Page 1

Compact

Combination 24V dc

Sink Input/Source

Output BOOLEAN

Control Module

1769-BOOLEAN

Reference Manual

Page 2

Important User Information

SHOCK HAZARD

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses

for solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that surfaces may be dangerous

temperatures.

Allen-Bradley, Compact I/O, MicroLogix 1500, RSLogix 500, CompactLogix, RSLogix 5000, RSNetWorx, and RSLinx are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Module Operation

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How to Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About the 1769-BOOLEAN Module. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Boolean Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1769-BOOLEAN Module Block Diagram. . . . . . . . . . . . . . . . . . . . . . 13

Wire the 1769-BOOLEAN Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Input and Output Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 14

Control Outputs Using Boolean Expressions . . . . . . . . . . . . . . . . . . . 15

Format of Boolean Expression . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Boolean Expression Configuration Restrictions. . . . . . . . . . . . . . . . . . 15

Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Output Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Output Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Output Delay and Duration Operation . . . . . . . . . . . . . . . . . . . . . 18

Boolean Control Mode Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Example 1: Duration > 0, Delay > TRUE Time . . . . . . . . . . . . . . 19

Example 2: Duration > 0, Delay < TRUE Time . . . . . . . . . . . . . . 21

Example 3: Duration > 0, Delay < TRUE Time,

Retriggering Ignored. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Example 4: Duration > 0, Delay = 0, Duration > TRUE Time . . 23

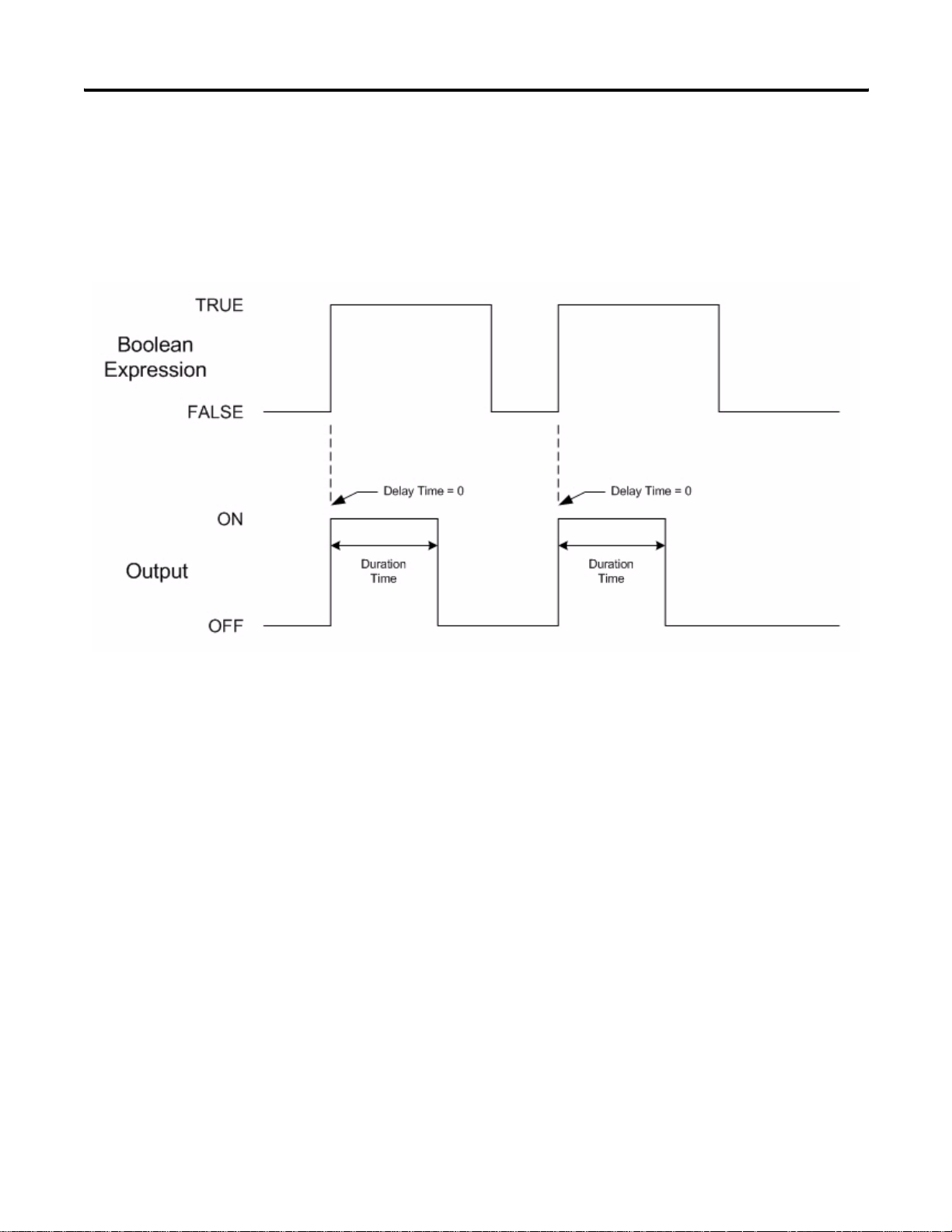

Example 5: Duration > 0, Delay = 0, Duration < TRUE Time . . 24

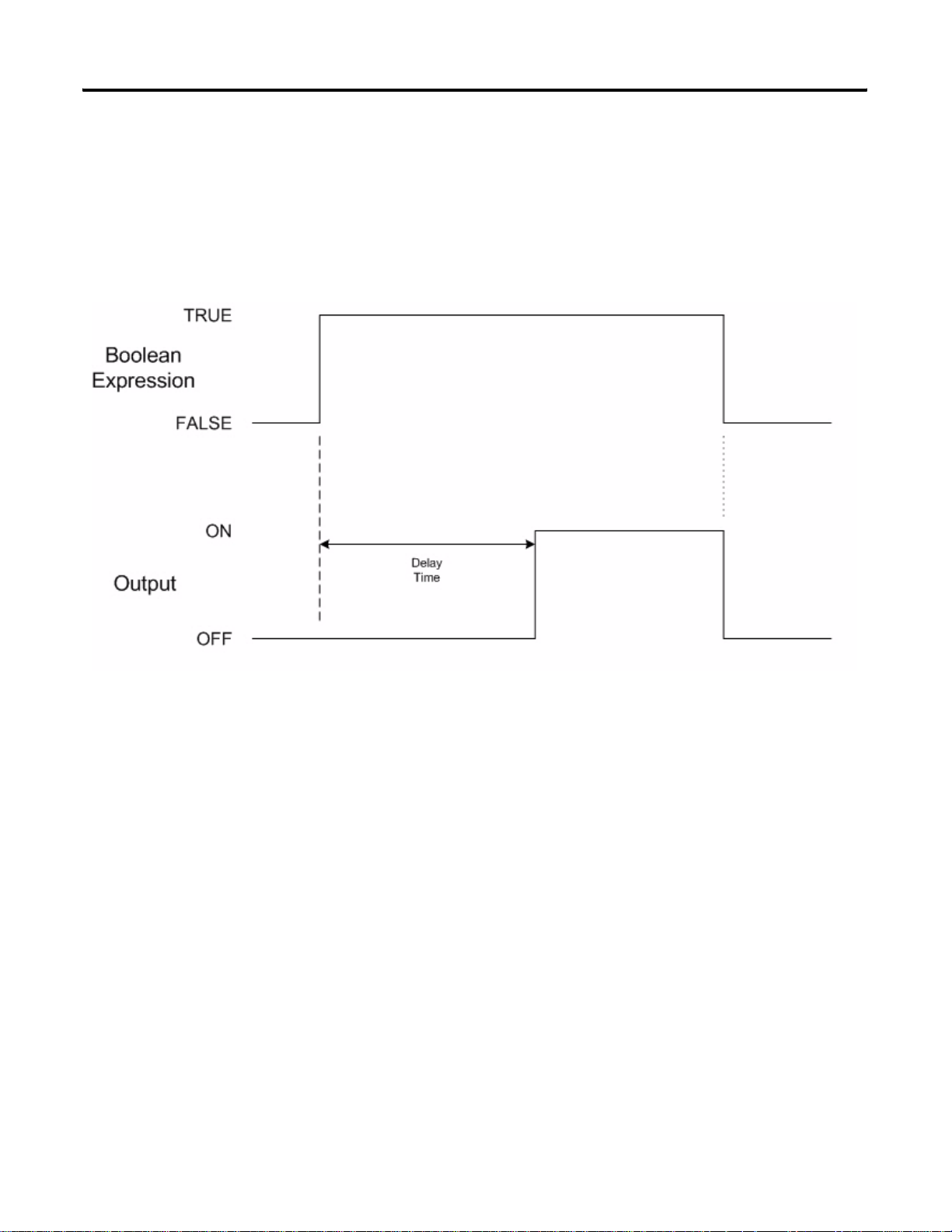

Example 6: Duration = 0, Delay < TRUE Time . . . . . . . . . . . . . . 25

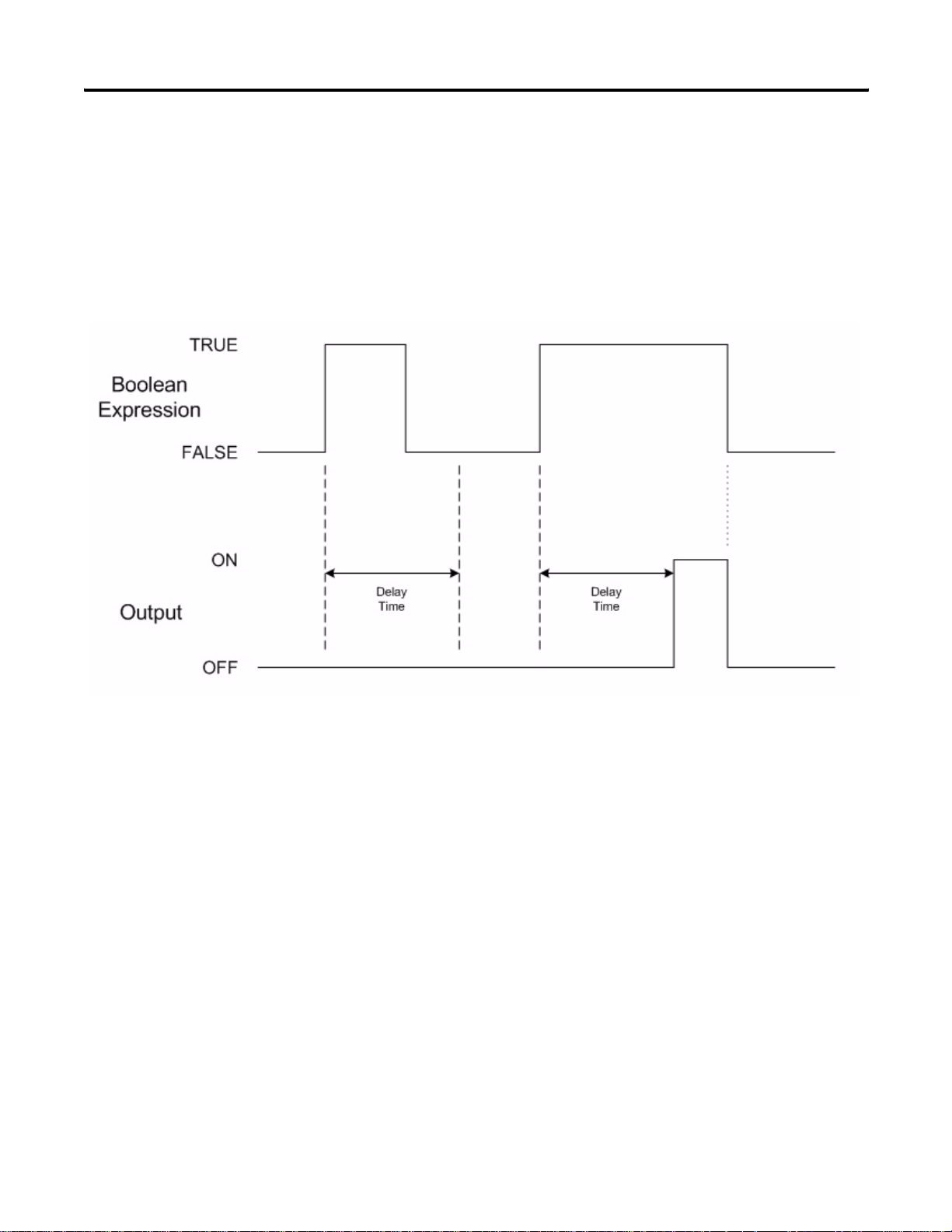

Example 7: Duration = 0, Delay > TRUE Time . . . . . . . . . . . . . . 26

Chapter 2

Installation and Wiring

3 Publication 1769-RM016A-EN-P - July 2006

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Compliance to European Union Directives . . . . . . . . . . . . . . . . . . . . . 27

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hazardous Location Considerations. . . . . . . . . . . . . . . . . . . . . . . . 29

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remove Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page 4

4

Module Data, Status, and

Configuration

Reduce Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Protect the Circuit Board from Contamination . . . . . . . . . . . . . . . 30

System Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mount the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Minimum Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Panel Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DIN Rail Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Replace a Single Module Within a System . . . . . . . . . . . . . . . . . . . . . . 34

Field Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

System Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Label the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remove the Finger-safe Terminal Block . . . . . . . . . . . . . . . . . . . . 37

Wire the Finger-safe Terminal Block . . . . . . . . . . . . . . . . . . . . . . . 37

Wire the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Input and Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Module Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Module Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1769-BOOLEAN Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . 42

1769-BOOLEAN Module Input Image. . . . . . . . . . . . . . . . . . . . . 43

1769-BOOLEAN Module Output Image . . . . . . . . . . . . . . . . . . . 43

1769-BOOLEAN Module Configuration File . . . . . . . . . . . . . . . . 43

1769-BOOLEAN Module Input Data File . . . . . . . . . . . . . . . . . . . . . 44

1769-BOOLEAN Module Output Data File . . . . . . . . . . . . . . . . . . . . 44

Direct Control of Module Outputs. . . . . . . . . . . . . . . . . . . . . . . . . 44

Virtual Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1769-BOOLEAN Module Configuration Data File . . . . . . . . . . . . . . 46

Input Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Input Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Program to Fault Enable (PFE) . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Program State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Program Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fault State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fault Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Output Control (DB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Output Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Output Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Output Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Publication 1769-RM016A-EN-P - July 2006

Page 5

Module Diagnostics and

Troubleshooting

1769-BOOLEAN Module

Specifications

5

Chapter 4

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Stand Clear of the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Program Alteration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Safety Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Power Cycle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Module Error Definition Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Module Error Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Extended Error Information Field . . . . . . . . . . . . . . . . . . . . . . . . . 61

Hardware Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Configuration Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Module Inhibit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Contacting Rockwell Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Appendix A

Temperature Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Transistor Output Transient Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Module Addressing and

Configuration with MicroLogix

1500

Configuration Using the RSLogix

5000 Generic Profile for

CompactLogix Controllers

Configure Modules in a Remote

DeviceNet System with a

1769-ADN DeviceNet Adapter

Index

Appendix B

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Input Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Output Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configure the 1769-BOOLEAN Module in a MicroLogix 1500 System

76

Appendix C

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configure the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configure I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Configure the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix D

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configuration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Add the DeviceNet Adapter to the Scanlist . . . . . . . . . . . . . . . . . . . . . 86

Configure the 1769-BOOLEAN Module Example . . . . . . . . . . . . . . . 88

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Publication 1769-RM016A-EN-P - July 2006

Page 6

6

Notes:

Publication 1769-RM016A-EN-P - July 2006

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual. This

preface covers the following topics:

• Who should use this manual

• How to use this manual

• Related publications

• Conventions used in this manual

Who Should Use This Manual

How to Use This Manual

Use this manual if you are responsible for designing, installing, programming,

or troubleshooting control systems that use the Allen-Bradley Compact I/O

system.

As much as possible, we organized this manual to explain, in a task-by-task

manner, how to install, configure, program, operate, and troubleshoot a

control system using the 1769 BOOLEAN module.

7 Publication 1769-RM016A-EN-P - July 2006

Page 8

8

Related Documentation

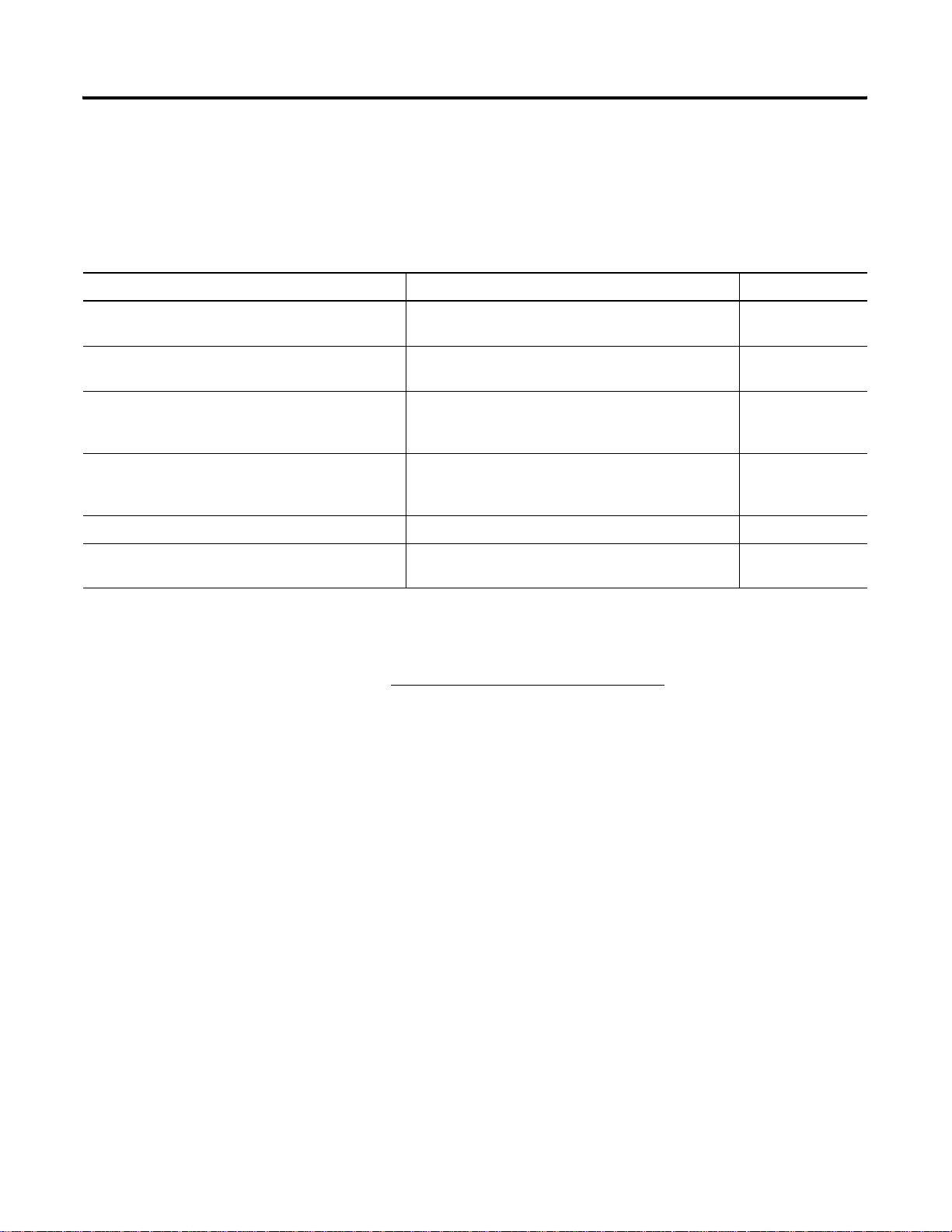

The table below provides a listing of publications that contain important

information about using Compact I/O modules.

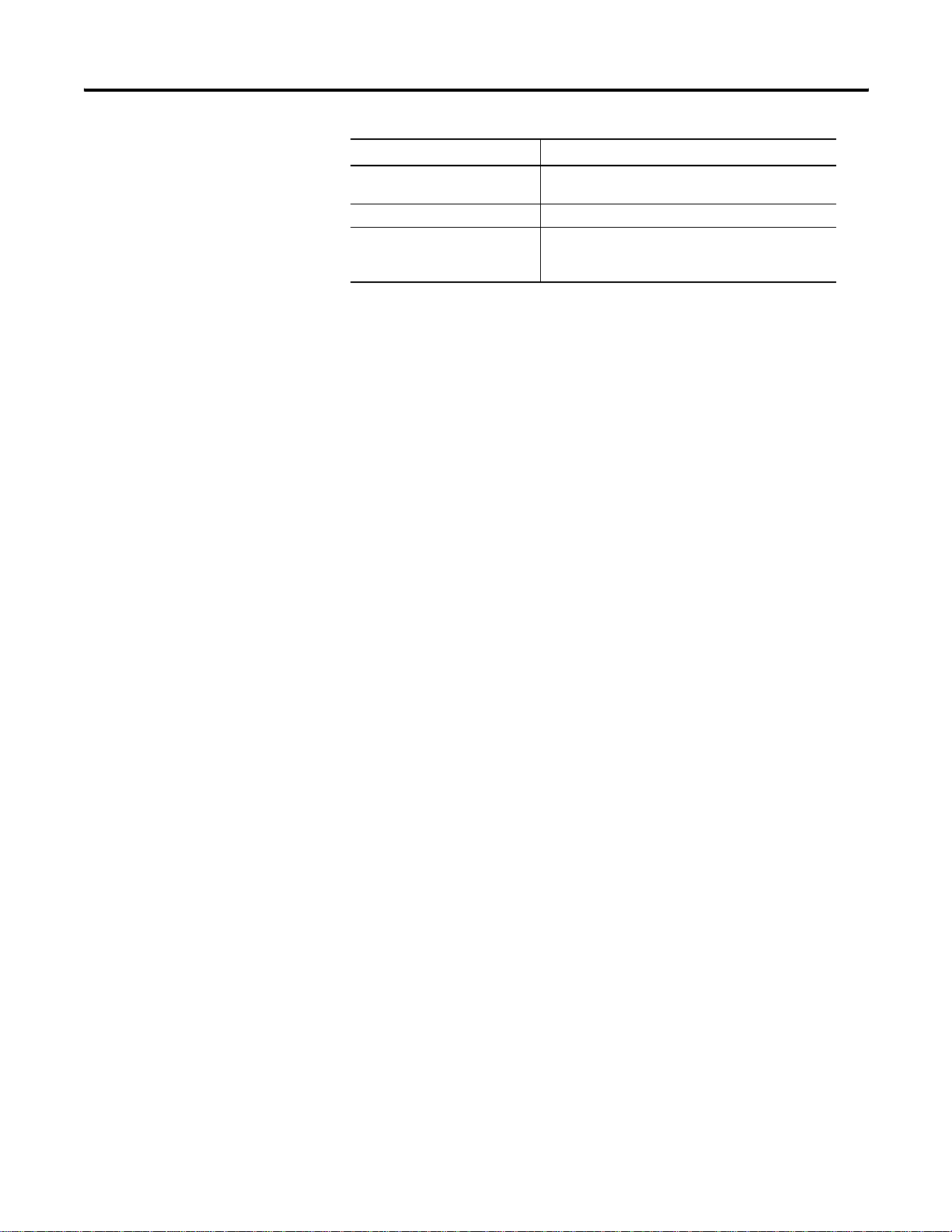

For Read this document Document number

A user manual containing information on how to install,

use and program your MicroLogix 1500 controller.

A user manual containing information on how to install,

and use your 1769-ADN DeviceNet adapter.

A user manual containing information on how to install,

use and program your 1769-L20 and 1769-L30

CompactLogix controllers.

A user manual containing information on how to install,

use and program your 1769-L31, 1769-L32C, 1769-L32E,

1769-L35CR and 1769-L35E CompactLogix controllers.

An overview of 1769 Compact I/O modules. Compact I/O System Selection Guide 1769-SG002

In-depth information on grounding and wiring

Allen-Bradley programmable controllers.

MicroLogix 1500 User Manual 1764-UM001

DeviceNet Adapter User Manual 1769-UM001

CompactLogix User Manual 1769-UM007

CompactLogix System User Manual 1769-UM011

Allen-Bradley Programmable Controller Grounding and

Wiring Guidelines

1770-4.1

If you would like a manual, you can:

• download a free electronic version from the Internet at

http://literature.rockwellautomation.com

• purchase a printed manual by contacting your local distributor or

Rockwell Automation representative.

Conventions Used in This Manual

Publication 1769-RM016A-EN-P - July 2006

We use the following conventions throughout this manual.

• Bulleted lists (like this one) provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Bold type is used for emphasis.

Page 9

Module Operation

Chapter

1

Overview

This chapter contains information about the following.

• Module description

• Module block diagram

• Input and output circuit diagrams

• Controlling outputs using Boolean expressions

– Format of Boolean expression

– Allowed variations of Boolean expressions

– Operands

– Operators

– Output delay control

– Output duration control

– Delay/Duration control rules and examples

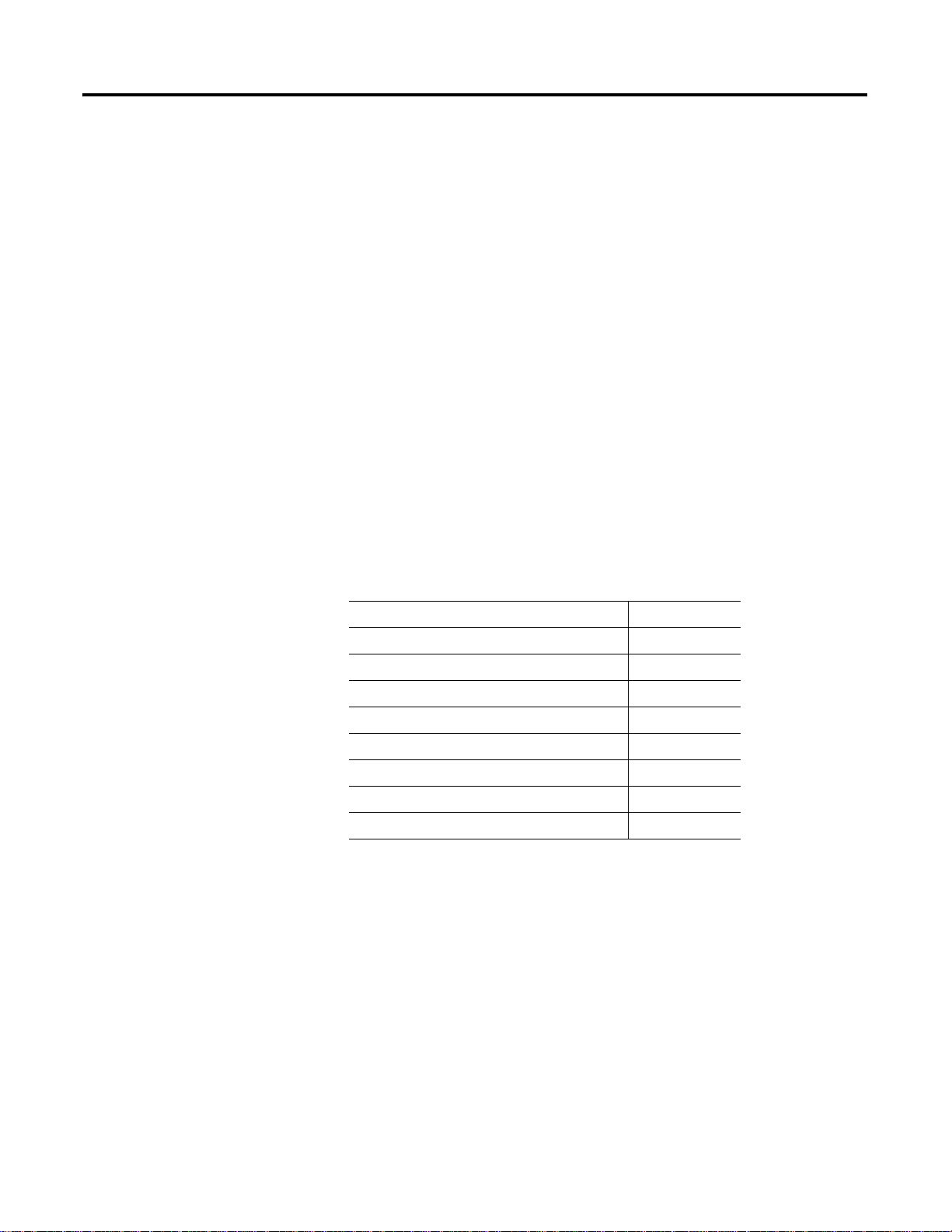

Topic Page

About the 1769-BOOLEAN Module 1

Module Description 11

Boolean Expressions 12

1769-BOOLEAN Module Block Diagram 13

Wire the 1769-BOOLEAN Module 14

Control Outputs Using Boolean Expressions 15

Boolean Expression Configuration Restrictions 15

Boolean Control Mode Examples 19

9 Publication 1769-RM016A-EN-P - July 2006

Page 10

10 Module Operation

About the 1769-BOOLEAN Module

The 1769-BOOLEAN module is a 24V dc combination input/output module.

The module outputs can be either directly controlled from your program or

independently controlled by the module using configured Boolean

expressions. These Boolean expressions are simple, logical combinations of

the module hardware input states and soft inputs controlled by your program.

When controlled by Boolean expression, the 1769-BOOLEAN module output

states can be conditioned using configured delay and duration settings. The

1769-BOOLEAN module supports interrupts to the system controller on

both input and output change of states

(1)

.

The Compact I/O system is suitable for use in an industrial environment

when installed in accordance with these instructions. Specifically, this

equipment is intended for use in clean, dry environments (Pollution degree

(2)

) and to circuits not exceeding Over Voltage Category II

2

(4)

60664-1)

.

(3)

(IEC

Publication 1769-RM016A-EN-P - July 2006

(1)

Interrupts from the module to the controller may not be supported by all controllers. Refer to your controller's

user manual for more information.

(2)

Pollution Degree 2 is an environment where, normally, only nonconductive pollution occurs except that occasionally a

temporary conductivity caused by condensation is expected.

(3)

Over Voltage Category II is the load-level section of the electrical distribution system. At this level, transient voltages are

controlled and do not exceed the impulse voltage capability of the product’s insulation.

(4)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Page 11

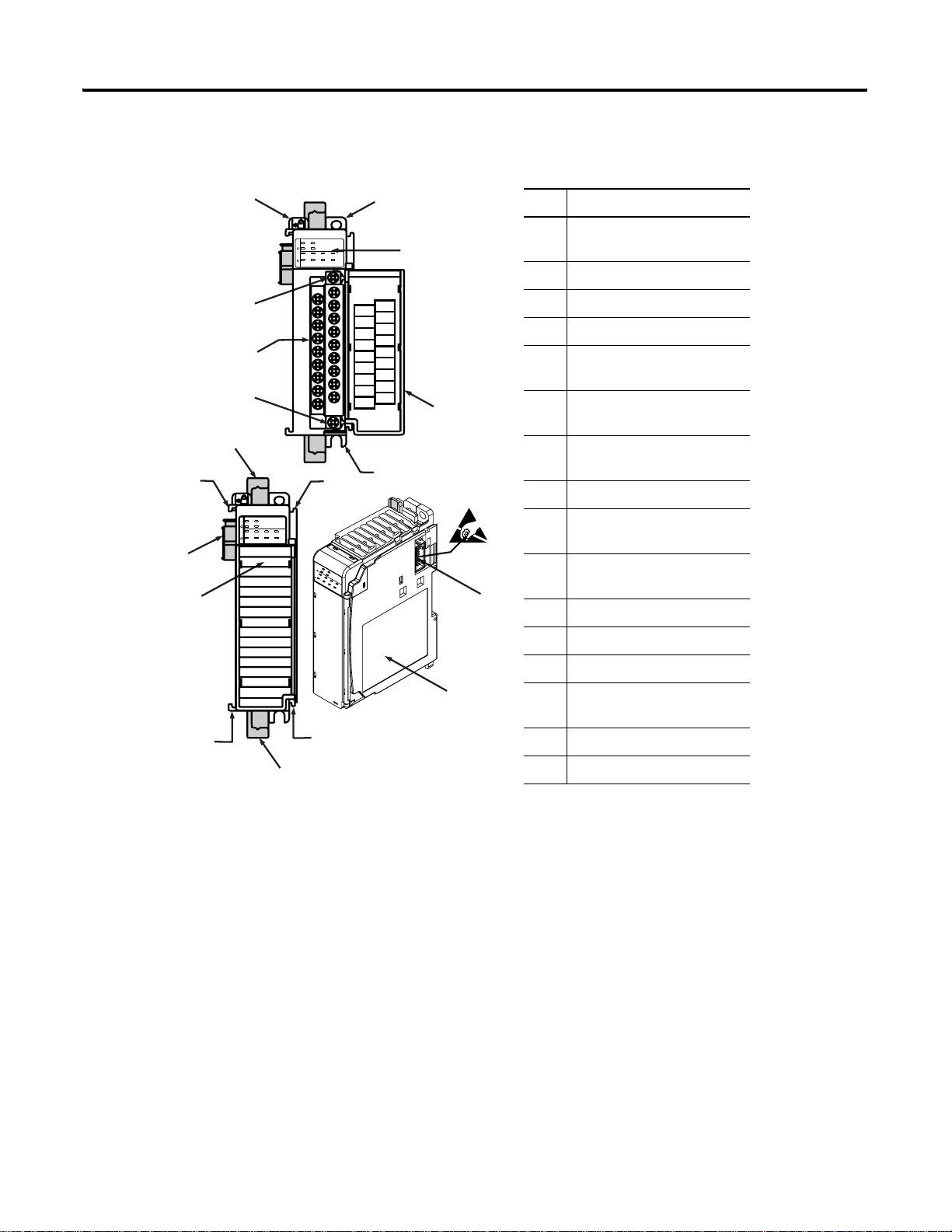

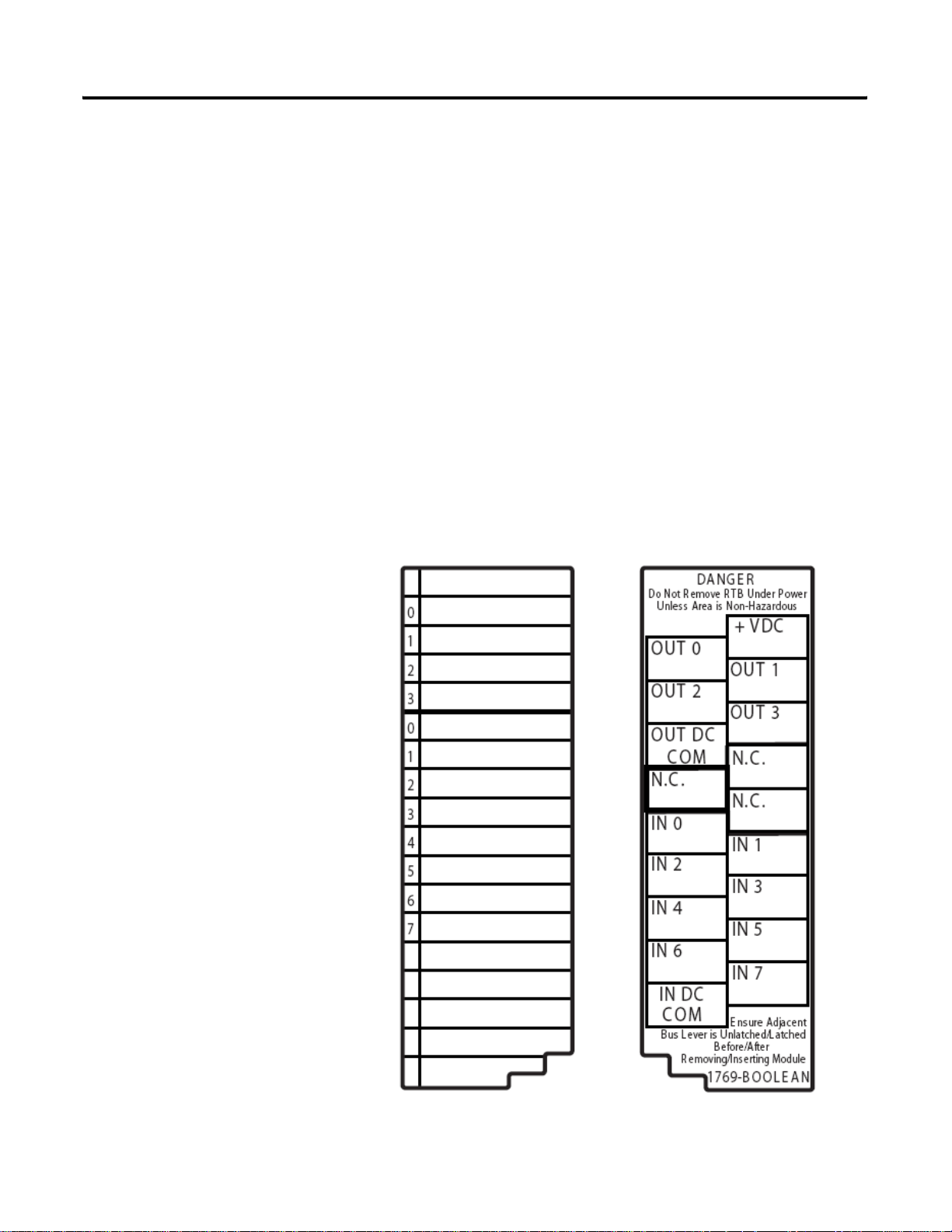

Module Description

1

5

b

Module Operation 11

7a

10a

10b

8a

10

0

2

1

3

0246

IN OUT

BOOLEAN

7531

7a

2a

DANGER

Do Not Remove RTB Under Power

Unless Area is Non-Hazardous

+VDC

OUT 0

OUT 1

OUT 2

OUT 3

OUT DC

COM

N.C.

N.C.

N.C.

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN DC

COM

Ensure Adjacent

Bus Lever is Unlatched/Latched

Before/After

Removing/Inserting Module

1769-BOOLEAN

2b

3

4

Item Description

1 Bus lever (with locking

function)

2a Upper panel mounting tab

2b Lower panel mounting tab

3 Module status LED

4 Module door with terminal

identification label

5a Movable bus connector

with female pins

5b Stationary bus connector

with male pins

6 Nameplate label

0

2

1

3

0246

IN OUT

7531

BOOLEAN

a

9

0

1

2

3

0

1

2

3

4

5

6

7

0

1

2

3

0

IN OUT

2

1

46

3

Boolean

5

7

7a Upper

tongue-and-groove slots

7b Lower

tongue-and-groove slots

5

8a Upper DIN rail latch

8b Lower DIN rail latch

9 Write-on label (user ID tag)

6

10 Removable terminal block (RTB)

with finger-safe cover

7b

7b

8b

10a RTB upper retaining screw

10b RTB lower retaining screw

Hardware Features

The 1769-BOOLEAN module contains a removable terminal block. The

module input circuits are isolated from the output circuits. Single-ground

applications can be supported by wiring the IN DC COM and the OUT DC

COM terminals together; however, this eliminates the isolation between the

input and output circuits provided by the module.

Module configuration is normally done via the controller programming

software. In addition, some controllers support configuration via the user

program. In either case, the controller memory stores the module

configuration. Refer to your controller's user manual for more information.

Publication 1769-RM016A-EN-P - July 2006

Page 12

12 Module Operation

Boolean Expressions

An expression is any legal combination of symbols that represents a value. An

expression that results in a value of either TRUE or FALSE is called a Boolean

expression. Every Boolean expression (except a null expression) consists of at

least one operand and can have one or more operators. Operands are values,

whereas operators are symbols that represent particular logical actions. For

example, in the expression

OUT = A AND B,

the value of OUT is either TRUE or FALSE and is determined by the value of

the expression “A AND B”. A and B are operands that also have a value of

TRUE or FALSE. The operator in the expression is the logical operator AND.

Other examples of logical operators are OR and XOR (exclusive-OR).

The 1769-BOOLEAN module outputs can be controlled based upon the

value of Boolean expressions configured by the program. An output state

(when in Boolean control mode) is determined by the state of that output’s

configured Boolean expression, with a value of TRUE corresponding to the

ON state and a value of FALSE corresponding to the OFF state.

Refer to Chapter 3, Module Data, Status, and Configuration on page 41, for

information on configuring control of the 1769-BOOLEAN module outputs

using Boolean expressions.

Publication 1769-RM016A-EN-P - July 2006

Page 13

Module Operation 13

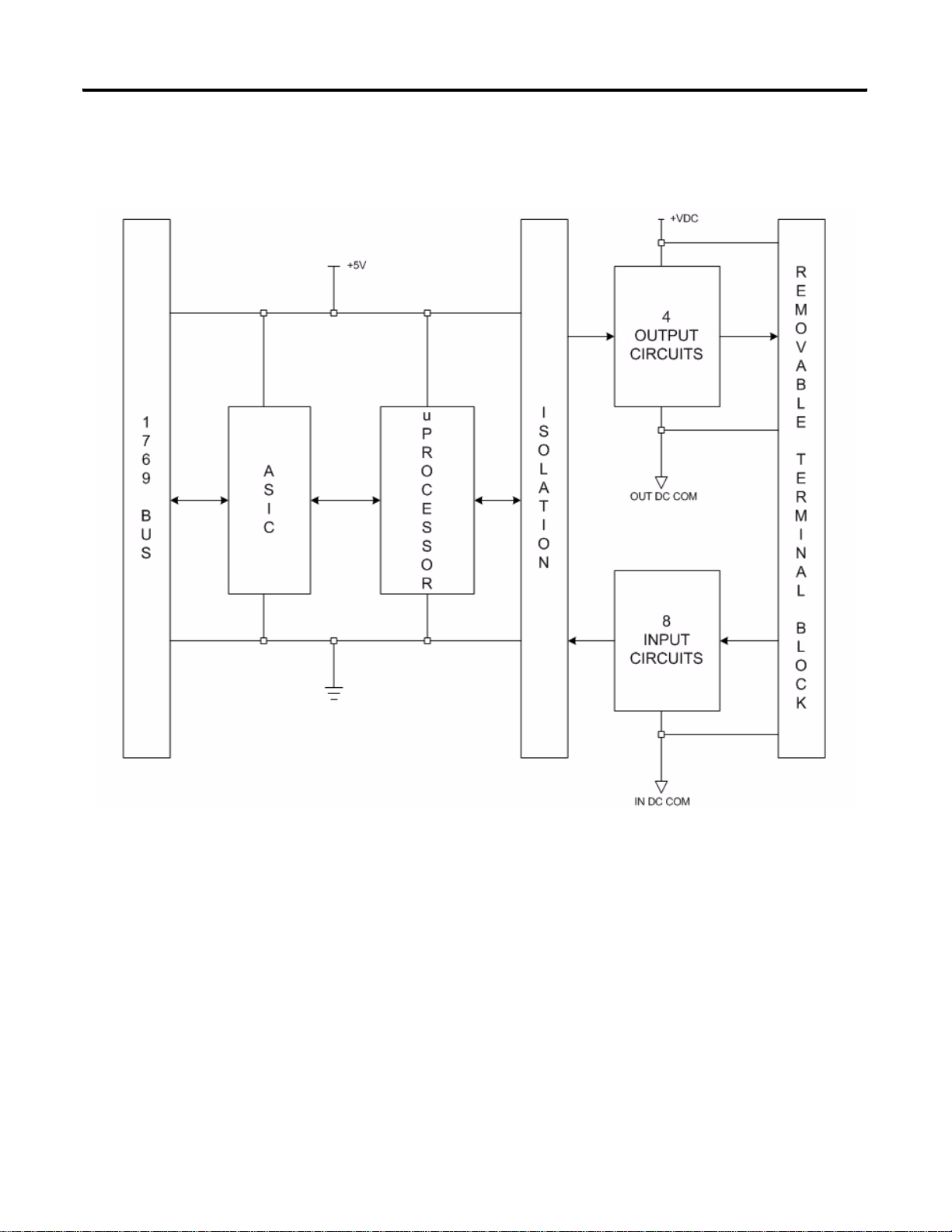

1769-BOOLEAN Module Block Diagram

The following figure is the block diagram for the 1769-BOOLEAN module.

1769-BOOLEAN Module Block Diagram

Publication 1769-RM016A-EN-P - July 2006

Page 14

14 Module Operation

Wire the 1769-BOOLEAN Module

Each terminal accepts as many as two wires with these restrictions.

Wire Type Wire Size Terminal

Screw Torque

Solid Cu-90 °C (194 °F) 2.08…0.34 mm

(14…22 AWG)

Stranded Cu-90 °C (194 °F) 1.31…0.34 mm

(16…22 AWG)

2

0.68 Nm (6 lb-in) 0.46 Nm (4.1

2

0.68 Nm (6 lb-in) 0.46 Nm (4.1

Retaining

Screw Torque

lb-in)

lb-in)

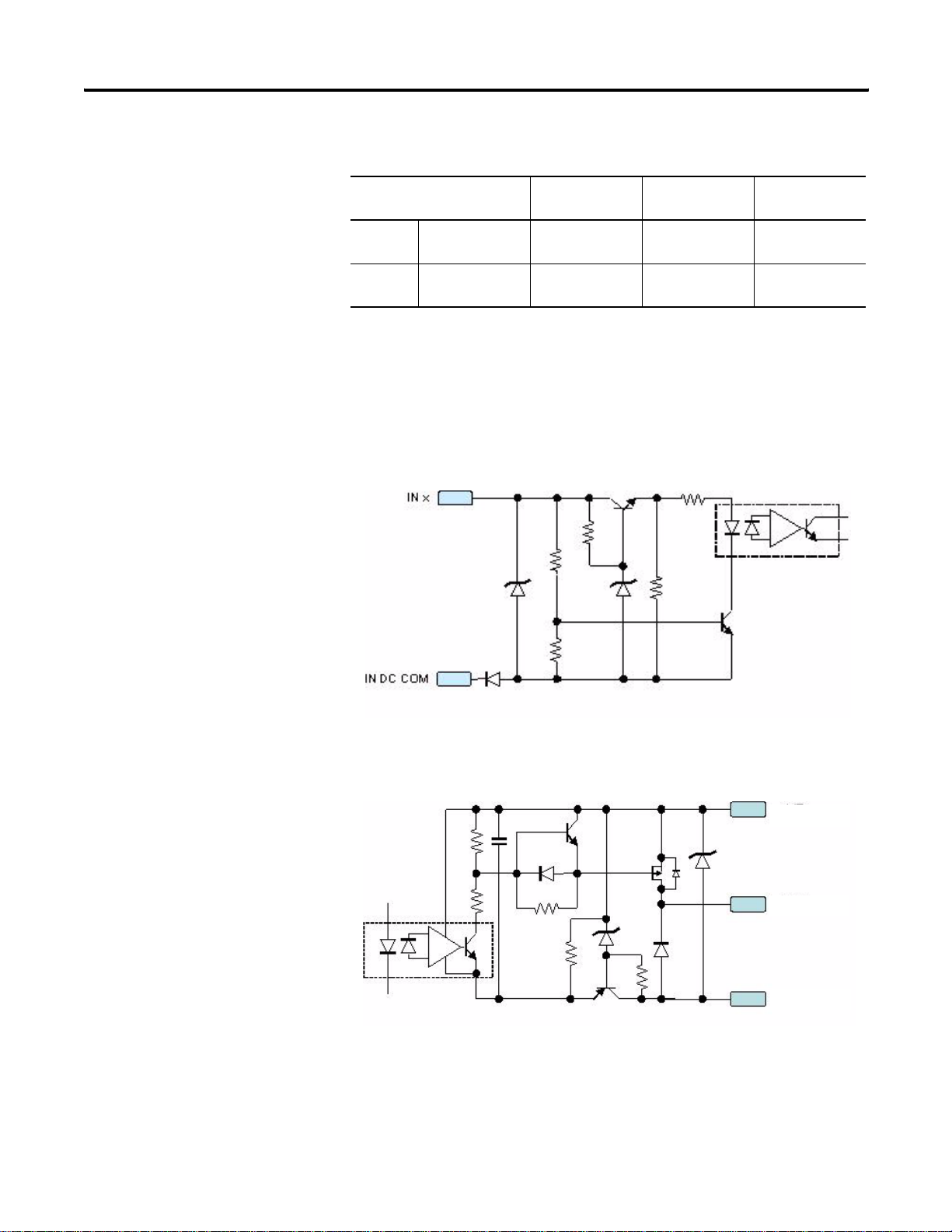

Input and Output Circuit Diagrams

The following figures illustrate the simplified input and output circuits.

Simplified Input Circuit Diagram

Publication 1769-RM016A-EN-P - July 2006

Simplified Output Circuit Diagram

+VDC

OUT x

OUT DC COM

Page 15

Module Operation 15

Control Outputs Using Boolean Expressions

You can configure the 1769-BOOLEAN module outputs to be controlled by

Boolean expression (Boolean control mode).

Format of Boolean Expression

Each output is controlled with a separate expression. The fixed format of each

Boolean expression is assumed to be of the form:

Output State = (A x B) y C

where A, B, and C are operands and x and y are logical operators you select.

The location of the parentheses in the fixed format indicates that the logical

operation represented by x is performed on operands A and B first, with the

result of that operation then used as the first operand for the logical operation

represented by y (with C being the second operand).

The parameter names assigned in the 1769-BOOLEAN module configuration

file that correspond to the operands and operators of the fixed format

Boolean expression above are:

A: Operand_A_#

Boolean Expression Configuration Restrictions

B: Operand_B_#

C: Operand_C_#

x: Operator_1_#

y: Operator_2_#

where the # symbol indicates the module output (OUT0 through OUT3).

The Boolean expressions controlling the output states have default values

assigned to each operand and operator. These default values assign “None” to

each operand and operator resulting in a “Null” expression. A “Null”

expression will be accepted by the module but will result in an output that will

always be in the OFF state.

The module will only accept the following variations of Boolean expressions

as valid (based on the fixed format expression (A x B) y C).

Publication 1769-RM016A-EN-P - July 2006

Page 16

16 Module Operation

Variations of Boolean Expressions

Variation Description

Null All operands and operators assigned a value of “None”.

A Only the first operand assigned a non-default value, all other

operands and all operators assigned a value of “None”.

A x B Only the first two operands and the first operator assigned a

non-default value, final operand and final operator assigned

a value of “None”

(A x B) y C All operands and operators assigned non-default values)

Operands

The operands in each output's Boolean expression can be configured to be

one of the following.

• None (default)

• Current state of one of the module's eight, real inputs

• Inverted, current state of one of the module's eight, real inputs

• Current state of one of the module's eight, virtual inputs (controlled by

the user program via the module's output data file)

• Inverted, current state of one of the module's eight, virtual inputs

Refer to Chapter 3, Module Data, Status, and Configuration on page 41, for

details on configuring the Boolean expression operands.

Operators

The operators in each output Boolean expression can be configured to be one

of the following (the operator's effect on a pair of operands is described).

Boolean Expression and the Related Operator Effect

Expression Operator Effect

None Default, no logical operation performed.

OR If either operand in TRUE, the result is TRUE.

AND Both operands must be TRUE for the result to be TRUE.

Publication 1769-RM016A-EN-P - July 2006

XOR Exclusive - OR, one operand must be TRUE and the other

FALSE for the result to be TRUE.

Refer to Chapter 3, Module Data, Status, and Configuration on page 41, for

details on configuring the Boolean expression operators.

Page 17

Module Operation 17

Output Delay

When configured for Boolean control, the module's outputs are directed ON

when the Boolean expression for each output channel is TRUE. The module

can be configured to add a delay between an output's Boolean expression

becoming TRUE and the output being placed into the ON state. The length of

this delay time for an output operating in Boolean control mode can be

configured to be between 0 (default) and 1 second in 1 ms increments.

Refer to Chapter 3, Module Data, Status, and Configuration on page 41, for

details on configuring the Boolean expression output delay.

Output Duration

When configured for Boolean control, if an output is directed ON as the result

of the output's Boolean expression becoming TRUE, and the Output Delay

time for that output has been satisfied, then the length of time an output stays

ON can be controlled by designating an Output Duration. The length of this

duration time for an output operating in Boolean control mode can be

configured to be either a fixed amount of time between 1 ms and 1 second (in

1 ms increments), or, the output can be configured to remain ON only as long

as its Boolean expression remains TRUE (duration time set to 0, this is the

default setting).

Refer to Chapter 3, Module Data, Status, and Configuration on page 41, for

details on configuring the Boolean expression output duration.

Publication 1769-RM016A-EN-P - July 2006

Page 18

18 Module Operation

Output Delay and Duration Operation

Since an output's Boolean expression can change in real time, configuring a

delay and/or duration time when an output is in Boolean control mode could

cause confusion.

The module shall operate in the following manner when output delay and/or

duration times are configured to non-default values (while an output is

configured for Boolean control).

When the Boolean expression controlling an output transitions from FALSE

to TRUE, the output will be directed ON after the delay time has expired only

if:

Case 1

• The output's duration time is not equal to 0. In this case the output

should be directed ON for the length of the duration time regardless of

the state of the output's Boolean expression and then should be directed

OFF regardless of the state of the Boolean expression.

• In Case 1 a “One-shot” type of function has been configured. The

output will be turned ON with a single pulse of configured delay time

and duration time when the output's Boolean expression becomes

TRUE. The length of time the Boolean expression remains TRUE does

not determine whether the “One-shot” pulse occurs. As long as the

duration time of the output has been configured to a value greater than

0, then a “One-shot” ON pulse will occur and the output will remain

ON for the length of the duration time. The output will then turn OFF

regardless of the state of the output's Boolean expression.

• Retriggering of the output is not supported. Any additional transitions

of the output's Boolean expression from FALSE to TRUE after the

initial transition to TRUE are ignored for a length of time equal to the

configured delay time added to the configured duration time. Once the

output's “One-shot” pulse duration is complete, and the output is

turned OFF, a FALSE to TRUE transition of the Boolean expression

will cause another “One-shot” ON pulse to occur.

Case 2

• The output's duration is equal to 0 and the output's Boolean expression

has maintained a state of TRUE for the entire delay time. The output

should then be directed OFF when the output's Boolean expression

becomes FALSE.

Publication 1769-RM016A-EN-P - July 2006

Page 19

Module Operation 19

• In Case 2 the output will follow the state of the Boolean expression as

long as the configured delay time has expired and the Boolean

expression has maintained a TRUE state. When an output's Boolean

expression transitions from FALSE to TRUE, the output will be turned

ON only if the Boolean expression has maintained a state of TRUE for

the entire length of the delay time. If the output's Boolean expression

transitions to FALSE before the configured delay time expires, then the

delay time should be terminated and the output should not be turned

ON. If the output's Boolean expression has maintained a TRUE state

for the full length of the delay time, the output will be turned ON and

will remain ON until the Boolean expression becomes FALSE.

• If an output's Boolean expression is configured with both the delay and

duration times set to 0, then the output simply follows the state of the

Boolean expression, ON when the expression is TRUE and OFF when

it is FALSE.

Boolean Control Mode Examples

The following examples illustrate the module's operation when an output is

configured in Boolean control mode. Examples 1…5 show module output

operation for Case 1 where the configured duration time is greater than 0.

Examples 6 and 7 show module operation for Case 2 where the configured

duration time is equal to 0.

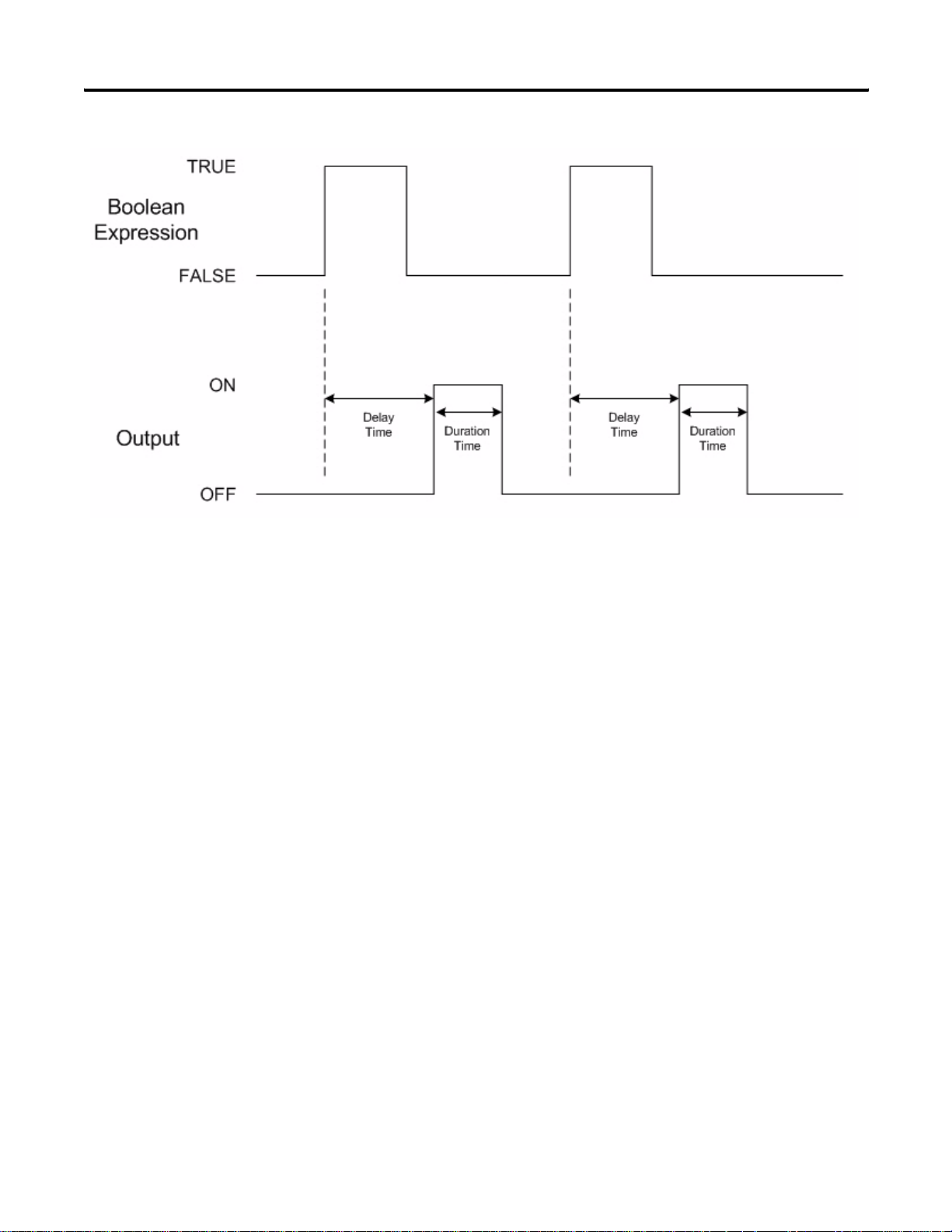

Example 1: Duration > 0, Delay > TRUE Time

In this example, the output is configured with a duration time greater than 0, a

delay time greater than 0, and the configured delay time is longer than the time

that the Boolean expression remains TRUE.

Since the configured duration time is greater than 0, a “One-shot” pulse

occurs on the output. The pulse starts an amount of time after the FALSE to

TRUE transition of the Boolean expression equal to the configured delay time.

The “One-shot” pulse lasts as long as the configured duration time even

though the Boolean expression transitions to FALSE. The second “One-shot”

pulse occurs on the output since there was a FALSE to TRUE transition in the

Boolean expression after the first “One-shot” pulse is completed.

Publication 1769-RM016A-EN-P - July 2006

Page 20

20 Module Operation

Publication 1769-RM016A-EN-P - July 2006

Page 21

Module Operation 21

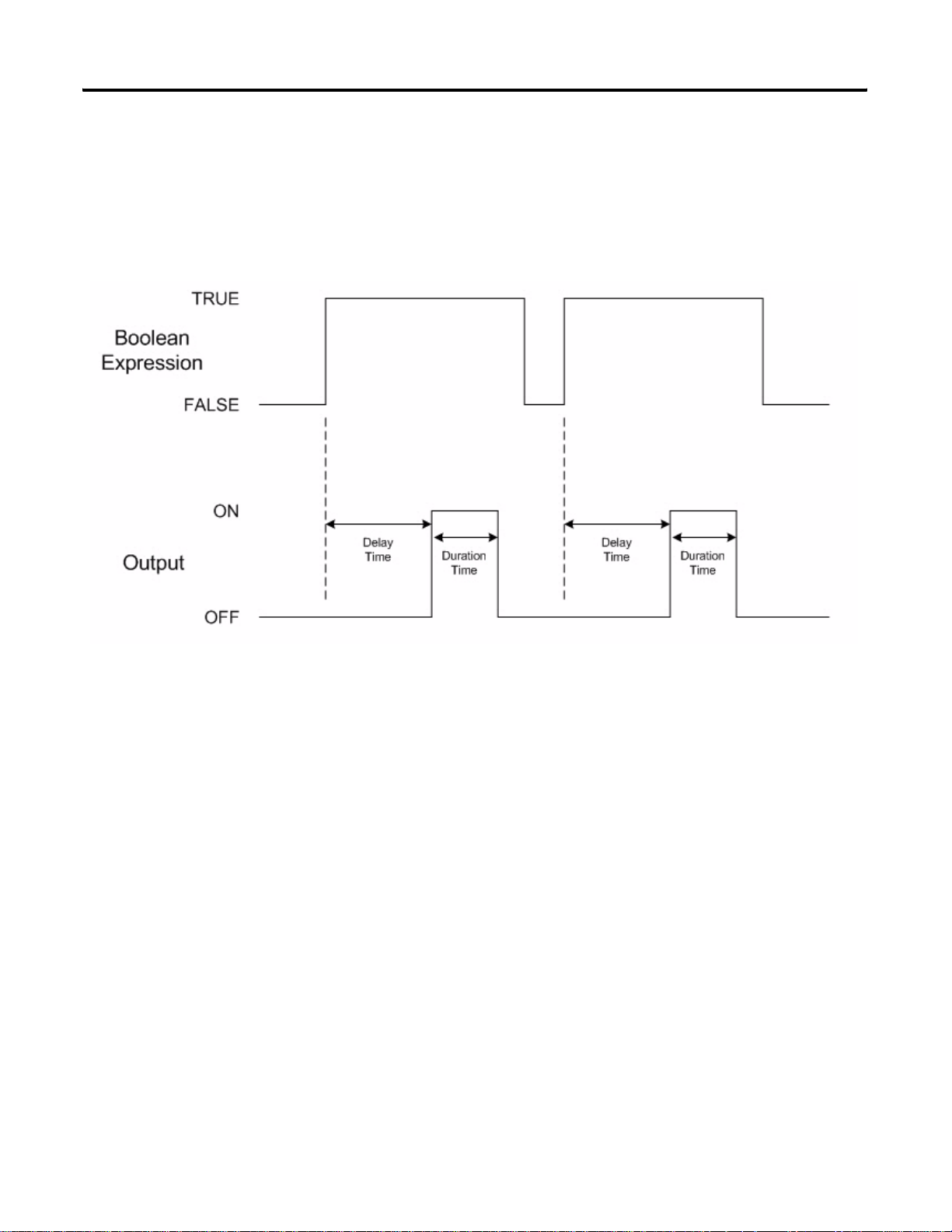

Example 2: Duration > 0, Delay < TRUE Time

In this example, the output is configured with a duration time greater than 0, a

delay time greater than 0, and the configured delay time is shorter than the

time that the Boolean expression remains TRUE.

Again, since the configured duration time is greater than 0, a “One-shot” pulse

occurs on the output. The pulse starts an amount of time after the FALSE to

TRUE transition of the Boolean expression equal to the configured delay time.

The “One-shot” pulse again lasts only as long as the configured duration time

even though the Boolean expression remains TRUE. The second “One-shot”

pulse occurs on the output since there was a FALSE to TRUE transition in the

Boolean expression after the first “One-shot” pulse is completed.

Publication 1769-RM016A-EN-P - July 2006

Page 22

22 Module Operation

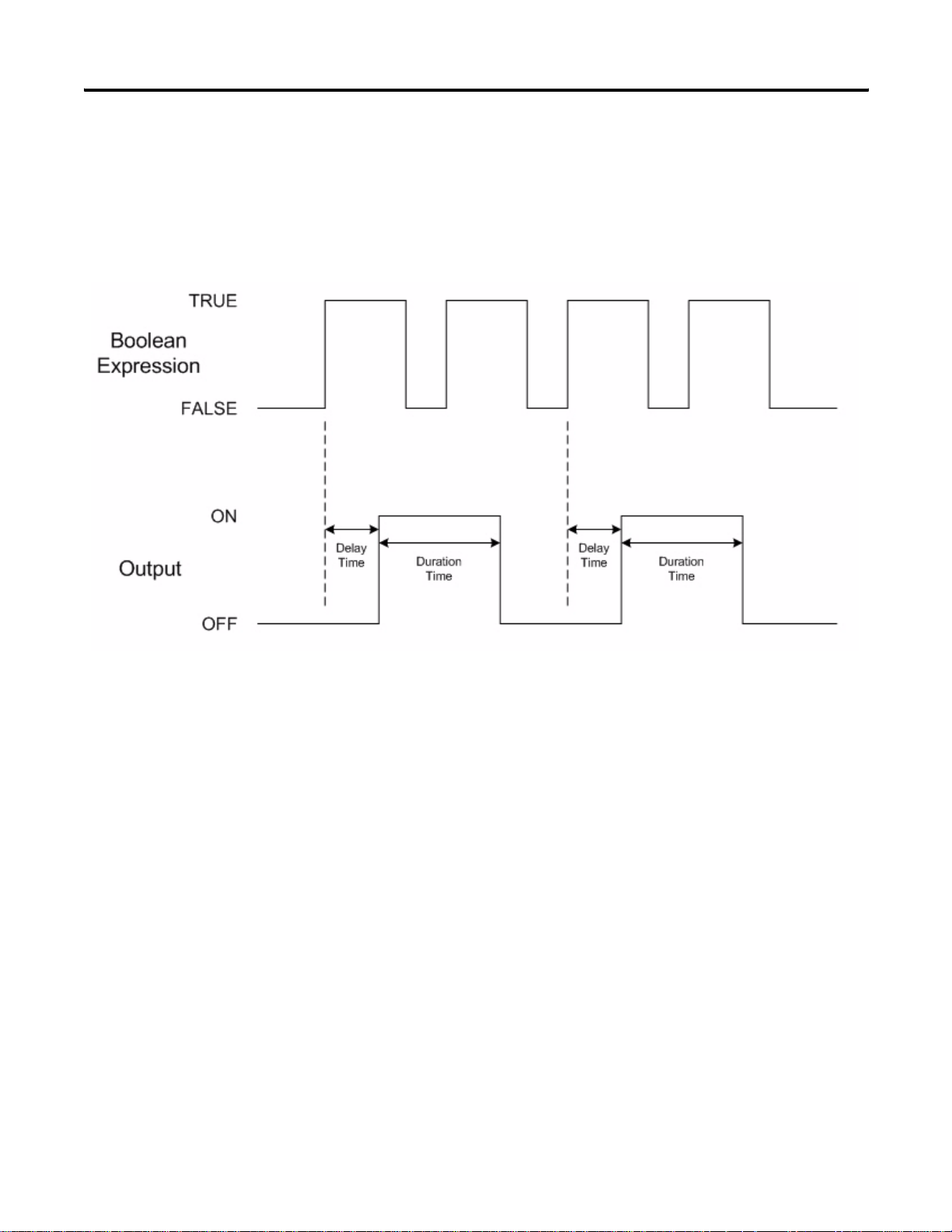

Example 3: Duration > 0, Delay < TRUE Time, Retriggering Ignored

In this example, the output is configured with a duration time greater than 0, a

delay time greater than 0, and multiple transitions of the Boolean expression

occur before the initial “One-shot” pulse duration is completed.

The first FALSE to TRUE transition of the Boolean expression causes a

“One-shot” pulse to occur. The pulse starts an amount of time after the

FALSE to TRUE transition of the Boolean expression equal to the configured

delay time. The “One-shot” pulse lasts as long as the configured duration time.

Since the second FALSE to TRUE transition of the Boolean expression occurs

before the initial “One-shot” pulse is completed, that transition of the Boolean

expression is ignored by the module. The third FALSE to TRUE transition of

the Boolean expression again causes a “One-shot” pulse, with the fourth

FALSE to TRUE transition of the Boolean expression again ignored by the

module since it occurs before the second “One-shot” pulse is complete.

Publication 1769-RM016A-EN-P - July 2006

Page 23

Module Operation 23

Example 4: Duration > 0, Delay = 0, Duration > TRUE Time

In this example, the output is configured with a duration time greater than 0, a

delay time equal to 0, and the configured duration time is longer than the time

that the Boolean expression remains TRUE.

Since the configured duration time is greater than 0, a “One-shot” pulse

occurs on the output. The pulse starts at the same time as the FALSE to

TRUE transition of the Boolean expression because the configured delay time

is equal to 0. The “One-shot” pulse lasts as long as the configured duration

time even though the Boolean expression transitions to FALSE.

Publication 1769-RM016A-EN-P - July 2006

Page 24

24 Module Operation

Example 5: Duration > 0, Delay = 0, Duration < TRUE Time

In this example, the output is configured with a duration time greater than 0, a

delay time equal to 0, and the configured duration time is shorter than the time

that the Boolean expression remains TRUE.

Again, since the configured duration time is greater than 0, a “One-shot” pulse

occurs on the output. The pulse starts at the same time as the FALSE to

TRUE transition of the Boolean expression because the configured delay time

is equal to 0. The “One-shot” pulse again lasts only as long as the configured

duration time even though the Boolean expression remains TRUE. The

second “One-shot” pulse occurs on the output since there was a FALSE to

TRUE transition in the Boolean expression after the first “One-shot” pulse is

completed.

Publication 1769-RM016A-EN-P - July 2006

Page 25

Module Operation 25

Example 6: Duration = 0, Delay < TRUE Time

In this example, the output is configured with a duration time equal to 0 (the

output will remain ON only if the Boolean expression remains TRUE), a delay

time greater than 0, and the Boolean expression continuously remains TRUE

for a length of time greater than the configured delay time.

Since the delay time is greater than 0, the output does not turn ON until the

Boolean expression has maintained a TRUE condition for a period of time

equal to the configured delay time. The output remains ON until the Boolean

expression becomes FALSE. The output immediately turns OFF since the

configured duration time is 0.

Publication 1769-RM016A-EN-P - July 2006

Page 26

26 Module Operation

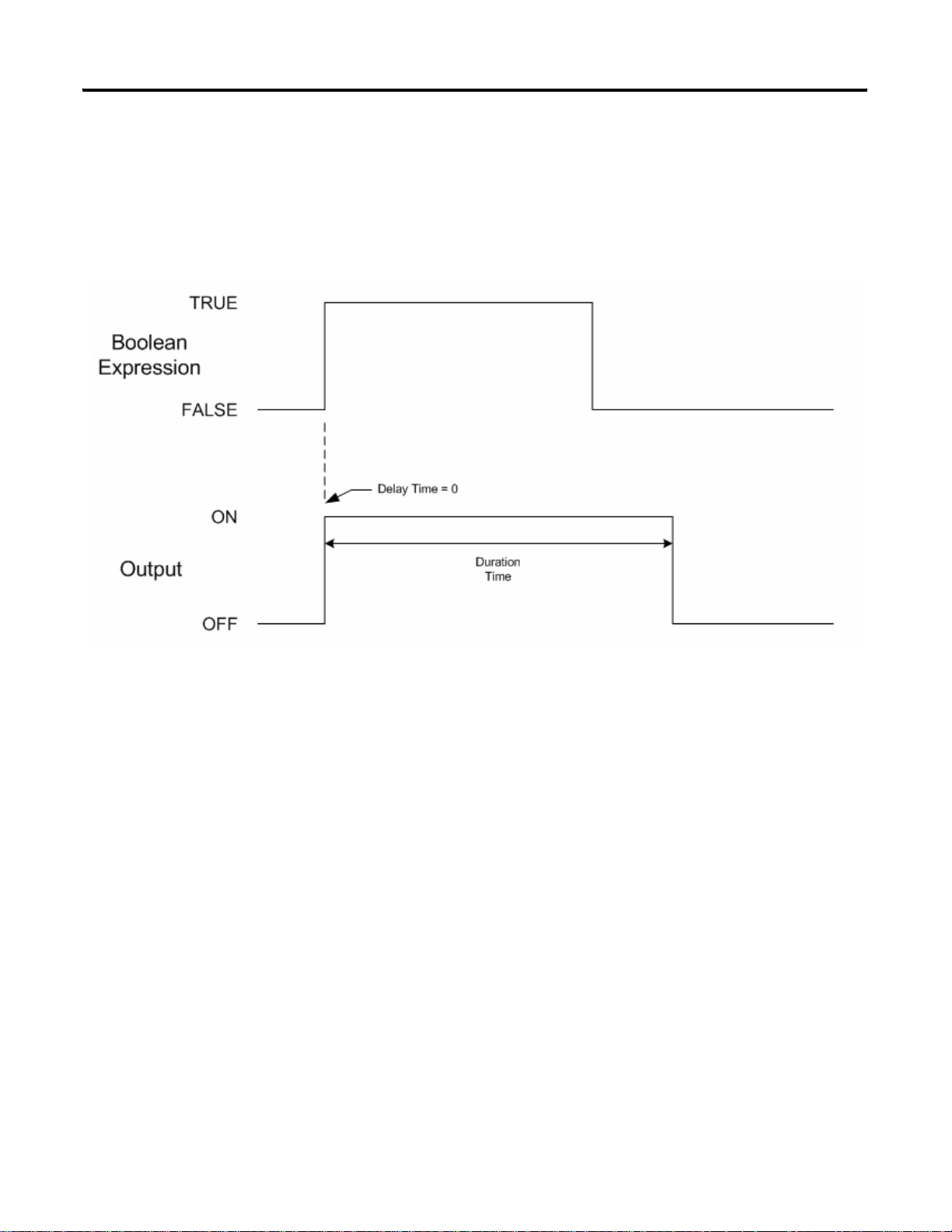

Example 7: Duration = 0, Delay > TRUE Ti me

In this example, the output is configured with a duration time equal to 0 (the

output will remain ON only if the Boolean expression remains TRUE) and a

delay time greater than 0. Conditions where the Boolean expression remains

TRUE both for less than and longer than the configured delay time are

illustrated.

Publication 1769-RM016A-EN-P - July 2006

The first instance that the Boolean expression goes to the TRUE state, but

does not remain continuously TRUE for a period of time exceeding the

configured delay time, it does not cause the output to turn ON. When this first

TRUE condition ends, the corresponding delay time event also ends. The next

time the Boolean expression becomes TRUE, a new delay time event begins.

This second TRUE event does continuously remain TRUE for longer than the

configured delay time and the output turns ON. The output remains ON until

the Boolean expression becomes FALSE, at which point it immediately turns

OFF since the configured duration time is 0.

Page 27

Installation and Wiring

Chapter

2

Overview

This chapter tells you how to:

• determine the power requirements for the module.

• avoid electrostatic damage.

• install the module.

• wire the module’s terminal block.

• wire input devices.

• wire output devices.

Topic Page

Compliance to European Union Directives 27 Power Requirements 28 General Considerations 28 System Assembly 31 Mount the Module 32 Replace a Single Module Within a System 34 Field Wiring Connections 35 Wire the Module 38

Compliance to European

This product is approved for installation within the European Union and EEA

regions. It has been designed and tested to meet the following directives.

Union Directives

EMC Directive

The analog modules are tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in whole

or in part, documented in a technical construction file:

• EN 61000-6-4:2001

Electromagnetic Compatibility (EMC) - Part 6-4: Generic Standards Emission Standard for Industrial Environments

• EN 61000-6-2:2001

Electromagnetic Compatibility (EMC) - Part 6-4: Generic Standards Immunity for Industrial Environments

This product is intended for use in an industrial environment.

27 Publication 1769-RM016A-EN-P - July 2006

Page 28

28 Installation and Wiring

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 – Equipment Requirements and Tests.

For specific information required by EN61131-2, see the appropriate sections

in this publication, as well as the following Allen-Bradley publications:

• Industrial Automation Wiring and Grounding Guidelines for Noise

Immunity, publication 1770-4.1

• Automation Systems Catalog, publication B113

Power Requirements

General Considerations

The module receives power through the bus interface from the +5V dc/+24V

dc system power supply. The maximum current draw for the

1769-BOOLEAN module is:

• 5V dc: 220 mA.

• 24V dc: 0 mA.

The Compact I/O system is suitable for use in an industrial environment

when installed in accordance with these instructions. Specifically, this

equipment is intended for use in clean, dry environments (Pollution degree

(1)

) and to circuits not exceeding Over Voltage Category II

2

60664-1).

(3)

(2)

(IEC

Publication 1769-RM016A-EN-P - July 2006

(1)

Pollution Degree 2 is an environment where, normally, only nonconductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level transient

voltages are controlled and do not exceed the impulse voltage capability of the product’ s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Page 29

Installation and Wiring 29

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

nonhazardous locations only. The following attention statement applies to use

in hazardous locations.

ATTENTION

Explosion Hazard

• Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect eq uipment unless

power has been switched off or the area is known to be

nonhazardous.

• Do not connect or disconnect components unless power has

been switched off or the area is known to be nonhazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

Prevent Electrostatic Discharge

ATTENTION

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch th e bus connector pins or the

terminal block on the module. Follow these guidelines when

you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components inside the module.

• Use a static-safe work station, if available.

• Keep the module in its static-shield box when it is not in

use.

Publication 1769-RM016A-EN-P - July 2006

Page 30

30 Installation and Wiring

Remove Power

ATTENTION

Remove power before removing or inserting this module. When

you remove or insert a module with power applied, an electrical

arc may occur. An electrical arc can cause personal injury or

property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion.

• causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector and may lead to premature

failure.

Reduce Noise

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference. Group your modules to minimize adverse

effects from radiated electrical noise and heat. Consider the following

conditions when selecting a location for the module. Position the module:

• away from sources of electrical noise such as hard-contact switches,

relays, and ac motor drives.

• away from modules that generate significant radiated heat, such as the

1769-IA16 module. Refer to the module’s heat dissipation specification.

Publication 1769-RM016A-EN-P - July 2006

Protect the Circuit Board from Contamination

The printed circuit board of the module must be protected from dirt, oil,

moisture, and other airborne contaminants. To protect the printed circuit

board, the system must be installed in an enclosure suitable for the

environment. The interior of the enclosure should be kept clean and the

enclosure door should be kept closed whenever possible.

Page 31

Installation and Wiring 31

System Assembly

2

The module can be attached to the controller or an adjacent I/O module

before or after mounting.

Refer to Panel Mounting Using the Dimensional Template on page 33, for

mounting instructions, or to DIN Rail Mount on page 34.

Refer to Replace a Single Module Within a System on page 34, for information

on working with a system that is already mounted.

3

4

1

6

1

5

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the unlocked

(fully right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure the

modules together (or to a controller).

4. Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

5. Push the bus lever back slightly to clear the positioning tab (3), using

your fingers or a small screwdriver.

Publication 1769-RM016A-EN-P - July 2006

Page 32

32 Installation and Wiring

6. Move the bus lever fully to the left (4) until it clicks, making sure it is

locked firmly in place, to allow communication between the controller

and module.

Mount the Module

ATTENTION

When attaching I/O modules, it is very important that

the bus connectors are securely locked together to be

sure of proper electrical connection.

7. Attach an end cap terminator (5) to the last module in the system by

using the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (6).

IMPORTANT

A 1769-ECR or 1769-ECL right or left end cap must be used to

terminate the end of the bus.

ATTENTION

During panel or DIN rail mounting of all devices, be sure that all

debris (that is, metal chips or wire strands) is kept from falling

into the module. Debris that falls into the module could cause

damage when you cycle power.

Publication 1769-RM016A-EN-P - July 2006

Minimum Spacing

Maintain spacing from enclosure walls, wireways, or adjacent equipment.

Allow 50 mm (2 in.) of space on all sides for adequate ventilation.

Space Requirements

Top

Side

Host Controller

Compact I/O

Bottom

Compact I/O

Compact I/O

Compact I/O

Compact I/O

Side

End Cap

Page 33

Installation and Wiring 33

Panel Mount

Mount the module to a panel using two screws per module. Use M4 or #8

panhead screws. Mounting screws are required on every module.

Panel Mounting Using the Dimensional Template

Spacing for one-and-a-half-wide modules 52.5 mm (2.067 in.).

Refer to the host controller documentation for this dimension.

Overall hole spacing tolerance:

±0.4 mm (0.016 in.).

Spacing for single-wide modules 35 mm (1.378 in.).

l Mounting

Locate holes every 17.5 mm (0.689 in.) to allow for a

mix of single-wide and one-and-a-half-wide modules

(for example, the 1769-OA16 module).

Host Controller

Panel Mounting Procedure Using Modules as a Template

This procedure lets you use the assembled modules as a template for drilling

holes in the panel. If you have sophisticated panel-mounting equipment, you

can use the dimensional template provided. Due to module mounting hole

tolerance, it is important to follow these procedures.

1. Assemble no more than three modules on a clean work surface.

2. Using the assembled modules as a template, carefully mark the center of

all module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel, and check for proper hole

alignment.

6. Attach the modules to the panel using the mounting screws.

TIP

If mounting more modules, mount only the last one of this group

and put the others aside. This reduces remounting time during

drilling and tapping of the next group.

7. Repeat steps 1…6 for any remaining modules.

Publication 1769-RM016A-EN-P - July 2006

Page 34

34 Installation and Wiring

DIN Rail Mount

The module can be mounted using the following DIN rails:

35 x 7.5 mm (EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latches. Press

the DIN rail mounting area of the module against the DIN rail. The latches

will momentarily open and lock into place.

Replace a Single Module Within a System

The module can be replaced while the system is mounted to a panel (or DIN

rail). Follow these steps in order.

1. Remove power.

ATTENTION

2. Remove the upper and lower mounting screws from the module to be

removed (or open the DIN latches using a flat-blade or Phillips

screwdriver).

3. Move the bus lever to the right to disconnect (unlock) the bus.

Remove power before removing or inserting this module. When

you remove or insert a module with power applied, an electrical

arc may occur. An electrical arc can cause personal injury or

property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion.

• causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector and may lead to premature

failure.

Publication 1769-RM016A-EN-P - July 2006

4. Move the right-side adjacent module's bus lever to the right (unlock) to

disconnect it from the module to be removed.

5. Gently slide the disconnected module forward.

If you feel excessive resistance, check that the module has been

disconnected from the bus, and that both mounting screws have been

removed (or DIN latches opened).

TIP

It may be necessary to rock the module slightly from front to

back to remove it, or, in a panel-mounted system, to loosen the

screws of adjacent modules.

Page 35

Installation and Wiring 35

6. Make sure that the bus lever, on the module to be installed and the

right-side adjacent module, are in the unlocked (fully right position)

before installing the replacement module.

7. Slide the replacement module into the open slot.

8. Connect the modules together by locking (fully left) the bus levers on

the replacement module and the right-side adjacent module.

9. Replace the mounting screws (or snap the module onto the DIN rail).

Field Wiring Connections

Use the following information to properly make field wiring connections.

Ground

Mount this product to a well-grounded mounting surface such as a metal

panel. Additional grounding connections from the module’s mounting tabs or

DIN rail (if used) are not required unless the mounting surface cannot be

grounded. Refer to the Allen-Bradley Industrial Automation Wiring and

Grounding Guidelines, publication 1770-4.1, for additional information.

Publication 1769-RM016A-EN-P - July 2006

Page 36

36 Installation and Wiring

System Wiring Guidelines

Consider the following when wiring your system.

General Guidelines

• Input and output channels are isolated from each other.

• Do not use the module’s NC terminals as connection points.

Label the Terminals

A removable, write-on label is provided with the module. Remove the label

from the door, mark the identification of each terminal with permanent ink,

and slide the label back into the door. Your markings (ID tag) will be visible

when the module door is closed.

Terminal Labels

Publication 1769-RM016A-EN-P - July 2006

Page 37

Installation and Wiring 37

Remove the Finger-safe Terminal Block

When wiring field devices to the module, it is not necessary to remove the

terminal block. If you remove the terminal block, use the write-on label on the

side of the terminal block to identify the module slot location and type. RTB

position can be indicated by circling either the R for right side or L for left

side.

Finger-safe Termin al Block

SLOT # _____

MODULE TYPE ______

To remove the terminal block, loosen the upper and lower retaining screws.

The terminal block will back away from the module as you remove the screws.

When replacing the terminal block, torque the retaining screws to 0.46 Nm

(4.1 lb-in).

Wire the Finger-safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the terminal screws to be wired.

2. Begin wiring at the bottom of the terminal block and move up.

Upper Retaining Screw

Lower Retaining Screw

Wire the

Finger-safe

Terminal Block

Publication 1769-RM016A-EN-P - July 2006

Page 38

38 Installation and Wiring

3. Route the wire under the terminal pressure plate.

You can use the bare wire or a spade lug.

The terminals accept a 6.35 mm (0.25 in.) spade lug.

Wire the Module

TIP

The terminal screws are non-captive. Therefore, it is possible to

use a ring lug (maximum 1/4 in. o.d. with a 0.139 in. minimum

i.d. (M3.5)) with the module.

4. Tighten the terminal screw making sure the pressure plate secures the

wire.

Recommended torque when tightening terminal screws is

0.68 Nm (6 lb-in).

TIP

If you need to remove the finger-safe cover , insert a screwdriver

into one of the square, wiring holes and gently pry the cover off.

If you wire the terminal block with the finger-safe cover

removed, you will not be able to put it back on the terminal

block because the wires will be in the way.

ATTENTION

To prevent shock hazard, care should be taken when wiring the

module to signal sources. Before wiring any module, disconnect

power from the system power supply and from any other source

to the module.

Publication 1769-RM016A-EN-P - July 2006

After the module is properly installed, follow the wiring procedure below.

1. String about 5 mm (3/16 in.) of insulation away to expose the end of the

wire at each end of a signal wire.

2. Connect one end of the signal wire to the terminal block.

Refer to Input and Output Wiring on page 39.

3. Connect the other end of the signal wire to the input or output device.

4. Repeat steps 1…3 for each signal wire.

Page 39

Installation and Wiring 39

O

g

t

N

Input and Output Wiring

This illustration describes the 1769-BOOLEAN module terminal layout.

1769-BOOLEAN Module Terminal Layout

OUT 0

OUT 2

UT DC COM

N.C.

IN 0

IN 2

IN 4

IN 6

IN DC COM

+VDC

OUT 1

OUT 3

N.C.

N.C.

IN 1

IN 3

IN 5

IN 7

Do Not Remove RTB

Under Power Unless Area

is Nonhazardous

DANGER

+VDC

OUT 0

OUT 1

OUT 2

OUT DC

COM

OUT 3

N.C.

N.C.

N.C.

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN DC

COM

Bus Lever is Unlatched/Latched

Before/After Removing/Insertin

Module

IN 7

Ensure Adjacen

1769-BOOLEA

Input/Output Wiring

Do not use the NC terminals

as connection points.

Publication 1769-RM016A-EN-P - July 2006

Page 40

40 Installation and Wiring

Notes:

Publication 1769-RM016A-EN-P - July 2006

Page 41

Chapter

Module Data, Status, and Configuration

3

Overview

This chapter examines the module's data tables and channel configuration

words.

Topic Page

1769-BOOLEAN Module Addressing 42

1769-BOOLEAN Module Input Data File 44

1769-BOOLEAN Module Output Data File 44

1769-BOOLEAN Module Configuration Data File 46

Module Inputs

The 1769-BOOLEAN module has eight, single-ended, 24V dc sinking inputs.

Sinking describes the current flow between the I/O module and the field

device. Sinking input circuits are driven by a current sourcing field device.

Field devices supplying the positive (+V) field supply voltage when ON will

source current to the 1769-BOOLEAN module inputs.

Module Outputs

The 1769-BOOLEAN module has four, single-ended, 24V dc sourcing

outputs. Sourcing describes the current flow between the I/O module and the

field device. Sourcing output circuits supply current to sinking field devices

when ON. Field devices connected to the dc common of the field supply

voltage are sinking field devices.

41 Publication 1769-RM016A-EN-P - July 2006

Page 42

42 Module Data, Status, and Configuration

1769-BOOLEAN Module Addressing

Slot e

Input Image

File

Slot e

Output Image

File

Slot e

Configuration

File

The 1769-BOOLEAN module memory map shows the input, output, and

configuration files for the module.

Input Image

2 Words

Output Image

2 Words

Configuration File

40 Words

Input Data - Real Inputs

Output Data Echo

Output Data - Direct Control

Virtual Inputs

Input Filter Control Word

Input Interrupt Control Word

Program to Fault Enable

Fault and Program State Configuration

Word 0, Bits 0…7

Word 1, Bits 0…3

Word 0, Bits 0…3

Word 1, Bits 0…7

Word 0, Bits 0…2

Word 1

Word 2, Bit 0

Words 3…7

Output Channel 0 Configuration

Output Channel 1 Configuration

Output Channel 2 Configuration

Output Channel 3 Configuration

Words 8…15

Words 16…23

Words 24…31

Words 32…39

Publication 1769-RM016A-EN-P - July 2006

Page 43

Module Data, Status, and Configuration 43

1769-BOOLEAN Module Input Image

The 1769-BOOLEAN module input image file represents real input data

states and output state data echo. Input word 0 contains the state of the

module's real inputs IN 0 through IN 7 in bits 0

directed state of the module's outputs OUT0 through OUT3 in bits 0

These output data echo bits indicate the state of the module's output control

circuits and do not represent the actual state of the outputs.

…7. Input word 1 contains the

…3.

TIP

You can access information in the input image file using the

programming software configuration screen.

1769-BOOLEAN Module Output Image

The 1769-BOOLEAN module output image file represents directed output

states in Direct Control mode and virtual input data states. Output word 0

contains the states to which the module's outputs will be set when the outputs

are configured for Direct Control mode.

Module outputs OUT0 through OUT3 are set in Direct Control mode using

output file word 0 bits 0

inputs V0 through V7 in bits 0

the customer's user program and can be used in a module output's Boolean

expression when the output is configured for Boolean Control.

TIP

…3. Output word 1 contains the values of the virtual

…7. These virtual inputs can be controlled in

You can access information in the output image file using the

programming software configuration screen.

1769-BOOLEAN Module Configuration File

The 1769-BOOLEAN module configuration file contains information that

you use to define the module's operation.

The configuration file is explained in more detail in 1769-BOOLEAN Module

Configuration Data File on page 46.

TIP

Not all controllers support program access to the configuration

file. Refer to your controller’s user manual.

Publication 1769-RM016A-EN-P - July 2006

Page 44

44 Module Data, Status, and Configuration

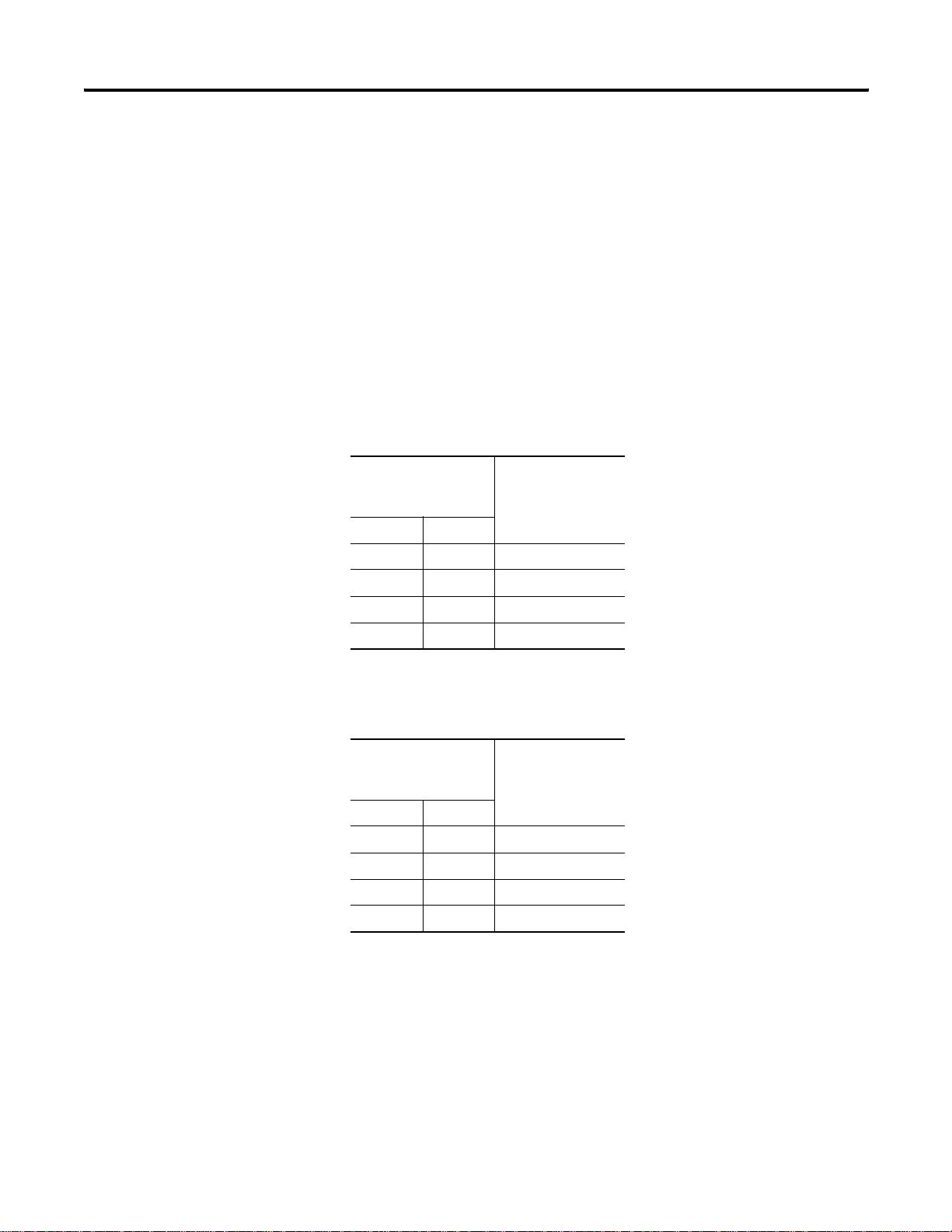

1769-BOOLEAN Module Input Data File

15 14 13 12 1 10 9 8 7 6 5 4 3 2 1 0

WORD

0

1

1769-BOOLEAN Module Output Data File

The input data file lets you access module input read data for use in the control

program, via word or bit access. The data file structure is shown in the table

below. For each module, word 0, bits 0

values of the real inputs. For each module, word 1, bits 0

…7 in the input data file contain the

…3 in the input data

file contain the state of the module's output control circuits.

1769-BOOLEAN Module Input Data File

Bit Position

IN7 IN6 IN5 IN4 IN3 IN2 IN1 IN0

03 02 01 00

TIP

Shaded bits always must be set to 0.

The output data file lets you access module write data for use in the control

program, via word or bit access. The data file structure is shown in the table

below.

1769-BOOLEAN Output Data File

Bit Position

15 14 13 12 1 10 9 8 7 6 5 4 3 2 1 0

0 OUT3 OUT2 OUT1 OUT0

WORD

1

TIP

V7 V6 V5 V4 V3 V2 V1 V0

Shaded bits must be set to 0.

Direct Control of Module Outputs

The module's outputs can be directly determined by the control program

when the outputs are configured to have Boolean Control disabled.

Refer to Output Control (DB) on page 51, for information on configuring the

module's outputs for direct control mode.

When a module output has Boolean Control disabled, the directed state of that

output is controlled by the corresponding bit (OUT0 through OUT3) in the

output data file. Setting the bit (1) turns the output ON, clearing the bit (0)

turns the output OFF.

Publication 1769-RM016A-EN-P - July 2006

Page 45

Module Data, Status, and Configuration 45

Virtual Inputs

The control program determines eight virtual inputs. The module's outputs

can be controlled by the module itself when the outputs are configured to use

Boolean Control mode.

Refer to Output Control (DB) on page 51, for information on configuring the

module's outputs for Boolean Control mode.

When a module output is configured for Boolean Control mode, the Boolean

expression controlling the output state can be configured to use any of the

virtual inputs (V0 through V7) as operands.

Refer to Operands on page 52, for information on configuring Boolean

expression operands.

The values of the virtual inputs can be updated by the control program at any

time. The most recent values will be used by the module in the Boolean

expressions that are controlling the module's outputs. Word 1, bits 0…7 of the

output data file are used to control the values of the virtual inputs. Setting a bit

(1) assigns a logical value of TRUE, clearing a bit (0) assigns a logical value of

FAL SE.

Publication 1769-RM016A-EN-P - July 2006

Page 46

46 Module Data, Status, and Configuration

1769-BOOLEAN Module

The configuration file determines how the module will operate. Parameters

such as input filtering, output control mode, and Boolean expressions are set

Configuration Data File

up using this file. This data file is readable and writable. The default value of

the configuration file is all 0's.

1769-BOOLEAN Module Configuration Data File

BIT

1514131211109876543210

0 Input Filter

1 IT_I7 EI_I7 IT_16 EI_I6 IT_I5 EI_I5 IT_I4 EI_I4 IT_I3 EI_I3 IT_I2 EI_I2 IT_I1 EI_I1 IT_I0 EI_I0

2

3

4 Program State

5

6

7

8

9

10

11

12

13

14

15

16 IT_O1 EI_O1 DB_1

17

18

19

20

21

22

23

24 IT_O2 EI_O2 DB_2

25

26

27

28

29

30

31

32 IT_O3 EI_O3 DB_3

33

34

35

36

37

38

39

IT_O0 EI_O0 DB_0

Operator_2_0 Operator_1_0

Output Delay 0

Output Duration 0

Operator_2_1 Operator_1_1

Output Delay 1

Output Duration 1

Operator_2_1 Operator_2_0

Output Delay 2

Output Duration 2

Operator_3_1 Operator_3_0

Output Delay 3

Output Duration 3

Program Value

Fault State

Fault Value

Operand A 0

Operand B 0

Operand C 0

Operand A 1

Operand B 1

Operand C 1

Operand A 2

Operand B 2

Operand C 2

Operand A 3

Operand B 3

Operand C 3

PFE

Publication 1769-RM016A-EN-P - July 2006

Page 47

Module Data, Status, and Configuration 47

IMPORTANT

Shaded bits must be set to 0. Default is all data file bits = 0.

The configuration file is typically modified using the programming software

configuration screen.

For information on how to configure the module using.

Hardware and Software See

MicroLogix 1500 and RSLogix 500 software Appendix B

CompactLogix and RSLogix 5000 software Appendix C

1769-ADN DeviceNet adapter and

RSNetWorx software

Appendix D

The configuration file can also be modified through the control program, if

supported by the controller.

Input Filtering

The 8 real inputs on the module are filtered using a common filter setting.

Word 0, b its 0

…2 are used to select the input filtering level. A 3-bit pattern for

the filter time controls the filter setting for the input channels.

Word 0 Filter Time

Bit 2 Bit 1 Bit 0

0 0 0 8000 µs

0 0 1 0 µs

0 1 0 100 µs

0 1 1 200 µs

1 0 0 500 µs

1 0 1 1000 µs

1 1 0 2000 µs

1 1 1 4000 µs

The default filter setting is 000 binary, selecting 8000

µs.

Publication 1769-RM016A-EN-P - July 2006

Page 48

48 Module Data, Status, and Configuration

Input Interrupts

The module will support 8 input interrupts - one each for the 8 real inputs (IN

0 to IN 7). Interrupts are not supported by all controllers. Refer to your

controller's user manual to determine if interrupts from expansion I/O

modules are supported.

Each real input can have one of 2 types of interrupts selected by the user. An

interrupt can be triggered on the following conditions (the interrupt will occur

after input filtering delay):

• The input changes state from OFF (0) to ON (1).

• The input changes state from ON (1) to OFF (0).

The type of interrupt is selected for each channel by control of the IT_I bits in

word 1 of the configuration data file as follows.

IT_I Interrupt Event

0

1

Input change of state OFF (0) ON (1)

Input change of state ON (1) OFF (0)

The default interrupt event setting is 0:

Input change of state OFF (0) ON (1).

Each real input's interrupt must be enabled before it will become active. Each

real input's interrupt is enabled or disabled using the EI_I bit for each input in

word 1 of the configuration data file. Set (1) the EI_I bit for an input to enable

the interrupt for that input, clear (0) the EI_I bit to disable the interrupt for

that input. The default state for each EI_I bit is 0 (interrupt disabled).

Program to Fault Enable (PFE)

If a system operating in program mode faults, this setting determines whether

the program or fault value is applied to the output. Word 2, bit 0 is used to

select the program to fault state control mode for the module's outputs. When

the bit is cleared (0), the module applies the program value determined by the

configuration data file's Program State and Program Value words. When the

bit is set (1), the module applies the fault value determined by the

configuration data file's Fault State and Fault Value words. The default setting

is 0, meaning the module applies the program value to the outputs when the

control system transitions from program mode to fault mode.

TIP

The MicroLogix 1500 and CompactLogix controllers do not yet

support alternate output states. This functionality is currently

only supported when the module is used on the DeviceNet

network via the 1769-ADN adapter.

Publication 1769-RM016A-EN-P - July 2006

Page 49

Module Data, Status, and Configuration 49

Program State

This configuration selection provides the individual selection for the control of

the module outputs when the system enters the program mode. Word 3, bits

…3 are used to select the program state control mode for module outputs

0

OUT0 through OUT3. When any of these bits are cleared (0) and the system

enters the program mode, the module holds that output's last state, meaning

that the output remains at the last value prior to the condition that caused the

control system to enter the program mode.

IMPORTANT

Hold last state is the default setting for the 1769-BOOLEAN

program state control bits.

When any of these bits are set (1) and the system enters the program mode, it

instructs the module to set the outputs to the corresponding user-specified

values from the configuration data file's Program Value word.

TIP

The MicroLogix 1500 and CompactLogix controllers do not yet

support program state control. This functionality is currently

only supported when the module is used on the DeviceNet

network via the 1769-ADN adapter.

Program Value

Use the Program Value word to set the values for the outputs to assume when

the system enters the program mode and the Program State bit for any outputs

are set (1). Word 4, bits 0

module outputs OUT0 through OUT3. A value of 0 in any bit will set the

corresponding output to the OFF state when the system enters program

mode. A value of 1 in any bit will set the corresponding output to the ON state

when the system enters the program mode. The default setting for the

Program Value word is 0 for all bits indicating that when applicable, all module

outputs should be set to the OFF state.

…3 indicate the values to apply to the corresponding

TIP

The MicroLogix 1500 and CompactLogix controllers do not yet

support program state control. This functionality is currently

only supported when the module is used on the DeviceNet

network via the 1769-ADN adapter.

Publication 1769-RM016A-EN-P - July 2006

Page 50

50 Module Data, Status, and Configuration

Fault State

This configuration selection provides the individual selection for the control of

the module outputs when the system enters the fault mode. Word 5, bits 0

are used to select the program state control mode for module outputs OUT0

through OUT3. When any of these bits are cleared (0) and the system enters

the fault mode, the module holds that output's last state, meaning that the

output remains at the last value prior to the condition that caused the control

system to enter the fault mode.

…3

IMPORTANT

Hold last state is the default setting for the 1769-BOOLEAN

fault state control bits.

When any of these bits are set (1) and the system enters the fault mode, it

instructs the module to set the outputs to the corresponding user-specified

values from the configuration data file's Fault Value word.

TIP

The MicroLogix 1500 and CompactLogix controllers do not yet

support fault state control. This functionality is currently only

supported when the module is used on the DeviceNet network

via the 1769-ADN adapter.

Fault Value

Use the Fault Value word to set the values for the outputs to assume when the

system enters the fault mode and the Fault State bits for any outputs are set

(1). Word 6, bits 0

outputs OUT0 through OUT3. A value of 0 in any bit will set the

corresponding output to the OFF state when the system enters fault mode. A

value of 1 in any bit will set the corresponding output to the ON state when

the system enters the fault mode. The default setting for the Fault Value word

is 0 for all bits indicating that when applicable, all module outputs should be

set to the OFF state.

…3 indicate the values to apply to the corresponding module

Publication 1769-RM016A-EN-P - July 2006

TIP

The MicroLogix 1500 and CompactLogix controllers do not yet

support fault state control. This functionality is currently only

supported when the module is used on the DeviceNet network

via the 1769-ADN adapter.

Page 51

Module Data, Status, and Configuration 51

Output Control (DB)

The outputs on the 1769-BOOLEAN module can be configured for two

modes of control: direct control mode or Boolean Control mode. Each output

is independently configured by use of the Disable Boolean (DB) control bits.

Word 8, bit 0 determines the output control mode for OUT0. The output

control modes for OUT1, OUT2, and OUT3 are determined similarly by bit 0

of words 16, 24, and 32. When an output's DB bit is cleared (0), the output is

configured for Boolean Control mode. When an output's DB bit is set (1), the

output is configured for direct control mode. The default setting for all DB

bits is 0 (Boolean Control mode).

Refer to Control Outputs Using Boolean Expressions on page 15, for details

on forming Boolean expressions to control the module's outputs.

Refer to Direct Control of Module Outputs on page 44, for details on

controlling the module's outputs directly from the control program.

Output Interrupts

The module will support four output interrupts - one each for the 4 outputs

(OUT0 through OUT3). Interrupts are not supported by all controllers. Refer

to your controller's user manual to determine if interrupts from expansion

I/O modules are supported.

Each output can have one of four types of interrupts selected by the user. An

interrupt can be triggered on the following conditions:

• The Boolean expression for the output transitions from FALSE to

TRUE.

• The output directed state transitions from OFF to ON.

• The Boolean expression for the output transitions from True to False.

• The output directed state transitions from ON to OFF.

Publication 1769-RM016A-EN-P - July 2006

Page 52