and the cooling

sequence for TAC Xenta 102-B:

Air flow

max.

Heating

Changeover via

network variable

Cooling

min.

Figure 5.3 Control sequence for TAC Xenta 102-B

Index Variable name Description

14

nviApplicMode

24

nciAppOptions

Application mode input

Application options

Cooling demand

5.2.6 Control sequence with TAC Xenta 102-EF and 102-VF

The air flow (cooling) and an electric heating coil or radiators for

TAC Xenta 102-EF or a heating water coil for TAC Xenta 102-VF

sequence controls the temperature. When the cooling sequence

should be run, the controller calculates an air flow setpoint to

VAV-Compact. Then the air flow controller sets the air flow to the

desired flow.

If the heating sequence should be run, the controller sets an

output to the heating coil, the thermo-actuators or the heating

valve. The air flow is set to a minimum value.

If the controller has a fan as an option, the fan is on when the

heating valve is open in TAC Xenta 102-VF or the electric

heating coil is on in TAC Xenta 102-EF.

The diagrams below illustrates the fan’s function for the

different control sequences.

5:8 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 41

TAC Xenta 102 Handbook Functional description

Air flow

100%

max.

min.

Air flow

TAC Xenta 102-EF

100%

max.

min. heat.

min.

Air flow

100%

max.

0%

0%

Heating

Heating

Heating

Fan enabled

Cooling

Cooling

demand

Fan disabled

Cooling

Cooling

demand

Fan enabled

Cooling

min.

0%

Air flow

TAC Xenta 102-VF

100%

max.

Heating

Fan disabled

Cooling

min. heat.

min.

0%

Figure 5.4 Control sequence for TAC Xenta 102-EF and TA C

Xenta 102-VF

Cooling

demand

Cooling

demand

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:9 (16)

Page 42

TAC Xenta 102 Handbook Functional description

5.3 More about functions

5.3.1 Air flow control

The air flow is controlled by an external air flow controller, for

example Belimo™ VAV-Compact. The air flow controller gets

a setpoint from the VAV controller.

VAV controller

Type: PI

Gain: 0-32,75; default value: 25

I-time: 0-60 minutes; default 15 minutes

Dead band: 0,2 °C

Control interval: 60 s

Air flow setpoints

Either one of the output Y1 (0–10 V), or nvoFlowSetpoint, which

represent the flow in per cent, can be used for the setpoint.

nvoFlowControlPt, is the desired flow in l/s.

Air flow monitoring

TAC Xenta 102 receives the current air flow values from the

air flow controller, by means of input Z1 (0–10 V) or nviBoxFlow.

The controller uses the air flow measurement to monitor deviations. Current air flow can be read by means of the network variable nvoBoxFlow. The above also applies to the slave mode.

Air flow limits

Air flow is limited in comfort and standby mode. The maximum

flow limit nciMaxFlow is used during normal operation. The mini-

mum flow limit nciMinFlowHeat is used when the electric heating

coil is enabled and there is no fan. If radiators are used or the

electric heating coil is on and a fan is used, then nciMinFlow is

used instead. The controller uses the minimum flow limit nciMin-

FlowStand in standby mode.

Nominal air flow

The configuration parameter nciNomFlow defines the nominal

flow through the VAV box. Both the air flow setpoints and

limits depend on the correct value being set in nciNomFlow.

5:10 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 43

TAC Xenta 102 Handbook Functional description

Index Variable name Description

2

nvoUnitStatus

6

nvoFlowControlPt

7

nvoBoxFlow

nvoFlowSetpoint

11

22

nviBoxFlow

28

nciVAVGain

29

nciVAVItime

33

nciMinFlow

34

nciMaxFlow

nciMinFlowHeat

35

36

nciMinFlowStand

37

nciNomFlow

Unit status output

Effective flow control output

Box flow output

Flow setpoint output

Box flow input

Gain for VAV

Integral time for VAV

Minimum flow

Maximum flow

Minimum flow heating

Minimum flow standby

Nominal flow

5.3.2 Heating and fan control

TAC Xenta 102-B

TAC Xenta 102-B changes to heating sequence by means of a

command via the network. When there is a heating demand in the

zone, the controller increases the hot air flow in the zone; at a

cooling demand, the controller increases the cold air flow. For this

reason, it is not appropriate to mix Xenta 102-B with other Xenta

102 models in an installation where Xenta 102-B is to control a

heating application, as TAC Xenta 102-EF and VF heat subtempered air instead.

Heating controller (102-VF)

Type: PI

Gain: 0–32,75; default value: 25

I-time: 0–60 minutes; default 15 minutes

Neutral zone: 0,2 °C

Control interval: 60 s

TAC Xenta 102-EF

Heating control in Xenta 102-EF is a one-stage on-off system. The

heating output control, K1, can control either an electric heating

coil or a thermo-actuator. Which model is valid is set by nciApp-

Options. If the electric heating coil is used then the control is

made with a hysteresis of ± 0,25 °C. If the thermal actuators for

radiators are used, the hysteresis is ± 0,1 °C.

When the heating sequence runs and the fan is enabled, both the

coil/radiators and the fan are on when there is a heating demand.

The controller starts the electric heating coil with a 60 second delay. The fan is turned off with a 120 second delay.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:11 (16)

Page 44

TAC Xenta 102 Handbook Functional description

TAC Xenta 102-VF

The heating sequence consists of control of the heating coil

combined with a minimum air heating flow, nciMinFlowHeat

(without a fan). A separate PI controller controls the heating

sequence.

Index Variable name Description

2

24

30

31

nvoUnitStatus

nciAppOptions

nciGainHeat

nciItimeHeat

Unit status output

Application options

Gain for heating controller

Integral time for heating controller

5.3.3 Air quality control

In order to maintain a good air quality TAC Xenta 102

controls the supply of air to the controlled zone. If the carbon

dioxide (CO

controller increases the air flow to the controlled zone.

) sensor indicates a high concentration of CO2, the

2

The air flow is proportional to the CO

level and is calculated

2

as a linear function between [nciSpaceCO2Low, nciMinFlow]

and [nciSpaceCO2High, nciMaxFlow].

The air flow is set to the highest value of those coming from the

air quality control and the cooling controller according to

figure 5.5 below.

Air flow

nciMaxFlow

nciMinFlow

CO2 level

nciSpaceCO2Low nciSpaceCO2High

Figure 5.5 Air quality control

The air quality control can be enabled independent of the cooling

controller and is enabled in comfort and bypass mode only.

The carbon dioxide concentration can be measured by means of a

permanent carbon dioxide sensor. The controller transforms the

analogue 0–10 V signal into a concentration in ppm by

muliplying it with the variable nciCO2PerVolt (ppm/volt).

Alternatively, you can use a LonTalk carbon dioxide measuring

node connected to the variable nviSpaceCO2. If nviSpaceCO2

has a valid value, the variable has a higher priority than the

electrically connected sensor.

5:12 (16), 0-004-7516-1 (GB) TAC AB, 1999-08-18

Page 45

TAC Xenta 102 Handbook Functional description

Not to open or close the damper in vain, the CO2 level must differ

by more than ±30 ppm from the latest read value.

nvoSpaceCO2 shows current carbon dioxide level in the zone. If

nviSpaceCO2 has a valid value, the current carbon dioxide level

will be identical to the input.

Current CO2 level is always sent, no matter which options are

set in the variable nciAppOptions. Air quality control is enabled

when bit 5=1 in nciAppOptions.

Index Variable name Description

9

nvoSpaceCO2

18

nviSpaceCO2

24

nciAppOptions

33

nciMinFlow

nciMaxFlow

34

39

nciCO2PerVolt

40

nciSpaceCO2Low

41

nciSpaceCO2High

Zone CO2 sensor output

Zone CO2 input

Application options

Minimum flow

Maximum flow

Conversion factor ppm CO2 per volt

Zone CO2 for closed damper

Zone CO2 for open damper

5.3.4 Window contact

TAC Xenta 102 is designed to be able to limit the energy consumption when a window in the room is open. You can connect

a local sensor directly to the controller, digital input X3, or use

nviEnergyHoldOff. The energy hold off is enabled when either

of these signals indicate an open window. The energy hold off is

made by the controller being set to off mode.

To be able to use a sensor (local or connected to the network),

bit 1 in nciAppOptions must be set to 1.

nvoEnergyHoldOff has the value of the locally connected sensor.

This is true even if bit 1 in nciAppOptions is set to 0.

If the energy hold off has been active for 60 seconds the window

contact alarm cuts out, bit 2 in nvoAlarmstatus (only in economy

and off modes).

Index Variable name Description

3

10

19

24

5.3.5 Occupancy sensor

nvoAlarmstatus

nvoEnergyHoldOff

nviEnergyHoldOff

nciAppOptions

Alarm status output

Energy hold off output

Energy hold off input

Application options

There can be a sensor connected to TAC Xenta 102 to

determine whether someone is in the room or not. If there is no

occupancy sensor connected, the controller supposes that there

is always someone in the room. The controller uses the

information to determine whether the operation mode should be

comfort or economy. When the controller is used stand-alone,

the sensor is used to choose between comfort mode or off mode.

See table 5.1 in chapter 5.2.1.

TAC AB, 1999-08-18 0-004-7516-1 (GB), 5:13 (16)

Page 46

TAC Xenta 102 Handbook Functional description

The sensor can be connected either directly to the controller, input

X2, or via the network, nviOccSensor. To be able to use a directly

connected sensor, bit 0 in nciAppOptions must be set to 1. When

nviOccSensor has received a valid value, this is used, whether

there is a directly connected sensor or not.

Bit 8 in nciAppOptions indicates whether input X2 should mean

normally open (NO) or normally closed (NC). Bit 8=0 means

normally open, Bit 8=1 normally closed.

The directly connected sensor’s value is sent out on the network

in nvoOccSensor. If there is no sensor connected (according to

nciAppOptions), the value OC_NUL is sent out.

There is a 20 minute delay before the operation mode is