Page 1

Installation Instructions

Compact I/O 1769-IF8 Analog Input Module

Inside

Module Description .................................................................................. 2

Module Installation...................................................................................3

System Assembly......................................................................................4

Mounting Expansion I/O ........................................................................... 5

Replacing a Single Module within a System ........................................... 7

Module Spare/Replacement Parts ...........................................................8

Field Wiring Connections..........................................................................8

I/O Memory Mapping .............................................................................13

Specifications ......................................................................................... 24

Hazardous Location Considerations .......................................................27

Environnements dangereux ....................................................................27

For More Information..............................................................................28

Publication 1769-IN067B-EN-P - September 2005

Page 2

2 Compact I/O 1769-IF8 Analog Input Module

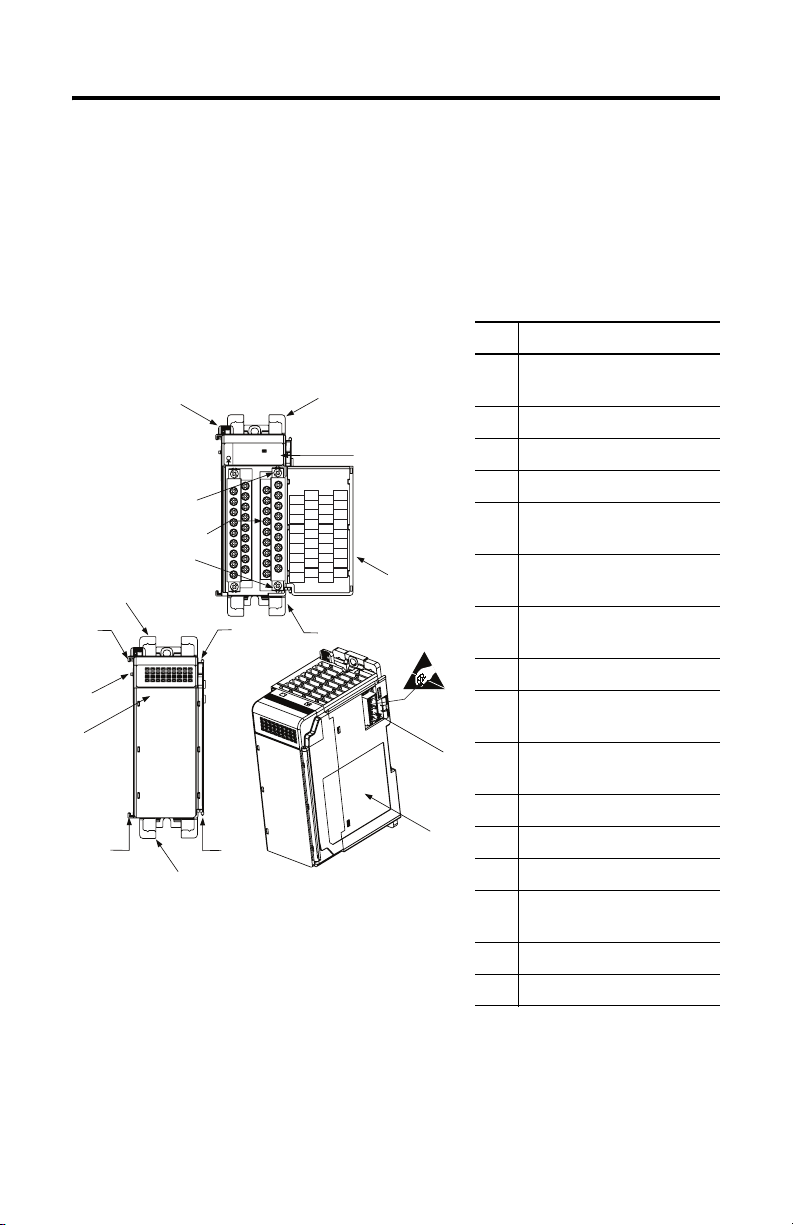

Module Description

V/I in 0-

ANLG Com

V/I in 1-

ANLG Com

V/I in 2-

ANLG Com

V/I in 3-

ANLG Com

NC

2a

WARNING -Do Not

Remove RTB Unless

Area is Non-Hazardous

V in 0+

V/I in 4-

I in 0+

ANLG Com

V in 1+

V/I in 5-

I in 1+

ANLG Com

V in 2+

V/I in 6-

I in 2+

ANLG Com

V in 3+

V/I in 7-

I in 3+

ANLG Com

NC

1769-IF8

2b

3

V in 4+

I in 4+

V in 5+

I in 5+

V in 6+

I in 6+

V in 7+

I in 7+

NC

NC

1

OK

INPUT

Analog

10a

10

10b

8a

7a

7a

5a

9

7b

7b

8b

Item Description

1 bus lever

(with locking function)

2a upper panel mounting tab

2b lower panel mounting tab

3 module status LED

4 module door with terminal

identification label

4

5a movable bus connector

with female pins

5b stationary bus connector

with male pins

6 nameplate label

7a upper

tongue-and-groove slots

7b lower

5b

tongue-and-groove slots

8a upper DIN rail latch

6

8b lower DIN rail latch

9 write-on label (user ID tag)

10 removable terminal block (RTB)

with finger-safe cover

10a RTB upper retaining screw

10b RTB lower retaining screw

Publication 1769-IN067B-EN-P - September 2005

Page 3

Compact I/O 1769-IF8 Analog Input Module 3

Module Installation

Compact I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for use

in clean, dry environments (Pollution degree 2

Over Voltage Category II

(2)

(IEC 60664-1).

Prevent Electrostatic Discharge

(1)

) and to circuits not exceeding

(3)

ATTENTION

Remove Power

ATTENTION

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch bus connector pins or the terminal

block. Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When not in use, keep the module in its static-shield box.

Remove power before removing or inserting this module. When

you remove or insert a module with power applied, an electrical

arc may occur. An electrical arc can cause personal injury or

property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally a

temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level transient voltages are

controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Publication 1769-IN067B-EN-P - September 2005

Page 4

4 Compact I/O 1769-IF8 Analog Input Module

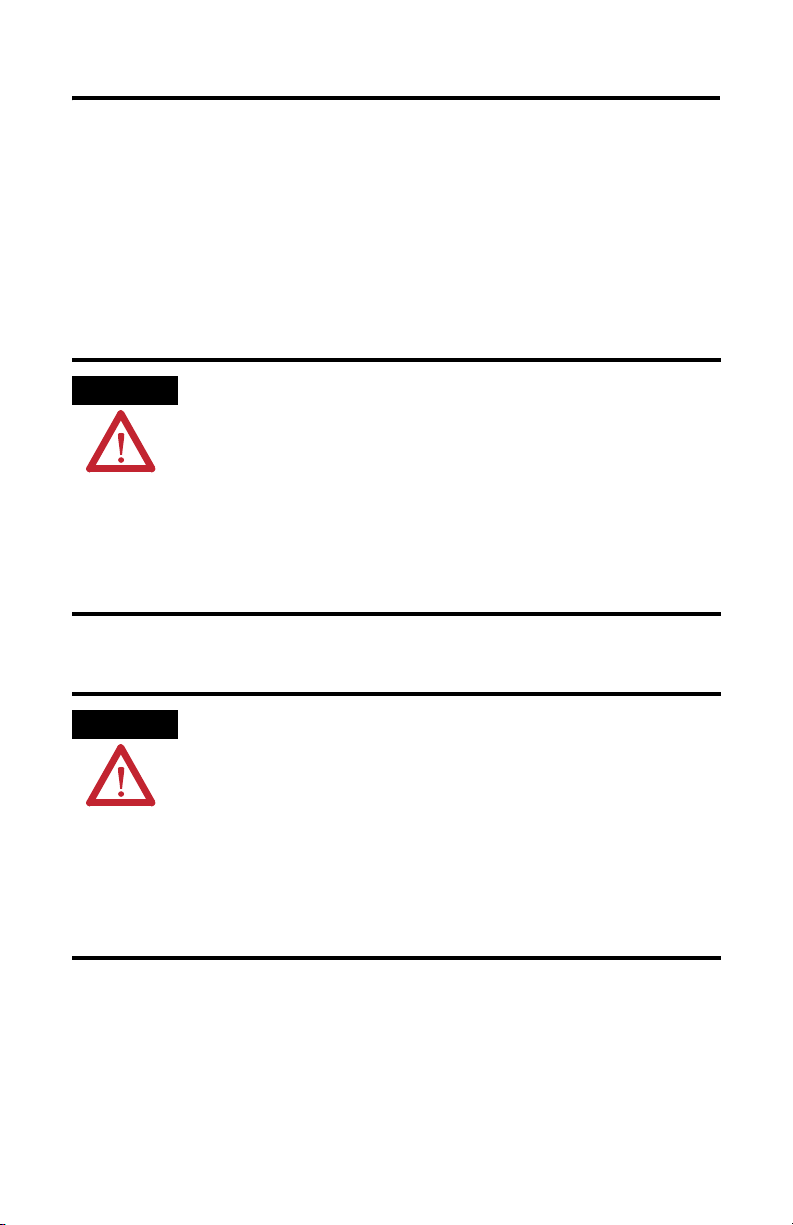

System Assembly

The module can be attached to the controller or an adjacent I/O module before or

after mounting. For mounting instructions, see “Panel Mounting” on page 6, or

“DIN Rail Mounting” on page 7. To work with a system that is already mounted, see

“Replacing a Single Module within a System” on page 7.

The following procedure shows you how to assemble the Compact I/O system.

3

4

2

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the unlocked

(fully right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure the modules

together (or to a controller).

4. Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

5. Push the bus lever back slightly to clear the positioning tab (3). Use your

fingers or a small screwdriver.

1

1

5

6

30536-M

Publication 1769-IN067B-EN-P - September 2005

Page 5

Compact I/O 1769-IF8 Analog Input Module 5

6. To allow communication between the controller and module, move the bus

lever fully to the left (4) until it clicks. Ensure it is locked firmly in place.

ATTENTION

When attaching I/O modules, it is very important that the bus

connectors are securely locked together to ensure proper

electrical connection.

7. Attach an end cap terminator (5) to the last module in the system by using

the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (6).

IMPORTANT

A 1769-ECR or 1769-ECL right or left end cap must be used to

terminate the end of the communication bus.

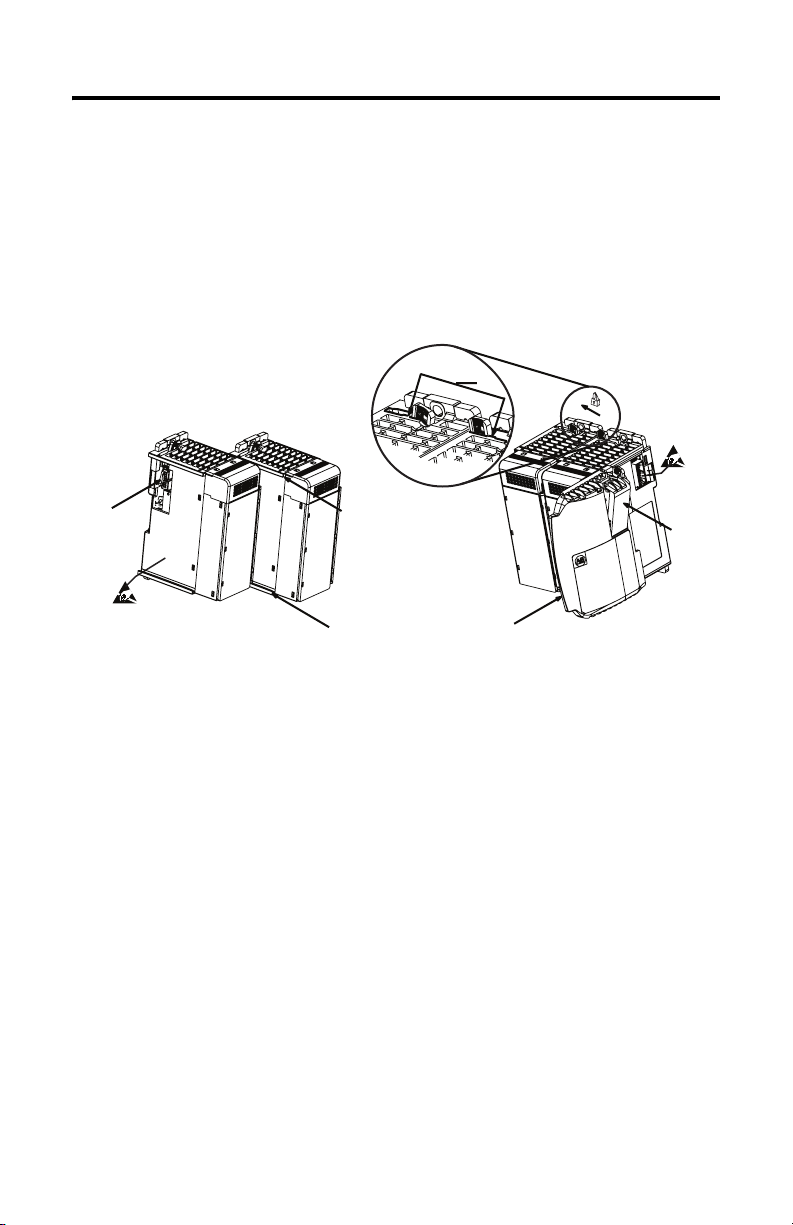

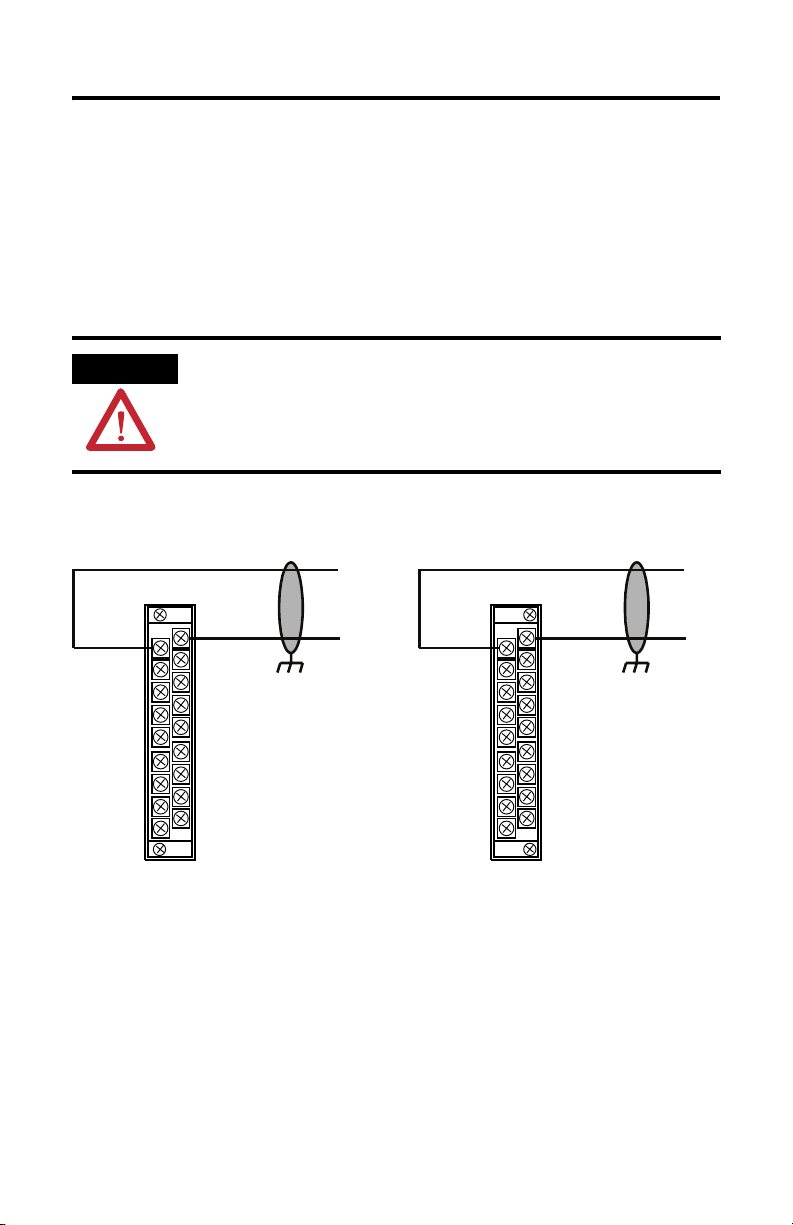

Mounting Expansion I/O

ATTENTION

During panel or DIN rail mounting of all devices, be sure that all

debris (metal chips, wire strands, etc.) is kept from falling into the

module. Debris that falls into the module could cause damage on

power up.

Minimum Spacing

Maintain spacing from

enclosure walls,

wireways, adjacent

equipment, etc. Allow 50

mm (2 in.) of space on all

sides for adequate

ventilation, as shown:

Top

Host Controller

Side Side

Compact I/O

Bottom

Compact I/O

Compact I/O

End Cap

Compact I/O

Compact I/O

Publication 1769-IN067B-EN-P - September 2005

Page 6

6 Compact I/O 1769-IF8 Analog Input Module

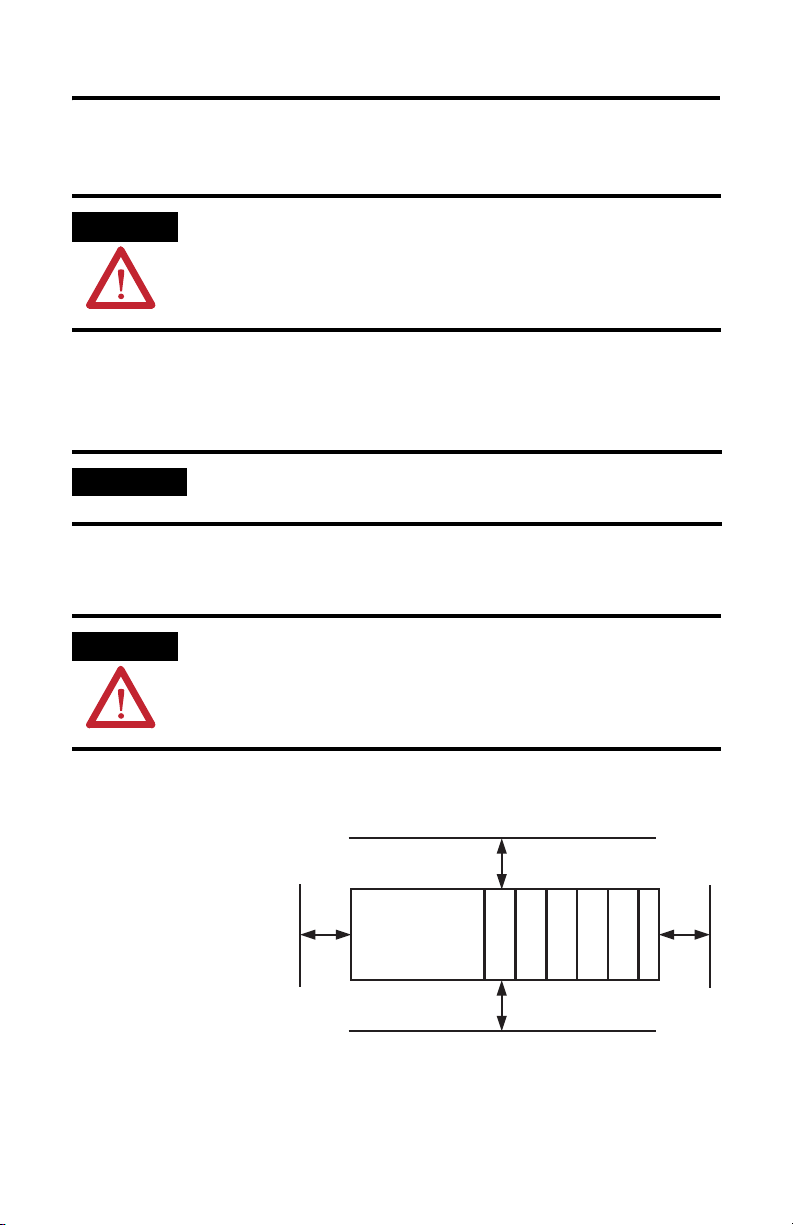

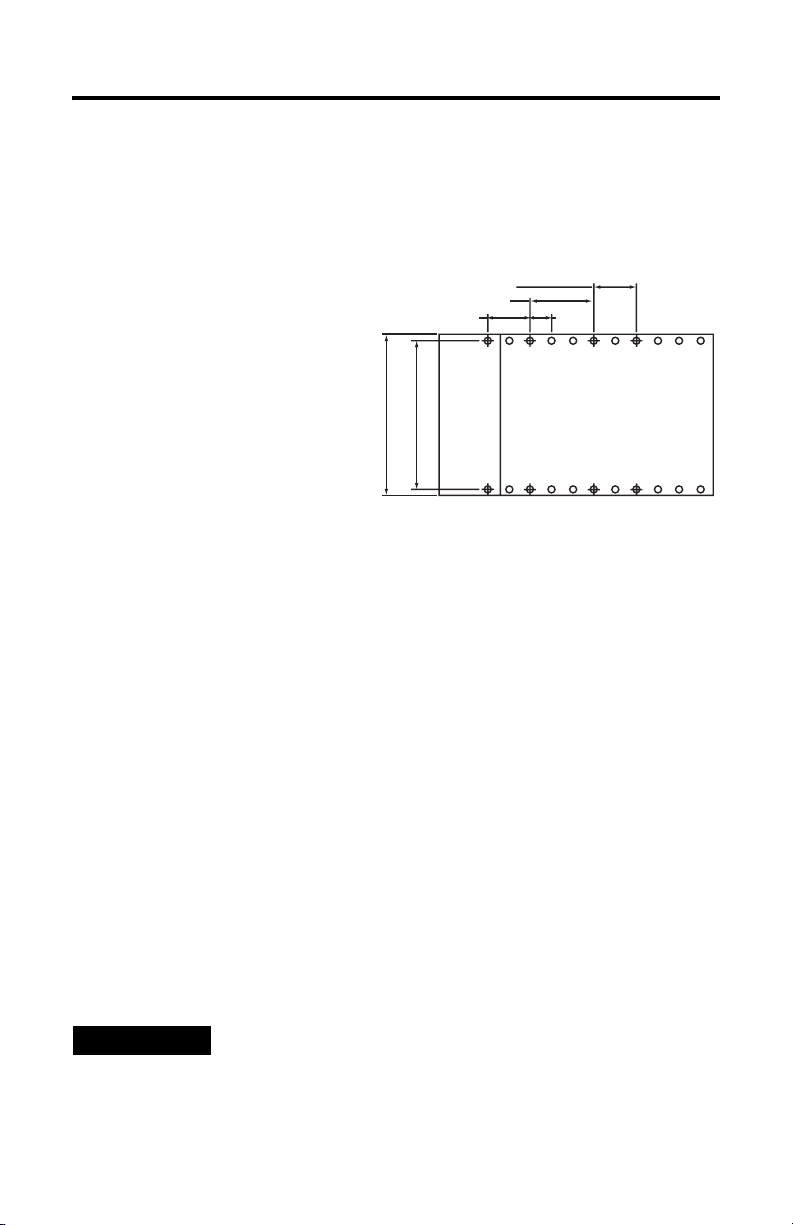

Panel Mounting

Mount the module to a panel using two screws per module. Use M4 or #8 panhead

screws. Mounting screws are required on every module.

Panel Mounting Using the Dimensional Template

Spacing for one-and-a-half-wide modules 52.5 mm (2.067 in).

Spacing for single-wide modules 35 mm (1.378 in).

Refer to host controller documentation for this dimension.

NOTE: Overall hole spacing

tolerance: ±0.4 mm (0.016 in.)

l Mounting

Locate holes every 17.5 mm (0.689 in) to allow for a

mix of single-wide and one-and-a-half-wide modules

(e.g., 1769-OA16).

Host Controller

Panel Mounting Procedure Using Modules as a Template

The following procedure allows you to use the assembled modules as a template

for drilling holes in the panel. If you have sophisticated panel mounting equipment,

you can use the dimensional template provided on

mounting hole tolerance, it is important to follow these procedures:

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel and check for proper hole alignment.

6. Attach the modules to the panel using the mounting screws.

NOTE

If mounting more modules, mount only the last one of this

group and put the others aside. This reduces remounting time

during drilling and tapping of the next group.

page 6. Due to module

7. Repeat steps 1 to 6 for any remaining modules.

Publication 1769-IN067B-EN-P - September 2005

Page 7

Compact I/O 1769-IF8 Analog Input Module 7

DIN Rail Mounting

The module can be mounted using the following DIN rails: 35 x 7.5 mm (EN 50 022

- 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latches. Press the DIN

rail mounting area of the module against the DIN rail. The latches will momentarily

open and lock into place.

Replacing a Single Module within a System

The module can be replaced while the system is mounted to a panel (or DIN rail).

Follow these steps in order:

1. Remove power. See important note on page 3.

2. On the module to be removed, remove the upper and lower mounting

screws from the module (or open the DIN latches using a flat-blade or

phillips-style screwdriver).

3. Move the bus lever to the right to disconnect (unlock) the bus.

4. On the right-side adjacent module, move its bus lever to the right (unlock)

to disconnect it from the module to be removed.

5. Gently slide the disconnected module forward. If you feel excessive

resistance, check that the module has been disconnected from the bus and

that both mounting screws have been removed (or DIN latches opened).

NOTE

6. Before installing the replacement module, be sure that the bus lever on the

module to be installed, and on the right-side adjacent module are in the

unlocked (fully right) position.

7. Slide the replacement module into the open slot.

8. Connect the modules together by locking (fully left) the bus levers on the

replacement module and the right-side adjacent module.

9. Replace the mounting screws (or snap the module onto the DIN rail).

It may be necessary to rock the module slightly from front to

back to remove it, or, in a panel-mounted system, to loosen

the screws of adjacent modules.

Publication 1769-IN067B-EN-P - September 2005

Page 8

8 Compact I/O 1769-IF8 Analog Input Module

Module Spare/Replacement Parts

• Terminal block, catalog number 1769-RTBN18 (1 per kit)

Field Wiring Connections

Grounding the Module

This product is intended to be mounted to a well-grounded mounting surface such

as a metal panel. Additional grounding connections from the module’s mounting

tabs or DIN rail (if used), are not required unless the mounting surface cannot be

grounded. Refer to Industrial Automation Wiring and Grounding Guidelines,

Allen-Bradley publication 1770-4.1, for additional information.

System Wiring Guidelines

Consider the following when wiring your system:

• All module commons (ANLG COM) are connected in the analog module.

The analog common (ANLG COM) is not connected to earth ground inside

the module.

• Do not use the analog module’s NC terminals as connection points.

• Channels are not isolated from each other.

• Use Belden™ 8761, or equivalent, shielded wire.

• Under normal conditions, the drain wire and shield junction must be

connected to earth ground via a panel or DIN rail mounting screw at the

analog I/O module end. Keep the shield connection to ground as short as

possible.

• To ensure optimum accuracy, limit overall cable impedance by keeping your

cable as short as possible. Locate the I/O system as close to your sensors or

actuators as your application will permit.

• If multiple power supplies are used with analog inputs, the power supply

commons must be connected.

(1)

In environments where high-frequency noise may be present, it may be necessary to directly ground cable shields to earth

at the module end and via a 0.1µF capacitor at the sensor end.

Publication 1769-IN067B-EN-P - September 2005

(1)

Page 9

Compact I/O 1769-IF8 Analog Input Module 9

+

–

–

• The 1769-IF8 module does not provide loop power for analog inputs. Use a

power supply that matches the input transmitter specifications.

• Differential analog inputs are more immune to noise than single-ended

analog inputs.

• Voltages on Vin+, V/Iin-, and Iin+ of the 1769-IF8 module must be within

±10V dc of analog common.

ATTENTION

Be careful when stripping wires. Wire fragments that fall into a

module could cause damage at power up. Once wiring is

complete, ensure the module is free of all metal fragments.

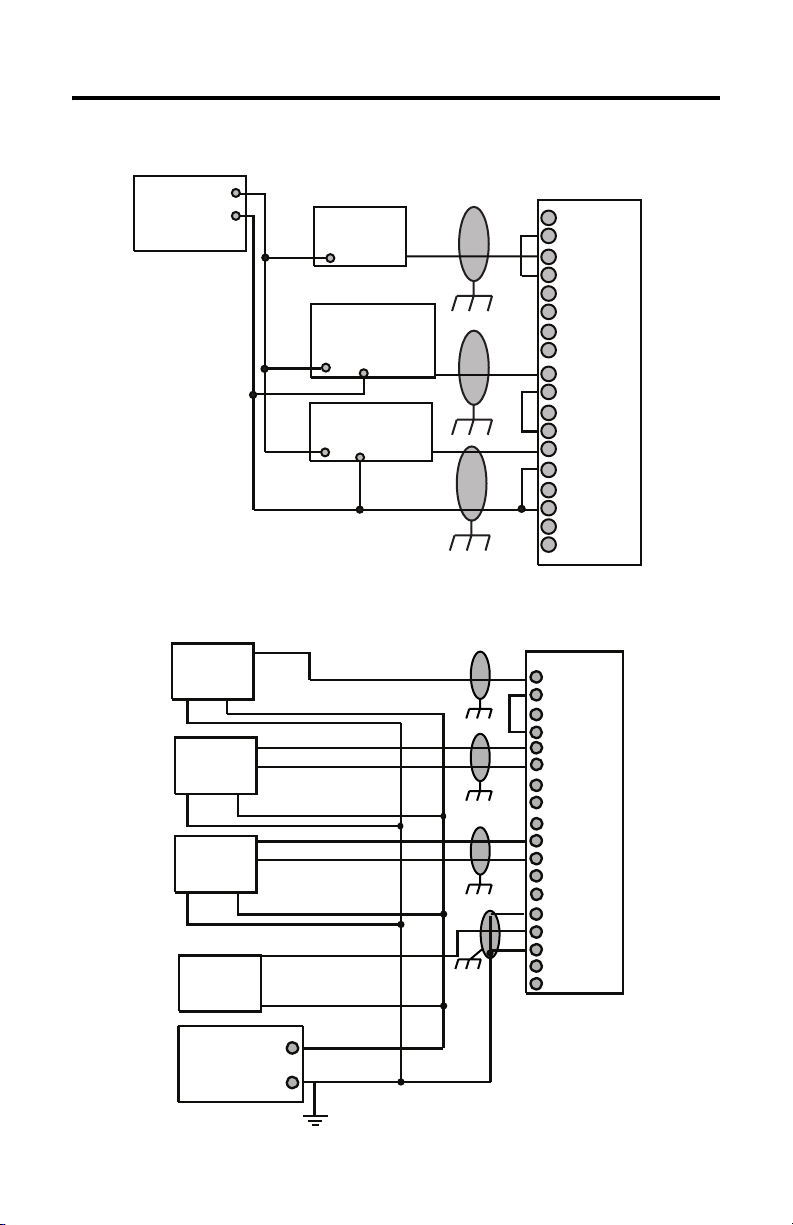

Wiring Differential Inputs

Belden 8761 cable (or equivalent)

V/I in 0-

ANLG Com

V/I in 1-

ANLG Com

V/I in 2-

ANLG Com

V/I in 3-

ANLG Com

NC

V in 0+

I in 0+

V in 1+

I in 1+

V in 2+

I in 2+

V in 3+

I in 3+

NC

+

earth ground the

shield locally at

the module

V/I in 4-

ANLG Com

V/I in 5-

ANLG Com

V/I in 6-

ANLG Com

V/I in 7-

ANLG Com

NC

analog source

V in 4+

I in 4+

V in 5+

I in 5+

V in 6+

I in 6+

V in 7+

I in 7+

NC

Publication 1769-IN067B-EN-P - September 2005

Page 10

10 Compact I/O 1769-IF8 Analog Input Module

–

–

Wiring Single-Ended Sensor/Transmitter Types

Sensor/Trans

mitter

Supply

1 The sensor power supply

must be rated Class 2.

+

-

(1)

Current

Transmitter

+

Signal

Voltage

Transmitter

+

Ground

Voltage

Transmitter

+

Ground

Signal

Signal

1769-IF8 Terminal Block

V in 0 +

in

0

-

V/I

I in 0 +

AN

LG

C

o

m

V in 1 +

in

1

-

V/I

I in 1 +

AN

LG

C

o

m

V in 2 +

V/I in 2

-

I in 2 +

AN

LG

C

o

m

V in 3 +

V/I

in

3

-

I in 3 +

AN

LG

C

o

m

NC

NC

Wiring for channels 4-7 are identical.

Wiring Mixed Transmitter Types

Single-ended

Signal

Voltage

Transmitter

+

–

Signal

Differential

Voltage

Transmitter

Supply

Differential

Current

Transmitter

Supply

2-Wire

Current

Transmitter

+

–

+

–

Signal

+

+

Signal

+

1769-IF8 Terminal Block

V in 0 +

V/I in 0 I in 0 +

ANLG Com

V in 1 +

V/I in 1 I in 1 +

ANLG Com

V in 2 +

V/I in 2 I in 2 +

ANLG Com

V in 3 +

V/I in 3 I in 3 +

ANLG Com

NC

NC

Sensor/

Transmitter

Supply

+

(1)

–

Publication 1769-IN067B-EN-P - September 2005

1 The sensor power supply

must be rated Class 2.

Wiring for channels 4-7 are identical.

Page 11

Compact I/O 1769-IF8 Analog Input Module 11

Labeling the Terminals

A removable, write-on label is provided with the module. Remove the label from

the door, mark the identification of each terminal with permanent ink, and slide the

label back into the door. Your markings (ID tag) will be visible when the module

door is closed.

upper retaining screw

lower retaining screw

wiring the

finger-safe

terminal block

Removing the Finger-Safe Terminal Block

When wiring field devices to the module, it is not necessary to remove the terminal

block. If you remove the terminal block, use the write-on label on the side of the

terminal block to identify the module slot location and type. RTB position can be

indicated by circling either the ‘R’ for right side or ‘L’ for left side.

To remove the terminal block, loosen the upper and lower retaining screws. The

terminal block will back away from the module as you remove the screws. When

replacing the terminal block, torque the retaining screws to 0.46 Nm (4.1 in-lbs).

Publication 1769-IN067B-EN-P - September 2005

Page 12

12 Compact I/O 1769-IF8 Analog Input Module

Wiring the Finger-Safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the terminal screws to be wired.

2. Route the wire under the terminal pressure plate. You can use the bare wire

or a spade lug. The terminals will accept a 6.35 mm (0.25 in.) spade lug.

NOTE

The terminal screws are non-captive. Therefore, it is possible

to use a ring lug [maximum 1/4 inch o.d. with a 0.139 inch

minimum i.d. (M3.5)] with the module.

3. Tighten the terminal screw making sure the pressure plate secures the wire.

Recommended torque when tightening terminal screws is 0.68 Nm (6 in-lbs).

NOTE

If you need to remove the finger-safe cover, insert a screw

driver into one of the square wiring holes and gently pry the

cover off. If you wire the terminal block with the finger-safe

cover removed, you will not be able to put it back on the

terminal block because the wires will be in the way.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wire Type Wire Size Terminal Screw

Torque

Solid Cu-90°C (194°F) #14 to #22 AWG 0.68 Nm (6 in-lbs) 0.46 Nm (4.1 in-lbs)

Stranded Cu-90°C (194°F) #16 to #22 AWG 0.68 Nm (6 in-lbs) 0.46 Nm (4.1 in-lbs)

Retaining Screw

Tor qu e

Publication 1769-IN067B-EN-P - September 2005

Page 13

I/O Memory Mapping

Compact I/O 1769-IF8 Analog Input Module 13

IMPORTANT

If you are using RSLogix 5000, version 15, please refer to RSLogix

5000, Version 15, Controller Tags on page 18.

Input Data File

For each input module, slot x, words 0-7 in the input data file contain the analog

values of the inputs.

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

0 SGN Analog Input Data Channel 0

1 SGN Analog Input Data Channel 1

2 SGN Analog Input Data Channel 2

3 SGN Analog Input Data Channel 3

4 SGN Analog Input Data Channel 4

5 SGN Analog Input Data Channel 5

6 SGN Analog Input Data Channel 6

7 SGN Analog Input Data Channel 7

8 Nu Time Stamp Value

9 Nu Nu Nu Nu Nu Nu Nu Nu S7 S6 S5 S4 S3 S2 S1 S0

10 L3 H3 U3 O3 L2 H2 U2 O2 L1 H1 U1 O1 L0 H0 U0 O0

11 L7 H7 U7 O7 L6 H6 U6 O6 L5 H5 U5 O5 L4 H4 U4 O4

The bits are defined as follows:

• SGN = Sign bit in two’s complement format

• Nu = Not used. Bit set to 0.

• Sx = General status bit for input channels 0 through 7.

• Lx = Low alarm flag bits for input channels 0 through 7.

• Hx = High alarm flag bits for input channels 0 through 7.

• Ux = Under-range flag bits for channels 0 through 7. When set, the input

signal is under normal range or an open circuit condition exists, in the case

of the 4-20 mA range.

• Ox = Over-range flag bits for channels 0 through 7.

Publication 1769-IN067B-EN-P - September 2005

Page 14

14 Compact I/O 1769-IF8 Analog Input Module

Output Data File

For each input module, slot x, word 0 in the output data file contains alarm unlatch

control bits.

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

(1)

0

(1)

CL Lx = Cancel Low Process Alarm Latch x. This lets you individually cancel each low process alarm latch. Cancel = 1.

(2)

CL Hx = Cancel High Process Alarm Latch x. This lets you individually cancel each high process alarm latch.

(2)

CL

L7

CLL6CLH6CLL5CLH5CLL4CLH4CLL3CLH3CLL2CLH2CLL1CLH1CLL0CL

CL

H7

H0

Publication 1769-IN067B-EN-P - September 2005

Page 15

Compact I/O 1769-IF8 Analog Input Module 15

Configuration Data File

The manipulation of the bits from this file is normally done with programming

software (e.g. RSLogix 500, RSNetworx for DeviceNet, etc.) during initial

configuration of the system. In that case, graphical screens are provided by the

programmer to simplify configuration. However, some systems, like the 1769-ADN

DeviceNet Adapter, also allow the bits to be altered as part of the control program,

using communication rungs. In that case, it is necessary to understand the bit

arrangement. Refer to the Compact™ Analog I/O User Manual, publication number

1769-UM002 for additional details.

Bit Position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word

0 Real Time Sample Value

1 ERTS Reserved

2 EC Reserved EA AL EI Reserved Input Filter Sel Chl0

3 Reserved Inpt Dta Fm Chl0 Reserved Inpt Tp/RngeSel Chl0

4 S Process Alarm High Data Value Channel 0

5 S Process Alarm Low Data Value Channel 0

6 S Alarm Dead Band Value Channel 0

7 Pad

8 EC Reserved EA AL EI Reserved Inpt Filter Sel Chl1

9 Reserved Inpt Dta Fm Chl1 Reserved Inpt Tp/RngeSel Chl1

10 S Process Alarm High Data Value Channel 1

11 S Process Alarm Low Data Value Channel 1

12 S Alarm Dead Band Value Channel 1

13 Pad

14 EC Reserved EA AL EI Reserved Input Filter Sel Chl2

15 Reserved Inpt Dta Fm Chl2 Reserved Inpt Tp/RngeSel Chl2

16 S Process Alarm High Data Value Channel 2

17 S Process Alarm Low Data Value Channel 2

18 S Alarm Dead Band Value Channel 2

19 Pad

20 EC Reserved EA AL EI Reserved Input Filter Sel Chl3

21 Reserved Inpt Dta Fm Chl3 Reserved Inpt Tp/RngeSel Chl3

22 S Process Alarm High Data Value Channel 3

23 S Process Alarm Low Data Value Channel 3

24 S Alarm Dead Band Value Channel 3

25 Pad

26 EC Reserved EA AL EI Reserved Input Filter Sel Chl4

Publication 1769-IN067B-EN-P - September 2005

Page 16

16 Compact I/O 1769-IF8 Analog Input Module

Bit Position

1514131211109876543210

Word

27 Reserved Inpt Dta Fm Chl4 Reserved Inpt Tp/RngeSel Chl4

28 S Process Alarm High Data Value Channel 4

29 S Process Alarm Low Data Value Channel 4

30 S Alarm Dead Band Value Channel 4

31 Pad

32 EC Reserved EA AL EI Reserved Input Filter Sel Chl5

33 Reserved Inpt Dta Fm Chl5 Reserved Inpt Tp/RngeSel Chl5

34 S Process Alarm High Data Value Channel 5

35 S Process Alarm Low Data Value Channel 5

36 S Alarm Dead Band Value Channel 5

37 Pad

38 EC Reserved EA AL EI Reserved Input Filter Sel Chl6

39 Reserved Inpt Dta Fm Chl6 Reserved Inpt Tp/RngeSel Chl6

40 S Process Alarm High Data Value Channel 6

41 S Process Alarm Low Data Value Channel 6

42 S Alarm Dead Band Value Channel 6

43 Pad

44 EC Reserved EA AL EI Reserved Input Filter Sel Chl7

45 Reserved Inpt Dta Fm Chl7 Reserved Inpt Tp/RngeSel Chl7

46 S Process Alarm High Data Value Channel 7

47 S Process Alarm Low Data Value Channel 7

48 S Alarm Dead Band Value Channel 7

49 Pad

• EC = Enable Channel

• Inpt Dta Fm Chlx = Input Data Format Select.

• EA = Enable Alarm.

• AL = Alarm Latch.

• EI = Enable Interrupt.

• Inpt Tp/Rnge Sel Chlx = Input Type/Range Select.

• Inpt Filter Sel Chlx = Input Filter Select.

• Reserved = Allows for future expansion.

• ERTS = Enable Real Time Sample.

Publication 1769-IN067B-EN-P - September 2005

Page 17

Compact I/O 1769-IF8 Analog Input Module 17

Define To Sele ct Make these bit settings

15 14 13 12 11 10 9 8 7-4 3 2 1 0

Input Filter

Selection/

-3 dB

Frequency

Enable

Interrupt

Process

Alarm Latch

Enable

Process

Alarms

Enable

Channel

Define Indicate this These bit settings

Input

Range

Select

Input Data

Select

60 Hz 0 0 0 0

50 Hz 0 0 0 1

10 Hz 0 0 1 0

250 Hz 0 0 1 1

500 Hz 0 1 0 0

Enable 1

Disable 0

Enable 1

Disable 0

Enable 1

Disable 0

Enable 1

Disable 0

15-11 10 9 8 7-4 3 2 1 0

-10 to +10V dc 0 0 0 0

0 to 5V dc 0 0 0 1

0 to 10V dc 0 0 1 0

4 to 20 mA 0 0 1 1

1 to 5V dc 0 1 0 0

0 to 20 mA 0 1 0 1

Raw/Proportional

Counts

Engineering Units 0 0 1

Scaled for PID 0 1 0

Percent Range 0 1 1

0 0 0

Publication 1769-IN067B-EN-P - September 2005

Page 18

18 Compact I/O 1769-IF8 Analog Input Module

RSLogix 5000, Version 15, Controller Tags

Use the following controller tags with RSLogix 5000, version 15.

Channel 0 and 1 Configuration Data

Channel 0 and 1 configuration data is shown below. The same information applies

to all channels.

- Local:1:C AB:1769_IF8:C:0

+ Local:1:C.RTSInterval INT Decimal

Local:1:C.RTSEn BOOL Decimal

+ Local:1:C.Ch0Filter SINT Decimal

Local:1:C.Ch0AlarmInterruptEn BOOL Decimal

Local:1:C.Ch0AlarmLatchEn BOOL Decimal

Local:1:C.Ch0AlarmEn BOOL Decimal

Local1:C.Ch0En BOOL Decimal

+ Local:1:C.Ch0Range SINT Decimal

+ Local:1:C.Ch0DataFormat SINT Decimal

+ Local:1:C.Ch0HAlarmLimit INT Decimal

+ Local:1:C.Ch0LAlarmLimit INT Decimal

+ Local:1:C.Ch0AlarmDeadband INT Decimal

+ Local:1:C.Ch1Filter SINT Decimal

Local:1:C.Ch1AlarmInterruptEn BOOL Decimal

Local:1:C.Ch1AlarmLatchEn BOOL Decimal

Local:1:C.Ch1AlarmEn BOOL Decimal

Local:1:C.Ch1En BOOL Decimal

+ Local:1:C.Ch1Range SINT Decimal

+ Local:1:C.Ch1DataFormat SINT Decimal

+ Local:1:C.Ch1HAlarmLimit INT Decimal

+ Local:1:C.Ch1LAlarmLimit INT Decimal

+ Local:1:C.Ch1AlarmDeadband INT Decimal

Publication 1769-IN067B-EN-P - September 2005

Page 19

Compact I/O 1769-IF8 Analog Input Module 19

Tag Nam e To Sele ct

Make These Bit Settings

(1)

15-8 7 6 5 4 3 2 1 0

Ch#Filter 60 Hz 0 0 0

50 Hz 0 0 1

10 Hz 0 1 0

250 Hz 0 1 1

500 Hz 1 0 0

Ch#AlarmInterruptEn Enable 1

Disable 0

Ch#AlarmLatchEn Enable 1

Disable 0

Ch#AlarmEn Enable 1

Disable 0

Ch#En Enable 1

Disable 0

Ch#Range -10…+10V dc 0 0 0

0…5V dc 0 0 1

0…10V dc 0 1 0

4…20 mA 0 1 1

1…5V dc 1 0 0

0…20 mA 1 0 1

Ch#DataFormat Raw/proportional

0 0

counts

Engineering units 0 1

Scaled for PID 1 0

Percent range 1 1

(1)

All bit positions left blank in table must be set to 0.

Publication 1769-IN067B-EN-P - September 2005

Page 20

20 Compact I/O 1769-IF8 Analog Input Module

Input Data

- Local:1:I AB:1769_IF8:I:0

+ Local:1:I.Fault DINT Binary

+ Local:1:I.Ch0Data INT Decimal

+ Local:1:I.Ch1Data INT Decimal

+ Local:1:I.Ch2Data INT Decimal

+ Local:1:I.Ch3Data INT Decimal

+ Local:1:I.Ch4Data INT Decimal

+ Local:1:I.Ch5Data INT Decimal

+ Local:1:I.Ch6Data INT Decimal

+ Local:1:I.Ch7Data INT Decimal

+ Local:1:I.RealTimeSample INT Decimal

+ Local:1:I.CombinedStatus SINT Binary

Local:1:I.Ch0Status BOOL Decimal

Local:1:I.Ch1Status BOOL Decimal

Local:1:I.Ch2Stattus BOOL Decimal

Local:1:I.Ch3Status BOOL Decimal

Local:1:I.Ch4Status BOOL Decimal

Local:1:I.Ch5Status BOOL Decimal

Local:1:I.Ch6Status BOOL Decimal

Local:1:I.Ch7Status BOOL Decimal

+ Local:1:I.Ch0_1Status SINT Binary

Local:1:I.Ch0OverRange BOOL Decimal

Local:1:I.Ch0UnderRange BOOL Decimal

Local:1:I.Ch0HAlarm BOOL Decimal

Local:1:I.Ch0LAlarm BOOL Decimal

+ Local:1:I.Ch1OverRange BOOL Decimal

Local:1:I.Ch1UnderRange BOOL Decimal

Local:1:I.Ch1HAlarm BOOL Decimal

Local:1:I.Ch1LAlarm BOOL Decimal

Publication 1769-IN067B-EN-P - September 2005

Page 21

Compact I/O 1769-IF8 Analog Input Module 21

+ Local:1:I.Ch2_3Status SINT Binary

Local:1:I.Ch2OverRange BOOL Decimal

Local:1:I.Ch2UnderRange BOOL Decimal

Local:1:I.Ch2HAlarm BOOL Decimal

Local:1:I.Ch2LAlarm BOOL Decimal

Local:1:I.Ch3OverRange BOOL Decimal

Local:1:I.Ch3UnderRange BOOL Decimal

Local:1:I.Ch3HAlarm BOOL Decimal

Local:1:I.Ch3LAlarm BOOL Decimal

+ Local:1:I.Ch4_5Status SINT Binary

Local:1:I.Ch4OverRange BOOL Decimal

Local:1:I.Ch4UnderRange BOOL Decimal

Local:1:I.Ch4HAlarm BOOL Decimal

Local:1:I.Ch4LAlarm BOOL Decimal

Local:1:I.Ch5OverRange BOOL Decimal

Local:1:I.Ch5UnderRange BOOL Decimal

Local:1:I.Ch5HAlarm BOOL Decimal

Local:1:I.Ch5LAlarm BOOL Decimal

+ Local:1:I.Ch6_7Status SINT Binary

Local:1:I.Ch6OverRange BOOL Decimal

Local:1:I.Ch6UnderRange BOOL Decimal

Local:1:I.Ch6HAlarm BOOL Decimal

Local:1:I.Ch6LAlarm BOOL Decimal

Local:1:I.Ch7OverRange BOOL Decimal

Local:1:I.Ch7UnderRange BOOL Decimal

Local:1:I.Ch7HAlarm BOOL Decimal

Local:1:I.Ch7LAlarm BOOL Decimal

Publication 1769-IN067B-EN-P - September 2005

Page 22

22 Compact I/O 1769-IF8 Analog Input Module

Tag

Name

Combined

Status

Ch0_1

Status

Ch2_3

Status

Ch4_5

Status

Ch6_7

Status

Bit Indicates This

7 6 5 4 3 2 1 0

Ch7

Status

Ch1

LAlarm

Ch3

LAlarm

Ch5

LAlarm

Ch7

LAlarm

Ch6

Status

Ch1

HAlarm

Ch3

HAlarm

Ch5

HAlarm

Ch7

HAlarm

Ch5

Status

Ch1

Under

Range

Ch3

Under

Range

Ch5

Under

Range

Ch7

Under

Range

Ch4

Status

Ch1

Over

Range

Ch3

Over

Range

Ch5

Over

Range

Ch7

Over

Range

Ch3

Status

Ch0

LAlarm

Ch2

LAlarm

Ch4

LAlarm

Ch6

LAlarm

Ch2

Status

Ch0

HAlarm

Ch2

HAlarm

Ch4

HAlarm

Ch6

HAlarm

Ch1

Status

Ch0

Under

Range

Ch2

Under

Range

Ch4

Under

Range

Ch6

Under

Range

Ch0

Status

Ch0

Over

Range

Ch2

Over

Range

Ch4

Over

Range

Ch6

Over

Range

Publication 1769-IN067B-EN-P - September 2005

Page 23

Compact I/O 1769-IF8 Analog Input Module 23

Output Data

- Local:1:O AB:1769_IF8:O:0

+ Local:1:O.AlarmUnlatch INT Binary

Local:1:O.Ch0HAlarmUnlatch BOOL Decimal

Local:1:O.Ch0LAlarmUnlatch BOOL Decimal

Local:1:O.Ch1HAlarmUnlatch BOOL Decimal

Local:1:O.Ch1LAlarmUnlatch BOOL Decimal

Local:1:O.Ch2HAlarmUnlatch BOOL Decimal

Local:1:O.Ch2LAlarmUnlatch BOOL Decimal

Local:1:O.Ch3HAlarmUnlatch BOOL Decimal

Local:1:O.Ch3LAlarmUnlatch BOOL Decimal

Local:1:O.Ch4HAlarmUnlatch BOOL Decimal

Local:1:O.Ch4LAlarmUnlatch BOOL Binary

Local:1:O.Ch5HAlarmUnlatch BOOL Decimal

Local:1:O.Ch5LAlarmUnlatch BOOL Decimal

Local:1:O.Ch6HAlarmUnlatch BOOL Decimal

Local:1:O.Ch6LAlarmUnlatch BOOL Decimal

Local:1:O.Ch7HAlarmUnlatch BOOL Decimal

Local:1:O.Ch7LAlarmUnlatch BOOL Decimal

Publication 1769-IN067B-EN-P - September 2005

Page 24

24 Compact I/O 1769-IF8 Analog Input Module

Specifications

General Specifications

Specification Value

Dimensions 118 mm (height) x 87 mm (depth) x 52.5 mm (width)

Approximate Shipping Weight

(with carton)

Storage Temperature -40°C to +85°C (-40°F to +185°F)

Operating Temperature 0°C to +60°C (32°F to +140°F)

Operating Humidity 5% to 95% non-condensing

Operating Altitude 2000 meters (6561 feet)

Vibration Operating: 10 to 500 Hz, 5G, 0.030 in. peak-to-peak

Shock Operating: 30G, 11 ms panel mounted

Agency Certification • C-UL certified (under CSA C22.2 No. 142)

Hazardous Environment Class Class I, Division 2, Hazardous Location, Groups A, B, C, D (UL 1604,

Radiated and Conducted Emissions EN50081-2 Class A

Electrical /EMC: The module has passed testing at the following levels:

• ESD Immunity (IEC1000-4-2) • 4 kV contact, 8 kV air, 4 kV indirect

• Radiated Immunity (IEC1000-4-3) • 10 V/m , 80 to 1000 MHz, 80% amplitude modulation,

• Fast Transient Burst (IEC1000-4-4) • 2 kV, 5kHz

• Surge Immunity (IEC1000-4-5) • 1 kV galvanic gun

• Conducted Immunity

(IEC1000-4-6)

(1)

Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency range is 30 MHz to

1000 MHz.

height including mounting tabs is 138 mm

4.65 in. (height) x 3.43 in (depth) x 2.07 in (width)

height including mounting tabs is 5.43 in.

450g (0.99 lbs.)

(20G, 11 ms DIN rail mounted)

Non-Operating: 40G panel mounted

(30G DIN rail mounted)

• UL 508 listed

• CE compliant for all applicable directives

C-UL under CSA C22.2 No. 213)

+900 MHz keyed carrier

• 10 V, 0.15 to 80MHz

(1)

Publication 1769-IN067B-EN-P - September 2005

Page 25

Compact I/O 1769-IF8 Analog Input Module 25

Input Specifications

Specification 1769-IF8

Analog Normal Operating

(1)

Ranges

Full Scale Analog Ranges

Number of Inputs 8 differential or single-ended

Bus Current Draw (max.) 120 mA at 5V dc

Heat Dissipation 3.24 Total Watts (The Watts per point, plus the minimum Watts, with all

Converter Type Delta Sigma

Response Speed per Channel Input filter and configuration dependent. See your user’s manual.

Resolution (max.)

Rated Working Voltage

(2)

(3)

Common Mode Voltage Range

Common Mode Rejection greater than 60 dB at 50 and 60 Hz with the 10 Hz filter selected,

Normal Mode Rejection Ratio -50 dB at 50 and 60 Hz with the 10 Hz filter selected, respectively.

Input Impedance Voltage Terminal: 220K Ω (typical)

Overall Accuracy

(1)

The over- or under-range flag will come on when the normal operating range (over/under) is exceeded. The module will

continue to convert the analog input up to the maximum full scale range. The flag automatically resets when within the

normal operating range.

(2)

Resolution is dependent upon your filter selection. The maximum resolution is achieved with the 10 Hz filter selected. For

resolution with other filter selections, refer to the user manual, publication 1769-UM002A-EN-P.

(3)

Rated working voltage is the maximum continuous voltage that can be applied at the input terminal, including the input

signal and the value that floats above ground potential (for example, 10V dc input signal and 20V dc potential above

ground).

(4)

For proper operation, both the plus and minus input terminals must be within ±10V dc of analog common.

(5)

Includes offset, gain, non-linearity and repeatability error terms.

(5)

Voltage: ± 10V dc, 0 to 10V dc, 0 to 5V dc, 1 to 5V dc

Current: 0 to 20 mA, 4 to 20 mA

(1)

Voltage: ± 10.5V dc, 0 to 10.5V dc, 0 to 5.25V dc, 0.5 to 5.25V dc

Current: 0 to 21 mA, 3.2 to 21 mA

70 mA at 24V dc

points energized.)

16 bits (unipolar)

15 bits plus sign (bipolar)

30V ac/30V dc

(4)

±10V dc maximum per channel

respectively.

Current Terminal: 250 Ω

Voltage Terminal: ±0.2% full scale at 25°C

Current Terminal: ±0.35% full scale at 25°C

Publication 1769-IN067B-EN-P - September 2005

Page 26

26 Compact I/O 1769-IF8 Analog Input Module

Specification 1769-IF8

Accuracy Drift with Temperature Voltage Terminal: ±0.003% per °C

Current Terminal: ±0.0045% per °C

Calibration The module performs autocalibration on channel enable and on a

Non-linearity (in percent full scale) ±0.03%

Repeatability

(1)

Module Error over Full

Temperature Range

(0 to +60°C [+32°F to +140°F])

Input Channel Configuration via configuration software screen or the user program (by writing a unique

Module OK LED On: module has power, has passed internal diagnostics, and is

Channel Diagnostics Over- or under-range by bit reporting, process alarms

Maximum Overload at Input

(2)

Terminals

System Power Supply Distance

Rating

Recommended Cable Belden™ 8761 (shielded)

Input Group to Bus Isolation 500V ac or 710V dc for 1 minute (qualification test)

Vendor I.D. Code 1

Product Type Code 10

Product Code 38

(1)

Repeatability is the ability of the input module to register the same reading in successive measurements for the same input

signal.

(2)

Damage may occur to the input circuit if this value is exceeded.

configuration change between channels.

±0.03%

Voltage: ±0.3%

Current: ±0.5%

bit pattern into the module’s configuration file). Refer to your controller’s

user manual to determine if user program configuration is supported.

communicating over the bus.

Off: Any of the above is not true.

Voltage Terminal: ±30V dc continuous, 0.1 mA

Current Terminal: ±32 mA continuous, ±7.6 V dc

8 (The module may not be more than 8 modules away from the system

power supply.)

30V ac/30V dc working voltage (IEC Class 2 reinforced insulation)

Publication 1769-IN067B-EN-P - September 2005

Page 27

Compact I/O 1769-IF8 Analog Input Module 27

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following ATTENTION statement applies to use

in hazardous locations.

WARNING

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not replace components or disconnect equipment

unless power has been switched off or the area is known

to be non-hazardous.

• Do not connect or disconnect components unless power

has been switched off or the area is known to be

non-hazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

AVERTISSEMENT

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Ne pas remplacer de composants ou déconnecter

l'équipement sans s'être assuré que l'alimentation est coupée

et que l'environnement est classé non dangereux.

• Ne pas connecter ou déconnecter des composants sans s'être

assuré que l'alimentation est coupée ou que l'environnement

est classé non dangereux.

• Ce produit doit être installé dans une armoire.

Publication 1769-IN067B-EN-P - September 2005

Page 28

28 Compact I/O 1769-IF8 Analog Input Module

For More Information

For Refer to this Document Pub. No.

A more detailed description of how to install

and use your Compact I/O with MicroLogix 1500

programmable controller.

Detailed information on installing,

programming, and troubleshooting your

Compact Analog I/O modules.

A detailed description of how to install and use

your Compact I/O with the 1769-ADN DeviceNet

Adapter.

An overview of the MicroLogix 1500 system,

including Compact I/O.

More information on proper wiring and

grounding techniques.

If you would like a manual, you can:

• download a free electronic version from the internet:

www.ab.com/micrologix or www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Automation representative

– visiting www.theautomationbookstore.com and placing your order

– calling 1.800.963.9548 (USA/Canada)

or 001.330.725.1574 (Outside USA/Canada)

MicroLogix 1500 Programmable

Controllers User Manual

Compact I/O Analog Modules User

Manual

1769-ADN DeviceNet Adapter User

Manual

MicroLogix 1500 Programmable

Controller with Compact I/O for

Expansion

Industrial Automation Wiring and

Grounding Guidelines

1764-UM001

1769-UM002

1769-UM001

1764-SO001

1770-4.1

MicroLogix and Compact are trademarks of Rockwell Automation.

Belden is a trademark of Belden, Inc.

Publication 1769-IN067B-EN-P - September 2005

Page 29

Notes:

Compact I/O 1769-IF8 Analog Input Module 29

Publication 1769-IN067B-EN-P - September 2005

Page 30

30 Compact I/O 1769-IF8 Analog Input Module

Notes:

Publication 1769-IN067B-EN-P - September 2005

Page 31

Notes:

Compact I/O 1769-IF8 Analog Input Module 31

Publication 1769-IN067B-EN-P - September 2005

Page 32

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our

products. At http://support.rockwellautomation.com, you can find technical manuals, a

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of

these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information, contact your

local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

United States 1.440.646.3223 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any technical

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number (see

Outside United States Please contact your local Rockwell Automation representative for return procedure.

support issues.

phone number above to obtain one) to your distributor in order to complete the return

process.

Publication 1769-IN067B-EN-P - September 2005 PN 40071-171-01(2)

1769-IN067A-EN-P March 2004 Copyright © 2005 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

´H'+g!¶2j¨

Loading...

Loading...