Page 1

Installation Instructions

Compact 32-point Solid-state 24V dc Source

Output Module

Catalog Number 1769-OB32T

Top ic Page

About the 1769-OB32T Module 5

Spare/Replacement Module Parts 6

Install the 1769-OB32T Module 6

Replace a Single Module Within a System 7

Mount Expansion I/O 8

Mount Module to Panel 9

Mount Module to DIN Rail 10

Output Wiring 10

Wiring Options for the I/O Module 12

Ground the 1769-OB32T Module 14

Label for the 1492 Interface Module 14

Assemble the Wire Contacts 15

Output Data File 16

Output Module’s Input Data File 16

Configuration File 17

Transistor Output Transient Pulses 20

Specifications 21

Additional Resources 23

About This Publication

Use this document as a guide when installing a Compact 32-point Solid-state 24V dc

Source Output Module.

Publication 1769-IN080A-EN-P - August 2006

Page 2

2 Compact 32-point Solid-state 24V dc Source Output Module

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you to identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be located on or inside the equipment, for example, a drive or motor, to

alert people that dangerous voltage may be present.

Labels may be located on or inside the equipment, for example, a drive or motor, to

alert people that surfaces may be at dangerous temperatures.

Publication 1769-IN080A-EN-P - August 2006

Page 3

Compact 32-point Solid-state 24V dc Source Output Module 3

Prevent Electrostatic Discharge

ATTENTION

Electrostatic discharge can damage integrated circuits or semiconductors if you

touch bus connector pins. Follow these guidelines when you handle the

module.

– Touch a grounded object to discharge static potential.

– Wear an approved wrist-strap grounding device.

– Do not touch the bus connector or connector pins.

– Do not touch circuit components inside the module.

– If available, use a static-safe work station.

– When not in use, keep the module in its static-shield box.

Remove Power

ATTENTION

Remove power before removing or inserting this module. When you remove or

insert a module with power applied, an electrical arc may occur. An electrical

arc can cause personal injury or property damage by:

– sending an erroneous signal to your system’s field devices, causing

– causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical resistance.

unintended machine motion.

Publication 1769-IN080A-EN-P - August 2006

Page 4

4 Compact 32-point Solid-state 24V dc Source Output Module

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

nonhazardous locations only. The following WARNING statement applies to use in

hazardous locations.

WARNING

Explosion Hazard

• Substitution of components may impair suitability for

Class I, Division 2.

• Do not replace components or disconnect equipment unless power is switched

off or the area is known to be nonhazardous.

• Do not connect or disconnect components unless power is switched off or the

area is known to be nonhazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

AVERTISSEMENT

Danger D’explosion

• La substitution de composants peut rendre cet équipement impropre à une

utilisation en environnement de Classe 1, Division 2.

• Ne pas remplacer de composants ou déconnecter l'équipement sans s'être

assuré que l'alimentation est coupée et que l'environnement est classé non

dangereux.

• Ne pas connecter ou déconnecter des composants sans s'être assuré que

l'alimentation est coupée ou que l'environnement est classé non dangereux.

• Ce produit doit être installé dans une armoire.

Publication 1769-IN080A-EN-P - August 2006

Page 5

Compact 32-point Solid-state 24V dc Source Output Module 5

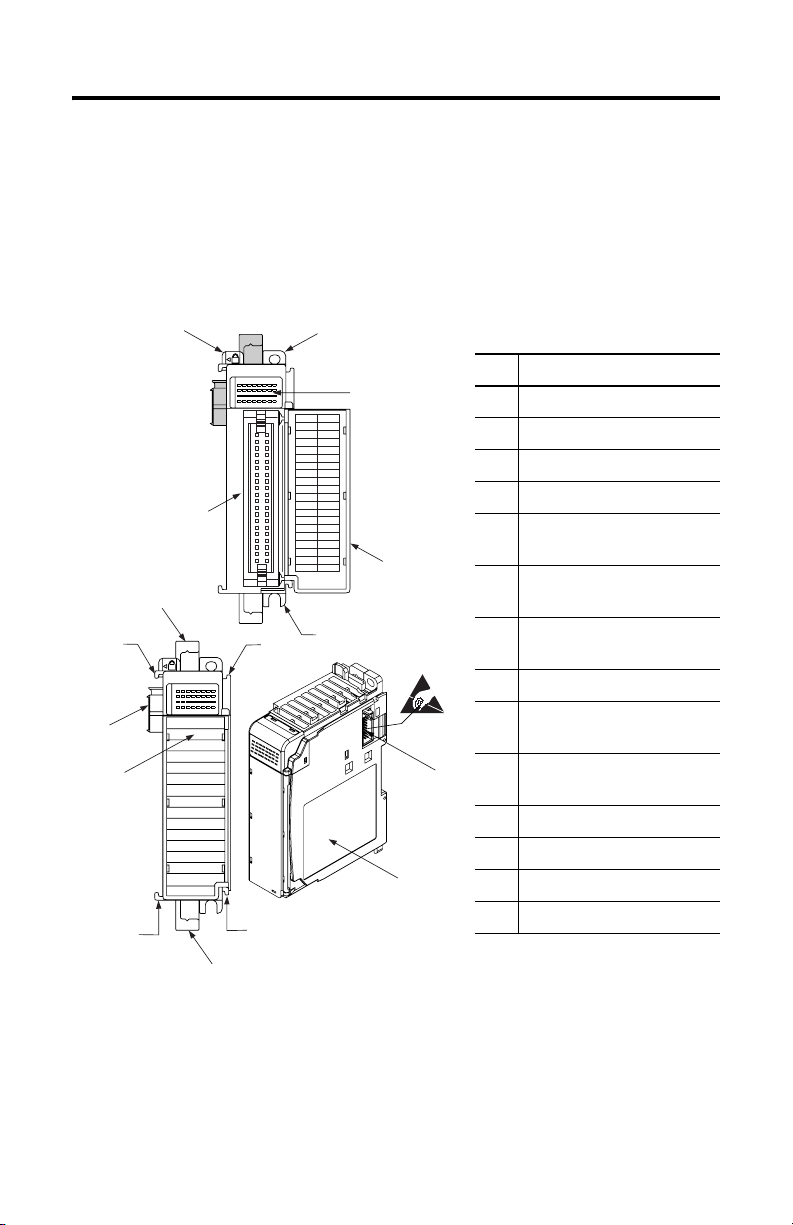

About the 1769-OB32T Module

Compact I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for use

in clean, dry environments (Pollution degree 2

(2)

Over Voltage Category II

(IEC 60664-1)

Module Description

1

10

8a

7a 7a

5a

9

7b 7b

8b

2a

+VDC2

+VDC1

+VDC2

+VDC1

OUT 16

OUT 0

OUT 17

OUT 1

OUT 18

OUT 2

OUT 19

OUT 3

OUT 20

OUT 4

OUT 21

OUT 5

OUT 22

OUT 6

OUT 23

OUT 7

OUT 24

OUT 8

OUT 25

OUT 9

OUT 26

OUT 10

OUT 27

OUT 11

OUT 28

OUT 12

OUT 29

OUT 13

OUT 30

OUT 14

OUT 31

OUT 15

DC COM 1 DC COM 2

DC COM 2 DC COM 1

1769-OB32T

2b

3

(1)

) and to circuits not exceeding

(3)

.

Labels

Item Description

1 Bus lever (with locking function)

2a Upper-panel mounting tab

2b Lower-panel mounting tab

3 I/O diagnostic LED indicators

4 Module door with terminal

4

5b

6

31563A-M

identification label

5a Movable bus connector

with female pins

5b Stationary bus connector

with male pins

6 Nameplate label

7a Upper

tongue-and-groove slots

7b Lower

tongue-and-groove slots

8a Upper DIN-rail latch

8b Lower DIN-rail latch

9 Write-on label (user ID tag)

10 MIL-C-83503 connector

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally a

temporary conductivity caused by condensation is expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level, transient voltages are

controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Publication 1769-IN080A-EN-P - August 2006

Page 6

6 Compact 32-point Solid-state 24V dc Source Output Module

Spare/Replacement Module Parts

You can order the 1746-N3 connector kit, which contains one connector and 40 terminals.

Install the 1769-OB32T Module

Attach the module to the controller or an adjacent I/O module before or after

mounting.

For mounting instructions, see Mount Module to Panel Using the Dimensional

Template on page 9, or Mount Module to DIN Rail on page 10.

Refer to Replace a Single Module Within a System on page 7 to work with a system

that is already mounted.

3

4

2

1

1

5

6

30536-M

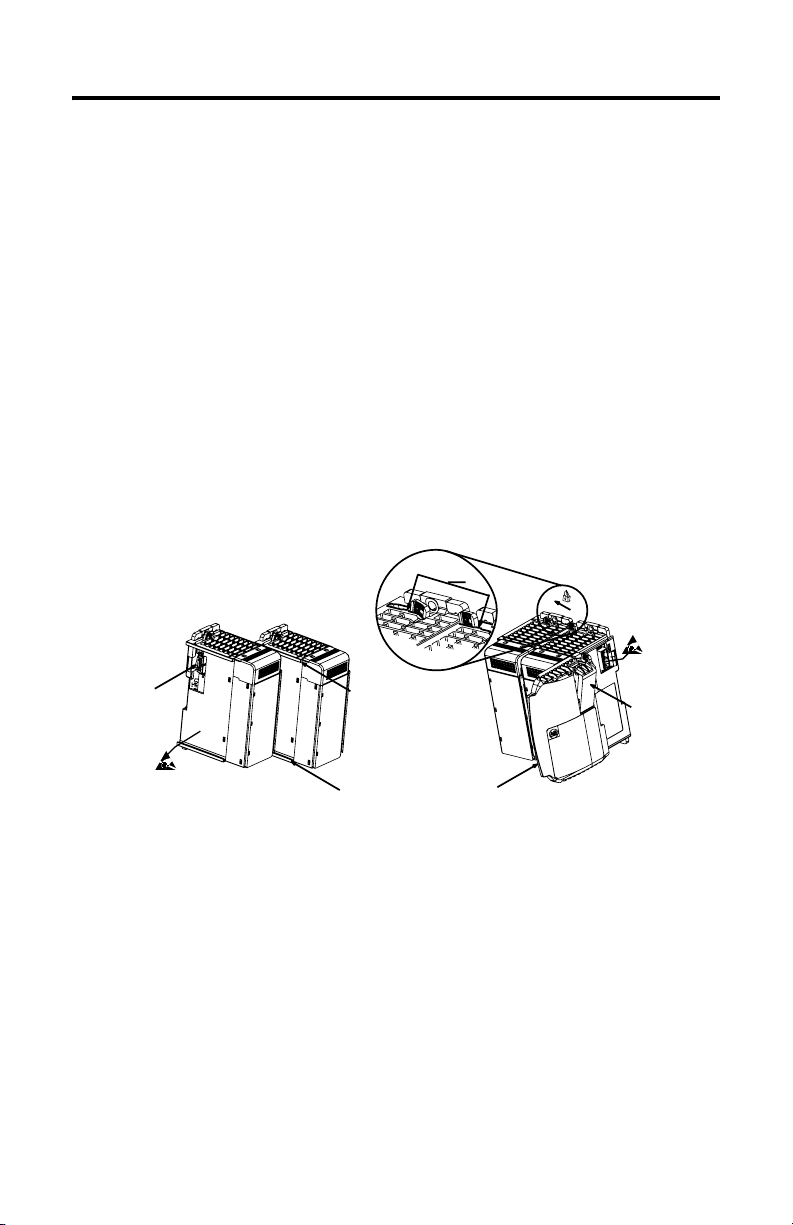

The following procedure shows you how to assemble the Compact I/O system.

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the unlocked

(fully-right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure the modules

together (or to a controller).

4. Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

Publication 1769-IN080A-EN-P - August 2006

Page 7

Compact 32-point Solid-state 24V dc Source Output Module 7

5. Use your fingers or a small screwdriver to push the bus lever back slightly to

clear the positioning tab (3).

6. To allow communication between the controller and module, move the bus

lever fully to the left (4) until it clicks, making sure it is locked firmly in

place.

ATTENTION

When attaching I/O modules, it is very important that the bus connectors are

securely locked together to be sure of proper electrical connection.

7. Attach an end-cap terminator (5) to the last module in the system by using

the tongue-and-groove slots as before.

8. Lock the end-cap bus terminator (6).

IMPORTANT

You must use a 1769-ECR or 1769-ECL right or left end cap to terminate the end

of the serial communication bus.

Replace a Single Module Within a System

The module can be replaced while the system is mounted to a panel (or DIN rail).

1. Remove power.

Refer to Remove Power on page 3.

2. Remove the upper and lower mounting screws from the module (or open

the DIN latches using a flat-blade or Phillips-style screwdriver).

3. Move the bus lever to the right to disconnect (unlock) the bus.

4. On the right-side adjacent module, move its bus lever to the right (unlock)

to disconnect it from the module to be removed.

5. Gently slide the disconnected module forward.

If you feel excessive resistance, check that the module is disconnected from

the bus and that both mounting screws are removed (or DIN latches

opened).

TIP

It may be necessary to rock the module slightly from front to back to remove it,

or, in a panel-mounted system, to loosen the screws of adjacent modules

Publication 1769-IN080A-EN-P - August 2006

Page 8

8 Compact 32-point Solid-state 24V dc Source Output Module

6. Be sure that the bus lever on the module and on the right-side adjacent

module are in the unlocked (fully-right) position before installing the

replacement module.

7. Slide the replacement module into the open slot.

8. Connect the modules by locking (fully-left) the bus levers on the

replacement module and the right-side adjacent module.

9. Replace the mounting screws (or snap the module onto the DIN rail).

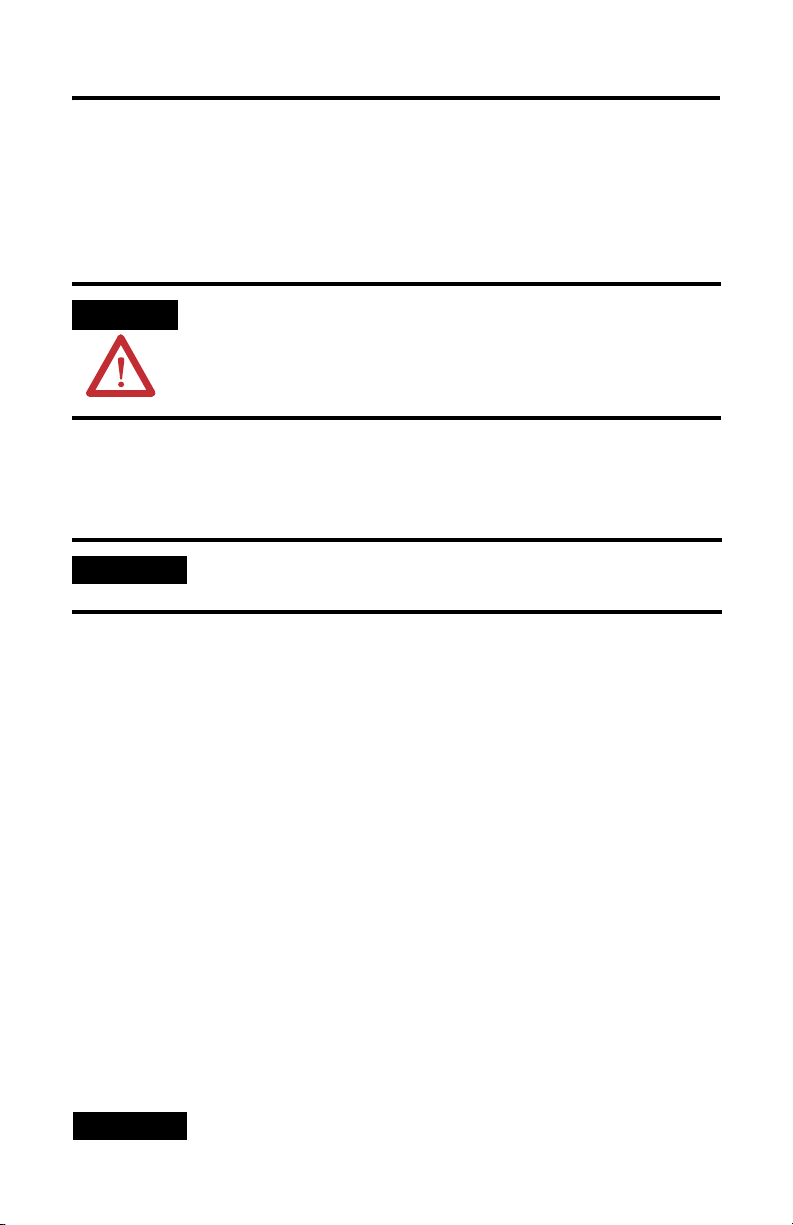

Mount Expansion I/O

ATTENTION

During panel or DIN rail mounting of all devices, be sure that all debris,

including metal chips or wire strands, is kept from falling into the module.

Debris that falls into the module could cause damage when cycling power.

Minimum Spacing

Maintain spacing from enclosure

walls, wireways, or adjacent

equipment. Allow 50 mm (2 in.) of

space on all sides for adequate

ventilation, as shown.

Top

Side Side

Controller

Compact I/O

Compact I/O

Bottom

Compact I/O

Compact I/O

End Cap

Compact I/O

Publication 1769-IN080A-EN-P - August 2006

Page 9

Compact 32-point Solid-state 24V dc Source Output Module 9

Mount Module to Panel

Mount the module to a panel using two screws per module. Use M4 or #8 panhead

screws. Mounting screws are required on every module.

Mount Module to Panel Using the Dimensional Template

Spacing for Single-wide Modules 35 mm (1.378 in.)

Spacing for One-and-a half-wide Modules 52.5 mm (2.067 in.)

Refer to Host Controller Documentation for This Dimension.

Host Controller

Overall hole spacing

tolerance: ±0.4 mm (0.016 in.).

Locate holes every 17.5 mm (0.689 in.) to allow for a mix of single-wide and

one-and-a-half-wide modules (for example, the 1769-OA16 module).

Mount Module to Panel Procedure Using Modules as a Template

This procedure lets you use the assembled modules as a template for drilling holes

in the panel. Due to module-mounting hole tolerance, it is important to follow this

procedure.

Refer to Mount Module to Panel Using the Dimensional Template on page 9 if you

have sophisticated panel-mounting equipment.

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screws.

5. Place the modules back on the panel, and check for proper hole alignment.

Publication 1769-IN080A-EN-P - August 2006

Page 10

10 Compact 32-point Solid-state 24V dc Source Output Module

6. Attach the modules to the panel using the mounting screws.

TIP

7. Repeat steps 1 to 6 for any remaining modules.

If mounting more modules, mount only the last one of this group and put the

others aside. This reduces the remounting time during drilling and tapping of

the next group.

Mount Module to DIN Rail

The module can be mounted using these DIN rails.

• 35 x 7.5 mm (EN 50 022 - 35 x 7.5)

• 35 x 15 mm (EN 50 022 - 35 x 15)

Before mounting the module on a DIN rail, close the DIN-rail latches. Press the

DIN-rail mounting area of the module against the DIN rail. The latches will

momentarily open and lock into place.

Output Wiring

ATTENTION

Publication 1769-IN080A-EN-P - August 2006

Accidentally wiring the module to an ac power source or applying reverse

polarity will damage the module.

Be careful when stripping wires. Wire fragments that fall into a module

could cause damage at power up. Once wiring is complete, ensure the

module is free of all metal fragments.

Page 11

Compact 32-point Solid-state 24V dc Source Output Module 11

Basic Wiring

(1)

of Output Devices

24V dc 24V dc

+VDC 1

+VDC 1

Simplified Output Circuit Diagram

VCC

(2)

to the 1769-OB32T Module

+VDC 2

+VDC 2

User SideLogic Side

G

VDC

S

TR1

ASIC

D

OUT

COM

(1)

Recommended Surge Suppression. Use a 1N4004 diode reverse-wired across the load for transistor outputs switching 24V

dc inductive loads. For additional details, refer to Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley

publication 1770-4.1.

(2)

Sourcing Output. Source describes the current flow between the I/O module and the field device. Sourcing output circuits

source current to sinking field devices. Field devices connected to the negative side (DC Common) of the field power supply

are sinking field devices. Europe: dc sinking input and sourcing output module circuits are the commonly used options.

Publication 1769-IN080A-EN-P - August 2006

Page 12

12 Compact 32-point Solid-state 24V dc Source Output Module

Wiring Options for the I/O Module

Included with your 32-point I/O module is a keyed 40-pin female connector and

crimp-type pins. These components let you wire I/O devices to the module using a

40-conductor cable or individual wires.

Refer to page 15 for connector/pin assembly instructions.

When assembled, align the female connector over the module’s male header using

the keying slot as a guide. Firmly lock them together with the upper and lower

retaining arms. 1492 pre-wired cables and interface modules can be used for

connecting external I/O.

There are two options for wiring the 32-point I/O module.

• Option 1 - Wire the 1746-N3 Connector

• Option 2 - Use Allen-Bradley 1492 Wiring Systems

Option 1 - Wire the 1746-N3 Connector

32-point

I/O Module

Keyed Female Connector (1746-N3)

Included with 32-point I/O Modules

Keyed Male

MIL-C-83503

Header

(1) Maximum cable length is dependent on how much voltage drop (current x (ohms/ft.) x (feet)) your system can tolerate. Your

system should take into account the minimum turn-on voltage required by external loads connected to the 32-point output

module, the minimum turn-on voltage required by the 32-point input module, and all of the voltage drops associated with

wiring to and from the load, sensors, terminal blocks, power sources and the module itself.

Panel Lights,

Buttons, Sensor

Contact pins provided with female

connector can accept 0.13…0.33 mm

(26…22 AWG) wires.

User Terminal Block (For

wire termination, refer to

page 14 for the wiring

diagrams of the I/O modules.)

(1)

31561-M

2

Publication 1769-IN080A-EN-P - August 2006

Page 13

Compact 32-point Solid-state 24V dc Source Output Module 13

Option 2 - Use Allen-Bradley 1492 Wiring Systems

32-point I/O Module

1492-CABLExx

(2)(3)

Connects 32-point Module

to DIN-rail Mountable

Male

MIL-C-83503

Header

Ter mina l Bl ock

8 mm (0.32 in.) REF.

0.2 to 4 mm2

(24 to 12 AWG)

(1)

1492-IFM40xx DIN-rail Mountable Terminal Block

31562-M

Allen-Bradley 1492 wiring systems are available for connecting 32-point I/O

modules to external I/O. These wiring systems include a pre-wired cable available

in four lengths: 0.5 m (1.6 ft), 1.0 m (3.3 ft), 2.5 m (8.2 ft), 5.0 m (16.4 ft). An

interface module for connecting external devices is also available. Cables are

equipped with keyed connectors at both ends for proper connections. Interface

modules are DIN-rail mountable and available with or without field-side status

indicating LED indicators. Stick-on labels are provided with the interface modules

to identify I/O-wiring termination points.

(1) To maintain group isolation provided by 32-point I/O modules, use a 1492 terminal block that provides group isolation.

Consult 1492 documentation or your Allen-Bradley Sales Office for additional information.

(2) Maximum cable length is dependent on how much voltage drop (current x (ohms/ft) x (ft)) your system can tolerate. Your

system should take into account the minimum turn-on voltage required by external loads connected to the 32-point output

module, the minimum turn-on voltage required by the 32-point input module, and all of the voltage drops associated with

wiring to and from the load, sensors, terminal blocks, power sources and the module itself. See the table on page

voltage drop values for the 1492 cables shown above.

(3) When using 1492-CABLExx, you won’t be able to close the I/O module door. Leave it open or detach the removable door.

13 for

Voltage Drop

Cat. No. Voltage Drop at 30 °C Voltage Drop at 60 °C

Series C cables V dc/dc com

(1)

wires

1492-CABLE005H 127 mV 34 mV 144 mV 38 mV

1492-CABLE010H 173 mV 45 mV 196 mV 51 mV

1492-CABLE025H 334 mV 83 mV 388 mV 95 mV

1492-CABLE050H 574 mV 147 mV 686 mV 169 mV

(1)

Voltage drop at max rated current of 2 A per conductor.

(2)

Voltage drop at max rated current of 0.5 A per output channel.

Output channel

(2)

wires

V dc/dc com wires Output channel

wires

Publication 1769-IN080A-EN-P - August 2006

Page 14

14 Compact 32-point Solid-state 24V dc Source Output Module

Ground the 1769-OB32T Module

This product is intended to be mounted to a well-grounded mounting surface such

as a metal panel. Additional grounding connections from the module’s mounting

tabs or DIN rail (if used) are not required unless the mounting surface cannot be

grounded.

Refer to Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley

publication 1770-4.1, for additional information.

Label for the 1492 Interface Module

Several different stick-on label sets are provided on a single card with 1492

interface modules. Each label set is identified with an I/O module catalog number

and words upper and lower to identify to which terminal strip the label should be

affixed.

The Terminal Block Labels table identifies the 1769-OB32T 32-point labels and their

location on the interface module. Peel off the appropriate label and apply it to the

interface module.

Terminal Block Labels

Bottom Terminal Block Top Terminal Block

+V1

+V1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CM1

CM1

+V2

+V2

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

CM2

CM2

Publication 1769-IN080A-EN-P - August 2006

Page 15

Compact 32-point Solid-state 24V dc Source Output Module 15

The 1492 interface module stick-on labels are abbreviated as follows: +V1 = V dc 1,

+V2 = V dc 2, CM1 = Com 1, and so on.

TIP

If the 1769-OB32T stick-on label set is not available, use the 1492 interface module

stick-on label set for 1746-OB32 modules.

If you decide to build your cable using another 1746-N3 to terminate the

cable at the 1492 interface-module end, wire it in the following manner:

Pin 1 to Pin 1, Pin 2 to Pin 2, Pin 3 to Pin 3, and so on.

Assemble the Wire Contacts

1. Strip the wire insulation (1).

Refer to the graphic under Step 4. Crimp pins can accept 0.13….33 mm2

(26…22 AWG) wire.

2. Insert the wire up to the wire stop (2).

3. Crimp with DDK crimp tool 357J-5538.

Equivalent Amp part numbers are: pin - #87666-2, connector - #102387-9,

and crimp tool - #90418-1.

TIP

If a crimp tool is not available, use the following crimping procedure:

Pins and connectors from different manufacturers cannot be

assembled together. For example, Amp pins cannot be used with a

DDK connector.

a. Crimp the wire barrel around the wire using small needle-nose pliers.

b. Crimp the insulation barrel around the wire insulation using small

needle-nose pliers.

c. Solder wire and wire barrel together using rosin core

(60% tin/40% lead) solder and soldering pencil.

Publication 1769-IN080A-EN-P - August 2006

Page 16

16 Compact 32-point Solid-state 24V dc Source Output Module

4. Insert the wire contact into the socket (3) (4).

Make sure that the tang (4) is properly latched by lightly pulling on the wire.

4 mm

4 mm

(5/32 in)

4 mm

4 mm

(5/32 in)

(5/32 in)

(1)

(5/32 in)

(2)

Wire

Stop

A

A

Tang

(3)

(4)

Output Data File

For each module, slot x, words 0…1 in the output data file contain the control

program’s directed state of the digital output points.

Output Data File

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

0wwwwwwwwwwwwwwww

1wwwwwwwwwwwwwwww

w = write

Output Module’s Input Data File

For each module, slot x, input data file words 0…1 contain the state of the

module’s output data (output data echo) file words 0…1. During normal operation,

these input bits represent the logic state that the outputs are directed to by the

control program. They are also dependent upon the:

• Program mode configuration (if supported by the controller).

• Fault mode configuration (if supported by the controller).

Publication 1769-IN080A-EN-P - August 2006

Page 17

Compact 32-point Solid-state 24V dc Source Output Module 17

Output Module’s Input Data File

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

0 r r r r r r r r r r r r r r r r

1 r r r r r r r r r r r r r r r r

r = read

IMPORTANT

The output module’s input data file reflects the output data echo of the

module, not necessarily the electrical state of the output terminals. It does not

reflect shorted or open outputs.

It is important to use this input word if the controller adapter supports the

Program mode or Fault mode function, and if it is configured to use them.

Configuration File

The read/writable configuration data file allows the setup of the hold last state and

user-defined safe-state conditions.

Manipulate these bits with programming software, such as, RSLogix 500 or

RSNetWorx for DeviceNet, during initial configuration of the system. In that case,

graphical screens are provided via the programmer to simplify configuration.

However, some systems, such as, 1769-ADN DeviceNet Adapter, also allow the bits

to be altered as part of the control program using communication rungs. In that

case, it is necessary to understand the bit arrangement.

Configuration File

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 PFE

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

2 Program State for Output Array Word 0

3 Program State for Output Array Word 1

4 Program Value for Output Array Word 0

5 Program Value for Output Array Word 1

6 Fault State for Output Array Word 0

7 Fault State for Output Array Word 1

8 Fault Value for Output Array Word 0

Publication 1769-IN080A-EN-P - August 2006

Page 18

18 Compact 32-point Solid-state 24V dc Source Output Module

Configuration File

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

9 Fault Value for Output Array Word 1

10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

12 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

13 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

14 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

15 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Program State Word

Condition Bit Setting

Word 1, the program state word, selects the hold

last state or user-defined safe state condition for

each individual output on a system transition

User-defined safe state 0

Hold last state 1

from Run to Program.

Program Value Word

The program value word, word 2, is used to

program the user-defined safe state value (0=Off,

1=On). Each output is individually configurable

for on or off.

Value Bit Setting

Off 0

On 1

Fault State Word

Word 3, the fault state word, selects the hold last

state or user-defined safe state condition for each

individual output on a system transition from Run

to Fault.

Fault Value Word

The fault value word, word 4, is used to program

the fault state value (0=Off, 1=On). Each output

is individually configurable for on or off.

Publication 1769-IN080A-EN-P - August 2006

Condition Bit Setting

User-defined safe state 0

Hold last state 1

Value Bit Setting

Off 0

On 1

Page 19

Compact 32-point Solid-state 24V dc Source Output Module 19

Program to Fault Enable Bit (PFE)

Word 0, bit 0, allows the selection of which data

value, the program or fault value, to apply to the

output if a system in Program mode undergoes a

system fault, resulting a change to Fault mode.

Value Applied Bit Setting

Program 0

Fault 1

Module Default Condition

The module’s default condition is all zeros, programming the conditions shown.

Program Conditions

Word or Bit Affected Condition Applied

Word 0, Bit 0 Program-to-fault Enable Program value

Word 1 Program state User-defined safe state

Word 2 Program value Off

Word 3 Fault state User-defined safe state

Word 4 Fault value Off

Publication 1769-IN080A-EN-P - August 2006

Page 20

20 Compact 32-point Solid-state 24V dc Source Output Module

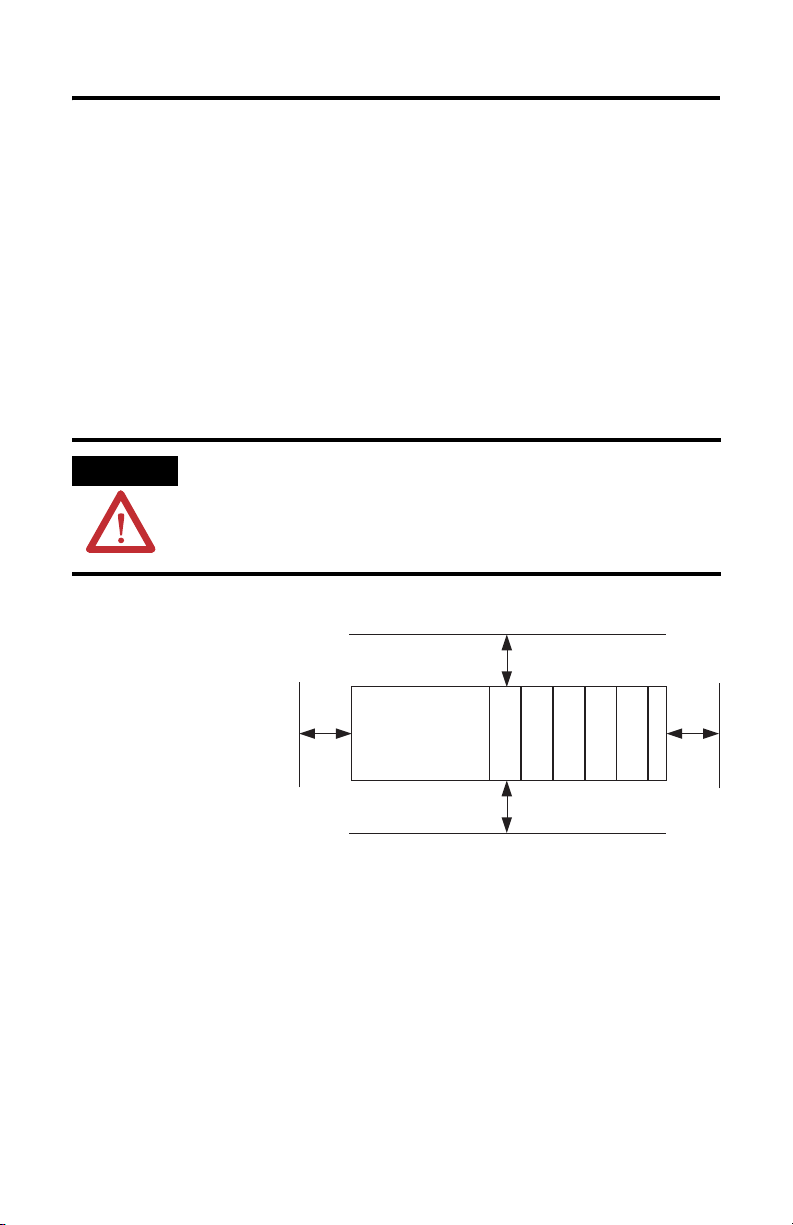

Transistor Output Transient Pulses

The maximum duration of the transient pulse occurs when minimum load is

connected to the output. However, for most applications, the energy of the

transient pulse is not sufficient to energize the load.

ATTENTION

The Transient Pulse Duration as a Function of Load Current graph illustrates that

the duration of the transient is inversely proportional to the load current. Therefore,

as the on-state load current increases, the transient pulse decreases. Power-up

transients do not exceed the time duration shown below, for the amount of loading

indicated, at 60 °C (140 °F).

A transient pulse occurs in transistor outputs when the external dc supply

voltage is applied to the output common terminals (for example, via the

master-control relay). The sudden application of voltage creates this

transient pulse. This condition is inherent in transistor outputs and is

common to solid state devices. A transient pulse can occur regardless of the

controller having power or not. Refer to your controller’s user manual to

reduce inadvertent operation.

Transient Pulse Duration as a Function of Load Current

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Time-Duration of transient (mS)

0.2

0.1

0.0

On-State Load Current (mA)

Publication 1769-IN080A-EN-P - August 2006

10009008007006005004003002001001

30519-M

Page 21

Compact 32-point Solid-state 24V dc Source Output Module 21

Specifications

Compact 32-point Solid-state 24V dc Source Output Module - 1769-OB32T

Attribute Value

Voltage Category 24V dc

Operating Voltage Range

Number of Outputs 32

Bus Current Draw, Max 220 mA @ 5V dc (1.10 W)

Heat Dissipation 4.76 Total W (The W per point, plus the min W, with all points

Signal Delay, Max – Resistive

Load

Off-state Leakage, Max

On-state Current, Min 1.0 mA

On-state Voltage Drop, Max 0.3V dc @ 0.5 A

Continuous Current Per Point, Max 0.5 A

Continuous Current Per Common,

Max

Continuous Current Per Module,

Max

Surge Current, Max

Dimensions (HxDxW), Approx. 118 x 87 x 35 mm (4.65 x 3.43 x 1.38 in.)

Approximate Shipping Weight

(with carton), Approx.

Power Supply Distance Rating 8 (The module may not be more than 8 modules away from the power

Output Point to Bus Isolation Verified by one of the following dielectric tests: 1200V ac for 2 s or

(1)

(2)

10.2…26.4V dc (source)

energized.)

Turn-on = 0.5 ms

Turn-off = 4.0 ms

0.1 mA @ 26.4V dc

2.0 A

4.0 A

2.0 A (Repeatability is once every 2 s for a duration of 10 ms.)

Height including mounting tabs is 138 mm (5.43 in.)

230 g (0.51 lbs)

supply.)

1697V dc for 2 s

(3)

75V dc working voltage (IEC Class 2 reinforced insulation)

Isolated Groups Group 1: outputs 0…15 (internally connected to DC COM 1)

Group 2: outputs 16…31 (internally connected to DC COM 2)

Vendor I.D. Code 1

Product Type Code 7

Product Code 79

Publication 1769-IN080A-EN-P - August 2006

Page 22

22 Compact 32-point Solid-state 24V dc Source Output Module

(1)

Typical Loading Resistor - To limit the effects of leakage current through solid state outputs, a loading resistor can be

connected in parallel with your load. Use a 56 k ohm, 1/4 W resistor for this module’s outputs, 24V dc operation.

(2)

Recommended Surge Suppression - Use a 1N4004 diode reverse-wired across the load for transistor outputs switching 24V

dc inductive loads. For additional details, refer to Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley

publication 1770-4.1.

(3)

Sourcing output - source describes the current flow between the I/O module and the field device. Sourcing output circuits

source current to sinking field devices. Field devices connected to the negative side (DC Common) of the field power supply

are sinking field devices. Europe: dc sinking input and sourcing output module circuits are the commonly used options.

Environmental Specifications

Attribute Value

Storage temperature -40…85 °C (-40…185°F)

Operating temperature 0…60 °C (32…140 °F)

Operating humidity 5…95% noncondensing

Operating altitude 2000 m (6561 ft)

Vibration, operating 10…500 Hz, 5 g, 0.030 in. max peak-to-peak

Shock, operating 30 g panel mounted (20 g DIN-rail mounted)

Shock, nonoperating 40 g panel mounted (30 g DIN-rail mounted)

Radiated and conducted emissions EN50081-2 Class A

Electrical /EMC The module has passed testing at the following levels

ESD immunity (IEC61000-4-2) 4 kV contact, 8 kV air, 4 kV indirect

Radiated immunity (IEC61000-4-3) 10V/m, 80…1000 MHz, 80% amplitude

Fast transient burst (IEC61000-4-4) 2 kV, 5 kHz

Surge immunity (IEC61000-4-4) 2 kV common mode, 1 kV differential mode

Conducted immunity

(IEC61000-4-6)

(1)

Conducted Immunity frequency range may be 150 kHz…30 MHz if the radiated immunity frequency range is 30…1000 MHz.

10V, 0.15…80 MHz

(1)

Certifications

Certification Value

Agency certification

(1)

Hazardous environment class Class I, Division 2, Hazardous Location, Groups A, B, C, D

(1)

See the Product Certification link at http://www.ab.com for Declarations of Conformity, certificates, and other certification

details.

Publication 1769-IN080A-EN-P - August 2006

• C-UL certified (under CSA C22.2 No. 142)

• UL 508 listed

• CE compliant for all applicable directives

(UL 1604, C-UL under CSA C22.2 No. 213)

Page 23

Compact 32-point Solid-state 24V dc Source Output Module 23

Additional Resources

You can view or download publications at

http://literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Rockwell Automation distributor or sales

representative.

Related Documentation

For Refer to This Document Pub. No.

A more detailed description of how to use

your Compact I/O with MicroLogix 1200/1500

programmable controllers

A more detailed description of how to install

and use your Compact I/O system with the

1769-ADN DeviceNet adapter

A more detailed description of how to install

and use your Compact I/O system with the

CompactLogix system

More information on proper wiring and

grounding techniques

MicroLogix 1200 and MicroLogix

1500 Programmable Controllers

Reference Manual

1769-ADN DeviceNet Adapter User

Manual

CompactLogix System User Manual 1769-UM007

Industrial Automation Wiring and

Grounding Guidelines

1764-RM001

1769-UM001

1770-4.1

Publication 1769-IN080A-EN-P - August 2006

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using its

products. At http://support.rockwellautomation.com

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of

these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information, contact your

local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

United States 1.440.646.3223 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any technical

support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number (see

Outside United States Please contact your local Rockwell Automation representative for return procedure.

Compact I/O, MicroLogix, CompactLogix, RSLogix 500, RSNetWorx for DeviceNet, Allen-Bradley, and Rockwell Automation

are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

phone number above to obtain one) to your distributor in order to complete the return

process.

, you can find technical manuals, a

Publication 1769-IN080A-EN-P - August 2006 PN 40071-219-01(1)

Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

´H',3!¶1d¨

Loading...

Loading...